-

0 items in quote

No products in the Quote Basket.

Diamond Core Drill Bits

Let us Help you

Improve & Optimize your Diamond Drilling & Machining Operation

FIND DIAMOND DRILLS BY

Material Type

FIND DIAMOND Core Drill Bits

By Bond Type

SMART CUT®

Technology

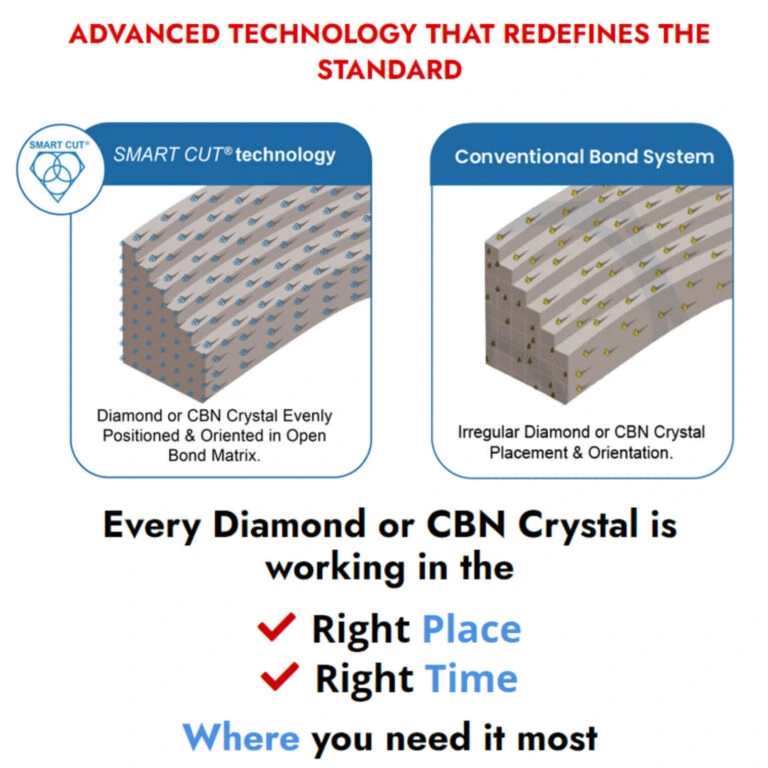

Advanced technology that redefines the standard. Every diamond or cbn crystal evenly positioned oriented in open bond matrix. Each crystal

Sintered (Metal Bond) Diamond

have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Available from stock in large variety of diameters, wall thicknesses, drill depths, mounting types, diamond sizes, concentrations, tolerances and also custom made to fit your specification.

Nickel Bond (Plated) Diamond Drills

usually have a single or 3 layers of diamonds, held by a tough durable nickel alloy. Diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation. Recommended for cutting softer and more gummy materials. Available from stock in large variety of specifications & custom made to fit your requirements

Braised Bond Diamond Drills

Brazed Bond Diamond Drills & Tools are perfect for drilling/machining tough-to-cut materials where fast stock removal is required. Including applications such as: non-metallic materials such as graphite epoxy, FRP, graphite, fiberglass, friction material, honeycomb and other composites. Available from stock in large variety of specifications & custom made to fit your requirements.

Chemical Vapor Deposition Diamond Drills

Used on softer and gummy materials where usually tungsten carbide tooling is used by wears out or has to be reshaped quickly. Applications such as machining graphite, hard carbon, green ceramic, carbon fiber, reinforced polymers, fiberglass, plastics, wood laminates, non ferrous metals

Polycrystalline Diamond Drills

PCD tools are used for processing aluminum and aluminum, aluminum alloys, copper, copper alloy, babbitt metal, wood, wood based fiber materials, aluminum oxide, reinforced floor boards, wear resistant plastic, Bakelite, graphite, stone materials, tungsten carbide, hard cartons. Epoxy resins, Fiberglass composites, Carbon-phenolic, Hard rubber, Plastics, Ceramics (unfired), Graphite

ACCESSORIES & CONSUMABLES

Diamond Drill

SMART CUT Coolant (Water Soluble)

SMART CUT Synthetic Water Soluble coolant (fully contamination free) will reduce heat & friction between diamond drill and material. And

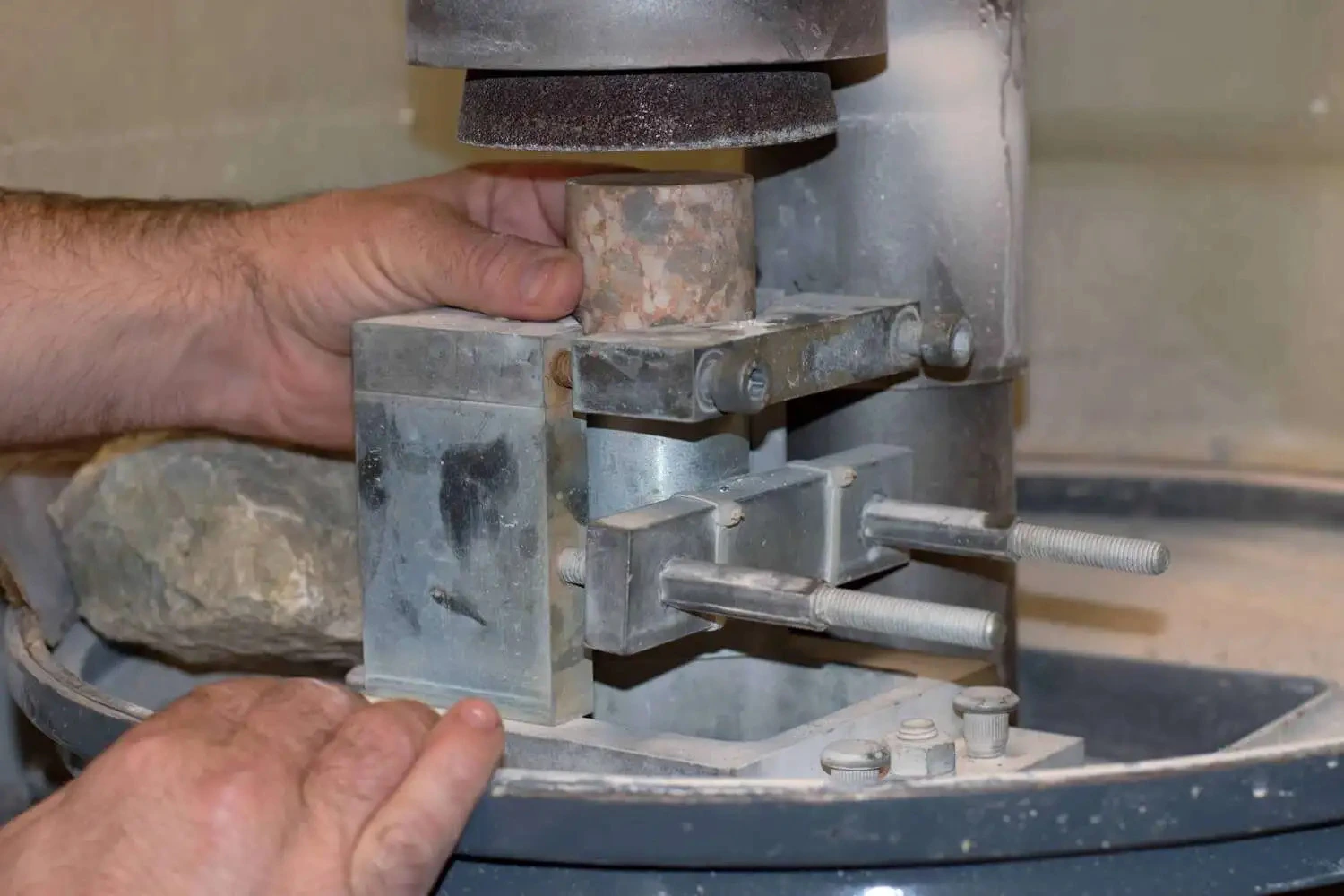

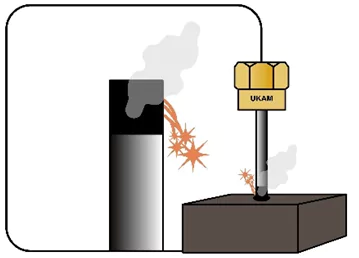

Precision Drilling Service & Process Development

On all types of Metallic Materials, Ceramics, Optics, Substrates & Wafers. Typical Dimensions of material we work with: Maximum Size

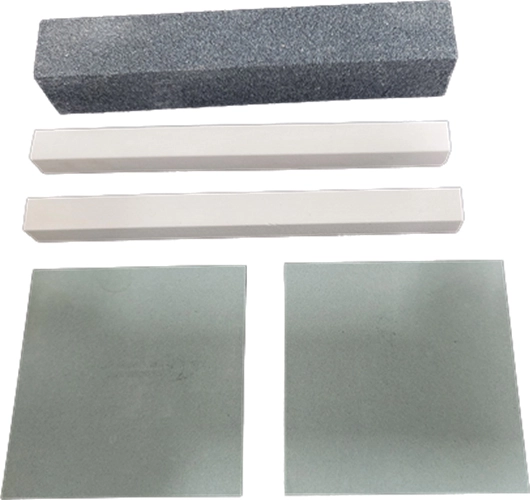

Dressing

Sticks

We offer large range of dressing stick specifications in wide range of sizes and shapes for most diamond drill applications.

Water Swivel

Adapters

Water Swivel Adapters (also known as drill head assemblies) are to supply high water. coolant, or air through the center

Shank

Adapters

Fits into drill press chuck allows the diamond drill to fit into drilling machine chuck or collets available with 3/8″

Drilling

Templates

Drilling templates allow minimize drill vibration, makes sure proper positioning of the drill, insuring accuracy and minimum chipping. These are

UKAM Industires Superhard Tools

Let us be a Partner in your success.

Leading American Diamond Drill & Tool Manufacturer

UKAM Industrial Superhard Tools, Leading US Diamond Drill Bits Manufacturer & Authority on Diamond Drills from .001” to 48” (.0254mm to 1219mm) diameter. For almost any material/application. Our Diamond Drill Bits are used Worldwide in Industry, Research & Development, Hobby, and Many Other Applications. Thousands of Diamond Drills & Diamond Drill Bits are available from inventory in many different specifications, outside & inside diameters, drilling depths, bond types, diamond grit sizes, mountings, & tolerances & Custom Manufacturing to fit your particular requirements with 1 week or less lead time (non minimum order)

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Why Choose SMART CUT® Diamond Core Drill Bits?

Optimize Your Application To Ultimate Level Of Efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

FIND DIAMOND DRILLS BY

Drill Type

Smart cut® Precision Diamond Drills & Tools

Are designed selected to provide maximum possible drill life for your desired cut quality and speed

- Diamond Core Drills Outside Diameters : 0.5 in. to 48" in. (12 mm to 1,219 mm)

- Diamond Solid Drill Diameters : As small as 0.002 in. (0.05 mm) & up

- Diamond & CBN Abrasive Sizes : 3 to 151 micron

- Diamond/CBN Abrasive Concentration : 25 to 200 con

-

Abrasive (Diamond/CBN) Types : Natural Diamond, Coated & Uncoated

Synthetic Diamond or CBN - Drill Depth : 5mm to 800mm

- Tolerances : Standard Tolerance On OD Or ID: + / - .004" (100 Microns) & Special Tolerances Up To .0005" (12 Microns Are Also Available)

- Wall Thickness : 0.5mm To 4mm (Ultra Thin Wall, Thin Wall, Standard Wall, Heavy Wall, Very Heavy Wall)

- Diamond Depth (diamond height): 1.58mm to 20mm

- Edge Type: Continuous Rim, Slotted, Segmented, Serrated.

- Mounting Type: Any Per Client Specification, Unmounted Core Drills, With Female Or Male Thread Or Straight Shank Per Specification

- Bond Type: Sintered (Metal Bond), Nickel Bond (Plated), Braised Bond, Chemical Vapor Deposition, Polycrystalline Diamond

- Bond Hardness: Super Soft to Super Hard

- Accessories : Coolants, dressing sticks, Water Swivels, Drilling Templates

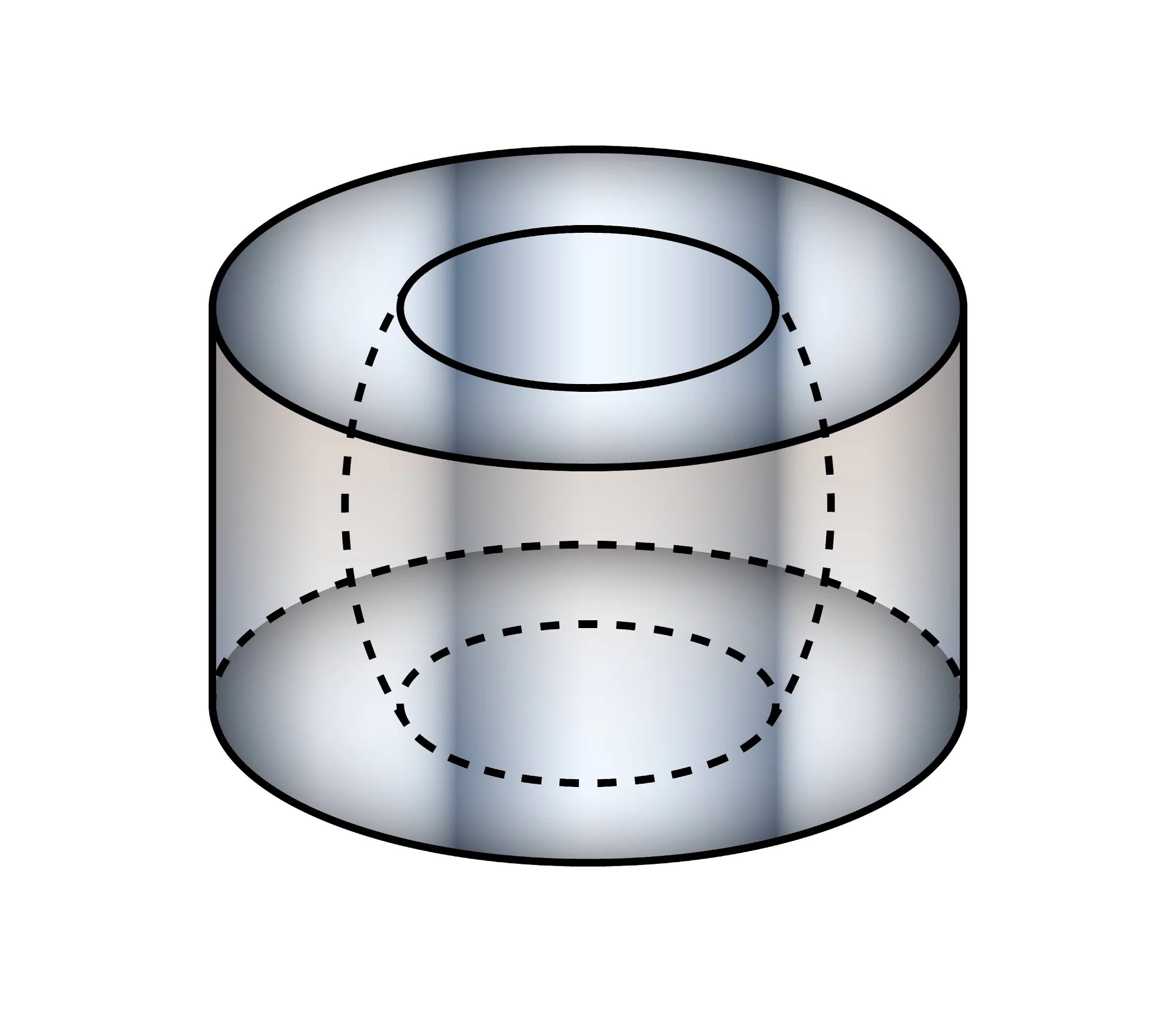

Diamond Core Drill & Drill Bit Types

- Diamond hollow core drills unmounted (tube only)

- diamond hollow core drills mounted (with female or male thread or straight shank per client spec)

- ID Core drills

- Non core formation

- Bottoming drills

- Diamond dual core drills

- Disintegrating drills

- Diamond chamfering tools

- Diamond core drills for ultra sonic drilling machines

- Concrete & construction diamond core bits

- Diamond seamers

- Diamond hole saws

Diamond Core Drill Wall Type & Kerf

- Ultra thin wall diamond core drills

- Thin wall diamond core drills

- Standard wall diamond core drills

- Heavy wall diamond core drills

- Continuous Rim (Crown) Diamond Core drills

- Slotted diamond core drills

- Segmented diamond core drills

Diamond Reamers, Diamond Threading tools, Diamond Engraving Tools, Diamond Radius Tools, Diamond Chamfer Tools, & many other custom tools made to your specifications

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms, milling, deburring, Thread grinding.

- Diamond carving points

- Diamond mounted points

- Diamond counter tools

- Diamond grinding pins

- Diamond routers

- Diamond ID grinding points

- Diamond jig grinding mandrels/pins

- Diamond countersinks

- Diamond counter bores etc

- Diamond Generating Tools

- Diamond Milling Tools

- Diamond face grinding tools

- Diamond Chamfer Tools

- Diamond Radius Tools

- Diamond Profiling Tools

- Diamond Ball Nose Tools

- Diamond Round End Tools

- Diamond Full Ball Tools

- Diamond Bottom Grinding Tools

- Diamond Reamers

- Diamond Honing Tools

- Diamond Tapered Hones

- Diamond Threading tools

- Diamond hole/bore finishing tools

- Diamond cone grinding tools

- Diamond burs for industry/hobby

- Diamond Profile Tools

- Diamond Radois Tools

- Diamond Radius Tools,

- Diamond Chamfer Tools

- Diamond expanding laps/mandrels

- Diamond Engraving Tools & Diamond CNC Engraving Tools

Micro Drills & tools

Diamond, CBN, CVD, PCD & Carbide

We manufacture Diamond Micro Drills & Tools from .001" (25 microns) and up. Large Variety of Standard Diamond Micro Drills & Core Drills are avialble from Stock and Made to your Specifications

Custom diamond and CBN micro drills, core drills, & tools can be manufacture to your specific requirements and drawings. High-precision tolerances are available with various head lengths, shank diameters, tip radiuses Carbide micro tooling with or without coatings such as CVD (chemical vapor deposition) and PCD (polycrystalline diamond) is also available for certain applications, where synthetic or natural diamond is not feasible or not economical to use

Let Us Help You Improve Diamond Drill & Bit Performance

- Eliminate / Minimize Chipping

- Improve Surface Finish Quality

- Preserve True Material Microstructure

- Reduce & Eliminate Material Deformation

- Increase Drill & Tool Life

- Improve Process Consistency

- Improve Productivity

- Maintain Consistent Cutting Speed

- Reduce Tool Change & Mounting Cost

- Reduce Cost

- Reduce Chipping

- Reduce Drill &Tool Wear

- Increase Process Consistency

- Increase Production Rate

- Improve Part Geometry & Tolerances

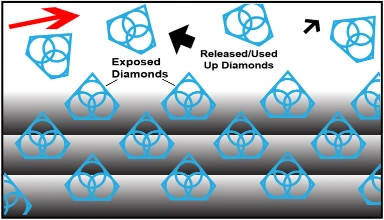

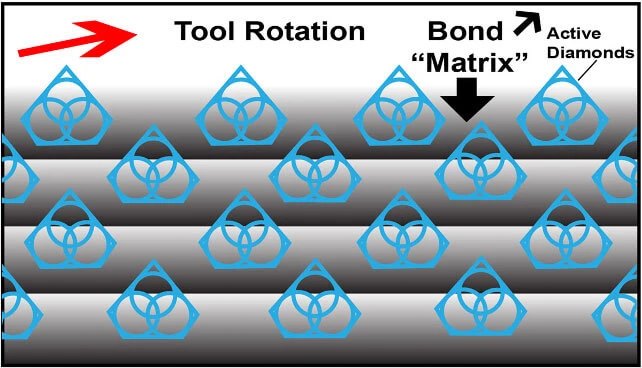

How SMART CUT® Sintered

(Metal bond) Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

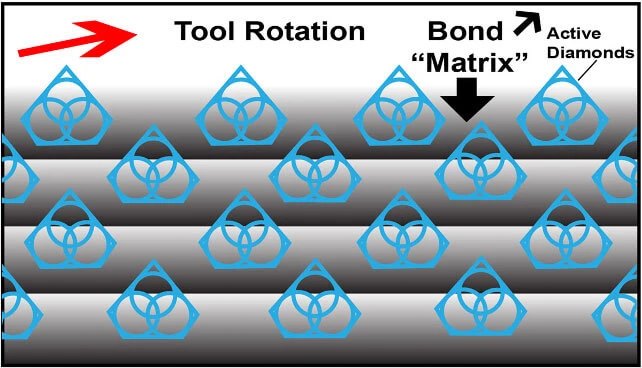

Step 2

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Find the Right Diamond Drills & Tools

For Your Application

Diamond Drill and Tools by itself is perhaps the most important factor in your drill operation.

The diamonds impregnated inside the bond matrix of the diamond drill/tool, are what actually participate in cutting action. No matter what drilling equipment and process you are using. You will not be able to obtain the material surface finish, and precision tolerances you need, if the drill or tool you are using is not right for your application.

UKAM Industrial Superhard Tools experience, precision manufacturing, modern quality control methods, allow us to control and regulate dozens of variables that affect diamond drill and tool life, quality of cut, surface finish.

We will work with you to determine your needs, and recommend the Right Diamond Drill & Solution for your specific material / application.

UKAM INDUSTRIAL SUPERHARD TOOLS

High Quality Standards & Product Consistency

Not all Diamond Drills are created equal. UKAM Industrial Superhard Tools uses only the highest quality diamonds and raw materials in Diamond Drills manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment. Our Diamond Drills are regularly used in demanding & mission critical applications.

LET US HELP YOU

We Are A Partner In Your Success

Our Knowledge Center

We highly suggest exploring our Knowledge Center, which contains valuable information, where you will find answers to most of your questions.

This valuable resource is offered to you FREE of charge, which is a rare benefit as many companies charge for similar information. We urge you to take advantage of this resource.

CUSTOM MADE

Have A Unique Requirement?

Let us make custom diamond drill or tool specifically designed for your application/ requirements

Just about any diamond/cbn Tool can be Designed and manufactured per your drawing or specifications

