-

0 items in quote

No products in the Quote Basket.

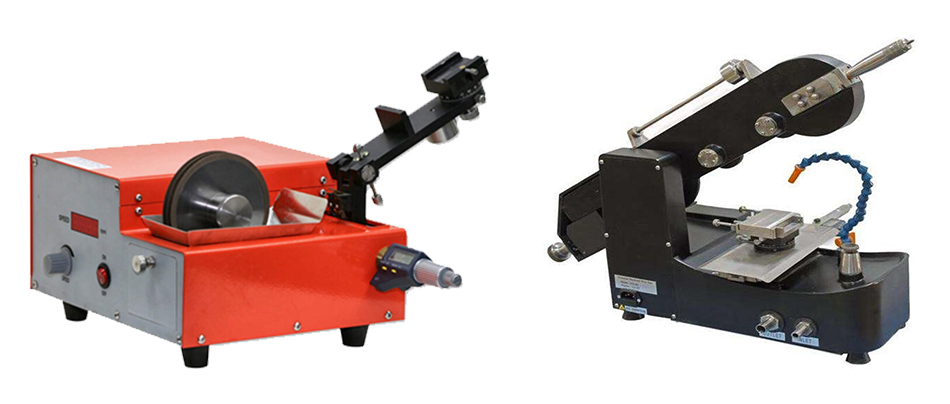

SMART CUT® 6011

Sectioning Saw

SMART CUT® 6011 is an Automatic Laboratory Diamond Saw is designed for precision cutting all type of materials up to 3″ diameter. The saw is equipped with 8″ diameter diamond blade and touch-push panel to achieve automatic control. The system features an integral coolant recirculation system which extends blade life and clears cutting debris to improve cutting rate and surface quality. Material is fed into the blade by several different methods by use of table attachments.

SMART CUT® 6011 is an Automatic Laboratory Diamond Saw is designed for precision cutting all type of materials up to 3″ diameter. The saw is equipped with 8″ diameter diamond blade and touch-push panel to achieve automatic control. The system features an integral coolant recirculation system which extends blade life and clears cutting debris to improve cutting rate and surface quality. Material is fed into the blade by several different methods by use of table attachments. A wide range of sample fixtures can be held by the saw. This method allows the workpiece to be mounted rapidly and conveniently without the need for mounting waxes or cements.

For Industrial and research operations, SMART CUT® 6011 offers an unparalleled combination of cut quality, accuracy, versatility, and affordability. Perfect for any metallurgical, ceramic and advanced materials laboratories combining heavy duty construction of a much larger cut off machine with the ability to make precision cuts worthy of the fines abrasive or diamond cut off machines. powerful 1 HP motor enables the user to cut through even the hardest materials.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

The variable speed spindle optimizes motor speed to provide the most efficient cutting rate for superior results. The feed rate is continuously adjustable and held constant through the cut.

