Diamond & CBN Wheels RESIN BOND

DIAMOND & CBN WHEELS

RESIN BOND

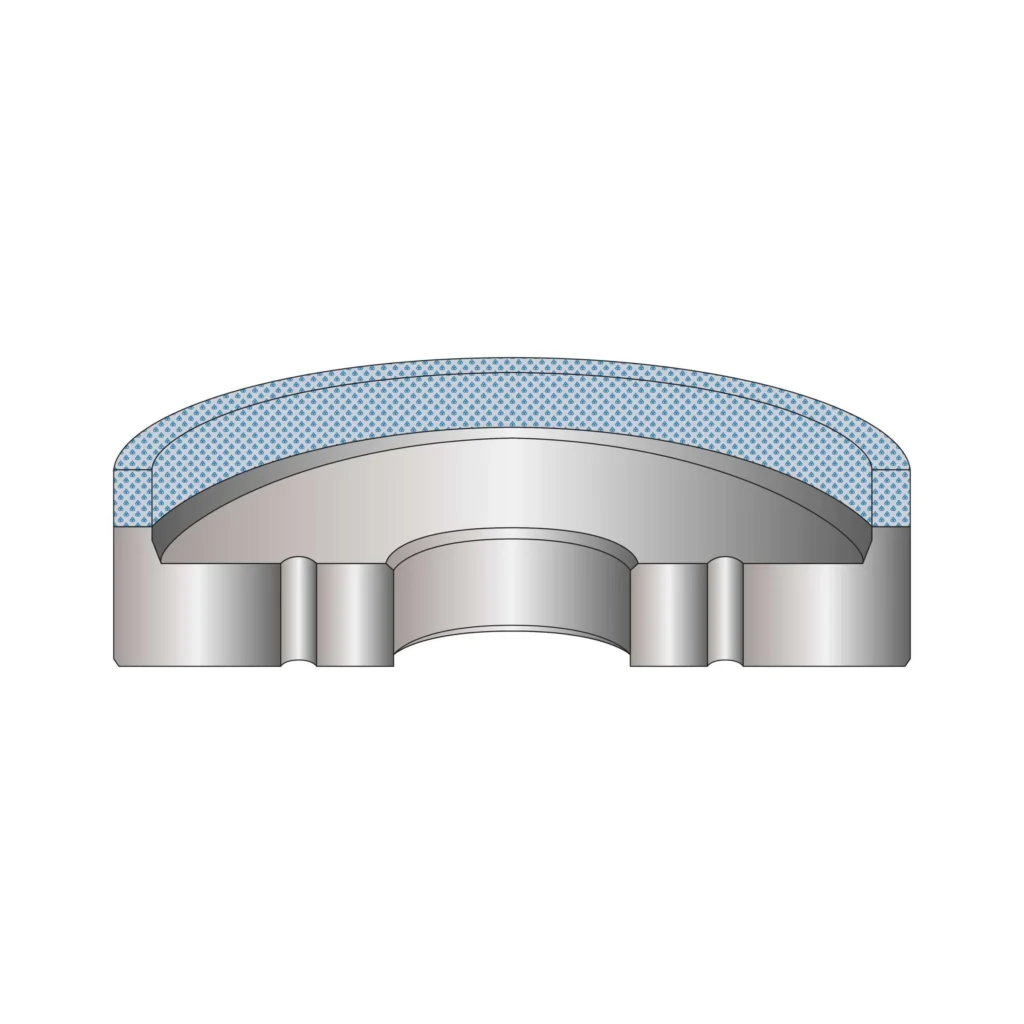

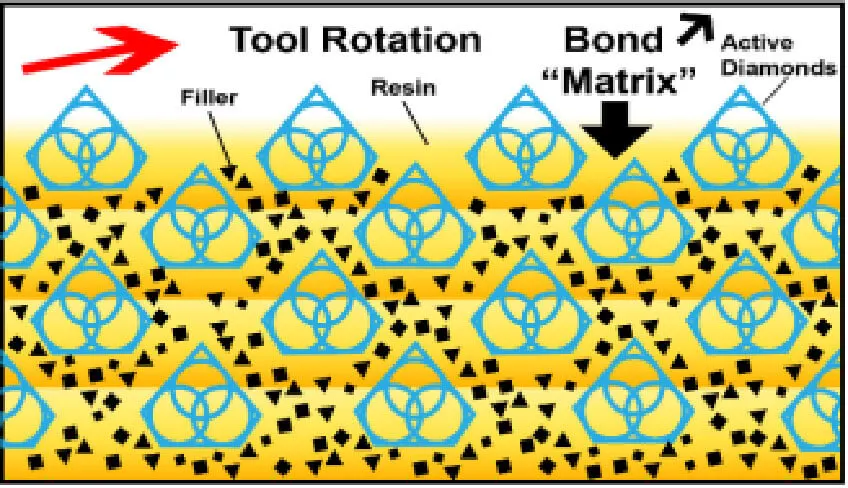

SMART CUT® Resin Bond Diamond & CBN Wheels are meticulously engineered to maximize operations and provide superior performance and cost-effectiveness for various industries and applications. Resin bond diamond &cbn wheels are produced using a combination of fillers and resins, is pressed under heat and can be easily dressed into various forms such as angle, straight, and special radius, ensuring a very fine finish for the user.

