-

0 items in quote

No products in the Quote Basket.

Custom Diamond Core Drills & Tools Manufacturing

Custom Manufacturing

Have a Unique Requirement or Diamond Core Drill & Tool Optimized for your particular application? Let Us Help

Just about any Diamond Core Drill & Tool can be Designed and Manufactured per customer drawing or specifications

No Minimum

Order Quantity

Fast Lead

Times

Precision Tolerances

Free

Consultation

Limitless

Possibilities

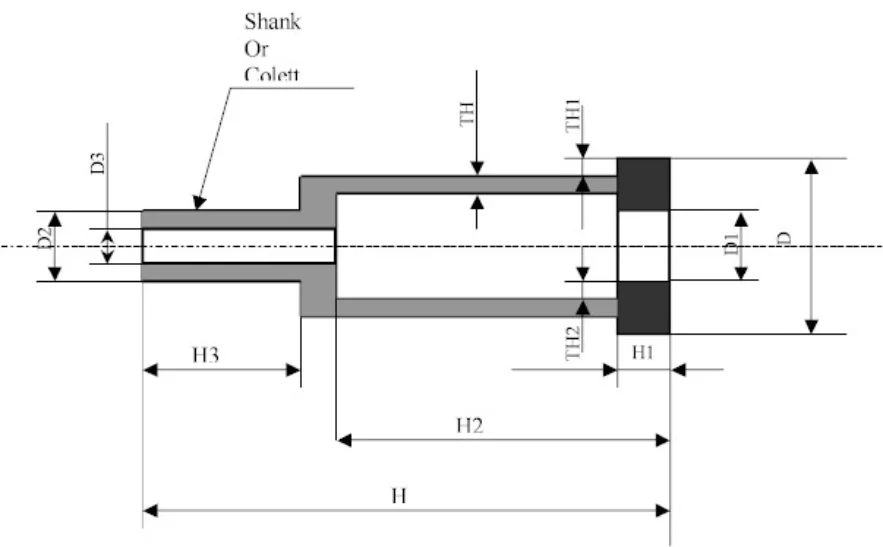

Diameters:

- D = Outside Diameter

- D1 = Inside Diameter

- D2 = Shank Diameter or female or male thread

- D3 = Shank Inside Diameter - no shank

HEIGHTS:

- H = Total Drill Length

- H1 = Diamond Depth (diamond height)

- H2 = Drilling Depth (how deep you can drill)

- H3 = Shank Length

THICKNESS:

- TH = Drill Tube Wall Thickness

- TH1 = Outside Diameter Diamond Section Relief

- TH2 = Inside Diameter Diamond Section Relief

- H3 = Shank Length

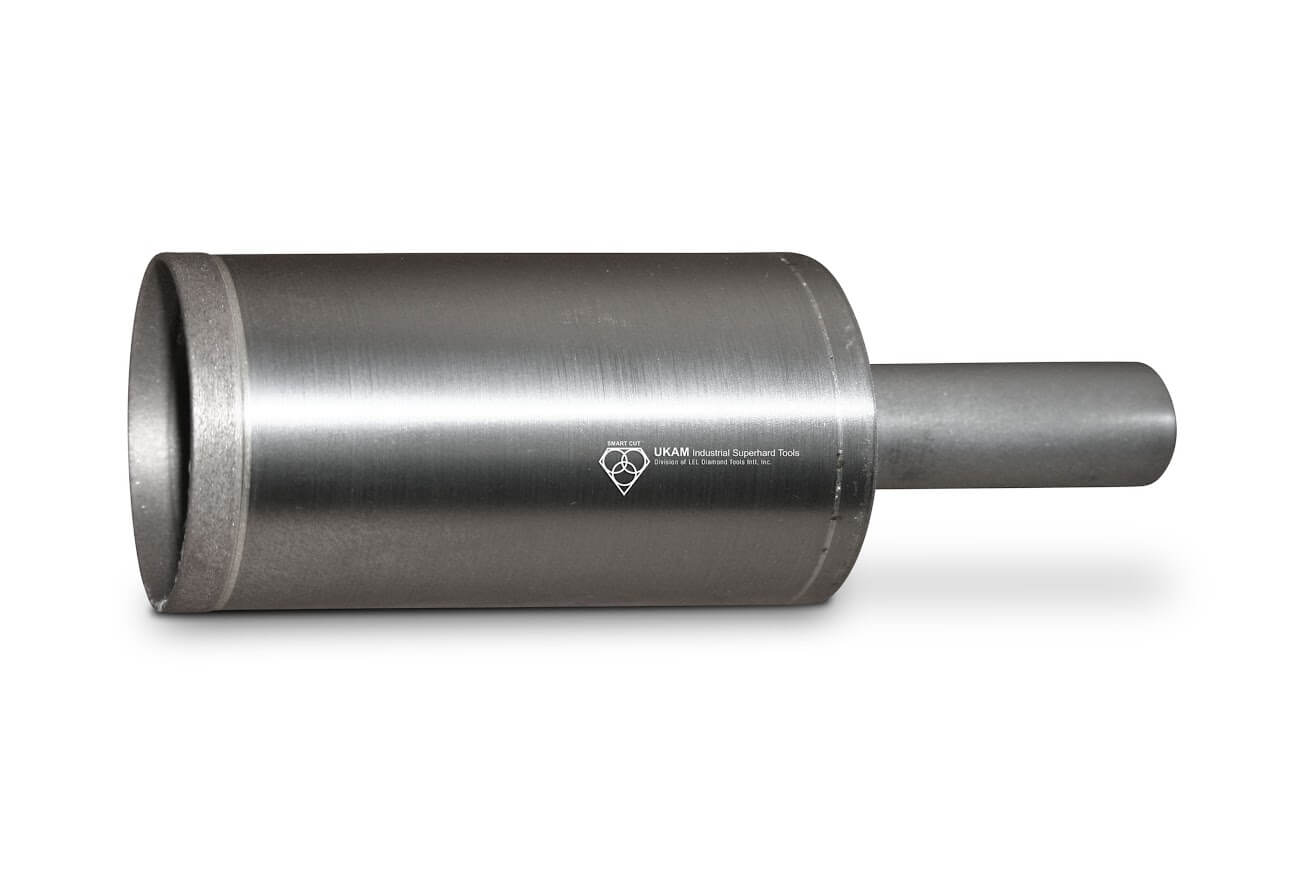

Example of Custom

Diamond Core Drill & Tool

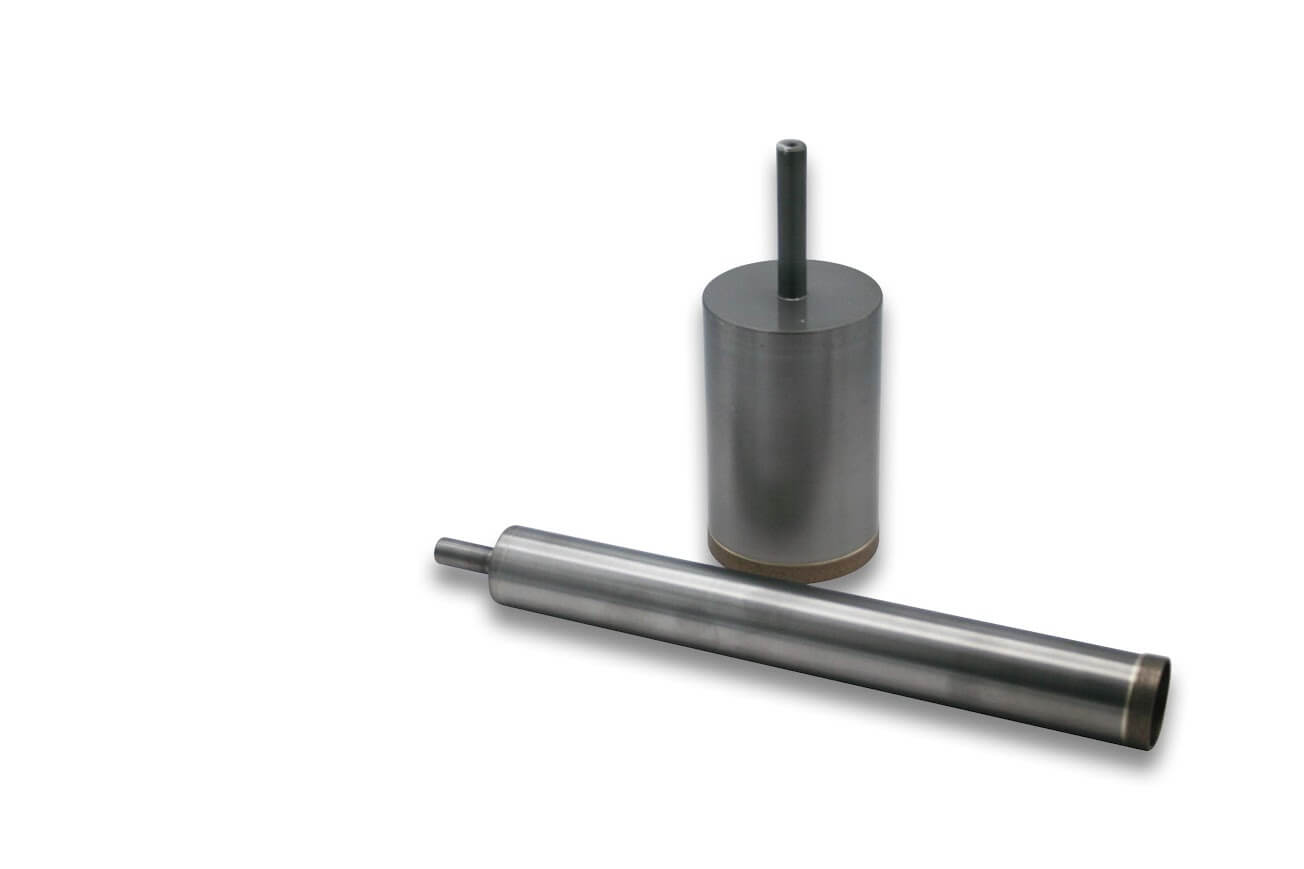

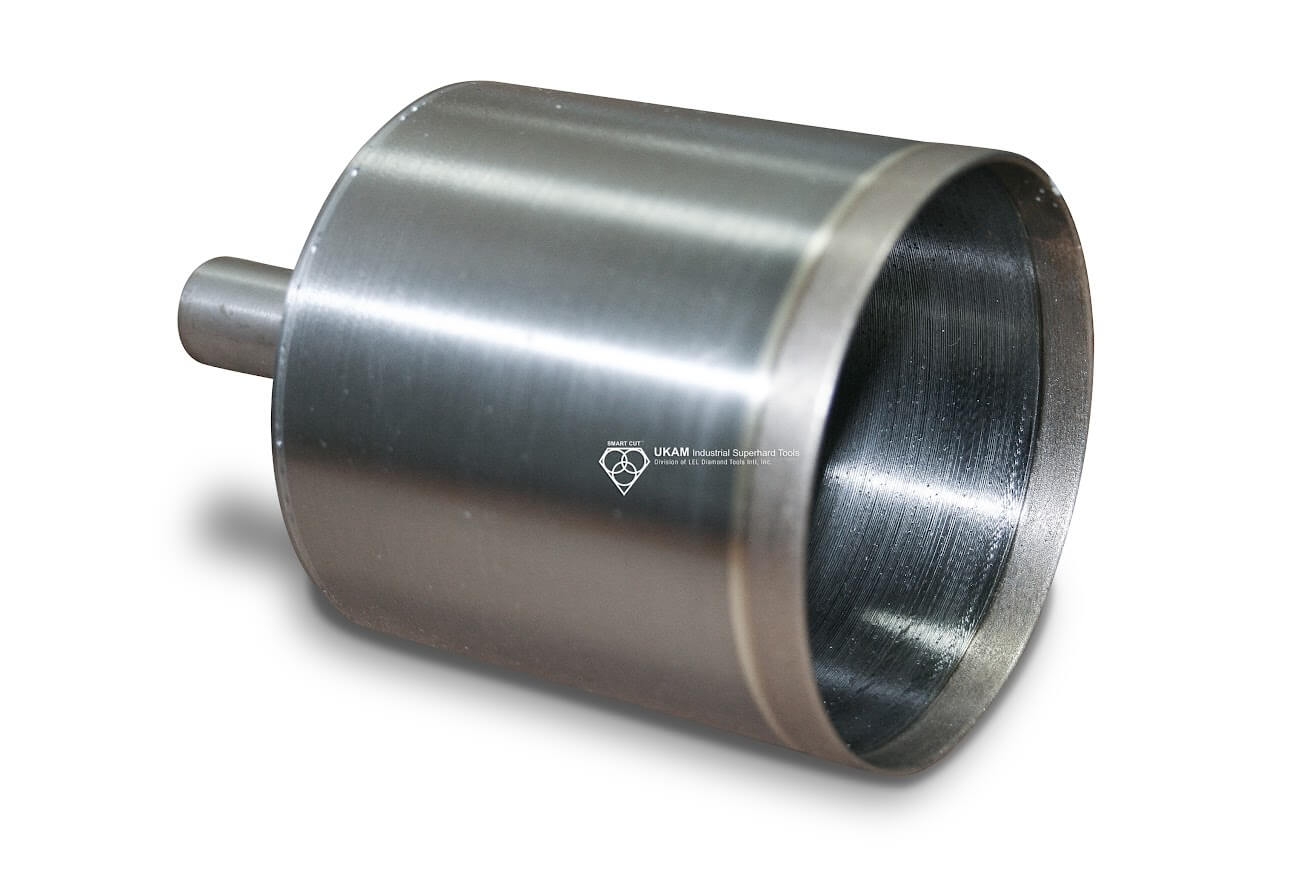

What We Do

We manufacture custom Diamond Core Drills & Tools to fit your specific requirements and specifications. We can manufacture over 30,000+ different types of custom Diamond Core Drills & Tools and consumables to better fit your particular material, application, specifications, and requirements.

Why Custom Tools?

Not all requirements are the same. We manufacture tools to fit your particular equipment, tolerances, surface finish, life span, and overall see the difference tools optimized for your application can make?

How We Work

We will work with you to determine your needs and develop the right bond formulation, concentration, and grit sizes. Our tools are designed and specially selected to provide the maximum possible tool life, for your desired cut quality and speed.

Custom

Diamond Core Drill & Tool Manufacturing Process

The following process describes the custom tool manufacturing process form initial first inquiry to final delivery.

-

1

Discovery

We discuss your specific requirement in detail to determine the best solution for your needs.

-

2

Recommend Solution

We provide you with recommend options for your application based on your requirements along with quotation and lead time.

-

3

Prepaire To Implement

When you are ready to order, we send you confirmation of the tool specification always in writting. Your order is placed in que to be produced within the quoted lead time.

-

4

Implement & Deliver

The finished products go through quality control process and also inspected for conformance to specification agreed upon. The order is packaged and shipped to you using your requested shipping method. Certificate of conformance or any other documentation can be provided upon request.

-

5

Service & Support

We follow up with you to receive feedback on the tool performance. We also provide usage recommendatios and technical support if needed.

Diamond Core Drill & Drill Specifications

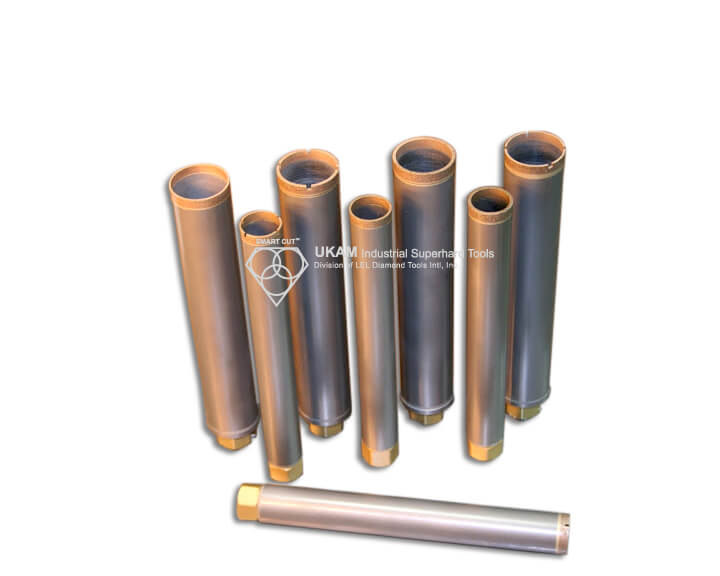

- Diamond Core Drills Outside Diameters : 0.5 in. to 48" in. (12 mm to 1,219 mm)

- Diamond Solid Drill Diameters : As small as 0.002 in. (0.05 mm) & up

- Diamond & CBN Abrasive Sizes : 3 to 151 micron

- Diamond/CBN Abrasive Concentration : 25 to 200 con

-

Abrasive (Diamond/CBN) Typesn : Natural Diamond, Coated & Uncoated

Synthetic Diamond or CBN - Drill Depth : 5mm to 800mm

- Tolerances : Standard Tolerance On OD Or ID: + / - .004" (100 Microns) & Special Tolerances Up To .0005" (12 Microns Are Also Available)

- Wall Thickckness : 0.5mm To 4mm (Ultra Thin Wall, Thin Wall, Standard Wall, Heavy Wall, Very Heavy Wall)

- diamond depth (diamond height): 1.58mm To 20mm And Fully Impregnated With Diamond (From OD To ID)

- Edge Type: Continuous Rim, Slotted, Segmented, Serrated.

- Mounting Type: Any Per Client Specification, Unmounted Core Drills, With Female Or Male Thread Or Straight Shank Per Specification

- Bond Type: Sintered (Metal Bond), Nickel Bond (Plated), Braised Bond, Chemical Vapor Deposition, Polycrystalline Diamond

- Bond Hardness: Super Soft to Super Hard

- Accessories : Coolants, dressing plates, and flanges

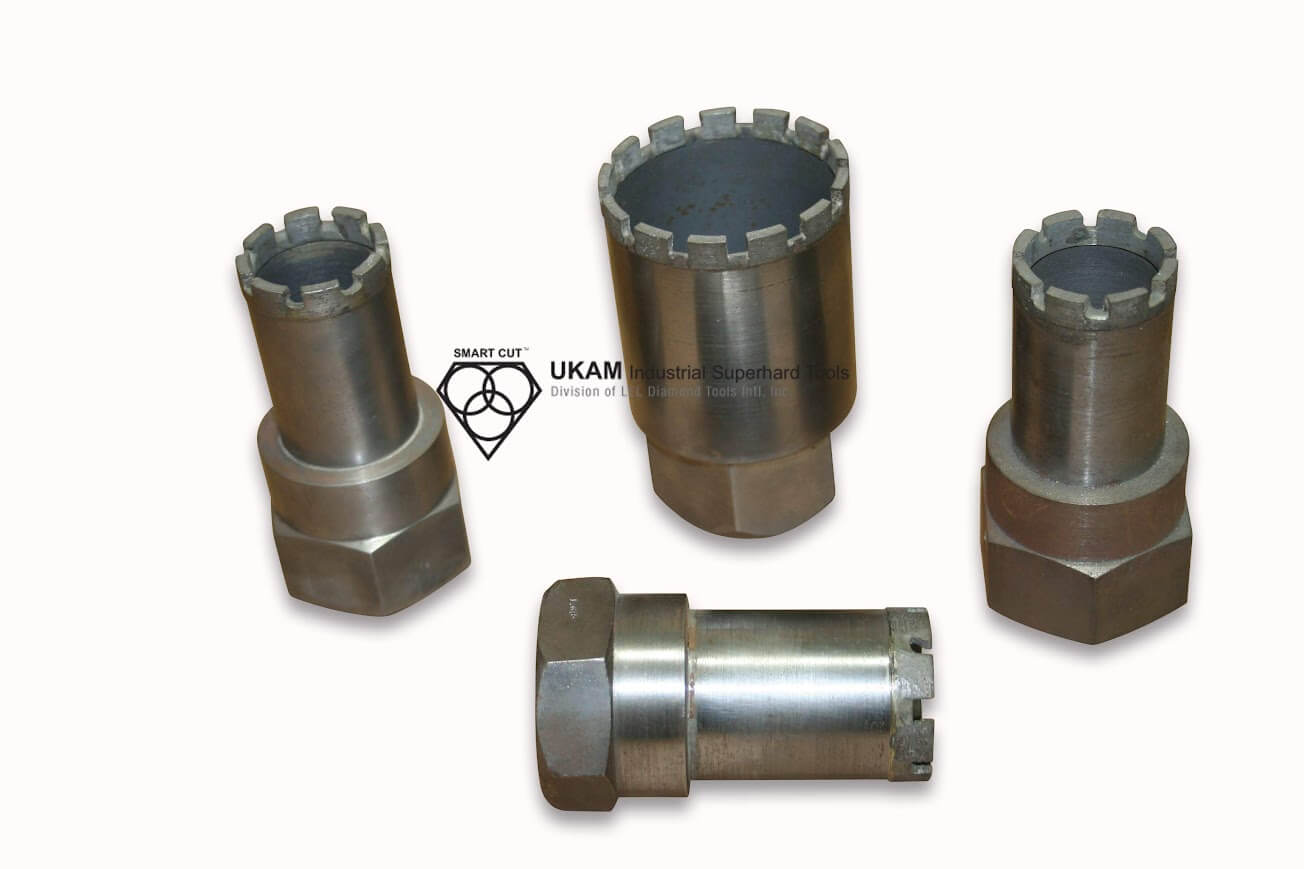

Diamond Core & Drill Types

- Diamond hollow core drills unmounted (tube only)

- diamond hollow core drills mounted (with female or male thread or straight shank per client spec)

- ID Core drills

- Non core formation

- Bottoming drills

- Diamond dual core drills

- Disintegrating drills

- Diamond chamfering tools

- Diamond core drills for ultra sonic drilling machines

- Concrete & construction diamond core bits

- Diamond seamers

- Diamond hole saws

- Ultra thin wall diamond core drills

- Thin wall diamond core drills

- Standard wall diamond core drills

- Heavy wall diamond core drills

- Continuous Rim (Crown) Diamond Core drills

- Slotted diamond core drills

- Segmented diamond core drills

Diamond Reamers, Diamond Threading tools, Diamond Engraving Tools, Diamond Radius Tools, Diamond Chamfer Tools, & many other custom tools made to your specifications

These tools are used for many different industries, grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms, milling, deburring, Thread grinding.

- Diamond carving points

- Diamond mounted points

- Diamond counter tools

- Diamond grinding pins

- Diamond routers

- Diamond ID grinding points

- Diamond jig grinding mandrels/pins

- Diamond countersinks

- Diamond counter bores etc

- Diamond Generating Tools

- Diamond Milling Tools

- Diamond face grinding tools

- Diamond Chamfer Tools

- Diamond Radius Tools

- Diamond Profiling Tools

- Diamond Ball Nose Tools

- Diamond Round End Tools

- Diamond Full Ball Tools

- Diamond Bottom Grinding Tools

- Diamond Reamers

- Diamond Honing Tools

- Diamond Tapered Hones

- Diamond Threading tools

- Diamond hole/bore finishing tools

- Diamond cone grinding tools

- Diamond burs for industry/hobby

- Diamond Profile Tools

- Diamond Radois Tools

- Diamond Radius Tools,

- Diamond Chamfer Tools

- Diamond expanding laps/mandrels

- Diamond Engraving Tools & Diamond CNC Engraving Tools

Frequently Asked Questions

Yes, we are happy to help. We will send you a question are asking many questions about your requirements, how the tool will be used and the usage environment. This information is very important for helping us understand your unique specifications and requirements. The more information you can provide the more accurate recommendation and solutions we can provide.

Usually there is no minimum order for custom tools, with few acceptations. We encourage you to try small quantity to make sure you are happy with the tool performance first. As additional fine tuning and improvements can be made based on your feedback.

Lead time varies depending on tool specification and current schedule. Usually the lead time range can be from 1 to 5 weeks. expedited lead time of 1 to 2 weeks is usually available at additional cost if needed

Prices are based on tool specification, tolerances, quantity and lead time. Our prices are pretty competitive for world market. We regularly export our products to dozens of different countries across all continents. Usually custom products in small quantity the pricing is usually higher then standard of the shelf products which are mass produced in large quantities.

We can provide hand sketch if needed. if you need drawing we can create in solid works or auto cad for a small fee which may be reimbursable upon receipt of order

Over many decades we have made and sold thousands of different types of unique and one of a kind tools for almost every application. we maintain records of bond formulations and specifications used over many years we have also acquired the “know how” of several other US tool manufacturers that have produced custom tools over many decades, some going far back as to 1960’s. we also have our own R & D research program and we regularly work with different research originations and outside consultants. Most of the time we produce the right tool formulation first time, but sometimes we can make additional improvements second

and third time around. Our goal is to make you happy

We ask lot of detailed question about tool specification and your usage process. Sometimes it may be worthwhile for you to send us your used tool so we can inspect it.

There are usually no returns or refunds for custom made tools. Unless we made an error and produced the tool not according to the agreed upon specification

Yes we can provide basic recommendations and recommended usage information. If you need specific hands on approach such as “process development” this can be done on case by case based for a fee. If we are not able to help we can often recommend independent outside consultant or organization that can assist.

Why Work With Us?

Comprehensive Source Of Information On Diamond Tools

The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality & Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency.

EXPECT MORE FROM YOUR TOOLS

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Share this Article...

02

Jun

Why use diamond

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...