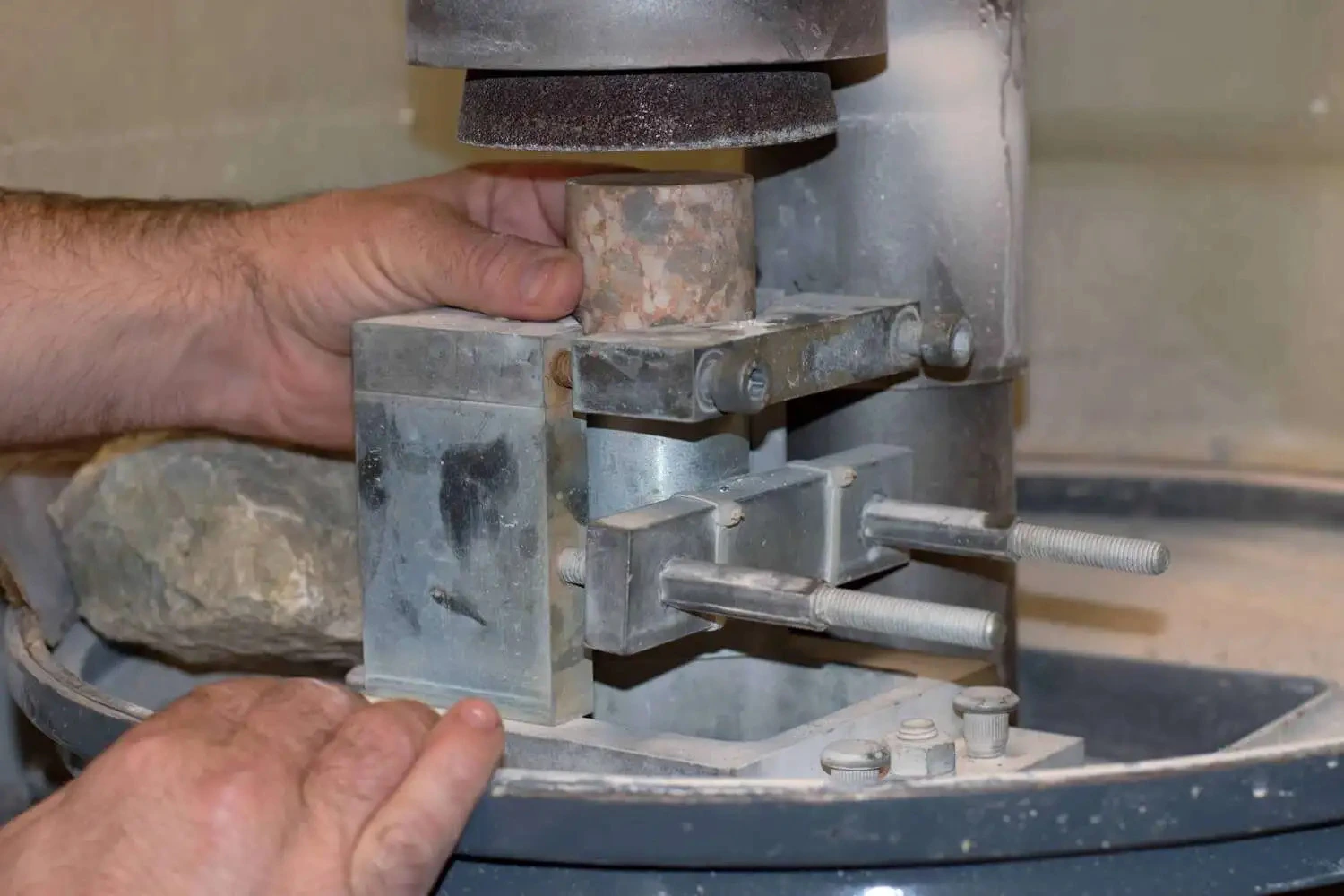

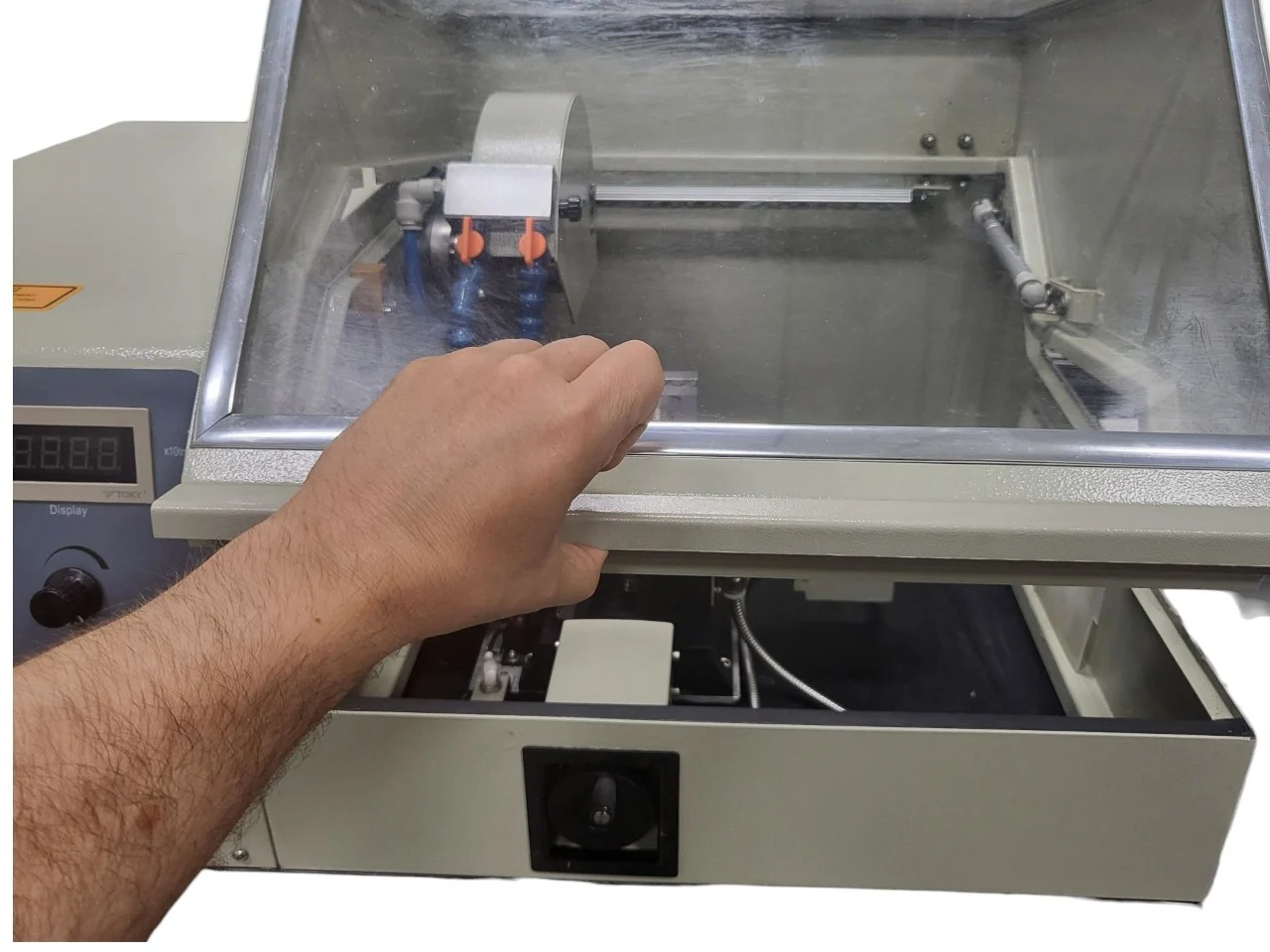

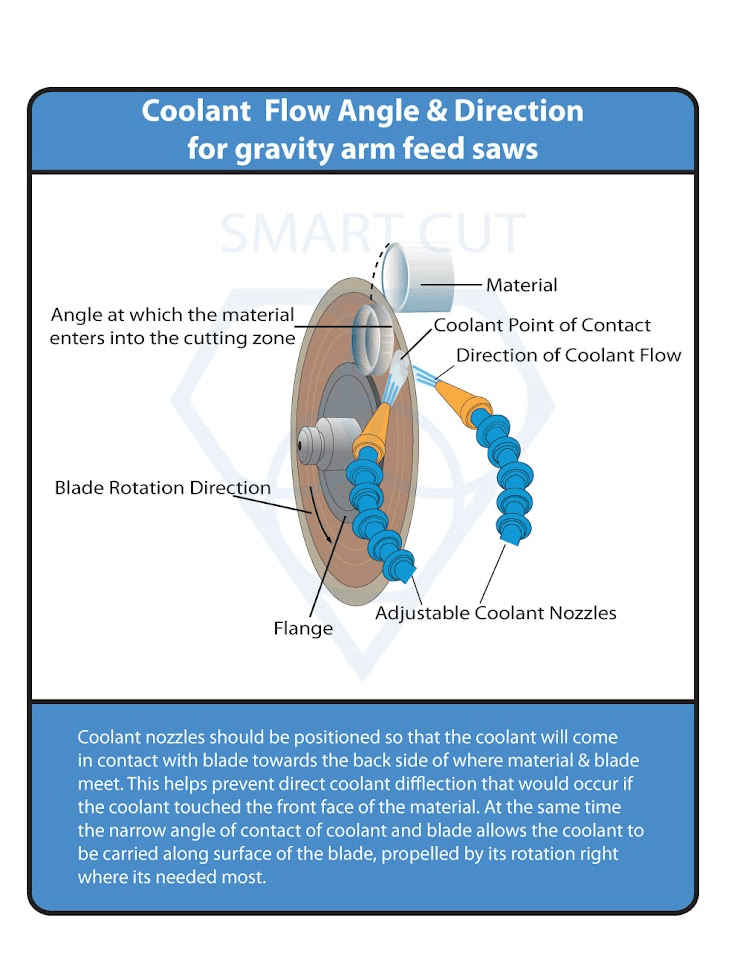

Coolant feeder is installed left below the table. it may be moved at any angle to change the coolant flowing direction. Connecting the coolant inlet to a circulating pump and the coolant outlet to a tank which the pump laced inside will build a circulating coolant system. Sample will be clamped tightly by the vice and machine will cut sample orderly following the program which is defined by the user including width, length, quantity cutting speed, feed rate and etc.

This machine uses pulse circuit to control the speed of a permanent magnet dc motor which is permanent magnet excitation and closed self coolant. it has the advanced short circuit protector and high stability voltage. Ensure to work normally at low speed no self induced vibration or abrupt speedup. The blade is installed on the main shaft and spins with it to implement cutting

The control part of the machine consists of 4.3″ color tough screen and PLC making easier operation and beautiful appearance. the cooling system is built in the machine may skillfully minimize parts deformation.

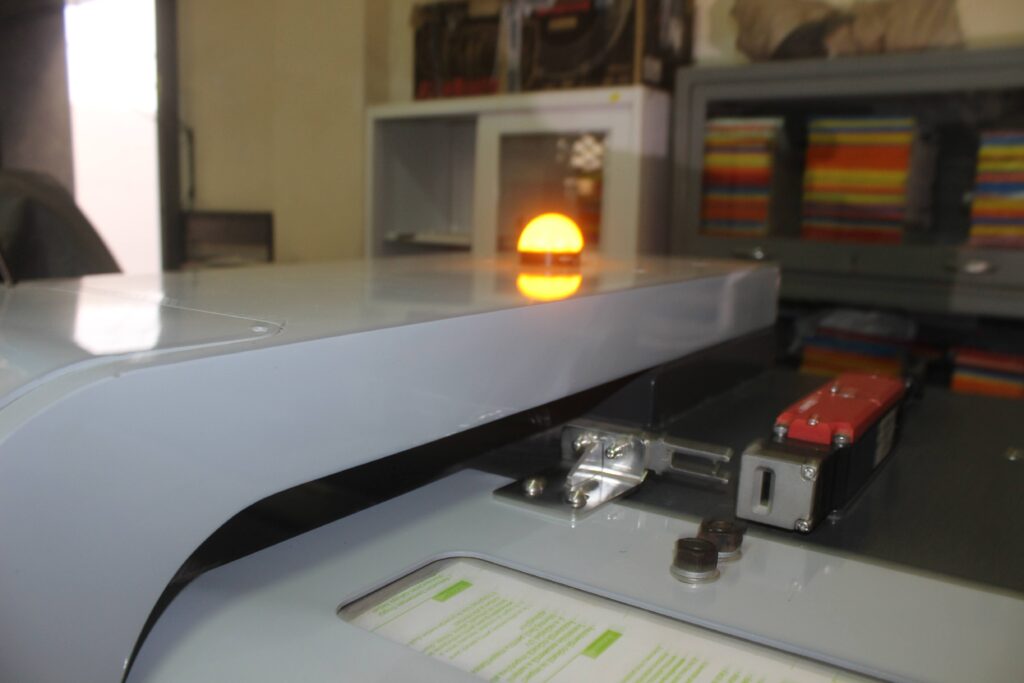

Special vice fully guarantees the cutting performance providing steady sample holding and precise measurement. this machine has a protective cover which will prevent coolant splash and insure enclosed cutting area. This cover also connects with the safety lock which when left unclosed will stop machine from cutting as a safety measure. Front panel of machine has large emergency stop button to power off the machine in an emergency.

SPECIFICATIONS

- RPM’S: 300-3500

- Motor: 1 HP high torque DC motor

- Blade Range: 6″ to 8″ (150mm to 200mm)

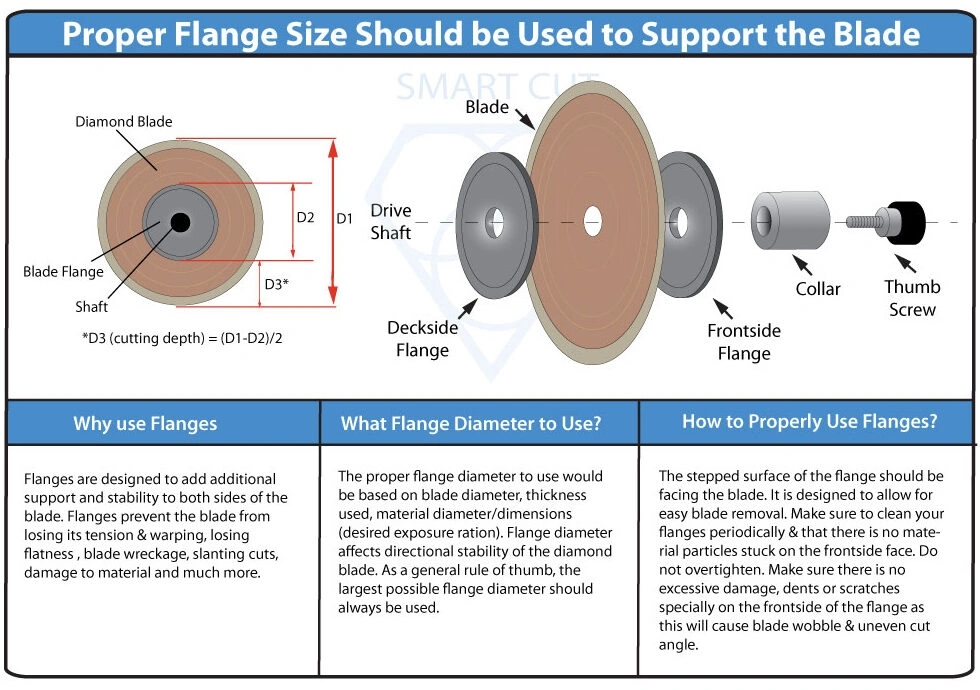

- 1″ dia spindle and 2″ flange

- Y AXIS TRAVEL LENGTH: 100mm

- X axis travel length: 80 mm

- Blade Size: 200mm

- vice open width: 60mm

- Programmable Y and X axis advancement via LCD panel to achieve automatic cutting with 0.01 mm precision

- Re-circulating coolant system with adjustable nozzles

- Protective splash cover with electronic safety interlock

- Quick clamp is included to make sample mount easy and fast

- power: 600w

- input voltage: AC220

- overall dimension: 734mm x 540mm x 475mm

- weight: 72 kg

ADVANTAGES

- Versatility in Cutting: Suitable for a wide range of materials, from ceramics to metals.The system may be readily converted to handle sample cutting requirements of most shapes, sizes and applications.

- Automatic Control: Touch-push panel facilitates automatic control, simplifying the cutting process.

- Variable Blade Speed: Blade speed is adjustable between 300-3500 RPM, offering flexibility based on material and desired finish.

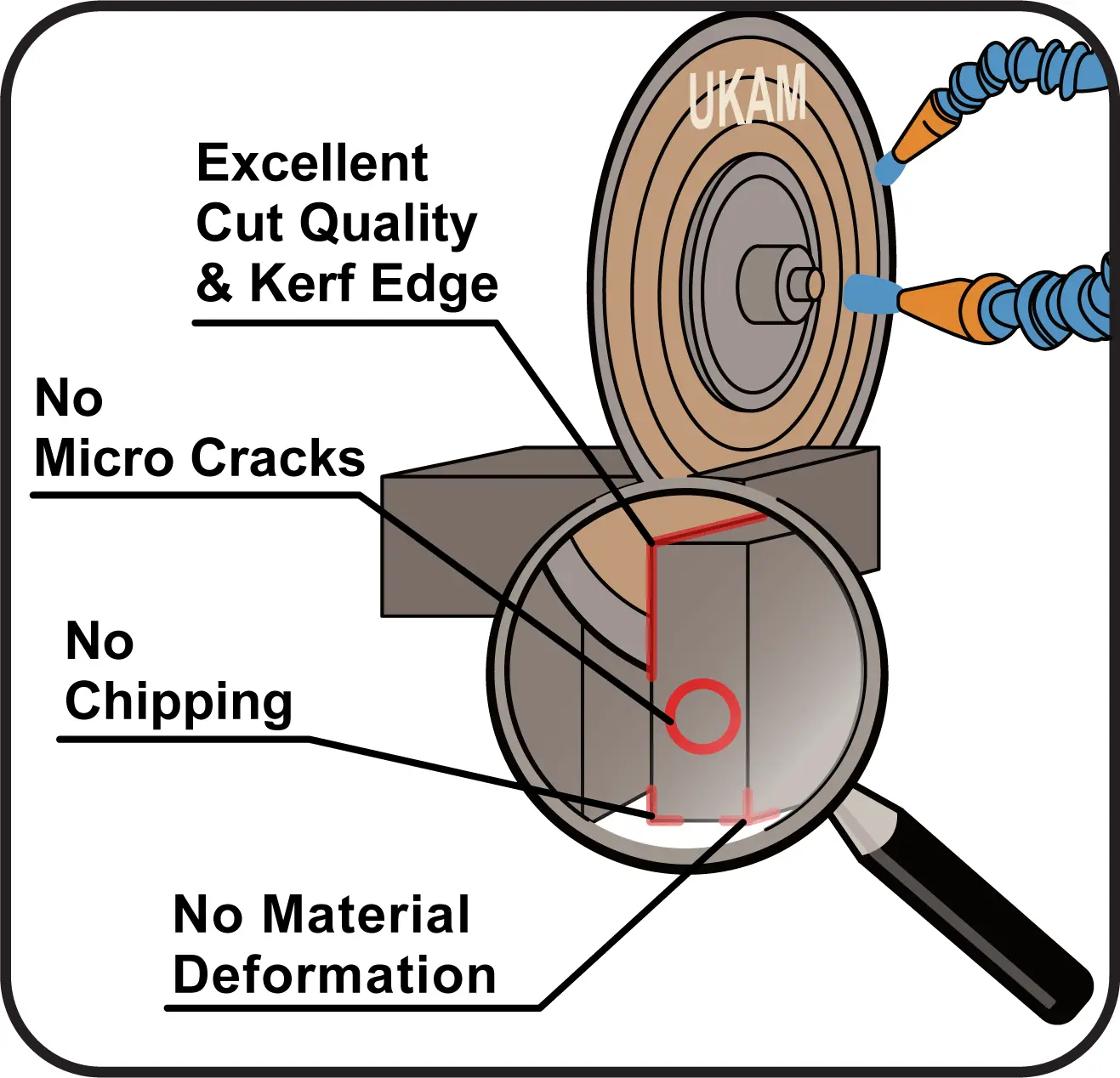

- High Precision: Programmable Y and X-axis advancements enable automatic cutting with a precision of 0.01 mm.The use of precision lead screws on all sample feeds means cuts may be positioned accurately

- Comprehensive Blade Set: Comes with three 8″ cutting blades, each designed for specific materials, ensuring optimal cutting performance.The system accepts a wide range of O.D. diamond and abrasive blades for standard cutting, and is readily adaptable to accept special ‘dicing’ blades for the smallest kerf.

- Sample Mounting Ease: The quick clamp feature simplifies and speeds up sample mounting.

- Effective Cooling System: The design includes adjustable nozzles for coolant re-circulation and a protective splash cover with electrical cooling.

- Safety Features: Contains a safety interlock system for enhanced operational safety.

- Compact Design: Despite its features, it maintains a compact size for ease of placement in labs.

BENEFITS:

- Minimal Blade Load / Very Easy to Use & Operate

- Best performance & price per cut

- Universal Application / Adjusts to fit almost any application

- Improve Cutting / Sectioning Speed

- Minimize Material Structure Deformation

- Improve Surface Finish Quality / Minimize burrs on edges

- Reduce Material Loss

- Perfect for Organizations on a Budget

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

The SMART CUT® 6011 is designed for precision cutting of a wide range of materials up to a 3-inch diameter.

It comes with an 8-inch diameter diamond blade.

The touch-push panel enables automatic control for a seamless cutting experience.

The integral coolant recirculation system extends the blade life, clears cutting debris, and improves both the cutting rate and the surface quality of the cut.

The saw can accommodate various table attachments that dictate the method by which material is fed into the blade.

Yes, the saw can hold a wide range of sample fixtures, allowing for quick and convenient mounting without the need for waxes or cements.

Industries and research areas such as metallurgy, ceramics, and advanced materials laboratories can benefit from its combination of heavy-duty construction and precision cuts.

The machine has a powerful 1 HP motor.

The variable speed spindle optimizes motor speed to provide efficient cutting rates and superior results across different materials.

The coolant feeder is located below the table on the left. It can be moved at any angle to adjust the coolant flow direction.

The machine utilizes a 4.3-inch color touch screen combined with a PLC for easier operation and a visually appealing interface.

The machine is equipped with a protective cover that prevents coolant splash and ensures an enclosed cutting area. This cover has a safety lock that, if left unclosed, will halt the machine’s operation. Additionally, there’s a large emergency stop button on the front panel.

The system is adaptable and can be converted to handle various sample cutting requirements in terms of shapes and sizes.

Yes, the system accepts a wide range of O.D. diamond and abrasive blades, and can also adapt to special ‘dicing’ blades for minimal kerf.

The tank has a 4-liter capacity.

The machine operates on 208V to 240V. If 110V power supply is needed, a 200W transformer should be ordered.

The RPM range is between 300 and 3500.

The Y axis has a travel length of 100mm, and the X axis has a travel length of 80mm.

Both the Y and X axes can be programmed via the LCD panel, enabling automatic cutting with 0.01mm precision.

The machine’s dimensions are 734mm x 540mm x 475mm, and it weighs 72 kg.

The SMART CUT® 6011 comes equipped with an 8-inch diameter diamond blade.

The vice has an open width of 60mm.

The feed rate is continuously adjustable and is held constant throughout the cut. Users can define parameters like width, length, quantity, cutting speed, feed rate, etc., using the touch-push panel.

The machine operates at 208V to 240V. If you require a 110V power supply, you will need to order a 200W transformer.

Ensure the system is connected correctly, with the coolant inlet linked to a circulating pump and the coolant outlet connected to a tank with the pump placed inside. This setup will establish a circulating coolant system.

Precision is achieved through the use of programmable Y and X axis advancement via the LCD panel, allowing for automatic cutting with 0.01 mm precision. The use of precision lead screws also ensures accurate positioning of cuts.

Yes, the system can readily adapt to special ‘dicing’ blades for minimal kerf, making it suitable for dicing operations.

The 4.3-inch color touch screen combined with the PLC simplifies the machine’s operation, provides a user-friendly interface, and ensures clear visualization of controls and settings.

The machine is designed for precision cutting of various materials, including but not limited to metals, ceramics, and advanced materials.

Besides the protective cover with a safety lock and the emergency stop button, the machine also has a built-in safety interlock in the splash cover. This ensures that any potential hazards, like coolant splash or unintended operation, are minimized.

Blade life varies depending on the type of material being cut, the frequency of usage, and the care taken during operations. Regular inspection and following manufacturer guidelines can help determine when a replacement is needed.

Regular cleaning after use, ensuring the coolant system is free from debris, inspecting the blade for wear, and checking the mechanical and electrical components for any issues will prolong the machine’s life. Always refer to the user manual for detailed maintenance guidelines.

OPERATING MANUALS

Download Operating Manuals

ACCESSORIES

Features:

- Automatic Precision Cutting: Designed for precision cutting of materials up to 3" in diameter using an 8" diamond blade.

- Touch-Push Control Panel: Features an easy-to-use touch-push panel for automatic control of the cutting process.

- Integrated Coolant Recirculation System: Built-in coolant system extends blade life, improves cutting efficiency, and clears cutting debris for better surface quality.

- Multiple Feeding Methods: Offers several feeding methods using table attachments to accommodate a wide range of sample sizes and types.

- Heavy Duty Construction: Equipped with a powerful 1 HP motor that enables cutting through tough materials.

- Variable Speed Spindle: Optimizes motor speed to achieve the most efficient cutting rate for superior results.

- Continuous Adjustable Feed Rate: The feed rate is adjustable and maintained consistently during the cut for precision.

- Pulse Circuit for Stable Operation: Uses pulse circuitry to control the permanent magnet DC motor, ensuring stable low-speed operation with no vibration or abrupt speed changes.

- Color Touchscreen Control: Equipped with a 4.3" color touchscreen and PLC for easy operation and an aesthetically pleasing design.

- Safety Features: Includes a protective cover to prevent coolant splash and a safety lock that halts the machine if the cover is open. Also features an emergency stop button for immediate shutdown.

- Versatile and Accurate Cutting: Precision lead screws on all sample feeds allow for accurate positioning of cuts.

- Long Cuts and Dicing Capability: The large work-table allows for long cuts, ideal for failure analysis, QA applications, or longitudinal sectioning of components.

- Accepts a Variety of Blades: Compatible with a wide range of O.D. diamond and abrasive blades, and adaptable for use with special dicing blades for fine kerfs.

- Recirculating Coolant System: A 4-liter heavy-duty coolant circulating tank is included, with a 12L/min flow rate and a built-in 40W fluid pump for efficient coolant circulation.

- Versatile Sample Holding: The saw includes a special vice for steady sample holding, ensuring precision cutting and consistent measurements.

- Power Supply: Operates on 208V ~240V power, with an option for 110V using a 200W transformer.

- Included Coolants: Comes with one quart of SMART CUT™ Water Soluble Coolant or Mineral Oil to reduce thermal stress, edge damage, and improve blade life.

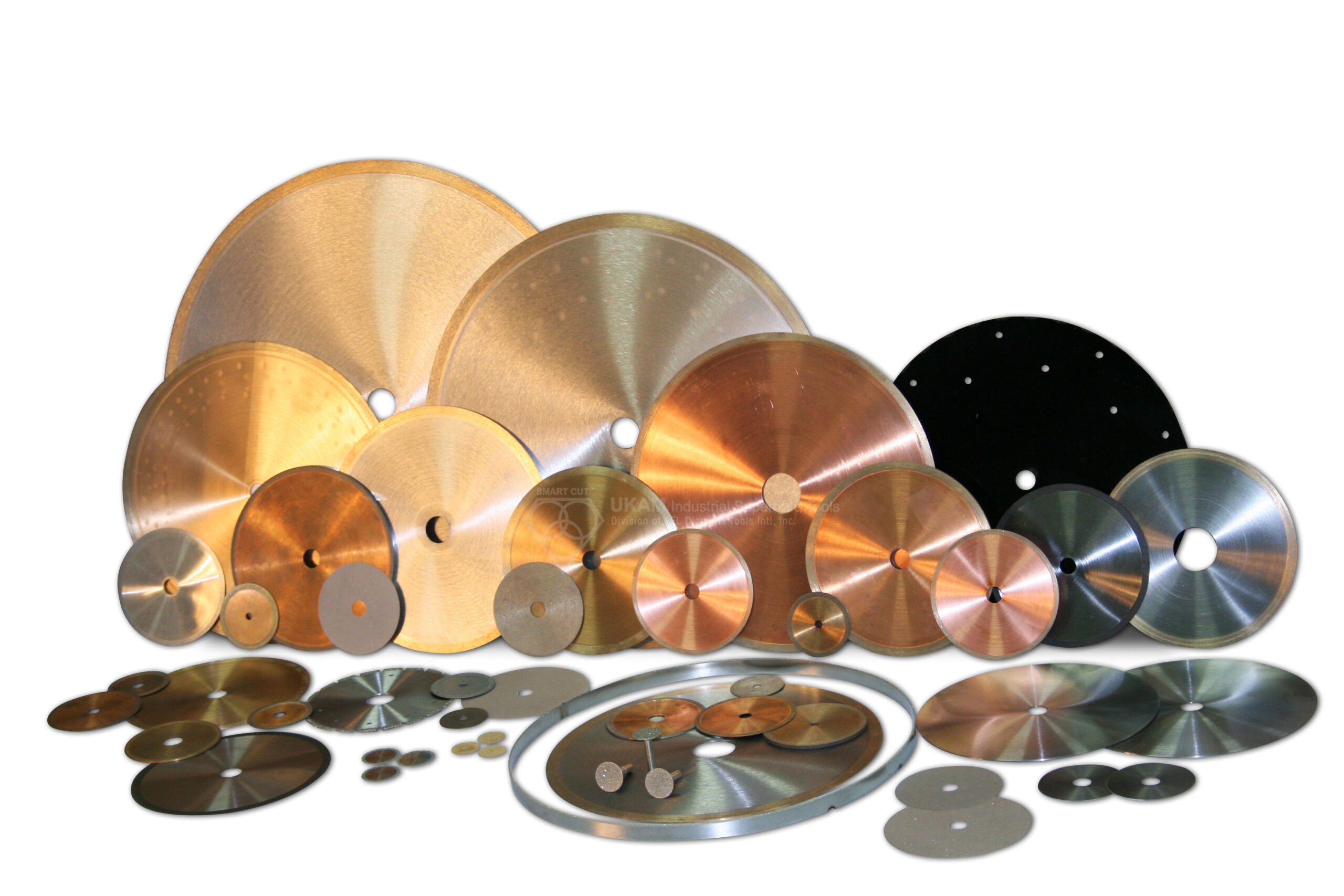

- Wide Range of Blade Specifications: Includes one diamond wafering blade of any specification free with the purchase, with a large variety of available blades for different applications.

Control Panel Operation

- Versatility – The system may be readily converted to handle sample cutting requirements of most shapes, sizes and applications.

- Cutting Accuracy – The use of precision lead screws on all sample feeds means cuts may be positioned accurately

- Long Cuts & Dicing – The large work-table and layout of the machine allows for long cuts to be achieved – perfect for failure analysis, and QA applications such as longitudinal sectioning of components. Sectioned workpieces may be an end in themselves, or the starting point for lapping and polishing

- Accepts Most Blade Types – The system accepts a wide range of O.D. diamond and abrasive blades for standard cutting, and is readily adaptable to accept special ‘dicing’ blades for the smallest kerf.

RECIRCULATING COOLANT SYSTEM:

4 liter capacity heavy duty coolant circulating tank is designed to provide coolant circulation for this saw

- Operation power: 208V ~240V (If you need 110V power supply, please order a 200W transformer)

- 4 Liters stainless steel tank with 1″ drain port and 1/4″ outlet port

- Built in 40W fluid pump, Flowing rate: 12L/min.

- Pumping height: 3 meters Max.

- Dimension: 270mm x220mm x320mm.

- Plastic Hose: 8.05mm O.D. 2.3m Length (7.5 feet)

- Water Inlet: 25.4mm I.D. 31.75mm O.D.

- Weight: 3kgs

SMART CUT® Coolants

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

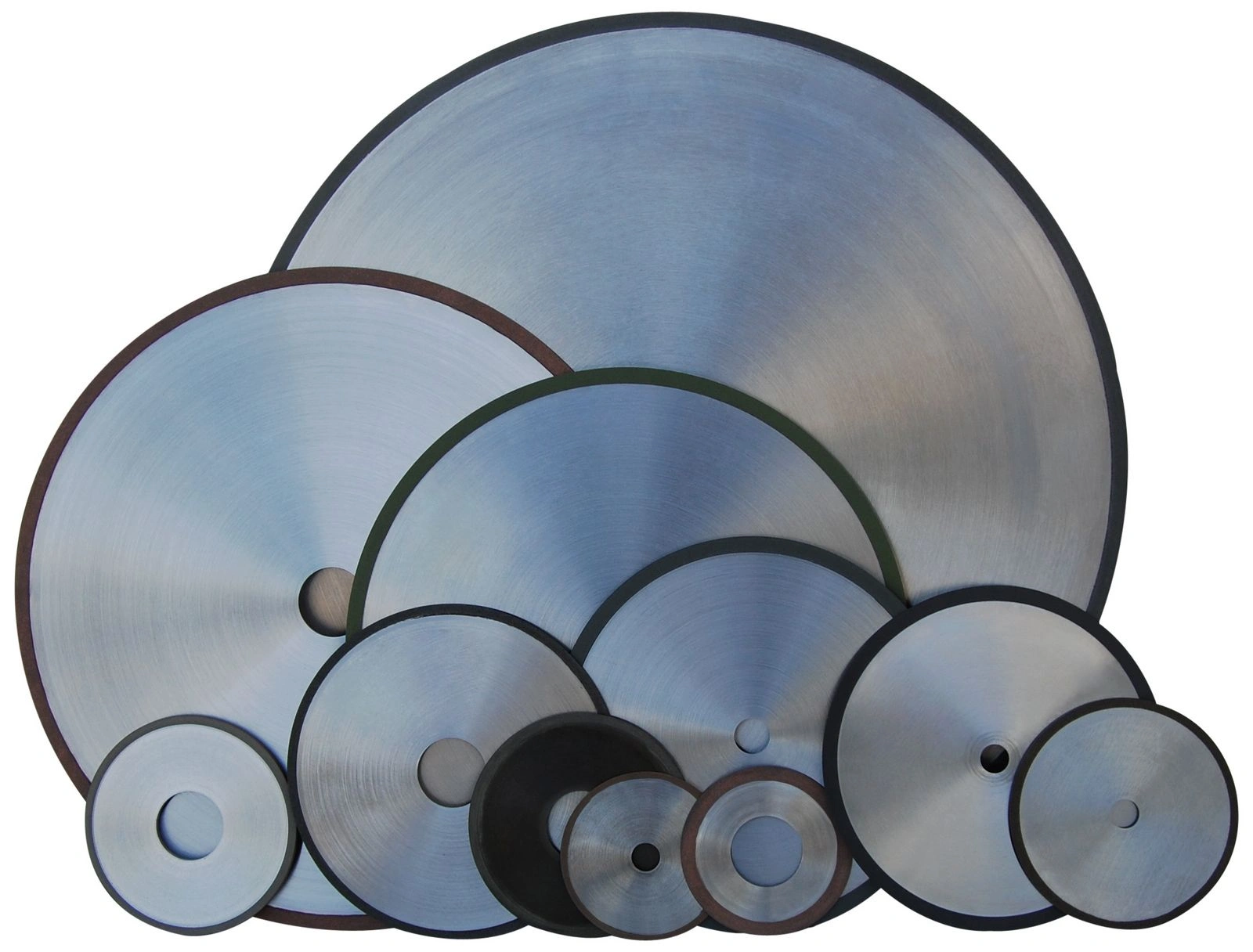

Largest Selecting of Diamond &

Cbn Wafering Blades Avaialble

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

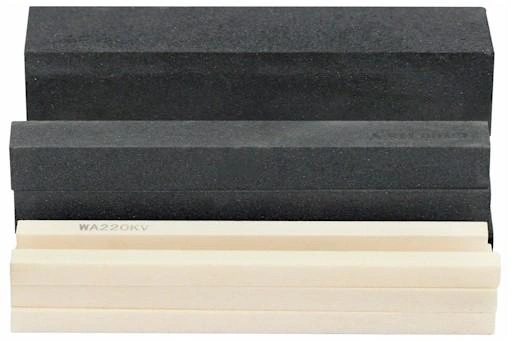

The Right Dressing Stick for Your Application

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

SMART CUT® 6015 – Automatic Precision Saw

SMART CUT® 6030 – Automatic Precision Saw

Recently Viewed Products

ARE YOU USING METALLOGRAPHY SECTIONING SAWS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR METALLOGRAPHY SECTIONING SAWS?

Knowledge Center

02

Jun

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and applications....

02

Jun

Diamond Wire Advantages & Application

Diamond Wire saws provide the most accurate cutting with the least amount of material deformation and chipping of material.

Share this Article with Friend or Colleague

HOW DIAMOND WIRE WORKS

Today diamond wire sawing is preferred by majority...

02

Jun

Troubleshooting Diamond Sawing Problems

Having issues with your diamond cutting operation? This Illustrated Guide can help. Learn the most common problems most people have in using diamond cutting blades. How to resolve them and avoid them in...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application, we...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering blades,...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high accuracy. To...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to understand...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...

19

Aug

Understanding & Calculating Return on Investment for Diamond & CBN Blades

The term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use