Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® Precision Gang Arbors & Hubs – Your Key to Precision Machining Excellence!

Are you in search of the ultimate solution for your OD grinding, vertical spindle grinding, precision slicing, and dicing needs? Look no further! SMART CUT® Precision Gang Arbors &Hubs are engineered to meet your machining requirements with unparalleled precision and versatility. For holding individual or gang stacked diamond blades or carbide saw blades.We can also provide large variety of schism and spacers of almost any thickness, materials and tolerance.

Compatible with Leading Equipment Brands

Our SMART CUT® Precision Gang Arbors & Hubs are the trusted choice of professionals and manufacturers across various industries. They seamlessly integrate with equipment from renowned brands like MTI, Disco, Veeco, K&S/ADT, MECO/FICO, and many others, ensuring compatibility and reliability.

INDUSTRIES USED IN:

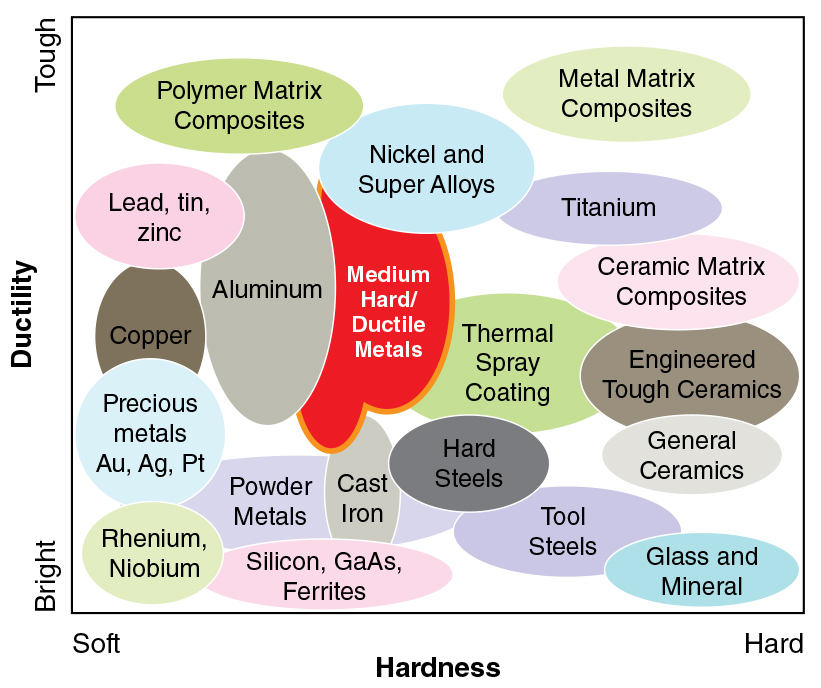

Ferrous & Non-Ferrous Metals:

SMART CUT arbors and hubs are designed to be versatile and can often accommodate non-standard or custom blade configurations. Contact SMART CUT to discuss your specific blade requirements.

Yes, SMART CUT arbors and hubs can be integrated into robotic automation systems, making them suitable for automated material handling and machining processes.

To select the correct size, consider the blade diameter, thickness, and the specifications of your machining equipment. SMART CUT’s technical support team can assist you in choosing the right size based on your application.

Yes, SMART CUT arbors and hubs can be employed for both roughing and finishing operations. Their precision and adaptability make them versatile tools for various stages of machining.

SMART CUT arbors and hubs may require balancing based on the specific application and equipment. Balancing should be performed as needed to ensure smooth and vibration-free machining at high speeds.

SMART CUT arbors and hubs are compatible with various cutting fluids and coolants commonly used in machining processes. It’s important to select the appropriate cutting fluid or coolant based on the material being machined and the specific machining requirements.

Common signs that maintenance or replacement may be needed include increased vibration during machining, reduced cutting accuracy, visible wear on components, and decreased cutting efficiency. Regular inspection can help detect these issues.

When changing blades or adjusting spacers, follow these general steps:

Ensure the machine is safely powered off.

Loosen any locking mechanisms on the arbor or hub.

Carefully remove or replace blades, making sure they are properly seated.

Adjust spacers as needed to achieve the desired configuration.

Tighten all locking mechanisms securely.

Conduct a visual inspection to verify the setup before resuming machining.

Yes, SMART CUT arbors and hubs can be used in both wet and dry machining processes. They are adaptable to various machining environments and can be paired with appropriate coolant or lubrication systems for wet machining when necessary.

The weight capacity of SMART CUT arbors and hubs depends on factors such as the material, size, and configuration. For applications with specific weight requirements, it’s advisable to consult with SMART CUT to select the most suitable product.

Safety is paramount when working with precision machining equipment. Always follow safety guidelines provided by the equipment manufacturer and ensure that operators are trained in safe operation practices. Proper personal protective equipment (PPE) should be worn when necessary.

Yes, SMART CUT arbors and hubs are compatible with CNC (Computer Numerical Control) machines. Their precision and versatility make them a valuable addition to CNC machining processes.

When not in use, SMART CUT arbors and hubs should be stored in a clean and dry environment, protected from dust and contaminants. It’s recommended to use appropriate storage racks or containers to prevent damage or distortion of the equipment.

SMART CUT Precision Gang Arbors & Hubs are primarily designed for external machining operations. For internal machining, you may need specialized tools or equipment, depending on your specific requirements.

The extended shaft capability allows you to work with larger workpieces or reach deeper into the machining area, providing greater flexibility in your machining processes and accommodating various setups.

Yes, SMART CUT arbors and hubs are designed to hold individual blades or gang-stacked blade configurations, offering versatility for different machining needs and applications.

Multiple pitches and shoulder positions on a single arbor or hub provide adaptability for diverse machining requirements. This feature allows you to fine-tune your setup and optimize your machining processes for different projects.

SMART CUT offers truing and restacking services to assist with maintaining the accuracy and performance of your equipment. Contact SMART CUT’s technical support team to inquire about these services and schedule truing and restacking as needed.

Ensure that the arbor or hub is securely fastened to your machining equipment according to manufacturer guidelines.

Check and confirm the concentricity and alignment of the blades and hubs.

Regularly inspect the blades and hubs for signs of wear and damage, replacing any worn components promptly.

Follow SMART CUT’s recommended maintenance schedule for cleaning and lubrication to keep your equipment in top condition.

Yes, these arbors and hubs can be integrated into automated machining systems, enhancing efficiency and precision in automated production processes.

Yes, SMART CUT arbors and hubs can be used with coolant or lubrication systems to help improve cutting efficiency and extend the lifespan of cutting tools.

SMART CUT Precision Gang Arbors & Hubs are designed to be versatile and can often be retrofitted onto existing machinery, provided they are compatible with the equipment’s specifications. It’s advisable to consult with SMART CUT to confirm compatibility and receive guidance on retrofitting.

Shoulder perpendicularity refers to the precision of the arbor or hub’s shoulder relative to its shaft. SMART CUT’s shoulder perpendicularity of 0.000050 inches ensures that the blade assembly is held accurately, minimizing errors in your machining processes.

Radial runout measures any deviation from a true circular path. It is crucial for precision machining as it directly affects the accuracy of the finished workpiece. SMART CUT’s radial runout of less than 0.0002 inches guarantees precise machining results.

Axial runout measures the concentricity of the blade assembly with the arbor or hub’s central axis. A low axial runout, as provided by SMART CUT (< 0.0002 inches), ensures that your blades are centered accurately, enhancing machining accuracy.

Yes, SMART CUT arbors and hubs are versatile and can securely hold both diamond blades and carbide saw blades, making them suitable for a wide range of machining applications.

SMART CUT Precision Gang Arbors & Hubs are commonly used in applications such as OD grinding, vertical spindle grinding, precision slicing, and dicing across various industries, including semiconductor manufacturing, electronics, and precision optics.

The choice of material depends on your specific machining needs. For corrosion resistance and lightweight applications, aluminum may be suitable, while steel and stainless steel offer durability. Titanium provides high strength and is ideal for demanding applications. Consult SMART CUT for material recommendations.

Having multiple diameters and thicknesses on the same arbor streamlines your machining setup. It reduces the need to change arbors frequently, saving time and improving efficiency.

Yes, these arbors and hubs are designed for reusability. By changing spacers and adapting the setup, you can use them for various machining applications, making them a cost-effective choice for manufacturers.

Restacking blades on SMART CUT arbors and hubs is designed to be user-friendly. While basic knowledge of blade handling is helpful, no specialized tools or extensive training are typically required.

Regular inspection and cleaning are recommended to maintain the performance of SMART CUT arbors and hubs. Following the manufacturer’s guidelines for maintenance and usage is essential for extended lifespan and consistent performance.

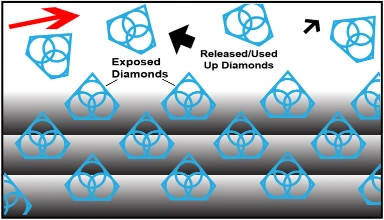

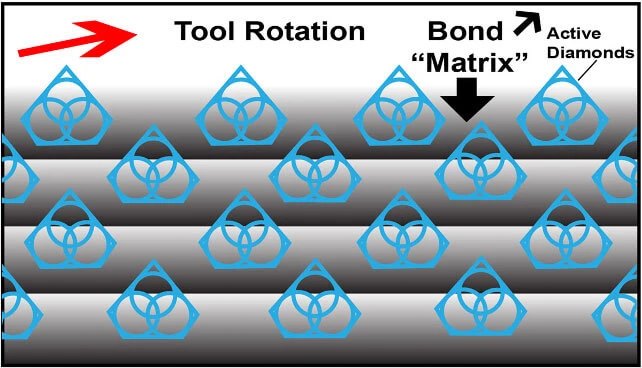

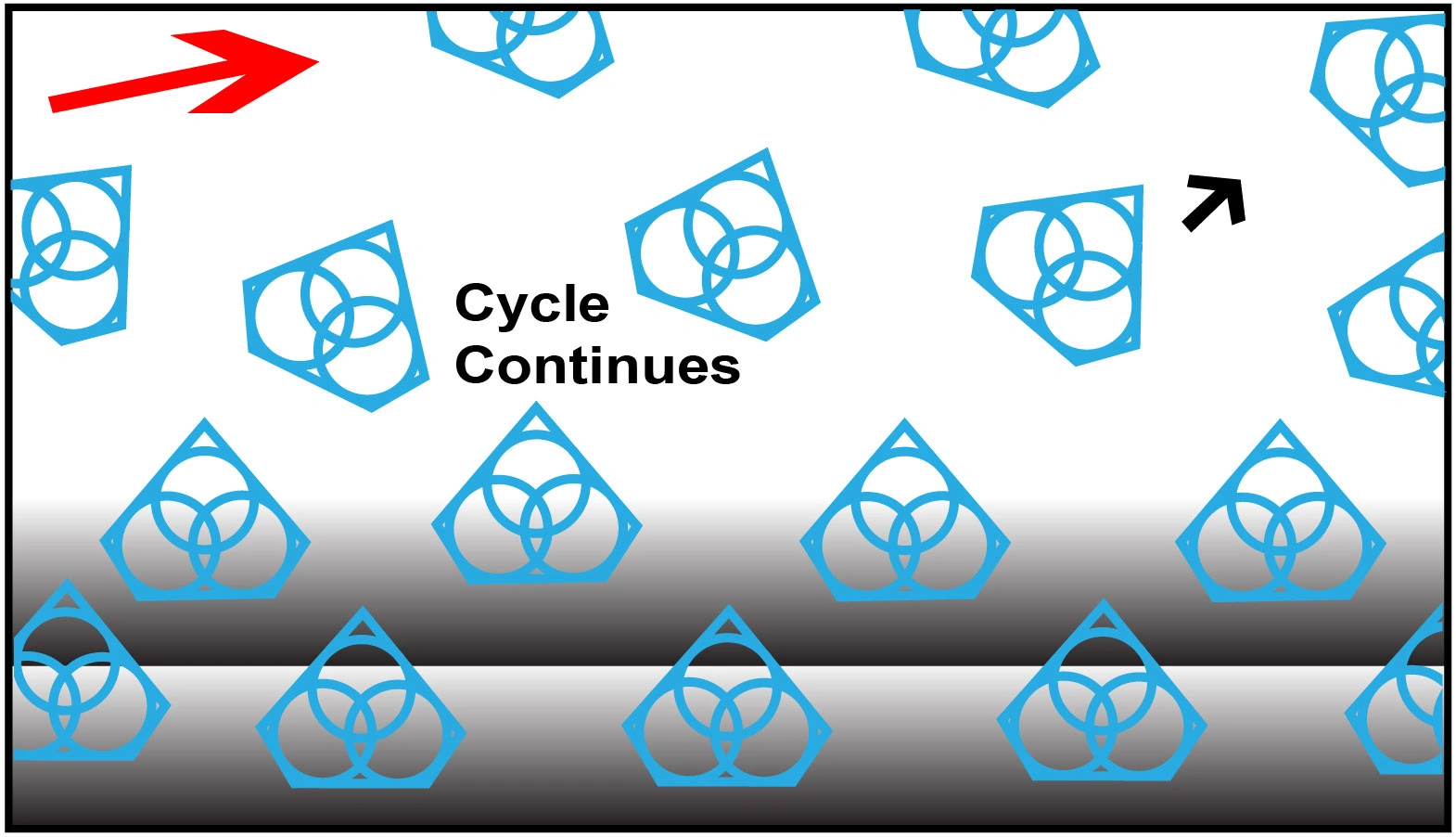

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

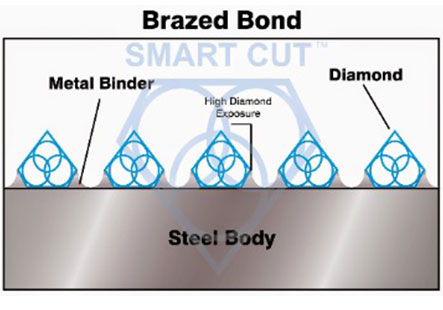

Brazed Diamond Tools are produced using and process that creates a fusion between the diamonds and the metal bond. While they may appear similar to electroplated (nickel bond) diamond tools. They are produced utilizing completely different process. Brazed Bond Diamond Tools are produced inside vacuum oven at a high temperature, single layer of diamond crystal bonded to steel body with very high diamond exposure. Not only does it promote high diamond exposure, but it also eliminates the loss of diamond particles through pull-out. The diamond section will not strip or peel from the steel body. This translates into multiple benefits, including: aggressive tools that last longer, cut faster, run cooler and load less, providing increased productivity and part consistency.

Diamond drills made utilizing SMART CUT® technology are much more aggressive than your conventional Tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional nickel bonded diamond CBN drills. SMART CUT® diamond CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

SMART CUT® Multi Layered Electroplated diamond cutting blade three diamond layers impregnated inside the bond matrix. Unlike Many Other blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

SMART CUT® Multi Layered Electroplated Diamond Drills are the best investment you can make! Although they may cost more than electroplated (nickel bond), Diamond Drills. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales