-

0 items in quote

No products in the Quote Basket.

Diamond Abrasive Flexible Sheet

SMART CUT® Diamond flexible abrasive sheet is perfect for creating your own custom tools for grinding, shaping, deburring, polishing, and sharpening. It comes in a Fine 600 grit (30 Microns) and is available in sizes of 50mm x 100mm (2" x 4") with a thickness of 0.3mm, featuring an adhesive backing.

To craft your personalized diamond abrasive tools, simply trim the sheet to your desired size and shape. This diamond sheet can be utilized both dry and wet. When using, let the diamond abrasive perform the work without exerting excessive pressure, particularly when dealing with corners or sharp edges. It's suitable for use on a variety of materials including all stone types, glass, ceramics, hard metals, granite, and marble.

Description

Specifications

Frequently Asked Questions

Industries Used In

Accessories

Recommendations

Description

Engineered for durability and efficient cutting, this material combines the robustness and flexibility of its backing material with the aggressive cutting power of diamonds.

This design is ideal for shaping various hard materials quickly and cost-effectively, including hard metals. It’s crafted to allow easy washing away of slurry with lubricants like water, preventing clogging. The pattern on the sheet ensures rapid removal of material while enabling you to achieve the desired level of honed or polished finish.

The integration of diamond powder onto a flexible cloth has led to the creation of an innovative generation of diamond tools. These tools exhibit a more potent cutting capability compared to other abrasive tools. Their flexibility, combined with the spacing between the islands on the cloth, allows for easy cutting with scissors. This feature enables the creation of a variety of shapes and sizes, previously limited to traditional abrasives.

All products made from this diamond cloth are color-coded, simplifying the process of identifying the mesh size. The range of these series products includes sheets, discs with either self-adhesive or Velcro backing, and belt types, catering to diverse application needs.

Specifications

Applications

The applications of diamond cloth are Wet grinding (lapping) harden steel of any hardness, tungsten carbide, hard ceramic coated steels, glass, hard ceramic, marble, granite and stone…etc,or for the lapping of mold and die.

|

Grift Size |

Color |

Bond Type |

Bond Type |

|||

|---|---|---|---|---|---|---|

|

50mm X 100mm |

100mm X 100mm |

1,170mm X 295mm |

690mm X 295mm |

|||

|

#60 #120 #200 #400 #600 #1000 #500 #1000 #8000 |

Green Black Red Yellow White Blue White Blue Orange |

Nickel Bond Nickel Bond Nickel Bond Nickel Bond Nickel Bond Nickel Bond Resin Bond Resin Bond Resin Bond |

10012 10014 10016 10018 10020 10022 10024 10026 10028 |

20014 20016 20018 20020 20022 20024 20026 20028 20030 |

30016 30018 30020 30022 30024 30026 30028 |

40030 40032 40034 |

Frequently Asked Questions

Diamond abrasive flexible sheets are tools used for grinding, polishing, and finishing surfaces. They are embedded with industrial-grade diamond particles, making them extremely hard and durable. These sheets are used for working on hard materials like stone, glass, ceramics, and hard metals.

Diamond abrasive sheets are embedded with diamonds, the hardest natural material, making them more durable and suitable for harder materials. In contrast, sandpaper uses materials like aluminum oxide or silicon carbide and is better for softer materials like wood and metal.

The main advantages include exceptional durability, precision in finishing, versatility for hard materials, reduced heat generation during use, and a range of grit sizes for different finishing needs. They are also cost-effective over time due to their longevity.

While they can be used on metal, especially hard metals, they are generally not the best choice for wood or softer metals, where traditional sandpaper is more effective and economical.

Yes, they are designed for multiple uses. Their durability means they have a longer lifespan compared to traditional sandpaper

The choice of grit size depends on your specific task. Lower grit numbers are coarser and suited for material removal, while higher numbers are finer and ideal for polishing and finishing.

Many diamond abrasive sheets are designed for both wet and dry use. Wet use can help reduce dust and may improve the finish quality.

They can be considered more environmentally friendly due to their durability and longer lifespan, which means less frequent replacement.

Always wear appropriate safety gear, such as gloves and eye protection. If using them dry, a dust mask is recommended to avoid inhaling any particles.

They are available at specialty hardware stores, industrial supply stores, and online marketplaces. They are more of a specialty item compared to standard sandpaper.

Store them in a dry, safe place where the abrasive surface is not in contact with other tools or surfaces that could damage it. They should be kept flat or gently rolled to avoid creasing.

Yes, sheets may vary in diamond grit size, the pattern of the abrasive coating, and the backing material, all of which can be optimized for different materials and applications.

Yes, many diamond abrasive sheets are designed to fit standard hand sanders. However, it’s important to check the compatibility with your specific sander model for optimal results.

They can often be cleaned with water and a mild detergent. For dry use, gently brushing off the debris with a soft brush can be effective. Avoid using harsh chemicals that might damage the diamond grit.

They can be used for certain automotive applications, particularly for working on hard materials like hardened steel parts. However, they are not typically used for standard bodywork or paint preparation.

The lifespan varies based on usage frequency, material being worked on, and care in use and storage. Generally, they last significantly longer than traditional sandpaper.

Yes, by selecting the appropriate grit size, diamond abrasive sheets can be used for both aggressive material removal (with coarser grits) and fine polishing (with finer grits).

Under normal use conditions, the risk is minimal. High-quality diamond abrasive sheets are designed to retain their abrasive particles. However, excessive force or inappropriate use can lead to premature wear.

The technique can vary depending on the material and desired outcome. Generally, using light to moderate pressure and consistent movement works well. For specific tasks, researching or consulting with a professional is recommended.

If used improperly, they can scratch or damage materials, especially softer ones. It’s important to choose the right grit size and apply appropriate pressure during use.

Extreme temperatures and humidity can affect both the sheet and the material being worked on. It’s best to use them in a controlled environment to ensure consistent results.

They are not recommended for very soft materials or surfaces where a coarse abrasive could cause damage. Always assess the material compatibility before use.

They should be disposed of in accordance with local regulations. Since they contain industrial diamonds, regular waste disposal might not be appropriate.

They can be used both ways. For manual use, they can be attached to a hand tool or used as is. For machine use, ensure they are compatible with your specific machine type.

Yes, they come in various shapes and sizes, including sheets, discs, and belts, to fit different tools and applications. Custom shapes may also be available for specific needs.

Yes, many diamond abrasive sheets are suitable for both wet and dry applications. Wet sanding can help reduce dust and may improve the finish, especially on hard materials.

Extreme temperatures can affect the bonding material that holds the diamonds in place. It’s generally best to use them at room temperature to maintain optimal performance.

The primary hazard is dust generation, especially when used on certain materials. Always use appropriate dust extraction and personal protective equipment.

They cannot be sharpened in the traditional sense. Once the diamond particles have worn down, the sheet will need to be replaced.

Quality can often be determined by the uniformity of the diamond coating, the strength of the backing material, and the reputation of the manufacturer. Reviews and professional recommendations can also be helpful.

They can remove rust and paint, especially from hard surfaces, but it’s important to choose the right grit size and use them carefully to avoid damaging the underlying material.

Yes, they can be effective on certain composite materials, especially those that are hard and dense. However, testing on a small area first is recommended.

While the initial cost is higher, their longevity and effectiveness, especially on hard materials, can make them more cost-effective in the long run.

They are suitable for both, but their cost and specialized nature make them more common in professional settings or for specific DIY projects involving hard materials.

Store them flat or gently rolled in a dry environment. Avoid folding or creasing the sheets, and keep them away from abrasive or sharp objects that could damage the diamond surface.

Keep them in a cool, dry place away from direct sunlight and extreme temperatures. Humidity can affect the backing material, so a controlled environment is ideal.

Yes, with the appropriate grit size and careful technique, they can be used for precision work, including in electronics and jewelry making.

While diamond sheets are durable and long-lasting, eco-friendlier alternatives might include abrasives made from sustainable materials. However, these alternatives may not offer the same level of hardness and durability.

Consider the material you’re working with, the desired outcome, and the specific properties of the abrasive. Diamond sheets are best for hard materials and precision work, while other abrasives might be better for softer materials or general-purpose sanding.

Are there any innovations or advancements in Diamond Abrasive Sheet technology I should be aware of?

Advancements in bonding technologies and diamond grit distribution continue to improve the effectiveness and lifespan of these sheets. Staying informed about new products from reputable manufacturers can provide insights into the latest innovations.

Yes, their flexibility allows them to conform to various shapes, including curved and irregular surfaces, making them suitable for detailed work.

Look for certifications that indicate quality and safety testing, such as ISO (International Organization for Standardization) or ANSI (American National Standards Institute) standards.

Wet use can enhance performance by reducing dust and preventing overheating of both the sheet and the workpiece. Dry use is more convenient for quick tasks or where water use is impractical.

Yes, they can often be cut to size, but it’s important to use the right tools and techniques to avoid damaging the sheet or reducing its effectiveness.

They generally have good chemical resistance, but it’s advisable to check the manufacturer’s specifications for information on chemical compatibility.

High humidity can affect the backing material, and extreme temperatures can affect the adhesive or bonding agents. Store in a stable, controlled environment.

Yes, they can be effective on these materials, but it’s important to use the correct grit size and technique to avoid damaging the fibers.

Currently, most diamond abrasive sheets are not biodegradable or easily recyclable due to the materials used. However, their long lifespan does contribute to waste reduction.

Use light to moderate pressure, choose the correct grit for your task, and employ consistent strokes. Overworking the material or using excessive force can reduce efficiency.

Avoid using them on inappropriate materials (like very soft surfaces), applying excessive pressure, or using a grit that is too coarse for your needs, as these can lead to poor results or damage.

Absolutely. Their precision and ability to produce a high-quality finish make them suitable for detailed artistic or decorative projects, especially on hard materials.

Diamond grit sizes are generally consistent with traditional grit sizes, but because diamonds are harder, a diamond sheet of a given grit will often perform more aggressively than its sandpaper equivalent.

Storing them flat in a protective sleeve or container is ideal. Avoid folding or rolling them tightly, which could damage the abrasive surface.

The higher cost limits their use to applications where their benefits (like durability and precision) justify the expense. They’re more common in industries where these factors are critical.

Follow local regulations for disposal. While they don’t typically contain hazardous materials, their durability means they won’t degrade quickly in a landfill.

Yes, they can be used on rotary tools if they are the correct size and shape. Ensure that the sheet is securely attached to the tool to prevent slippage.

They can be very effective for sharpening hard materials like carbide or high-speed steel tools, but it’s important to use the correct technique and grit size.

When it no longer effectively removes material or produces the desired finish, it’s time to replace it. Look for visible wear or a decrease in performance.

While they can sharpen hard materials, including some knives, ensure that any sheet used in food-related applications is food-safe and won’t contaminate the food.

Standard first aid measures apply, such as cleaning cuts or abrasions thoroughly. Seek medical attention for any serious injuries.

They are generally resistant to weather conditions, but it’s always best to use them in a stable environment to ensure consistent results.

They are generally not recommended for standard automotive body work, as they are too aggressive for body panels and paint.

Brand recommendations can vary based on specific needs and budgets. Look for well-established brands with good reviews and industry reputation.

Collect and dispose of the dust in accordance with local environmental regulations, especially when working with hazardous or toxic materials.

Extreme caution should be used when working on antiques or historical items. Consult a restoration expert before proceeding, as the aggressive nature of these sheets can easily damage such items.

Store them in a dry, stable environment. Avoid exposure to corrosive chemicals or extreme conditions that could degrade the bonding agent or the diamond grit

Diamond sheets are better for larger, flat surfaces or when you need more physical control. Diamond paste is better for intricate, detailed work or surfaces that require a very fine finish.

They can be used for educational purposes but require supervision and instruction, especially regarding safety and proper technique.

Yes, but with caution. The aggressive nature of diamond abrasives can easily scratch or damage these materials if not used properly.

Use them at the recommended speed and pressure, avoid bending or folding, and clean them regularly to remove debris. Proper storage and handling are also key to prolonging their life.

Yes, they can be used underwater, especially since water can prevent dust and overheating. Ensure the backing material is also suitable for underwater use.

Avoid using them on extremely soft or delicate materials where they might cause damage. Also, do not use them in environments where their dust could pose a hazard, such as in areas with flammable gases or dust.

Diamond sheets are typically more aggressive and have a longer lifespan than ceramic abrasives, making them more cost-effective in the long run, despite a higher initial cost. They are especially superior for very hard materials.

Caution is needed. While diamond sheets are efficient in heat dissipation, the friction can still generate heat which might affect heat-sensitive materials.

Storage solutions that keep the sheets flat and protected are ideal. Avoid containers where they might be bent or where other tools can scratch their surface.

Professional settings must adhere to regulations regarding dust extraction, personal protective equipment, and proper disposal of abrasive waste. Always follow local guidelines and industry best practices.

Yes, their precision and ability to work on hard materials make them suitable for many precision engineering tasks.

If used on hazardous materials, the sheets might need to be disposed of as hazardous waste. Consult local regulations for guidance.

Look for visible signs of wear, such as a reduction in the abrasive quality or changes in the sheet’s texture. Decreased performance is also an indicator.

They are commonly used in sectors like gemstone and glass processing, precision metalworking, and in the manufacturing of ceramics and hard metal components.

Yes, they are often used as part of a multi-step process, especially where different levels of abrasiveness are required, from rough grinding to fine polishing.

Some brands focus on sustainability in their manufacturing processes. Research brands that prioritize eco-friendly practices or use sustainably sourced materials.

Their long lifespan and efficiency support lean principles by reducing waste and the need for frequent replacements, thus contributing to more streamlined and cost-effective processes.

Yes, they are suitable for hard aerospace materials, including titanium and certain composites, but always follow industry-specific guidelines for material treatment

Ongoing advancements in material science may lead to even more efficient and longer-lasting diamond abrasives. Stay updated with industry news and manufacturer releases for the latest developments.

Diamond abrasive sheets typically exhibit excellent heat resistance due to the inherent properties of diamonds. They are less likely to deteriorate from heat generated during grinding or polishing compared to many other abrasives.

Absolutely. Their precision and ability to handle hard materials make them ideal for detailed sculpting work in stone, metal, and other hard materials.

Using them with water (wet sanding) can significantly reduce dust generation. Additionally, using proper dust extraction systems and working in well-ventilated areas can help.

While the initial cost may be higher than some traditional tools, their longevity and efficiency can make them more cost-effective over time, especially for tasks involving hard materials

Professional settings should provide training on the correct use of these sheets, including handling, safety precautions, and proper use of personal protective equipment.

They can be used on such materials, but with great care to avoid damaging the delicate structure. A finer grit and gentle technique are recommended.

Consider the hardness of the material and the desired outcome. Use coarser grits for material removal and finer grits for finishing. Manufacturer guidelines can also provide specific recommendations

In humid or marine environments, protect the sheets from moisture and corrosion by storing them in a dry, airtight container. Regular cleaning and drying after use are also beneficial.

Yes, they can be used for such tasks, especially where the hardness of the floor material requires a more aggressive abrasive, like concrete or stone floors.

Their long lifespan means fewer replacements and less waste generated over time, which can be seen as an environmental benefit. However, the environmental impact of diamond extraction should also be considered.

Diamond abrasive sheets offer more flexibility and can be more cost-effective for certain applications, especially those requiring a flat or flexible abrasive surface. Diamond-coated tools might be preferred for more specialized or heavy-duty tasks.

They can be used for certain applications in these industries, especially where hard materials like silicon wafers are involved. However, extreme precision and care are required.

Specific recycling programs for these sheets are rare, but it’s worth checking with the manufacturer or local waste management services. Otherwise, follow standard disposal guidelines for abrasive materials.

Yes, they are suitable for grinding and polishing in precision optics, provided the correct grit size and technique are used to avoid damaging the delicate surfaces.

The main limitation is the sheet’s size and the user’s ability to effectively manipulate the material and the abrasive. For very thick or large materials, machinery or larger abrasive formats might be more appropriate.

Diamond Abrasive Flexible Sheets are typically thicker and used for grinding, polishing, and finishing surfaces, especially hard materials. Diamond Foil, on the other hand, is much thinner, almost like a foil, and is often used for precision applications where extreme flexibility and a finer touch are required.

Diamond Abrasive Sheets generally offer greater durability due to their thicker construction. Diamond Foil, while effective, is more delicate and may not withstand heavy or rough use.

Yes, both can be used on hard materials, but the sheets are typically better for tougher jobs, while the foil is suited for more delicate or precision tasks.

Diamond Abrasive Sheets are generally more versatile in terms of the range of materials they can work on and the types of tasks they can handle, from aggressive grinding to fine polishing.

The cost can vary, but Diamond Foil tends to be more specialized and can be more expensive per unit area compared to Diamond Abrasive Sheets

Diamond Foil is often better for detailed and precision work due to its thinner and more flexible nature, allowing for finer control.

Diamond Abrasive Sheets are often used in a manner similar to regular sandpaper, either manually or attached to tools. Diamond Foil, being thinner, might require more careful handling and is often used for delicate, precision applications.

Yes, both can typically be used for wet applications, but it’s always best to check the manufacturer’s specifications to be sure.

Diamond Foil is often preferred in industries requiring high precision, such as in the manufacturing of certain electronics, optics, or fine jewelry.

Generally, Diamond Abrasive Sheets have a longer lifespan due to their thicker and more robust construction. Diamond Foil, while effective, may wear out more quickly due to its thinness.

Diamond Abrasive Sheets are typically easier to store and maintain due to their more robust nature. Diamond Foil, being thinner and more delicate, requires careful handling and storage to prevent damage.

Yes, both come in various grades and qualities, which can affect their performance, lifespan, and cost.

While it can be used on a variety of materials, its best use is on harder materials where its precision capabilities are most beneficial. Its effectiveness on soft materials would depend on the specific application and required finish.

Both have similar environmental impacts in terms of production and disposal. However, the longer lifespan of Diamond Abrasive Sheets might lead to less frequent replacement and, consequently, a slightly lower environmental footprint over time.

Diamond Abrasive Flexible Sheets are typically more flexible and adaptable to various surfaces, ideal for hand-held use. Metal Bond Diamond Discs are more rigid, often used with machines, and are excellent for heavy-duty grinding tasks due to their durability and strength.

Resin Bond Diamond Discs generally provide a smoother finish than Diamond Abrasive Sheets. They are preferred for fine polishing, especially where a high-gloss finish is desired, as resin bonds can hold smaller diamond particles more evenly.

Yes, in many cases. Their flexibility allows them to be used on a variety of surfaces and contours, making them suitable for more intricate or detailed work.

Metal Bonded Abrasives are typically more durable and suitable for prolonged heavy-duty use. Diamond Abrasive Sheets, while durable, may wear out faster under intense grinding conditions.

Diamond Abrasive Sheets can be more cost-effective for small-scale or detailed work. Metal and Resin Bond Diamond Discs are often more expensive, reflecting their specialized use and longer lifespan.

It depends on the specific product. Some Diamond Abrasive Sheets are designed to be adaptable to certain machines, while others are intended for hand use only.

Diamond Abrasive Sheets are often used manually or attached to hand tools, offering more control for detailed work. Diamond Abrasive Discs are typically machine-operated, suitable for larger, more uniform surfaces.

Both can be used for wet applications, but Metal Bond Diamond Discs are often preferred for their durability and effectiveness in wet conditions.

Resin Bond Diamond Discs generally provide a higher quality finish, especially for fine polishing tasks, due to their ability to hold finer diamond particles more evenly.

For hard, dense materials like stone or concrete, Metal Bond Diamond Discs are often preferred. For softer or more delicate materials, or for detailed work, Diamond Abrasive Sheets may be more suitable.

The impact is similar, though the longer lifespan of Diamond Discs might lead to less frequent replacement and a slightly lower environmental footprint over time.

While there is some overlap, Diamond Discs are generally better for larger, more uniform surface work, and Diamond Sheets are more suited for detailed or contour work.

Yes, due to their flexibility and size, Diamond Abrasive Sheets are typically easier to store and require less maintenance than rigid Diamond Discs.

Safety considerations are similar, involving eye protection, dust control, and proper handling. However, machine-operated Diamond Discs may require additional safety measures due to the machinery involved.

Yes, Diamond Abrasive Sheets are versatile and can be used in both DIY and professional settings. Diamond Discs are also widely used in professional environments, especially for tasks requiring heavy-duty grinding or polishing.

Metal Bond Diamond Discs typically remove material faster due to their rigid structure and are more suitable for rapid stock removal. Diamond Abrasive Sheets may be slower but offer more control, especially on delicate surfaces.

Yes, Diamond Abrasive Sheets can often be cut to specific sizes or shapes to suit particular applications, offering a degree of customization similar to certain types of Diamond Discs.

Diamond Abrasive Sheets generally have a lower initial cost but may have a higher long-term cost if they need to be replaced more frequently. Resin Bond Diamond Discs can be more expensive upfront but may offer better long-term value due to their durability.

Diamond Foil is particularly advantageous for extremely precise and delicate applications, such as in fine jewelry making or precision engineering, where its ultra-thin and flexible nature allows for very detailed work.

Diamond Abrasive Sheets are often considered easier to use, especially for beginners or in hand-held applications, due to their flexibility and adaptability. Diamond Discs may require more skill or specific machinery to operate effectively.

Diamond Abrasive Sheets are commonly available and can be found in many hardware stores. Specialized Diamond Discs, particularly those for industrial applications, might be less readily available and may require purchase from specialized suppliers.

Waste disposal considerations are similar for both, with the main difference being the frequency of disposal due to the typically longer lifespan of Diamond Discs.

Absolutely. Many professionals use a combination of both, utilizing Diamond Discs for initial, heavy grinding and Diamond Abrasive Sheets for finer, more detailed work or finishing.

Industries Used In

Tab Content

Accessories

Tab Content

Recommendations

- Mind the Pressure Distribution When using the sheets, especially on softer materials, ensure that the pressure is evenly distributed. Uneven pressure can lead to gouges in the material and uneven wear on the abrasive sheet.

- Angle of Application: Pay attention to the angle at which you hold the abrasive sheet against the workpiece. The angle can affect the efficiency of material removal and the final finish.

- Use for Finishing Edges and Corners: Diamond abrasive sheets are excellent for finishing edges and corners where precision is required. Their flexibility allows them to conform to irregular shapes and tight spaces.

- Layering Sheets: In some applications, layering two or more sheets can provide a cushioned, more uniform sanding surface. This technique can be useful when working on curved or contoured surfaces.

- Avoiding Cross-Contamination Between Different Grits: If you’re using multiple grit sizes, be careful to avoid cross-contamination. Clean the workpiece and your hands when switching between different grits to maintain the integrity of the finish.

- Sequential Sanding Steps: When working towards a highly polished finish, progress through the grits in sequential steps without skipping any. Skipping grits can leave deeper scratches that are difficult to remove.

- Check Sheet Orientation: Some diamond abrasive sheets are directional, meaning they are designed to be used in a specific orientation relative to the workpiece. Check for any directional indicators on the sheet or packaging.

- Monitor Sheet Temperature : If the sheet gets too hot during use, it can lose its effectiveness and potentially damage the workpiece. If you notice excessive heat, stop and allow time for cooling.

- Use in a Well-Lit Area: Good lighting is essential for quality work, especially when working on detailed or precision tasks. It helps in accurately assessing the progress and finish quality

- Environmental Conditions: Be mindful of the environmental conditions in your workspace. High humidity or extreme temperatures can affect both the performance of the sheet and the material you’re working on.

- Safe Disposal of Used Sheets: Dispose of used diamond abrasive sheets safely. While they are not typically hazardous, they should be disposed of in a way that prevents accidental injury or environmental harm.

- Record Keeping for Professional Use: If using these sheets in a professional setting, keep records of their usage. This helps in tracking their performance and understanding when they are due for replacement.

- Regular Inspection for Wear and Tear: Frequently inspect the sheets for signs of wear, tear, or any damage. Using worn-out or damaged sheets can lead to inefficient work and potentially damage the workpiece.

- Avoid Using on Unsuitable Materials: While diamond abrasive sheets are versatile, using them on unsuitable materials can lead to rapid wear of the sheet or damage to the material. Always ensure the sheet is appropriate for the material you’re working on.

- Proper Hand Positioning for Manual Sanding: When sanding manually, use the whole hand or a block to apply pressure. This helps in even distribution of force and prevents finger marks on the workpiece.

- Use with Compatible Machinery: If using the sheets with machinery (like orbital sanders or grinders), ensure the machinery is compatible with the sheets in terms of size, speed, and attachment method..

- Compatibility with Materials: Ensure that the coolant is compatible with the material you are cutting. Some materials may react adversely with certain coolants.

- Avoid Sharp Folds: When handling the sheets, avoid making sharp folds or bends, as this can break the abrasive surface and render the sheet less effective.

- Cutting Precision: For very precise cuts, a slower RPM may be beneficial as it allows for more control.

- Limit Exposure to Moisture: If the sheets are not designed for wet applications, limit their exposure to moisture as this can affect the adhesive or the backing material.

- Proper Cleaning of Sheets: Some diamond abrasive sheets can be cleaned to extend their life. Use appropriate cleaning methods, such as gentle brushing or rinsing with water, depending on the sheet’s design.

- Use in Controlled Environments: For precision work, use the sheets in controlled environments where factors like dust, temperature, and humidity are managed.

- Alternate Between Sheets: If you have multiple sheets, alternate between them to allow time for each sheet to rest and potentially extend their lifespan.

- Understand the Limitations: While diamond abrasive sheets are highly effective, they do have limitations. Understanding these can help set realistic expectations about their performance and lifespan.

- Document Usage for Specific Projects: Keeping a record of which sheets (and grits) were used for specific projects can be helpful for future reference, especially if you achieve desired results and want to replicate them.

- Mind the Storage Orientation: For sheets not in use, store them either hanging vertically or lying flat. This prevents them from bending or curling, which could affect their performance.

- Rotate Sheets During Use: If the sheet is larger than the tool or hand block, rotate it periodically to ensure even wear across the entire surface.

- Be Aware of Dust Accumulation: Especially in dry sanding, dust can accumulate quickly. Regularly clean off the dust from both the workpiece and the sheet to maintain optimal performance and visibility.

- Consider Sheet Thickness for Specific Tasks: Thicker sheets might be more durable and suitable for heavy-duty tasks, while thinner sheets can be better for detailed work. Choose the thickness based on the specific requirements of your project.

- Use a Stabilizing Hand or Tool : For precise work, use a stabilizing hand or tool to guide the abrasive sheet and maintain control over the sanding or polishing process.

- Avoid Excessive Bending of the Sheet: While diamond abrasive sheets are flexible, excessive bending or folding, especially at sharp angles, can damage the abrasive surface or the backing material.

- Check for Sheet Compatibility with Chemicals: If using chemicals in your process (like solvents or cleaners), ensure that the diamond abrasive sheet is compatible and won’t be degraded by these chemicals.

