Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

CONTROLLED AUTOMATED REMOVAL OF MATERIAL TO YOUR DESIRED PARAMETERS

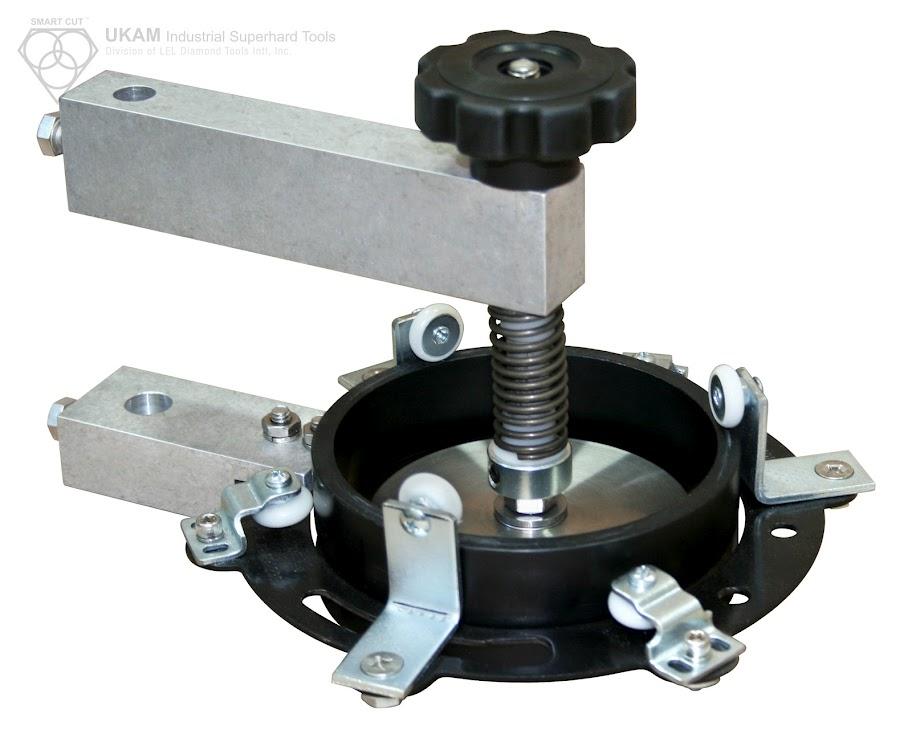

SMART CUT® Simple Precision Grinding/Polishing Head is a cutting-edge solution designed for precision grinding and polishing, offering full control over material removal while maintaining consistency in flatness and pressure. With this innovative tool, operators can easily adjust the grinding/polishing pressure and specify the exact amount of material to be removed, ensuring tailored results for each application. Once set, the head will automatically apply the pre-determined pressure and stop once the desired amount of material has been removed, allowing for seamless, hands-off operation.

This versatile tool is especially effective for high-precision cross-sectioning and sample preparation, making it an invaluable asset for industries focused on failure analysis, yield analysis, quality control, research and development, and materials science. The SMART CUT® Simple Precision Grinding/Polishing Head ensures uniform material removal, delivering consistent results even for the most delicate and hard-to-handle materials.

How It Works:

INDUSTRIES USED IN:

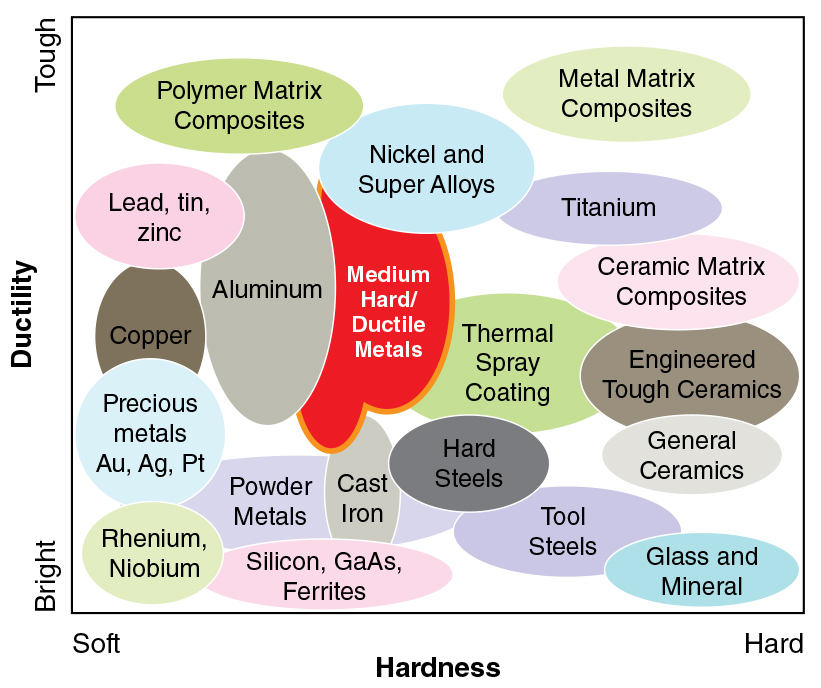

Ferrous & Non-Ferrous Metals:

The SMART CUT® Simple Precision Grinding/Polishing Head is capable of handling a wide variety of materials, including metals, ceramics, composites, advanced ceramics, semiconductors, and other hard materials. It’s perfect for use in applications such as failure analysis, yield testing, and research and development.

Setting the pressure and material removal amount is simple. You can use a thickness gauge or caliper to measure the desired material removal, then adjust the stop to the appropriate position. The operator then sets the pressure using the machine’s control panel, and the head will automatically apply that pressure during operation.

Yes, the SMART CUT® Simple Precision Grinding/Polishing Head is compatible with both 8″ and 12″ machines, offering flexibility for a variety of setups and applications.

The maximum material thickness depends on the material being processed, but the grinding/polishing head can handle substantial material removal with precision. It is designed to deliver controlled, uniform results regardless of the material thickness.

Once the operator has set the desired material removal and pressure parameters, the SMART CUT® head will automatically stop once the pre-set material has been removed. This feature ensures accuracy and eliminates the need for constant monitoring during the process.

While the SMART CUT® Simple Precision Grinding/Polishing Head is designed for high-precision applications, it can also handle moderate-to-high throughput environments where consistent and repeatable results are essential. However, for extreme production runs, additional automation or equipment may be required.

This tool is ideal for precision grinding and polishing, making it beneficial in various applications such as failure analysis, yield analysis, quality control, research and development, metallography, and sample preparation. It is commonly used in industries such as electronics, materials science, and semiconductors.

The SMART CUT® Simple Precision Grinding/Polishing Head stands out for its precise, automated material removal, adjustable pressure control, and ability to handle a wide range of materials. Its automatic stop feature ensures that the process stops once the set parameters have been met, reducing the need for operator intervention.

The head is designed for ease of maintenance, with simple cleaning procedures and minimal wear parts. Regular checks and calibrations are recommended to ensure consistent performance. Refer to the operating manual for specific maintenance and troubleshooting instructions.

Yes, the SMART CUT® head is versatile and can be used for both grinding and polishing applications. This flexibility makes it suitable for various stages of material processing, ensuring high-quality, finished results.

The optimal operating environment is a clean, well-ventilated space with minimal vibrations. Proper setup and calibration are essential to achieve the best results. It’s important to ensure that the machine it is connected to is compatible and operating within the manufacturer’s specified parameters.

The material removal can be adjusted based on the sample size using a thickness gauge or caliper. Once the desired material removal amount is determined, the stop is adjusted accordingly to ensure the tool grinds or polishes to the correct depth.

Yes, the SMART CUT® Simple Precision Grinding/Polishing Head is versatile and can be used for both small and large sample sizes. It is equipped with adjustable settings to ensure accurate and controlled material removal regardless of the sample size, making it ideal for both high-precision research and large-scale production environments.

Absolutely. The SMART CUT® head is specifically designed for precision cross-sectioning, providing consistent results in applications such as failure analysis, quality control, and research & development. Its precise material removal capabilities ensure uniformity and accuracy during cross-sectioning of delicate and hard-to-handle materials.

The SMART CUT® head offers highly precise material removal, with controllable pressure and pre-set material thickness settings. The precision of the tool makes it perfect for applications that require extremely tight tolerances, such as microelectronics, advanced ceramics, and materials testing. The automated stop feature ensures that the exact material removal is achieved, reducing operator error.

Yes, the SMART CUT® Simple Precision Grinding/Polishing Head can be used with a variety of abrasive materials, including diamond, silicon carbide, and aluminum oxide. The type of abrasive material used will depend on the specific application and the material being processed, ensuring optimal grinding or polishing results.

For optimal results, it is important to carefully calibrate the pressure settings and material removal parameters based on the sample and desired outcome. Regular maintenance and proper cleaning of the grinding/polishing head will also help ensure consistency and extend the tool’s lifespan. It’s also essential to ensure that the machine the head is connected to is properly set up to handle the load and speed required.

The SMART CUT® Simple Precision Grinding/Polishing Head is built for long-lasting performance and durability. Its lifespan will depend on the frequency of use, the materials being processed, and the maintenance practices followed. Regular care and periodic checks will help prolong its life and maintain high precision over time.

The automatic stop feature ensures that the SMART CUT® head stops once the set material removal has been achieved, eliminating the potential for over-grinding or under-grinding. This reduces the need for continuous supervision and allows the operator to focus on other tasks, while also ensuring that the desired result is consistently achieved.

While the SMART CUT® head is excellent for both grinding and polishing, it can be used exclusively for polishing if required. By adjusting the pressure settings and material removal parameters, the tool can be fine-tuned for polishing applications, delivering a high-quality finish on a wide variety of materials.

The SMART CUT® head is highly customizable in terms of pressure settings, material removal rates, and sample handling. Custom configurations can be discussed with SMART CUT® directly to meet specific needs. Additionally, various accessories, such as sample holders or adjustable stops, may be available depending on the application.

Advisable to have a basic understanding of grinding and polishing techniques.

The SMART CUT® head is designed for minimal maintenance. Regular checks for wear and tear on parts such as the grinding surfaces and adjustment mechanisms are recommended. Keeping the tool clean and lubricating moving parts as necessary will help ensure smooth operation and longevity. Specific maintenance instructions are included in the user manual.

Yes, the SMART CUT® head can be integrated into automated systems for high-throughput applications. The automatic material removal and stop features are ideal for use in automated setups, allowing the grinding/polishing process to be streamlined and performed with minimal human intervention, increasing productivity and consistency in production environments.

Tab Content

samples are placed into rings provided) pressure is controllable. can be used for 8′ and 12″ machine).

Set how much material you wish to remove, by using thickness gage or caliper. place adjusted stop. The polishing head will continue to grind material until it reaches adjusted stop.

Optimize your application to ultimate level of efficiency

The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales