| 1 |

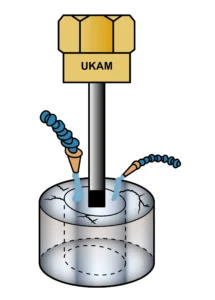

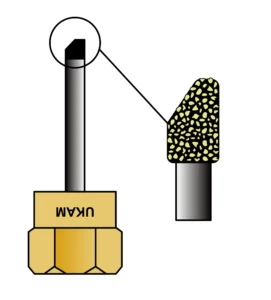

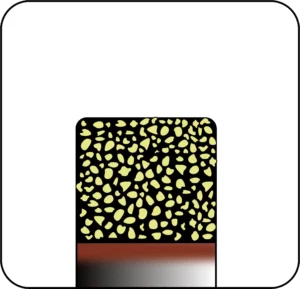

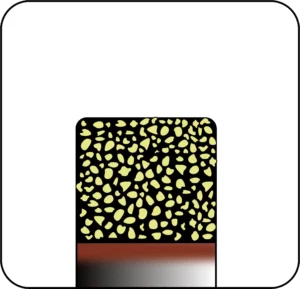

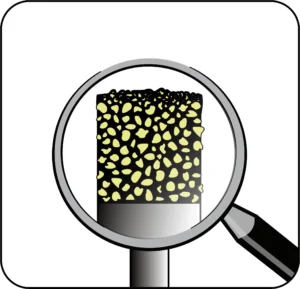

Excessive Drill Wear

Signs: Rapid reduction in Diamond Drills diameter; visible wear on the cutting edges

|

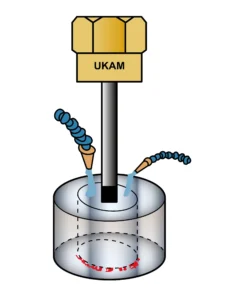

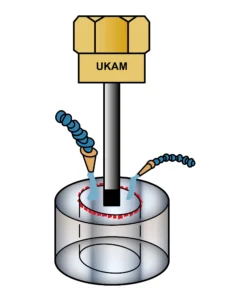

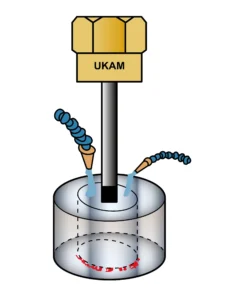

- Incorrect feed rate or speed;

- Inadequate coolant;

- Material hardness

- Inappropriate drill specification

- Inappropriate wall thickness of diameter and dimensions of material

- Bond Hardness too Soft

- Incorrect RPM’s or Feed Rate

- Using Incorrect Coolant

- Coolant Not affectively used

- Not Dressing the Drill

- Poor Equipment Maintenance

|

- Reduced cutting efficiency;

- Increased drill time

- Process Inconsistency & Inefficiency

|

- Adjust feed rate and speed;

- Ensure adequate coolant flow;

- Use a drill suited for the material’s hardness

- Optimize Drill Specification

- Optimize Type of Coolant Used and How It Reaches Drilling Zone

- Optimize Drill RPM’s & Fee Rate

- Check the Condition of your Drilling Equipment

- Make sure the diamond drill is being dressed properly

|

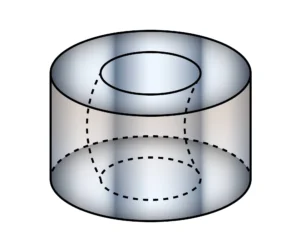

| 2 |

Diamond Drills Breakage

Signs: Sudden snapping or fracturing of the diamond drill; visible cracks or chips on the diamond drill

|

- Excessive pressure

- Misalignment; Material defects

|

- Sudden halt in drilling

- Potential damage to workpiece

|

- Apply correct pressure;

- Ensure proper alignment;

- Inspect material for defects before drilling

|

| 3 |

Poor Surface Finish

Signs: Rough or uneven hole finish; excessive burring around the hole entrance or exit

|

- Inadequate coolant;

- Worn Diamond Drill

- Incorrect feed rate or speed

|

- Rough hole surface

- Potential need for post-processing

|

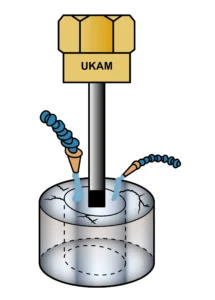

- Ensure proper coolant flow;

- Replace or sharpen diamond drill;

- Adjust feed rate and speed

|

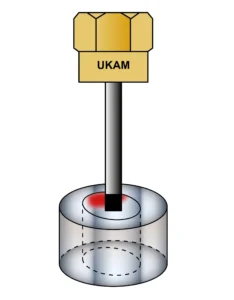

| 4 |

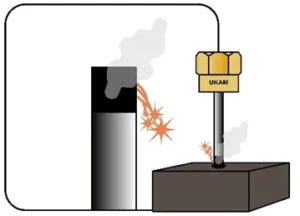

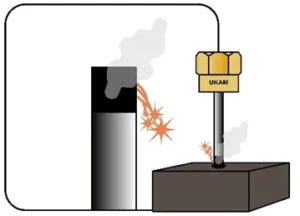

Diamond Drill or Material Overheating

Signs: Excessive heat generation; discoloration of the Diamond Drills or material; smoke or burning smell

|

- Insufficient coolant;

- High feed rate or speed;

- Prolonged drilling without breaks

- Incorrect Coolant or Mix Ratio Used

- Inadequate Amount of Coolant Reaching Drilling zone

- Incorrect Diamond Drill Specification

|

- Premature wear of the drill;

- Potential thermal damage to the material

- Possible Chipping

- Possible Material Micro Cracking

- Possible Material Deformation

- Change in Material Properties

|

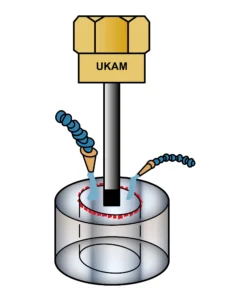

- Optimize Coolant:

- Align the coolant nozzles

- Increase coolant flow

- Use specialized water soluble coolant

- Adjust feed rate and speed

- Allow intermittent breaks during drilling

- Try using diamond drill more optimized for the application

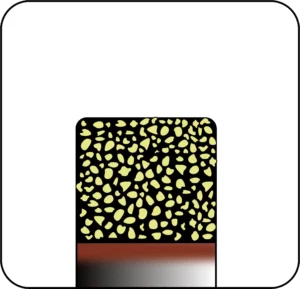

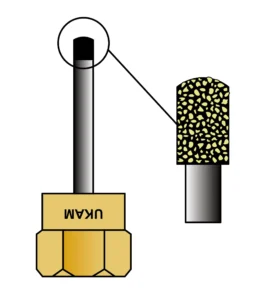

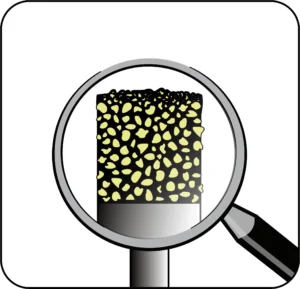

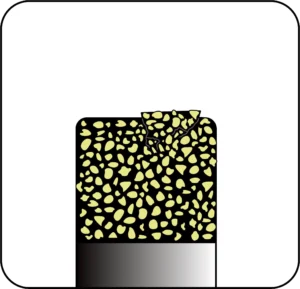

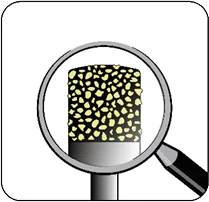

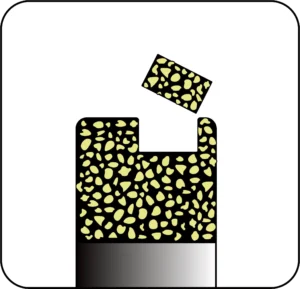

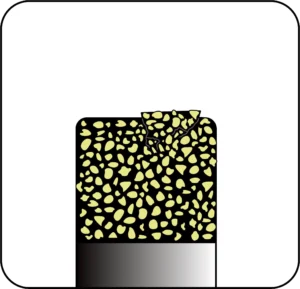

|

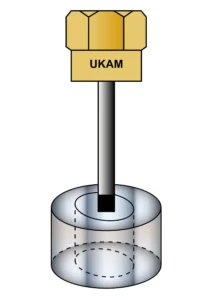

| 5 |

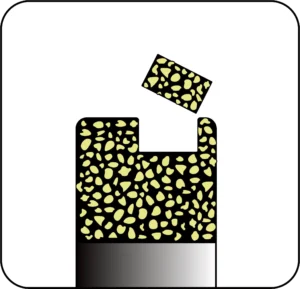

Core Ejection Issues

Signs: Difficulty in removing the core from the material; the core sticks or breaks during ejection

|

- Inadequate core breaker;

- Incorrect drill design;

- Material adhesion

|

- Difficulty in removing the core;

- Potential damage to the core or hole

|

- Use an adequate core breaker;

- Choose the correct drill design;

- Apply release agents if necessary

|

| 6 |

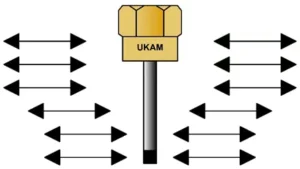

Diamond Drills Wonders

Signs: Diamond Drill deviates from the intended path; uneven hole diameter; off-center hole entrance or exit

|

- Misalignment;

- Uneven surface;

- Inadequate drill rigidity

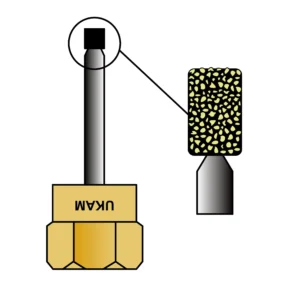

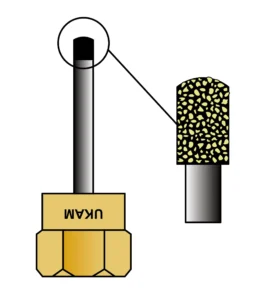

|

- Inaccurate hole location;

- Potential damage to workpiece

|

- Ensure proper alignment;

- Flatten surface before drilling;

- Use a more rigid drill setup

|

| 7 |

Material Cracking

Signs: Visible cracks in the material around the hole; chipping or flaking of the material surface

|

- Excessive pressure;

- Thermal shock;

- Material flaws

|

- Cracks in the material;

- Compromised structural integrity

|

- Reduce pressure;

- Ensure proper coolant temperature;

- Inspect and pre-treat material if necessary

|

| 8 |

Diamond Drills Glazing

Signs: Smooth, shiny surface on the Diamond Drills edges; reduced cutting debris; increased force required to drill

|

- Inadequate coolant;

- Too low feed rate;

- Material abrasiveness

|

- Reduced cutting ability;

- Increased friction and heat

|

- Increase coolant flow;

- Adjust feed rate;

- Use a drill suited for abrasive materials

|

| 9 |

Inconsistent Hole Size

Signs: Hole diameter varies from top to bottom or between multiple holes; holes not consistent with Diamond Drills size

|

- Drill wear;

- Misalignment;

- Material heterogeneity

|

- Holes not meeting tolerance;

- Potential rework or scrap

|

- Monitor and replace Diamond Drills as needed;

- Ensure proper alignment;

- Adjust process for material variance

|

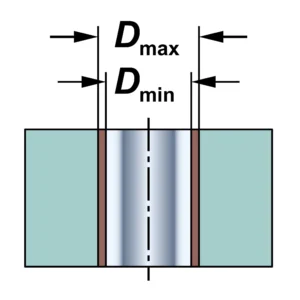

| 10 |

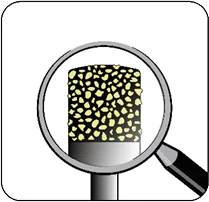

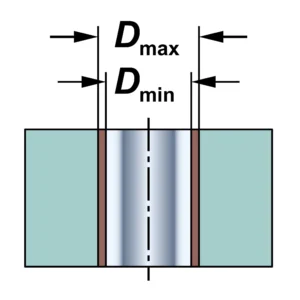

Inaccurate Hole Tolerances

Sings: Holes are consistently larger or smaller than the specified diameter. Measurement of the hole diameter shows deviation from the design specifications.

|

- Diamond wear or damage

- Inaccurate Diamond Drill size

- Misalignment or instability during drilling.

- Excessive Run Out

- Inaccurate Tolerances

- Runout on Collet or Chuck

- Incorrect Material Mount

- Incorrect Drilling Equipment

- Incorrection Drill Specification

- Not Maintaining the Drill

- Incorrect Drilling Technique runout

|

- Compromised precision in hole dimensions;

- Potential for part rejection or rework.

|

- Regularly inspect and replace worn or damaged diamond drills

- Verify diamond drill size before use.

- Ensure drill and workpiece stability and alignment.

|

| 11 |

Noise and Vibration

Signs: Unusual sounds during operation; excessive shaking or movement of the drill or workpiece

|

- Misalignment;

- Loose components;

- Inadequate mounting

|

- Unpleasant working conditions;

- Potential inaccuracies in drilling

|

- Check and correct alignment;

- Tighten all components;

- Ensure proper mounting and support

|

| 12 |

Drill Jamming

Signs: Diamond Drills gets stuck in the material; difficulty in advancing or retracting the drill

|

- Material swarf build-up;

- Inadequate lubrication;

- Diamond Drills misalignment

|

- Interrupted drilling process;

- Potential for Diamond Drills breakage

|

- Clean Diamond Drills regularly;

- Ensure proper lubrication;

- Check and correct Diamond Drills alignment

|

| 13 |

Sound Fluctuation

Signs: Irregular or intermittent cutting sounds; changes in drilling noise patterns

|

- Diamond Drills wear;

- Loose components;

- Inconsistent material density

|

- Inconsistent drilling performance;

- Potential for inaccuracies

|

- Inspect and replace worn diamond drills;

- Tighten loose components;

- Adjust drilling parameters for material

|

| 14 |

Diamond Drill Overloading

Signs: Excessive power consumption or increased load on the drilling machine

|

- Dull diamond drill; Inadequate coolant;

- Material hardness

|

- Increased operational costs;

- Potential overheating of machine

|

- Sharpen or replace diamond drill;

- Ensure adequate coolant flow;

- Use a drill suited for the material’s hardness

|

| 15 |

Slow/ Inefficient Drilling

Signs: Slow drilling progress; increased time to penetrate material

|

- Blunt drill edges

- Inadequate drilling speed

- Hard or abrasive material

- Incorrect Drill Specification

- Coolant not adequately reaching the drilling zone

- Incorrect feed rates

- Material core (plug) is stuck inside core drill

- Poor Equipment Maintenance

- Operator Oversight

|

- Prolonged drilling time;

- Increased wear on diamond drill

- Higher Process Cost

- Loss of Productivity

|

- Dress the diamond drill

- Adjust drilling speed;

- Select a more suitable Diamond Drills for the material

- Use Larger (coarser) Diamond

- Use Softer Bond Matrix

- Optimize rpm’s and fee rate

- Try higher RPM’s

|

| 16 |

Diamond Drill Overheating

Signs: Discoloration or burn marks on the material around the hole

|

- Excessive friction; Inadequate coolant;

- Too high drilling speed

|

- Aesthetic damage to material;

- Potential structural damage

|

- Reduce drilling speed; Increase coolant flow;

- Adjust drilling parameters

|

| 17 |

Diamond Drill Instability

Signs: Chattering or bouncing of the diamond drill

|

- Unstable drill setup;

- Worn drill bearings or spindle; Misalignment

|

- Poor hole quality;

- Potential damage to Diamond Drills or material

|

- Stabilize drill setup;

- Replace worn components; Ensure proper alignment

|

| 18 |

Debris Accumulation

Swarf or debris accumulation around the Diamond Drills or in the hole

|

- Inadequate chip removal;

- Insufficient coolant flow; Incorrect drill design

|

- Blocked drilling path;

- Potential for Diamond Drills overheating

|

- Improve chip removal; Increase coolant flow;

- Use a drill with appropriate chip removal design

|

| 19 |

Trouble Starting Hole

Signs: Difficulty in starting the hole; Diamond Drills skidding or slipping on the material surface

|

- Inadequate surface preparation;

- Diamond Drills not sharp enough; Incorrect angle of entry

|

- Inaccurate hole initiation;

- Potential for surface damage

|

- Prepare surface properly;

- Sharpen or replace diamond drill; Ensure correct angle of entry

|

| 20 |

Drill Vibrating

Signs: Excessive tool vibration or machine movement

|

- Imbalanced diamond drill;

- Loose machine components; Uneven work surface

|

- Reduced drilling accuracy;

- Increased wear on machine and diamond drill

|

- Balance diamond drill;

- Tighten loose components; Ensure work surface is even and stable

|

| 21 |

Drilling Heat Buildup

Signs: Unusual or excessive heat in the drill chuck or spindle

|

- Overworked drill motor;

- Inadequate lubrication; Excessive drilling speed

|

- Potential damage to drill or machine;

- Reduced lifespan of components

|

- Allow motor to cool periodically;

- Ensure proper lubrication; Adjust drilling speed

|

| 22 |

Decline in Drilling Performance

Signs: Reduced cutting speed despite constant machine settings

|

- Diamond Drills wear;

- Hardening of the material;

- Inadequate coolant

|

- Increased drilling time;

- Potential for overheating

|

- Inspect and replace the diamond drill;

- Adjust coolant flow;

- Review material specifications

|

| 23 |

Short Drill Life

Signs: Frequent need for Diamond Drills replacement

|

- Excessive wear rate;

- Unsuitable Diamond Drills material;

- Incorrect drilling parameters

|

- Increased operational costs;

- Downtime for replacements

|

- Choose appropriate Diamond Drills material;

- Optimize drilling parameters;

- Regularly inspect diamond drills

|

| 24 |

Diamond Drill Jammed

Signs: Diamond Drills becomes lodged or jammed in the hole

|

- Swarf build-up;

- Inadequate hole clearance;

- Material deformation

|

- Interrupted drilling process;

- Potential for Diamond Drills damage

|

- Ensure adequate hole clearance;

- Use appropriate Diamond Drills design;

- Regularly clear swarf

|

| 25 |

Drill Life Inconsistency

Signs: Inconsistent Diamond Drills life across similar operations

|

- Variable material properties;

- Inconsistent machine calibration;

- Fluctuating operating conditions

|

- Unpredictable maintenance schedule;

- Variable drilling performance

|

- Standardize material selection; Calibrate machines regularly;

- Monitor and stabilize operating conditions

|

| 26 |

Excessive Drilling Noise

Excessive noise from the drilling machine

|

- Worn or damaged machine components; Misalignment;

- Unbalanced load

|

- Unpleasant working environment;

- Potential for machine damage

|

- Inspect and replace damaged components;

- Align and balance machine;

- Distribute load evenly

|

| 27 |

Drill Angle Instability

Difficulty in maintaining the desired drilling angle

|

- Unstable machine setup; Worn machine components;

- Inadequate operator training

|

- Inaccurate hole angle;

- Compromised hole integrity

|

- Stabilize machine setup;

- Replace worn components; Provide adequate training

|

| 28 |

Diamond Drill Deflection

Increased occurrence of Diamond Drills deflection

|

- Inadequate drill rigidity; Uneven material density;

- Incorrect Diamond Drills design

|

- Inaccurate hole dimensions;

- Potential for off-center drilling

|

- Use a more rigid drill setup;

- Assess material density;

- Choose the correct Diamond Drills design

|

| 29 |

Diamond Drill Tube Wear

Visible wear or damage on the drill sides/body

|

- Abrasive material;

- Inadequate coolant;

- High feed rate or speed

|

- Reduced Diamond Drills effectiveness;

- Increased heat generation

|

- Use diamond drills designed for abrasive materials;

- Ensure proper coolant flow; Adjust feed rate and speed

|

| 30 |

Feed Rate Issues

Difficulty in controlling Diamond Drills feed rate

|

- Inconsistent material density;

- Worn machine components;

- Inadequate operator control

|

- Inconsistent drilling performance;

- Potential for material damage

|

- Assess material density;

- Maintain machine components; Train operators adequately

|

| 31 |

Material Bottom Side Deformation

Excessive burring or material deformation at the hole exit

|

- Too high feed rate;

- Inadequate support for the material;

- Dull diamond drill

|

- Poor hole quality;

- Additional finishing required

|

- Adjust feed rate;

- Provide adequate material support;

- Sharpen or replace the diamond drill

|

| 32 |

Diamond Drills Wondering

Diamond Drills “walking” or drifting at the start of drilling

|

- Uneven starting surface;

- Diamond Drills not perpendicular to material;

- Inadequate clamping

|

- Inaccurate hole start;

- Potential for material damage

|

- Flatten starting surface;

- Ensure Diamond Drills is perpendicular; Secure material properly

|

| 33 |

Excessive Wear on One Drill Side

Signs: Excessive wear on one side of the diamond drill

|

- Misalignment;

- Uneven material hardness;

- Improper Diamond Drills rotation

|

- Asymmetrical Diamond Drills wear;

- Reduced Diamond Drills life

|

- Check and correct alignment;

- Assess material properties;

- Ensure proper Diamond Drills rotation

|

| 34 |

Diamond Drill Overheating

Changes in Diamond Drills coloration (e.g., bluing, yellowing)

|

- Overheating due to high friction;

- Inadequate coolant supply

- Excessive drilling speed

- Diamond Crystal too Fine for the application

- Bond Matrix is too High

- Inappropriate Drill Specification

|

- Potential loss of Diamond Drills hardness;

- Reduced cutting efficiency

- Material Deformation

- Material Burring, chipping, cracking

- Diamond section breakage or cracking

- Drill stops drilling

|

- Optimize drilling speed;

- Increase coolant flow;

- Monitor Diamond Drills temperature

- Increase RPM’s

- Make sure the RPM’s are recommended for the application

- Use dressing stick to dress the drill

- Consider using diamond drill more optimized for the application

|

| 35 |

Drilling Depth Issues

Signs: Difficulty in achieving the required hole depth

|

- Inadequate Diamond Drills length;

- Material hardening at deeper levels;

- Diamond Drills deflection

|

- Incomplete drilling;

- Inaccurate hole depth

|

- Use the correct length diamond drill;

- Adjust drilling parameters for depth;

- Ensure drill rigidity

|

| 36 |

Drilling Torque Variations

Fluctuations in drilling torque or resistance

|

- Inconsistent material composition;

- Worn diamond drill; Clutch or gearbox issues

|

- Inconsistent drilling performance;

- Potential for stalling or jamming

|

- Assess material consistency;

- Replace worn diamond drills; Service clutch or gearbox

|

| 37 |

Material Discoloration

Material discoloration around the hole

|

- Excessive heat generation; Chemical reaction with coolant;

- Material sensitivity

|

- Aesthetic or structural material damage;

- Potential weakening of material

|

- Adjust drilling parameters;

- Check and replace coolant;

- Assess material sensitivity

|

| 38 |

Chip Removal Issues

Signs: Increased difficulty in chip removal

|

- Inadequate flute design; High material ductility;

- Insufficient coolant pressure

|

- Clogged diamond drill;

- Reduced drilling efficiency;

- Potential overheating

|

- Optimize flute design;

- Adjust drilling parameters for ductile materials;

- Increase coolant pressure

|

| 39 |

Diamond Drills Stalling

Diamond Drills fails to cut or progress through the material

|

- Diamond Drills wear or damage;

- Material hardness exceeds Diamond Drills capacity;

- Incorrect Diamond Drills type

|

- Stalled drilling process;

- Potential for Diamond Drills damage

|

- Inspect and replace diamond drill;

- Use a Diamond Drills suited for the material hardness;

- Ensure correct Diamond Drills type

|

| 40 |

Diamond Section Glazed Over

Signs: Unusual or rapid Diamond Drills dulling

|

- Abrasive material;

- Inadequate coolant;

- Incorrect drilling parameters

- Diamond Crystals too Friable

- Bond Matrix too High

- Drilling speed is too High or low

- Incorrect drilling speed

- Incorrect drill specification

|

- Frequent Diamond Drills replacement;

- Increased operational costs

- Diamond drill slows down

- Diamond drill stops drilling altogether

- Diamond Drill Overheats

- Possible Material Deformation

- Material Burring, Chipping, & cracking

- Possible Diamond Section Breakage

|

- Select diamond drills designed for abrasive materials;

- Optimize coolant flow;

- Adjust drilling parameters

|

| 41 |

Diamond Drill Suddenly Stops

Sudden increase in drilling noise or vibration

|

- Diamond Drills or machine component failure;

- Material fracture;

- Loose fixtures

|

- Potential for immediate halt in drilling;

- Safety hazard

|

- Stop drilling immediately;

- Inspect Diamond Drills and machine;

- Secure all fixtures

|

| 42 |

Uneven Wear on Diamond Section

Uneven wear on the drills diamond section surface

|

- Uneven material hardness;

- Diamond Drills not level with material;

- Inconsistent feed pressure

|

- Uneven drilling;

- Reduced Diamond Drills life

|

- Assess material for uniformity;

- Level Diamond Drills with material;

- Apply consistent feed pressure

|

| 43 |

Diamond Drills “pulls” into the material unexpectedly

|

- Too aggressive feed rate;

- Diamond Drills design not suited for material;

- Inadequate clamping of material

|

- Loss of control over drilling;

- Potential for over-drilling or material damage

|

- Adjust feed rate;

- Select appropriate Diamond Drills design;

- Ensure material is clamped securely

|

| 44 |

Difficulty in Starting Hole

Difficulty in hole start or Diamond Drills skating on material surface

|

- Lack of pilot hole or starting point;

- Hard or slippery material surface;

- Worn Diamond Drills tip

|

- Inaccurate hole placement;

- Increased time for hole initiation

|

- Create a pilot hole or use a center punch;

- Assess and prepare material surface;

- Replace or sharpen Diamond Drills tip

|

| 45 |

Drill Mounting Overheating

Excessive accumulation of heat in the Diamond Drills shank

|

- High friction in the chuck;

- Over-tightening of the diamond drill;

- Inadequate lubrication in chuck area

|

- Potential for Diamond Drills or chuck damage;

- Reduced Diamond Drills life

|

- Adjust chuck tightness;

- Ensure proper lubrication;

- Monitor and manage friction levels

|

| 46 |

Wall Smoothness Variability

Inconsistent hole wall smoothness

|

- Fluctuating feed rate; Diamond Drills vibration;

- Material inhomogeneity

|

- Variable hole quality;

- Potential need for post-processing

|

- Stabilize feed rate;

- Minimize Diamond Drills vibration;

- Assess material for consistency

|

| 47 |

Edge Sharpness Loss

Diamond Drills unable to retain cutting edge sharpness

|

- Material abrasiveness; Inadequate cooling;

- Incorrect Diamond Drills material

|

- Frequent Diamond Drills re-sharpening or replacement;

- Increased downtime

|

- Use diamond drills designed for abrasive materials;

- Optimize cooling; Select appropriate Diamond Drills material

|

| 48 |

Sharp Decline in Drill Performance

Sudden decrease in drilling performance

|

- Takes lot longer to drill

- Decrease in drilling speed & feed rate

- Sudden material hardness change;

- Diamond Drills reaching end of life

|

- Slowed drilling progress;

- Potential for Diamond Drills failure

|

- Clean flutes regularly; Assess material for consistency;

- Monitor Diamond Drills life and replace as needed

|

| 49 |

Diamond Drills Bending

Diamond Drills bending or flexing during operation

|

- Excessive length to diameter ratio;

- Inadequate support for diamond drill; High lateral pressure

|

- Diamond Drills deflection;

- Inaccurate hole dimensions

|

- Use diamond drills with appropriate length to diameter ratio;

- Ensure Diamond Drills is adequately supported;

- Minimize lateral pressure

|

| 50 |

Shank or Drill Mount Fracture

Premature shank wear or failure

|

- Excessive chuck pressure;

- Misalignment in chuck;

- Repeated high-torque scenarios

|

- Reduced Diamond Drills life;

- Potential for Diamond Drills s lippage or breakage

|

- Adjust chuck pressure;

- Ensure proper alignment in chuck;

- Monitor and manage torque levels

|

| 51 |

Loss of Concentricity

Diamond Drills loses concentricity

|

- Worn spindle or bearings;

- Improper Diamond Drills installation;

- Material side forces

|

- Hole diameter inconsistency;

- Reduced drill accuracy

|

- Service or replace spindle/bearings;

- Ensure proper Diamond Drills installation;

- Stabilize material during drilling

|

| 52 |

Increased Diamond Drills side play

|

- Worn chuck jaws;

- Overuse or wear of Diamond Drills shank;

- Misalignment in drill setup

|

- Reduced precision;

- Potential for hole deviation

|

- Replace or adjust chuck jaws;

- Replace worn diamond drills;

- Ensure proper alignment in setup

|

| 53 |

Intermittent Drilling Action

Diamond Drills exhibits intermittent cutting action

|

- Intermittent material hardness;

- Fluctuating feed rate;

- Diamond Drills vibration

|

- Inconsistent hole quality;

- Potential for material damage

|

- Assess material for consistency;

- Stabilize feed rate; Minimize Diamond Drills vibration

|

| 54 |

Excessive coolant consumption

Excessive coolant consumption

|

- Coolant leaks;

- Inefficient coolant delivery system;

- High evaporation rate

|

- Increased operational costs;

- Potential for inadequate cooling

|

- Check for and repair leaks;

- Optimize coolant delivery system;

- Assess coolant type and application

|

| 55 |

Coolant Foaming

Coolant foaming or discoloration

|

- Contamination;

- Chemical reaction with materials;

- Incorrect coolant mixture

|

- Reduced cooling efficiency;

- Potential for material or tool corrosion

|

- Identify and remove contaminants;

- Assess material compatibility;

- Check and adjust coolant mixture

|

| 56 |

Diamond Drills exhibits premature wear patterns

|

- Material abrasiveness;

- Inadequate coolant;

- Incorrect drilling parameters

|

- Reduced Diamond Drills life;

- Increased replacement frequency

|

- Select diamond drills for abrasive materials;

- Optimize coolant flow;

- Adjust drilling parameters

|

| 57 |

Poor Drill Alignment

Difficulty in maintaining Diamond Drills alignment during deep hole drilling

|

- Diamond Drills deflection;

- Inadequate machine rigidity;

- Misalignment in setup

|

- Hole deviation at depth;

- Reduced hole accuracy

|

- Use drill guides or bushings;

- Ensure machine rigidity;

- Check and correct alignment

|

| 58 |

Material fuses to the diamond drill

|

- Excessive heat generation;

- Material ductility;

- Inadequate coolant or feed rate

|

- Stalled drilling process;

- Potential for material waste

|

- Optimize feed rate;

- Use suitable coolant;

- Select appropriate Diamond Drills material

|

| 59 |

Oversized Holes

Diamond Drills produces oversized holes

|

- Diamond Drills wear;

- Material thermal expansion;

- Diamond Drills wobble

|

- Hole size inconsistency;

- Reduced dimensional accuracy

|

- Replace worn diamond drills;

- Control material temperature;

- Check and correct Diamond Drills mounting

|

| 60 |

undersized holes

Diamond Drills produces undersized holes

|

- Incorrect Diamond Drills sizing;

- Material compression;

- Inadequate cutting pressure

|

- Hole size inconsistency;

- Potential for rework or scrap

|

- Verify Diamond Drills size;

- Assess material properties;

- Adjust cutting pressure

|

| 61 |

Drill Mounting Deformation

Diamond Drills shank wear or deformation

|

- Excessive chuck pressure;

- Misalignment in chuck;

- Repeated high-torque scenarios

|

- Reduced Diamond Drills life;

- Potential for Diamond Drills slippage or breakage

|

- Adjust chuck pressure; Ensure proper alignment in chuck;

- Monitor and manage torque levels

|

| 62 |

Inconsistent drilling speed

Inconsistent drilling speed despite constant settings

|

- Variable voltage supply; Worn or damaged motor;

- Mechanical issues in drill feed mechanism

|

- Inconsistent drilling performance;

- Potential for reduced precision

|

- Check and stabilize power supply;

- Service or replace motor;

- Inspect and repair feed mechanism

|

| 63 |

Excessive Dust Generation

Excessive dust or debris generation during drilling

|

- Inadequate dust extraction;

- High material brittleness;

- Incorrect Diamond Drills type

|

- Poor visibility and working conditions;

- Potential health hazards

|

- Improve dust extraction system;

- Adjust drilling parameters;

- Select appropriate Diamond Drills type

|

| 64 |

Difficulty Removing Diamond Drill from Material

Diamond Drills fails to disengage properly from the material |

- Material adhesion; Vacuum effect in the hole;

- Mechanical issues with drill retraction

|

- Difficulty in Diamond Drills removal;

- Potential for Diamond Drills or material damage

|

- Apply release agents;

- Ensure proper hole ventilation;

- Inspect and repair retraction mechanism

|

| 65 |

Unusual wear or damage on non-cutting parts of the diamond drill

|

- Contact with debris or workpiece;

- Handling or storage issues;

- Accidental collisions

|

- Reduced Diamond Drills life;

- Potential for inaccuracies in drilling

|

- Protect Diamond Drills during non-use;

- Ensure proper handling and storage;

- Avoid collisions

|

| 66 |

frequent recalibration Required

Diamond Drills requires frequent recalibration or adjustment

|

- Inconsistent material hardness;

- Thermal expansion of drill or material;

- Wear and tear of drill components

|

- Increased downtime for recalibration;

- Potential for reduced accuracy

|

- Assess material consistency;

- Monitor temperature effects;

- Regularly inspect and maintain drill components

|

| 67 |

Difficulty in achieving straight hole walls

|

- Diamond Drills deflection; Inadequate machine stability;

- Uneven material density

|

- Hole wall irregularities;

- Reduced hole quality

|

- Use more rigid drill setup;

- Enhance machine stability;

- Assess and accommodate material density

|

| 68 |

Rough Surface at Entrance or Exit

Diamond Drills produces a rough hole entrance or exit

|

- Inadequate Diamond Crystal Sharpness & Exposure;

- High feed rate

- Material chipping or flaking

- Diamond Crystal too Coarse or Fine

- Drilling Speed too High or Low

- Insufficient Coolant reaching the drilling zone

- Incorrect diamond drill application

|

- Poor hole quality

- Potential for additional finishing processes

- Process Inconsistency

- Loss of Productivity

- Higher Cost

- Scrap Parts

|

- Dress the Diamond Drill

- Adjust feed rate

- Optimize drilling parameters for material

- User Finer diamond grit size

- Optimize Diamond Concentration

- Use Softer Bond Matrix

- Use Different Bond Type

- Make Sure Coolant is reaching drilling zone

- Make sure the material is supported and does not move

|

| 69 |

Material Delamination

Material layers separate or delaminate during drilling

|

- High drilling pressure;

- Inadequate support for layered materials;

- Diamond Drills not suited for layered materials

|

- Layer separation;

- Compromised material integrity

|

- Reduce drilling pressure; Provide adequate support;

- Use diamond drills designed for layered materials

|

| 70 |

Tapered Hole

Diamond Drills produces a tapered hole

|

- Diamond Drills not perpendicular to material;

- Worn or damaged diamond drill;

- Inconsistent material density

|

- Hole dimension inconsistencies;

- Reduced hole quality

|

- Ensure Diamond Drills is perpendicular;

- Replace worn or damaged diamond drills;

- Assess material density

|

| 71 |

Bell Mouthed Hole

Diamond Drills produces a bell-mouthed hole

|

- Excessive Diamond Drills wear at the tip; Inadequate support for material;

- Diamond Drills wobbling

|

- Hole diameter inconsistency;

- Compromised hole geometry

|

- Replace or sharpen diamond drill;

- Ensure material is adequately supported;

- Stabilize Diamond Drills to prevent wobble

|

| 72 |

Difficulty Maintaining Consistent Hole Depth

Difficulty in maintaining consistent hole depth

|

- Inconsistent feed rate;

- Fluctuating Diamond Drills pressure;

- Material compressibility

|

- Variable hole depth;

- Potential for incomplete drilling

|

- Stabilize feed rate; Apply consistent pressure;

- Account for material compressibility

|

| 73 |

Holes with Rough Interior Surface

Diamond Drills produces a hole with a rough interior surface

|

- Blunt diamond drill;

- High feed rate;

- Abrasive material

|

- Poor hole interior finish;

- Potential for additional processing

|

- Sharpen or replace diamond drill;

- Adjust feed rate;

- Use diamond drills suitable for abrasive materials

|

| 74 |

Material Burning

Material burns or smokes during drilling

|

- Excessive friction; Inadequate coolant;

- Too high drilling speed

|

- Potential thermal damage to material;

- Safety hazard

|

- Reduce drilling speed; Increase coolant flow;

- Monitor and adjust drilling parameters

|

| 75 |

Irregular Shape Holes

Diamond Drills produces a hole with an irregular shape

|

- Diamond Drills deflection;

- Material inhomogeneity;

- Inadequate clamping of material

|

- Compromised hole geometry;

- Reduced precision

|

- Minimize Diamond Drills deflection;

- Assess material uniformity;

- Ensure material is clamped securely

|

| 76 |

Excessive Wear on Drills Body

Excessive tool wear on the diamond drill’s non-cutting areas

|

- Contact with workpiece during retraction;

- Abrasive debris in the work area;

- Inadequate tool storage

|

- Reduced tool life;

- Potential for tool failure

|

- Avoid contact with workpiece during retraction;

- Keep work area clean; Store tools properly

|

| 77 |

hole with a conical entrance

Diamond Drills produces a hole with a conical entrance

|

- Diamond Drills not entering material straight;

- Inadequate material surface preparation;

- Diamond Drills tip wear

|

- Inaccurate hole entrance geometry;

- Potential for rework

|

- Ensure straight Diamond Drills entry;

- Prepare material surface properly;

- Inspect and maintain Diamond Drills tip

|

| 78 |

Drill Stuck Inside Chuck or Collet

Difficulty in Diamond Drills removal after drilling

|

- Material contraction or warping;

- Vacuum effect in the hole;

- Diamond Drill expansion due to heat

|

- Stuck diamond drill;

- Potential for tool or material damage

|

- Allow material and Diamond Drills to cool;

- Ensure proper hole ventilation;

- Apply release agents if necessary

|

| 79 |

Hole with a stepped profile

Diamond Drills produces a hole with a stepped profile

|

- Diamond Drills retraction and re-entry;

- Material hardness variation;

- Inconsistent feed rate

|

- Stepped hole profile;

- Compromised hole integrity

|

- Avoid unnecessary Diamond Drills retraction;

- Assess material for hardness variation;

- Stabilize feed rate

|

| 80 |

Shank Corrosion

Diamond Drills shank shows signs of corrosion or rust

|

- Exposure to corrosive substances;

- Inadequate tool maintenance;

- High humidity storage conditions

|

- Reduced tool life;

- Potential for tool failure

|

- Avoid exposure to corrosive substances;

- Maintain tools properly;

- Store in low humidity conditions

|

| 81 |

Chipping at Hole Exit

Diamond Drills produces a hole with a rough or chipped exit

|

- Sudden material exit support loss;

- High exit feed rate;

- Brittle material

|

- Poor hole exit quality;

- Potential for material damage

|

- Support material at exit point;

- Reduce feed rate at hole exit;

- Adjust drilling parameters for material

|

| 82 |

Diamond Drill Uneven Exposure

Diamond Drills shows uneven diamond exposure

|

- Uneven wear;

- Inconsistent diamond distribution;

- Material abrasiveness

|

- Inconsistent cutting performance;

- Reduced Diamond Drills life

|

- Ensure even Diamond Drills wear;

- Select diamond drills with consistent diamond distribution

- Adjust for material abrasiveness

|

| 83 |

Over Exposed Diamond Crystals

Signs: Diamond protrude from bond material within minimal support its bond matrix. Visible amount of diamond pullout

|

- Inadequate bond matrix hardness

- Excessive wear rate of the bond matrix

- Improper bond matrix composition for the material being drilled.

|

- Increased risk of diamond loss;

- Reduced diamond drill life and efficiency.

|

- Select a diamond drill with a bond matrix of appropriate hardness for the material

- Optimize drilling parameters to reduce wear rate of the bond matrix

- Ensure the bond matrix composition is suitable for the material and drilling conditions.

|

| 84 |

Excessive Premature Diamond Loss

Signs: Diamond section shows signs of high amount of lost diamond crystal from the bond matrix

|

- Excessive drilling pressure.

- Impact with very hard or abrasive materials.

- Inadequate bond hardness relative to the material being drilled.

|

- Reduced cutting efficiency;

- Increased wear and tear on the diamond drill.

|

- Adjust drilling pressure to appropriate levels.

- Assess and match the diamond drill specifications with the material hardness.

- Select a diamond drill with a bond hardness that is appropriate for the material.

|

| 85 |

Crushed Diamond Crystals

Signs: Diamond crystals in bond show signs of high amount of fracture

|

- Excessive drilling pressure

- Impact with very hard or abrasive materials

- Inadequate bond hardness relative to the material being drilled.

|

- Reduced cutting efficiency

- Increased wear and tear on the diamond drill

|

- Adjust drilling pressure to appropriate levels

- Assess and match the diamond drill specifications with the material hardness

- Select a diamond drill with a bond hardness that is appropriate for the material.

|

| 86 |

Diamond Crystal Premature Loss of Sharp Point

Signs: Diamond crystals premature glazing (loss of sharp point) and poor exposure from bond matrix

|

- Premature diamond wear

- Inappropriate drilling parameters for the material

- Insufficient diamond protrusion from the bond.

|

- Slower drilling process;

- Increased wear on the diamond drill and machinery.

|

- Monitor and adjust for diamond wear

- Tailor drilling parameters to the specific material

- Check and ensure adequate diamond protrusion for effective cutting

|

| 87 |

Diamond Drill Stops Drilling

Diamond Drills experiences sudden loss of cutting ability

|

- Diamond grit pull-out;

- Bond material failure;

- Impact or excessive load

|

- Immediate halt in drilling progress;

- Potential for Diamond Drills damage

|

- Inspect Diamond Drills for damage;

- Select diamond drills with appropriate bond material;

- Avoid excessive loads

|

| 88 |

Wider Hole on entrance & exit

Diamond Drills produces a hole with a double-diameter profile

|

- Diamond Drills size change during operation;

- Material layer hardness change; Diamond Drills slippage

|

- Hole dimension inconsistency;

- Compromised hole integrity

|

- Ensure consistent Diamond Drills size;

- Assess material layers for hardness

- Secure Diamond Drills properly

|

89

|

Diamond Drills Loss of Profile

Diamond Drills shows signs of abnormal flattening or rounding

|

- Excessive pressure;

- Soft bond material for given material;

- High temperature during drilling

|

- Reduced cutting efficiency;

- Premature Diamond Drills wear

|

- Adjust drilling pressure;

- Select bond material suited for the material;

- Manage drilling temperature

|

90

|

Excessive Drilling Noise

Diamond Drills produces excessive noise during retraction

|

- Material snagging on diamond drill;

- Inadequate retraction speed;

- Diamond Drills misalignment

|

- Unpleasant noise;

- Potential for Diamond Drills or material damage

|

- Ensure smooth Diamond Drills path;

- Adjust retraction speed;

- Align Diamond Drills properly

|

91

|

Diamond Drill Slipping

Diamond Drills experiences intermittent engagement with the material

|

- Diamond Drills bouncing;

- Inconsistent material surface;

- Worn Diamond Drills bearings or spindle

|

- Inconsistent drilling;

- Potential for hole defects

|

- Stabilize Diamond Drills engagement;

- Flatten material surface;

- Service or replace bearings or spindle

|

| 92 |

Tapered Hole

Diamond Drills produces a hole with a tapered exit

|

- Diamond Drills withdrawal angle;

- Inadequate support at hole exit;

- Material deformation

|

- Hole exit dimension inconsistency;

- Reduced hole quality

|

- Control Diamond Drills withdrawal angle;

- Support material at hole exit;

- Account for material deformation

|

93

|

Diamond Section Coming Off

Diamond Drills shows signs of solder failure or diamond section coming off

|

- Excessive heat;

- Mechanical shock;

- Improper Diamond Drills use

|

- Potential for segment detachment;

- Compromised drilling performance

|

- Manage heat generation;

- Avoid mechanical shocks;

- Use Diamond Drills as intended

|

| 94 |

Hole Waviness

Diamond Drills produces a hole with an irregular or wavy profile

|

- Diamond Drills vibration;

- Inconsistent feed rate;

- Material inhomogeneity

|

- Hole profile irregularity;

- Compromised hole quality

|

- Minimize Diamond Drills vibration;

- Stabilize feed rate;

- Assess material for consistency

|

|

94

|

Material Burring

Signs: Raised edges or small fragments of material at the hole entrance or exit

|

- Dull or damaged diamond drill edges.

- Excessive feed rate or pressure.

- Inadequate support for the material at the drilling point.

- Diamond drill vibration or instability.

- Material properties such as ductility or softness.

- Inadequate or improper use of coolant.

|

- Compromised hole quality;

- Potential for additional finishing work or material damage.

- Reduced quality of hole finish; Potential for increased post-processing work.

|

- Inspect and replace or sharpen diamond drills as necessary.

- Adjust feed rate and pressure to appropriate levels.

- Provide stable support for the material during drilling.

- Stabilize the drill setup to minimize vibration.

- Select diamond drills and drilling parameters suitable for the material’s properties.

- Optimize coolant flow and type to enhance cutting conditions.

|

| 95 |

Material Scratches

Sings: Visible scratches or grooves on the surface of the material around the drilled hole

|

- Foreign particles between the diamond drill and material.

- Diamond drill misalignment or wobbling.

- Rough handling or improper storage of the diamond drill causing edge damage.

|

- Aesthetic damage to the material;

- Potential for reduced structural integrity.

|

- Ensure a clean working environment and clean material surface.

- Check and correct diamond drill alignment.

- Handle and store diamond drills properly to prevent damage.

|

| 96 |

Material Smearing

Signs: Material residue adhering to the sides of the drilled hole

|

- Excessive heat generation during drilling.

- Inadequate or improper use of coolant.

- Soft or ductile material that tends to smear.

|

- Compromised hole quality;

- Potential for inaccurate hole dimensions and increased finishing work.

|

- Optimize drilling parameters to manage heat.

- Ensure proper coolant flow and application.

- Select diamond drills and drilling parameters suitable for the material’s properties.

|

| 97 |

Material Pull Out

Sings: Material fragments or chunks dislodged from the hole walls

|

- Abrupt or excessive pressure at the start of drilling.

- Diamond drill not properly aligned or secured.

- Surface irregularities or material brittleness.

|

- Compromised surface finish and structural integrity of the hole entrance;

- Potential for material waste or rework.

|

- Gradually apply pressure and start drilling at a reduced speed.

- Ensure diamond drill alignment and secure clamping.

- Inspect material surface and prepare adequately before drilling.

|

| 98 |

Top Sided Chipping

Sings: Uneven or rough edges around the hole entrance

|

- Abrupt or excessive pressure at the start of drilling.

- Diamond drill not properly aligned or secured.

- Surface irregularities or material brittleness.

- Diamond drill vibration or instability.

- Inadequate material support at the drilling point.

- Incorrect or worn diamond drill for the material type.

|

- Compromised surface finish and structural integrity of the hole entrance;

- Potential for material waste or rework.

- Reduced quality of hole entrance;

- Potential for additional processing or finishing work.

|

- Gradually apply pressure and start drilling at a reduced speed.

- Ensure diamond drill alignment and secure clamping.

- Inspect material surface and prepare adequately before drilling.

- Stabilize the drill setup to minimize vibration.

- Provide stable support for the material at the drilling point.

- Select and use the correct, sharp diamond drill for the material.

|

| 99 |

Bottom Side Chipping

Sings: Chipping or flaking on the exit side of the drilled hole

|

- Sudden release of pressure as the diamond drill exits the material.

- Lack of supporting material or backing plate at the exit point.

- Excessive feed rate or pressure as the diamond drill completes the hole.

- Diamond drill vibration or wobbling.

- Material brittleness or susceptibility to chipping.

- Inadequate or improper use of coolant.

|

- Compromised finish and integrity of the hole exit;

- Potential for material waste or rework.

- Reduced quality of hole finish;

- Potential for additional processing or finishing work.

|

- Gradually reduce pressure and feed rate before the diamond drill exits the material.

- Use a backing plate or support material to provide stability at the exit point.

- Monitor and adjust drilling parameters as the diamond drill nears the exit side.

- Stabilize the drill setup to minimize vibration.

- Select diamond drills and drilling parameters suitable for the material’s properties.

- Optimize coolant flow and type to enhance cutting conditions.

|

| 100 |

Excessive Backside Chipping

Chipping or flaking on the exit side of the drilled hole

|

- Sudden release of pressure as the diamond drill exits the material.

- Lack of supporting material or backing plate at the exit point.

- Excessive feed rate or pressure as the diamond drill completes the hole.

|

- Compromised finish and integrity of the hole exit;

- Potential for material waste or rework.

|

- Gradually reduce pressure and feed rate before the diamond drill exits the material.

- Use a backing plate or support material to provide stability at the exit point.

- Monitor and adjust drilling parameters as the diamond drill nears the exit side.

|

| 101 |

Consistently Spaced Chipping

Signs: Chipping or flaking observed predominantly on one side of the drilled hole

|

- Regular imperfections or inclusions in the material.

- Cyclic loading or vibration during drilling.

- Periodic engagement of damaged or irregular diamond drill segments.

|

- Compromised hole integrity and finish;

- Potential for reduced structural strength of the hole.

|

- Assess material quality and plan drilling to avoid imperfections.

- Stabilize the drilling process to minimize vibration.

- Inspect the diamond drill for damage and ensure uniform segment distribution.

|

| 102 |

One Sided Chipping

Sings: Chipping or flaking observed predominantly on one side of the drilled hole

|

- Diamond drill misalignment or tilt.

- Uneven material support or surface.

- Inconsistent pressure or side loading during drilling.

|

- Compromised hole integrity and aesthetics;

- Potential for material waste or rework.

|

- Ensure proper diamond drill alignment and machine calibration.

- Provide even and stable support for the material.

- Apply consistent and straight drilling pressure.

|

| 103 |

Diamond Drill Gummed Up

|

- Accumulation of cutting debris in the diamond segments.

- Inadequate or improper use of coolant.

- Drilling soft, gummy materials that clog the diamond drill.

|

- Slower drilling process;

- Increased effort and time required for drilling.

|

- Clean the diamond drill regularly to remove debris.

- Ensure proper coolant flow and application.

- Use diamond drills designed for specific materials to reduce clogging.

|

| 104 |

Nick of Diamond Section Chipped Out

visible nick or missing segment in the diamond section |

- Impact with hard inclusions or foreign objects.

- Excessive force or pressure.

- Diamond drill fatigue or overuse.

|

- Reduced cutting efficiency;

- Potential for uneven drilling or further diamond drill damage.

|

- Inspect material for hardness and inclusions before drilling.

- Apply appropriate force and pressure.

- Regularly inspect diamond drills for wear and replace as necessary.

|

| 105 |

Crack in Diamond Section

Sings: Visible cracks in the diamond section of the diamond drill

|

- Mechanical stress or impact.

- Thermal shock due to rapid temperature changes.

- Material defects or inclusions in the diamond section.

|

- Reduced structural integrity of the diamond drill;

- Potential for diamond section failure.

|

- Avoid excessive force or pressure during drilling.

- Manage temperature changes and ensure proper coolant use.

- Inspect diamond drills for material quality and avoid using bits with visible defects

|

| 106 |

Drill Tube Fractured From Collet

Fracture or separation at the brazed joint between the drill tube and brass collet

|

- Inadequate brazing process or material.

- Excessive mechanical stress or torque.

- Thermal stress due to extreme temperature changes.

|

- Loss of drill stability;

- Immediate halt in drilling;

- Potential for damage to the workpiece or drilling equipment.

|

- Ensure high-quality brazing with appropriate materials and techniques.

- Apply torque within the specified limits.

- Avoid rapid temperature changes during drilling operations.

|

| 107 |

Difficulty in screwing or unscrewing Drill

Difficulty in screwing or unscrewing the diamond drill from the machinery

|

- Deformation or damage to the collet thread

- Material build-up or galling in the threads

- Cross-threading or misalignment during attachment.

|

- Increased setup time;

- Potential for thread damage or inability to properly secure the drill tube.

|

- Inspect and repair any damaged threads

- Clean and maintain the threads to prevent material build-up.

- Ensure proper alignment and careful handling when attaching or detaching the drill tube.

|

Brian Farberov

Brian Farberov