Application Recommendations

-

Posted by

Brian Farberov

Brian Farberov

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as the recommended blade types, coolant options, RPMs, feed rates, and mounting methods to ensure high-quality results and efficient throughput. By exploring specific material requirements and common concerns, this guide offers valuable insights into selecting the ideal dicing parameters for each application.

Table of Contents

ToggleDICING SOLUTIONS FOR PACKAGE SINGULATION

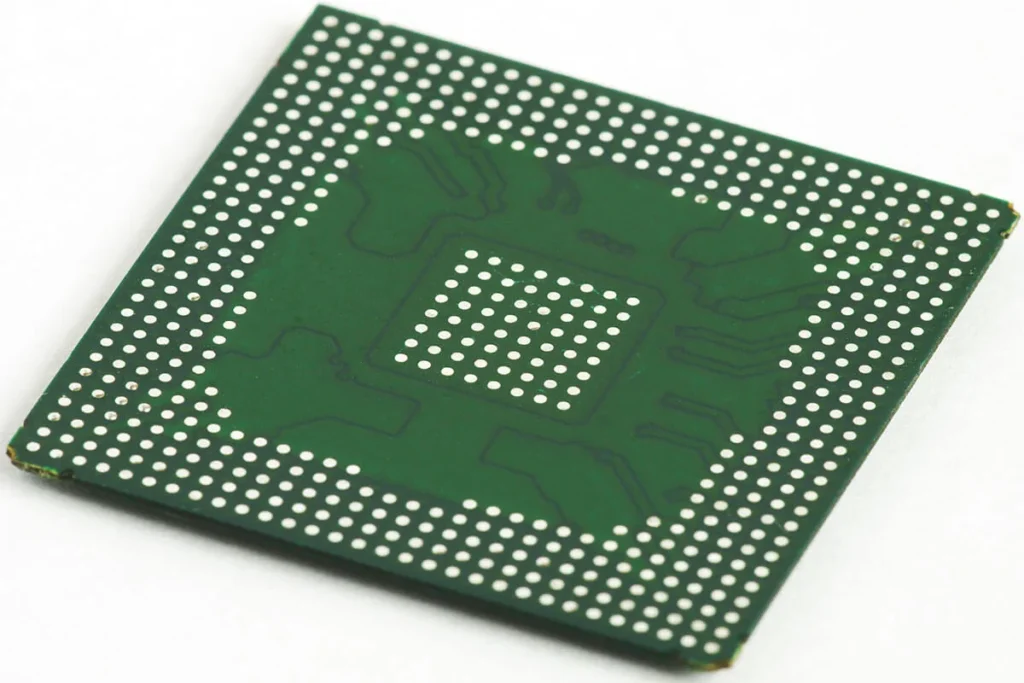

BGA (Ball-Grid Array)

Common Materials: FR4 and epoxy mold compound

Variations:

- LFBGA (Low-Profile Fine-Pitch)

- TFBGA (Thin & Fine-Pitch)

- W-BGA (Window-Type)

- FC-BGA (Flip Chip)

- VFBGA (Very Fine-Pitch)

- POP (Package-on-Package)

- SIP (System-in-Package)

- SD (Secure Digital)

- Micro SD Card

- CBGA (Ceramic)

- PBGA (Plastic)

- UFBG (Ultra-Fine)

- MBGA (Micro)

Typical Concerns:

- Chipping

- Blade Wear

- Heat Buildup

- Vibration

- Spindle Rounout

- Die Contamination

- Edge Cracking

- Kerf Width Variation

- ESD

- Die Fly Off

- Coolant Residue

- Subsurface Damage

Dicing Blade Recommendation:

-

SMART CUT HYBRID BOND or sintered (metal bond) series

SMART CUT HYBRID BOND or sintered (metal bond) series

-

Diamond size: 30 - 55 microns

Diamond size: 30 - 55 microns

-

Blade Thickness: .008” - .014”

Blade Thickness: .008” - .014”

Dicing Process Recommendations:

-

Feed rate: 50-250 mm/sec

Feed rate: 50-250 mm/sec

-

Spindle speed: 20-40 krpm depending on blade O.D.

Spindle speed: 20-40 krpm depending on blade O.D.

-

Multi panel mounting on UV tape

Multi panel mounting on UV tape

-

Minimal dressing so as not to create a large radius on the blade edge

Minimal dressing so as not to create a large radius on the blade edge

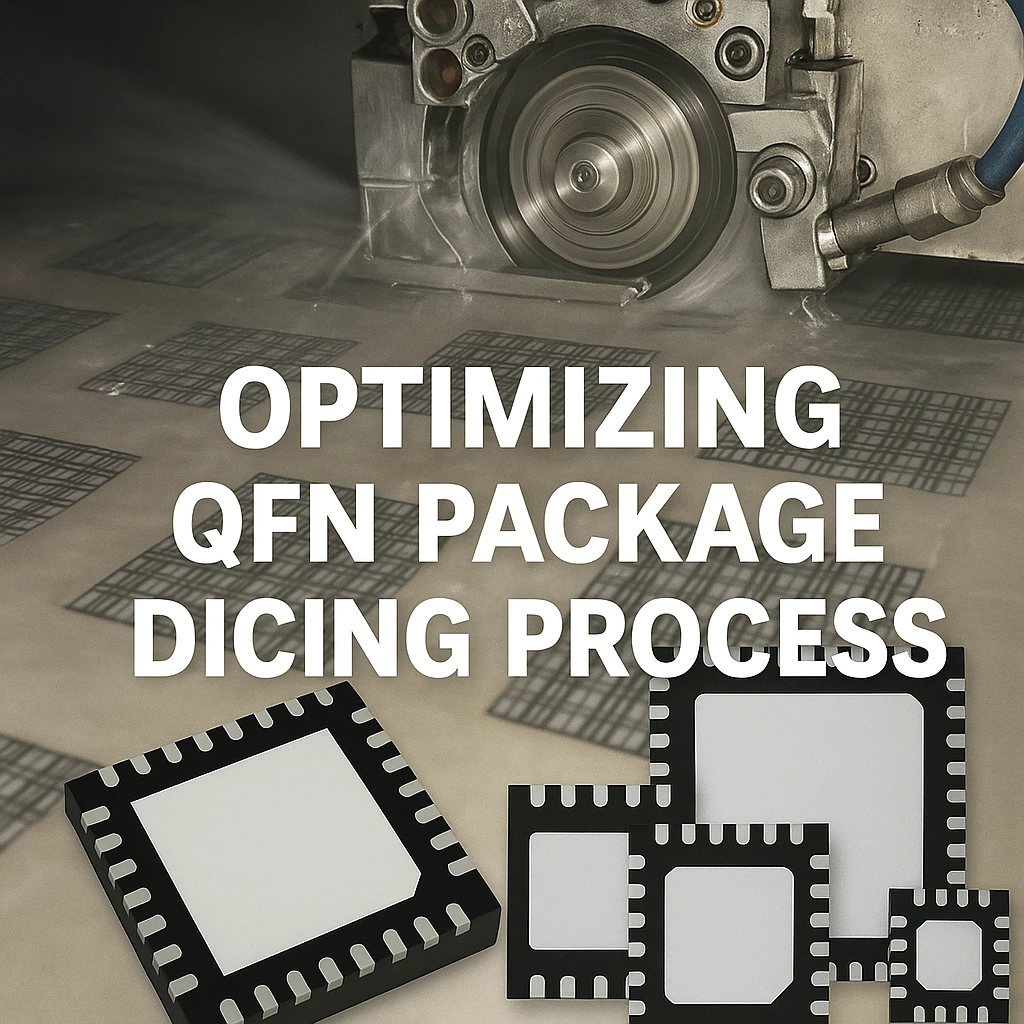

Variations:

- HVQFN (Heatsink Very-Thin)

- MLF (Micro Lead Frame)

- FUSION QUADR

- (VQFP: Very Thin Quad Flat Package)

- HQFN (High Power)

Typical Concerns:

- Chipping

- Burrs

- Lead smearing

- Melting

Dicing Blade Recommendation:

- SMART CUT HYBRID BOND or sintered (metal bond) series

- Diamond grit size: 45 – 88 microns

- Thickness: .008” – .020”

Dicing Process Recommendations:

- Feed rate: Half Etched substrates 30-75 mm/sec, Full Copper substrates 15-30 mm/sec

- Spindle speed: 22-35 krpm depending on blade O.D.

- Multi panel mounting on UV tape

- Override process over one substrate to reach final feed rate

LED (Light-Emitting Diode)

Variations:

Chip LED, High Power LED.

Typical Concerns:

- Copper burrs

- End of blade life due to limited exposure

- Throughput (maximize UPH)

Dicing Blade Recommendation:

- SMART CUT HYBRID BOND or Nickel Bond series

- Diamond size: 10,13 & 17 microns

- Thickness: .003” – .008”

Dicing Process Recommendations:

- Feed rate: 80-150 mm/sec

- Spindle speed: 25-30 krpm

- Multi panel mounting on UV tape

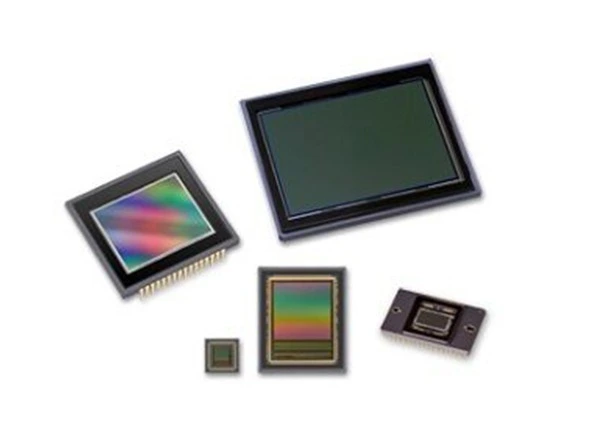

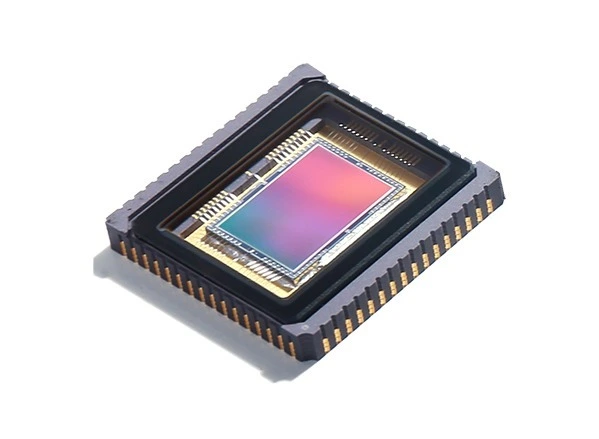

CMOS (Complementary Metal-Oxide Semiconductor)

Common Materials - Borosilicate Glass, HTCC (High Temperature Co-fired Ceramics).

Variations:

CIS (CMOS Image Sensor) Glass Lid, CIS (CMOS Image Sensor) Substrate.

Typical Concerns:

- Chip Damage and Breakage

- Cutting Precision and Kerf Control

- Heat Dissipation

- Surface Quality

- Blade Life & Consistency

Dicing Blade Recommendation:

- Bond Type: Resin Bond, Sintered (Metal Bond), Hybrid Bond, Nickel bond

- Diamond Size: 2 to 30 microns

- Kerf Thickness:10 to 30 microns

Dicing Process Recommendations:

- Feed rate: 80-150 mm/sec

- Spindle speed: 25-30 krpm

- Multi panel mounting on UV tape

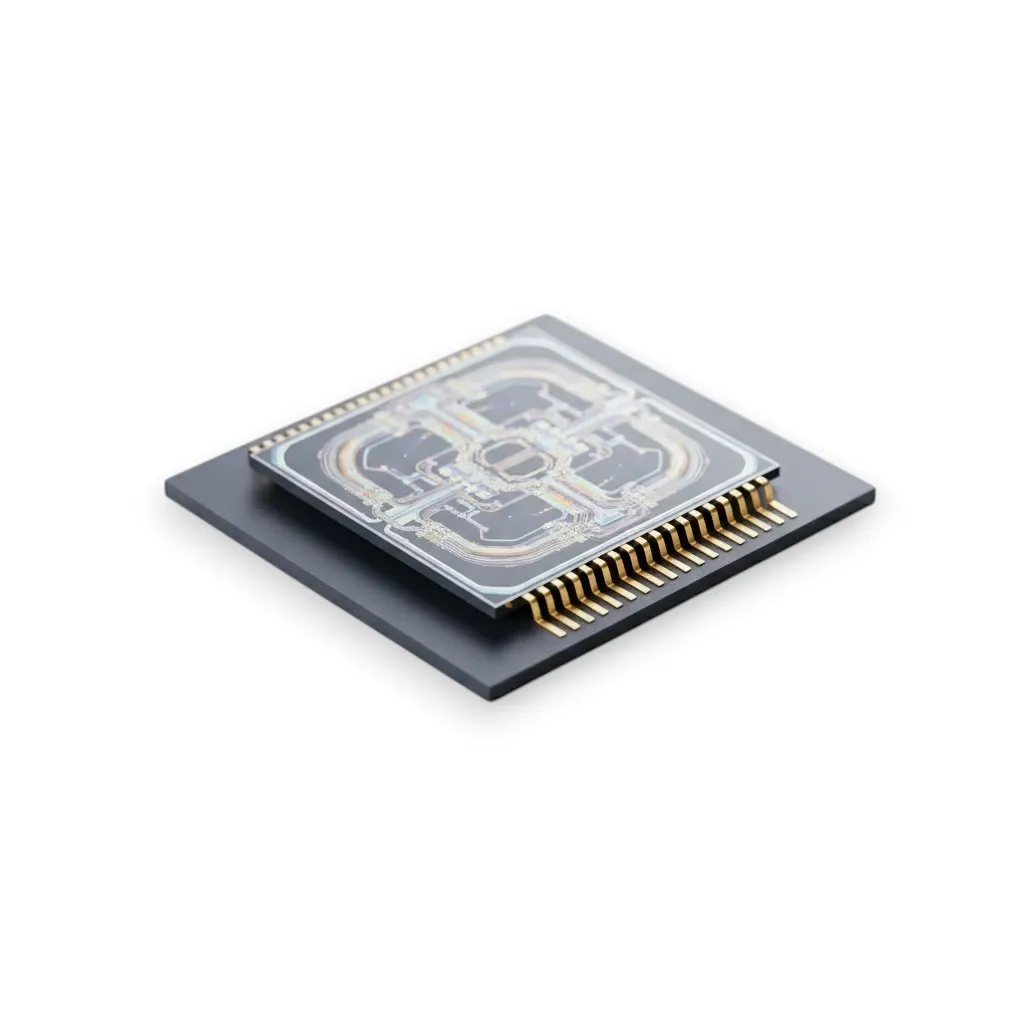

DWDM (Dense Wavelength Division Mulitplexing) Filters

Variations:

SAW (Surface Acoustic Wave) Filter devices, Beam Splitters, Passive Components

Typical Concerns:

- Top-side and back-side chipping

- Cut perpendicularity

- Kerf side surface finish

Dicing Blade Recommendation:

- SMART CUT series Resin, HYBRID, & Sintered (metal bond) blades

- Diamond size: 30 – 45 microns (resin) and 7 – 15 microns (sintered)

- Thickness: .006″ – .012”

Dicing Process Recommendations:

- Feed rate: 4 – 20 mm/sec

- Spindle speed: 20 – 30 krpm (2″) 10 – 15 krpm (4″)

- SMART CUT® XP Dicing Coolant Lubricant Surfacant may reduce chipping and improve surface finish

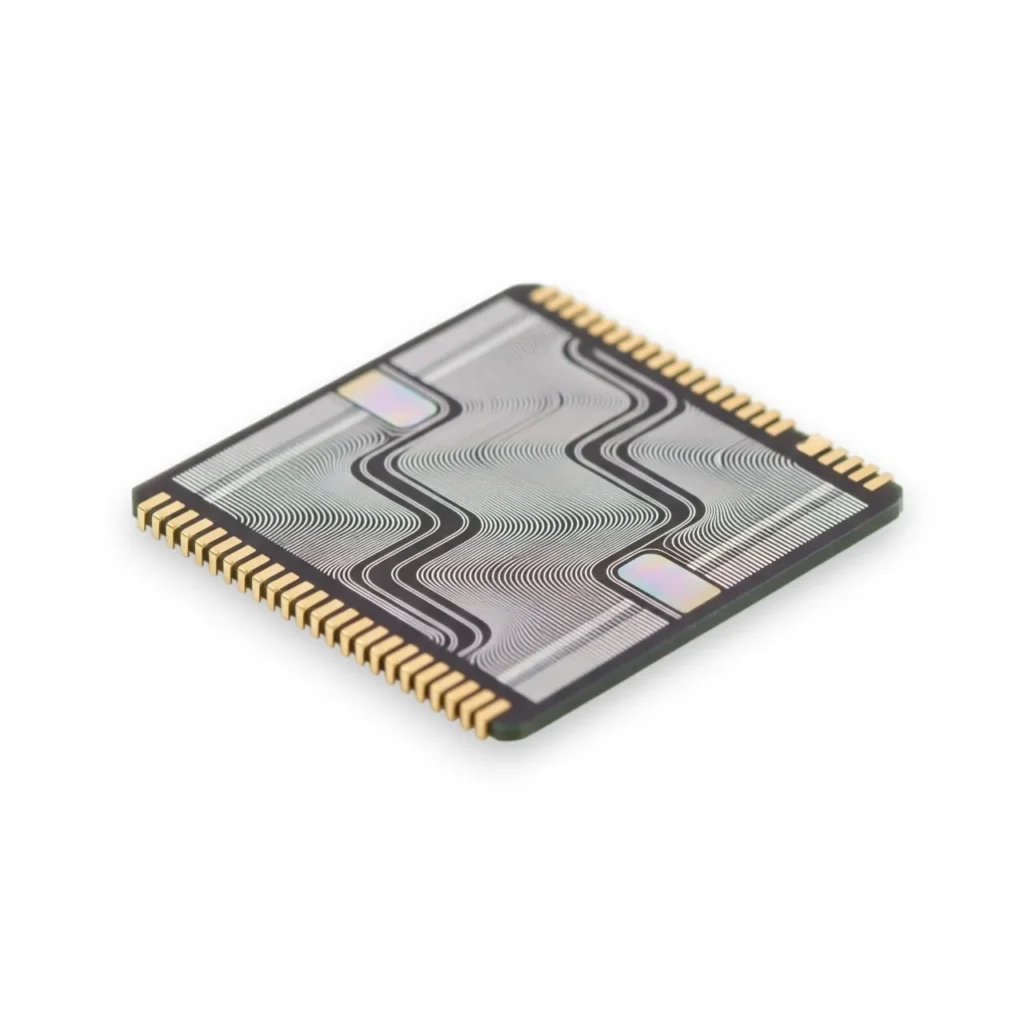

HDD (Hard Disk Drive)

Typical Concerns:

- High Mechanical (internal) stress

- burrs

- large kerf width

- lack of accuracy

Dicing Blade Recommendation:

- Bond Type: Resin Bond, Sintered (Metal Bond)

- Diamond Size: 1 to 25 microns

- Kerf Thickness: 15 to 100 microns

Dicing Process Recommendations:

- Feed Rates: 1 mm/s to 5 mm/s

- RPM’s: 15,000 RPM to 30,000 RPM

- Mounting Type: Vacuum chucks or magnetic chucks

- Coolant Used: Water-soluble coolants

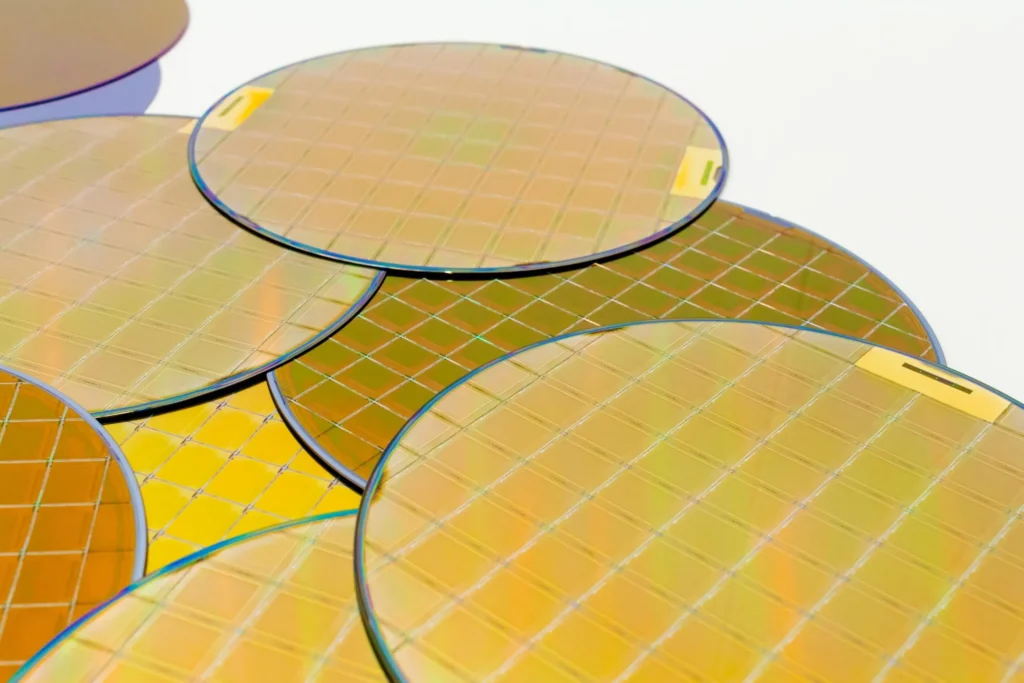

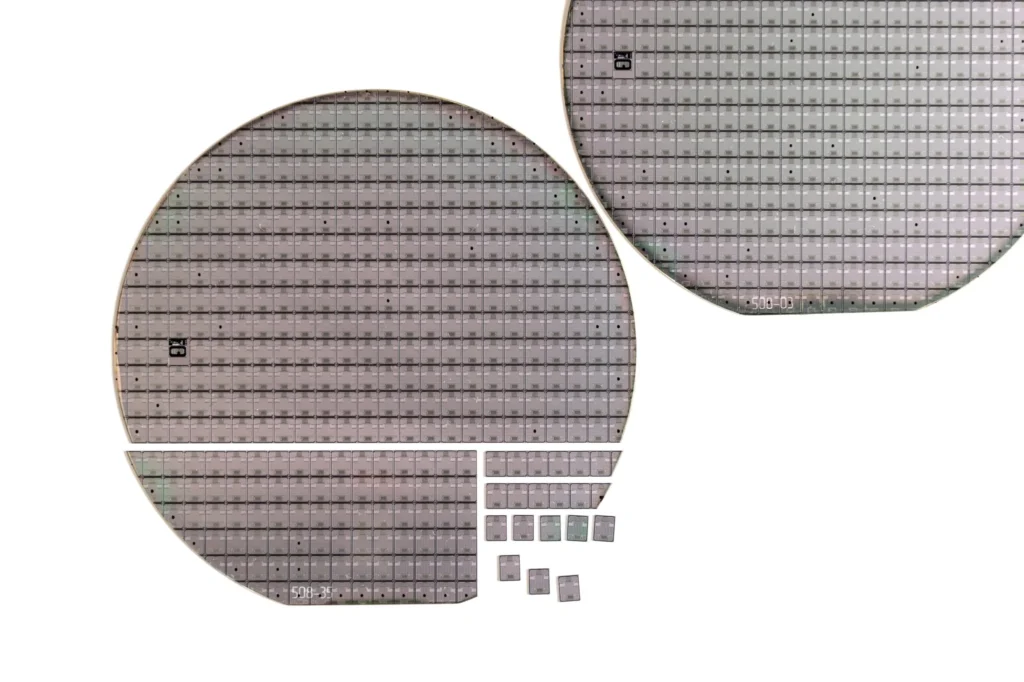

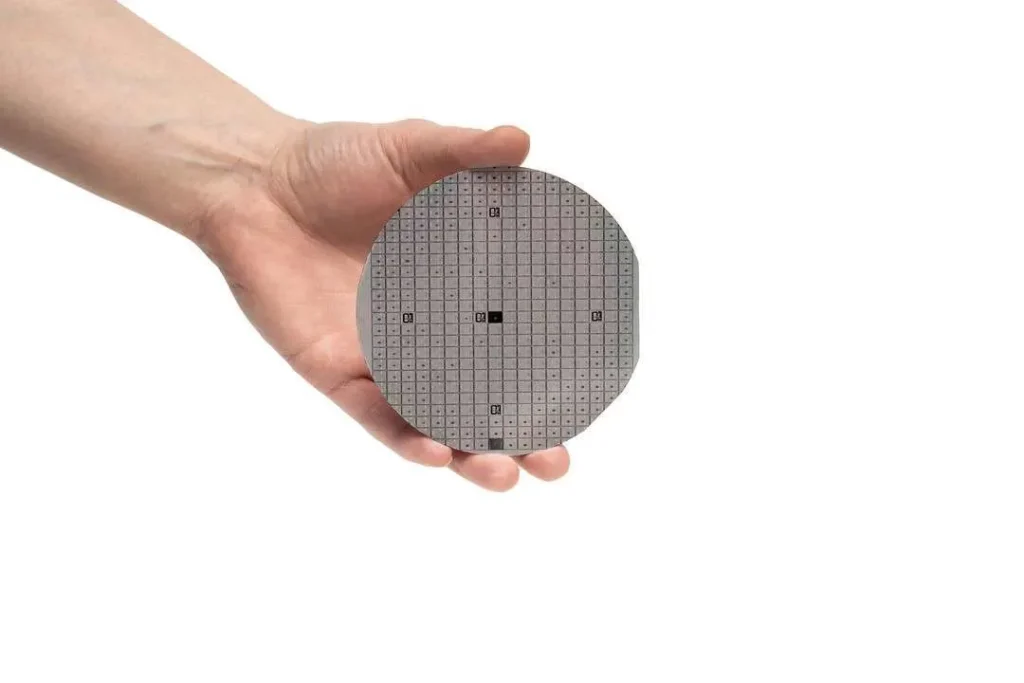

Semiconductor Wafer

Typical Concerns:

- Chipping

- Blade Wear

- Heat Buildup

- Vibration

- Spindle Rounout

- Die Contamination

- Edge Cracking

- Kerf Width Variation

- ESD

- Die Fly Off

- Coolant Residue

- Subsurface Damage

Dicing Blade Recommendation:

- SMART CUT Nickel Bond or HYBRID series

- Diamond size: 4 – 6 microns

- Thickness: .0008” – .0016”

Dicing Process Recommendations:

- Feed rate: 25 – 75 mm/sec

- Spindle speed: 30 – 50 krpm

- Mounting: Blue or UV tape

- Cooling type: DI water with and without additives

- Carbon dioxide bubbler is optional

Silicon & GaAs are the two most common materials used for semiconductor wafers. Wafers are typically available in sizes up to 12″ in diameter, with 6″ and 8″ most popular. Typical thicknesses are between 100 – 650 microns.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

Select right Diamond Dicing Blade for your application

Dicing Blade Operations Recommendations

Optimizing your Diamond Dicing Performance

Trouble Shooting Dicing Problems

Application Recommendations

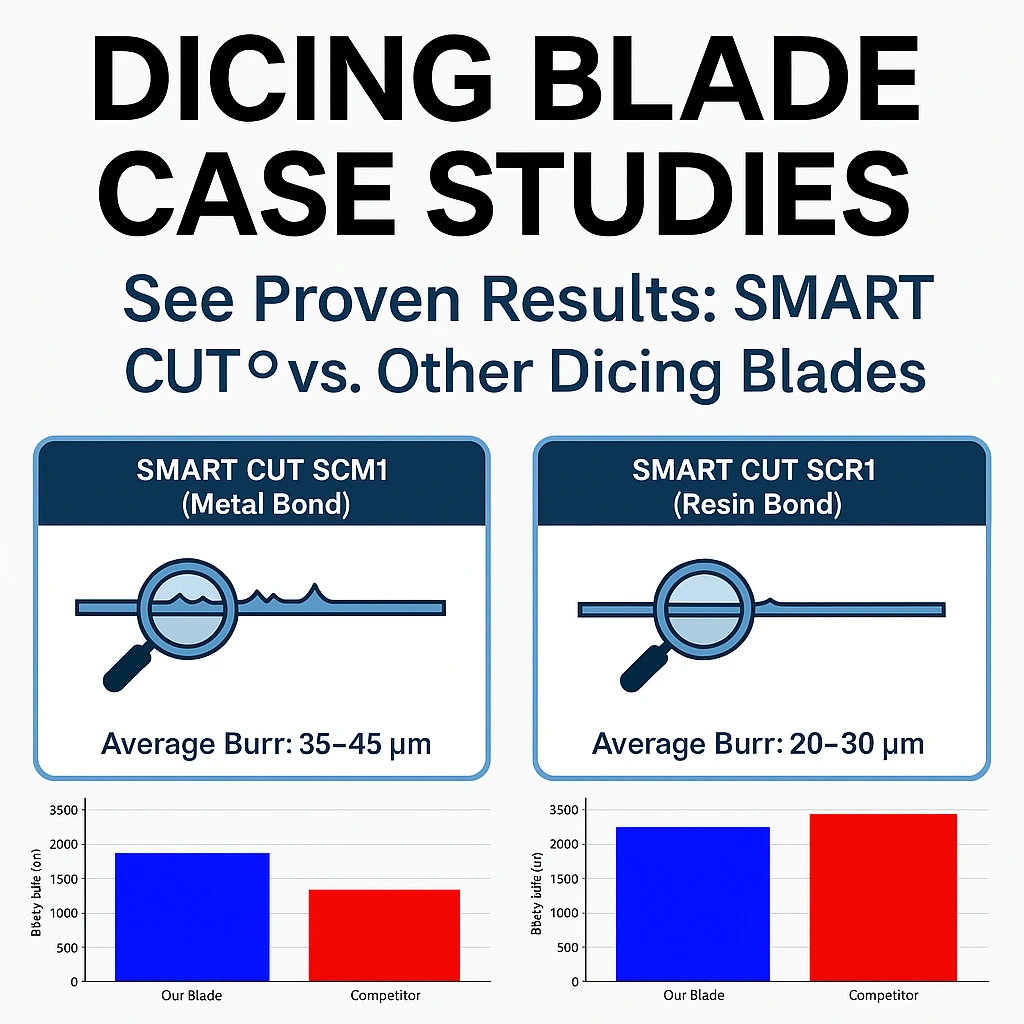

Dicing Blade Case Studies

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Selecting the Right Wafer Dicing Saw Practical Guide

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

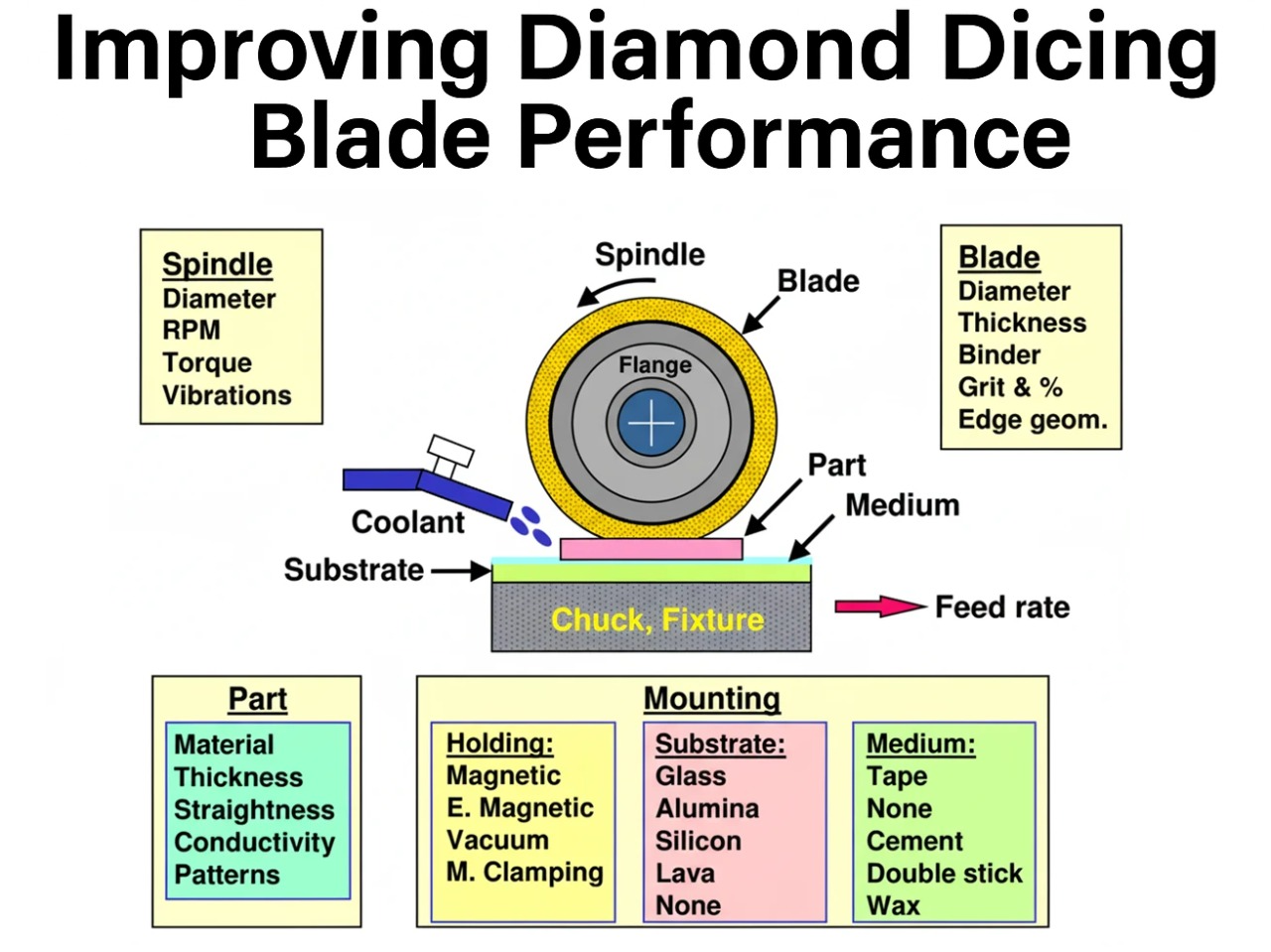

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

Selecting the Right Dicing Surfactant / Fluid for Your Application

How to Use SMART CUT XP Dicing Surfactants

Dicing Surfactants Guide

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Diamond vs CBN (cubic boron nitride) Tools

Choosing The Correct Diamond Bond Type

Selecting the Right Coolant Method for your Diamond & CBN Tools

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.