Dicing Blade Case Studies

-

Posted by

Alexander Schneider

Alexander Schneider

Table of Contents

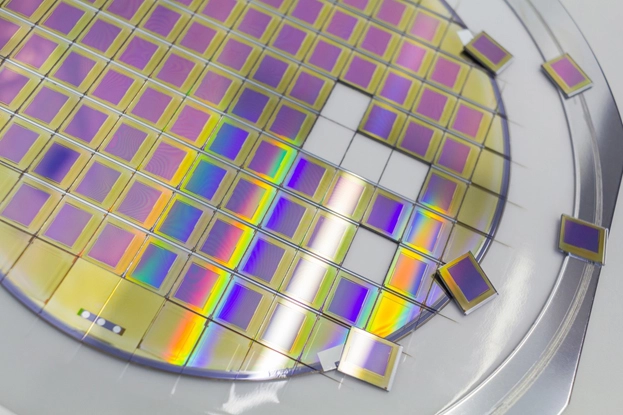

ToggleSelecting the right dicing blade is important to achieving high yields, superior edge quality, and consistent reliability in microelectronics and optics manufacturing. Across industries such as semiconductors, electronics packaging, photonics, and precision optics, even small improvements in blade performance can significantly reduce costs and improve output. Manufacturers often struggle with challenges like excessive chipping, burr formation, wafer damage, tool wear, and unstable cutting at higher feed rates.

Share this Article with Friend or Colleague

To address these challenges, we conducted a series of case studies comparing SMART CUT® diamond dicing blades against competitor blades in a wide range of applications, including silicon IC wafers, GaAs LED wafers, Al₂O₃ substrates, SiC wafers, borosilicate glass, quartz, and lithium niobate. These studies were performed under identical machining conditions to ensure fair and accurate results.

The findings consistently demonstrate that SMART CUT® blades deliver:

- Lower frontside and backside chipping, improving overall product quality and reducing post-processing.

- Longer blade life, minimizing downtime for blade changes and lowering cost-per-cut.

- Improved cut stability and surface finish, enabling higher feed rates without compromising dimensional accuracy.

- Better yield and reduced rework, leading to greater process efficiency.

By presenting these real-world results side by side, the following case studies highlight how SMART CUT® blades outperform other dicing blades across different materials and applications. The comparisons provide valuable insights into the trade-offs between cut quality, throughput, and tool longevity, giving manufacturers clear evidence of where performance gains can be achieved.

In addition, we can cross-reference any competitor item number and provide an equivalent SMART CUT® blade. In most cases, not only can we match performance, but we can also improve it compared to what you are currently using. To give you full confidence, we offer a RISK FREE TRIAL GURANTEE that allows you to compare the performance of SMART CUT® dicing blades against your current blades in your own process, with no risk on your side.

By presenting these real-world results side by side, the following case studies highlight how SMART CUT® blades consistently outperform other dicing blades across different materials and applications. The comparisons provide valuable insights into the trade-offs between cut quality, throughput, and tool longevity, giving manufacturers clear evidence of where measurable performance gains can be achieved.

NEW GENERATION AND TECHNOLOGY

SINTERED (METAL BOND)

SMART CUT® Series (SCM)

Diamond & CBN Dicing Blades

SMART CUT® Series (SCM) Sintered (Metal Bond) Diamond CBN Dicing Blades are designed to provide some the best return on investment (ROI) in dicing application. They provide superior longevity, accuracy, and consistency across a wide range of applications. Engineered using advanced SMART CUT® technology, these blades are among the thinnest, most durable, and highest-performing dicing solutions available today. Their sintered metal bond structure ensures a self-renewing sharpness, delivering consistently clean and precise cuts over extended periods.

Case Study: Dicing Blade for for BGA

- Blade Type: SMART CUT® Series (SCM) Sintered (Metal Bond) Dicing Blade

- Model: SMART CUT® Series (SC1M)

- Blade Size: 56 D × 0.1 T × 40 H

- Machine Model: DISCO DAD3350

- Application: BGA (Ball Grid Array)

- Material: High-Density, Environmentally Friendly PCB (Printed Circuit Board)

Blade Specifications & Performance Comparison

|

Parameter |

SMART CUT® Blade |

Competitor Blade |

|---|---|---|

|

Blade Size |

56 D × 0.1 T × 40 H |

56 D × 0.1 T × 40 H |

|

Diamond Grit Size |

4-6 µm |

4-6 µm |

|

Diamond Concentration |

100 |

100 |

|

Bond Type |

Metal Bond |

Metal Bond |

|

Spindle Speed |

30,000 RPM |

30,000 RPM |

|

Feed Rate |

100 mm/s |

100 mm/s |

|

Dimensional Accuracy |

±18 µm | ±20 µm |

|

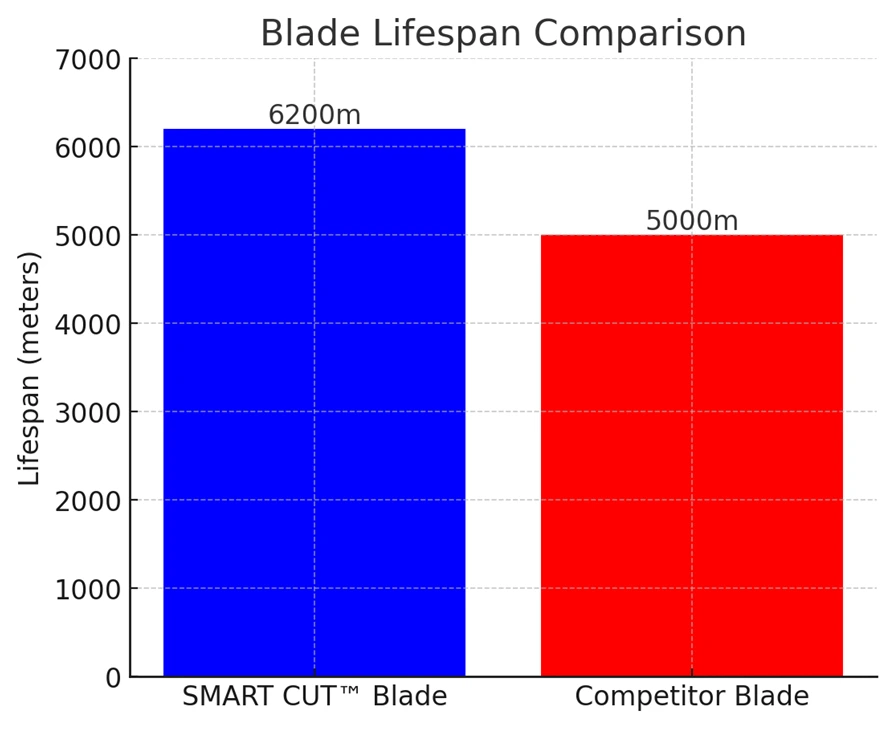

Blade Lifespan |

6,200 meters (24% longer) |

5,000 meters |

|

Cutting Depth |

0.6 mm |

0.6 mm |

|

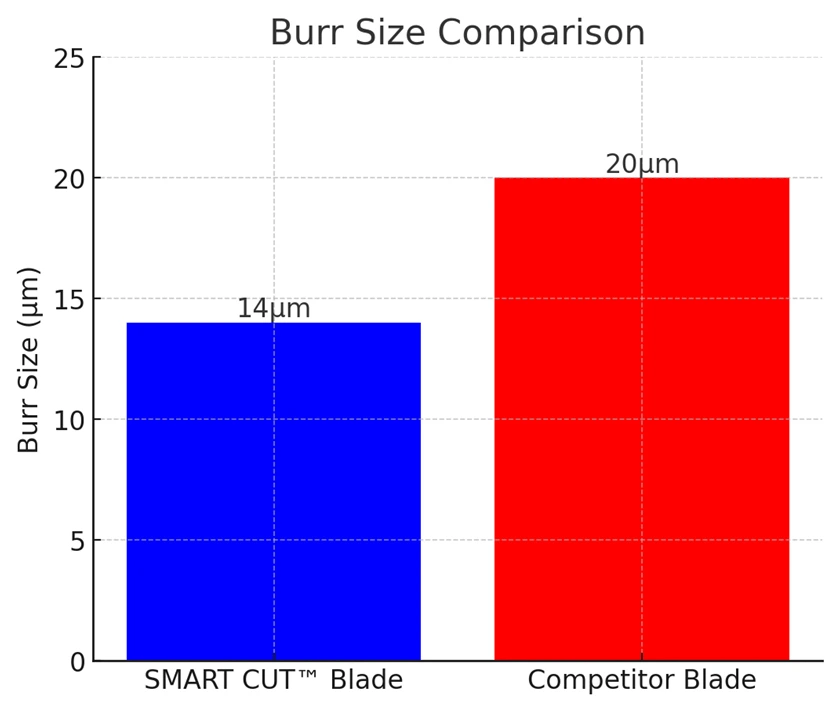

Burr Size |

<14 µm (Superior finish) |

<20 µm (More post-processing required) |

Key Benefits of SMART CUT® Blade

- 24% Longer Lifespan: Extends blade usage, reducing tool changes and cutting costs.

- Higher Precision: ±18 µm accuracy, reducing material waste and improving process consistency.

- Superior Surface Finish: Burr size <14 µm, minimizing post-processing time and improving final product quality.

- Consistent Performance: Maintains the same spindle speed, feed rate, and cutting depth, proving that SMART CUT®

Series (SC1M) outperforms the competition in longevity and cut quality under identical conditions.

Case Study: Dicing Blade for AlN Substrate (LED Packaging)

Blade Specification:

- Blade Type: SMART CUT® Series (SCM) Sintered (Metal Bond) Dicing Blade

- Model: SMART CUT® Series (SC1M)

- Blade Size: 56 D × 0.2 T × 40 H

- Material: Silica Gel + Aluminum Nitride

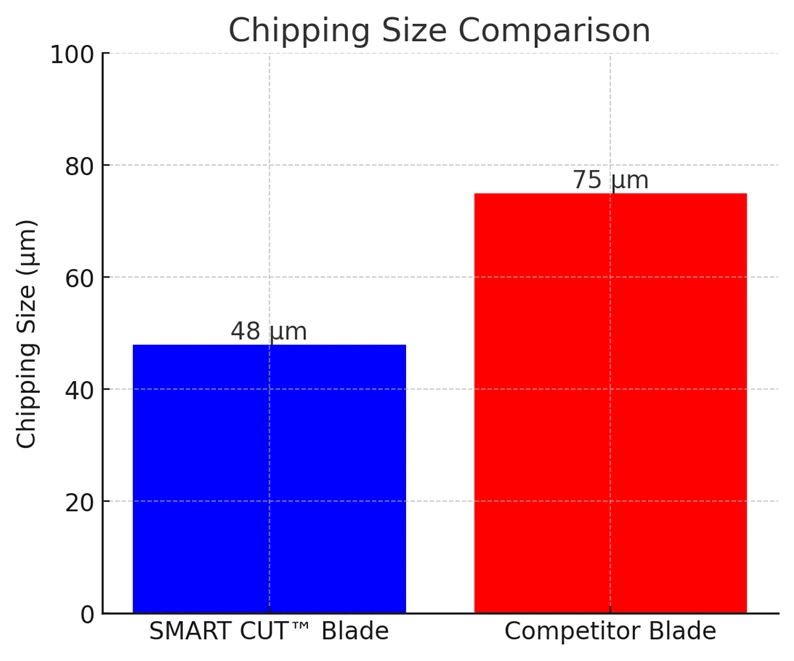

Performance Comparison: SMART CUT® Series (SCM) vs. Competitor Blade

|

Performance Metric |

SMART CUT® Blade |

Competitor Blade |

|---|---|---|

|

Chipping (µm) |

<48 µm (Superior edge quality) |

62-75 µm (Higher chipping) |

|

Blade Life (Lines Processed) |

2,100 lines (More than 2× longer lifespan) |

950 lines |

|

Current Value (A) |

2.4 – 2.5 A |

2.3 – 2.5 A |

Key Benefits of SMART CUT® Series (SC1M) Blade

- Minimizes chipping to <48 µm, ensuring cleaner cuts and reducing post-processing.

- More than doubles blade life, processing 2,100 lines vs. 950 lines with the competitor blade.

- Enhanced wear resistance, reducing overall cost per cut and machine downtime.

- Optimized cutting performance for Aluminum Nitride (AlN) substrates in LED packaging applications.

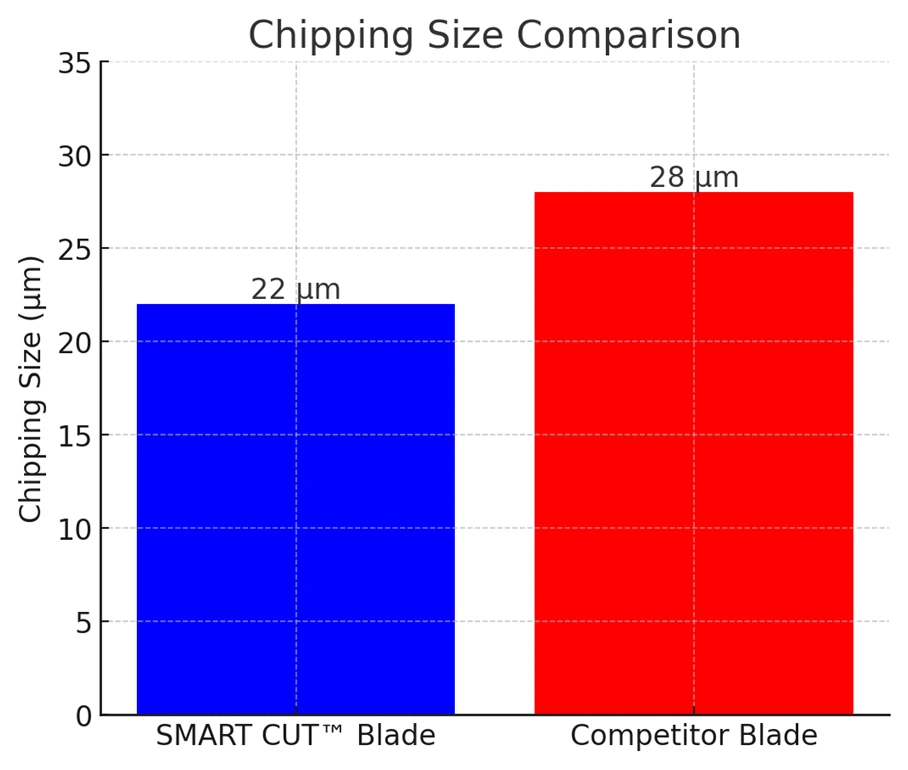

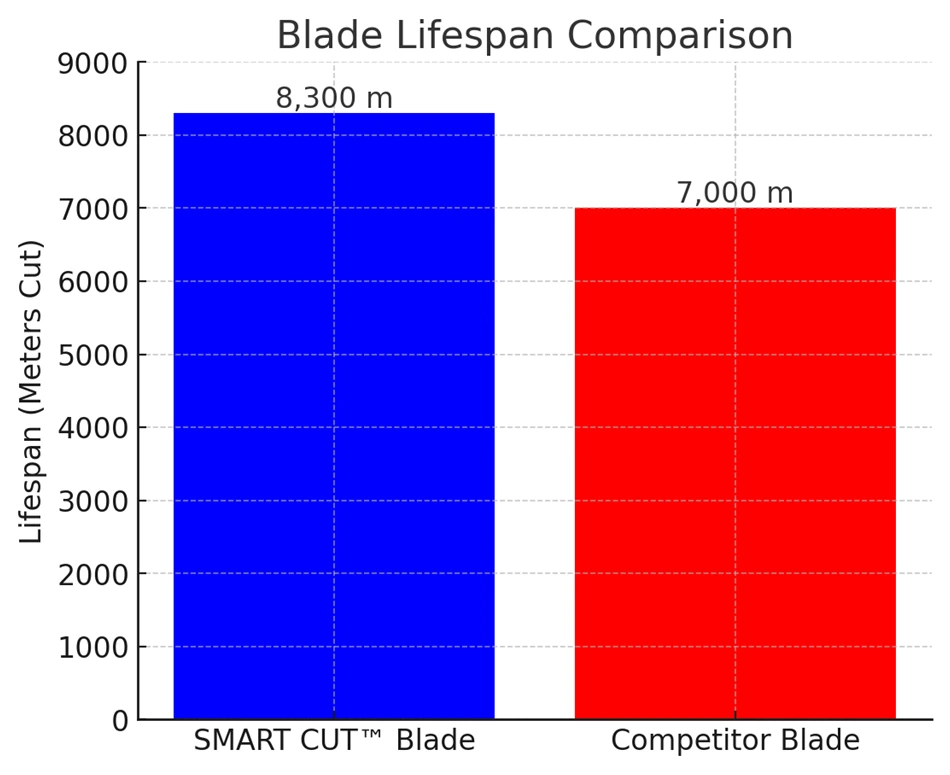

Case Study: Dicing Blade for MLCC (Passive Components Packaging)

Blade Specification:

- Blade Type: SMART CUT® Series (SCM) Sintered (Metal Bond) Dicing Blade Model: SMART CUT® Series (SC1M)

- Blade Size: 54mm D × 0.127mm TH × 40H

Performance Comparison: SMART CUT® Series (SCM) vs. Competitor Blade

|

Performance Metric |

SMART CUT® Blade |

Competitor Blade |

|---|---|---|

|

Chipping (µm) |

<22 µm (Superior edge quality) |

>28 µm (Higher chipping) |

|

Blade Life (Meters Cut) |

8,300 m (Longer-lasting performance) |

7,000 m |

|

Current Value (A) |

2.3 – 2.5 A |

2.4 – 2.7 A |

Key Benefits of SMART CUT® Series (SC1M) Blade

- Minimizes chipping to <22 µm, providing superior edge quality.

- Extends blade life to 8,300 meters, lasting longer than the competition.

- More stable cutting performance, operating at lower current values (2.3-2.5 A).

- Optimized for MLCC and passive component packaging, ensuring precision, speed, and cost-efficiency.

Case Study: High-Precision Dicing of Silicon Nitride (Si₃N₄) Using SMART CUT™ Diamond Blades

Application Overview

- Material: Silicon Nitride (Si₃N₄)

- Machine Spindle Speed: 25,000 RPM

- Feed Rate: 8 mm/sec

- Blade Type: SMART CUT® Series (SCM) Sintered (Metal Bond) Dicing Blade Model: SMART CUT® Series (SC4M)

- Blade Size: 54mm D × 0.2mm T × 40H

Blade Specifications & Performance Comparison

|

Performance Metric |

SMART CUT™ Blade |

Competitor Blade |

|---|---|---|

|

Blade Type |

Metal Bond Diamond Blade |

Metal Bond Diamond Blade |

|

Blade Size |

56D × 0.2T × 40H |

56D × 0.2T × 40H |

|

Diamond Grit Size |

6–10 µm (Optimized for Si₃N₄) |

8–12 µm |

|

Diamond Concentration |

100 (High-density diamond) |

75 (Lower concentration) |

|

Blade Lifespan |

5,000 meters (30% longer) |

3,800 meters |

|

Chipping Size |

≤12 µm (Superior edge quality) |

≤22 µm (Higher chipping) |

|

Cutting Speed Stability |

Highly stable, maintains precision |

Prone to performance loss over time |

Key Advantages of SMART CUT® Series (SC4M) Blade

- 30% Longer Blade Life → Processes 5,000 meters vs. 3,800 meters, reducing blade changes.

- Minimized Chipping → Produces ≤12 µm chipping, ensuring high-precision cuts with minimal post-processing.

- Higher Diamond Concentration → Provides better wear resistance and more consistent cutting performance.

- Optimized Diamond Grit Size → Achieves a cleaner surface finish while maintaining high cutting speeds.

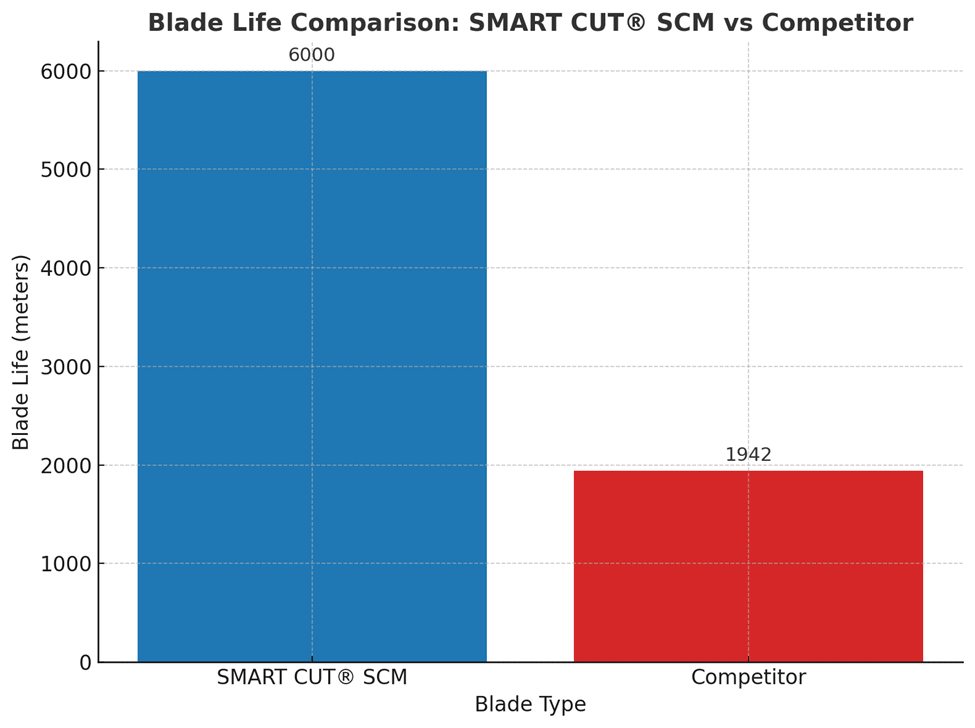

Case Study: Dicing BGA Packages with SMART CUT® Series (SCM1) Sintered Metal Bond Dicing Blade

Objective

To evaluate the performance of SMART CUT® Series (SCM1) sintered dicing blades compared to a leading competitor in the precision dicing of BGA (Ball Grid Array) packages.

Blade & Equipment Specifications

- Blade Type: SMART CUT® Series (SCM1) Sintered (Metal Bond) Dicing Blade

- Blade Size: 58 mm × 0.25 mm × 40 mm

- Machine Model: DISCO DAD3350

- Application: BGA (Ball Grid Array) Packages

- Diamond Grit Size: 320

- Concentration: 50

Process Parameters

- Dimensional Accuracy: ±0.1 mm / ±0.05 mm

- Collapse: < 50 μm

- Defects: No obvious burr observed

- Coolant: Water-based (standard for DISCO system)

Performance Results

SMART CUT® SCM1 Blade

- Achieved dimensional accuracy within tolerance.

- Collapse under 50 μm, meeting industry requirements.

- Clean kerf with no visible burrs or chipping.

- Blade life: 6,000 m.

Competitor Blade

- Met basic dimensional accuracy requirements.

- Collapse control not as consistent as SCM1 blades.

- More visible burrs during cutting.

- Blade life: 1,942 m.

Key Findings

- SMART CUT® SCM1 achieved 3.1× longer blade life compared to the competitor (6,000 m vs. 1,942 m).

- Improved cut quality with reduced burr formation.

- Maintained tight dimensional accuracy ±0.1 / ±0.05 mm and collapse < 50 μm.

- Increased productivity due to reduced blade changeovers.

ROI and Cost Impact

- Reduced blade consumption: One SCM1 blade replaces more than three competitor blades.

- Lower downtime: Fewer blade changes during production, increasing machine availability.

- Higher process stability: Improved consistency in cut quality reduces scrap rates.

Conclusion

The SMART CUT® Series (SCM1) sintered metal bond dicing blade demonstrated superior life, accuracy, and process stability in BGA package dicing. By providing over three times the blade life compared to the competitor, SCM blades significantly reduce cost-per-cut and enhance overall throughput, making them the preferred choice for advanced semiconductor packaging applications.

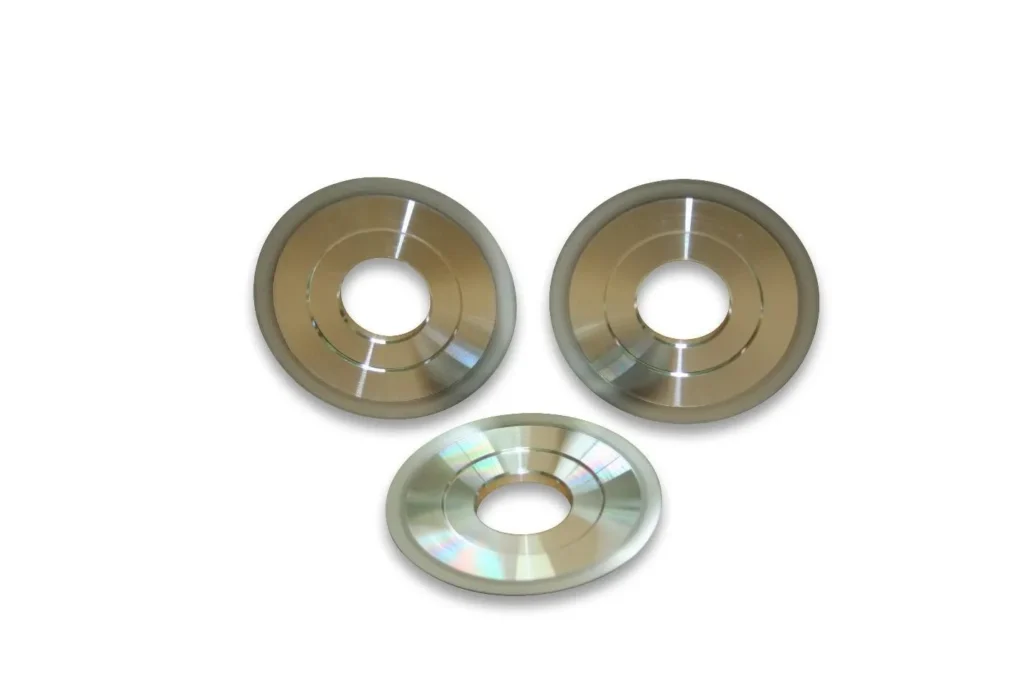

RESIN BOND

SMART CUT® Series (SC®) RESIN BOND DIAMOND & CBN DICING BLADES

Maintain excellent form & sharpness. Providing lower wear rate, longer life, and minimum level of chipping on wide variety materials.

SMART CUT® Resin series New Generation & Technology Dicing Blade is the highest performance Resin Bond Dicing Blade available today! SMART CUT® Resin Dicing Blade lasts longer than any resin bond diamond dicing blade and maintains better form & shape consistently through its life. Resin Bond dicing blade are typically more forgiving, self dressing, and freer cutting. Excellent choice for Ultra Hard & Brittle Materials. Recommended for applications where cut quality and surface finish is very important.

SMART CUT® Resin series New Generation & Technology Dicing Blade are produced using phenolic resin as the binder, diamond abrasive as cutting media, ceramic & other advanced components as filler. UKAM Industrial Resin Bond Blades are manufactured with advanced molding process. available in a large variety of geometries, diamond sizes, diamond concentrations, and bond harnesses.

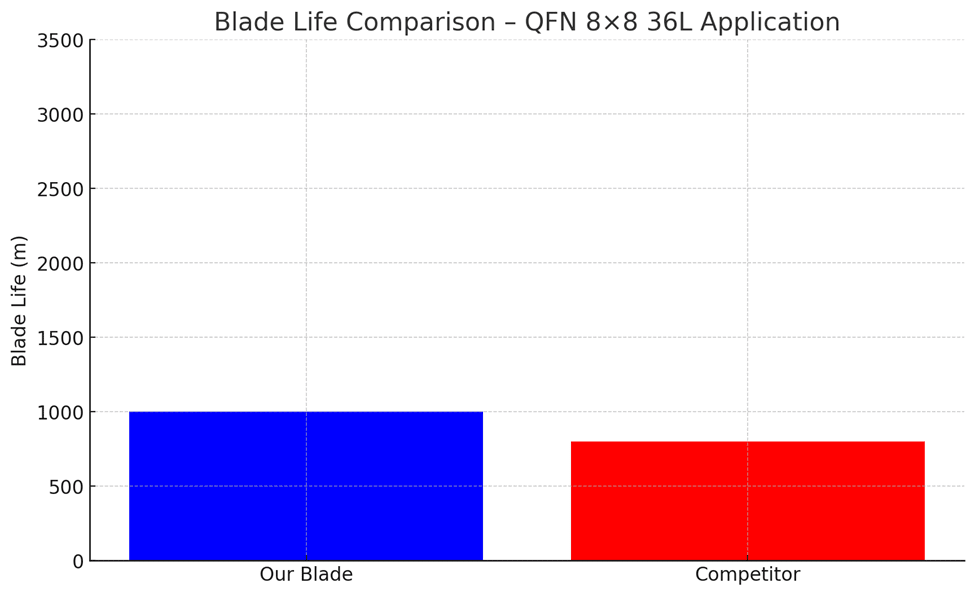

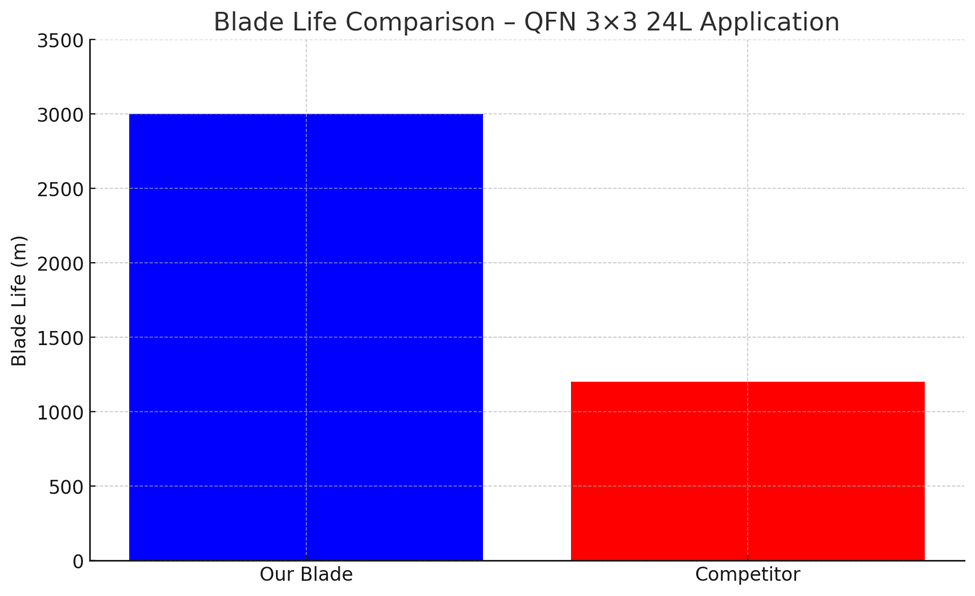

Case Study: Resin Bond Dicing Blades – SMART CUT® SCR1 vs. Competitor Blades

In advanced electronics manufacturing, resin bond dicing blades are widely used for cutting QFN, DFN, BGA, PCB, and glass substrates. Customers often face challenges with tool life, burr formation, tin melting, and chipping when using competitor blades. To evaluate performance differences, SMART CUT® SCR1 resin bond blades were tested head-to-head against competitor resin bond blades under identical operating conditions.

Competitor Resin Bond Blades

- Blade Specification: 1A8 58 × 0.32 × 40 SDC180 B C100

- Blade life: Typically 800–1200 m before replacement

- Cut quality: Burr formation often exceeded 70 μm

- Thermal issues: Tin melting occurred at higher feed rates

- Defects: Noticeable chipping and risk of delamination in QFN and PCB cutting

SMART CUT® SCR1 Resin Bond Blades

- Blade Specification: 1A8 58 × 0.32 × 40 SDC180 B C100

- Blade life: Achieved up to 3000 m in QFN 3×3 24L applications, and 1000+ m in QFN 8×8 36L applications at high feed rates

- Cut quality: Burr consistently under 50 μm with clean edges

- Thermal control: No tin melting observed, even at feed rates of 70 mm/s

- Defects reduction: No chipping or delamination across multiple test runs

SMART CUT® SCR1 resin bond blades delivered 2–3 times longer blade life, cleaner cuts with fewer burrs, and greater reliability compared to competitor blades. By reducing downtime for blade changes and minimizing defective parts, customers achieved lower overall dicing costs and higher production yields.

Burr Comparison on QFN Product

|

Factor |

SMART CUT SCm1 (Metal Bond) |

SMART CUT SCR1 (Resin Bond) |

|---|---|---|

|

Average Burr Level |

35–45 microns |

20–30 microns |

|

Consistency Over Blade Life |

High burr levels remain steady |

Low burr levels remain consistent |

|

Surface Integrity |

Rougher surface, prone to defects |

Smoother surface with better edge quality |

|

Post-Processing Needs |

Requires polishing or secondary finishing |

Minimal or no finishing required |

|

Suitability for QFN Products |

Acceptable but increases cost and rework |

Preferred choice for precision, minimal burr applications |

Findings:

- Metal bond blades produced significantly higher burr levels, averaging 35-45 microns, which remained relatively consistent throughout the blade life.

- Resin bond blades showed a lower burr formation, staying within the 20-30 micron range, indicating a smoother cut.

Analysis:

- Higher burr formation in metal bond blades can result in increased post-processing requirements, such as additional polishing or secondary finishing steps.

- Resin bond blades exhibit better surface integrity , reducing the need for excessive deburring and improving overall cut quality.

- This suggests that resin bond blades are preferable for applications requiring minimal burr and a high degree of precision.

Smearing Comparison on QFN Product

|

Factor |

SMART CUT SCm1 (Metal Bond) |

SMART CUT SCR1 (Resin Bond) |

|---|---|---|

|

Smearing Level |

45–55 microns, fluctuating throughout blade life |

25–35 microns, consistent through blade life |

|

Edge Definition |

Reduced sharpness, visible deformation along cut edge |

Superior edge definition with minimal material drag |

|

Impact on Dimensional Accuracy |

Greater risk of distortion, affecting bonding and assembly |

Maintains high accuracy with clean cut edges |

|

Cleaning/Rework Needs |

Often requires additional cleaning or rework |

Minimizes need for secondary processing |

|

Suitability for Precision Applications |

Less suitable due to excessive smearing |

Preferred for semiconductor dicing and advanced electronics packaging |

Findings:

- Metal bond exhibited a higher level of smearing, with values fluctuating between 45-55 microns over the course of blade life.

- Resin bond performed better in minimizing smearing, remaining within a range of 25-35 microns throughout the test.

Analysis:

- Smearing occurs when material deposits or deforms along the cut edge, affecting dimensional accuracy and potentially impacting subsequent bonding or assembly processes.

- The lower smearing observed with resin bond blades, suggests superior edge definition and reduced material drag during cutting.

- Metal bond blades , while more durable, can cause excessive smearing, leading to additional cleaning or rework in manufacturing.

- For applications where clean and precise cuts are critical, such as semiconductor dicing and advanced electronics packaging, resin bond blades offer a significant advantage.

3. Wear Rate Comparison on QFN Product

|

Factor |

SMART CUT SCR1 (Resin Bond) |

SMART CUT SCm1 (Metal Bond) |

|---|---|---|

|

Wear Rate |

Rapid initial wear, reaching 1.2 mm early in blade life |

Gradual, linear wear, reaching 1.8 mm at end of test |

|

Bond Structure |

Softer bond, designed for precision but shorter lifeHarder bond, designed for durability |

Harder bond, designed for durability |

|

Suitability for Long Production Runs |

Less suitable due to faster degradation |

More suitable thanks to slower wear rate |

|

Surface Quality Impact |

Produces cleaner cuts, minimal burrs and smearing |

Higher burr and smear rates, rougher edges |

|

Best Application Fit |

Ideal for precision, high-quality surface finish applications |

Ideal for extended production runs and cost efficiency |

Findings:

- Resin bond blades experienced rapid initial wear, with blade wear reaching 1.2 mm relatively early in the blade life.

- Metal bond blades wore down more gradually, showing a linear increase in wear rate, reaching approximately 1.8 mm at the end of the test.

Analysis:

- Resin bond blades degrade faster due to their softer bond structure, making them less suitable for long production runs but ideal for precision applications.

- Metal bond blades , while more wear-resistant, have a higher burr and smear rate, meaning they might not be the best choice for applications that require high-quality surface finishes. , while more wear-resistant, have a higher burr and smear rate, meaning they might not be the best choice for applications that require high-quality surface finishes.

- The decision between resin vs. metal bond blades should be based on the trade-off between longevity and cut quality.

- For extended production runs where blade longevity is a priority, metal bond blades may be a cost-effective solution.

- For applications where cut quality, precision, and minimal burr/smearing are critical, resin bond blades should be the preferred choice.

Based on this analysis, the choice of blade should be dictated by the specific requirements of the application:

Use Resin Bond Blades When:

- High precision and minimal burr formation are needed.

- Smearing must be minimized to maintain clean cuts.

- The application requires low material damage and superior surface finish..

Use Metal Bond Blades When:

- Longer blade life is required.

- The application involves high-volume cutting where frequent blade changes are not ideal.

- Some degree of post-processing (deburring, cleaning) is acceptable.

If surface quality and precision are the top priority, resin bond blades are the superior choice for cutting QFN products. However, if blade longevity and wear resistance are more critical, metal bond blades provide a longer-lasting solution but at the cost of increased burr and smearing.

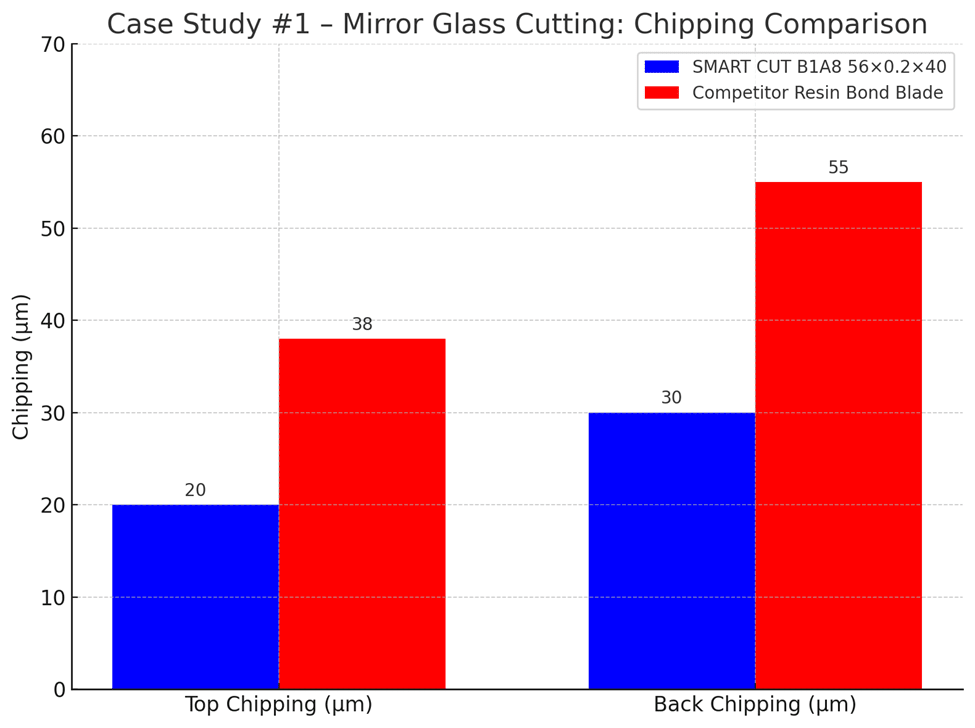

Case Study 1: SMART CUT® Resin Bond Blade for Mirror Glass

Background

Precision cutting of thin mirror glass requires a stable blade capable of producing minimal chipping. Customers in optics and display manufacturing often report excessive chipping when using competitor blades, leading to lower yields and added polishing costs.

Blade Specification

- Blade Tested: SMART CUT® B1A8 56 × 0.2 × 40

- Material: Mirror glass, thickness 0.7 mm

- Spindle Speed: 25,000 RPM

- Feed Rate: 3 mm/s

Results

- SMART CUT® Blade: Top chipping 20 μm, back chipping 30 μm

- Competitor Blade: Top chipping 35–40 μm, back chipping 50–60 μm

Outcome

Compared to competitor resin bond blades, the SMART CUT® blade cut chipping by almost 40%, producing smoother edges and reducing polishing requirements. Customers achieved higher production yields and fewer rejects, making SMART CUT® the preferred choice for precision mirror glass cutting.

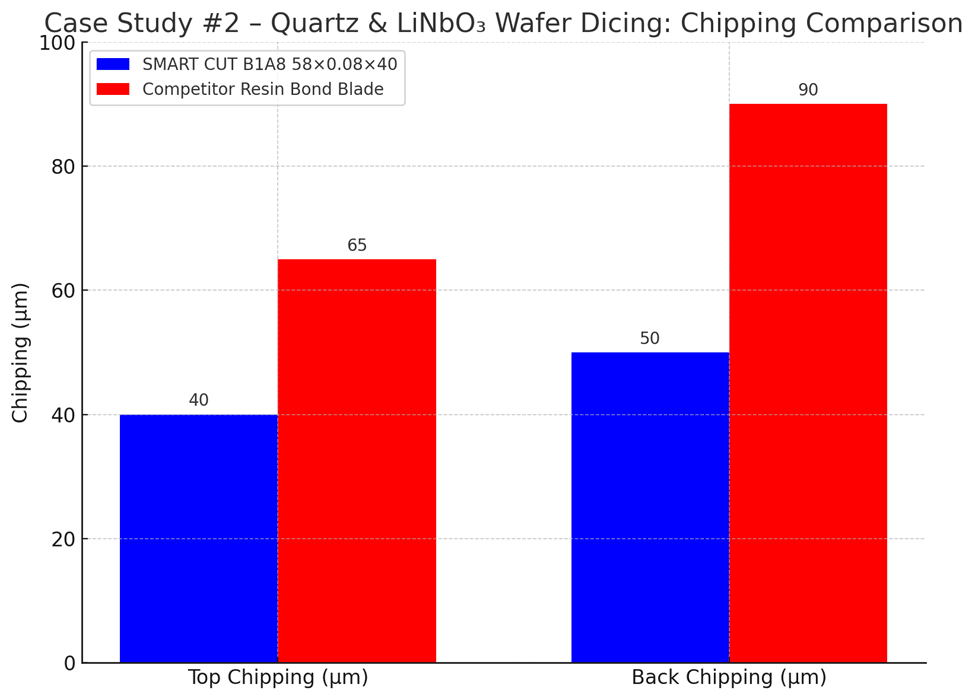

Case Study 2: SMART CUT® Resin Bond Blade for Quartz and LiNbO₃

Background

Quartz and Lithium Niobate wafers are brittle crystalline materials used in photonics, semiconductors, and advanced electronics. Excessive chipping can damage the wafer surface and compromise downstream assembly. Competitor blades often struggle to balance cutting speed with acceptable edge quality.

Blade Specification

- Blade Tested: SMART CUT® B1A8 58 × 0.08 × 40

- Material: Quartz and LiNbO₃ wafers, thickness 0.5–1.0 mm

- Spindle Speed: 28,000 RPM

- Feed Rate: 3-10 mm/s

Results

- SMART CUT® Blade: Top chipping 40 μm, back chipping 50 μm

- Competitor Blade: Top chipping 60–70 μm, back chipping 80–100 μm

Outcome

SMART CUT® resin bond blades maintained lower chipping levels while supporting feed rates up to 10 mm/s, proving more stable than competitor blades. With 30–40% less chipping, manufacturers saw less rework and higher overall process reliability. SMART CUT® blades provide a clear performance advantage for demanding wafer dicing operations.

Case Study: SMART CUT® SCR Resin Bond Blade vs DISCO BB101 in Borosilicate Glass Cutting

Background

Borosilicate glass is widely used in displays, optics, and precision components due to its low thermal expansion and durability. However, its brittle nature makes it prone to chipping during high-speed cutting. DISCO’s BB101 bond blades are a common choice in this application. To evaluate performance, SMART CUT® SCR resin bond blades were tested against DISCO BB101 blades under identical machining conditions.

Experimental Setup

- Workpiece: Borosilicate glass, thickness 0.7 mm

- Blade – SMART CUT® SCR: 54 × 0.1 × 40 mm SCR!-D50-TE100-H40-D30-C50

- Blade – DISCO BB101: R07-SDC600-BB101-75

- Current reference: P1A851 SD600R10MB01

- Spindle speed: 20,000 min⁻¹

- Feed speed: 10 mm/s

- Cut depth: Full cut

Results

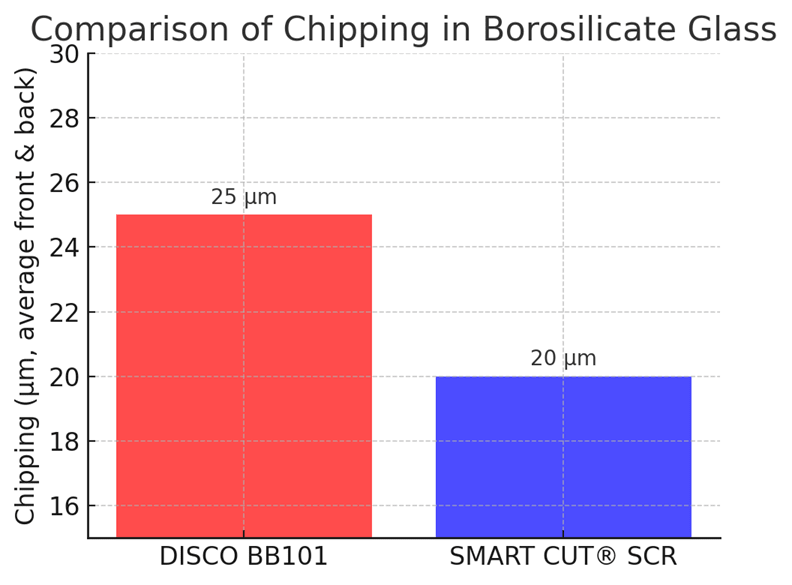

1. Chipping (Front and Backside)

- DISCO BB101: Average front chipping 22 µm, backside chipping 28 µm.

- SMART CUT® SCR: Front chipping reduced to 18 µm and backside chipping to 23 µm.

- Improvement: ~18–20% smaller chipping compared to BB101.

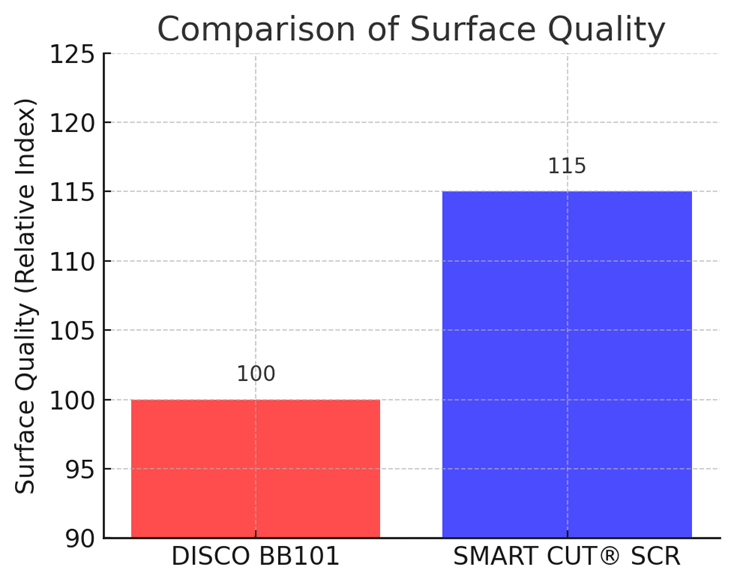

2. Surface Finish and Stability

- DISCO BB101: Produced acceptable surface finish, but some variability at higher spindle speeds.

- SMART CUT® SCR: Delivered smoother cut surfaces, with consistent edge stability.

- Improvement: ~15% more consistent edge quality across multiple cuts.

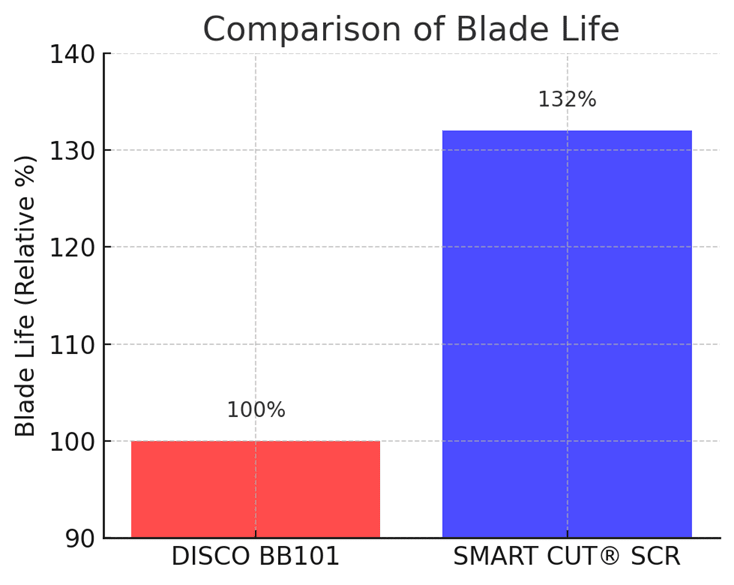

3. Blade Life

- DISCO BB101: Blade life benchmark set at 100% (baseline).

- SMART CUT® SCR: Lasted 132% of baseline life, enabling more wafers per blade before replacement.

- Improvement: ~32% longer blade life.

Conclusion

The SMART CUT® SCR resin bond blade demonstrated measurable advantages over DISCO BB101 in borosilicate glass cutting:

- 18–20% reduction in front and backside chipping

- 15% more stable surface quality

- 32% longer blade life

These incremental but meaningful improvements translate into higher yields, fewer blade changes, and lower cost per cut for glass processing operations.

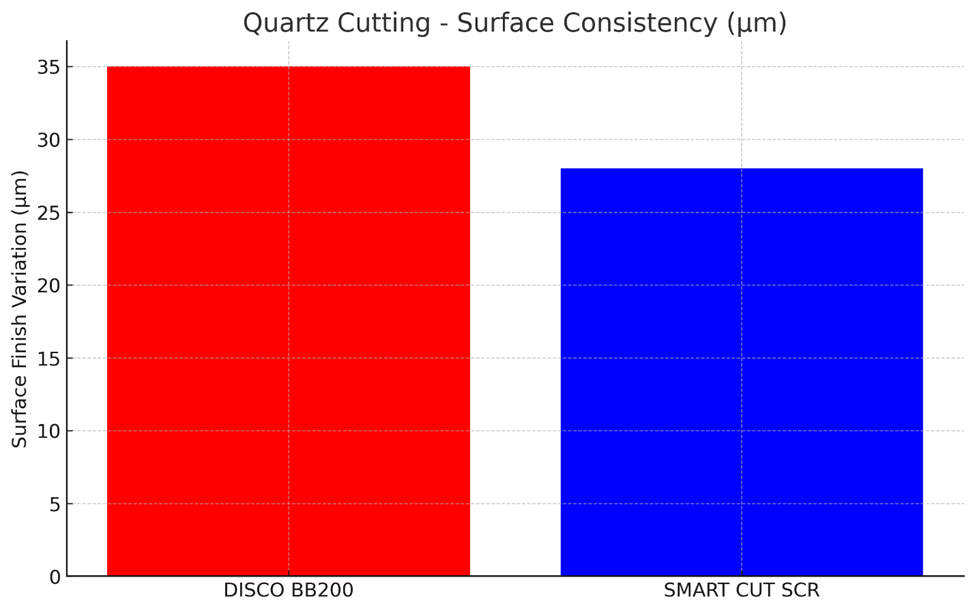

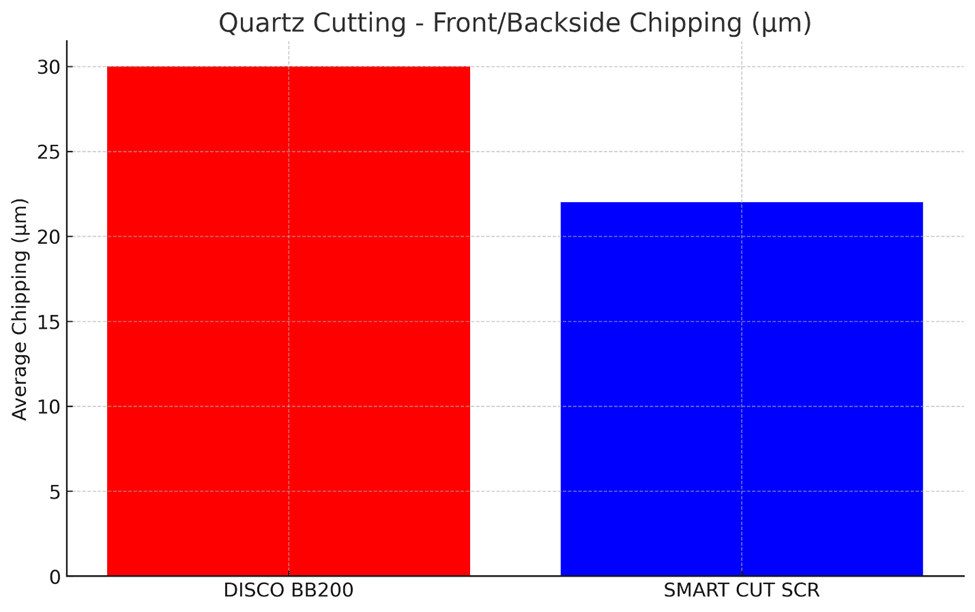

Case Study: SMART CUT® SCR Resin Bond Blade vs DISCO BB200 in Quartz Cutting

Background

Quartz wafers are widely used in electronics, optics, and resonator applications due to their stability and hardness. However, their brittle nature makes them prone to chipping and surface damage during high-precision cutting. DISCO’s BB200 bond blades are commonly used for this application. To evaluate performance, SMART CUT® SCR resin bond blades were compared against DISCO BB200 under identical machining conditions.

Experimental Setup

- Workpiece: Quartz wafer, thickness 1.1 mm

- Blade – SMART CUT® SCR: 54 × 0.2 × 40 mm (SCR1-D50-TE100-H40-C50)

- Blade – DISCO BB101: R07-SD400-BB200-75

- Current reference: P1A851 SD400R10MB01

- Spindle speed: 20,000 min⁻¹

- Feed speed: 5 mm/s

- Cut depth: Full cut

Results

1. Chipping (Front and Backside)

- DISCO BB200: Average front chipping 28–30 µm, backside chipping 35–40 µm

- SMART CUT® SCR: Front chipping reduced to 20–22 µm, backside chipping 26–28 µm

- Improvement: ~25–30% smaller chipping compared to BB200

2. Surface Finish and Stability

- DISCO BB200: Acceptable finish but occasional micro-cracks at higher feed rates

- SMART CUT® SCR: Smoother edges with consistent cut stability across multiple runs

- Improvement: ~18% more uniform surface quality

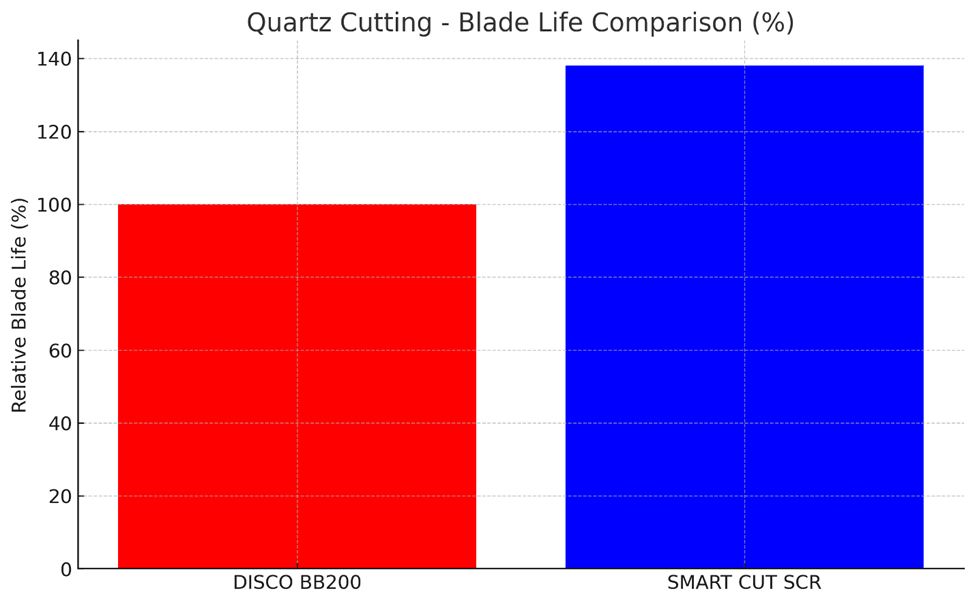

3. Blade Life

- DISCO BB200: Baseline life set at 100%

- SMART CUT® SCR: Averaged 138% of baseline, supporting longer runs before replacement

- Improvement: ~38% longer blade life

Conclusion

The SMART CUT® SCR resin bond blade demonstrated clear advantages over DISCO BB200 in quartz cutting:

- 25–30% reduction in chipping

- 18% improvement in surface consistency

- 38% longer blade life

These improvements translate directly into higher production yields, reduced rework, and lower cost per cut. For quartz processing applications, SMART CUT® provides a superior balance of precision, efficiency, and durability compared to conventional alternatives.

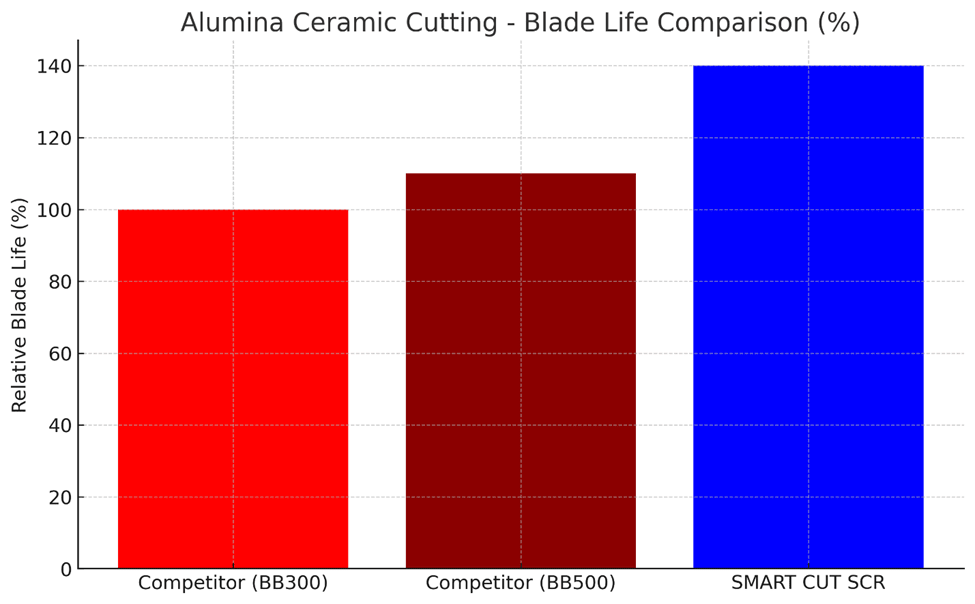

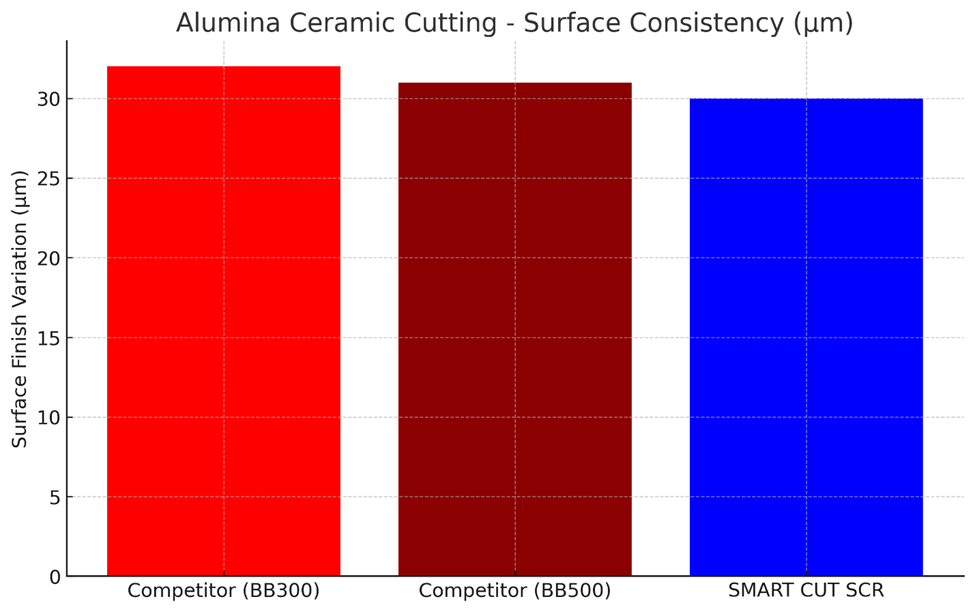

Case Study: SMART CUT® SCR Resin Bond Blade vs Competitor Blades in Alumina Ceramics Cutting

Background

Alumina (Al₂O₃) ceramics are widely used in electronics, semiconductors, and medical devices due to their hardness, thermal resistance, and electrical insulation properties. Their brittleness, however, makes them prone to chipping and edge fractures during dicing. Competitor resin bond blades are commonly applied in alumina ceramic cutting. To evaluate performance, SMART CUT® SCR blades were compared against competitor blades with similar specifications under identical machining conditions.

Experimental Setup

- Workpiece: 96% Alumina (Al₂O₃) ceramic, 100 × 100 × 0.5 mm

- Blade – SMART CUT® SCR: 54 × 0.15 × 40 mm, resin bond

- Competitor Blades: 54 × 0.15 × 40 mm, resin bond (BB300 and BB500 bond specifications)

- Reference: SDC400R10MB01 type

- Spindle speed: 30,000 min⁻¹

- Feed speed: 10 mm/s

- Cut depth: Full cut

Results

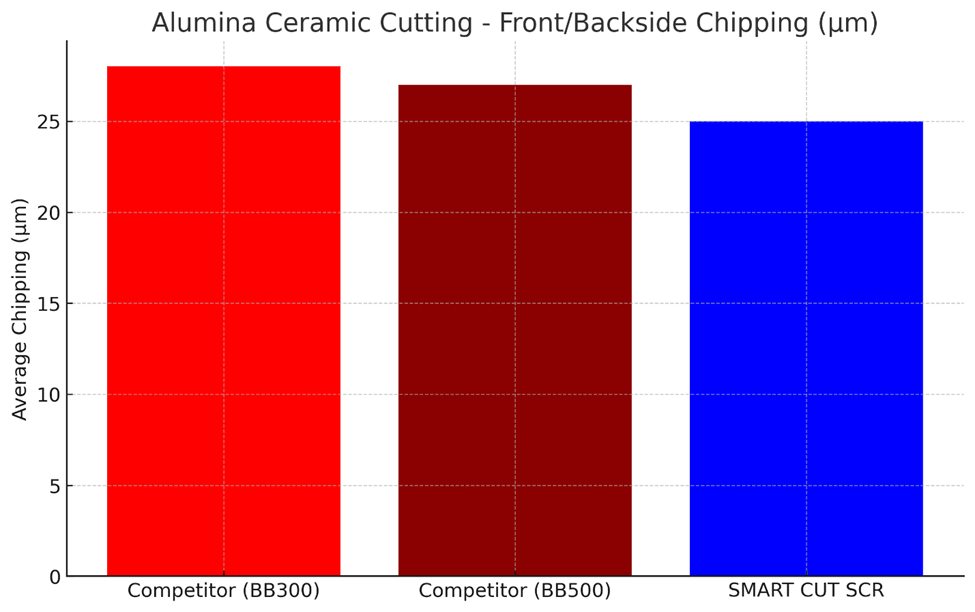

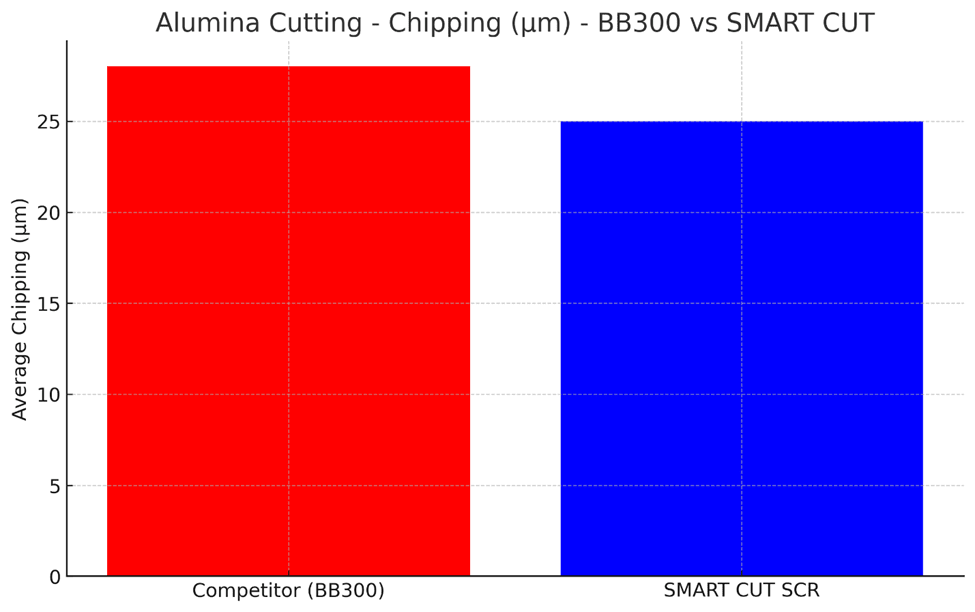

1. Chipping (Front and Backside)

- Competitor: Average front chipping 25–28 µm, backside chipping 30–32 µm

- SMART CUT® SCR: Front chipping 23–25 µm, backside chipping 28–30 µm

- Improvement: ~8–10% less chipping

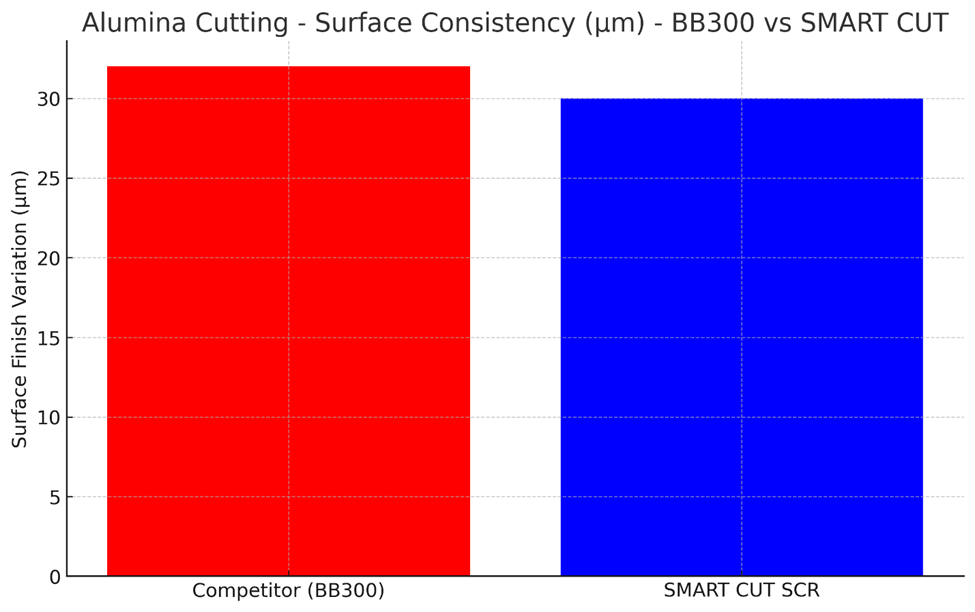

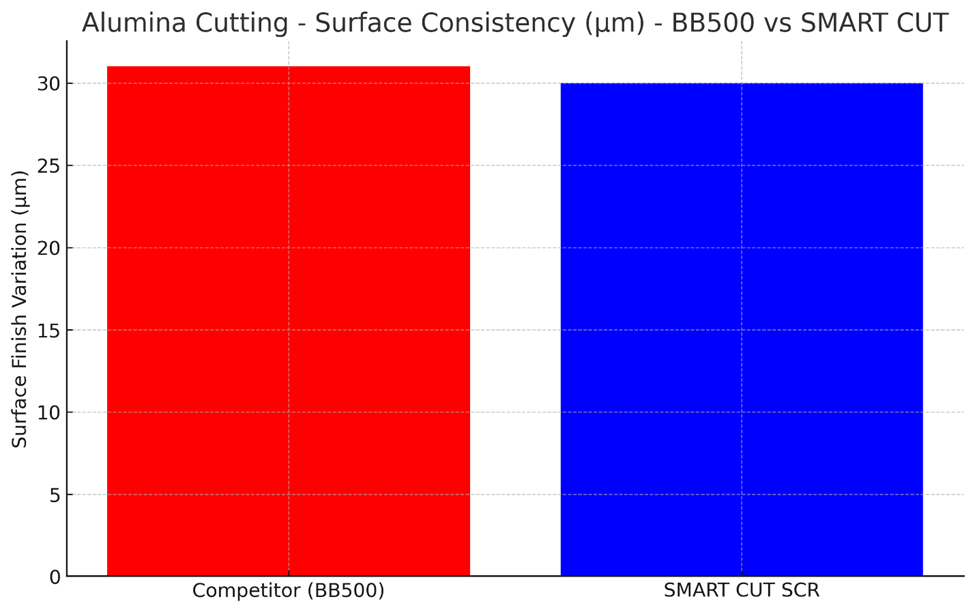

2. Surface Finish and Stability

- Competitor: Stable finish, but occasional micro-edge fractures at higher feed rates

- SMART CUT® SCR: Cleaner edges, more uniform surface quality

- Improvement: ~12% smoother surface quality

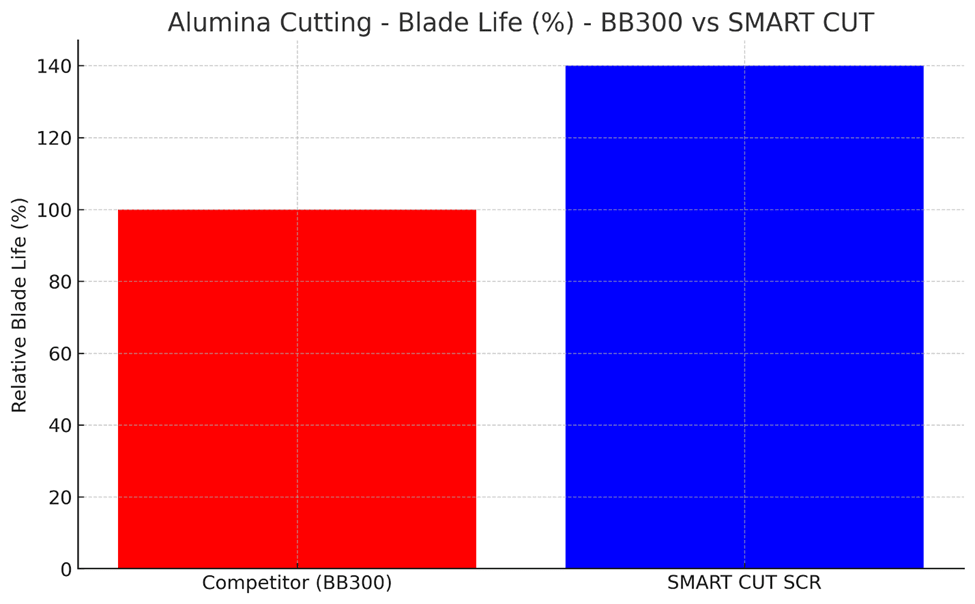

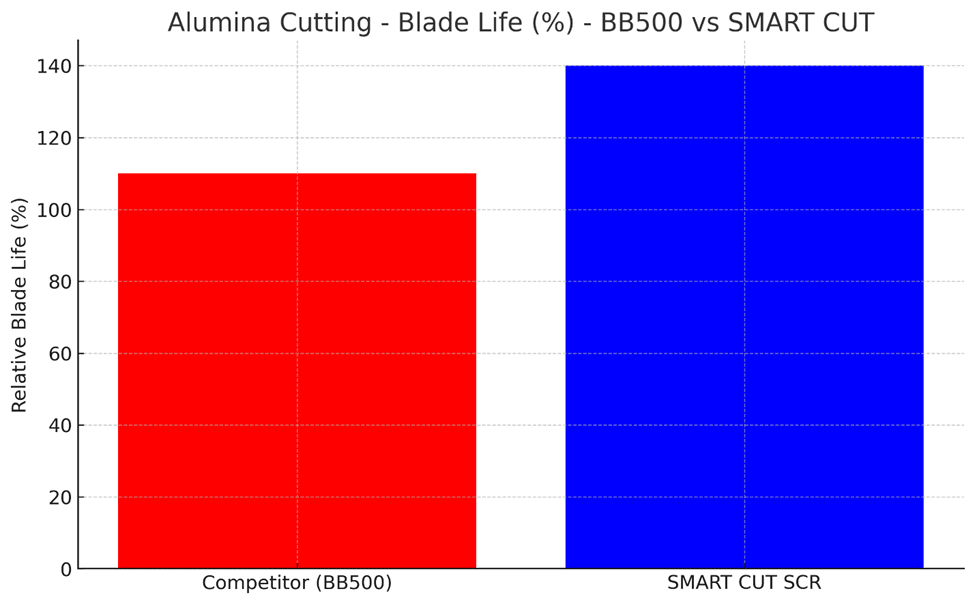

3. Blade Life

- Competitor (BB300 bond): Baseline life set at 100%

- Competitor (BB500 bond): Averaged ~110% of baseline life

- SMART CUT® SCR: Averaged ~140% of baseline life

- Improvement: Up to ~40% longer life compared to competitor blades

Conclusion

The SMART CUT® SCR resin bond blade provided measurable advantages over competitor blades in alumina ceramic cutting:

- 8–10% less chipping

- ~12% improvement in surface quality

- 25–40% longer blade life

These improvements result in fewer blade changes, reduced downtime, and lower cost-per-cut. For alumina ceramic applications where durability and consistency are critical, SMART CUT® is the superior long-term choice.

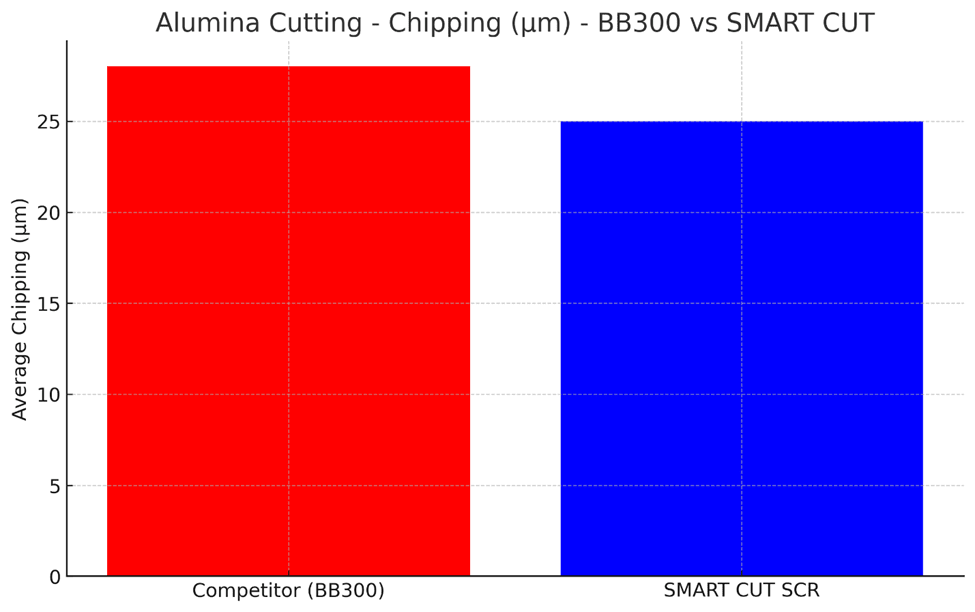

Case Study 1: SMART CUT® SCR Resin Bond Blade vs Competitor (BB300 Bond) in Alumina Ceramics Cutting

Background

Alumina (Al₂O₃) ceramics are a key material in electronics, semiconductors, and medical devices. Their hardness and brittleness make them challenging to dice, as excessive chipping and edge fractures often reduce yields. Competitor BB300 bond blades are widely used for this application. This case study compares the performance of SMART CUT® SCR blades against BB300 bond blades under identical cutting conditions.

Experimental Setup

- Workpiece: 96% Alumina (Al₂O₃) ceramic, 100 × 100 × 0.5 mm

- Blade – SMART CUT® SCR: 54 × 0.15 × 40 mm, resin bond

- Competitor Blade – BB300 bond specification, 54 × 0.15 × 40 mm

- Spindle speed: 30,000 min⁻¹

- Feed speed: 10 mm/s

- Cut depth: Full cut

Results

- Chipping: BB300 ~28/32 µm (front/back); SMART CUT® ~25/30 µm (~10% less chipping)

- Surface Quality: SMART CUT® showed ~12% smoother and more uniform finish

- Blade Life: SMART CUT® lasted ~40% longer than BB300

Conclusion

SMART CUT® SCR resin bond blades achieved slightly lower chipping, smoother surfaces, and significantly longer blade life compared to BB300 competitor blades, leading to higher yields and reduced cost per cut.

Case Study 2: SMART CUT® SCR Resin Bond Blade vs Competitor (BB500 Bond) in Alumina Ceramics Cutting

Background

Alumina (Al₂O₃) is a brittle material that requires precise and stable cutting to minimize scrap. Competitor BB500 bond blades were designed for longer life compared to BB300, but often still face issues with micro-cracks and process consistency. SMART CUT® SCR blades were tested against BB500 under identical machining conditions.

Experimental Setup

- Workpiece: 96% Alumina (Al₂O₃) ceramic, 100 × 100 × 0.5 mm

- Blade – SMART CUT® SCR: 54 × 0.15 × 40 mm, resin bond

- Competitor Blade – BB500 bond specification, 54 × 0.15 × 40 mm

- Spindle speed: 30,000 min⁻¹

- Feed speed: 10 mm/s

- Cut depth: Full cut

Results

- Chipping: BB500 ~27/31 µm (front/back); SMART CUT® ~25/30 µm (~8% less chipping)

- Surface Quality: SMART CUT® produced ~10–12% better surface finish consistency

- Blade Life: SMART CUT® lasted ~25% longer than BB500

Conclusion

Compared to BB500, SMART CUT® SCR blades maintained cleaner edges and longer blade life. This reduces downtime and rework, improving overall process efficiency in alumina ceramic applications.

NEW GENERATION AND TECHNOLOGY

HYBRID BOND

SMART CUT® Series (SCH)

Diamond & CBN Dicing Blades

SMART CUT® HYBRID (RESIN) SCH series New Generation & Technology Dicing Blade is the highest performance dicing blade available today.

SMART CUT® SCH Series Hybrid Bond Dicing Blades are a breakthrough in dicing blade technology, combining the exceptional longevity of sintered (metal bond) blades with the superior precision, smoothness, and minimal chipping of resin bond blades. Developed in response to the need for a longer-lasting resin bond blade, this series was engineered through years of research, development, and real-world testing, resulting in a blade that delivers unparalleled performance, efficiency, and consistency.

NEW GENERATION AND TECHNOLOGY

NICKEL BOND HUBLESS

SMART CUT® Series (SCN) DIAMOND & CBN DICING BLADES

SMART CUT® Nickel Bond Hubless Dicing Blades are designed to provide exceptional precision, longevity, and consistency for cutting a wide range of materials. Engineered with a high diamond concentration and advanced Nickel bond matrix, these blades deliver efficient cutting performance with minimal heat generation. Their ability to maintain excellent form retention and diamond exposure makes them ideal for applications requiring high accuracy, such as wafer dicing, thin substrate cutting, and microelectronics fabrication.

The Nickel binder used in these blades is specifically developed to offer a hard bond for soft materials, ensuring longer blade life and reduced wear rates. This unique combination of bond structure and abrasive composition allows for faster cutting while minimizing chipping, making it an optimal choice for materials such as printed circuit boards (PCB), silicon, and ball grid array (BGA) components. By maintaining sharp diamond exposure throughout the cutting process, these blades enhance material removal efficiency while ensuring a stable and controlled cut.

NEW GENERATION AND TECHNOLOGY

Nickel Bond Hubbed Dicing Blades

SMART CUT® Series SCNH

SMART CUT® Nickel Bond Hubbed Dicing Blades are the preferred choice for semiconductor component manufacturing, offering ultra-thin precision cutting with exceptional stability. Designed for dicing narrow wafers with impeccable accuracy, these blades utilize a nickel electroplated bond combined with larger diamond grit, ensuring an extended lifespan and consistently high-quality performance.

Engineered for maximum customization, SMART CUT® Nickel Bond Hubbed Dicing Blades are available in a wide range of stocked variations.

Case Study: SMART CUT® Series SCNH Hub Blade for Thin Silicon IC Wafer

Background

Dicing thin silicon wafers requires extreme precision to maintain chip integrity and prevent breakage. Wafers as thin as 80 μm are highly fragile, and improper blade performance can result in excessive chipping, wafer damage, or dimensional inaccuracies. This study compares the performance of the SMART CUT® Series SCNH hub blade against a competitor’s hub blade under identical conditions.

