Diamond & CBN Wheels WithSMART CUT® Technology

Let us Help you

Improve & Optimize your Grinding Operation

Best Return

on Investment

Attractive Cost of

Ownership

Diamond & CBN Wheels in stock

Custom Manufacturer with Fast Lead times

Unmatched

Prices in North America

Unmatched Experience & Technical Support

UKAM Industires Superhard Tools

Let us be a Partner in your Success.

UKAM Industrial Superhard Tools manufactures and offers a full range of diamond & CBN wheels, diamond grinding wheels, diamond polishing discs and diamond cup wheels for almost any application. Starting from 0.5” (12.7mm) to 20” (500mm) diameter in 5 different bond types for just about any material / application. We produce and offer diamond & cbn wheels for Industry, Research & Development, hobby and contractor application to fit almost any type of equipment.

Thousands of diamond & cbn wheels are available from stock and we also produce almost any specification per your requirement or drawing with fast lead times and no minimum order quantities.

we have the Experience, Tradition & People to improve and optimize diamond your machining operation. Let us be a Partner in your Success.

FIND DIAMOND & CBN WHEELS

By Bond Type

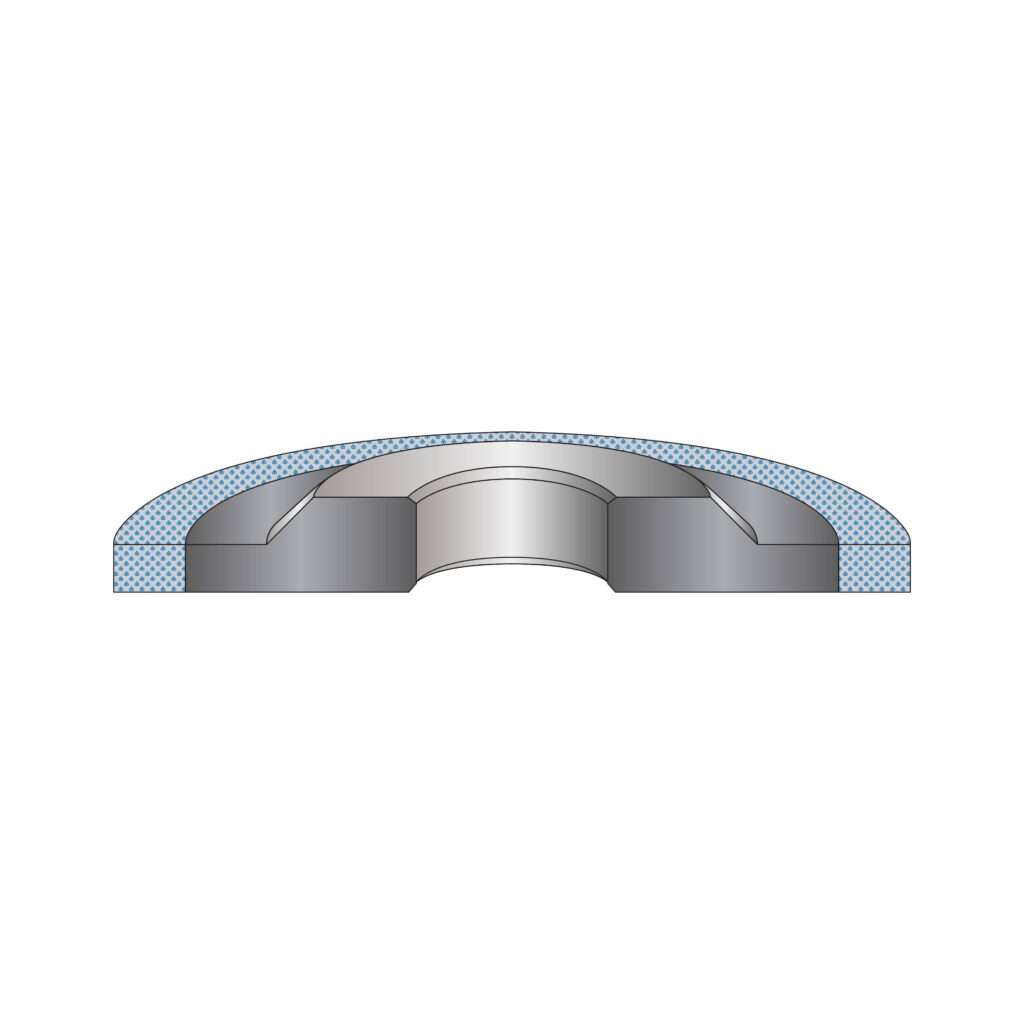

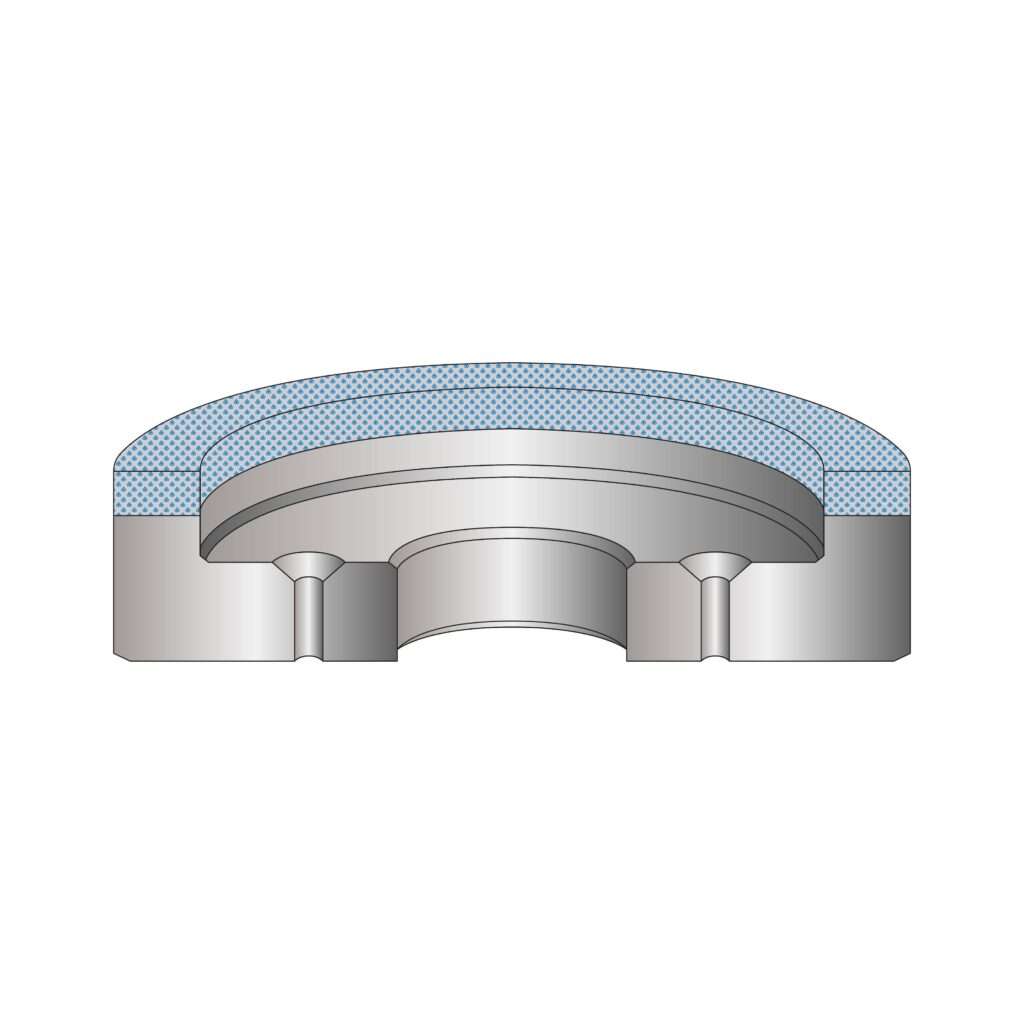

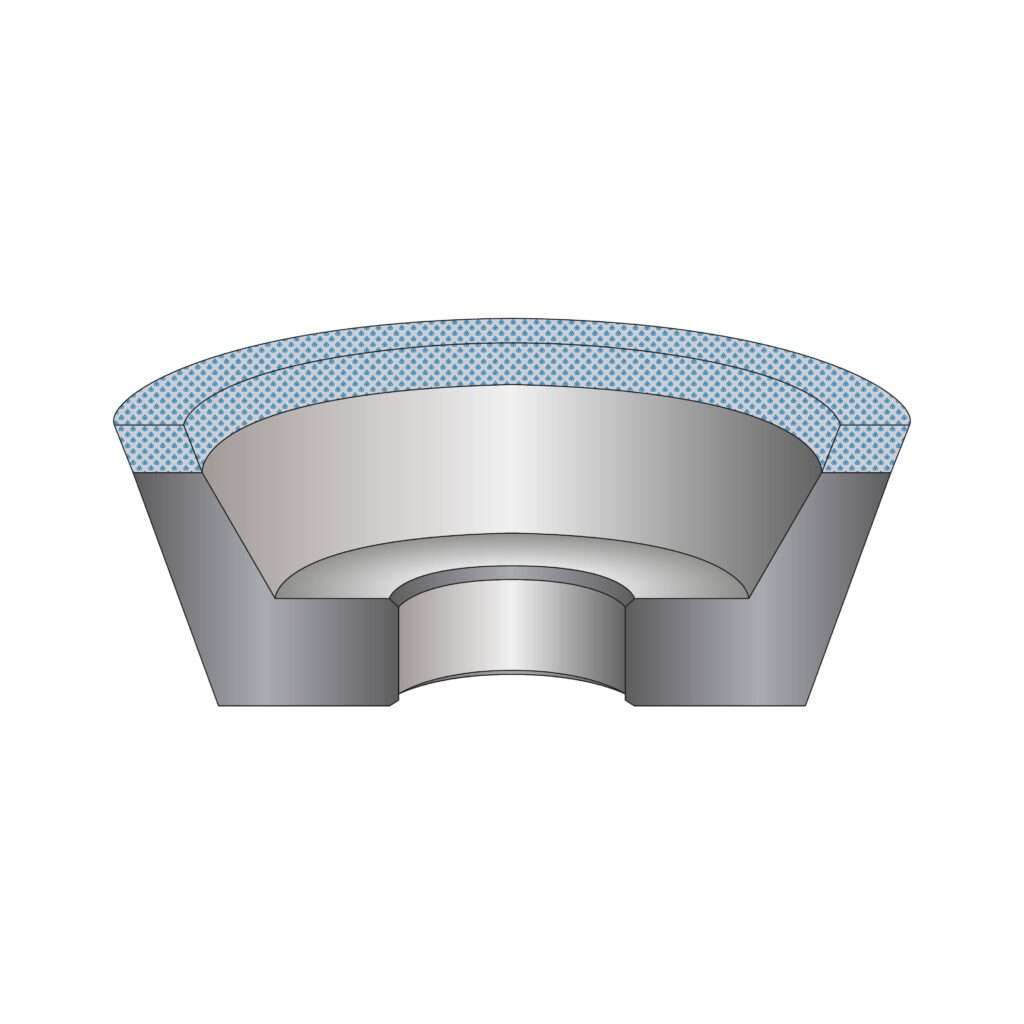

Sintered (metal bond)

Sintered (metal bond) is a metallurgical bond with multiple layers of diamonds impregnated inside the metal matrix.

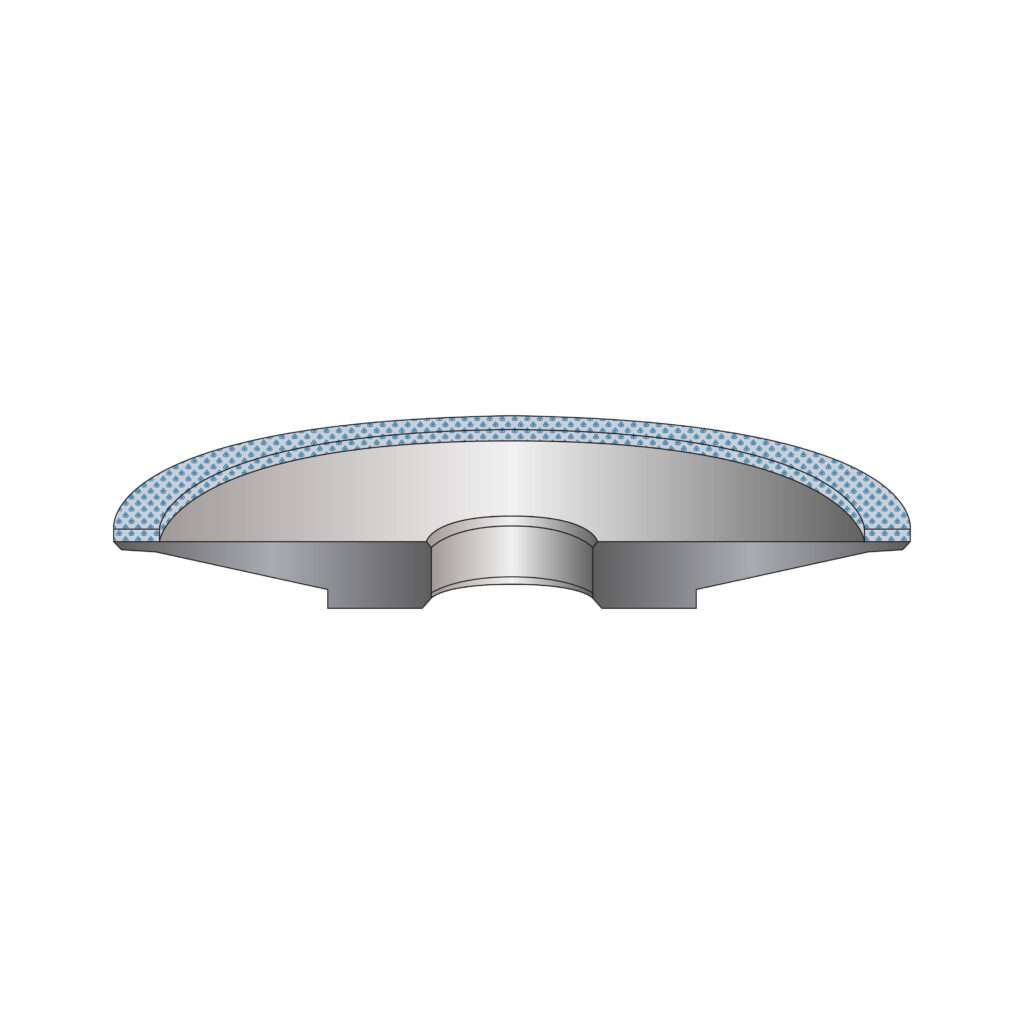

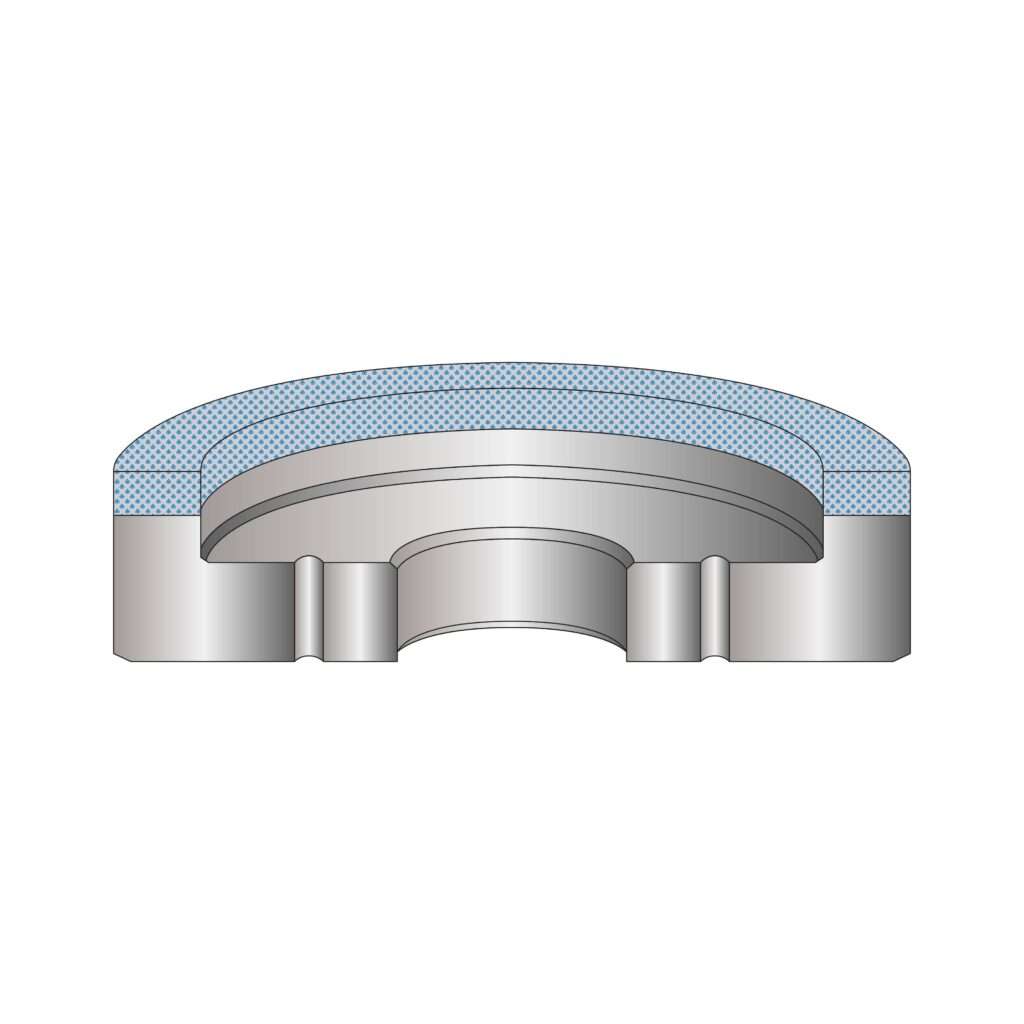

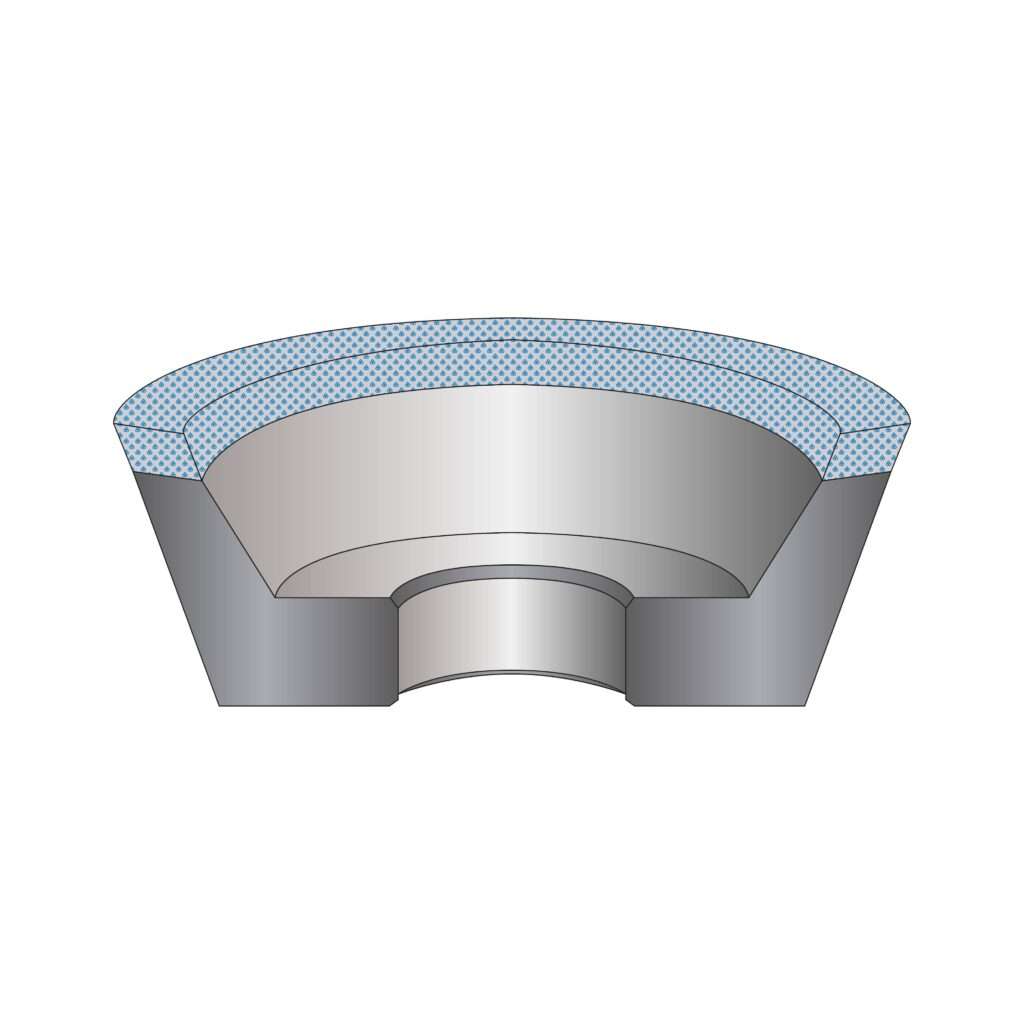

Resin Bond

Resin Bond is a Organic bond matrix that is formed by high pressure and high temperature.

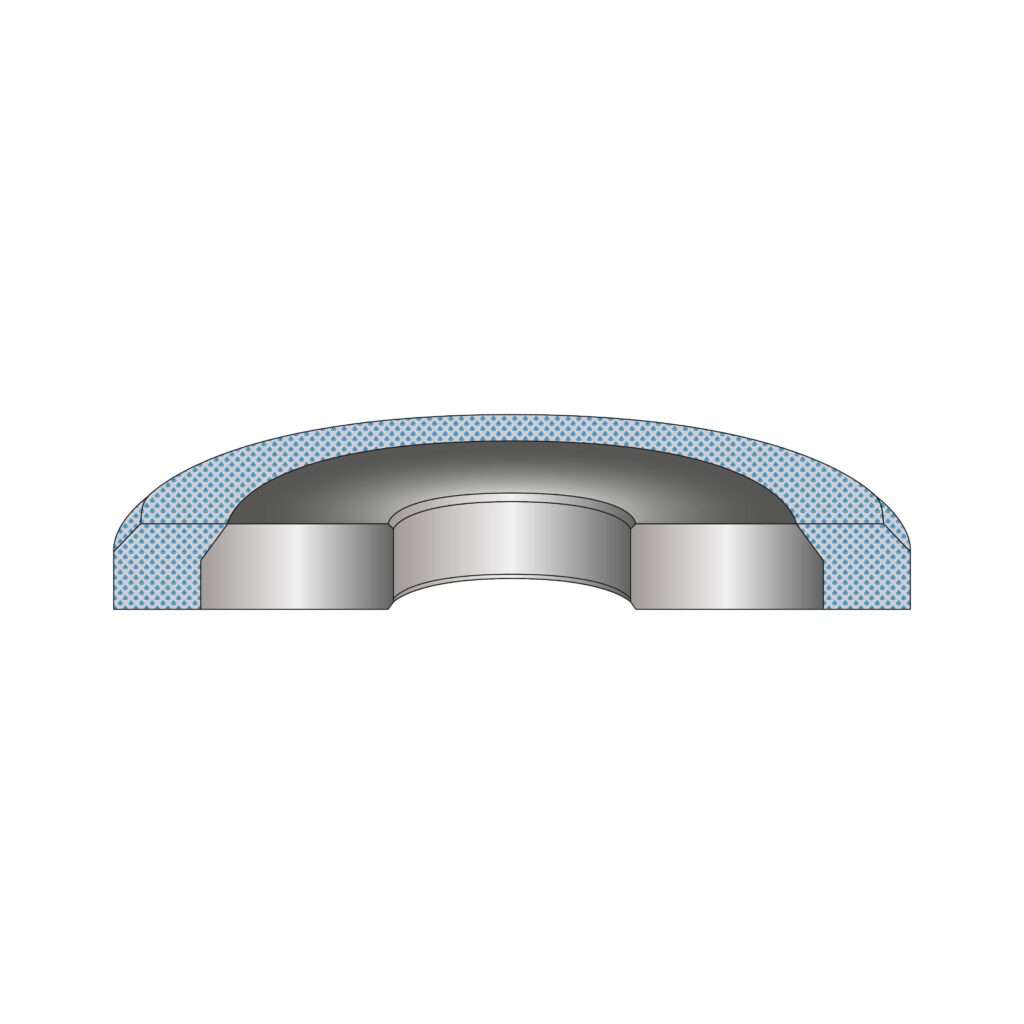

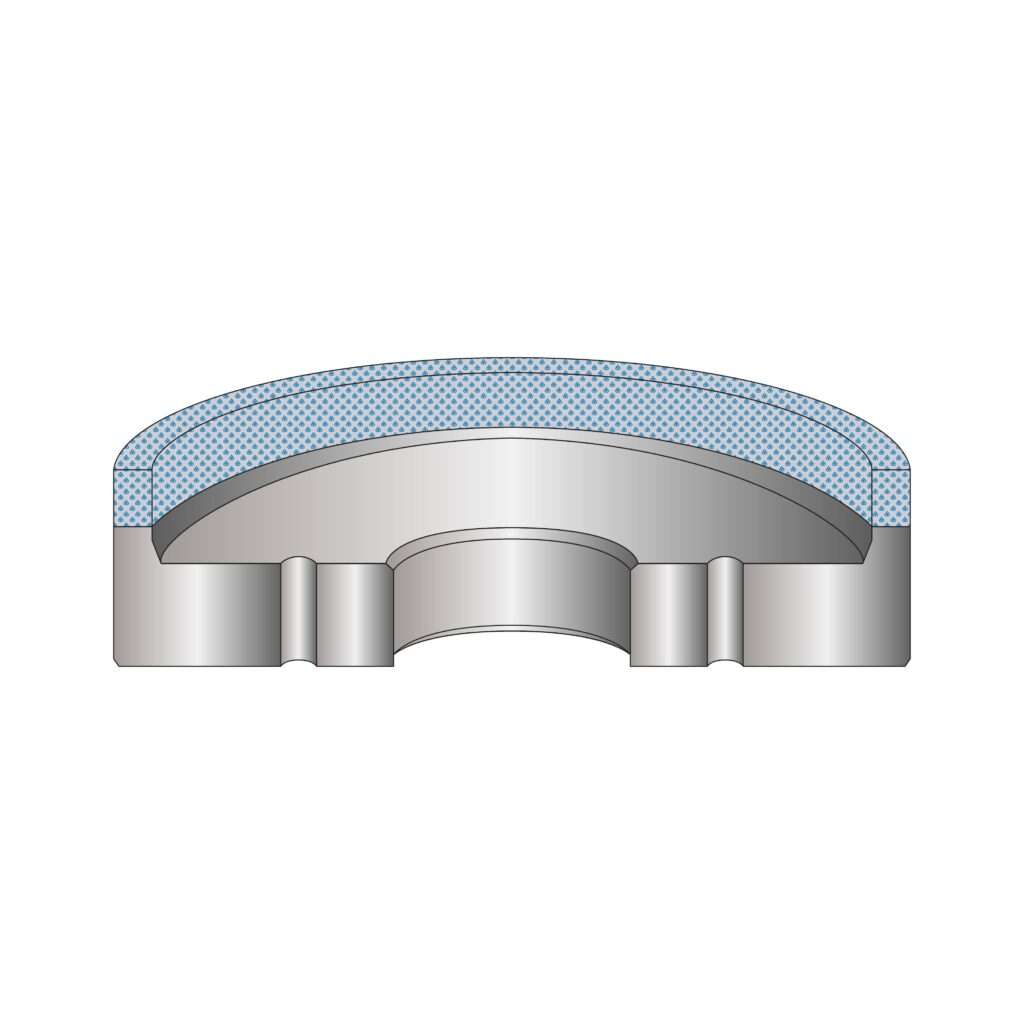

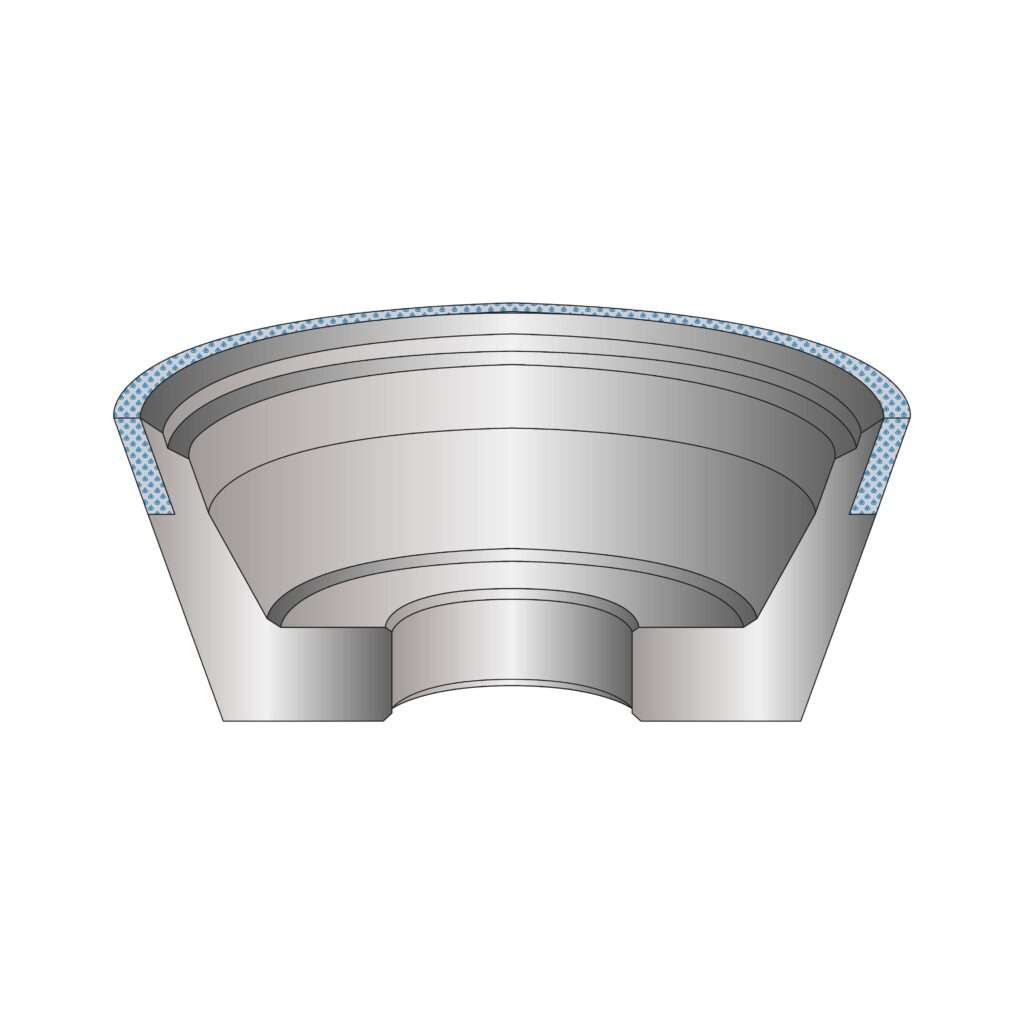

Hybrid Bond

Hybrid Bond is a between resin and sintered (metal bond). Life span is longer then resin bond, while maintains better form & shape consistently through its life similar to sintered (metal bond)

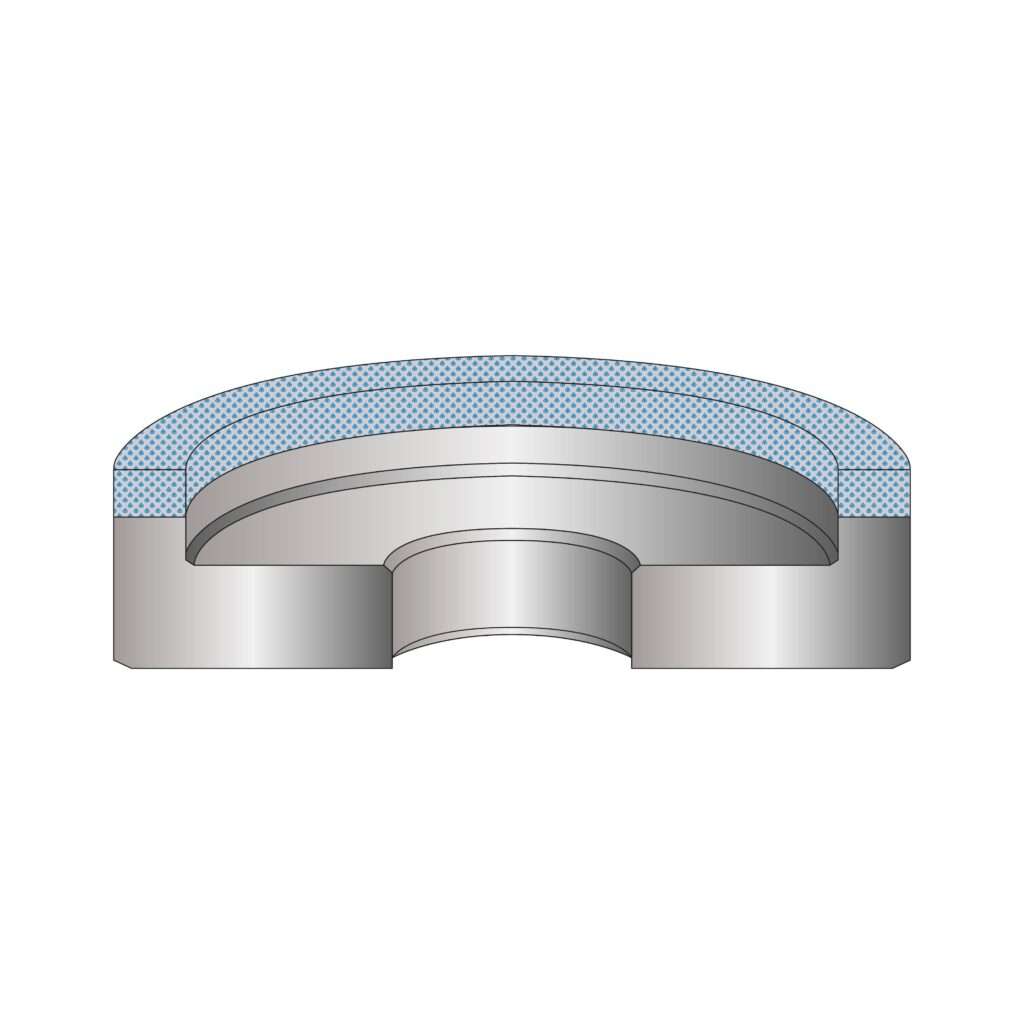

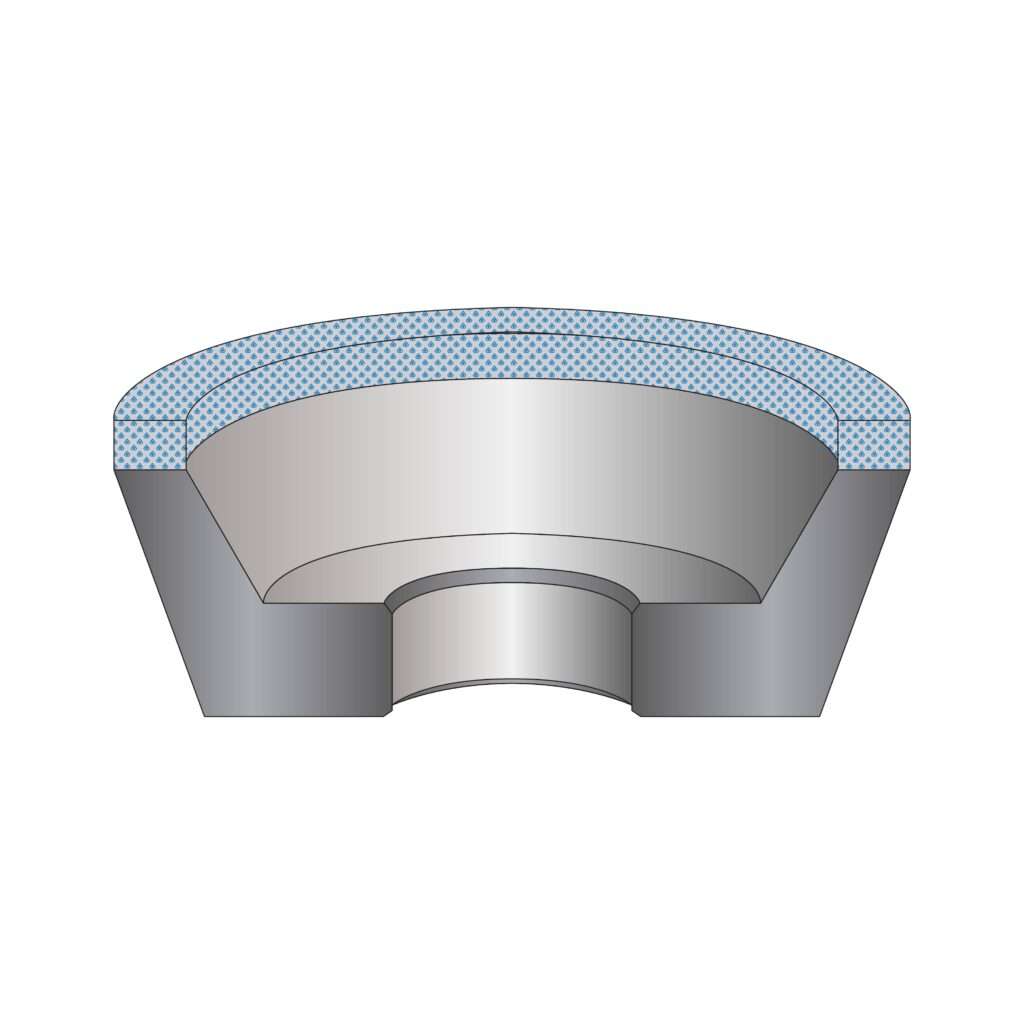

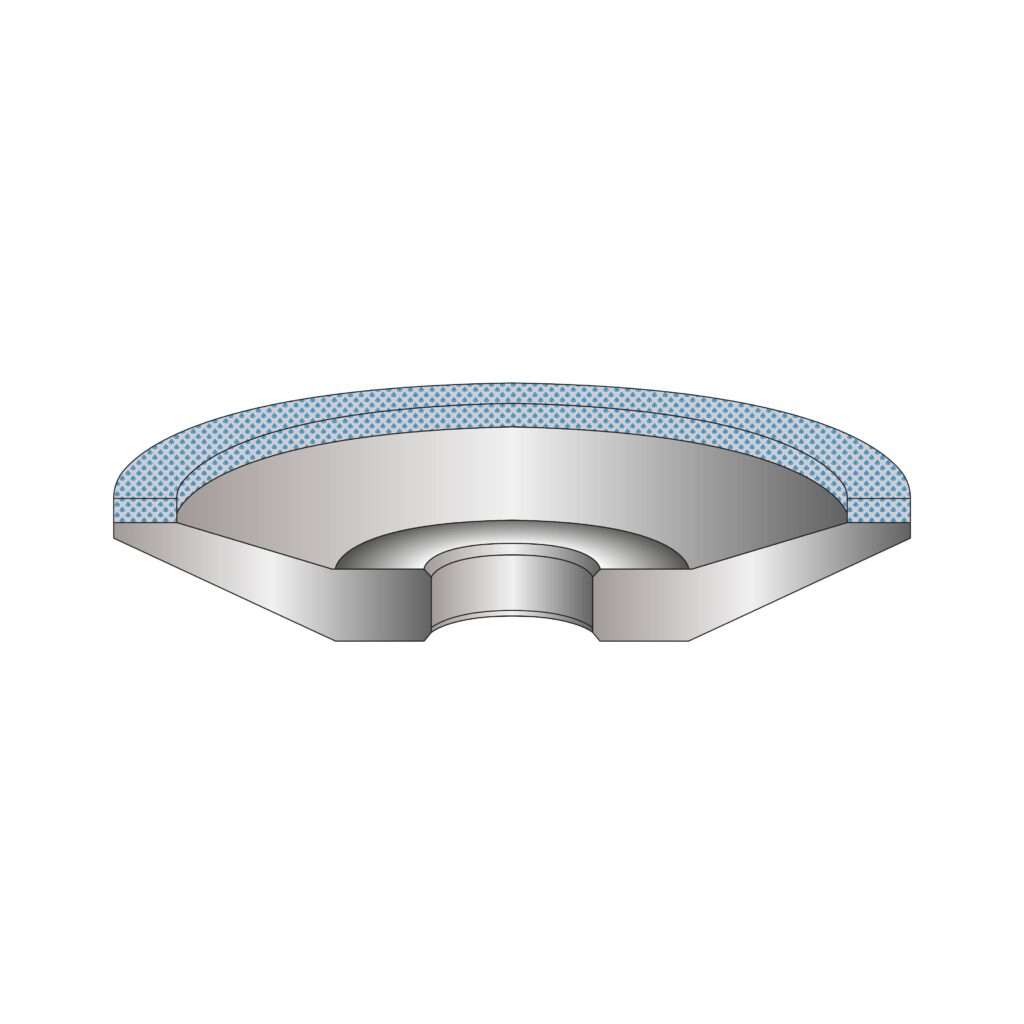

Electroplated (Nickel Bond)

Nickel Bond is a Galvanic process where diamond is deposited on steel body in chemical solution by time.

Vitrified Bond

Fired Ceramic Bond matrix, which is very brittle and porous. Also known as ceramic bond. Based on fusible glasses combined with fillers and abrasive grains.

Braised Bond

Brazed Bond Diamond Tools are perfect for machining tough-to-cut materials where fast stock removal and deep cuts are required.

Find Diamond & CBN Wheels

By Wheel & Tool shape

DIAMOND & CBN WHEELS

Accessories

Diamond Wheel Adapters / Hubb

We offer large variety of grinding wheel adapters used to attach grinding wheels to different types of grinding machines and spindles. They serve the purpose of adapting the mounting configuration of the grinding wheel to match the specific requirements of the machine or tool being used.

Coolants

We produce and offer large variety of coolants to use with diamond & cbn tools and consumables coolants help reduce amount of heat generated, cooling both the tool and material Use of coolant helps increase tool life, improve cutting speed, surface finish, minimize chipping, reducing cracking.

Dressing Sticks

Large variety of dressing sticks are available from stock in different sizes, specifications used to dress all types of diamond tools dressing is the process of sharpening & exposing diamonds particles in bond matrix for them to freely penetrate into the material, minimize load and improve cutting spee.

Diamond Dressers

Used for truing and dressing conventional abrasive and super abrasive (diamond/cbn) wheels. Truing is to restore the wheels profile and dressing is opening the abrasive layers remove stock or closing to finish the face of the wheel. Single point, multi point, chisel shape, straight, angle, and radius configurations. We provide diamond dressers to match your wheel topography, to performing with superior strength and versatility & custom manufacturing.

CAPABILITIES & SPECIFICATIONS

Diamond & CBN Wheel

SMART CUT® Diamond & CBN Wheels

SMART CUT® Diamond & CBN Wheels are designed and specially selected to provide maximum possible life, for your desired Surface Finish & Speed

- Diameters Available: 0.3mm to 1219mm

- Core Available: Steel, Stainless Steel Bronze, Steel with memory, Hight Carbon Steel, Tungsten carbide, fully impregnated with diamond

- Thicknesses available: .004 (100 microns) to any thickness in .005" (5micron) increments

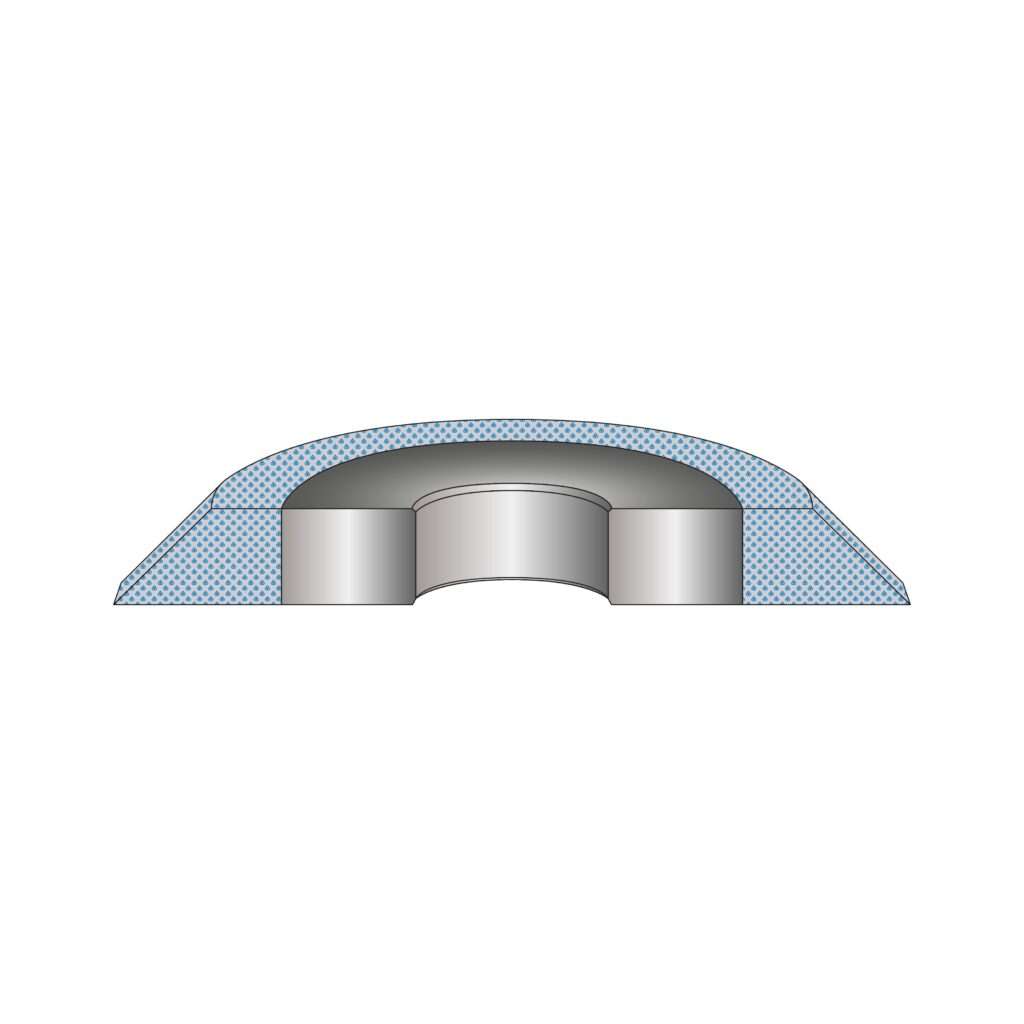

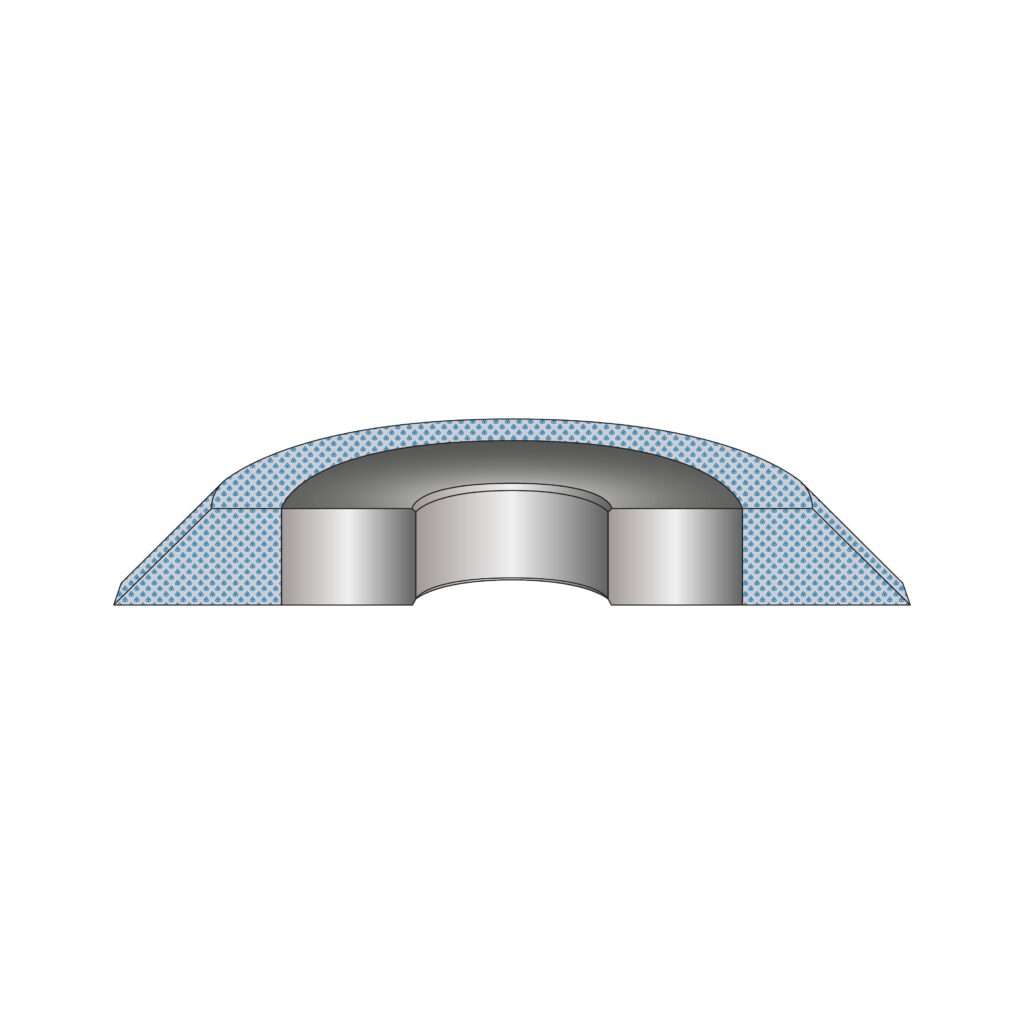

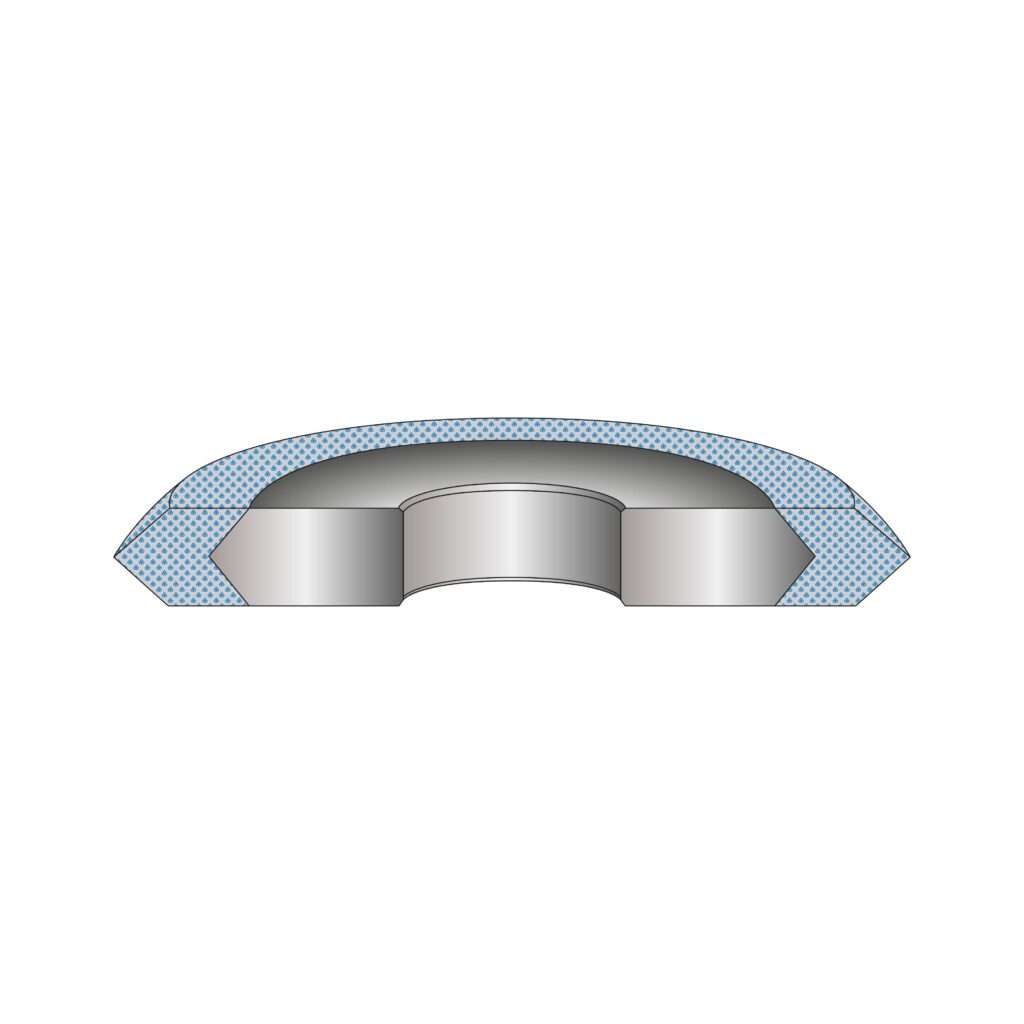

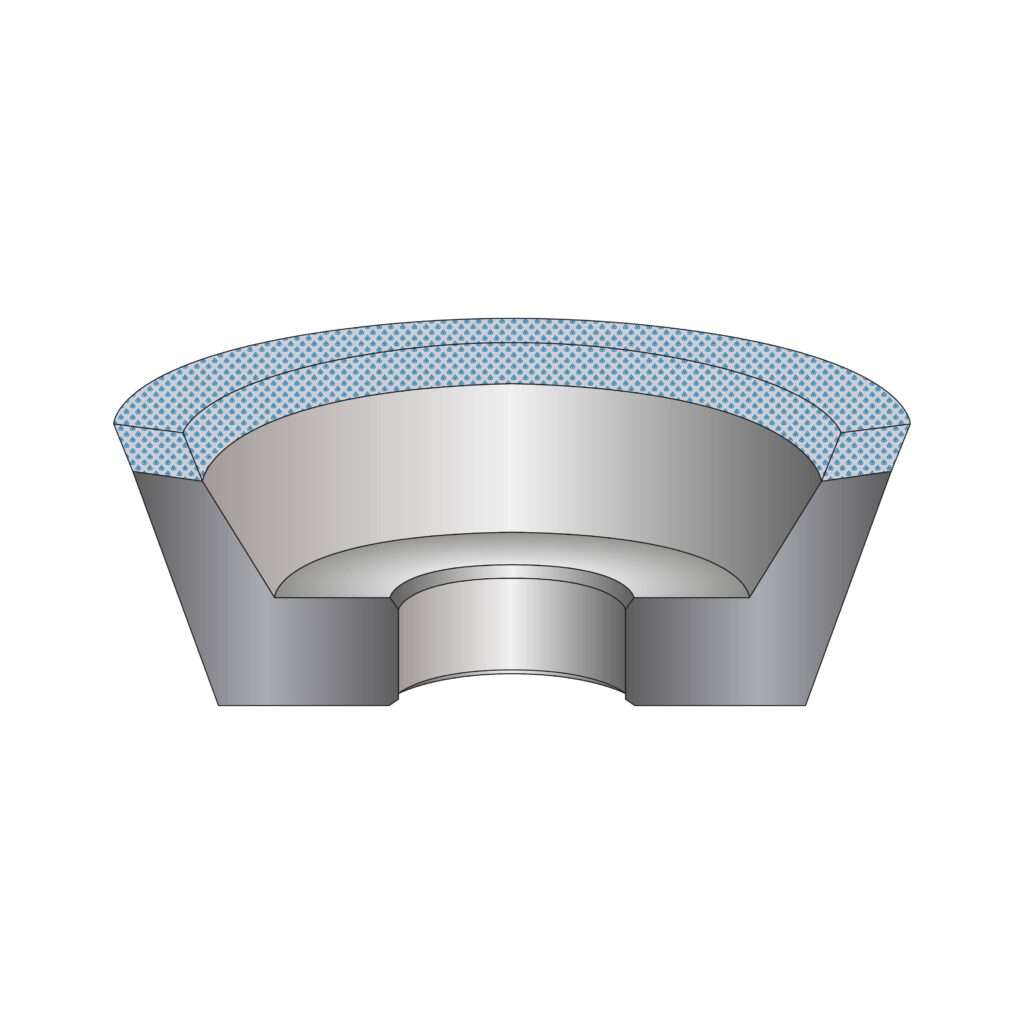

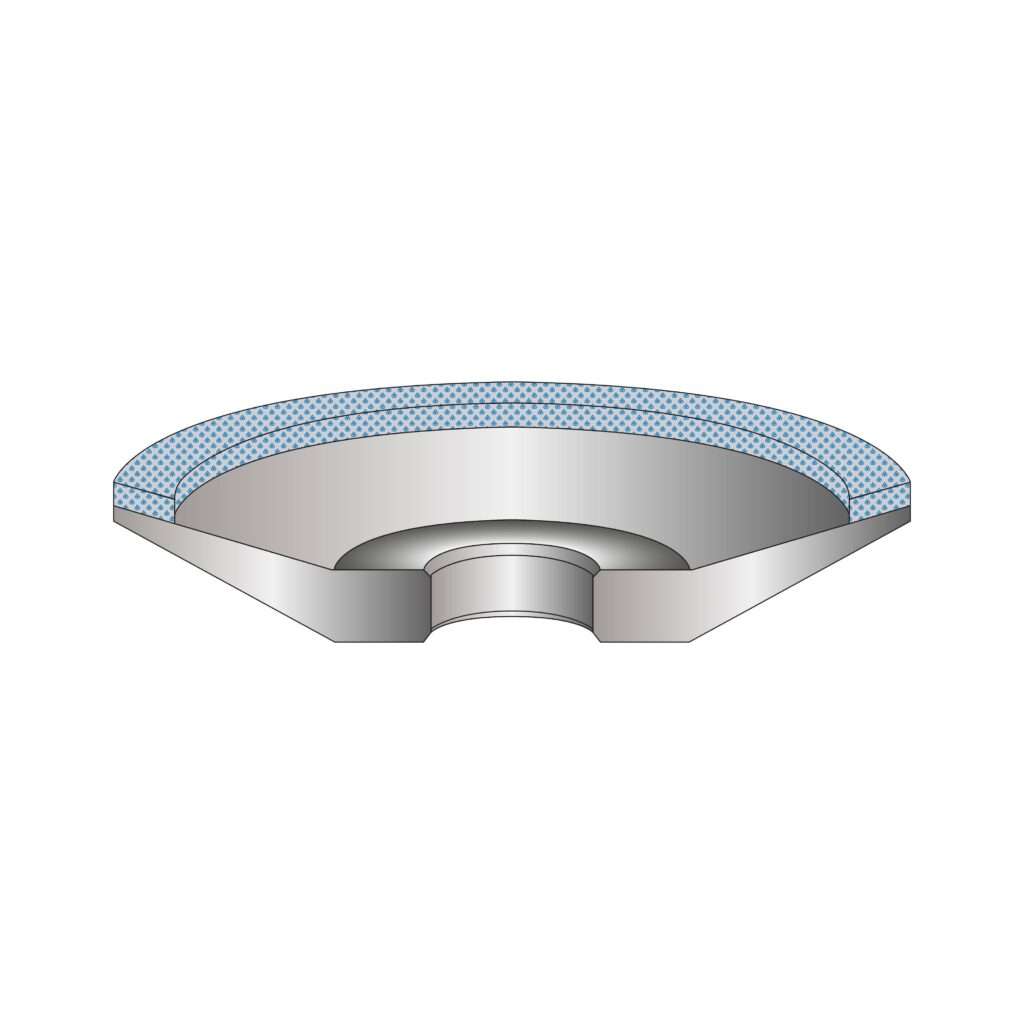

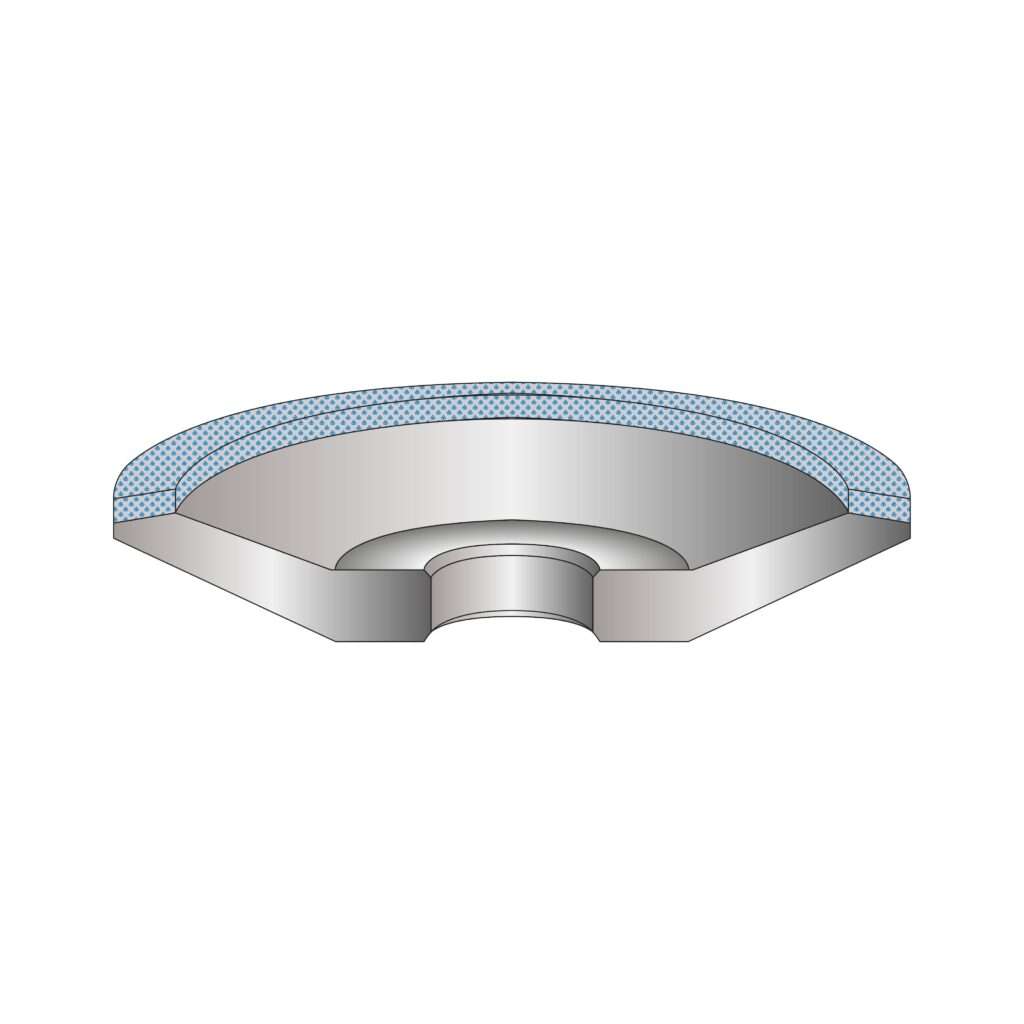

- Edge Shape: 1A1R, 1A1, 1E1, 1M1, 1N1, 1V1, 1A8, 1E8, 1zm8, 1N8, 1V8 1A1, 14U1, 6A2, 6A2 Sp, 9A3, 12A2-45, 11V9-70, 12S2-4SSS 15v5-45(other kerf angels and radiuses can be produced upon request)

- Arbor sizes available (inside diameters): any arbor size. Standard are 1/8. 1/4. 3/8. 1/2, 5/83/4. 1", 1.25" 40mm, 2.75" 3.5. For most wheels We can alter the arbor size to anything you need, almost same day and can also produce any arbor size. Wheels mounted on straight shank and mandel available.

- Bond Hardness: Super Soft, Soft Medium, Hard

- Diamond type: synthetic diamond, synthetic, coated diamond and cbn (cubic bron nitride)

- Tolerances Available: ODT tolerance + .050/.000 Arbor Hole tolerance +.0001/-.000mm Thickness +.002/-.001 Core Thickness:+.0001/-.001

- Edge Type: Continuos Rim, Slotted, Segmented. Serrated, band saw blades, wire blades.

- Diamond concentration: low, medium and high (from 10 con to150 con)

DOWNLOAD OUR DIAMOND AND CBN WHEEL CATALOG

Contact us for Free Quote

& Application recommendation today!

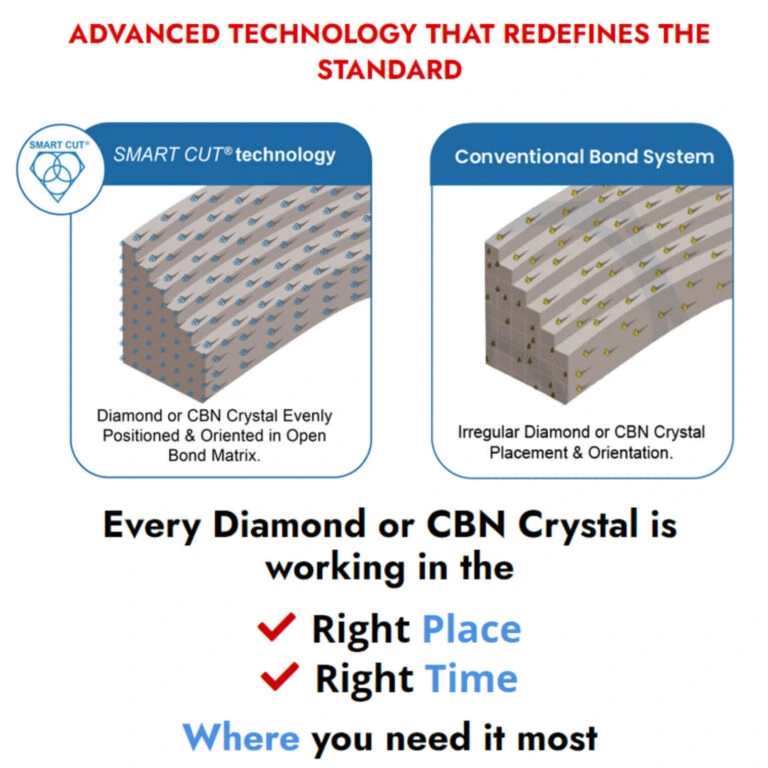

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

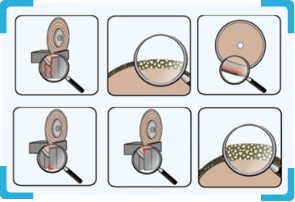

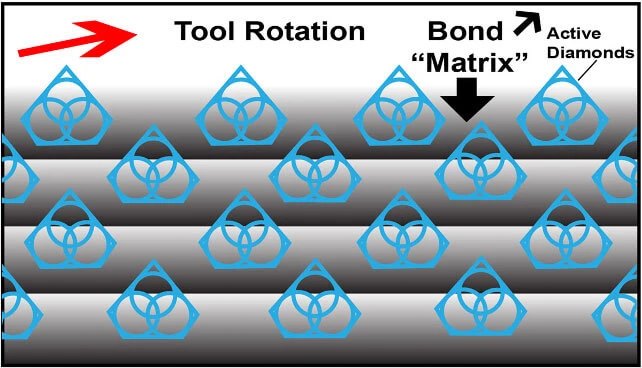

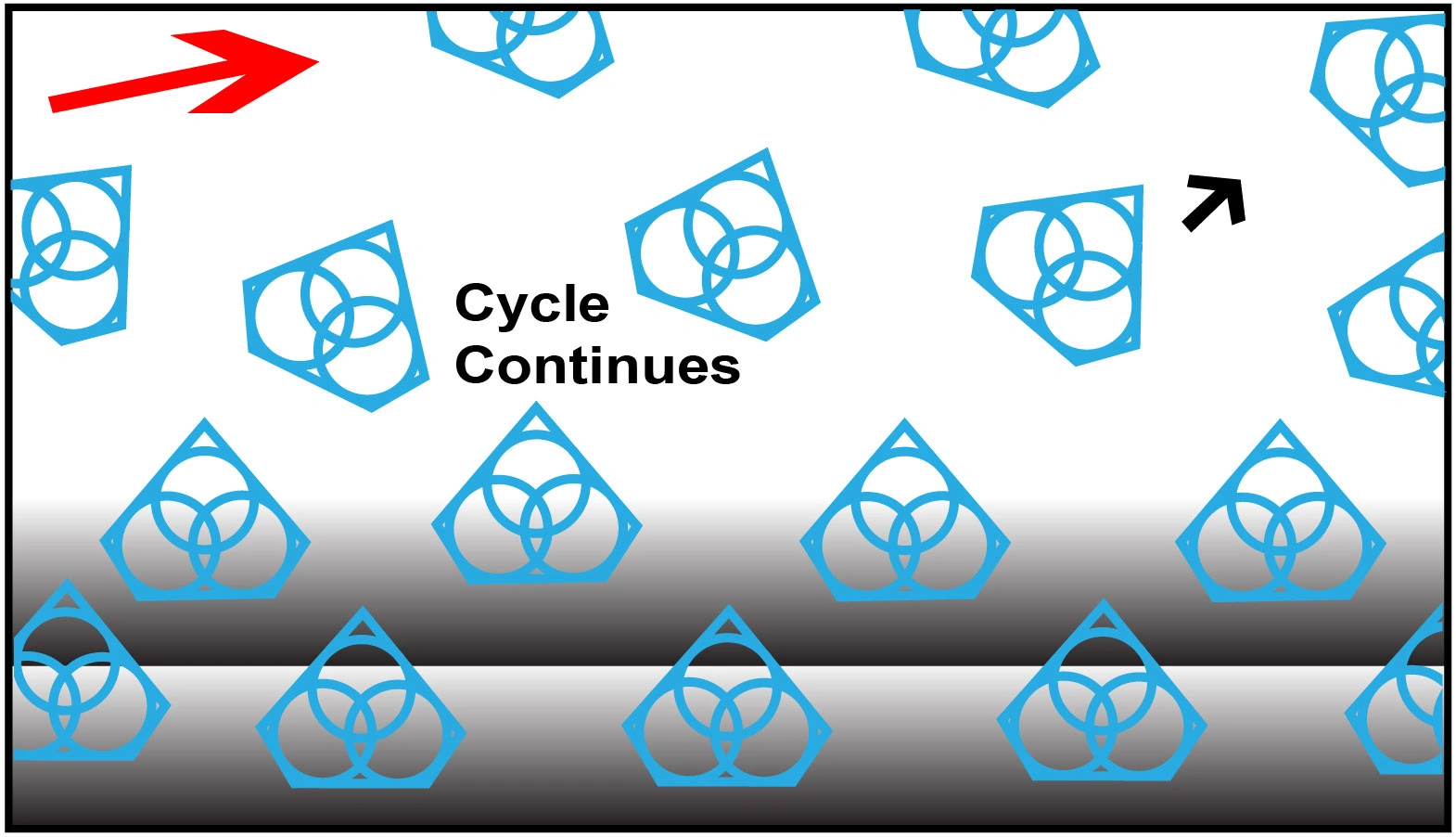

How SMART CUT® Bond Works?

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

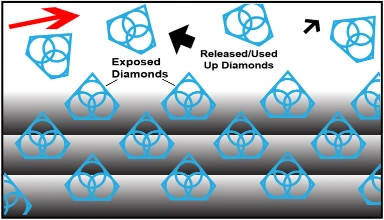

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

DIAMOND VS CBN (Cubic Boron Nitride) Wheels

- Alloy steels (45-68 RC)

- Carbon tool steels (45-68 RC)

- Die steel (45-68 RC)

- High speed steel (45-68 RC)

- Chilled cast iron

- Ni Hard

- Forged steel

- Meehanite iron

- Moly chrome steel rolls

- Inconel 600

- Rene

- Incoloy

- Monel

- Stellite

- Colmonoy

- Waspoloy

Why Choose SMART CUT® Diamond & CBN Wheels?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Diamond & CBN Wheel Equipment Used on:

- Jungner

- Safag

- Kiner

- Scheneberger

- Pe Te We

- Schutte

- Rollomatic

- Sorenco

- Saacke, Gebr

- Anca

- Griffo

- Cinicinnati

- Haas

- M. Deckel

- Haro

- EWAG

- Hawema

- Huffmann

- And Many More

Why Work With Us?

Comprehensive Source Of Information On Diamond & CBN Wheels

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting, drilling, grinding and polishing on the web. Find everything you ever wanted to know about diamond & cbn wheels.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond & cbn wheels available in stock. we regularly produce custom diamond & cbn wheels to better fit customers specific needs & specifications. Just about any diamond tool can be designed and manufactured per customer drawing or specifications.

Experience Makes All The Difference

Over the years we have enjoyed working with all types if the clients, regardless of size. Proprietary bond chemistry, precision, manufacturing methods, modern, quality control methods, allow us to control and regulate the dozen of variables that affect diamond & cbn wheels life, quality of cut, surface finish.

Umatched Technical Support

We Are A Partner In Your Success

We develop close ties with our customers is the foundation of our business. At the core of the company is a team of world class engineer, knowledge customer service personnel here to serve you, Whether is designing of manufacturing a special solution. we will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer

One of the few remaining independent U.S. Diamond Tool and machine builders. We have the experience & tradition. to help you remain at frontier of technology. Our experience has been further enhanced by acquiring assets and process from some of the oldest American tool manufacturers along with their decade of experience and R&D. This has positioned as as one of the most experienced computer companies in the industry .

Unmatched Quality And Consistency

Our unique bond formations, tool design, stringent requirements, and utilization of exceptionally, high quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allows us to control and regulate the dozen of variable that effect life tool, quality and consistency.