-

0 items in quote

No products in the Quote Basket.

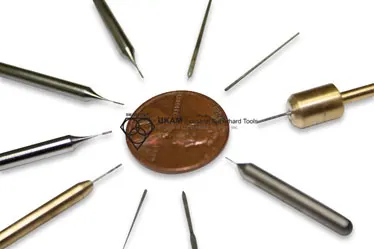

SMART CUT 025DTE

MINATURE TWISTED ELECTROPLATED DIAMOND SOLID DRILLS

SMART CUT® 025DTE Miniature Twisted Electroplated Diamond Solid Drills are high-performance precision tools designed for micro-drilling and reaming applications in a wide variety of materials. These drills are especially well-suited for drilling pearls, where material sensitivity and surface integrity are critical. Their twisted flute design promotes faster material removal and improved chip evacuation, enabling significantly higher drilling speeds compared to standard diamond drills. This advanced geometry also contributes to smoother hole finishes and reduced risk of cracking or chipping, making them ideal for delicate materials such as natural and cultured pearls, beads, ceramics, glass, composites, shells, and even certain metals and hardened materials in niche applications.

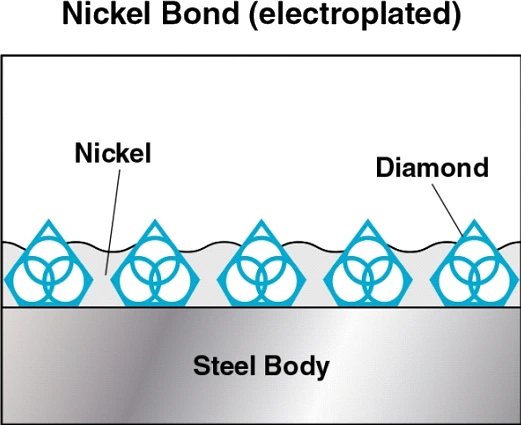

The electroplated diamond layer is applied directly onto a solid steel shank, exposing sharp diamond particles that enhance cutting efficiency and tool longevity.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

These drills are known for their accuracy, stability, and ability to maintain consistent performance across extended use, even in high-precision applications such as jewelry making, watch manufacturing, dental lab work, and scientific sample preparation. Available from stock in diameters ranging from 1.00 mm to 2.00 mm in 0.10 mm increments, SMART CUT® 025DTE twisted diamond drills provide an ideal balance of speed, precision, and surface quality.

These drills are commonly used in conjunction with other diamond tooling, such as flat-bottom cylinder diamond solid drills, especially when performing step drilling or enlarging pre-drilled holes. In many cases, users begin with a flat-bottom drill to create the initial hole and follow up with a twisted drill for reaming or final sizing, taking advantage of the high feed rate and improved finish these drills offer.

Custom specifications are available upon request, including non-standard diameters, extended lengths, specific diamond grit sizes, and alternative shank configurations. This allows end users to tailor the tool precisely to their application and material requirements.

SPECIFICATIONS

Bond Type: Nickel Bond (Plated)

Edge Type: Hollow tube

Diamond Grit Size: Medium Fine

Package Contains 3 pcs

Tube Shank Diameter is slightly smaller than diameter of diamond drill tip Overall Length:

Recommended Operating Speed: 9,000-12,000

Maximum Operating Speed: 30,000

Diamond height: 5mm (.20″)

Tolerance on Outside Diameter: +/- 0.05mm (.002″)

Always drill with a coolant and use submerged-pressure sensitive feed.

Recommended Coolant: water, for ultra hard materials best results will be achieved with mineral oil or synthetic water soluble coolant.

FREQUENTLY ASKED QUESTIONS

Twisted diamond drills are specialized tools designed for drilling pearls and enlarging/reaming holes in a wide range of materials. They offer faster drilling speeds compared to most other types of diamond drills and are particularly popular for drilling pearls.

Our Twisted Diamond Drills are available in sizes ranging from 1mm to 2mm in diameter, with 0.1mm increments. These sizes are ideal for various applications, including pearl drilling and hole enlargement in different materials.

Yes, we offer custom specifications upon request. If you have specific requirements for your drilling needs, please contact us, and we’ll be happy to assist you.

The item number for the 0.75mm Twisted Diamond Drill is 6ED75

Electroplated diamond drills are most effective on softer materials, typically ranging from 6 to 1 on the Mohs scale of hardness. They can also work on harder materials, up to 9 on the Mohs scale, although the drill life will be significantly reduced in such cases. These drills are ideal for softer, ductile, and gummable materials.

Electroplated Diamond Drills are not recommended for very abrasive materials like sandstone and concrete, as they will wear out quickly on these surfaces. These drills are best suited for less abrasive materials.

Electroplated diamond drills find applications in various industries, including glass, composite, photonics, optics, and hobby/craft applications. They are often used by beginners and hobbyists but are not recommended for professional or serious industrial use.

In a few applications, Electroplated Diamond Drills can be used without coolant, but it is recommended to use a coolant for best results. They are more forgiving to operator/user drilling mistakes compared to other types of diamond drills/bits.

Electroplated Diamond Drills can be used with various equipment, including high-speed drill presses, mounted handpiece drills (such as Foredom & Dremel), and high-speed air spindles.

All drills are packaged in clear jewel boxes to ensure they are secure and do not move during transit. Additionally, micro drills have special inserts for added security.

Electroplated diamond tools have a single layer of diamonds held by a durable nickel alloy. This construction allows diamond particles to protrude from the bond matrix, providing a faster cutting action with minimal heat generation. Unlike sintered or resin bond diamond tools, the diamonds in electroplated tools stay on the surface of the tool, allowing for fast material removal.

Certainly, please refer to the “SPECIFICATIONS TAB” section in the product description for detailed specifications, including bond type, diamond grit size, recommended operating speed, and more.

The performance of a diamond drill/bit can be evaluated based on various criteria, including diamond drill life, material hardness, drill speed and power, use of coolant, drilling depth, and more. Please refer to the “USAGE RECOMMENDATIONS (TAB)” section for detailed information on evaluating and comparing diamond drills.

Electroplated Diamond Drills are ideal for softer materials due to their high diamond concentration and maximum diamond particle exposure. They offer a faster drilling action with minimum heat generation, providing a smooth surface finish and less thermal damage to the part being drilled.

Electroplated Diamond Drills are generally less expensive than metal bond and hybrid bond drills. They are a cost-effective choice for applications on softer, non-abrasive materials. However, they have a shorter lifespan compared to these other types of drills, making them more suitable for smaller and occasional use.

For best results and longer drill life, it is recommended to use Electroplated Diamond Drills when drilling less than 1/4″ (6.35mm) into the material. Drilling thicker materials, especially harder ones like granite, may result in a decline in performance and drill life.

Yes, Electroplated Diamond Drills are suitable for precision work, and they can provide high-quality results with minimal damage to the material being drilled. They are often used in applications that require precision and smooth surface finish.

For most applications, it is recommended to use a coolant when using Electroplated Diamond Drills. Water is a suitable coolant for many materials, but for ultra-hard materials, the best results can be achieved with mineral oil or synthetic water-soluble coolant. Proper coolant usage helps extend drill life and improve drilling performance.

Electroplated Diamond Drills are primarily designed for small and occasional use. While they can serve the needs of beginners and hobbyists, they are not typically recommended for professional or serious industrial applications. For such purposes, other types of diamond drills such as sintered (metal bond) may be more appropriate

When using any diamond drill, including Electroplated Diamond Drills, it’s essential to follow safety guidelines. Ensure you wear appropriate safety gear, work in a well-ventilated area, and take precautions to prevent accidents during drilling. Always refer to the manufacturer’s safety recommendations and guidelines.

Select the drill size that matches the diameter of the hole you need to create or enlarge. Be sure to consider the material you’re working with and whether it falls within the recommended hardness range for Electroplated Diamond Drills.

The lifespan of Electroplated Diamond Drills can vary based on several factors, including the material being drilled, the drill’s size, the operator’s experience, and the use of coolant. Typically, they are considered consumable tools with a limited lifespan, and their longevity can range from several holes to dozens of holes, depending on the mentioned variables.

Electroplated Diamond Drills are not typically designed for re-sharpening or reconditioning. Once the diamonds wear out or become dull, the drill’s performance will decline, and it is usually more cost-effective to replace the drill with a new one. They can be dressed if needed

Yes, Electroplated Diamond Drills are suitable for jewelry-making and are often used for drilling beads, pearls, clock faces, and other intricate jewelry components. They are valued for their precision and ability to create clean, smooth holes.

When using Electroplated Diamond Drills with high-speed equipment, always ensure that the equipment is in good working condition and properly secured. Follow safety guidelines for high-speed drills and wear appropriate protective gear, including safety glasses and gloves, to prevent accidents.

Electroplated Diamond Drills are forgiving in the sense that they tend to be less prone to chipping or breaking when used incorrectly or with improper feed rates. This characteristic makes them a good choice for beginners and novice users who may not have extensive experience with diamond drilling.

Yes, we offer quantity discounts for bulk purchases of Electroplated Diamond Drills. Please contact our sales team or check our website for more information on available discounts for larger orders.

Yes, Electroplated Diamond Drills can be used with handheld rotary tools like Dremel or Foredom. These tools provide precision and control, making them suitable for intricate and detailed drilling work.

In glass and composite industries, Electroplated Diamond Drills offer excellent performance due to their ability to maintain a smooth surface finish with minimal thermal damage. They are also known for their precision, making them ideal for applications where accuracy and quality are crucial.

When using coolants with Electroplated Diamond Drills, it’s important to consider proper disposal methods for coolant waste to minimize environmental impact. Follow local regulations and guidelines for the safe disposal of coolants and ensure they are not released into the environment.

Yes, Electroplated Diamond Drills can be used on curved surfaces and irregular shapes. Their flexibility and precision make them versatile tools for drilling holes in various shapes and profiles.

Yes, you can order replacement drills or individual drill sizes separately based on your needs. Our product listings include item numbers for each size, allowing you to select and purchase the specific drill sizes you require.

When working with harder materials, it’s essential to use proper coolant, maintain the recommended drilling speed, and avoid excessive pressure. These precautions can help extend the lifespan of Electroplated Diamond Drills when drilling harder substances.

The recommended operating speed for Electroplated Diamond Drills typically falls within the range of 9,000 to 12,000 RPM (revolutions per minute). Operating within this range helps ensure optimal performance and drill longevity.

Yes, safety data sheets (SDS) or material safety information for our products is available and can be obtained by contacting our customer support team.

Yes, Electroplated Diamond Drills are suitable for delicate and brittle materials. Their precise drilling action and minimal heat generation make them a good choice for materials that may crack or shatter when subjected to excessive force or heat.

Yes, Electroplated Diamond Drills are commonly used for drilling holes in ceramics and porcelain. Their ability to provide a clean and precise hole makes them valuable tools in pottery and ceramics applications.

To maintain the condition of your Electroplated Diamond Drills, ensure they are cleaned after each use to remove debris and residue. Store them in a dry and secure location to prevent damage. Regularly inspect the drills for wear and replace them when necessary.

Yes, Electroplated Diamond Drills are suitable for precision drilling in electronics and microelectronics applications. Their ability to create clean, precise holes makes them valuable tools for these industries.

You should consider replacing an Electroplated Diamond Drill when you notice a significant decrease in drilling efficiency, such as slower drilling speeds, increased heat generation, or a decline in the quality of the holes produced. It’s essential to replace the drill before it becomes completely ineffective.

In general, Electroplated Diamond Drills are compatible with a wide range of materials. However, for specialized applications or unique materials, it’s advisable to consult with our technical support team to ensure compatibility and optimal performance.

Yes, Electroplated Diamond Drills are commonly used for creating holes in gemstones and precious stones due to their precision and ability to produce clean and accurate holes without damaging the material.

When drilling hard materials like ceramics or glass, it’s crucial to use proper coolant, maintain the recommended operating speed, and avoid excessive pressure. Additionally, periodically check the drill for wear, and replace it as needed to maintain optimal performance.

Yes, Electroplated Diamond Drills are suitable for creating holes in ceramic tiles, making them valuable tools for various home improvement and DIY projects that involve tiling.

You can contact our customer support and sales teams by visiting our website and using the provided contact information, including phone numbers and email addresses. We’re here to assist you with any additional questions or requests you may have.

It’s advisable to use a steady and controlled drilling technique when using Electroplated Diamond Drills. Apply even pressure and avoid excessive force, which can lead to premature wear or damage to the drill. Additionally, make sure the workpiece is securely clamped or held in place to prevent movement during drilling.

Electroplated Diamond Drills are not typically recommended for drilling hardened steel or metal alloys, as these materials are generally too hard for effective drilling with electroplated tools. Consider using specialized diamond tools designed for drilling hard metals.

To ensure the longevity of Electroplated Diamond Drills, store them in a dry and secure location, away from moisture and contaminants. It’s a good practice to keep them in their original packaging or a dedicated storage container to prevent damage or contamination.

While Electroplated Diamond Drills are primarily designed for drilling holes, they can be used for some shaping or contouring applications, especially when precision is required. However, for extensive shaping tasks, other diamond tools may be more suitable.

When using Electroplated Diamond Drills with high-speed equipment, be sure to wear appropriate personal protective equipment (PPE), including safety glasses or goggles and gloves, to protect against potential hazards. Follow safety guidelines provided by the equipment manufacturer.

Regularly clean Electroplated Diamond Drills after each use to remove debris and residue. Inspect the drills for any signs of wear, damage, or diamond depletion. Replace worn or damaged drills promptly to maintain optimal performance.

Yes, Electroplated Diamond Drills are suitable for creating holes in fiberglass and composite materials. Their precision and ability to produce clean holes make them valuable tools for working with these materials.

Our technical support team can provide recommendations on selecting the appropriate coolant for your specific application. The choice of coolant may depend on the material being drilled and other factors, and we can assist you in making the right selection.

Yes, we offer custom specifications for Electroplated Diamond Drills upon request. If you have unique drilling needs or specific requirements, please contact our sales team to discuss customization options.

When drilling deep holes with Electroplated Diamond Drills, it’s important to maintain a stable drilling setup and ensure proper coolant flow to dissipate heat. Monitor the drill’s condition throughout the drilling process and replace it if wear becomes excessive.

Yes, Electroplated Diamond Drills are suitable for art and sculpture projects involving stone or marble. Their precision and ability to create intricate patterns or shapes make them valuable tools for artists and sculptors.

The key advantages of using Electroplated Diamond Drills for drilling jewelry components include their ability to create clean and precise holes in various materials such as gemstones, pearls, and metals. They are ideal for creating intricate designs and maintaining the integrity of valuable jewelry materials.

Electroplated Diamond Drills can be used with CNC machines for automated drilling tasks, providing precision and repeatability in drilling operations. However, compatibility with specific CNC machines may vary, so it’s advisable to confirm compatibility with your equipment.

INDUSTRIES USED IN

Composites

Gem Stones

Sapphire

Silicon

Glass Materials

Lapidary

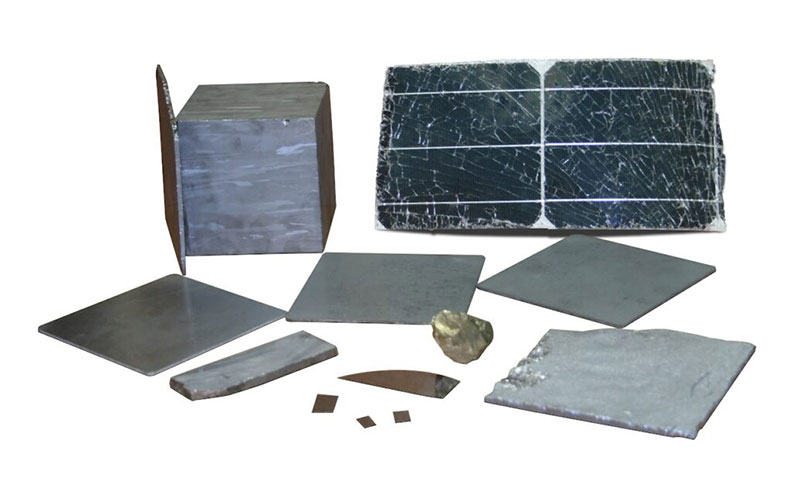

Stone

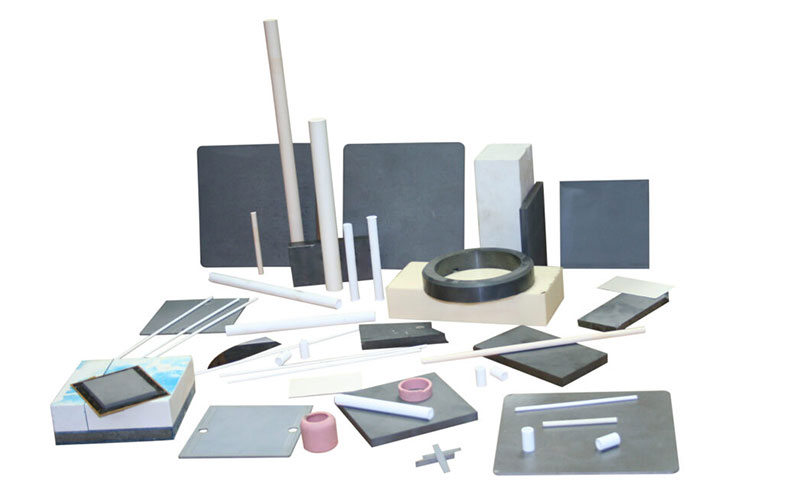

Advanced Ceramics

Photonics

ACCESSORIES

Showing 1 – -1 of 16 results Showing all 16 results Showing the single result No results found

Sort by Name A – Z

Filters Sort results

Reset Apply

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $26.72 | Max: Min: 1 Step: 1 | |||

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $22.46 | Max: Min: 1 Step: 1 | |||

1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 | |||

$154.87 | Max: Min: 1 Step: 1 | ||||

$154.87 | Max: Min: 1 Step: 1 | ||||

$235.00 | Max: Min: 1 Step: 1 |

USAGE RECOMMENDATION

02

Jun

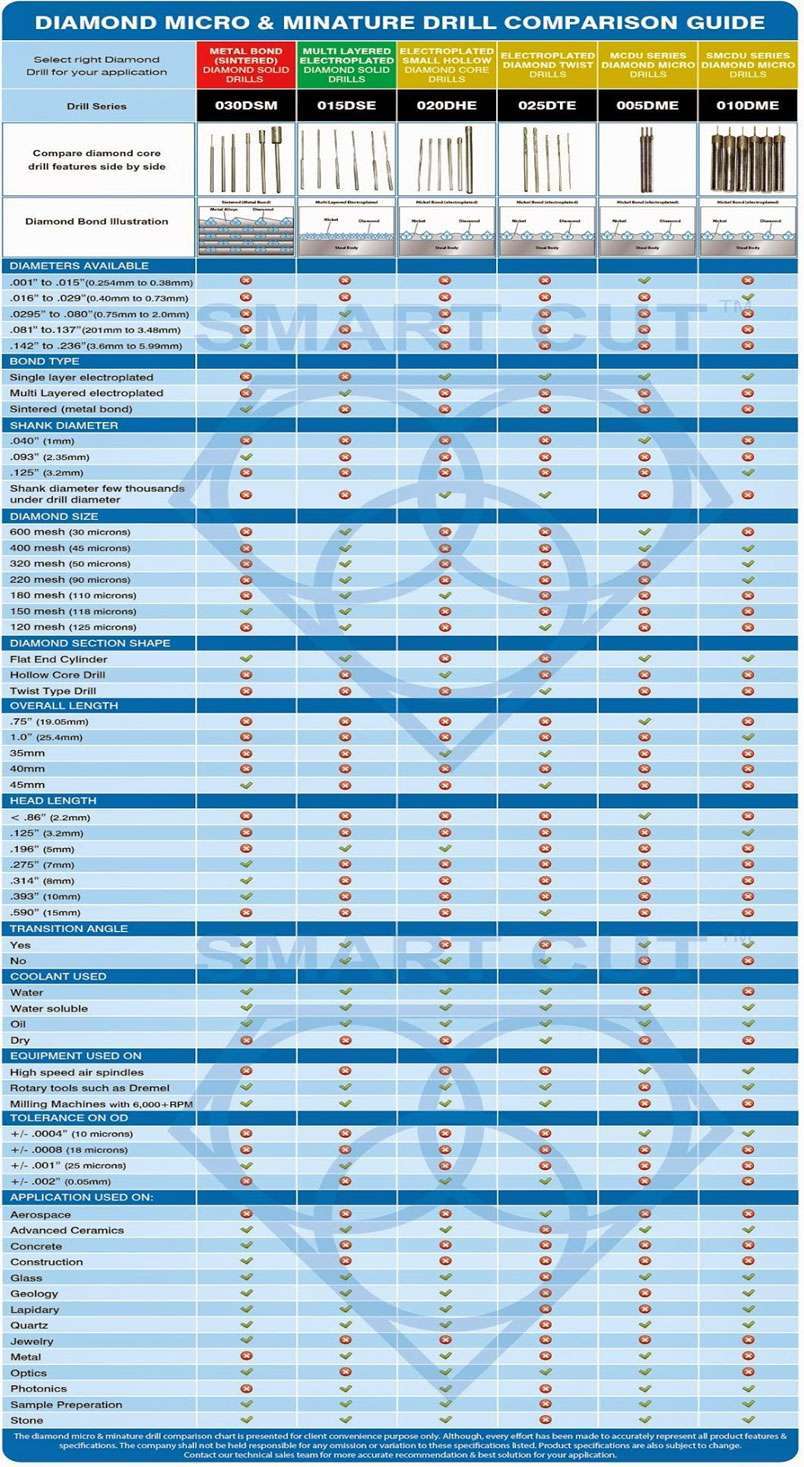

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will…

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided…

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind…

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,…

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency….

02

Jun

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read…

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide…

Diamond Solid Thin Drills SMART CUT™ technology vs. Conventional Diamond Solid Drills

Not all electroplated diamond solid are created equal. Contrary to popular belief, diamond drills are not a commodity. Large differences in drill life and overall performance exist from manufacturer to manufacturer. If the diamonds fall into you hole after drilling just a few holes. The inexpensive diamond drill is no longer a bargain, no matter how much you paid for it. Find out more

Comparing & Evaluating Diamond Solid Drills 0.75mm to 2.5mm

The performance of a diamond drill/bit for just about any application / material can be evaluated under various criteria. The importance of any criteria depends on your requirements. Diamond Drill Life – The life of a diamond drill/bit is determined by the number of holes or it can drill (parts machined). It is fairly difficult to estimate the life of diamond drill. Diamond drill life is affected by various factors such as the application, bond type, drill manufacturer, and experience of user in properly using the drill. Diamond drill life will be discussed in further detail in this guide below. The following considerations play a major role in diamond drill life:

- Hardness and abrasiveness of the material being drilled

- Speed and power of drill

- Amount of pressure used (feed rate)

- Proper use of coolant (type of coolant, coolant force, & direction)

- Drilling Depth

- Material Holding Method

- Operator experience (Understanding Proper Diamond Drill Usage Principals and Adjusting them as need to better fit their particular application & objectives)

- Overall age and condition of drilling equipment (precision, accuracy, & repeatability of drilling equipment used)

- Quality, hardness, sharpness, and mesh size of the diamonds

- Hardness of the bond compared to the material being drilled

- Experience and technology of manufacturer in keeping diamonds in the bond

Equipment Used on:

- High Speed Drill Press

- Mounted Hand Piece Drill (such as: Foredom & Dremel),

- High Speed Air Spindles

Features

- Twisted Flute Design

- Electroplated Diamond Bond

- Solid Steel Shank Construction

- Diameters from 1.00 mm to 2.00 mm

- 0.10 mm Increment Availability

- Fine Grit Diamond Options

- High Diamond Exposure

- Micro-Precision Manufacturing

- Compatible with Rotary and High-Speed Equipment

- Custom Specifications Available

Advantages

- Faster Drilling Speeds

- Ideal for Pearls and Delicate Materials

- Excellent Hole Finish

- Superior Diamond Exposure

- Precision and Accuracy

- Versatile Application Range

- Available in Fine Increments

- Compatible with Other Tools

- Custom Options Available

- Consistent Performance

SMART CUT® 025DTE

Sold in Package of 4 pcs

Showing 1 – -1 of 10 results Showing all 10 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Item No. | Outside Diameter | Maximum Drill Depth | Price(package of 4 pcs) | Quantity | Add to Cart |

|---|---|---|---|---|---|

1.0 mm (.040") | 1.18" (30mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.1mm (.043") | 1.18" (30mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.2mm (.047") | 1.18" (30mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.3mm (.051") | 1.18" (30mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.4mm (.055") | 1.18" (30mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.5 mm (.059") | 1.18" (30mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.6mm (.0629") | 1.37" (35mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.7 mm (.069") | 1.37" (35mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.9mm (.0748") | 1.37" (35mm) | $25.99 ea | Max: Min: 1 Step: 1 | ||

1.8mm (.0708") | 1.37" (35mm) | $25.99 ea | Max: Min: 1 Step: 1 |

6ED75, 6ED10, 6ED11, 6ED12, 6ED13, 6ED14, 6ED15, 6ED16, 6ED17, 6ED19, 6ED 18,

Quantity Discounts are Available

RECOMMENDED APPLICATIONS

For Electroplated Diamond Drills

Electroplated diamond drills usually have a single layer of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster drilling action with minimum heat generation. Electroplated Diamond Drills provide excellent performance on softer materials ranging from 6 to 1 on mohs scale of hardness. While electroplated diamond drills, specifically manufactured by UKAM Industrial, will still work on harder materials (up to 9 on mohs scale). Diamond drill life will be (very short) significantly reduced. Diamonds stay on the surface of the drill allowing for fast material removal. Perfect for softer, more ductile, and gummable materials.

Not recommended for drilling very abrasive materials such as sandstone and concrete (they will wear out on these materials almost immediately). Electroplated Diamond Drills last less than metal bond, hybrid bond drills and are the least expensive diamond drills available. They provide very smooth surface finish quality & less thermal damage to the part being drilled.

Electroplated diamond drills are frequently used in glass and composite industries (as well as some photonics / optics) applications. Electroplated Diamond Drills are designed for small & occasional use. They are widely used by beginning diamond drill users (novices) in numerous hobby/craft applications. Such as drilling beads, clock faces, and etc. (not recommended for professional or serious industrial use).

They are also usually more forgiving to operator/user drilling mistakes than most other types of diamond drills/bits. Electroplated core drills are just about the only type of diamond drill that may be used dry (without coolant) in a few applications if needed. Best performance and results will be achieved when drilling less than 1/4" (6.35mm) into material. Performance/Life in many harder materials (granite as an example) will decline when drilling thicker materials.

SPECIAL PACKAGING FOR ALL DRILLS

All drills are packaged in clear jewel box shown on right.

Micro Drills have special inserts not shown here to make sure it is secure and does not move in transit.

Manufactured Using The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Related Products

SMART CUT® 030DSM

METAL BOND (SINTERED) DIAMOND SOLID DRILLS

SMART CUT 030DSM, Metal Bond (Sintered) Diamond Solid Drills have hundreds of layers of diamond impregnated inside the metal matrix. Will last significantly longer than electroplated diamond solid drills. Recommended for drilling Ultra Hard Materials (harder than 8 on mohes scale or 60 on Rockwell Scale. Available in stock from 0.8mm to 6mm diameter. Sintered (Metal Bond) diamond solid miniature/thin drills – have hundreds of layers of diamond impregnated inside metal matrix. These miniature drills will last significantly longer than electroplated diamond solid drills. Recommended for drilling Ultra Hard Materials (harder than 8 on mohes scale or 60 on Rockwell Scale and clients that need very long life span. Varying with application and material, an average electroplated diamond sold drill drill will last you 10 to 15 holes. Metal Bond (Sintered) Diamond Solid Drill may last as much as 120+ holes (when used properly).SMART CUT® 020DHE

MINATURE ELECTROPLATED DIAMOND HOLLO CORE DRILLS

SMART CUT® 020DHE Electroplated miniature hollow core drills are precision-engineered tools designed for drilling small, holes in a wide range of materials. These drills consist of a steel tube with a diamond coating applied to the tip, ensuring superior cutting ability even in the hardest and most brittle materials. Available from stock in diameters ranging from 1 mm to 3.5 mm OD. SMART CUT® 020DHE hollow core plays an important role in enhancing stability, particularly in deep drilling applications. This feature allows for precise control, ensuring the drill remains aligned throughout the process. It also minimizes deflection and bending, common issues when using solid drills for small-diameter, deep holes. As a result, users can achieve more accurate and clean-cut drilling with reduced risks of damage to both the tool and the material.SMART CUT® 015DSE

SMART CUT Series 015DSE Multi Layered Electroplated solid drills are flat cylinder shape with transition angle. These miniature diamond drills have high diamond concentration and give a smother, faster drilling action with minimum heat generation. The multiple layers of diamond coating which provides best diamond adhesion in the bond matrix. This provides longer life span, compared to standard and comparable electroplated miniature drills. Higher level of consistency and better surface finish. Most popular type of diamond drills for drilling small holes for jewelry (stone, glass, & many other materials). Multiple layers of diamond provide longer drilling life, faster & freer drilling. Available from stock from 0.75mm to 2.5mm

Recently Viewed Products

ARE YOU USING RIGHT LAPIDARY BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT LAPIDARY BLADES?

Knowledge Center

02

Jun

Select Right Diamond Drill for your Application

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will...

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind...

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,...

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency....

02

Jun

Micro Drilling Guide

Share this Article with Friend or Colleague

In order for you to get the most out of your diamond micro drill or carbide / high speed steel micro drill, we strongly urge you to read...

02

Jun

Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

Share this Article with Friend or Colleague

There are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the...

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

https://ukam.com/wp-content/uploads/2024/07/diamond-drill-troublehsooting-guide.mp4

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide...

09

Sep

Understanding & Calculating Return on Investment for Diamond Core Drills & Other Tools

The term "ROI" (Return On Investment) is widely used across industries, often interpreted differently depending on the context. However, few truly understand what ROI represents and its specific implications, particularly in the context of diamond...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

19

Sep

Why Use Diamond Drills?

Diamond, known as the hardest material on Earth, enables diamond drills and tools to grind away material at a micro (nano) scale. This extreme hardness allows diamond tools to effectively work on materials with a...