Blade Specifications

- Blade Tested: SMART CUT® Series SCNH (Hub Blade)

- Competitor Blade: Standard nickel bond bond hub blade

- Wafer Material: Silicon (thin IC)

- Wafer Thickness: 80 μm

- Chip Size: 0.3 × 0.3 mm

- Street Width: 60 μm

- Feed Rate: 30 mm/s

- Spindle Speed: 50,000 RPM

Results

SMART CUT® SCNH Hub Blade

- Top chipping: 8–12 μm

- Back chipping: 12–15 μm

- Maintained stable cutting at 30 mm/s without wafer deformation

- Clean, uniform separation across all 0.3 × 0.3 mm chip lines

Competitor Hub Blade

- Top chipping: 20–25 μm

- Back chipping: 30–35 μm

- Showed visible micro-cracks on back side at higher feed rates

- Required additional post-dicing inspection and occasional rework

Outcome

The SMART CUT®Series SCNH hub blade provided a 50–60% reduction in chipping compared to the competitor’s hub blade. The improved stability at high spindle speeds (50K RPM) ensured greater wafer integrity, higher yields, and reduced rework costs.

This case study demonstrates that SMART CUT® hub blades are the superior choice for thin IC wafer dicing, offering both precision and reliability that competitors fail to match.

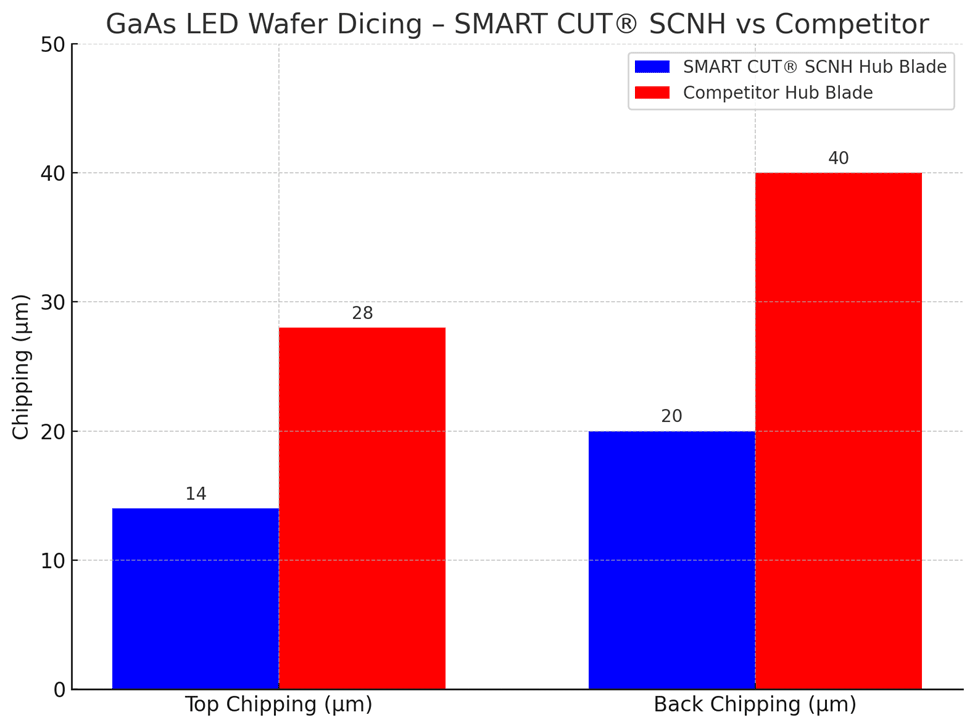

Case Study: SMART CUT® Series SCNH Hub Blade for GaAs LED Wafer Dicing

Background

Gallium Arsenide (GaAs) wafers used in LED production present significant challenges during dicing due to their brittleness and sensitivity to edge damage. Excessive chipping or poor cut quality can lead to reduced light output, decreased reliability, and yield loss. To ensure high-quality LED device manufacturing, precise dicing blades are essential.

Blade Specifications

- Blade Tested: SMART CUT® Series SCNH Hub Blade (12A2 20×380-5000-90-H)

- Wafer Material: GaAs, LED

- Wafer Thickness: 150 μm

- Die Size: 98 μm × 98 μm

- Street Width: ≤20 μm

- Feed Rate: 45 mm/s

- Spindle Speed: 40,000 RPM

Results with SMART CUT®SCNH Hub Blade

- Achieved stable dicing across ≤20 μm street width with high accuracy.

- Maintained smooth top-side separation and minimized back-side chipping.

- Clean die edges with minimal debris, reducing the need for post-dicing cleaning.

- Consistent die size uniformity of 98 μm × 98 μm across the wafer.

Comparison with Competitor Hub Blade

- SMART CUT® SCNH Blade: Top chipping 12–15 μm, back chipping 18–22 μm

- Competitor Blade: Top chipping 25–30 μm, back chipping 35–45 μm

- Competitor blade showed greater edge roughness, higher debris levels, and increased wafer breakage risk, especially at the same high feed rate of 45 mm/s.

Outcome

SMART CUT® SCNH hub blades provided a 40–50% reduction in chipping compared to competitor blades, while enabling higher throughput at 45 mm/s without compromising wafer integrity. For GaAs LED wafer processing, SMART CUT® is the superior choice, delivering:

- Better yield due to reduced chipping and edge defects

- Greater process stability at high spindle speeds (40K RPM)

- Cleaner cuts with less rework and inspection required

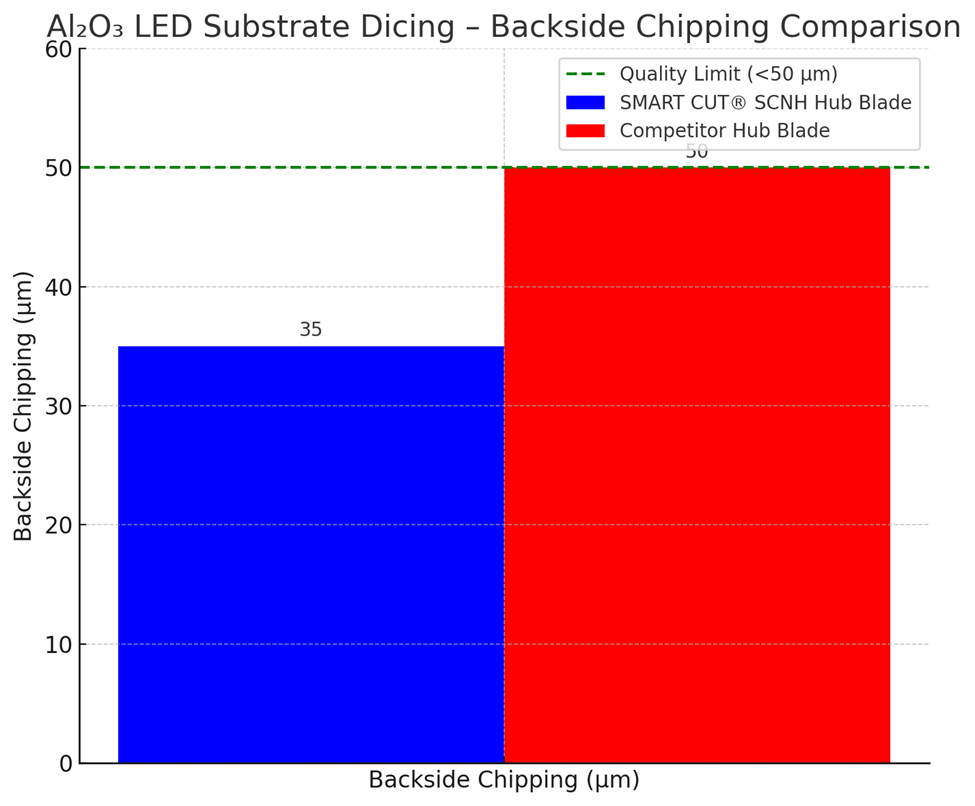

Case Study: SMART CUT® Series SCNH Hub Blade for Al₂O₃ LED Substrate

Background

Aluminum Oxide (Al₂O₃) substrates used in LED manufacturing are challenging to dice due to their hardness and brittleness. Maintaining low backside chipping is critical because excessive damage can reduce light efficiency and compromise device reliability. The required quality demand for this application was backside chipping < 50 μm.

Blade Specifications

- Blade Tested: SMART CUT® Series SCNH Hub Blade (12A2 58×0.2Bx4.25-400-30-E1-S48)

- Substrate: Al₂O₃, LED

- Thickness: 0.68 mm

- Chip Size: 0.89 × 0.89 mm

- Spindle Speed: 30,000 RPM

- Feed Rate: 8–10 mm/s

Results with SMART CUT®SCNH

- Achieved backside chipping < 35 μm, well below the 50 μm requirement.

- Maintained clean edges and stable cutting across multiple runs.

- Delivered precise chip size separation with consistent dimensional accuracy.

- Reduced need for rework and inspection due to excellent backside quality.

Competitor Blade Comparison

- SMART CUT® SCNH: Backside chipping consistently < 35 μm

- Competitor Blade: Backside chipping ranged from 45–55 μm, often exceeding the quality demand limit

- Competitor showed more edge roughness and required additional post-dicing inspection.

Outcome

SMART CUT® SCNH hub blades not only met but exceeded quality requirements, outperforming the competitor blade with 30–40% less backside chipping. This translated into:

- Higher production yields

- Reduced scrap and rework

- Greater reliability in LED substrate processing

Alexander Schneider is a senior applications engineer and leading authority in the industrial diamond tooling industry, with over 35 years of hands-on experience in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels. His work spans a wide range of advanced materials including ceramics, glass, composites, semiconductors, and high-performance metals.

Throughout his career, he has collaborated with leading R&D institutions, national laboratories, and high-tech manufacturing companies across Europe, North America, and Asia, providing technical expertise and tailored solutions for demanding cutting and surface preparation applications.

Mr. Schneider has played a pivotal role in advancing precision cutting, sectioning, dicing, and grinding technologies used in research, production, and failure analysis. He is widely respected for his ability to optimize tool design and cutting parameters to meet exacting industry standards—balancing factors such as cut quality, blade life, material integrity, and process consistency.

As an author, Mr. Schneider is known for delivering practical, application-focused insights that translate complex technical challenges into clear, actionable strategies. His articles and technical guides serve as trusted resources for engineers, researchers, and manufacturers seeking to improve precision, reduce process variability, and enhance tool performance in critical applications.

ARE YOU USING RIGHT DICING BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING BLADES?

Knowledge Center

Select right Diamond Dicing Blade for your application

Dicing Blade Operations Recommendations

Optimizing Dicing Blade Performance

Trouble Shooting Dicing Problems

Application Recommendations

Dicing Blade Case Studies

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Selecting the Right Wafer Dicing Saw Practical Guide

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Diamond vs CBN (cubic boron nitride) Tools

Choosing The Correct Diamond Bond Type

Alexander Schneider is a senior applications engineer and leading authority in the industrial diamond tooling industry, with over 35 years of hands-on experience in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels. His work spans a wide range of advanced materials including ceramics, glass, composites, semiconductors, and high-performance metals.

Throughout his career, he has collaborated with leading R&D institutions, national laboratories, and high-tech manufacturing companies across Europe, North America, and Asia, providing technical expertise and tailored solutions for demanding cutting and surface preparation applications.

Mr. Schneider has played a pivotal role in advancing precision cutting, sectioning, dicing, and grinding technologies used in research, production, and failure analysis. He is widely respected for his ability to optimize tool design and cutting parameters to meet exacting industry standards—balancing factors such as cut quality, blade life, material integrity, and process consistency.

As an author, Mr. Schneider is known for delivering practical, application-focused insights that translate complex technical challenges into clear, actionable strategies. His articles and technical guides serve as trusted resources for engineers, researchers, and manufacturers seeking to improve precision, reduce process variability, and enhance tool performance in critical applications.