- Use Adequate Lighting for Precision Work: Good lighting is crucial for precision work to ensure you can see the progress of your work and achieve the desired finish.

- Be Cautious with Edge Work: When working on edges or sharp corners, be cautious as these areas can wear down the sheet more quickly and potentially lead to tearing.

- Balance Between Speed and Quality: Find a balance between working speed and the quality of finish. Rushing the process can lead to mistakes or a lower quality finish.

- Consider Environmental Impact:Be aware of the environmental impact of your work, especially regarding dust generation and disposal of used sheets.

- Use the Right Pressure for the Material : Different materials require different amounts of pressure. Harder materials might need more pressure, while softer materials require a lighter touch.

- Prepare for Clean-Up: Have a plan for clean-up post-sanding or polishing, especially if working with materials that generate hazardous dust.

- Educate Yourself on Material-Specific Techniques: Different materials may require specific sanding or polishing techniques. Educate yourself on the best practices for the materials you are working with.

- Stay Patient and Focused: Quality sanding and polishing require patience and focus. Rushed work often leads to mistakes or poor-quality finishes.

- Regularly Check for Debris: During use, check the abrasive surface for debris or material build-up. This can reduce the effectiveness of the sheet and potentially scratch the workpiece.

- Use a Dust Extraction System: If available, use a dust extraction system to minimize airborne particles, especially when working in an enclosed space or with hazardous materials.

- Be Mindful of Directional Sanding: Some applications may benefit from sanding in a particular direction, especially when working with materials like wood or certain metals, to achieve the best finish or to avoid damage.

- Consider Using a Padding Layer: For certain applications, using a padding layer between the sheet and the tool or block can provide a more uniform pressure distribution, especially on uneven surfaces.

- Avoid Using Worn-Out Sheets for Precision Work: Once a sheet starts showing signs of wear, it may no longer be suitable for precision work, though it could still be used for rougher, initial stages of sanding.

- Periodically Change Sanding Angles: Changing the angle of sanding periodically can help achieve a more uniform surface and reduce the chances of creating grooves or patterns in the material.

- Be Cautious with Highly Abrasive Materials: When working with materials that are highly abrasive themselves, such as certain ceramics or hardened steels, be aware that they can cause rapid wear on the diamond sheet.

- Use Gentle Motions for Delicate Materials: For delicate or brittle materials, use gentle, controlled motions to avoid cracking or chipping the material

- Optimize Your Workstation: Ensure your workstation is set up ergonomically to prevent strain or injury, especially during long or repetitive tasks.

- Dispose of Sheets Responsibly: Be mindful of the environmental impact when disposing of used abrasive sheets. Follow any relevant guidelines or regulations for disposal of such materials.

- Keep a Usage Log: Especially in professional settings, keeping a log of usage can help track the performance and lifespan of the sheets, aiding in future purchasing decisions.

- Stay Informed About Material Safety Data Sheets (MSDS): For certain materials, refer to their MSDS for safety information, especially when sanding can release harmful substances.

- Use Sheets in a Ventilated Area: Ensure adequate ventilation in your working area to avoid the accumulation of harmful dust, especially when working with materials like fiberglass or certain metals.

- Be Prepared for Emergency Situations: Have a plan in place for emergency situations, such as accidental inhalation of dust or contact with eyes.

- Respect the Sheet’s Limitations: Understand that while diamond abrasive sheets are highly effective, they have their limitations and are not suitable for every type of material or application.

- Seek Feedback on Your Work: If possible, get feedback on your finished work to learn and improve your technique over time.

- Stay Organized: Keep your abrasive sheets and related tools organized. This not only helps in finding the right tool when needed but also in maintaining the condition of the sheets.

- Be Aware of Static Electricity: In some cases, sanding can generate static electricity. Be cautious, especially in environments where this could pose a risk.

- Clean the Work Area Post-Completion: After completing your task, clean the work area thoroughly to remove any residual dust or debris.

- Continuous Learning and Improvement: Sanding and polishing are skills that can always be improved. Continuously learn and adapt your techniques for better results.

TROUBLE SHOOTING GUIDE

|

Problem |

Possible Causes |

Solutions |

|---|---|---|

|

Sheet is not effectively sanding |

Dull or worn-out abrasive surface |

Replace with a new sheet |

|

Incorrect grit size for the task |

Use a sheet with an appropriate grit size for the material and desired finish |

|

|

Clogged with debris |

Clean the sheet, or if it’s too clogged, replace it |

|

|

Sheet is tearing easily |

Excessive pressure during use |

Use lighter pressure |

|

Improper storage leading to brittleness |

Store sheets flat or gently rolled, avoid folding |

|

|

Using a sheet not suited for the tool or hand block |

Ensure compatibility between the sheet and the tool or block |

|

|

Workpiece is getting scratched |

Contamination with larger grit particles |

Clean the workpiece and sheet thoroughly before use |

|

Using a worn-out or damaged sheet |

Inspect the sheet before use and replace if damaged |

|

|

Applying uneven pressure |

Distribute pressure evenly during sanding |

|

|

Sheet is not adhering to the tool |

Worn-out backing |

Replace the sheet |

|

Incompatible tool and sheet attachment system |

Ensure the attachment system of the sheet matches the tool |

|

|

Excessive dust generation |

Sanding too aggressively |

Use a gentler approach and proper dust extraction methods |

|

Lack of dust extraction system |

Use a dust extraction system or ensure adequate ventilation |

|

|

Heat buildup on the workpiece |

High friction due to excessive pressure or speed |

Reduce pressure and/or speed, use wet sanding if applicable |

|

Continuous use without breaks |

Take regular breaks to allow the tool and workpiece to cool |

|

|

Uneven finish |

Inconsistent sanding pattern |

Use consistent strokes and regularly change sanding areas |

|

Skipping grit sizes |

Progress through grit sizes sequentially without skipping |

|

|

Not using the entire surface of the sheet |

Rotate the sheet to use different areas and ensure even wear |

|

|

Rapid wear of the sheet |

Using on unsuitable material |

Ensure the sheet is appropriate for the material you’re working on |

|

Too much pressure |

Use lighter pressure and let the abrasive do the work |

|

|

Sheet quality |

Use higher quality or more suitable sheets for your task |

|

|

Sheet is not flexible enough |

Improper storage (e.g., high humidity) |

Store in a dry, controlled environment; avoid moisture exposure |

|

Material of the sheet |

Select sheets with a more suitable backing material for flexibility |

|

|

Insufficient or inappropriate coolant |

Use the correct coolant and ensure proper flow |

|

|

Poor finish quality |

Using the wrong grit progression |

Use the correct sequence of grit sizes, gradually moving from coarse to fine |

|

Inadequate surface preparation |

Properly clean and prepare the surface before starting |

|

|

Old or worn-out sheet |

Replace the sheet with a new one |

|

|

Difficulty in handling sheets |

Improper size for the tool or hand |

Cut or select sheets that properly fit your tool or hand size |

|

Lack of experience |

Practice with different techniques and handling methods |

|

|

Ineffective on hard materials |

Low diamond concentration |

Use sheets with a higher diamond concentration |

|

Inappropriate grit size |

Use a coarser grit for initial stages, then move to finer grits |

|

|

Sheet detaching from backing |

Adhesive failure |

Store sheets in a cool, dry place to preserve adhesive quality |

|

Wear and tear |

Replace sheets when the backing starts to deteriorate |

|

|

Dust control issues |

Inadequate dust extraction |

Use a proper dust extraction system or improve ventilation |

|

Dry sanding on materials that generate hazardous dust |

Consider wet sanding methods if suitable for the material |

|

|

Overheating of the sheet |

Excessive speed on power tools |

Adjust the tool to a lower speed setting |

|

Continuous use without breaks |

Take regular breaks to allow the sheet to cool down |

|

|

Difficulty in achieving uniform finish |

Uneven pressure application |

Use a sanding block or tool to apply even pressure |

|

Inconsistent sanding motion |

Maintain consistent and uniform strokes during sanding |

|

|

Sheet slipping on the tool |

Worn-out attachment system |

Check and replace the attachment system if necessary |

|

Incompatible tool and sheet |

Ensure the sheet and tool are compatible in terms of size and attachment |

|

|

Sheet loses abrasiveness quickly |

Inadequate diamond quality |

Choose sheets with higher-quality diamonds |

|

Overuse of a single area |

Rotate and use different parts of the sheet to ensure even wear |

|

|

Difficulty in sanding corners or curves |

Sheet too rigid |

Opt for more flexible sheets or those with a thinner backing |

|

Incorrect technique |

Use a rolling or rocking motion to better navigate curves and corners |

|

|

Sheet bunching up or creasing |

Improper handling or storage |

Store flat or rolled, handle gently to avoid creasing |

|

Using sheets that are too large |

Cut the sheets to a more manageable size |

|

|

Inconsistent scratch patterns |

Varying grit sizes on the same sheet |

Ensure uniform grit size across the sheet; avoid mixing grits |

|

Improper sanding technique |

Use consistent, overlapping strokes |

|

|

Sheet not conforming to surface shapes |

Backing material too stiff |

Use sheets with a more flexible backing for contoured surfaces |

|

Incorrect sheet size |

Use appropriately sized sheets for the workpiece |

|

|

Difficulty with wet sanding |

Sheet not designed for wet use |

Ensure the sheet is rated for wet sanding |

|

Water degrading the sheet |

Use water sparingly and according to manufacturer recommendations |

|

|

Machine calibration issues |

Calibrate the saw according to manufacturer’s guide |

|

|

Excessive material removal |

Too coarse a grit |

Start with a finer grit or apply less pressure |

|

Applying too much pressure |

Let the abrasive do the work; apply minimal pressure |

|

|

Sheet glazing over |

Material smearing on the sheet |

Clean the sheet regularly; check if the material is suitable for diamond abrasives |

|

Insufficient diamond exposure |

Use a dressing tool to expose fresh diamond particles |

|

|

Improper feed rate |

Adjust the feed rate for more efficient cutting |

|

|

Sheet not effective on soft materials |

Grit too coarse |

Use a finer grit for softer materials |

|

Excessive pressure |

Apply lighter pressure to avoid digging into the material |

|

|

Difficulty in manual sanding |

Hand fatigue |

Use a sanding block for better grip and pressure distribution |

|

Inefficient sanding motion |

Use long, uniform strokes for more efficient sanding |

|

|

Sheet edges fraying |

Rough handling or use |

Handle the sheets gently; avoid aggressive use near edges |

|

Cutting sheets improperly |

Use sharp tools to cut sheets cleanly |

|

|

Sheet is scratching the workpiece |

Debris trapped under the sheet |

Clean the workpiece and sheet to remove trapped particles |

|

Hard particles embedded in the sheet |

Inspect the sheet for embedded particles and replace if necessary |

|

|

Reduced effectiveness over time |

Saturation with material being sanded |

Clean the sheet regularly to remove build-up |

|

Reduced effectiveness over time |

Saturation with material being sanded |

Clean the sheet regularly to remove build-up |

|

Difficulty in achieving high polish |

Replace the sheet when diamonds are worn down |

|

|

Difficulty in achieving high polish |

Using the wrong sequence of grits |

Follow the correct progression from coarser to finer grits |

|

Inadequate time spent on each grit |

Spend enough time with each grit size before moving to the next finer grit |

|

|

Sheet is slipping during use |

Inadequate securing method |

Ensure the sheet is properly secured to the tool or hand block |

|

Worn-out securing mechanism |

Replace or repair the securing mechanism of the tool or hand block |

|

|

Uneven wear of the sheet |

Concentrating on one area too long |

Move the sheet around the workpiece to distribute wear evenly |

|

Improper storage causing warping |

Store the sheets flat or properly rolled to prevent warping |

|

|

Difficulty with detailed work |

Sheet size too large for detailed areas |

Cut the sheet into smaller pieces for detailed work |

|

Lack of appropriate tools |

Use tools like detail sanders for intricate areas |

|

|

Sheet leaving residue on workpiece |

Incompatible materials |

Ensure the material of the workpiece is compatible with the diamond sheet |

|

Excessive heat melting the backing |

Reduce speed or pressure to avoid overheating |

|

|

Sheet not conforming to small details |

Too thick or rigid |

Use thinner or more flexible sheets for detailed work |

|

Inappropriate backing material |

Choose sheets with a more suitable backing for detailed applications |

|

|

Discoloration of the workpiece |

Heat buildup |

Use lower speed or pressure, and allow the workpiece to cool |

|

Reaction between sheet and material |

Check for any chemical reactions between the sheet material and the workpiece |

|

|

Noise or vibration during use |

Loose attachment |

Secure the sheet firmly to the tool or hand block |

|

Incompatible tool speed |

Adjust the tool speed to a suitable level for the sheet |

|

|

Rapid depletion of sheets |

Using sheets beyond their lifespan |

Replace sheets regularly to maintain effectiveness |

|

Incorrect storage leading to premature aging |

Store in a cool, dry place away from direct sunlight and moisture |

|

|

Sheet losing flexibility |

Exposure to extreme temperatures |

Store in a temperature-controlled environment |

|

Age and repeated use |

Replace old or excessively used sheets |

|

|

Inconsistent abrasive action |

Uneven diamond distribution |

Choose higher-quality sheets with uniform diamond distribution |

|

Varying pressure during use |

Maintain consistent pressure while sanding |

|

|

Difficulty in maintaining sheet flatness |

Improper handling or storage |

Handle gently and store flat or properly rolled |

|

Humidity affecting the backing material |

Store in a low-humidity environment |

|

|

Sheet not cutting as expected |

Diamond grit too fine for the material |

Use a coarser grit for initial cuts |

|

Dulling of diamonds over time |

Replace the sheet when diamonds appear to be dulled |

|

|

Workpiece contamination |

Transfer of material from sheet to workpiece |

Clean the sheet and workpiece regularly to prevent transfer |

|

Chemical reaction with certain materials |

Test the sheet on a small area of the workpiece first |

|

|

Sheet edges curling up |

Improper storage or handling |

Store sheets flat and handle them carefully to avoid bending |

|

Use of inappropriate adhesives |

Ensure that any adhesives used are compatible with the sheet material |

|

|

Difficulty in achieving a mirror finish |

Skipping necessary intermediate grits |

Use all necessary intermediate grits for a gradual and even finish |

|

Not spending enough time on finer grits |

Spend adequate time on each finer grit to fully refine the surface |

|

|

Sheet becoming discolored |

Chemical reaction with the workpiece or environment |

Avoid using the sheet with reactive materials and store in a chemically neutral environment |

|

Overheating during use |

Reduce friction by adjusting speed, pressure, and using lubricants if applicable |

|

|

Sheet producing excessive noise |

Resonance with the tool or workpiece |

Adjust the tool speed or change the method of application |

|

Ensure the sheet is securely attached to the tool |

||

|

Difficulty in sheet removal from tool |

Overly strong adhesive used |

Use a less aggressive adhesive or a different attachment method |

|

Sheet tearing during removal |

Gently peel the sheet off; consider using sheets with stronger backing |

|

|

Sheet not performing well on specific materials |

Incompatibility with certain materials |

Research and use sheets specifically designed for the material in question |

|

Lack of experience with the material |

Practice on scrap pieces to understand how the material interacts with the sheet |

|

|

Sheet is not performing well at high speeds |

Not designed for high-speed use |

Check the manufacturer’s specifications for optimal speed range |

|

Heat buildup at high speeds |

Reduce speed or use intermittent sanding to allow cooling |

|

|

Difficulty in manual sanding on large surfaces |

Sheet size too small |

Use larger sheets or attach sheets to a larger block for better coverage |

|

Hand fatigue |

Take regular breaks or use a power tool if possible |

|

|

Use of corrosive coolants |

Switch to a non-corrosive coolant |

|

|

Sheet is gumming up |

Sanding material that is too soft or gummy |

Use a less aggressive grit or a different type of abrasive |

|

Lack of proper lubrication |

Use appropriate lubricants to prevent gumming |

|

|

Sheet is not adhering to curved surfaces |

Backing material too stiff |

Use sheets with more flexible backing for curved surfaces |

|

Improper technique |

Use a softer touch and allow the sheet to conform to the curves |

|

|

Difficulty in achieving straight edges |

Hand sanding without a guide |

Use a straight edge or guide for precision work |

|

Sheet shifting during use |

Secure the sheet more firmly to the sanding block or tool |

|

|

Sheet is causing excessive dust |

Material being sanded is very dusty |

Use appropriate dust extraction and personal protective equipment |

|

Dry sanding method |

If possible, switch to wet sanding to reduce dust |

|

|

Sheet is not effective on wet surfaces |

Not designed for wet use |

Ensure the sheet is suitable for wet sanding |

|

Water degrading the backing material |

Use water-resistant sheets for wet sanding |

|

|

Difficulty in cleaning the sheet |

Difficulty in cleaning the sheet |

Use a soft brush or cloth to clean the sheet; for stubborn debris, rinse with water if appropriate |

|

Material stuck to the sheet |

If material is stuck and cannot be removed, the sheet may need to be replaced |

|

|

Sheet is wearing out unevenly |

Uneven pressure during use |

Practice applying even pressure across the sheet |

|

Sanding on uneven surfaces |

Use a more flexible sheet or a softer backing pad for uneven surfaces |

|

Grift Size |

Color |

Bond Type |

Bond Type |

|||

|---|---|---|---|---|---|---|

|

50mm X 100mm |

100mm X 100mm |

1,170mm X 295mm |

690mm X 295mm |

|||

|

#60 #120 #200 #400 #600 #1000 #500 #1000 #8000 |

Green Black Red Yellow White Blue White Blue Orange |

Nickel Bond Nickel Bond Nickel Bond Nickel Bond Nickel Bond Nickel Bond Resin Bond Resin Bond Resin Bond |

10012 10014 10016 10018 10020 10022 10024 10026 10028 |

20014 20016 20018 20020 20022 20024 20026 20028 20030 |

30016 30018 30020 30022 30024 30026 30028 |

40030 40032 40034 |

Uses:

- Great for smoothing glaze drips or sharp edges

- Works well on high-fired ceramic. tile, stone or glass

- Good for smoothing of bisque-ware

Benefits

- Can be used wet or dry

- Flexible for getting in tight areas

- Doesn't disintegrate in water like sandpaper

- Much faster than sandpaper

- Much longer-lasting than sandpaper

- Requires fewer strokes and less force than sandpaper

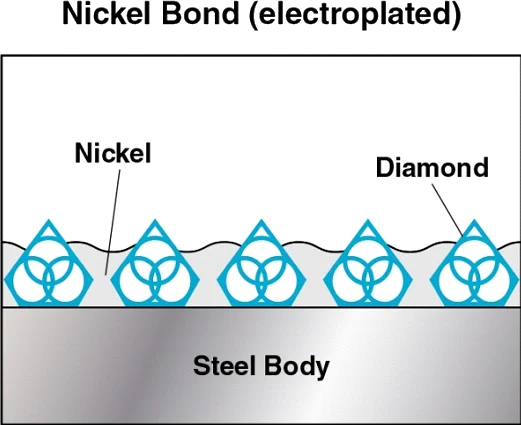

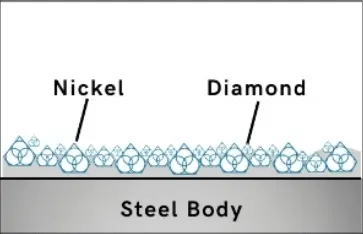

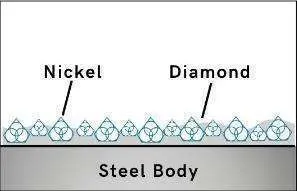

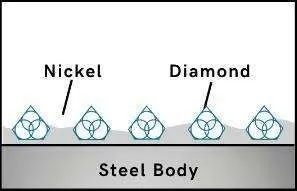

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside.

Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Flexible Sheet

Diamond Abrasive Flexible Sheet – Nickel Bond (Plated)

Selected high quality diamonds are electroplated with a nickel matrix through a special flexible stainless steel mesh, or a very strong flexible backing cloth, which achieves a very strong fast grinding and finishing product.

Flexible Sheet

Diamond Abrasive Flexible Sheet – Resin Bond

The finer resin polishing grades are bonded with a resin matrix on to a very strong flexible backing cloth for a smooth grinding action to achieve an excellent polished finish.

Wet Working

SMART CUT® diamond sheets have been designed to be used wet to achieve the maximum performance, finish and life.

Dry Working

Some of the nickel bond flexible sheets can be used dry without coolant on certain applications.

Advantages:

Exceptional Hardness and Durability :

Diamonds are the hardest known natural material. This extreme hardness makes diamond abrasive sheets highly effective at grinding, shaping, or polishing harder materials like stone, glass, ceramics, and hard metals. They also tend to have a longer lifespan compared to other abrasive materials like silicon carbide or aluminum oxide.

Precision and Consistency :

Diamond abrasives provide a high level of precision and consistency in finishing surfaces. They are capable of producing exceptionally smooth and uniform finishes, which is crucial in applications requiring high precision, such as in the optics industry or in fine metalworking.

Versatility :

These sheets can be used on a variety of materials, making them versatile tools in both industrial and craft contexts. They can be used on materials that are difficult to work with using other types of abrasives.

Flexibility :

The flexibility of these sheets allows them to be used on contoured or irregular surfaces, which is particularly useful in detailed work or in situations where rigid tools cannot reach or effectively process the material.

Reduced Heat Generation :

Diamond abrasives can be more efficient in heat dissipation, reducing the risk of heat damage to the workpiece. This is particularly important in precision applications where thermal distortion can be a concern.

Variety of Grit Sizes :

Like other abrasive materials, diamond sheets come in a range of grit sizes, allowing for everything from rapid material removal to fine polishing. This range makes them suitable for multiple stages of a finishing process.

Improved Safety and Reduced Dust :

When used properly, diamond abrasive sheets can produce less dust than some other abrasive materials, which is beneficial for both the working environment and the health and safety of the user.

Cost-Effectiveness Over Time :

Although diamond abrasive sheets might have a higher initial cost compared to other abrasive materials, their durability and longevity can make them more cost-effective in the long run, especially in industrial or high-volume settings.

Water Compatibility :

Many diamond abrasive sheets can be used with water, which can further reduce dust and heat, and improve the quality of the finish.

Eco-Friendliness :

Due to their durability and longevity, these sheets can be seen as more environmentally friendly, as they need to be replaced less frequently than other abrasive materials.

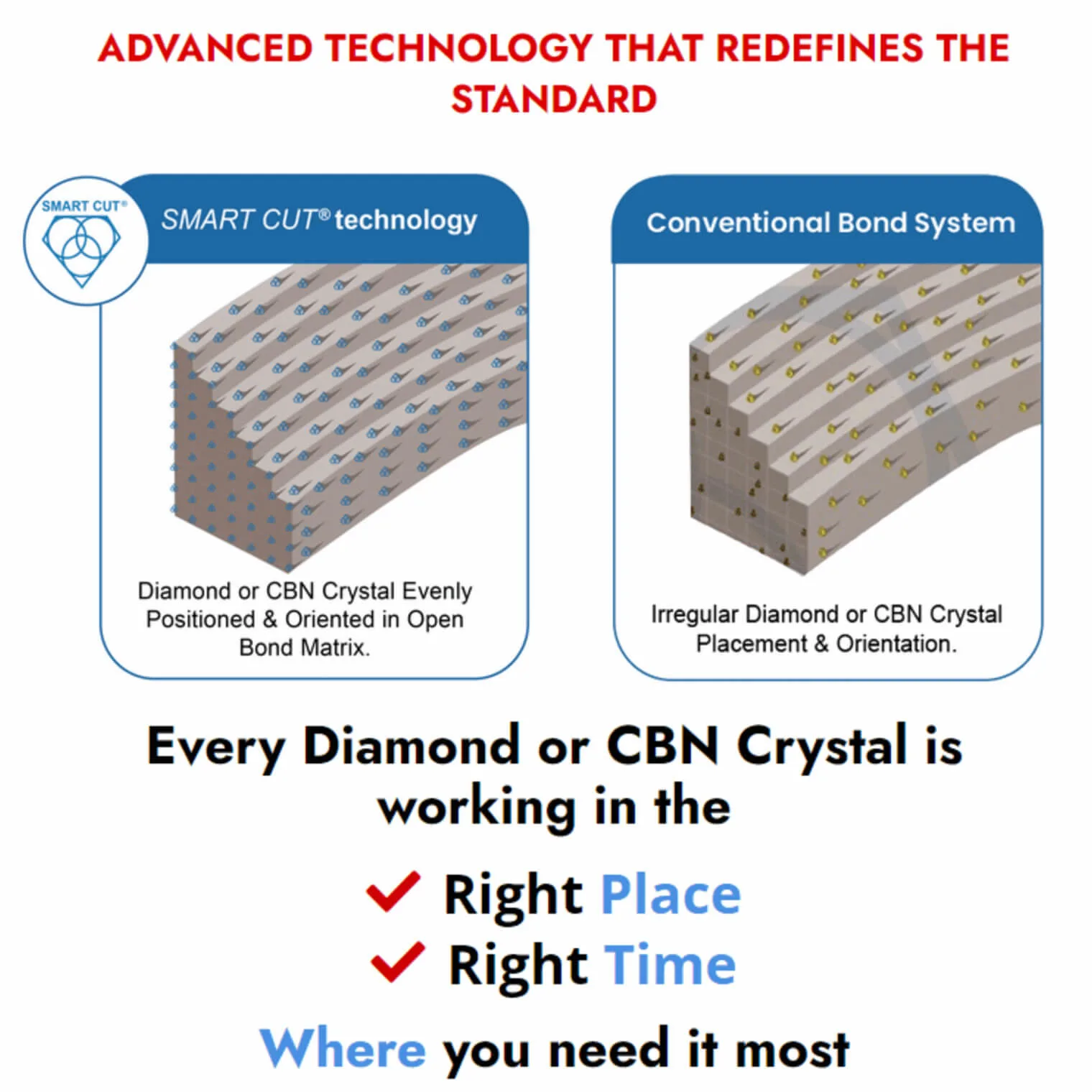

How SMART CUT® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Faster

Cutting Action

Diamond & CBN tools made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

Manufactured Using

The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Best

Performance & Value on the Market

SMART CUT® Resin Bond, CBN Blades are the best investment you can make! While the initial investment in CBN blades may be higher than traditional abrasive wheels, their long lifespan and efficiency often result in a lower cost per cut. This can provide to significant savings in time and money.

Longer

Life

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional material (sintered), resin, and nickel bonded diamond & CBN tools. SMART CUT® diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

More

Consistent Performance

SMART CUT® Series Resin Bond, CBN Blades have hundreds of diamond layers impregnated inside the resin matrix. Unlike Many Other Blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Expect More From Your Tools

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

ARE YOU USING RIGHT diamond Abrasive Sheet

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT diamond Abrasive Sheet?

Knowledge Center

02

Jun

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...