No Minimum

Order Quantity

Fast Lead

Times

Precision Tolerances

Free

Consultation

Limitless

Possibilities

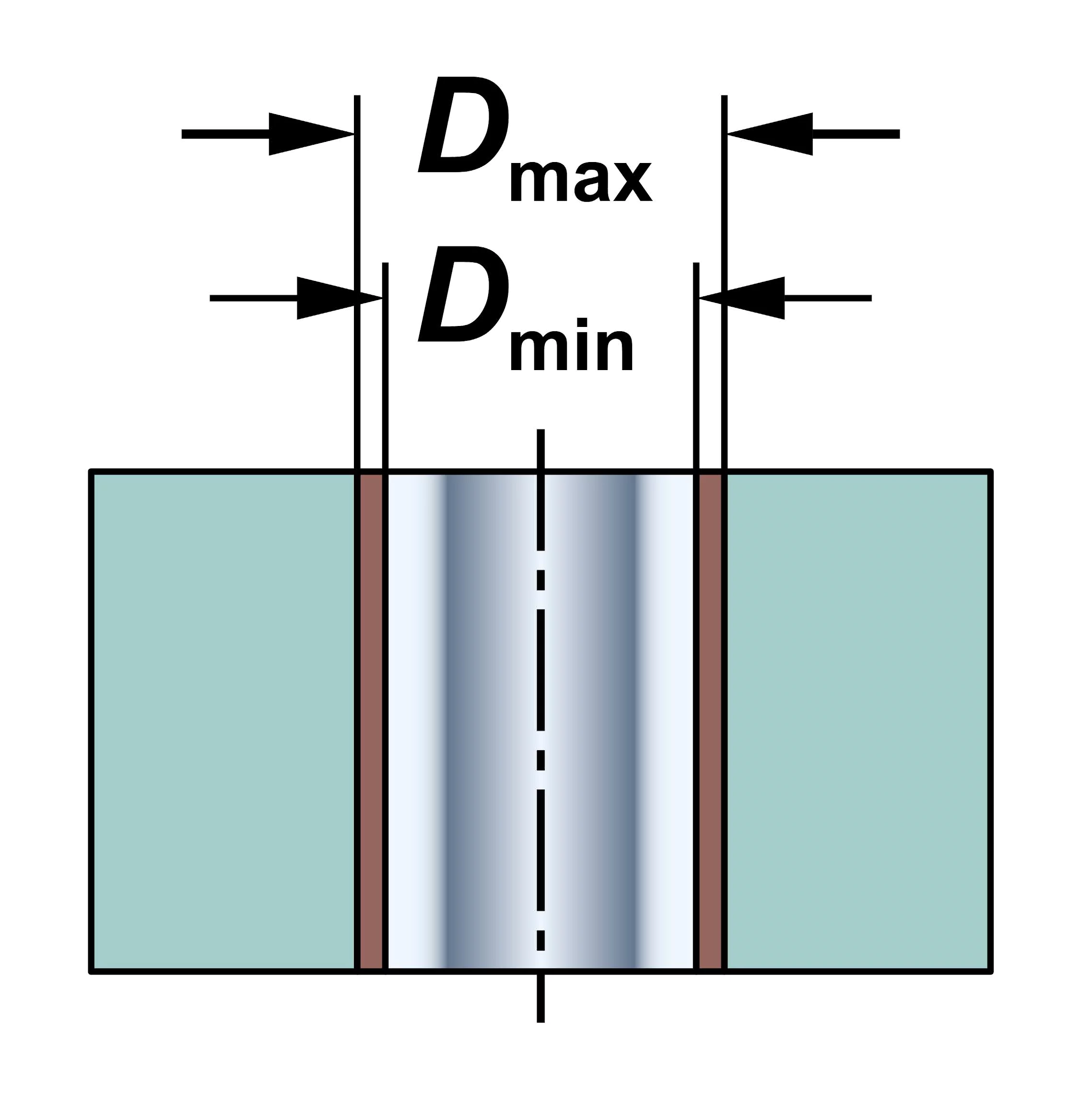

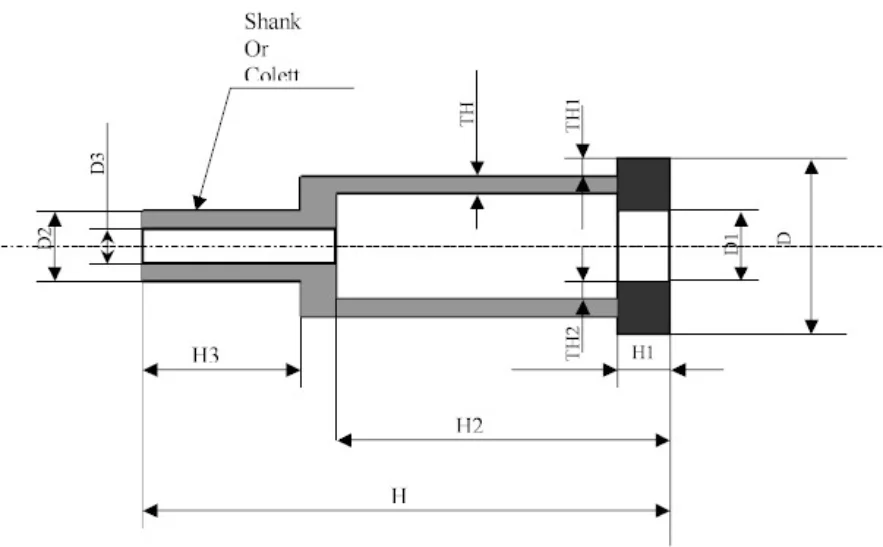

Diameters:

- D = Outside Diameter

- D1 = Inside Diameter

- D2 = Shank Diameter or female or male thread

- D3 = Shank Inside Diameter - no shank

HEIGHTS:

- H = Total Drill Length

- H1 = Diamond Depth (diamond height)

- H2 = Drilling Depth (how deep you can drill)

- H3 = Shank Length

THICKNESS:

- TH = Drill Tube Wall Thickness

- TH1 = Outside Diameter Diamond Section Relief

- TH2 = Inside Diameter Diamond Section Relief

- H3 = Shank Length

Why Work With Us?

Comprehensive Source Of Information On Diamond Drills & Tools

We understand that your success depends on select the right diamond drill & too, and optimizing your parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond drills & industrial diamond tools.

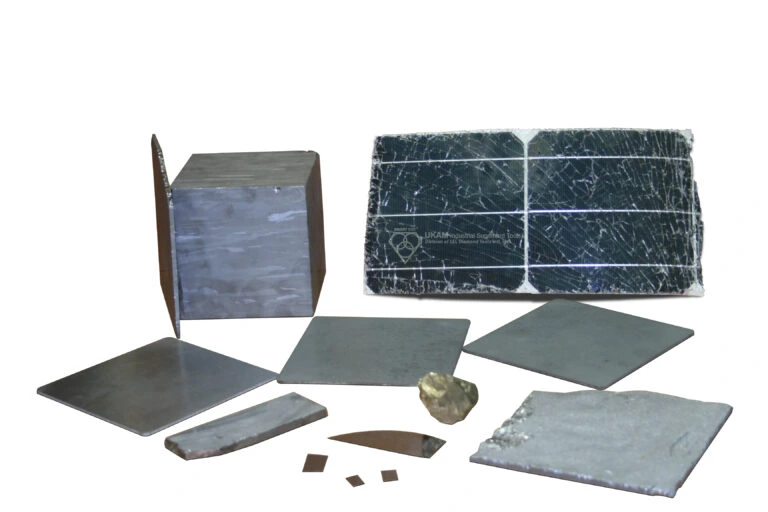

Large Inventory & Custom Manufacturing

Largest Inventory of Diamond Drills & Tools in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY" Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary drill chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect drill life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after drilling.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

ARE YOU USING RIGHT DIAMOND CORE DRILLS & TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND CORE DRILLS & TOOLS?

Knowledge Center

02

Jun

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will...

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind...

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,...

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency....

02

Jun

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read...

02

Jun

Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

Share this Article with Friend or Colleague

There are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the...

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

https://ukam.com/wp-content/uploads/2024/07/diamond-drill-troublehsooting-guide.mp4

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide...

09

Sep

Understanding & Calculating Return on Investment for Diamond Core Drills & Other Tools

The term "ROI" (Return On Investment) is widely used across industries, often interpreted differently depending on the context. However, few truly understand what ROI represents and its specific implications, particularly in the context of diamond...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

19

Sep

Why Use Diamond Drills?

Diamond, known as the hardest material on Earth, enables diamond drills and tools to grind away material at a micro (nano) scale. This extreme hardness allows diamond tools to effectively work on materials with a...