Over a hundred resin bond formulations are available using hundreds of various fillers, diamond coatings, resins, molding pressures, curing cycles & temperatures. We have a stock program that includes most popular resin bond tool specifications for various industries and custom manufacture based on your requirements.

WHY RESIN BOND

Diamond & CBN Wheels

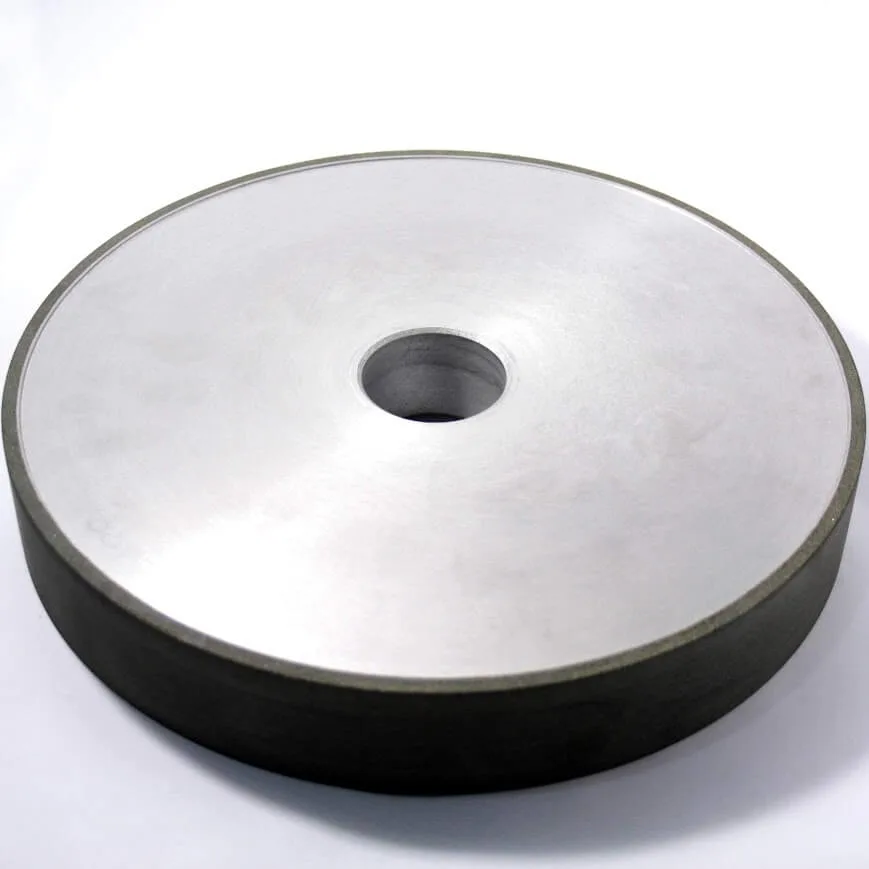

The Resin Bond Diamond & CBN Wheels are the most popular bond system for superabrasive grinding wheels, catering to grinding needs for tungsten carbide tools, ceramics, glass, ferrites, refractories, and semi-conductors. Its features include good elasticity, superior surface finish, and highly efficient grinding performance, all at a reasonable cost.

When it comes to wet or dry grinding, off-hand grinding, and centerless grinding, Phenolic resins are the standard in the industry for general purpose tool room use. On the other hand, Polyimide resins offer significant performance improvements over generic phenolic resins, with benefits including greater stock removal, better form holding, higher temperature tolerance, and minimal wear during grinding.

Invest in our SMART CUT Resin Bond Grinding Wheels today and experience the difference in durability, performance, and yield. Its time you Expect more from your tools!

Characteristics Resin Bond

The Resin Bond is formed by high pressure and high temperature with phenolic resin as its bonding agent. This bond is softer compared to others and is ideal for applications that require a smooth surface. The resin bond’s self-sharpening characteristic comes from its ability to expose new sharp diamond particles as the bond wears down, minimizing chipping and potentially eliminating secondary finishing operations.

Best Cut Quality & Surface Finish: These wheels are recommended for applications that prioritize cut quality and surface finish. They are superior to their sintered counterparts in delivering a far superior surface finish. Ideal for cutting, grinding, and polishing hard, brittle, or delicate materials such as ceramics, glass tubing, optical glass, carbides, composites, and exotic metals where low heat generation or improved surface finish is desired. The use of CBN, Resin bond Tools is recommended for cutting and grinding hard steels above Rc 60 at high speeds.

Moreover, the diamond and CBN crystals used for these wheels are unique and cater specifically to resin bond requirements. The crystals are often metal-coated and unevenly shaped to improve crystal retention and provide the self-sharpening characteristic of the resin bond.

CHARACTERISTICS OF

Resin Bond Diamond & CBN Wheels:

- Main Boding Agent: Phenolic Resin, Polyimide Resin

- Dressability : Excellent

- Hardness : Soft

- Required RPM's : High

- Shape of Diamond & CBN Used : Irregular Shape Crystal

- Cost : Medium

- Form Holding : Good

- Lifespan : Long

- Cutting Action : Good / Excellent

- Can be Used Dry : sometimes (depending on tool type, diamond size and type)

Features

- Variety of grit sizes ranging from 300 to 3 microns for desired surface finish, cutting speed, and tool life

- Available in diameters ranging from .020″ (.5mm) to 20″ (500mm)

- Stock program of popular wheels used across many different applications

- Custom specifications can be produced per your requirements with short lead times

- Can be used wet or dry

- Most universal & can be used on widest variety of applications

Advantages

- Softest of all the Bond

- Self Sharpening

- Best Surface Finish

- Best Cut Quality

- Minimum Heat Generation

- Faster Cutting Speeds

- Minimal Wear

- Wide Range of Applications

- Typically Used for Very Hard Materials

Benefits

- Better Surface Finish

- Less Chipping

- Minimum & No Material Deformation

- No Glazing

- Minimum Heat Generation

- Faster & Freer Cutting Action

- Better Value

- Universal Application

- LongerLife

- Precision Tolerances

- EasytoUse

- Almost Unlimited Number of Options

- Custom Manufacturing

- Faster Return On Investment

Industries Used in

Diamond & CBN Wheels

Standard, Resin Bond

Find Diamond & CBN Wheels

By Wheel & Tool shape

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

How SMART CUT® Resin Bond Works?

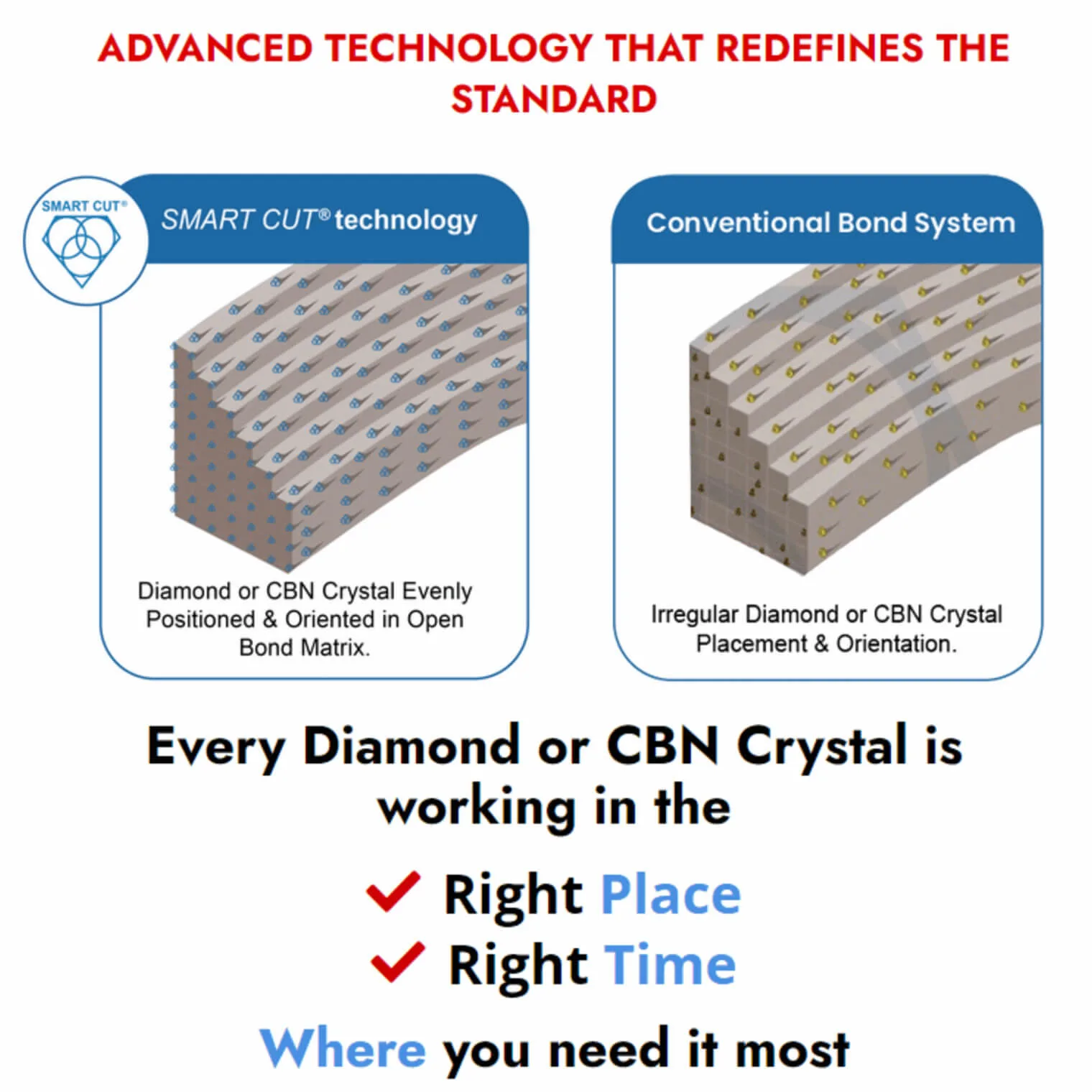

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT® Diamond Resin Bond, immediately penetrate into the material, grinding and polishing as they cut.

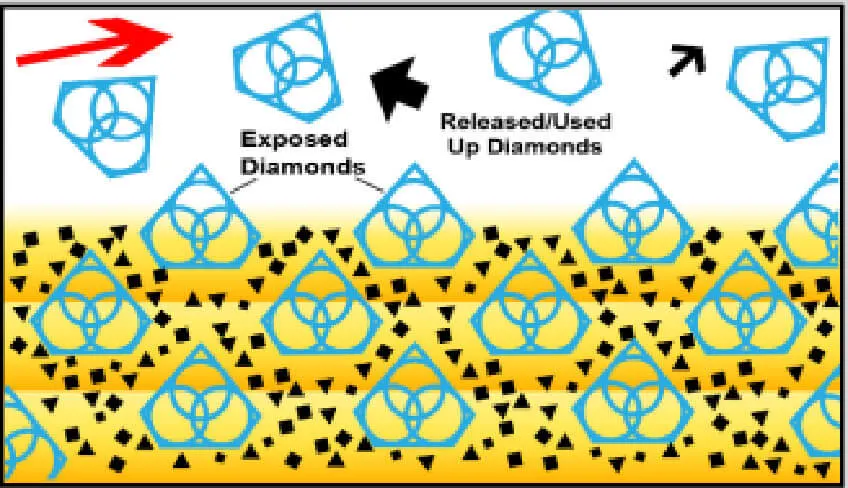

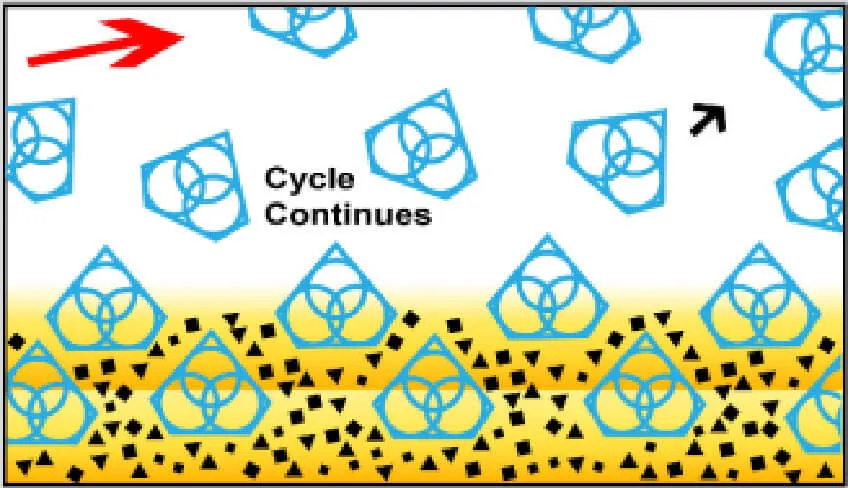

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Resin Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

The newly exposed diamonds don't effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Resin Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools