-

0 items in quote

No products in the Quote Basket.

NEW GENERATION AND TECHNOLOGY

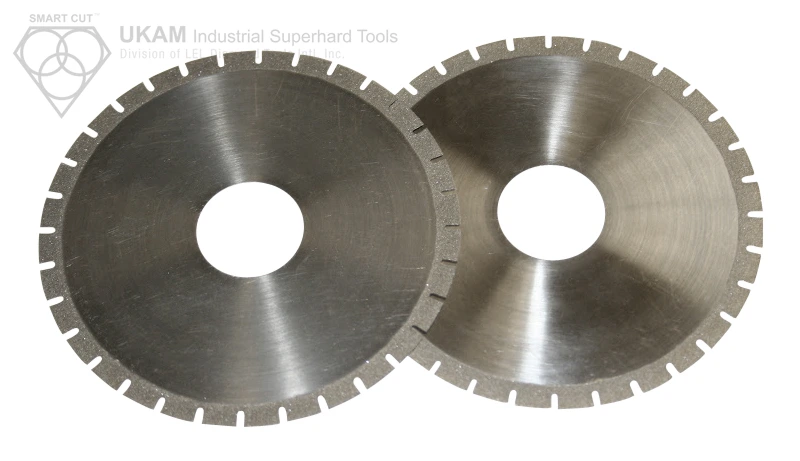

NICKEL BOND HUBLESS

SMART CUT® Series (SCN) DIAMOND & CBN DICING BLADES

SMART CUT® Nickel Bond Hubless Dicing Blades are designed to provide exceptional precision, longevity, and consistency for cutting a wide range of materials. Engineered with a high diamond concentration and advanced Nickel bond matrix, these blades deliver efficient cutting performance with minimal heat generation. Their ability to maintain excellent form retention and diamond exposure makes them ideal for applications requiring high accuracy, such as wafer dicing, thin substrate cutting, and microelectronics fabrication.

The Nickel binder used in these blades is specifically developed to offer a hard bond for soft materials, ensuring longer blade life and reduced wear rates. This unique combination of bond structure and abrasive composition allows for faster cutting while minimizing chipping, making it an optimal choice for materials such as printed circuit boards (PCB), silicon, and ball grid array (BGA) components. By maintaining sharp diamond exposure throughout the cutting process, these blades enhance material removal efficiency while ensuring a stable and controlled cut.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

ACCESSORIES

USAGE RECOMMENDATION

CASE STUDIES

DESCRIPTION

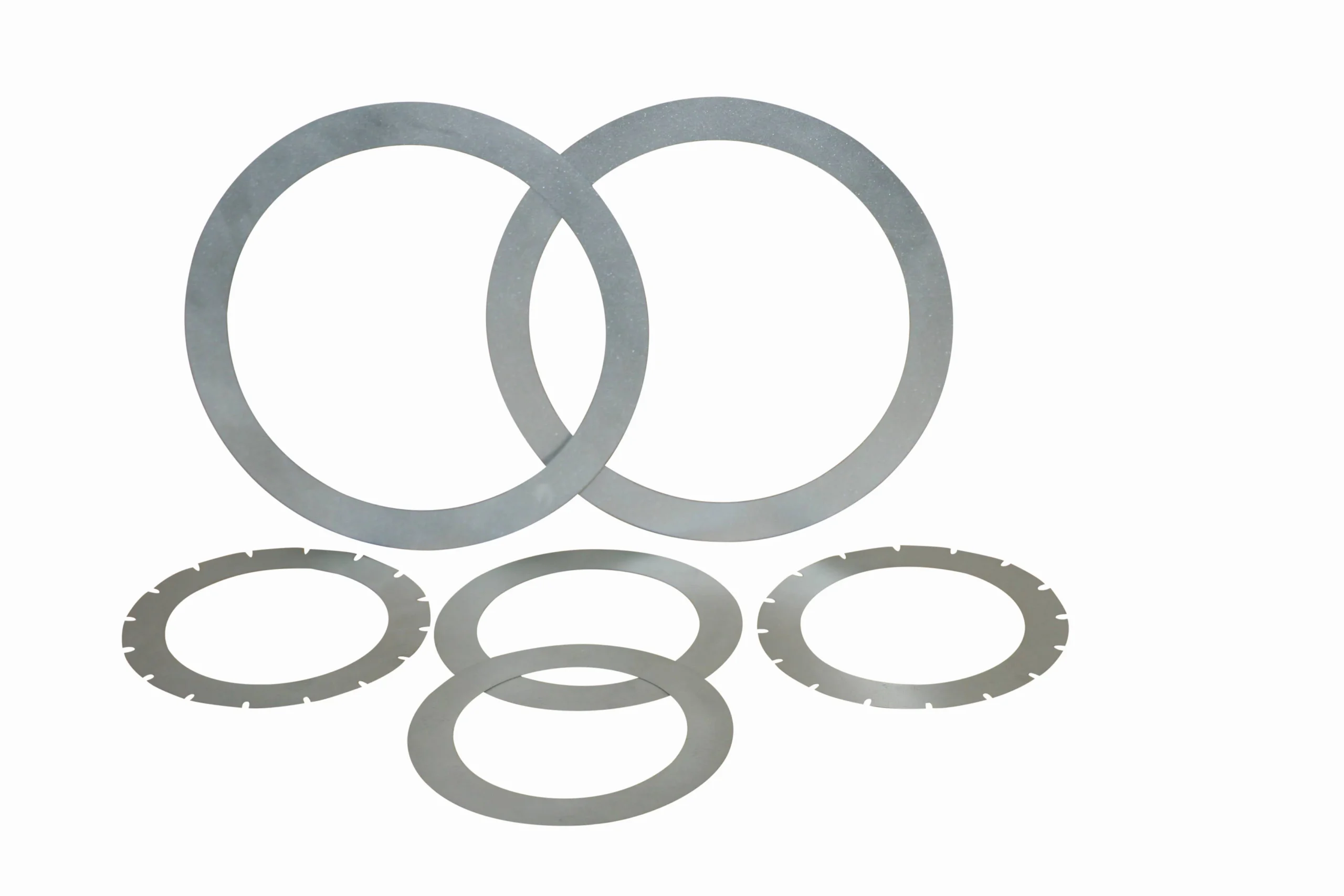

SMART CUT® Nickel Bond Hubless Blades are available in a variety of configurations to meet diverse application needs. Blade thickness ranges from 50 µm (2 mil) to 300 µm (12 mil), allowing for precise customization based on material requirements. The diamond grit size varies from 3 µm to 50 µm, providing versatility across different levels of cutting precision. Custom serration designs and various edge shapes are also available, further enhancing cutting performance for specialized applications.

These blades are engineered for superior cutting results, offering maximum performance and reliability. With excellent form and corner-holding characteristics, they maintain the industry’s best tolerances. Their advanced design minimizes chipping, ensuring a cleaner and smoother finish while significantly reducing blade wear. By extending blade life and optimizing cutting speed, these blades enhance process efficiency, reduce material loss, and lower overall operational costs. Their non-glazing properties enable a faster cutting action while improving surface finish quality, making them a preferred choice for high-precision applications. Additionally, superior coolant retention improves thermal management, preventing material deformation and ensuring a stable cutting process.

SPECIFICATIONS

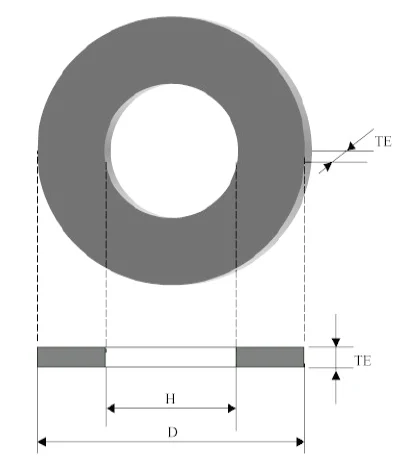

Blade Dimensions:

- Outer Diameter (D): 2.05″ – 4.60″ (52mm – 116.84mm)

- Blade Thickness (TE): 0.002″ – 0.080″ (0.051mm – 2.0mm)

- Inside Diameter (H): 1.250″ – 3.50″ (31.75mm – 88.9mm)

- Blade Tolerance (T): Available in multiple configurations for precise applications

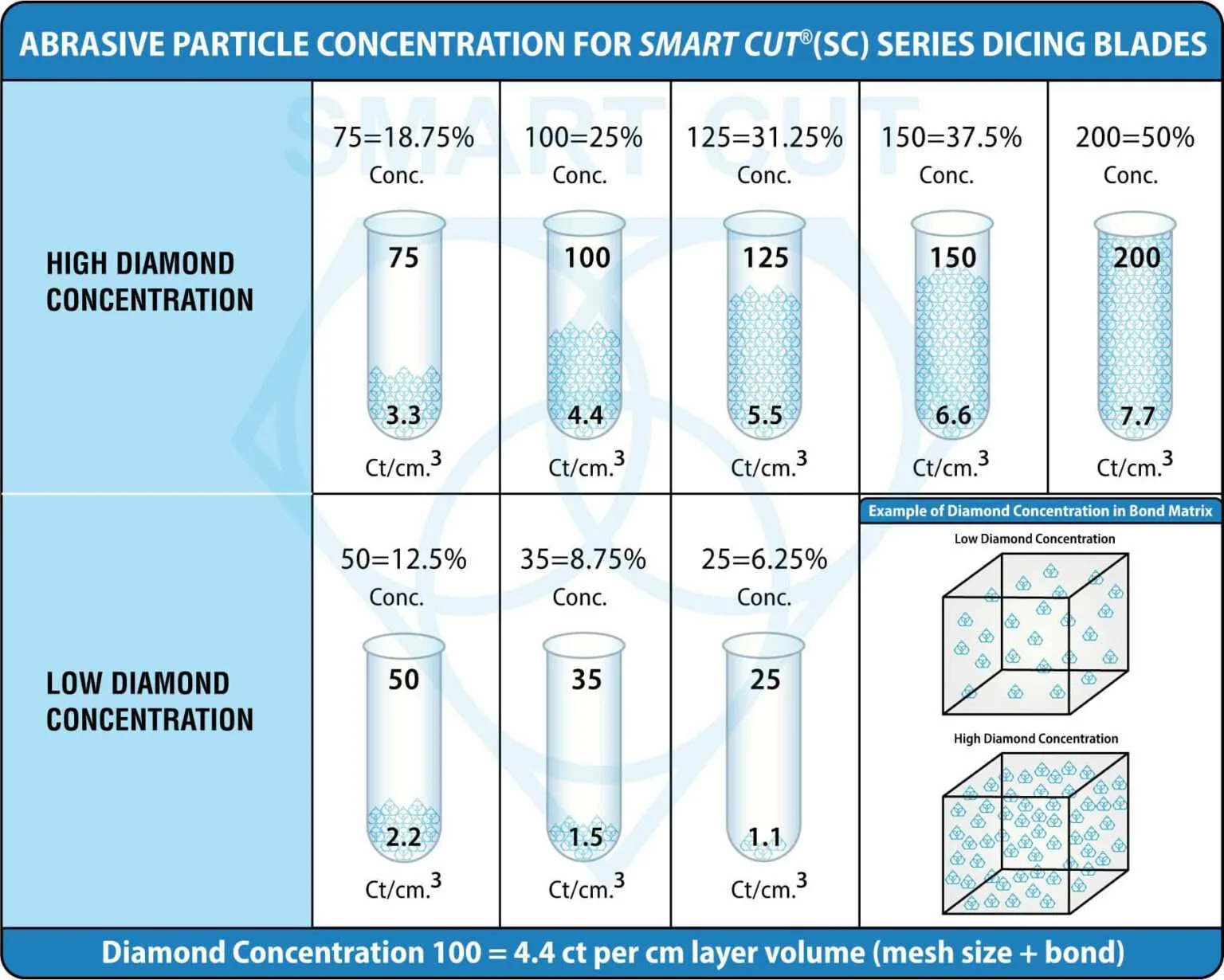

Diamond or CBN Concentration:

- Available concentrations: 25, 35, 50, 75, 100, 125, 150, 200

Nickel Bond Characteristics:

- Hard bond structure ideal for cutting soft materials

- Longer blade life with a reduced wear rate

- Optimized for applications including PCB, Silicon, and BGA

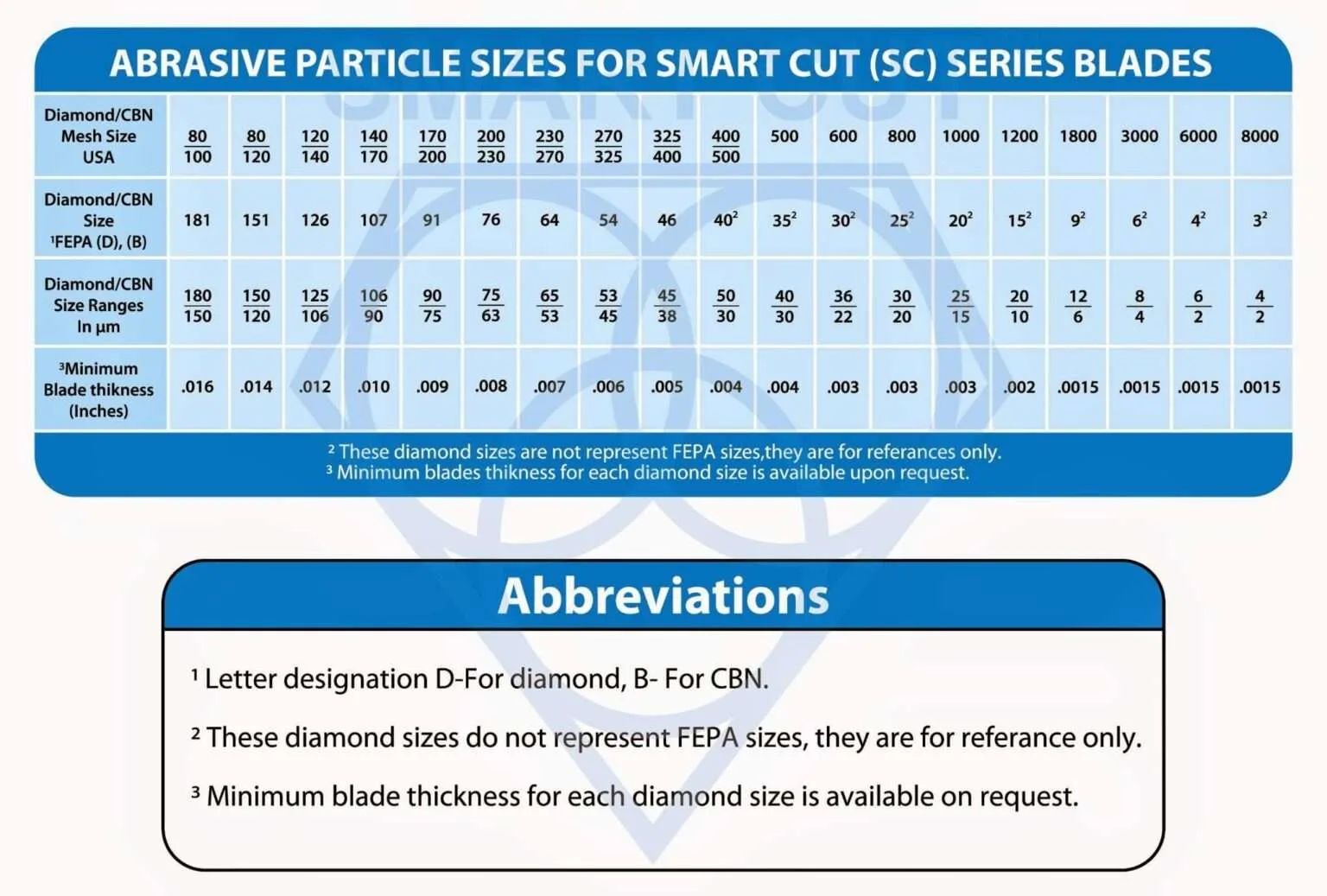

Diamond Grit Size Range:

- Available Sizes: 3 µm – 50 µm

- Application-Specific Diamond Size Recommendations:

- FR4 and BT Resin: 10 µm, 13 µm, 17 µm

- PBGA FR4 and Epoxy Molding: 30 µm, 50 µm

- Multi-Layer Capacitors & Green Ceramic: 30 µm, 50 µm, 70 µm

- Micro Positioners (PZT): 6-8 µm, 10 µm

- Tape Heads (Ferrite): 3-6 µm, 10 µm, 13 µm

- Magnetic Heads (TiC): 3-6 µm, 10 µm, 13 µm

- Silicon Wafers: 15 µm – 50 µm

Optional Blade Features:

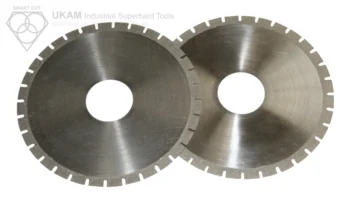

- Serration Options: Available for Nickel Bond Blades with various edge shapes

- Abrasive Particle Concentration Options:

- High Diamond Concentration: 75 (18.75%), 100 (25%), 125 (31.25%), 150 (37.5%), 200 (50%)

- Low Diamond Concentration: 50 (12.5%), 35 (8.75%), 25 (6.25%)

SMART CUT® Nickel Bond Hubless Dicing Blades provide superior performance,

FREQUENTLY ASKED QUESTIONS

SMART CUT® Nickel Bond Hubless Dicing Blades offer exceptional durability, high precision, and extended blade life. Their hard nickel bond structure provides superior form retention, excellent corner sharpness, and minimal blade wear, making them ideal for cutting soft materials such as PCB, silicon wafers, and BGA packages.

The nickel bond structure is designed to provide a hard but wear-resistant matrix that securely holds the diamonds in place. This results in a freer, faster cutting action, reduced glazing, and minimal heat generation, leading to cleaner cuts and improved surface finish.

Nickel Bond Hubless Dicing Blades are optimized for cutting soft and delicate materials, including PCB, FR4, epoxy molding, silicon wafers, BGA, multi-layer capacitors, green ceramics, micro positioners (PZT), ferrite tape heads, magnetic heads (TiC), and other microelectronic components.

These dicing blades are available in thicknesses ranging from 0.002″ to 0.080″ (0.051mm to 2.0mm), allowing for ultra-precise cutting applications.

The available diamond grit sizes range from 3 µm to 50 µm, offering flexibility for various precision cutting applications.

SMART CUT® Nickel Bond Hubless Dicing Blades come in multiple diamond concentration levels, including 25, 35, 50, 75, 100, 125, 150, and 200, allowing for customized cutting performance based on material hardness and application requirements.

Serrations help improve coolant flow and reduce cutting resistance, enhancing cutting efficiency and extending blade life. SMART CUT® Nickel Bond Blades can be customized with various serration patterns to suit specific application needs.

Higher diamond concentration blades (75–200) provide increased cutting speed, longer life, and reduced chipping, making them ideal for high-volume production. Lower concentration blades (25–50) offer smoother cuts with less material stress, which is beneficial for fragile materials.

Nickel bond blades provide a harder and more wear-resistant bond than resin bond blades, making them more durable and effective for cutting soft materials. Compared to traditional metal bond blades, they offer improved coolant retention, faster cutting action, and better surface finish quality.

The inside diameter (ID) of the blade determines its compatibility with different dicing equipment. SMART CUT® Nickel Bond Hubless Dicing Blades are available in ID sizes ranging from 1.250″ to 3.50″ (31.75mm to 88.9mm) to fit a variety of machines. Most popular is 40mm.

Due to their advanced bond structure, SMART CUT® Nickel Bond Hubless Dicing Blades require minimal dressing, reducing downtime and increasing productivity.

Selecting the right blade depends on several factors, including material type, thickness, cutting precision, surface finish requirements, and production volume. Contact us for expert recommendations based on your specific application needs.

Yes, SMART CUT® Nickel Bond Hubless Dicing Blades are designed for compatibility with most industry-standard dicing saws used in semiconductor, microelectronics, and advanced material processing industries.

Yes, we offer custom configurations, including different blade diameters, thicknesses, diamond grit sizes, serrations, and inside diameters to meet specific application requirements.

You can purchase SMART CUT® Nickel Bond Hubless Dicing Blades directly from UKAM Industrial Superhard Tools. Contact us today for a quote or consultation on selecting the best blade for your application.

These blades are engineered with a hard nickel bond that securely holds the diamond particles in place, ensuring a consistent cutting edge. The high diamond protrusion ratio allows for cleaner cuts, reducing micro-fractures and minimizing chipping, even on delicate materials.

A water-based coolant is typically recommended to optimize heat dissipation, prevent material deformation, and extend blade life. Using a properly maintained coolant system also helps improve surface finish and maintain consistent cutting performance.

Thinner blades produce finer cuts with minimal material loss, making them ideal for precision applications requiring tight tolerances. Thicker blades offer greater durability and stability for high-throughput production but may require adjustments in cutting speed and feed rate.

The lifespan depends on multiple factors, including material type, cutting parameters, coolant usage, and blade concentration. Higher diamond concentration blades generally last longer, while proper dressing and cooling techniques help extend blade life.

Yes, SMART CUT® Nickel Bond Hubless Dicing Blades are designed for high-speed dicing. Their optimized bond structure prevents glazing and allows for faster cutting action, improving productivity without sacrificing cut quality.

While these blades perform best with proper coolant usage, they can be used in dry cutting applications for specific materials. However, dry cutting may lead to increased heat generation, which can impact blade longevity and material quality.

Smaller grit sizes provide smoother finishes and finer cuts, while larger grit sizes enable faster material removal and extended blade life. The ideal grit size depends on material hardness, thickness, and surface finish requirements.

Higher diamond concentrations provide longer blade life and improved cutting speed, making them suitable for hard or high-density materials. Lower concentrations are better for applications where minimal material stress and high precision are required.

Yes, SMART CUT® Nickel Bond Hubless Dicing Blades are fully compatible with automated dicing systems used in semiconductor manufacturing, electronics, and precision materials processing.

Proper mounting is essential to ensure optimal performance. It is recommended to use precision flanges and ensure proper blade alignment to prevent vibration, improve cut accuracy, and extend blade life.

These blades feature advanced nickel bond technology, offering improved wear resistance, enhanced coolant retention, superior form stability, and a sharper cutting edge compared to conventional metal bond or resin bond dicing blades.

Yes, custom blade configurations are available, including modifications in diameter, thickness, grit size, concentration, edge geometry, and serration patterns to meet specific cutting requirements.

The recommended RPMs vary based on blade diameter, material type, and application requirements. Contact us with your specifications for detailed RPM recommendations.

To maximize blade performance, use appropriate coolant, maintain correct feed rates and RPMs, ensure proper blade dressing when necessary, and follow best practices for mounting and handling.

Yes, SMART CUT® Nickel Bond Hubless Dicing Blades are available in ultra-thin configurations, making them ideal for precision wafer dicing with minimal material loss and maximum accuracy.

Industries that rely on SMART CUT® Nickel Bond Hubless Dicing Blades include semiconductors, microelectronics, PCB manufacturing, LED packaging, photonics, MEMS, medical devices, and aerospace applications requiring precision cutting.

Blade wear can lead to loss of sharpness, increased chipping, and higher cutting forces. Regular monitoring, proper dressing, and using the right blade specifications for your material can significantly reduce wear and maintain cut quality.

Signs that indicate blade replacement is needed include increased chipping, slower cutting speeds, excessive heat generation, poor surface finish, and increased cutting force requirements.

These blades utilize an advanced nickel bond structure that enhances diamond retention and maintains sharpness for longer periods. Unlike standard metal or resin bond blades, SMART CUT® Nickel Bond blades offer superior wear resistance, reduced chipping, and improved cutting speed while maintaining excellent form stability.

The hubless design allows for a thinner blade profile and greater flexibility in high-precision cutting applications. It reduces weight, lowers rotational resistance, and provides a more uniform cutting action, making it particularly useful for delicate materials such as silicon wafers, PCBs, and multi-layer capacitors.

Yes, these blades are designed for through-cutting applications where high accuracy and minimal material loss are required. Their ability to maintain sharpness ensures clean and precise cuts in high-value materials.

Yes, the high precision and thin kerf of these blades make them an excellent choice for grooving and slotting operations in microelectronics, optics, and semiconductor applications.

Cutting speed depends on material hardness, diamond grit size, bond type, blade thickness, feed rate, and the applied load. Properly optimizing these variables can significantly enhance performance and extend blade life.

Higher diamond concentration allows for faster cutting speeds and longer blade life but may require greater cutting forces. Lower diamond concentrations provide smoother finishes and finer cuts with minimal material stress. The right concentration should be chosen based on the specific cutting application.

No, these blades are designed to minimize heat generation. The nickel bond matrix allows for efficient heat dissipation, especially when used with a proper coolant system, reducing the risk of material damage or deformation.

Store the blades in a clean, dry environment, preferably in their original packaging. Avoid exposure to humidity, extreme temperatures, and contaminants that could affect blade integrity and performance.

Thinner blades produce a finer kerf, reducing material waste and improving yield, making them ideal for applications requiring minimal material loss. However, ultra-thin blades may require careful handling to avoid flexing or premature wear.

Feed rates depend on the material being cut, blade diameter, thickness, and concentration. Generally, softer materials allow for higher feed rates, while harder materials require slower, more controlled cutting speeds to prevent excessive wear.

While these blades can be used in dry applications, wet cutting with a proper coolant system is strongly recommended to extend blade life, reduce heat buildup, and improve surface finish quality.

To minimize vibrations, ensure the blade is properly mounted, the spindle and machine components are in good condition, and the appropriate feed rates and cutting forces are applied. Using a properly selected coolant can also help improve stability.

Excessive chipping can be caused by improper diamond grit size, incorrect blade thickness, high feed rates, or excessive cutting forces. Adjusting these parameters and ensuring proper coolant usage can help improve cut quality.

Regular cleaning and proper storage help maintain blade performance. If necessary, light dressing can be used to restore cutting efficiency. Avoid using aggressive dressing techniques that could damage the bond structure.

Yes, SMART CUT® Nickel Bond Hubless Dicing Blades are widely used in high-precision applications like MEMS, photonics, and microelectronics, where tight tolerances, low material stress, and high surface finish quality are required.

To optimize performance for high-volume production, use proper cooling, maintain consistent feed rates, regularly inspect the blade for wear, and select the correct blade specifications based on material type and processing conditions.

ACCESSORIES

USAGE RECOMMENDATION

01

Jun

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of…

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how to…

02

Jun

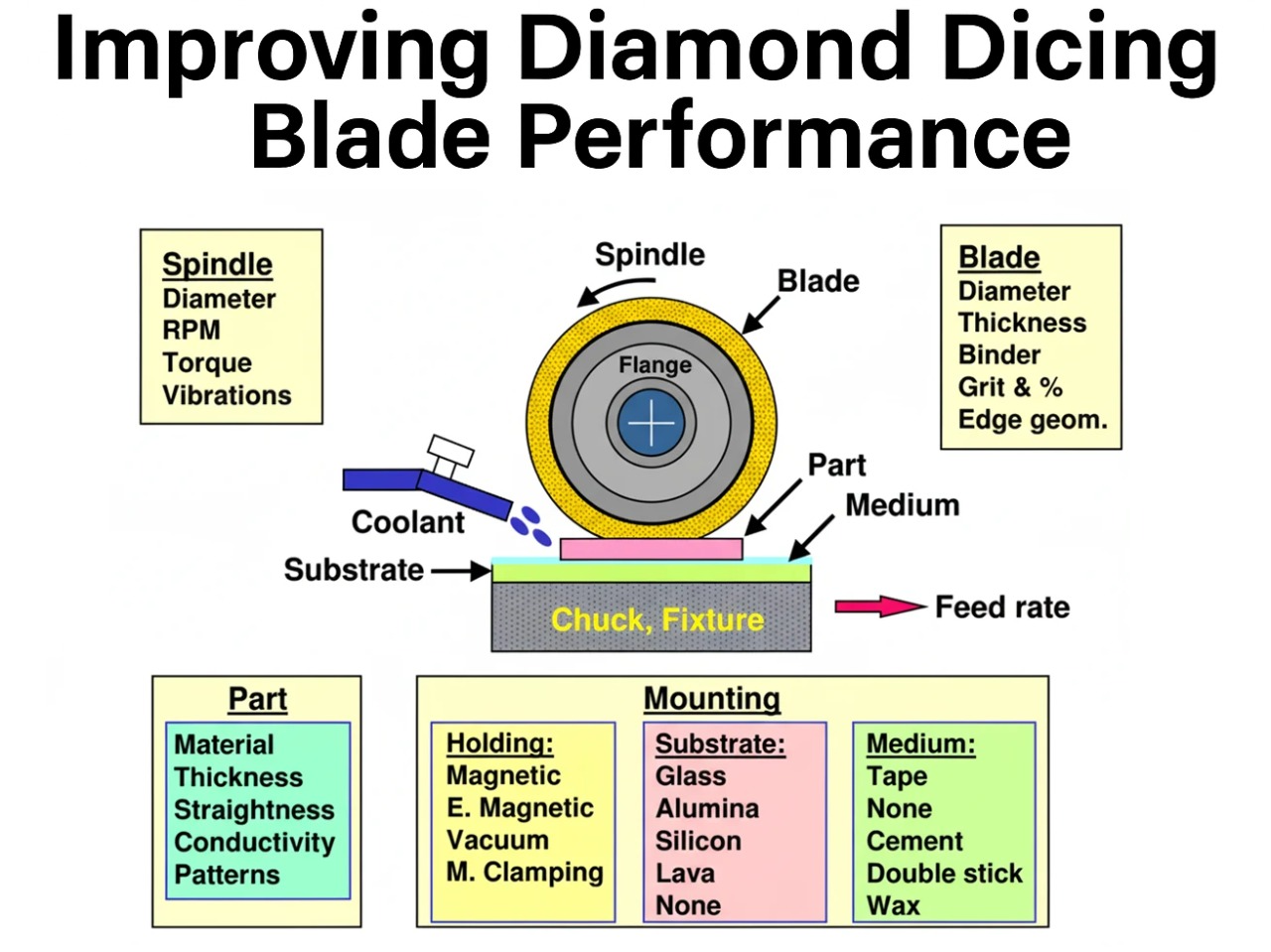

Optimizing your Diamond Dicing Performance

Share this Article with Friend or Colleague

The performance of diamond dicing blades is influenced by a wide range of interdependent variables, and understanding these factors is essential for selecting the correct blade specifications and…

02

Jun

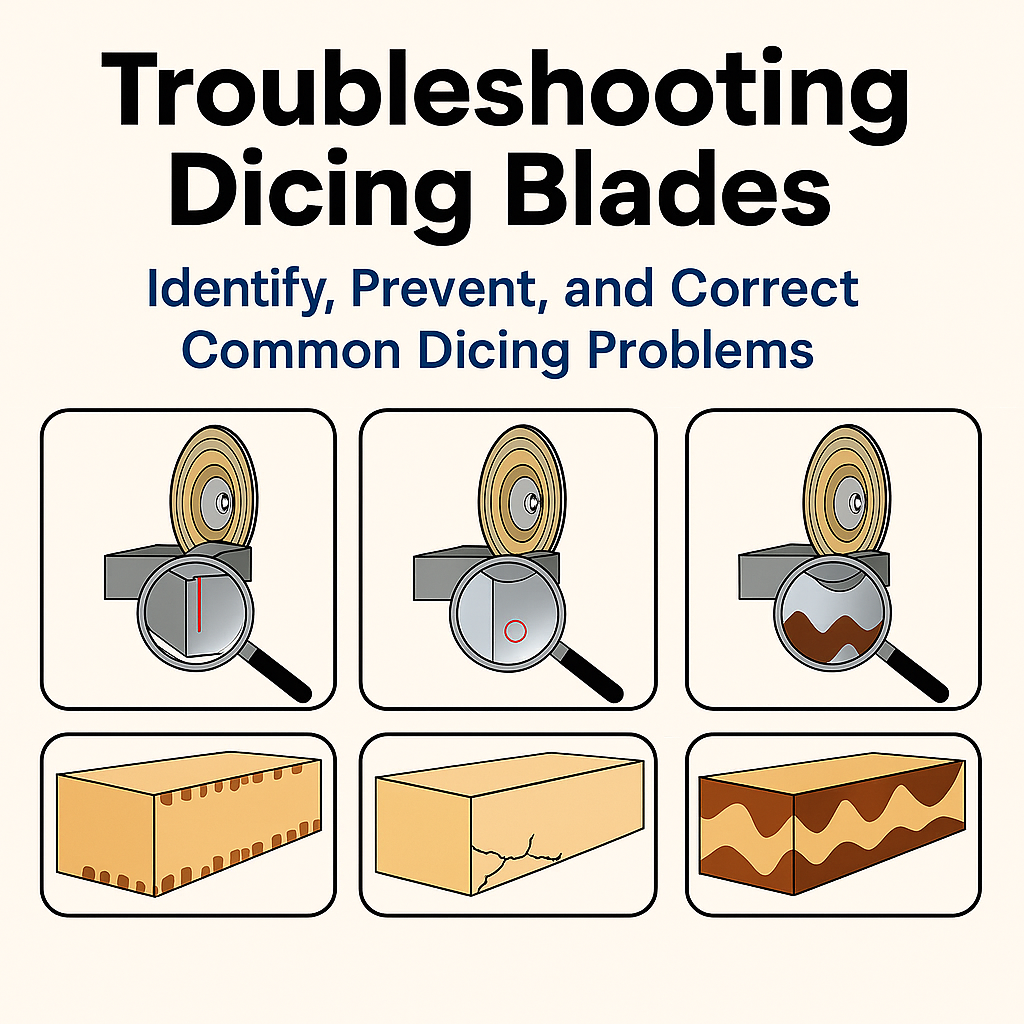

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR…

02

Jun

Application Recommendations

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as…

CASE STUDIES

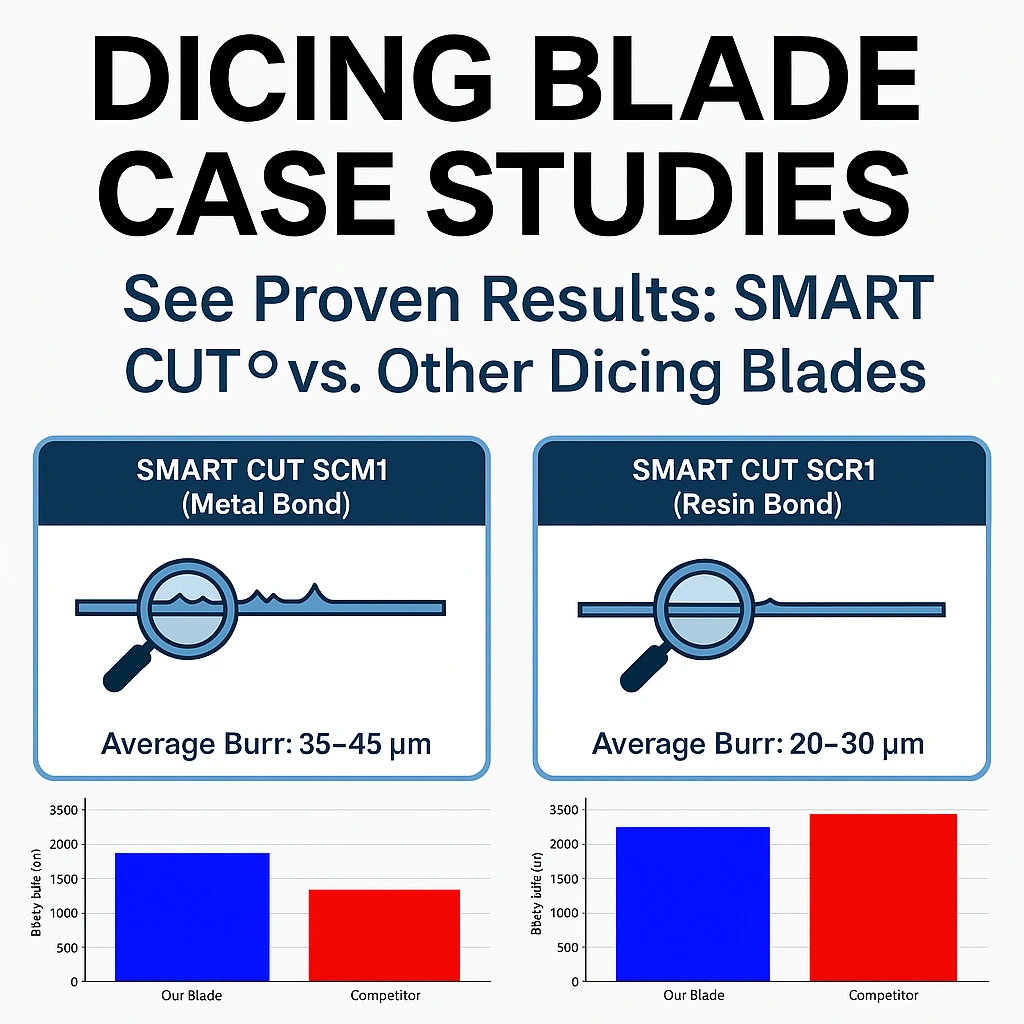

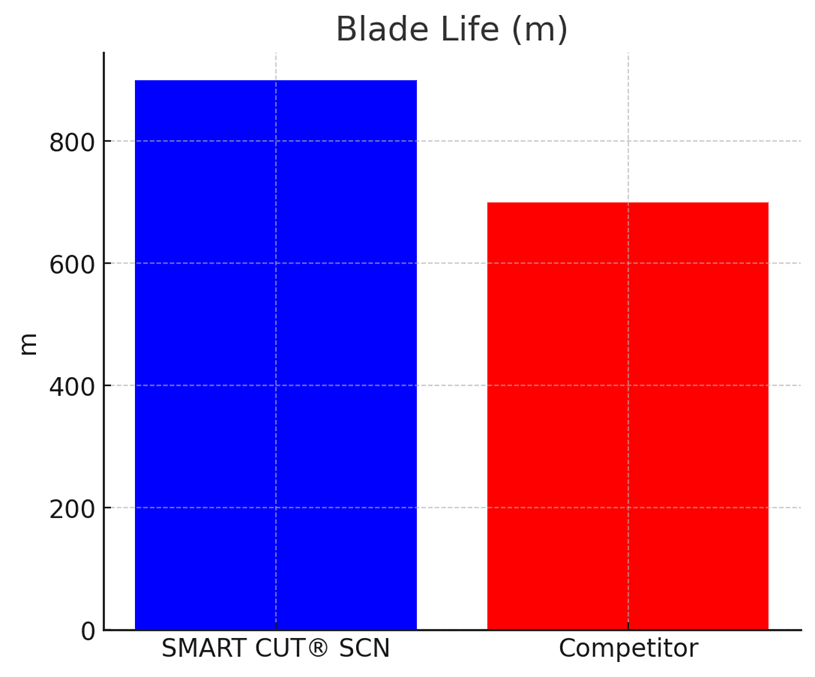

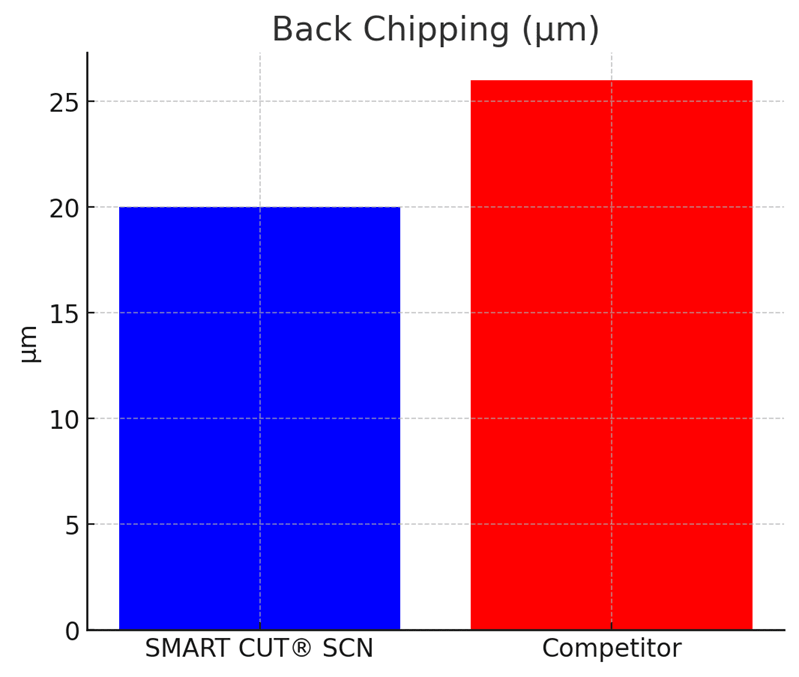

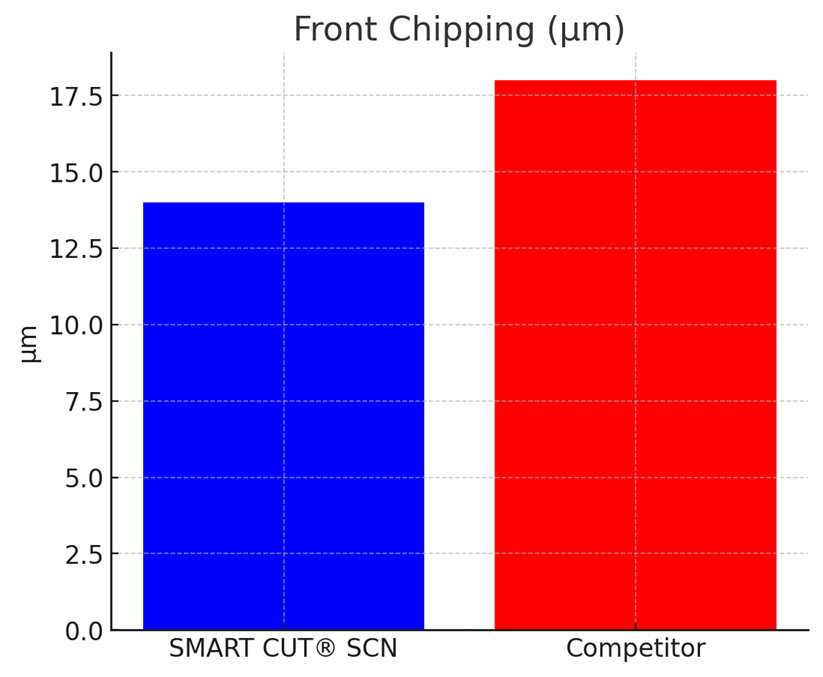

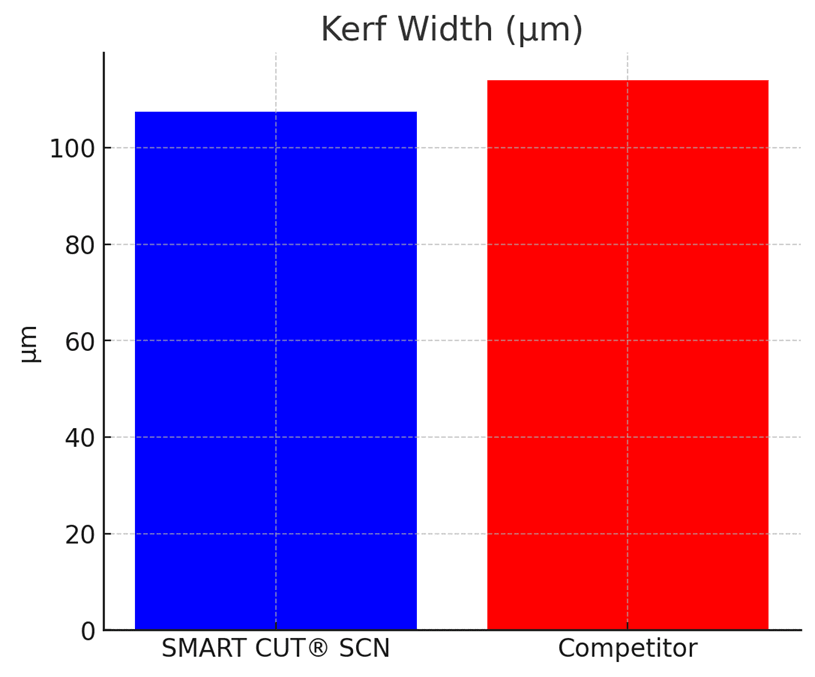

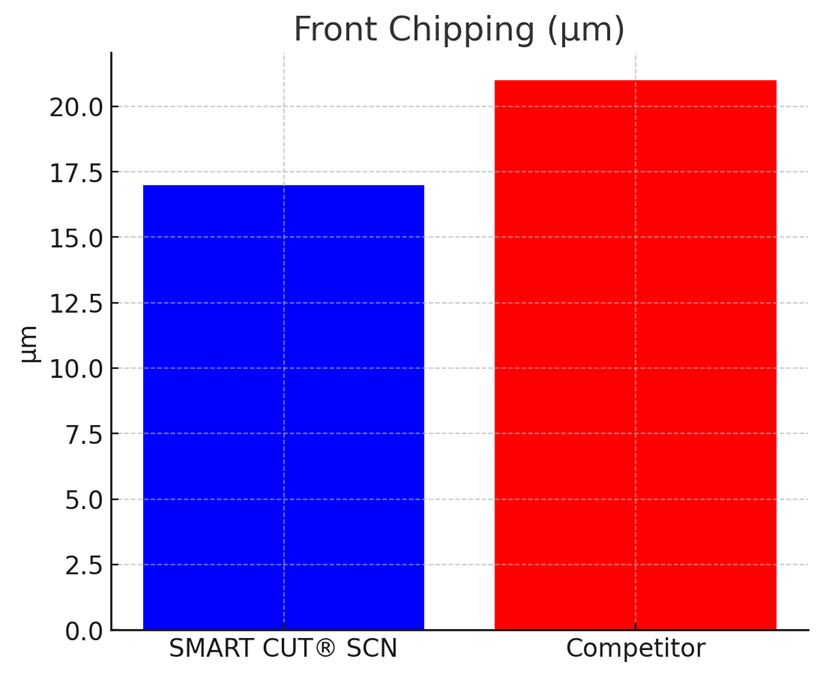

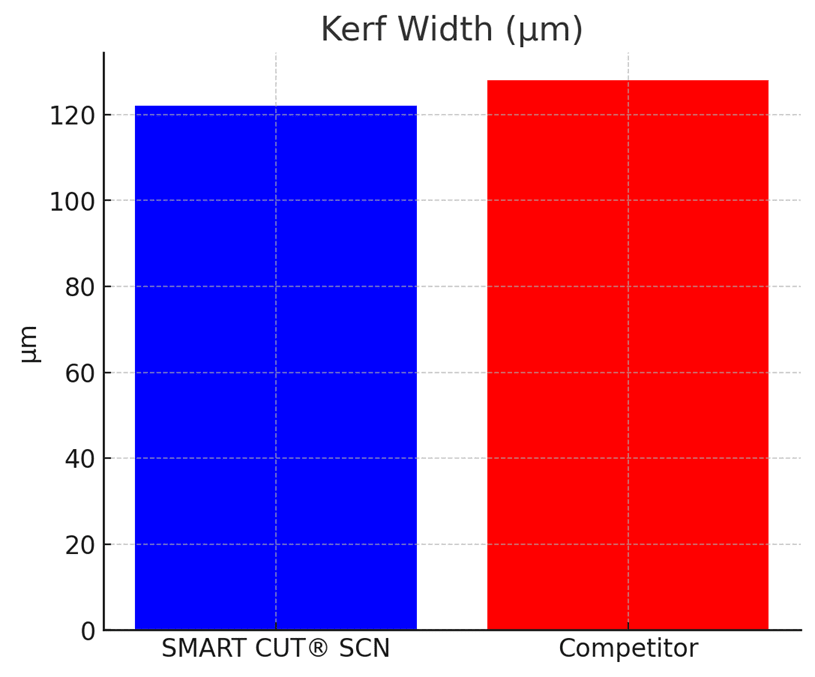

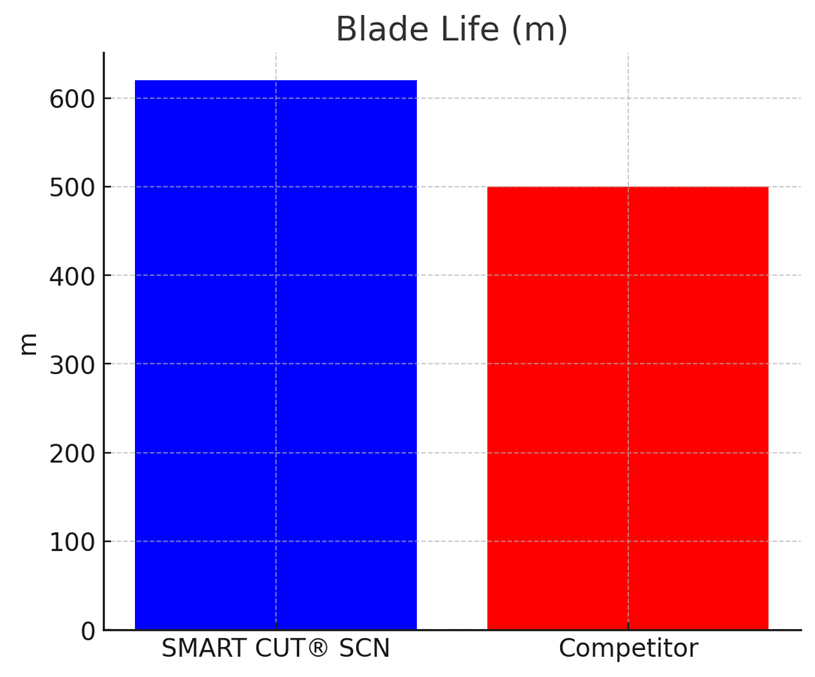

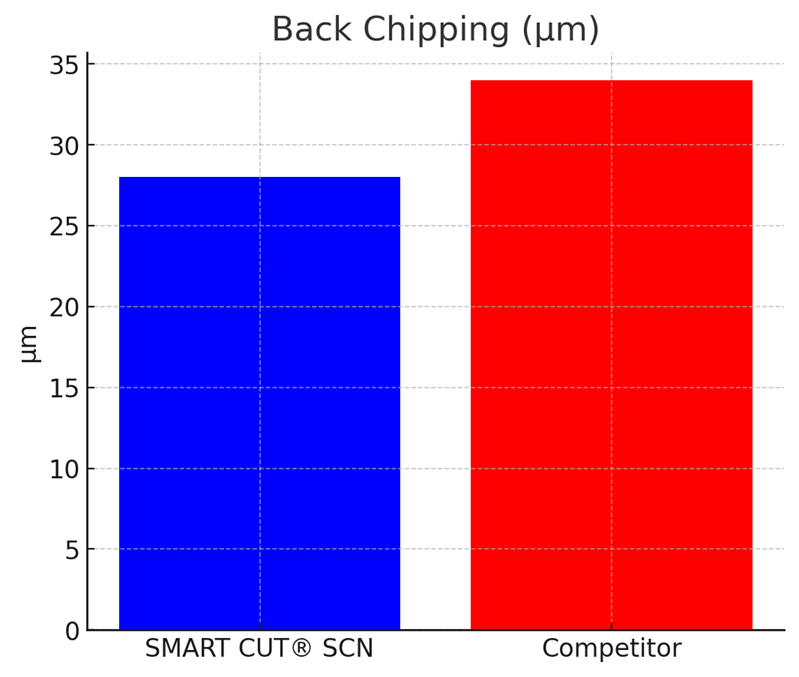

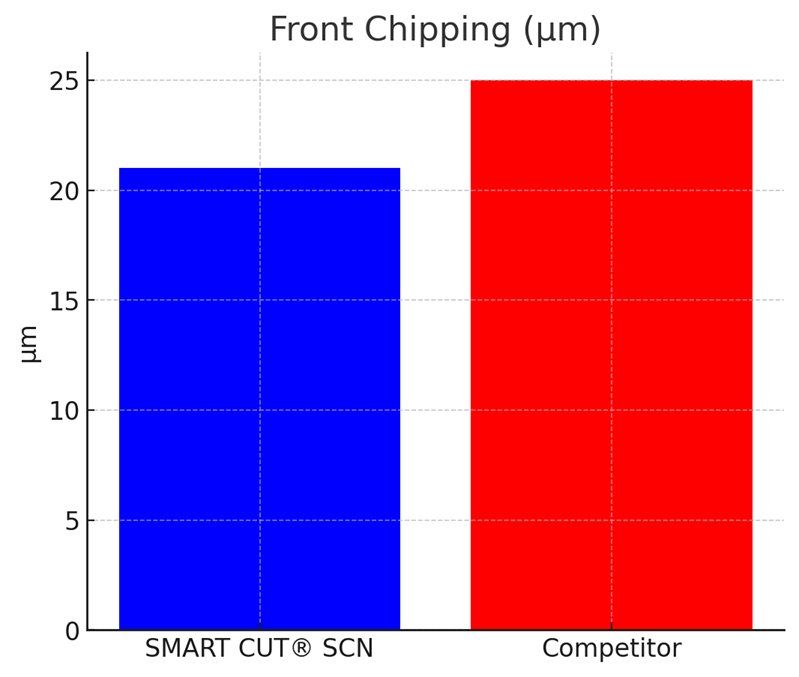

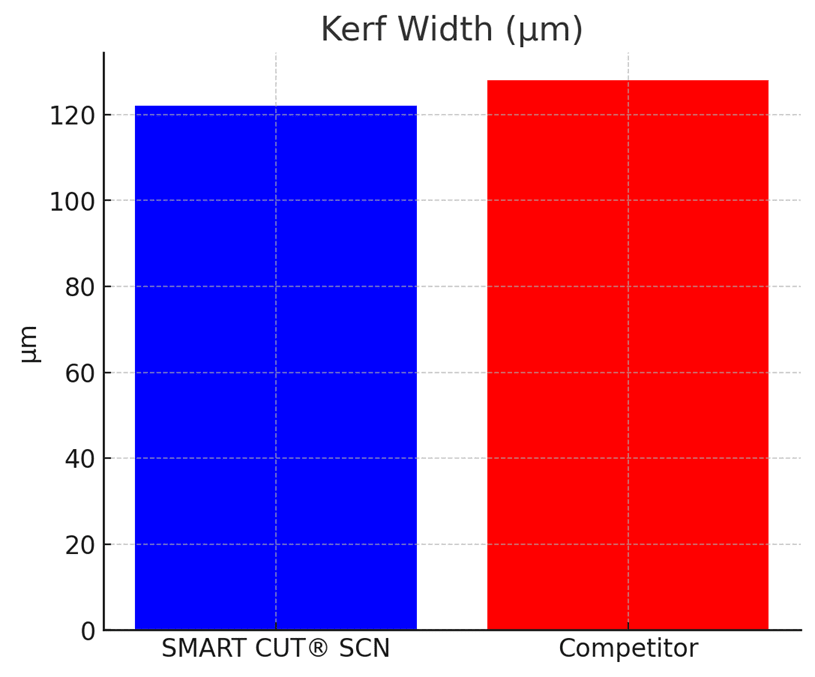

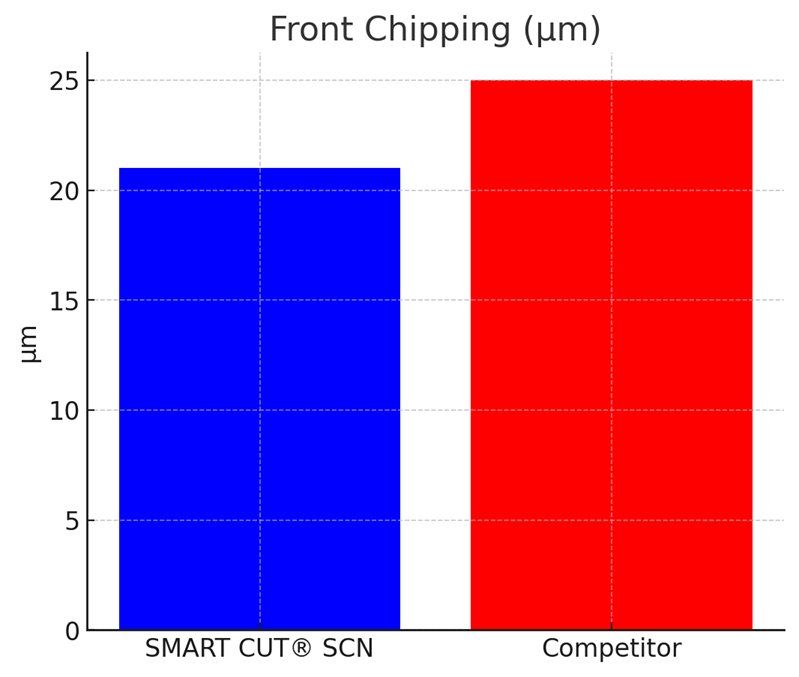

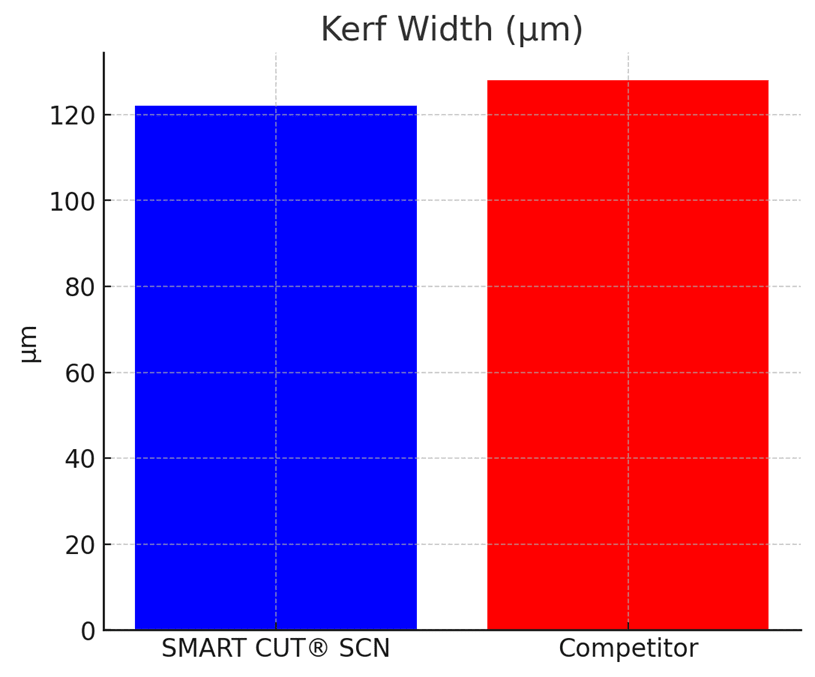

Electroformed nickel bond hubless blades are the industry standard for fine-kerf silicon wafer dicing, but not all blades perform equally. Even when two blades have the same size and bond type, variations in electroforming quality, diamond distribution, and manufacturing tolerances can lead to large differences in kerf consistency, chipping, and tool life. This study compares SMART CUT® SCN Nickel Bond Hubless Blades against a leading competitor’s hubless nickel bond blades under identical dicing conditions. Both blades were tested on the same dicing saw, with flange runout confirmed at ≤5 µm before cutting. In controlled side-by-side testing, SMART CUT® SCN Nickel Bond Hubless Blades delivered superior results compared to competitor nickel bond hubless blades. With narrower kerf width, ~23% lower backside chipping, and ~29% longer blade life, SMART CUT® SCN blades enabled manufacturers to achieve higher die yield, reduced rejects, and fewer blade changeovers. Even within the same bond category, SCN blades clearly provided better cost-per-cut economics and greater process stability. Gallium Arsenide (GaAs) wafers are widely used in RF devices, LEDs, and high-frequency integrated circuits because of their superior electron mobility and direct bandgap properties. However, GaAs is brittle and prone to backside chipping and edge fracture during dicing. These defects can reduce die strength and reliability, increasing scrap rates. Hubless nickel bond blades are often chosen for their thin kerf capability, but performance can vary significantly depending on the blade’s bond uniformity, diamond exposure, and electroforming quality. This study compares SMART CUT® SCN Nickel Bond Hubless Blades with a leading competitor’s nickel bond hubless blades under identical operating conditions. Both blades were tested on the same spindle and flange setup, with runout confirmed ≤5 µm before processing. The SMART CUT® SCN Nickel Bond Hubless Blade demonstrated clear advantages over a competitor’s nickel bond hubless blade in GaAs wafer dicing. By producing a narrower kerf, ~20% lower backside chipping, and ~24% longer blade life, SCN blades enabled higher die yield, greater process stability, and reduced operational costs. These improvements are especially valuable for GaAs, where edge integrity and fracture resistance directly affect device reliability. Borosilicate glass is commonly used in optics, displays, labware, and microfluidic substrates due to its low thermal expansion, excellent chemical durability, and high resistance to thermal shock. Its hardness and brittleness, however, present challenges in precision dicing. Excessive backside chipping reduces yield, while abrasive wear shortens blade life. Nickel bond hubless blades are often selected for their ability to achieve narrow kerfs and precise cuts, but the balance between cut quality, kerf stability, and blade longevity is critical. This study compared SMART CUT® SCN Nickel Bond Hubless Blades with a competitor’s nickel bond hubless blades under identical machining conditions to evaluate their performance in borosilicate glass dicing. Both SCN and competitor blades were mounted on identical hubless flanges with ≤5 µm runout. The SMART CUT® SCN Nickel Bond Hubless Blade demonstrated measurable advantages over a competitor’s nickel bond hubless blade in borosilicate glass dicing. By delivering a narrower kerf, ~18% reduction in backside chipping, and ~24% longer life, SCN blades improved both yield and process stability. These results highlight the SCN blade as the preferred choice for manufacturers requiring precision, consistency, and cost efficiency in glass substrate processing. Silicon Carbide (SiC) is among the most difficult semiconductor materials to dice due to its extreme hardness, high fracture toughness, and thermal conductivity. SiC is increasingly used in power electronics, automotive devices, and high-frequency applications, which demand precise cuts with minimal chipping to maintain die reliability. Conventional dicing blades often struggle with accelerated wear and inconsistent cut quality. Nickel bond hubless blades offer fine kerfs, but their performance depends heavily on diamond grit retention, bond strength, and electroforming precision. This study compares SMART CUT® SCN Nickel Bond Hubless Blades to a leading competitor’s nickel bond hubless blades under controlled SiC wafer dicing conditions. Both blades were mounted on identical hubless flanges. Spindle runout was verified at ≤5 µm before testing. The SMART CUT® SCN Nickel Bond Hubless Blade outperformed a competitor’s nickel bond hubless blade in SiC wafer dicing. By delivering a narrower kerf, ~21% lower chipping, and ~28% longer blade life, SCN blades provided superior yield, greater process stability, and reduced cost per cut. These advantages are especially critical for SiC-based power electronics and automotive applications, where both die strength and cutting efficiency directly affect overall device reliability and manufacturing economics.

Case Study 1: SMART CUT® SCN Nickel Bond Hubless Blade vs. Competitor Nickel Bond Hubless Blade in Silicon Wafer Dicing

Background

Experimental Setup

Results

Kerf Width

Chipping (Front/Back)

Blade Life

Cutting Stability

Conclusion

Case Study 2: SMART CUT® SCN Nickel Bond Hubless Blade in Gallium Arsenide (GaAs) Wafer Dicing

Background

Results

Kerf Width

Chipping (Front/Back)

Blade Life

Observations

![]()

![]()

Conclusion

Case Study 3: SMART CUT® SCN Nickel Bond Hubless Blade in Borosilicate Glass Substrate Dicing

Background

Results

Kerf Width

Chipping (Front/Back)

Blade Life

Observations

Conclusion

Case Study 4: SMART CUT® SCN Nickel Bond Hubless Blade in Silicon Carbide (SiC) Wafer Dicing

Background

Results

Kerf Width

Chipping (Front/Back)

Blade Life

Observations

![]()

![]()

Conclusion

SMART CUT® Nickel Bond Hubless Dicing Blades set the standard for precision cutting across industries that require accuracy, efficiency, and consistency. With their ability to maintain sharpness, reduce process variability, and deliver high-quality results, they provide an ideal solution for advanced material processing. Contact us today for more information or to request a quote and discover how SMART CUT® dicing blades can optimize your cutting operations.

Features

- Excellent form & corner holding characteristics

- Best tolerances in the industry

- Superior Cut Quality

- Unmatched Consistency

- Universal Application

- Requires Minimal Dressing

Benefits

- Increases Blade Life

- Reduce Chipping

- Reduce Blade Wear

- Increase Process Consistency

- Maintain Consistent Cutting Speed

- Minimum Loss of Material

- Reduce Cost

Advantages

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

- Faster Cutting Speed

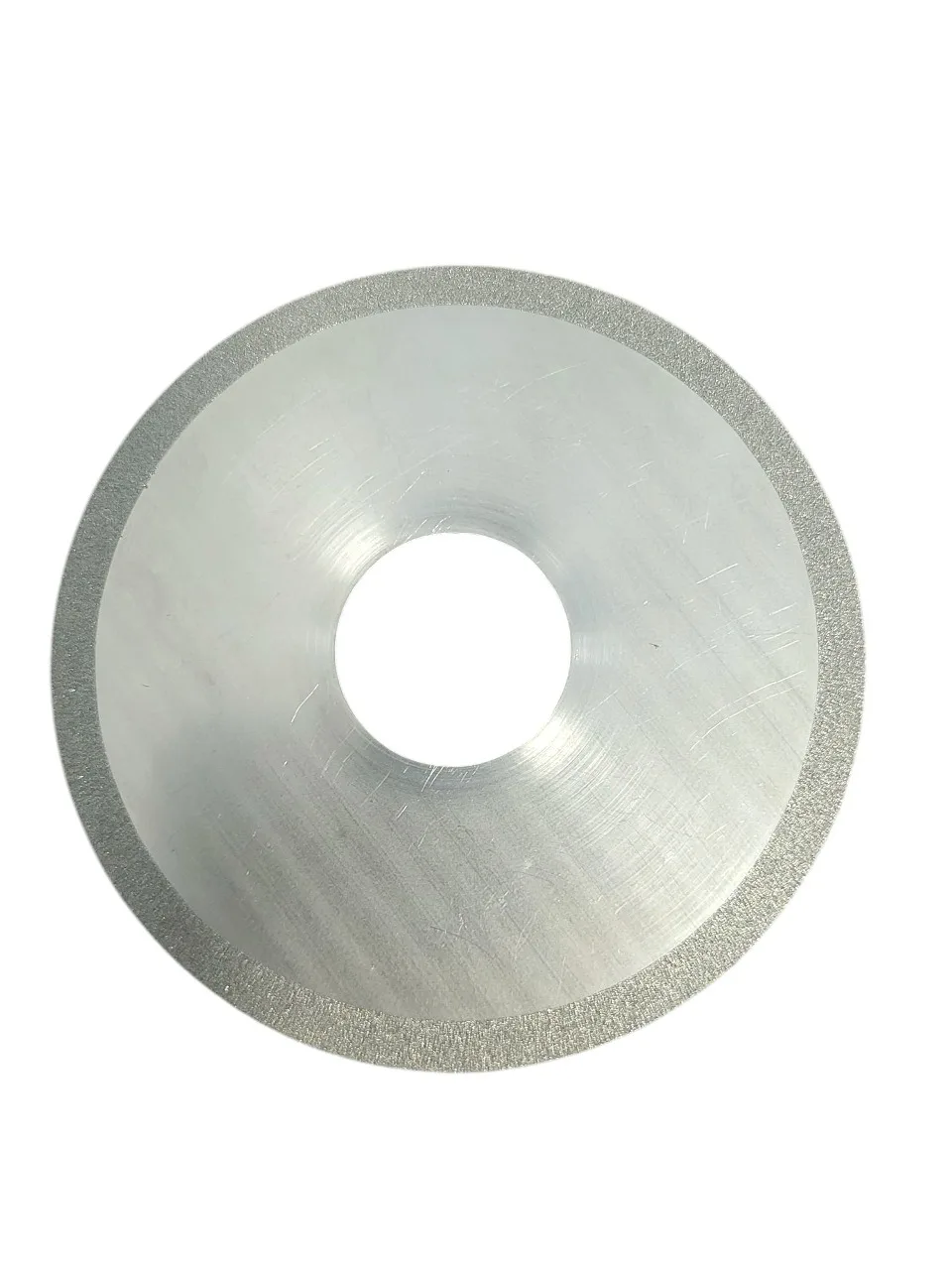

SMART CUT® Steel Core Nickel Dicing Blades

SMART CUT® Steel Core Nickel Dicing Blades are designed for precision cutting applications that demand high performance and durability. These blades are particularly well-suited for delicate and precise materials, such as Green Ceramics and Ball Grid Array (BGA) components, especially in processes like the Tape Process.

The Steel Core Nickel Dicing Blades are produced using a steel core with nickel binder that coats only the rim (cutting edge) of the blade, ensuring optimal cutting performance. This design provides higher rigidity & structural integrity due to the steel core, making them better suited for high-stress cutting operations and materials that require consistent, stable cutting performance. The maintains its form during demanding cutting operations.

These blades are perfect for deep or aggressive cutting, grooving, and slicing of a variety of materials, The added rigidity minimizes blade deflection, which is critical for maintaining consistent performance and protecting the workpiece from damage.

These blades are available in a range of thicknesses, from 300µm to 750µm. The diamond grit sizes for these blades range from 10µm to 70µm, For enhanced performance and versatility, serrations are available for Steel Core Nickel Dicing Blades. The serrated edges improve the blade's ability to cut through challenging materials and can reduce cutting forces, allowing for smoother operations when dealing with harder or more brittle materials. Additionally, these blades can be customized with various edge shapes to accommodate specific cutting needs. The customizable edge profiles help achieve the desired cut quality, surface finish, and chip resistance, making these blades ideal for precise, high-throughput applications.

Why Work With Us?

Best Return

on Investment

Attractive Cost of

Ownership

Thousands of Diamond & CBN Blades in stock

Custom Manufacturer with Fast Lead times

Unmatched

Prices in North America

Unmatched Experience & Technical Support

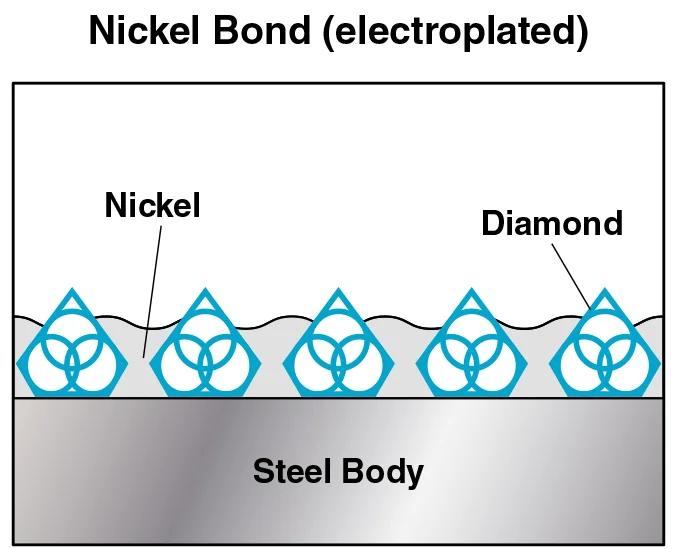

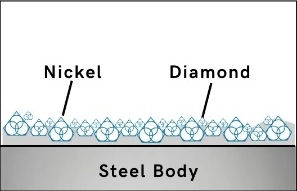

About Nickel (Plated) Bond

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough, durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process, electroplated diamonds are able to retain their original shape and dimensions throughout their working life. Unlike sintered) metal bond or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Silicon wafer dicing is usually done with the plated diamond blade (hubbed or hubbless) which has proven most effective for this application. The Kerfs are typically in the 1-3 mil. range using a nominal spindle speed of 30,000 RPM with feed rates as high as 8 inch per sec.

How SMART CUT® Nickel Bond Works?

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT® Nickel Bond, immediately penetrate into the material, grinding and polishing as they cut.

- Different Product

- Different Technology

- Different Company

Expect MORE from your tools

How SMART CUT® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT® Diamond Bond, immediately penetrate into the material, grinding and polishing as they cut.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 2

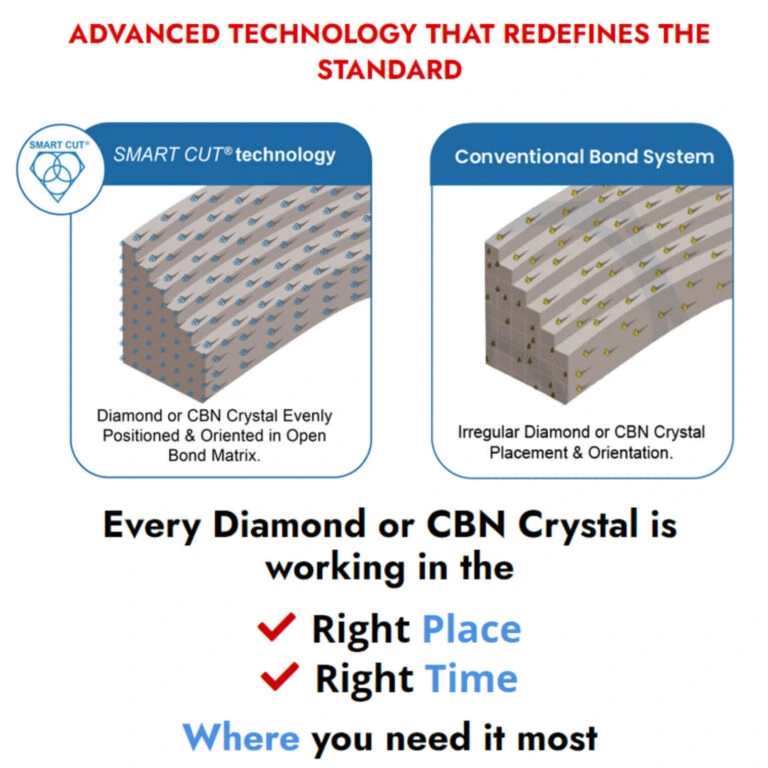

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Contact Us for FREE Quote & Recommendation

We will work with you to determine your needs, and recommend the right parameters for your specific material/application.

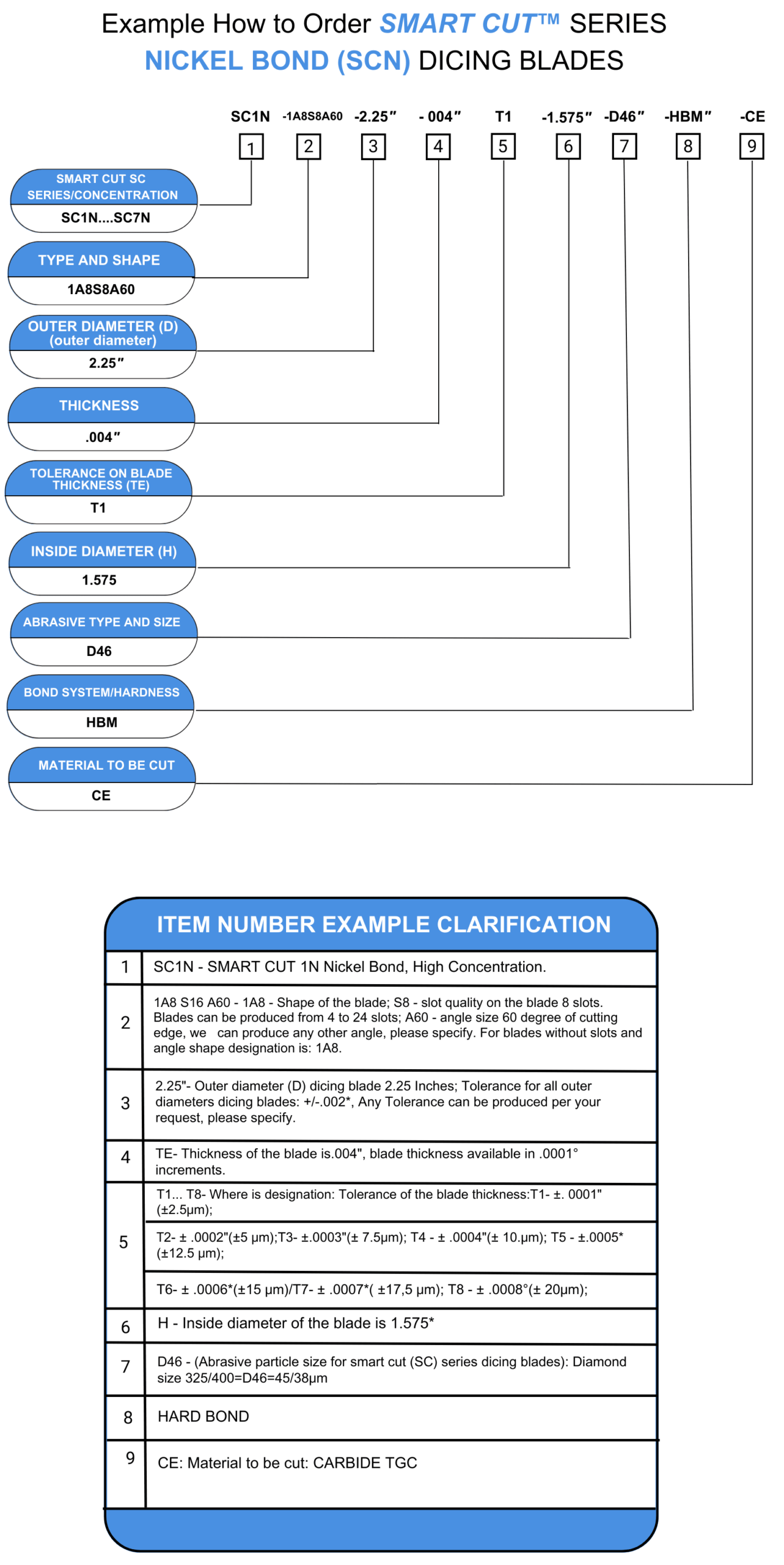

SMART CUT® Series SCN

Nickel bond Specifications

Size Designation: D X TE X H, Where: D-Outside Blade Diameter, TE –Blade Thickness, H- Blade Inside Diameter.

Note: Our standard Tolerance on Outside Diameter for all blades is +/-.002”, tolerance. Higher tolerances are available upon request

Below is a guide to help you select the right Diamond Size for your Nickel Bond Hubless Dicing Blades for your application

** Letter Abbreviations: D-FOR DIAMOND, B -FOR CBN.

Usage Recommendations

Handling

Please note that nickel bond dicing blades are not 100% resilient, that is if a blade is deformed through mishandling it will allays retain a certain amount of that deformation. Though that some mishandling may not have noticeable impart on the cut quality (this would depend on parameters required and the amount of damage done). Nevertheless, proper handling procedure is important to the safe use, and overall robustness of any precision grinding process.

- Always inventory the blades in the original package as packaged from us. This will not only protect the blades, but allow the necessary blade information to be available on hand.

- Store the package away from obvious hazards such as water, hear and dust.

- Clean hands and clean bench is required for any inspection or inventory purposes.

- Handle the blades using the inside diameter hole whenever possible.

Cleaning

- A careful and through cleaning is an important step to a reliable diamond glade cutting process. Below are some guideless.

- All cleaning should be done in an area that is as particulate free as possible, a clean room is optimal, but not absolutely required.

- Use a residue free cleaning solvent, isopropyl alcohol is recommend, but acetone is also acceptable.

- Use clean, laboratory grade lint free wipes.

- Always visually inspect for any debris or particulate that might be imbedded or otherwise requires special or added treatment to remove.

Mounting (Stacking)

There a re numerous mounting systems (Arbor, Hub, Flange) each requiring slightly different components and procedures. Below are some recommendation:

- The mounting hardware (arbor, hub, flange) and the stacking components (Spacers, Blades) must be clean of any debris.

- A through visual inspection for burrs dings dents or other damage.

- Mechanically inspect the mounting hardware for axial and radial run out to verify that all is within specification.

- Assemble and inspect per manufacturer instructions.

Truing

The truing of a diamond blade is an important step towards a repeatable and robust cutting process. Without this step the blade or the material can become damaged due to the “hammering” caused by excessive radial run out of the blades. This damage can lead to inconsistent blade performance and cut quality, and in extreme circumstances blade failure.

Dressing

Blade dressing is an important part of precision cutting process. With an optimized dressing system and intervals the cutting forces will be stable and predictable

Use the blade recommend dressing system (stick, plate or board) and process. This will optimize the diamond protrusion for maximum blade life and cut quality. Deviations from those recommendations should be used with considerable causation.

There are many variables involved with the selection of a suitable blade dressing systems. Including bond type, bond hardness & bond structure. Abrasive size and type, abrasive concentration, the blade form and size.

Generally speaking the size of abrasive particles used in the dressing system (whether stick, plate or board) should be slightly larger than the abrasive size of nickel bonded dicing blade being dressed.

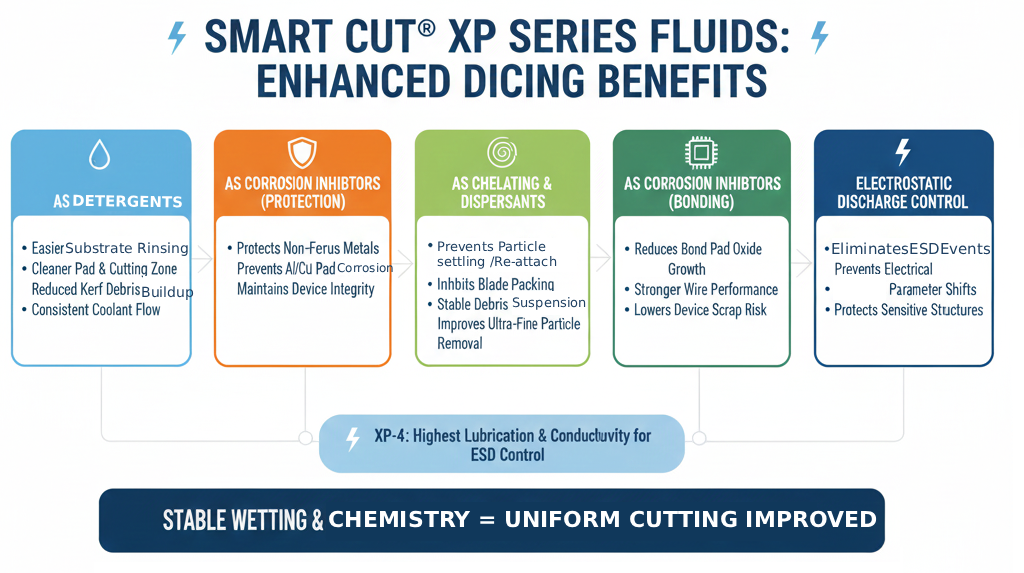

SMART CUT® XP Dicing Fluid, Coolant, & Surfactant

Available in 4 Different Formulas to Fit Most Dicing Applications

XP-1 is a general-purpose dicing fluid within the SMART CUT® range, designed to reduce debris, improve tool life, and prevent corrosion, while ensuring smooth cutting and protecting sensitive materials from ESD.

XP-2 enhances lubrication for demanding applications, offering superior cutting speeds, tool longevity, and advanced cleaning capabilities for tough materials like SiC and sapphire.

XP-3 is ideal for high-pressure systems, offering consistent cooling performance without foam buildup.

XP-4 specifically protects electrostatic-sensitive components by eliminating ESD, reducing defects, and extending tool life during the dicing process.

Why Work With Us?

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency.

Expect More From Your Tools

Related Products

Hybrid Bond Dicing Blades

Nickel Bond Hubbed Dicing Blades

Resin Bond Dicing Blade

SMART CUT® Water Soluble Dicing Coolant

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Tungsten Carbide Dicing Blades

ARE YOU USING RIGHT DIAMOND & CBN TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN TOOLS?

01

Jun

Select right Diamond Dicing Blade for your application

Selecting the right dicing blade for your application requires careful consideration of several key variables that influence both performance and cost. The type of material being cut, the depth of the required cuts, the level...

02

Jun

Dicing Blade Operations Recommendations

Share this Article with Friend or Colleague

Selecting the right dicing blade parameters often involves a trial and error process, many aspects of which can be mitigated through experience and a deep understanding of how to...

02

Jun

Optimizing your Diamond Dicing Performance

Share this Article with Friend or Colleague

The performance of diamond dicing blades is influenced by a wide range of interdependent variables, and understanding these factors is essential for selecting the correct blade specifications and...

02

Jun

Trouble Shooting Dicing Problems

Guide on most common dicing problems and how to resolve them

Share this Article with Friend or Colleague

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET USHELP YOU

CONTACT US

HAVING ISSUES WITH

YOUR...

02

Jun

Application Recommendations

This article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as...

02

Jun

Dicing Blade Case Studies

Selecting the right dicing blade is important to achieving high yields, superior edge quality, and consistent reliability in microelectronics and optics manufacturing. Across industries such as semiconductors, electronics packaging, photonics, and precision optics, even small...

01

Jun

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Share this Article with Friend or Colleague

Dicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of...

27

Aug

Selecting the Right Wafer Dicing Saw Practical Guide

Selecting the proper wafer dicing saw is a important decision for manufacturers, researchers, and engineers working with large variety of materials. Whether processing silicon wafers in microelectronics, ceramics in materials science, or glass substrates in...

26

Nov

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Semiconductor wafers are the foundation of nearly all modern electronics, from integrated circuits and photonic devices to advanced power components. As device geometries shrink and packaging density increases, the requirements placed on wafer dicing processes...

17

Sep

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

Many companies still judge diamond dicing blades by purchase price alone. At first, the cheapest blade may appear to be the best choice. However, price does not equal cost. The real economics of diamond dicing...

18

Sep

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

The making of the integrated circuit is a long and complex process that involves many critical steps. In most cases, the wafer travels to multiple facilities before it is completed and turned into the final...

19

Sep

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

Diamond dicing is one of the most important step in semiconductor & microelectronics manufacturing package. Although the process itself does not add direct value to the finished device, it has a decisive impact on yield,...

08

Dec

Selecting the Right Dicing Surfactant / Fluid for Your Application

Selecting the correct dicing surfactant / fluid is essential for stable cutting, consistent kerf quality, and long blade life. Each operation places specific demands on lubrication, cooling, foaming control, and electrostatic behavior. You must choose...

09

Dec

How to Use SMART CUT XP Dicing Surfactants

SMART CUT® XP dicing surfactants should be introduced into the saw water supply in a controlled and consistent manner to ensure proper dilution, stable chemical performance, and uniform delivery to the cutting zone. Correct dosing equipment and proper...

09

Dec

Dicing Surfactants Guide

Dicing surfactants support stable and consistent wafer dicing. You use them as part of a complete dicing fluid designed to cool the blade, flush debris, and protect exposed device surfaces. Modern semiconductor wafers contain smaller...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Nov

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...