Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

The 15V9 Diamond & CBN (Cubic Boron Nitride) Grinding Wheels are designed for a wide array of high-precision, high-efficiency applications. Here are some of their primary uses:

INDUSTRIES USED IN:

Ferrous & Non-Ferrous Metals:

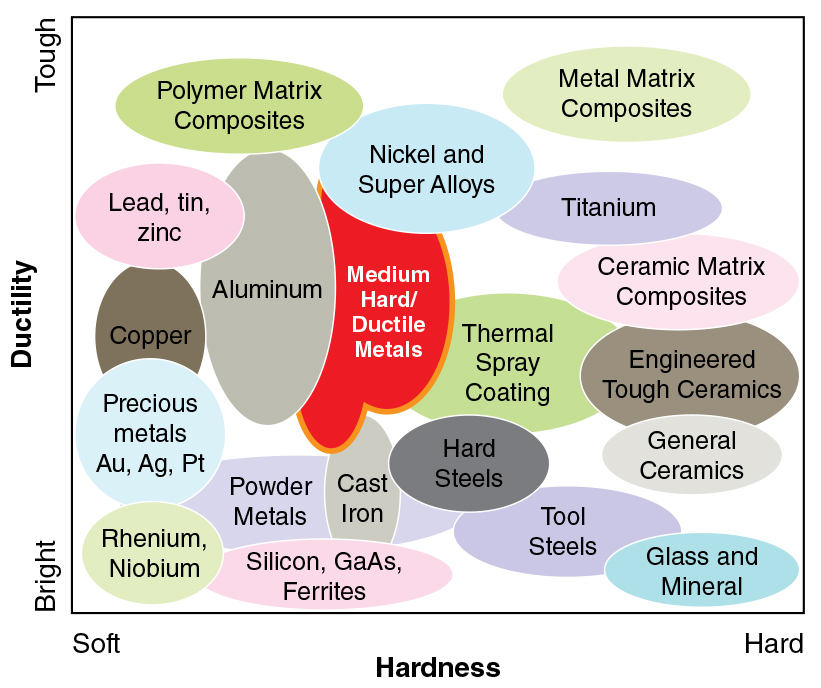

The 15V9 Diamond Wheels are suitable for grinding hard, non-ferrous materials, such as carbide, ceramics, glass, and other abrasive materials. The CBN Wheels are designed to grind ferrous materials such as hardened steels and high-speed steels.

These wheels are compatible with various CNC grinding machines, precision grinders, and tool and cutter grinders. It’s important to check the specific machine compatibility based on the wheel’s dimensions and mounting requirements.

Yes, custom sizes are available upon request. You’ll need to provide the required dimensions, tolerances, and any other specifications your particular application may need.

Always refer to the machine’s manual Ensure that the wheel is properly mounted and secured, and that you are following all safety procedures.

Operating speeds vary based on the wheel size and composition. Always adhere to the maximum speed rating provided and consult our engineering team for recommended speed for your specific grinding task.

Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Ensure the work area is secure, the wheel is free from damage, and the machine guards are in place.

Grit size selection depends on the material being ground and the finish required. Coarser grits are used for rapid material removal, while finer grits are used for a smoother finish. Consult with our engineering team for recommendations on grit size for your specific application.

Store the wheels in a dry, temperature-controlled environment away from direct sunlight, heat, and cold. Keep them in their original packaging to prevent damage.

Yes, both Diamond and CBN wheels can be dressed. Use a dressing stick appropriate for the type of wheel, or a machine dresser, and follow the dressing procedure recommended by the wheel manufacturer.

The life of a grinding wheel depends on the frequency of use, the materials being ground, and the operating conditions. Inspect the wheel regularly for wear and replace it when it no longer performs satisfactorily or if it becomes damaged or worn down to the manufacturer’s recommended limit.

Apart from regular dressing, the wheels should be inspected for signs of wear, damage, or imbalance. Keep the wheels clean and free of any buildup that could affect performance.

CBN wheels have a significantly longer life and provide a consistent cutting edge compared to conventional wheels. They also allow for higher speed operations and can produce finer finishes with less heat generation on the workpiece.

Yes, the 15V9 wheels can be used for both wet and dry grinding, although wet grinding is generally recommended to improve the wheel life and to reduce dust and heat.

These wheels are generally more environmentally friendly than some other abrasive products because they last longer and reduce the need for frequent replacement. Additionally, when used with proper coolant, they minimize airborne particles.

If a wheel becomes out of balance, it should be rebalanced using the proper balancing equipment. Operating an unbalanced wheel can be dangerous and can lead to poor surface finishes and decreased wheel life.

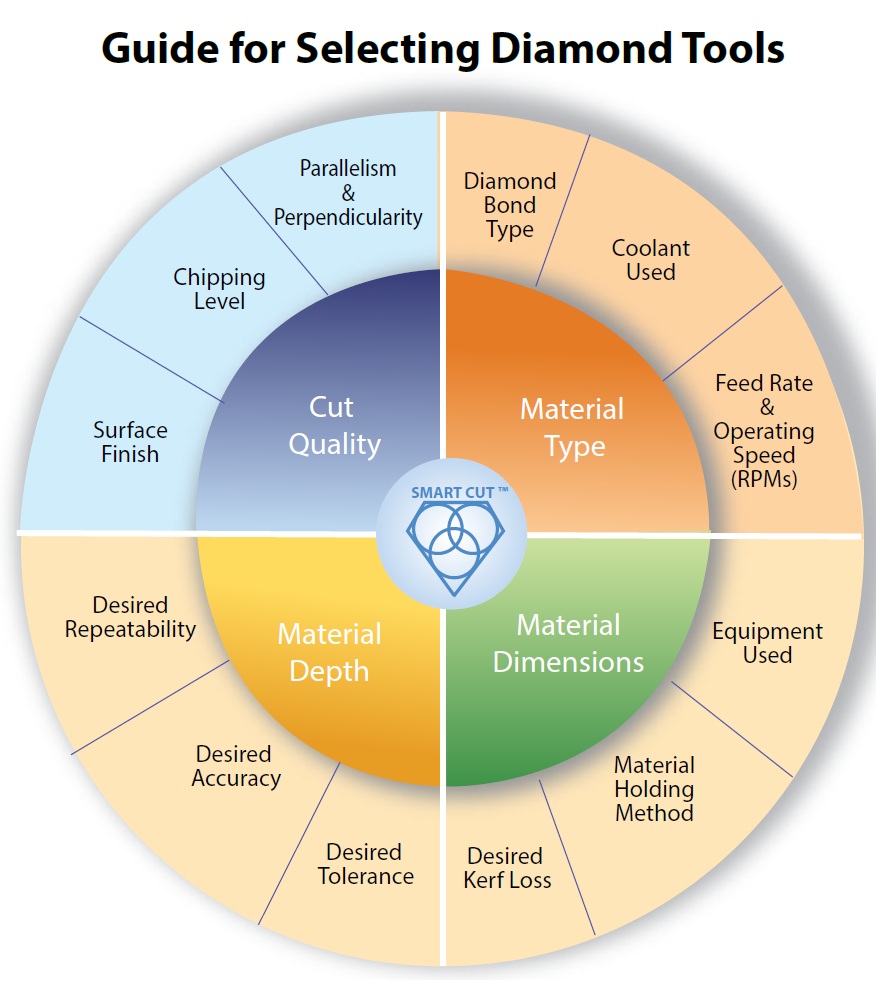

Yes, 15V9 wheels come with various bond types, including resin, hybrid and other bonds, each offering different performance characteristics suitable for various applications and materials.

Signs that it’s time to dress the wheel include a decrease in grinding performance, changes in the sound of the grind, visible glazing on the wheel, or any irregularities on the surface.

While not excessively fragile, diamond and CBN wheels should be handled with care to prevent damage. They should be shipped in proper packaging to avoid impacts that could cause chipping or cracking.

It’s not recommended to use the same wheel for different materials, especially if they require different grinding dynamics. Using the same wheel can compromise its effectiveness and the finish of the materials.

If stored properly, the 15V9 Diamond & CBN Grinding Wheels have an indefinite shelf life. However, it’s a good practice to use the wheels within a few years from the date of manufacture to ensure the best performance.

Yes, materials that can cause a chemical reaction with the bond or abrasive should be avoided. For example, grinding steel with a diamond wheel can lead to carbon dissolving into the steel and eroding the diamond grit.

Disposal should be carried out in accordance with local regulations. Contact local waste management services for proper disposal methods, as the wheels are made of materials that may require special handling.

Depending on the wheel’s condition and the bond type, some wheels can be reconditioned or re-profiled

Yes, 15V9 wheels are specifically designed for precision profile grinding. Their shape and construction allow for detailed and accurate grinding operations.

High temperatures can cause the bond to break down and may affect the integrity of the abrasive grains. It’s important to use adequate coolant and proper grinding parameters to manage temperature during grinding.

The surface finish can be adjusted by selecting the appropriate grit size, using the correct wheel speed, feed rate, and by dressing the wheel properly to achieve the desired finish.

The profile of the wheel determines the shape of the grind and can influence factors such as contact area, cutting action, and chip clearance. Correct wheel profile is crucial for achieving the desired grinding result.

Yes, these wheels are often used for sharpening high-speed steel and carbide tools due to their precision and the superior finish they can provide.

The best wheel speed depends on the material hardness, wheel diameter, and desired outcome. Consult our engineering team for the optimal speed for various materials.

Store the wheels in a cool, dry place away from extreme temperatures and humidity to prevent the bond from deteriorating or the wheel from warping.

The 15V9 wheel has a unique toroid shape that is designed for certain profile grinding tasks, offering advantages in angle precision and access to intricate part geometries.

Prevent chipping by ensuring the wheel is properly dressed, operating at the correct speed, and not applying excessive force during grinding. Also, ensure that the workpiece is securely fixed.

Yes, a new wheel should be properly conditioned or broken in to expose fresh abrasive grains and to ensure the wheel performs optimally from the start.

Yes, these wheels are versatile and can be used on both manual and CNC grinding machines as long as the mounting and operating parameters are compatible.

An unbalanced wheel can cause vibration, leading to a poor surface finish, increased wear on the machine, and reduced operator comfort. Wheel balancing is essential for precision grinding.

Using the wrong bond type can result in poor performance, such as rapid wear, suboptimal surface finishes, or damage to the workpiece and wheel.

15V9 wheels are ideal for precision grinding, shaping, and finishing applications, including tool and cutter sharpening, end mill and drill bit reconditioning, profile grinding, and flute grinding.

Choose diamond wheels for grinding carbide, ceramics, and other non-ferrous materials. Opt for CBN wheels for grinding hardened steels, high-speed steels, and ferrous alloys.

Yes, the design of the 15V9 wheel allows for both profile and plunge grinding applications.

Wheel glazing, unusual noises, burning of the workpiece, reduced grinding performance, or visible wheel wear are indicators that the wheel needs dressing.

While tolerances can be application-specific, 15V9 wheels are capable of achieving tolerances within a few microns, depending on the machine, wheel specification, and operator skill.

Indicators of a worn-out wheel include extensive physical wear visible on the wheel, consistent underperformance even after dressing, or any form of damage such as cracks or chips.

Regular dressing and correct storage will maintain the wheel shape and dimensions. If the wheel loses its shape, it may need to be professionally trued.

Common mistakes include using the wrong wheel type for the material, incorrect mounting, excessive force, and improper wheel speed, which can all lead to premature wheel wear or damage.

ent

Extreme temperatures and humidity can affect the wheel bond and its performance. It’s best to store and use these wheels in controlled environments.

15V9 wheels are generally not designed for side grinding due to their angled edge and profile. They are best used for the applications for which they were specifically designed.

Recycling of industrial grinding wheels varies depending on the material and local regulations. Consult with the manufacturer or local waste management authorities for proper recycling practices.

Spindle speed will depend on the wheel’s diameter and the material being ground. Refer to the manufacturer’s specifications and recommended operating speeds.

Apply grinding fluid directly to the cutting area to ensure efficient cooling and chip removal. The type of fluid and flow rate can significantly affect the grinding quality and wheel life.

Use consistent grinding parameters, maintain a regular dressing schedule, and ensure the machine and wheel are in good condition.

Wheel hardness influences the self-sharpening ability of the wheel. A harder wheel retains its grit longer but may not self-sharpen as effectively, which can lead to glazing. Conversely, a softer wheel will self-sharpen more easily but may wear down faster.

Yes, 15V9 wheels come in a variety of grit sizes to accommodate different levels of finish and material removal rates.

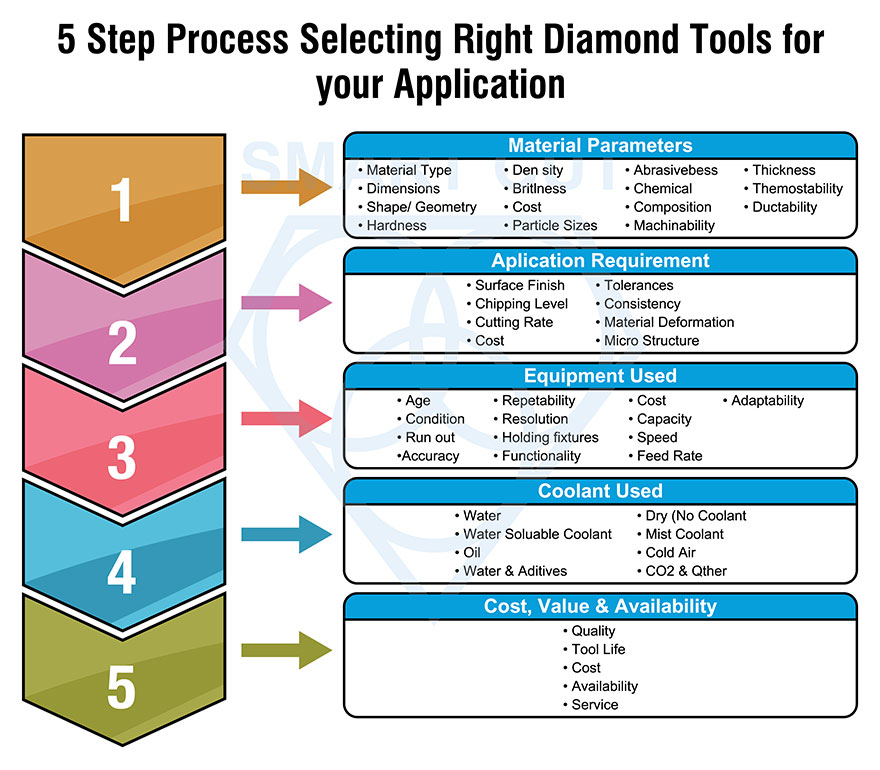

Consider the material to be ground, the required finish, the grinding machine capabilities, the hardness of the wheel, and the complexity of the component geometry.

Minor damage may be corrected by dressing, but if the wheel is cracked or extensively chipped, it should not be used. Consult with our engineering team if there’s any uncertainty about wheel integrity.

Incorrect wheel speeds can lead to suboptimal grinding results, wheel damage, increased wear, and potential safety hazards.

Dressing frequency depends on the material being ground, the amount of material removal, and the desired surface finish. Monitor the grinding process and wheel condition to determine the right interval.

Yes, we offeroffer custom profiling services for wheels to meet specific application needs.

Check the dressing of the wheel, ensure that it is properly balanced and mounted, verify the grinding parameters, and inspect the workpiece fixture for rigidity.

Synthetic diamond wheels typically offer more consistent performance due to the uniformity of the synthetic diamond crystals. Natural diamond may have variations that affect the grinding process.

Yes, if the machines have compatible mounting and operational specifications. However, it’s important to adjust the grinding parameters to each machine’s capabilities.

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

SMARTC2G | 1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | ||

SMARTC1G | 1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | ||

SMARTC4A | 5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | ||

SMARTC7A | 55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | ||

UKAMDRST10 | 1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | ||

UKAMDRST11 | 1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | ||

UKAMDRST13 | 1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | ||

UKAMDRST4 | 1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | ||

UKAMDRST5 | 2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | ||

UKAMDRST7 | 1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | ||

UKAMDRST8 | 2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 |

we manufacture custom tools to fit your specific requirements and specifications. We have the capability to manufacture over 30,000+ different types of custom diamond & cbn tools and consumables to better fit your particular material, application, specifications, and requirements

Not all requirements are the same. We manufacture tools to fit your particular equipment, tolerances, surface finish, life span, and overall see the difference tools optimized for your application can make?

We will work with you to determine your needs, and develop the right bond formulation, concentration, and grit sizes. Our tools are designed and specially selected to provide maximum possible tool life, for your desired cut quality and speed.

The following process describes custom tool manufacturing process form initial first inquiry to final delivery.

We discuss your specific requirement in detail to determine the best solution for your needs.

We provide you with recommend options for your application based on your requirements along with quotation and lead time.

When you are ready to order, we send you confirmation of the tool specification always in writting. Your order is placed in que to be produced within the quoted lead time.

The finished products go through quality control process and also inspected for conformance to specification agreed upon. The order is packaged and shipped to you using your requested shipping method. Certificate of conformance or any other documentation can be provided upon request.

We follow up with you to receive feedback on the tool performance. We also provide usage recommendatios and technical support if needed.

To place an order, you can contact our customer service team via phone, email, or our website. You will need to provide specific details about your grinding application, including material to be ground, required wheel dimensions, and desired grit size.

Yes, we are happy to help. We will send you a question are asking many questions about your requirements, how the tool will be used and the usage environment. This information is very important for helping us understand your unique specifications and requirements. The more information you can provide the more accurate recommendation and solutions we can provide.

Usually there is no minimum order for custom tools, with few acceptations. We encourage you to try small quantity to make sure you are happy with the tool performance first. As additional fine tuning and improvements can be made based on your feedback.

Lead time varies depending on tool specification and current schedule. Usually the lead time range can be from 1 to 5 weeks. expedited lead time of 1 to 2 weeks is usually available at additional cost if needed

Prices are based on tool specification, tolerances, quantity and lead time. Our prices are pretty competitive for world market. We regularly export our products to dozens of different countries across all continents. Usually custom products in small quantity the pricing is usually higher then standard of the shelf products which are mass produced in large quantities.

Over many decades we have made and sold thousands of different types of unique and one of a kind tools for almost every application. we maintain records of bond formulations and specifications used over many years we have also acquired the “know how” of several other US tool manufacturers that have produced custom tools over many decades, some going far back as to 1960’s. we also have our own R & D research program and we regularly work with different research originations and outside consultants. Most of the time we produce the right tool formulation first time, but sometimes we can make additional improvements second and third time around. Our goal is to make you happy

We ask lot of detailed question about tool specification and your usage process. Sometimes it may be worthwhile for you to send us your used tool so we can inspect it.

Yes we can provide basic recommendations and recommended usage information. If you need specific hands on approach such as “process development” this can be done on case by case based for a fee. If we are not able to help we can often recommend independent outside consultant or organization that can assist.

For a custom wheel order, you should provide the following information:

• Type of wheel (Diamond or CBN)

• Wheel dimensions (diameter, thickness, and arbor hole size)

• Grit size

• Material to be ground

• Grinding machine details

• Desired surface finish

Yes, you can request a specific bond type based on your grinding application. Common bond types include resin, vitrified, metal, and electroplated.

The lead time for custom wheels varies depending on the complexity of the wheel and our current production schedule. Typical leads times range from 4 to 5 weeks. Expedited lead time of 1 to 2 weeks is also available at additional cost if needed. Our customer service team will provide an estimated delivery date when you place your order.

Due to the custom nature of these wheels, they are typically non-returnable. However, if the wheel does not meet the specified requirements or is defective, we will work with you to resolve the issue.

Yes, you can order a sample wheel to test on your application before placing a bulk order. We highly encourage that you test the wheel for your particular application in your environment. Please contact our customer service team for more information.

Yes, we offer discounts for bulk orders. Please contact our sales team for more information.

Proper care and maintenance are essential to ensure the longevity and performance of your wheel. You should regularly clean the wheel, check for any damage, and use it at the recommended speed. Additionally, it’s important to use the correct coolant and dressing tools.

Yes, we can customize the wheel profile to meet your specific requirements. Please provide detailed drawings or specifications of the profile you need when placing your order.

Diamond wheels are suitable for grinding non-ferrous and non-metallic materials such as glass, ceramics, and tungsten carbide. CBN wheels are ideal for grinding ferrous materials such as steel, cast iron, and nickel-based alloys.

Yes, we have a team of experienced engineers and technicians who can provide technical support and advice for your specific grinding application.

Yes, you can request specific tolerances for your custom wheel. Please provide the required tolerances when placing your order, and we will do our best to meet your specifications.

Once your order has been placed, you will receive an order confirmation with a tracking number. You can use this number to track the status of your order on our website or contact our customer service team for updates.

We will do our best to accommodate any changes to your order, but please note that changes may not be possible once the production process has started.

We accept various payment methods, including credit card, PayPal, and bank transfer. Please contact our sales team for more information.

Cancellations are handled on a case-by-case basis. If the production process has not started, we may be able to cancel your order. However, once production has begun, cancellations are generally not accepted.

A balanced wheel is essential for optimal performance and safety. If you notice any vibrations or irregularities during operation, your wheel may be out of balance. Please contact our technical support team for assistance with balancing your wheel.

Yes, we offer a warranty on our custom wheels. The length and terms of the warranty will depend on the specific wheel and application. Please contact our sales team for more information.

The grit size should be selected based on the material to be ground and the desired surface finish. A coarser grit is generally used for rapid material removal, while a finer grit is used for a smoother finish. Our technical support team can help you choose the right grit size for your application.

Yes, we can manufacture custom wheels to fit specific brands and models of grinding machines. Please provide the make and model of your machine when placing your order.

Yes, we ship custom wheels internationally. Please contact our sales team for more information on shipping options and costs.

Resin bonds are flexible and suitable for grinding materials that are prone to heat damage. Vitrified bonds are rigid and offer high precision grinding. Metal bonds are durable and suitable for grinding hard materials. Electroplated bonds have a single layer of abrasive and are used for precision grinding.

A custom wheel may be necessary if your application requires specific dimensions, grit sizes, bond types, or shapes that are not available in standard wheels. Our technical support team can help you determine if a custom wheel is necessary for your application.

Diamond is the hardest known material and is suitable for grinding non-ferrous and non-metallic materials. CBN is the second-hardest known material and is suitable for grinding ferrous materials.

Yes, you can request a specific concentration of Diamond or CBN in your custom wheel. The concentration will affect the wheel’s performance and life.

Please refer to local regulations and guidelines for disposing of grinding wheels. In general, worn-out wheels should be treated as industrial waste and disposed of accordingly.

Yes, we can manufacture custom wheels with specific colors or logos. Please provide your requirements when placing your order.

Yes, we can manufacture a custom wheel with different abrasive grains to suit specific grinding applications.

Always wear safety goggles, gloves, and other appropriate personal protective equipment when using any grinding wheel. Follow the manufacturer’s guidelines and safety instructions for your specific grinding machine.

The performance of a custom wheel can be measured in terms of material removal rate, wheel wear rate, surface finish quality, and overall efficiency.

The wheel speed will depend on the specific grinding application, material to be ground, and the wheel’s dimensions. Our technical support team can help you determine the optimal wheel speed for your application.

Yes, you can specify the hardness level for your custom wheel, which will affect its grinding performance.

Our custom wheels comply with industry standards and regulations, including ANSI, ISO, and OSHA. Specific certifications may vary depending on the wheel and application.

Yes, you can request a custom wheel with specific porosity to achieve desired grinding performance and coolant flow.

You can conduct a trial run with the custom wheel on your grinding machine, following all safety guidelines. Observe the wheel’s performance in terms of material removal rate, surface finish quality, and overall efficiency. Our technical support team can assist you in evaluating the wheel’s performance.

Factors that affect the life of a custom wheel include the type of material being ground, the grit size, bond type, wheel speed, and coolant usage.

Yes, you can specify whether the custom wheel is intended for wet or dry grinding, and we will manufacture the wheel accordingly.

The bond type should be selected based on the material to be ground, desired surface finish, and grinding machine characteristics. Our technical support team can help you choose the right bond type for your application.

The minimum order quantity for a custom wheel depends on the specific requirements and dimensions of the wheel. For most wheels there is no minimum order quantities. Please contact our sales team for more information.

Yes, you can specify the face width or thickness for your custom wheel, and we will manufacture the wheel accordingly.

The wheel bond plays a crucial role in holding the abrasive grains together. The bond type affects the wheel’s wear rate, grinding performance, and the finish quality of the workpiece.

If you’re not satisfied with the performance of your custom wheel, please contact our customer service team immediately. We will work with you to address any issues and find a suitable solution.

The abrasive concentration in a wheel is typically measured as a percentage of the volume of abrasive grains to the total volume of the wheel. A higher concentration means more abrasive grains and typically results in a longer wheel life and better performance.

The wheel’s hardness affects its ability to resist wear and maintain its shape during grinding. A harder wheel typically lasts longer but may produce a rougher surface finish.

Yes, we can manufacture custom wheels with specific arbor hole sizes to fit your grinding machine.

Yes, we can manufacture custom wheels with specific grinding face geometries to meet your unique requirements. Please provide detailed drawings or specifications when placing your order.

Factors to consider when choosing the grit size include the material to be ground, desired surface finish, and grinding operation type. A finer grit is typically used for finishing operations, while a coarser grit is used for roughing operations.

Yes, we can manufacture custom wheels designed specifically for grinding materials such as glass or ceramics.

Wheel balance is critical for achieving optimal grinding performance and preventing vibration and machine wear.

Yes, you can specify the bond hardness for your custom wheel, which will affect its grinding performance.

The wheel diameter affects the peripheral speed of the wheel, which in turn influences the grinding performance and resulting surface finish.

The type of abrasive grain (e.g., Diamond, CBN, aluminum oxide) affects the wheel’s hardness, sharpness, and heat resistance, which in turn influences the grinding performance.

Yes, we can manufacture custom wheels with specific profiles for gear grinding applications. Please provide detailed specifications or drawings when placing your order.

Factors to consider when choosing the bond type include the material to be ground, grinding operation type, wheel speed, and desired surface finish.

Wheel speed affects the material removal rate, heat generation, and resulting surface finish of the workpiece.

Yes, we can manufacture custom wheels with specific porosity levels to meet specific grinding requirements.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond & CBN tools with SMART CUT technology make any work much faster & easier, Thousands of sharp and high quality diamond or CBN particles oriented and evenly distributed on both matrix, allow most jobs to be completed by applying little or only moderate amount of pressure even on the most toughest and challenging materials. Freeing the user from constantly having to dress and renew the diamond layer.

Diamond & CBN tools with SMART CUT® technology require minimum dressing, the bond renews itself.

Diamond & CBN Wheels are produced using only the highest quality raw materials are used in manufacturing process. Utilizing world class quality control, inspection, and measurement equipment. Highly Experienced Engineers constantly monitor and control all material input & output at all stages of manufacturing process. Insuring product consistency for use in demanding & sensitive applications SMART CUT® DIAMOND & CBN wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing.

Diamond & CBN tools made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional material (sintered), resin, and nickel bonded diamond & CBN tools. SMART CUT® diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

SMART CUT® Diamond & CBN Wheels are the best investment you can make! Although we may not always be the lowest cost solution provider. Our Diamond & CBN wheels can provide the best ROI. Designed for users that understand and appreciate quality. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Optimize your application to ultimate level of efficiency

Diamond Concentration – Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Sectioning/Wafering Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is significantly slower cutting speed. Low diamond concentration is recommended and widely used for cutting ultra hard and brittle materials.

Low Diamond Concentration - typically low concentration wafering blades should be for cutting ultra hard and brittle materials such as ceramics and glass. In Low Concentration Wafering Blades, diamond works by fracture process. Pressure on each diamond crystal/particle is higher which provides enough stress to chip off small flakes in the cut.

High Diamond Concentration - High concentration diamond wafering blades are recommended for cutting metals, plastics and polymers. In this application, materials cut by a plowing mechanism. In this applications diamond plough through the material, work hardened strips of materials become brittle and break off. The greater number of diamond by volume, the quicker the cutting action will be. Increasing the number of diamond s also lowers the per unit force. For metals where it is possible to induce deep deformation layers, a lower per unit force is desirable to reduce the deformation during the cut.

Wafering blade thickness typically ranges from .006” to .040” (1mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material/sample due to the thickness of blade passing though the material/sample. Blade thickness is important for users requiring most minimal amount of material loss during sectioning

For example if the user requires precision position of the cutting plane relative to the detail on the sample (IC circuit for example), a thinner and smaller diameter blade would be best for this application. Blades ranging from 3” to 5” (75mm to 125mm) in diameter and thickness .006” to .015” (0.2mm to 0.4mm) would be bet suited for this purpose. There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, load/feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker wafering blades are more stiff and can whistand higher loads/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as in University laboratory.

.

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain, and material microstructure damage you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in material micro damage. If you are cutting fragile, more delicate materials then finer mesh size diamond wafering blades are recommended.

Metal bonding offers long life and durability, while resin bonding creates less heat, provides better surface finish and is well suited for cutting hard, delicate or brittle materials.

typically wafering blade diameters range form 3” (75mm) to 8” (200mm). Wafering blade diameter should be selected based on material diameter and thickness being cut. Smaller diameter wafering blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and heavier samples at higher loads and speeds than smaller blades

load/feed rate applied to wafering blades typically vary from 10-1000 grams. Generally, harder specimens are cut at higher loads and speeds (e.g. ceramics and minerals) and more brittle specimens are cut at lower loads and speeds (e.g. electronic silicon substrates). The Speeds/RPM’s you are using, shape/geometry of the specimen, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness.

Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire and alumina generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Most wafering blades are used between 50 to 6,000 RPM’s Typically harder and more denser materials such as Silicon Carbide, are cut at higher RPM’s/speeds Where more brittle materials such as silicon wafers and gallium arsenide are cutting at lower RPM’s. Low Speed saws RPM’s are typically limited from 0 to 600 RPM’s. Where high speed saws offer much large variety of cutting speeds from 0 to 6,000 RPM’s.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales