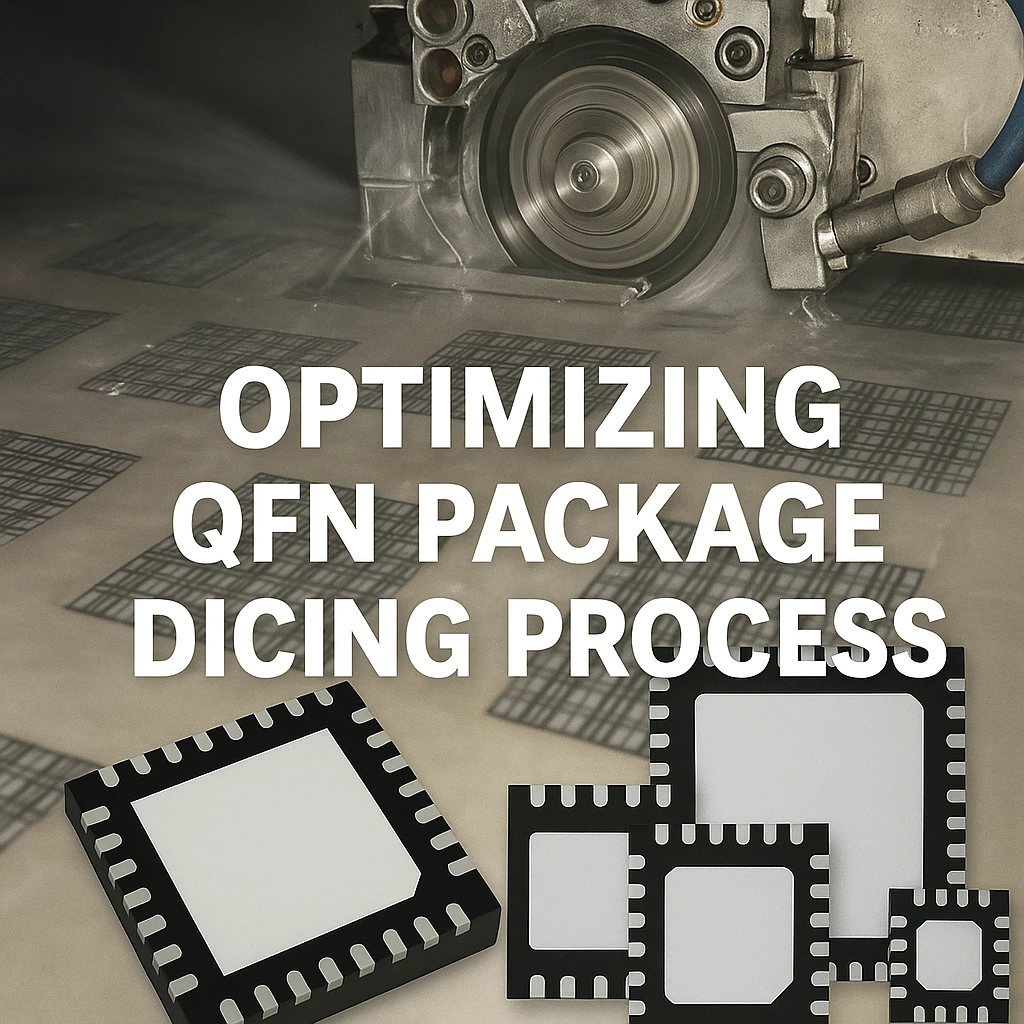

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

-

Posted by

Ayan Sadyk

Ayan Sadyk

Table of Contents

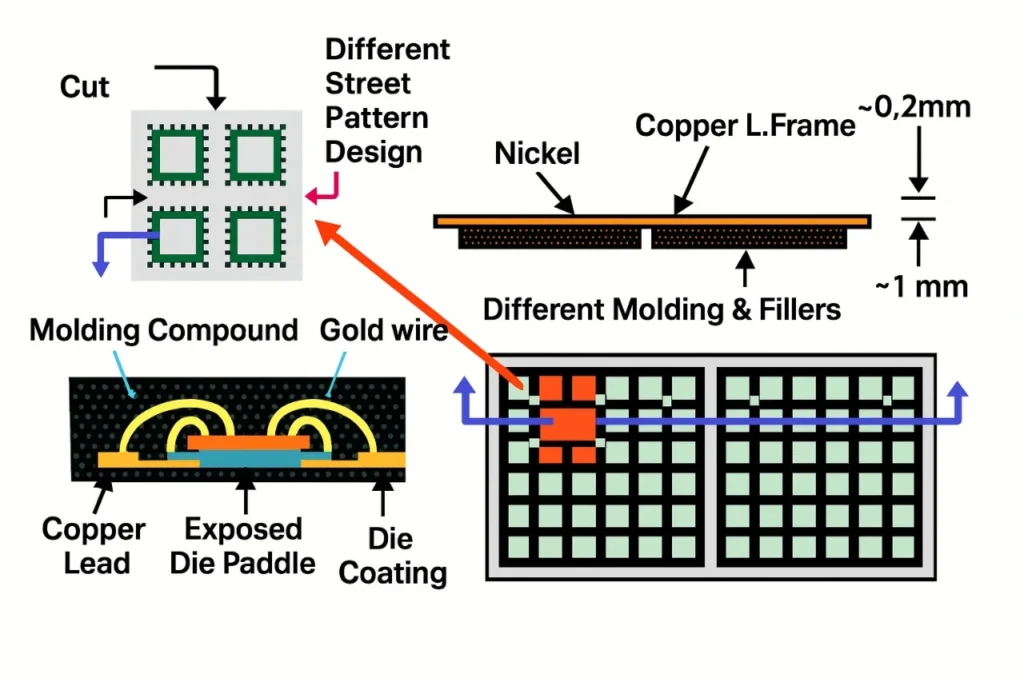

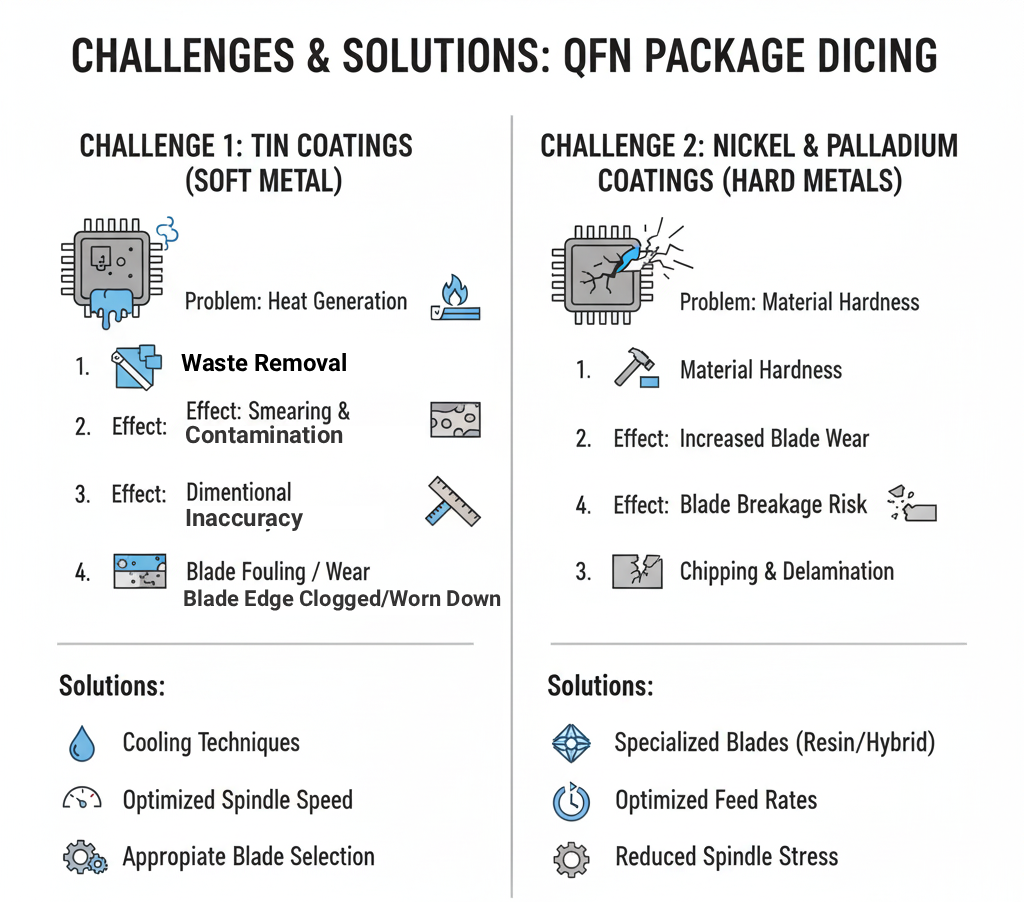

ToggleDicing QFN packages presents several challenges due to the composition of materials and the precision required for clean, defect-free cuts. These challenges arise from the multi-layered structure of QFN packages, which often include tin (Sn) coatings, nickel/palladium (Ni/Pd) plating, and composite substrate materials. Each of these layers introduces specific difficulties that must be managed to ensure high-yield, high-quality production.

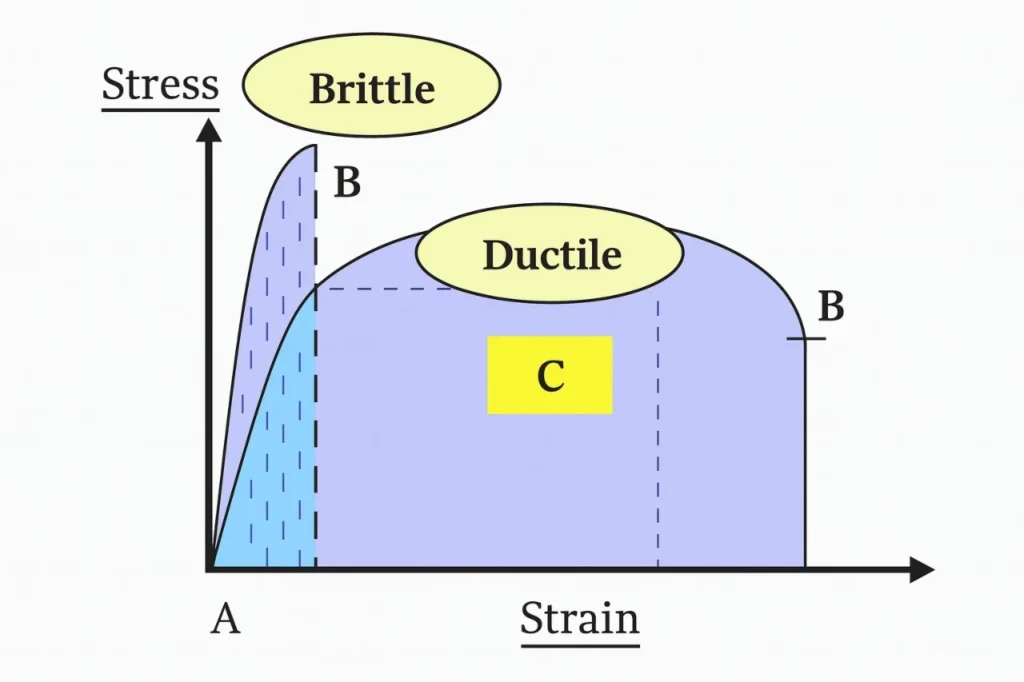

One of the primary challenges in dicing QFN packages is dealing with tin coatings, which are commonly used for their excellent solderability. However, during the dicing process, the friction between the cutting blade and the material generates heat, which can cause the tin layer to soften or even melt. This results in smearing and surface contamination, which can affect subsequent bonding or assembly steps. Additionally, lead melting can alter the dimensional accuracy of the cut, making it difficult to maintain tight tolerances. Melted tin can also accumulate on the dicing blade, reducing cutting efficiency and necessitating frequent blade cleaning and maintenance. To mitigate these issues, proper cooling techniques, optimized spindle speeds, and appropriate blade selection must be employed to minimize heat generation and material smearing.

Nickel and palladium coatings, which serve as barrier layers to enhance corrosion resistance and improve solder joint reliability, introduce another significant challenge. These metals are much harder than tin, making them more difficult to cut. Their abrasive nature leads to increased blade wear, reducing blade life and requiring frequent replacements. The hardness of these coatings also puts excessive stress on the dicing blade, increasing the risk of premature breakage, particularly when using fine-grit blades. In some cases, improper cutting parameters can cause chipping or delamination at the edges of the package, which compromises the integrity of the QFN device. Overcoming these issues requires the use of specialized resin-bonded diamond blades & hybrid bond dicing blades designed for cutting hard metals, along with optimized feed rates and spindle speeds that reduce blade stress while maintaining precision.

Blade Life is another major concern in QFN dicing. The repeated transition between soft materials like tin and hard coatings like nickel and palladium accelerates blade wear. As a result, manufacturers often face frequent blade replacements, which increases production costs and downtime. Additionally, as blades wear down, the quality of the cuts may become inconsistent, leading to higher rejection rates and negatively impacting overall yield. More frequent blade replacements and process interruptions further contribute to rising manufacturing expenses. Specialized dicing blades with optimized bond matrices and grit sizes must be used to strike a balance between sharpness and durability. Regular blade dressing and proper coolant application can also extend blade life, improving efficiency and reducing costs.

Burr formation and smearing present another critical challenge in QFN dicing. Rough or incomplete cuts can result in burrs along the edges of the package, which can interfere with electrical contacts during assembly. Soft materials like tin tend to smear, contaminating the workpiece and causing adhesion or bonding issues in later processing stages. These defects often require additional post-processing steps such as deburring or edge polishing, which increase both production time and costs

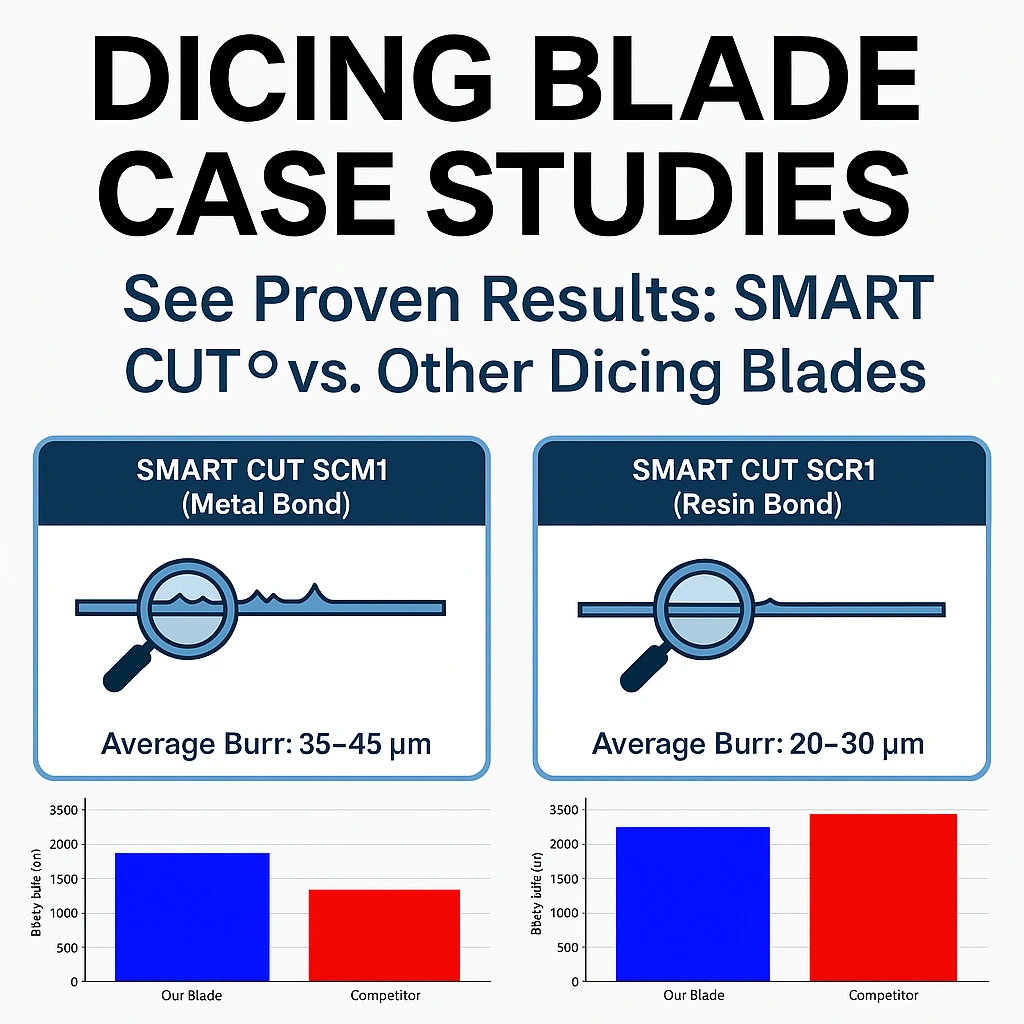

When selecting the right dicing blade for cutting QFN (Quad Flat No-Lead) products, understanding key performance metrics such as burr formation, smearing, and wear rate is essential. The following analysis is based on the performance of resin bond and metal bond blades, highlighting their advantages and limitations based on measured results.

1. Burr Comparison on QFN Product

Findings:

-

Metal bond blades produced significantly higher burr levels, averaging 35-45 microns, which remained relatively consistent throughout the blade life.

Metal bond blades produced significantly higher burr levels, averaging 35-45 microns, which remained relatively consistent throughout the blade life.

-

Resin bond blades showed a lower burr formation, staying within the

20-30 micron range, indicating a smoother cut.

Resin bond blades showed a lower burr formation, staying within the

20-30 micron range, indicating a smoother cut.

Analysis:

-

Higher burr formation in metal bond blades can result in increased post-processing requirements, such as additional polishing or secondary finishing steps.

Higher burr formation in metal bond blades can result in increased post-processing requirements, such as additional polishing or secondary finishing steps.

-

Resin bond blades exhibit better surface integrity , reducing the need for excessive deburring and improving overall cut quality.

Resin bond blades exhibit better surface integrity , reducing the need for excessive deburring and improving overall cut quality.

-

This suggests that resin bond blades are preferable for applications requiring minimal burr and a high degree of precision.

This suggests that resin bond blades are preferable for applications requiring minimal burr and a high degree of precision.

2. Smearing Comparison on QFN Product

Findings:

-

Metal bond exhibited a higher level of smearing, with values fluctuating between 45-55 microns over the course of blade life.

Metal bond exhibited a higher level of smearing, with values fluctuating between 45-55 microns over the course of blade life.

-

Resin bond performed better in minimizing smearing, remaining within a range of

25-35 microns throughout the test.

Resin bond performed better in minimizing smearing, remaining within a range of

25-35 microns throughout the test.

Analysis:

-

Smearing occurs when material deposits or deforms along the cut edge, affecting dimensional accuracy and potentially impacting subsequent bonding or assembly processes.

Smearing occurs when material deposits or deforms along the cut edge, affecting dimensional accuracy and potentially impacting subsequent bonding or assembly processes.

-

The lower smearing observed with resin bond blades, suggests superior edge definition and reduced material drag during cutting.

The lower smearing observed with resin bond blades, suggests superior edge definition and reduced material drag during cutting.

-

Metal bond blades , while more durable, can cause excessive smearing, leading to additional cleaning or rework in manufacturing.

Metal bond blades , while more durable, can cause excessive smearing, leading to additional cleaning or rework in manufacturing.

-

For applications where clean and precise cuts are critical, such as semiconductor dicing and advanced electronics packaging, resin bond blades offer a significant advantage.

For applications where clean and precise cuts are critical, such as semiconductor dicing and advanced electronics packaging, resin bond blades offer a significant advantage.

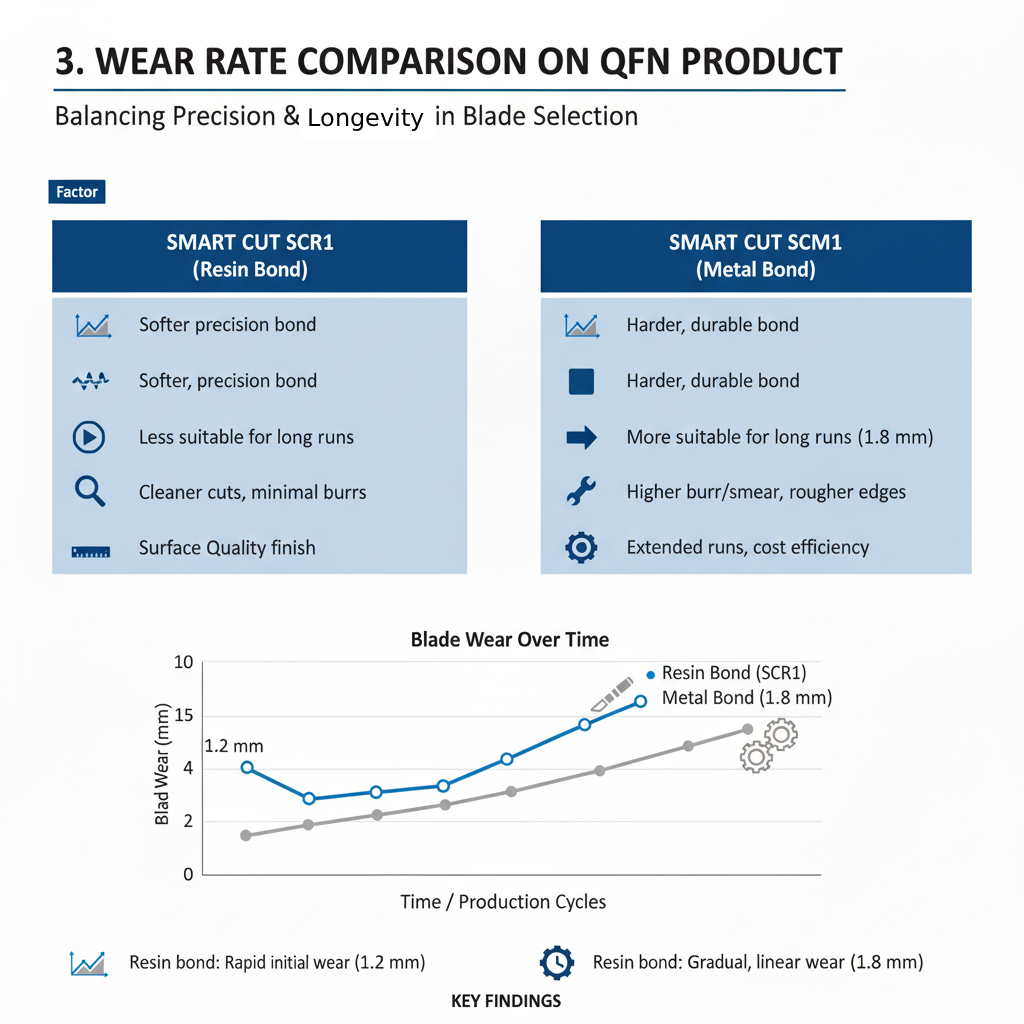

3. Wear Rate Comparison on QFN Product

Findings:

-

Resin bond blades experienced rapid initial wear, with blade wear reaching 1.2 mm relatively early in the blade life.

Resin bond blades experienced rapid initial wear, with blade wear reaching 1.2 mm relatively early in the blade life.

-

Metal bond blades wore down more gradually, showing a

linear increase in wear rate, reaching approximately 1.8 mm at the end of the test.

Metal bond blades wore down more gradually, showing a

linear increase in wear rate, reaching approximately 1.8 mm at the end of the test.

Analysis:

-

Resin bond blades degrade faster due to their softer bond structure, making them less suitable for long production runs but ideal for precision applications.

Resin bond blades degrade faster due to their softer bond structure, making them less suitable for long production runs but ideal for precision applications.

-

Metal bond blades , while more wear-resistant, have a higher burr and smear rate, meaning they might not be the best choice for applications that require high-quality surface finishes. , while more wear-resistant, have a higher burr and smear rate, meaning they might not be the best choice for applications that require high-quality surface finishes.

Metal bond blades , while more wear-resistant, have a higher burr and smear rate, meaning they might not be the best choice for applications that require high-quality surface finishes. , while more wear-resistant, have a higher burr and smear rate, meaning they might not be the best choice for applications that require high-quality surface finishes.

-

The decision between resin vs. metal bond blades should be based on the trade-off between longevity and cut quality.

The decision between resin vs. metal bond blades should be based on the trade-off between longevity and cut quality.

-

For extended production runs where blade longevity is a priority, metal bond blades may be a cost-effective solution.

For extended production runs where blade longevity is a priority, metal bond blades may be a cost-effective solution.

-

For applications where cut quality, precision, and minimal burr/smearing are critical, resin bond blades should be the preferred choice.

For applications where cut quality, precision, and minimal burr/smearing are critical, resin bond blades should be the preferred choice.

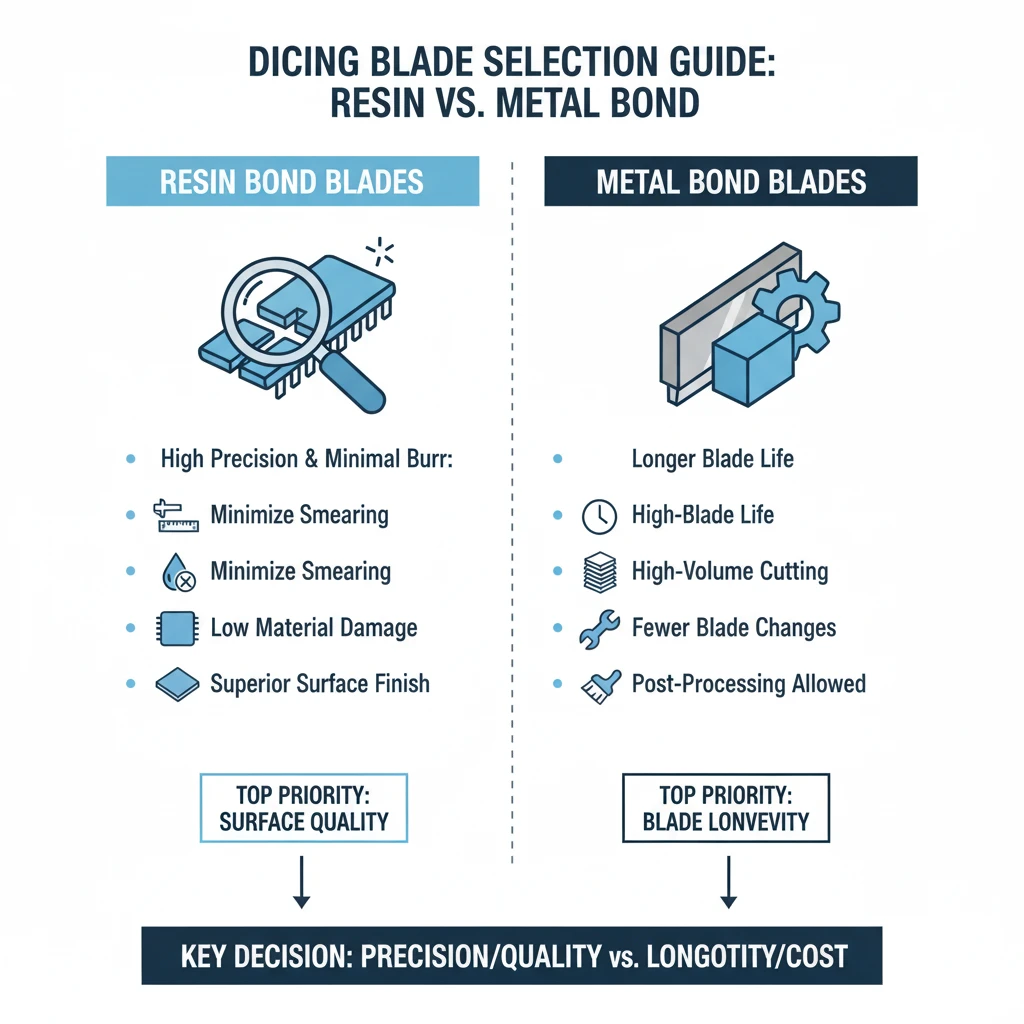

Based on this analysis, the choice of blade should be dictated by the specific requirements of the application:

Use Resin Bond Blades When:

-

High precision and minimal burr formation are needed.

High precision and minimal burr formation are needed.

-

Smearing must be minimized to maintain clean cuts.

Smearing must be minimized to maintain clean cuts.

-

The application requires low material damage and superior surface finish..

The application requires low material damage and superior surface finish..

Use Metal Bond Blades When:

-

Longer blade life is required.

Longer blade life is required.

-

The application involves high-volume cutting where frequent blade changes are not ideal.

The application involves high-volume cutting where frequent blade changes are not ideal.

-

Some degree of post-processing (deburring, cleaning) is acceptable.

Some degree of post-processing (deburring, cleaning) is acceptable.

If surface quality and precision are the top priority, resin bond blades are the superior choice for cutting QFN products. However, if blade longevity and wear resistance are more critical, metal bond blades provide a longer-lasting solution but at the cost of increased burr and smearing.

Comparing Sintered (Metal bond) & Resin Bond Dicing Blades for QFN

|

Parameter |

Resin Bond Blade |

Metal Bond Blade |

|---|---|---|

|

|

|

|

Cut Quality |

Excellent (low burr, low smear) |

Moderate (high burr, high smear) |

|

Blade Life |

Shorter (higher wear rate) |

Longer (slower wear rate) |

|

Smearing |

Low |

High |

|

Burr Formation |

Low |

High |

|

Cutting Speed |

Faster |

Slower |

|

Best for |

Precision cuts, minimal post-processing |

Long production runs, high durability |

-

If the primary concern is surface quality and precision, resin bond blades are the superior choice.

If the primary concern is surface quality and precision, resin bond blades are the superior choice.

-

If maximizing blade life and minimizing replacement frequency is the goal, metal bond blades are preferred, but additional finishing steps may be required.

If maximizing blade life and minimizing replacement frequency is the goal, metal bond blades are preferred, but additional finishing steps may be required.

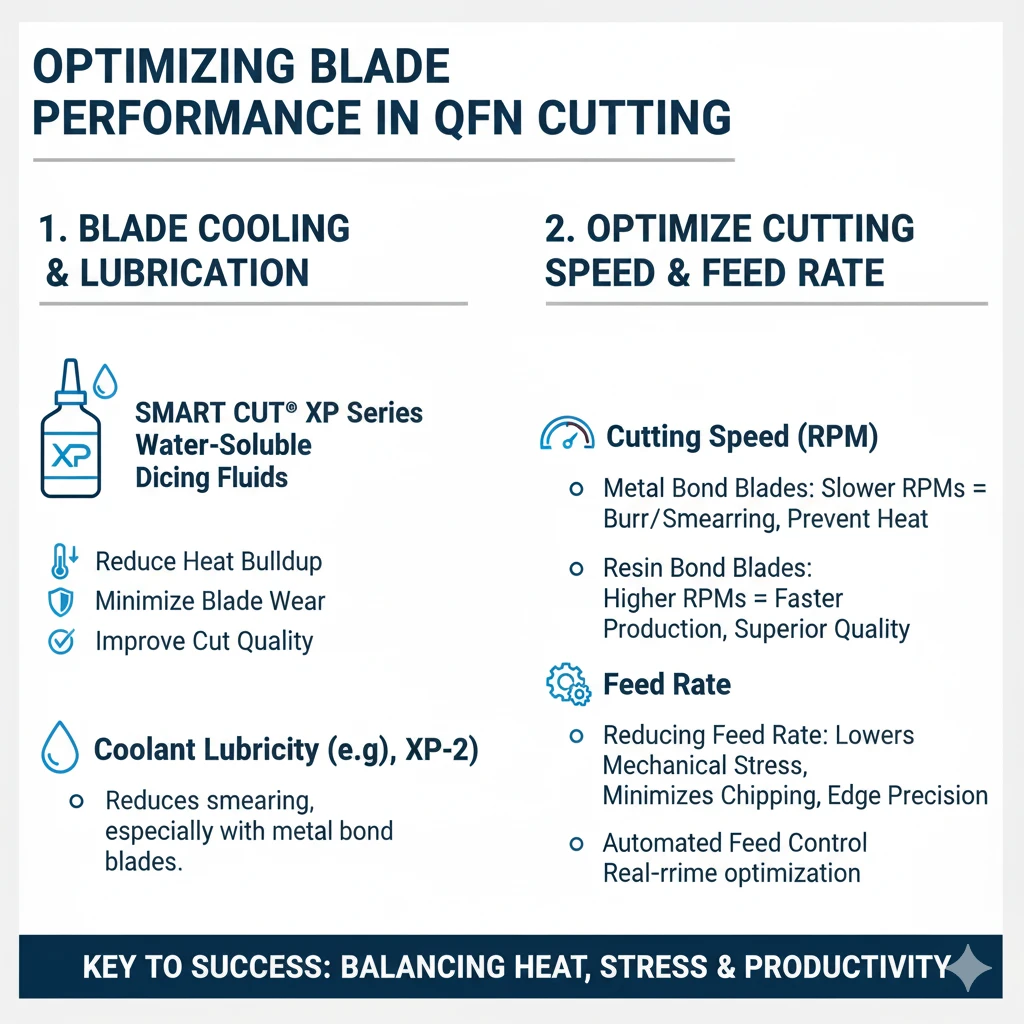

Optimizing Blade Performance in QFN Cutting

Several key factors influence cutting efficiency, productivity, and cost-effectiveness. Understanding these considerations helps refine the selection process and improve overall performance.

Blade cooling and lubrication play a crucial role in cutting results. The use of appropriate coolants, such as SMART CUT® XP Series water-soluble dicing fluids, helps reduce heat buildup, minimize blade wear, and improve cut quality. Selecting a coolant with higher lubricity, like XP-2, may further reduce smearing, particularly when using metal bond blades, which tend to generate more friction during cutting.

Optimizing cutting speed and feed rate is another critical factor. Slower cutting speeds, or lower RPMs, help reduce burr formation and smearing with metal bond blades by preventing excessive heat buildup. Resin bond blades, on the other hand, can tolerate higher RPMs, allowing for faster production cycles while maintaining a superior cut quality. Reducing the feed rate lowers mechanical stress on the blade, minimizing chipping and improving edge precision. Implementing an automated feed control system enables real-time optimization of cutting parameters based on blade wear and material resistance.

Process Parameters for Optimized Dicing of QFN Packages

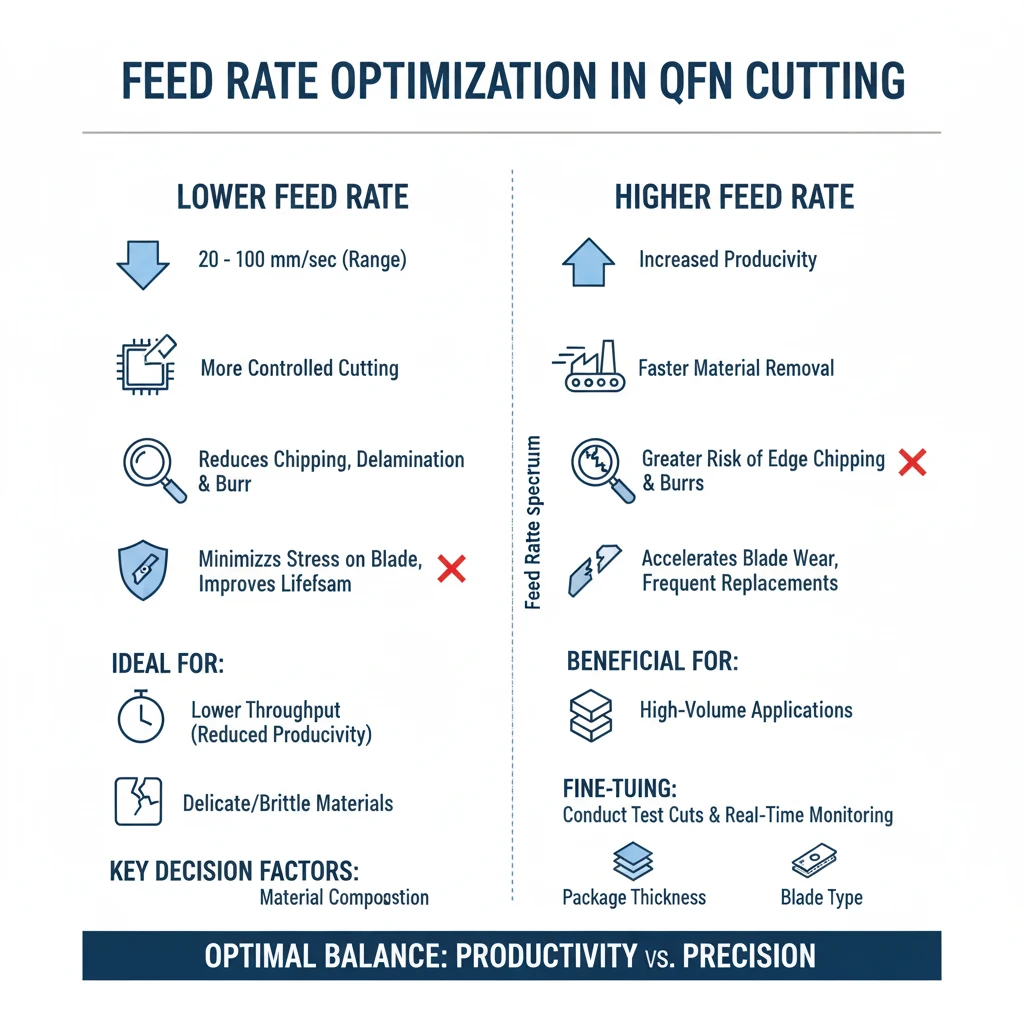

Achieving optimal dicing results for QFN packages requires precise control over process parameters, particularly feed rate and spindle speed. These parameters play a critical role in ensuring clean cuts, minimizing defects, and extending blade life. A well-optimized dicing process not only enhances the quality of the final product but also improves manufacturing efficiency by reducing rework and material waste.

Feed Rate Optimization

The feed rate, which refers to the speed at which the dicing blade moves through the material, is a crucial factor in determining cut quality and blade longevity. For QFN dicing, the recommended feed rate ranges from 20 to 100 mm/sec. Selecting the appropriate feed rate depends on multiple factors, including the material composition, the thickness of the QFN package, and the type of dicing blade used.

A lower feed rate allows for more controlled cutting, reducing the likelihood of chipping, delamination, and burr formation. This is particularly important when working with delicate or brittle materials, where sudden force can cause structural damage to the package edges. Slower feed rates also minimize stress on the blade, improving its lifespan and maintaining cut precision. However, the trade-off is lower throughput, which can reduce production efficiency in high-volume environments.

Conversely, a higher feed rate increases productivity by allowing faster material removal. This is beneficial for applications requiring high output, but it also introduces a greater risk of defects such as edge chipping and excessive burr formation. Additionally, aggressive feed rates can accelerate blade wear, leading to more frequent blade replacements and higher operating costs.

To determine the ideal feed rate, manufacturers should conduct test cuts, evaluating cut quality and blade performance under different conditions. Fine-tuning the feed rate based on real-time monitoring can help achieve the right balance between productivity and precision.

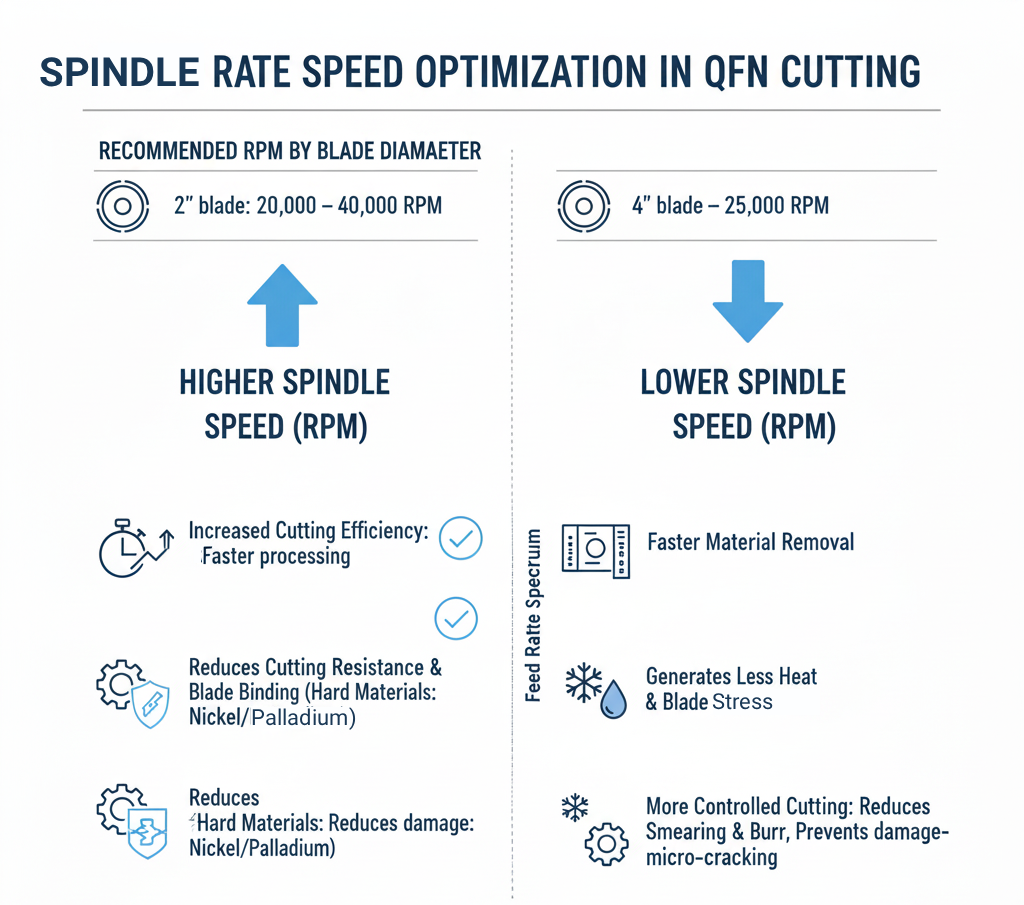

Spindle Speed Optimization

Spindle speed, measured in revolutions per minute (RPM), directly affects cutting efficiency, heat generation, and blade wear. The optimal spindle speed varies depending on the blade diameter, with recommended ranges as follows:

-

2” blade: 20,000 – 40,000 RPM

2” blade: 20,000 – 40,000 RPM

-

3” blade: 15,000 – 25,000 RPM

3” blade: 15,000 – 25,000 RPM

-

4” blade: 8,000 – 15,000 RPM

4” blade: 8,000 – 15,000 RPM

Higher spindle speeds improve cutting efficiency by increasing the number of cutting actions per second, leading to smoother cuts and faster processing. A high spindle speed is particularly advantageous when working with hard materials such as nickel-palladium coatings, as it reduces cutting resistance and prevents blade binding. However, excessive spindle speeds can generate excess heat, which may cause thermal damage to sensitive materials, leading to micro-cracking or warping of the QFN package.

Lower spindle speeds generate less heat and place less stress on the blade, making them ideal for softer materials like tin. Operating at a slower speed allows for more controlled cutting, reducing smearing and burr formation. However, cutting at too low of a speed can result in inefficient material removal and increased friction, which may lead to blade clogging and premature wear.

Achieving the correct spindle speed requires careful consideration of material properties, blade specifications, and desired cut quality. Real-time adjustments based on monitoring spindle load and temperature can help prevent defects while maintaining optimal productivity.

Balancing Feed Rate and Spindle Speed for Optimal Performance

The relationship between feed rate and spindle speed must be carefully balanced to achieve high-quality dicing results. If the feed rate is too high while the spindle speed is too low, the blade may struggle to cut through the material efficiently, resulting in increased chipping and blade wear. On the other hand, a high spindle speed combined with a slow feed rate can lead to excessive heat buildup, which may cause material degradation or melting in tin-coated layers.

To optimize the process, manufacturers should:

-

Use higher spindle speeds with moderate feed rates when cutting harder materials like nickel-palladium layers to improve cutting efficiency and blade longevity.

Use higher spindle speeds with moderate feed rates when cutting harder materials like nickel-palladium layers to improve cutting efficiency and blade longevity.

-

Employ lower spindle speeds with slower feed rates when dicing softer or more delicate materials to reduce smearing and improve cut precision.

Employ lower spindle speeds with slower feed rates when dicing softer or more delicate materials to reduce smearing and improve cut precision.

-

Monitor blade condition and cut quality throughout the process to identify the ideal parameter settings for specific QFN configurations.

Monitor blade condition and cut quality throughout the process to identify the ideal parameter settings for specific QFN configurations.

Blade maintenance and dressing also impact cutting performance. Metal bond blades require frequent dressing to maintain cutting efficiency and minimize burrs. Resin bond blades naturally expose new diamonds as the bond wears, reducing the need for frequent dressing but leading to a higher consumption rate. Utilizing dressing sticks or automatic blade conditioning systems extends blade life and ensures consistent performance over time.

A thorough cost-benefit analysis helps determine whether resin or metal bond blades provide the best long-term value for a specific application. While sintered (metal bond) blades last longer, the higher levels of burr and smearing may increase post-processing costs related to cleaning, secondary machining, or polishing.

Resin bond blades wear faster but may reduce total processing time by delivering superior cut quality from the start. A proper return on investment calculation should consider factors such as blade replacement frequency, post-processing costs, impact on overall production efficiency, and yield improvements due to reduced material damage.

Material composition should also be factored into blade selection. When cutting QFN products with softer metals, such as copper leadframes, resin bond blades help prevent material deformation and excessive smearing. However, for QFN packages that incorporate harder composite layers, such as ceramic-filled epoxy molding compounds, metal bond blades may offer better longevity. In such cases, optimizing cutting parameters is essential to avoid excessive burr formation and material damage.

For specialized applications requiring both long blade life and high-quality cuts, hybrid solutions may provide an alternative. Hybrid bond dicing blades that combine resin and metal bond characteristics offer a balance between durability and surface finish. Customizing diamond concentration and grit size further fine-tunes blade performance based on the specific composition of the QFN materials.

Ultimately, selecting the right blade depends on production priorities. If precision, minimal burr formation, and reduced post-processing are the main concerns, resin bond blades are the preferred choice. If extended blade life and minimal blade replacement are more critical, metal bond blades provide a cost-effective solution, though additional finishing steps may be required. By considering factors such as lubrication, cutting speed, feed rate, blade maintenance, cost analysis, and material composition, manufacturers can achieve the optimal balance between quality, efficiency, and longevity in QFN cutting operations.

The cutting environment plays a crucial role in determining burr formation, smearing, and blade wear. Maintaining consistent temperature control during cutting operations helps prevent excessive heat buildup, which can accelerate blade degradation and negatively impact cut quality. Temperature fluctuations, particularly in dry cutting conditions or high-speed operations, pose a serious challenge to maintaining optimal blade performance.

An increase in temperature, especially in dry or high-speed cutting, leads to the softening of the resin bond matrix, causing premature wear and reducing the blade’s ability to retain diamond particles effectively. This results in inconsistent cutting performance and higher blade consumption. In contrast, metal bond blades suffer from excessive heat in a different way—prolonged exposure to high temperatures can cause diamond dulling by leading to graphitization or oxidation, reducing cutting efficiency and increasing smearing.

To mitigate these effects, employing temperature-controlled coolants is critical. Water-soluble dicing fluids, such as SMART CUT® XP Series coolants, help dissipate heat, preventing excessive temperature spikes that contribute to bond breakdown and smearing. Selecting the right coolant formulation also influences surface finish and blade longevity; SMART CUT® XP-2 high-lubricity coolants are particularly effective in reducing friction at the cutting interface, whereas SMART CUT®XP-3 low-foaming coolants ensure consistent performance in high-speed operations where foaming could become problematic.

Application Example

Beyond coolant selection, ensuring proper airflow regulation within the machining area further reduces thermal expansion effects on both the blade and workpiece. Controlled airflow helps stabilize cutting temperatures, preventing sudden heat fluctuations that could alter cutting accuracy. In some cases, localized cooling systems such as directed air jets or cryogenic cooling may be implemented to provide additional temperature stabilization, especially when working with heat-sensitive materials like ceramics, composite laminates, or semiconductor substrates.

Additionally, monitoring humidity levels in the cutting environment is essential for processes where electrostatic discharge (ESD) sensitivity is a concern. Excessively dry air can increase static buildup, particularly when working with brittle or electrically charged materials. Using SMART CUT® XP-4 ESD-sensitive dicing fluids can help neutralize static buildup at the cutting interface, ensuring stable cutting conditions and preventing material contamination due to electrostatic attraction.

Finally, implementing real-time temperature monitoring and adaptive process control can significantly improve consistency and blade longevity. Modern machine vision systems and infrared sensors allow for continuous tracking of cutting temperature, automatically adjusting coolant flow rates and air circulation based on live process data. Integrating predictive analytics into cutting systems can help anticipate thermal stress points, making real-time optimizations to reduce blade wear and improve yield rates.

Balancing Cutting Pressure and Blade Force

Applying excessive pressure during the cutting process leads to increased material deformation, affecting overall cut precision. Resin bond blades, being more sensitive to pressure changes, can experience rapid wear or uneven wear patterns when excessive force is applied. Metal bond blades, while more robust, are prone to creating heat-affected zones if pressure is too high, leading to localized material hardening and increased burr formation. Implementing a force-controlled feed mechanism ensures that the blade applies only the necessary pressure for optimal material removal. Advanced monitoring systems, such as force-feedback mechanisms in automated cutting systems, allow real-time adjustments based on blade condition and material resistance.

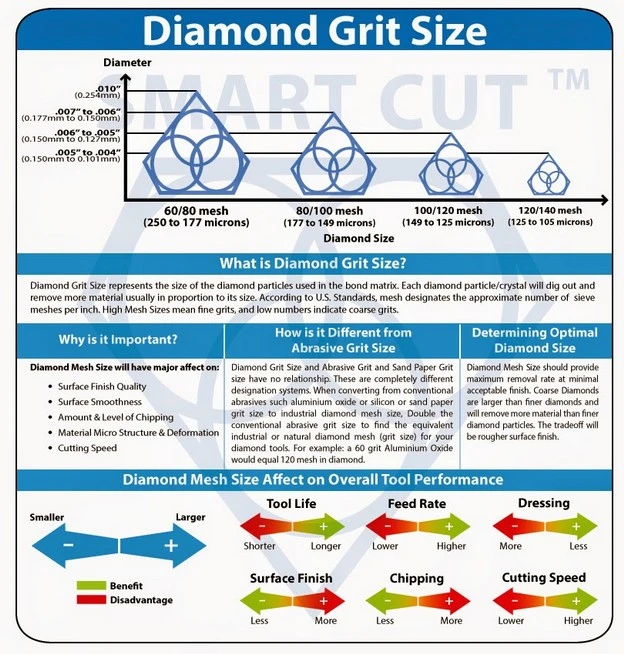

Effect of Blade Geometry and Grit Size Selection

Blade geometry, including thickness, side relief, and diamond grit size, significantly impacts performance in QFN cutting. Thinner blades reduce material loss (kerf width) and minimize cutting resistance, leading to a lower chance of chipping and cracking. However, a thinner kerf also means higher susceptibility to blade deflection, requiring careful control of RPMs and feed rate to maintain cut accuracy.

The selection of diamond grit size influences both cut speed and surface finish. Finer grit sizes (higher mesh numbers) produce a smoother surface with lower burr and smear levels, making them ideal for high-precision applications. Coarser grit sizes (lower mesh numbers) provide faster material removal rates but may leave rougher edges, requiring additional post-processing. In many cases, manufacturers use multi-step cutting where an initial coarse-grit cut is followed by a fine-grit finishing cut to balance speed and quality.

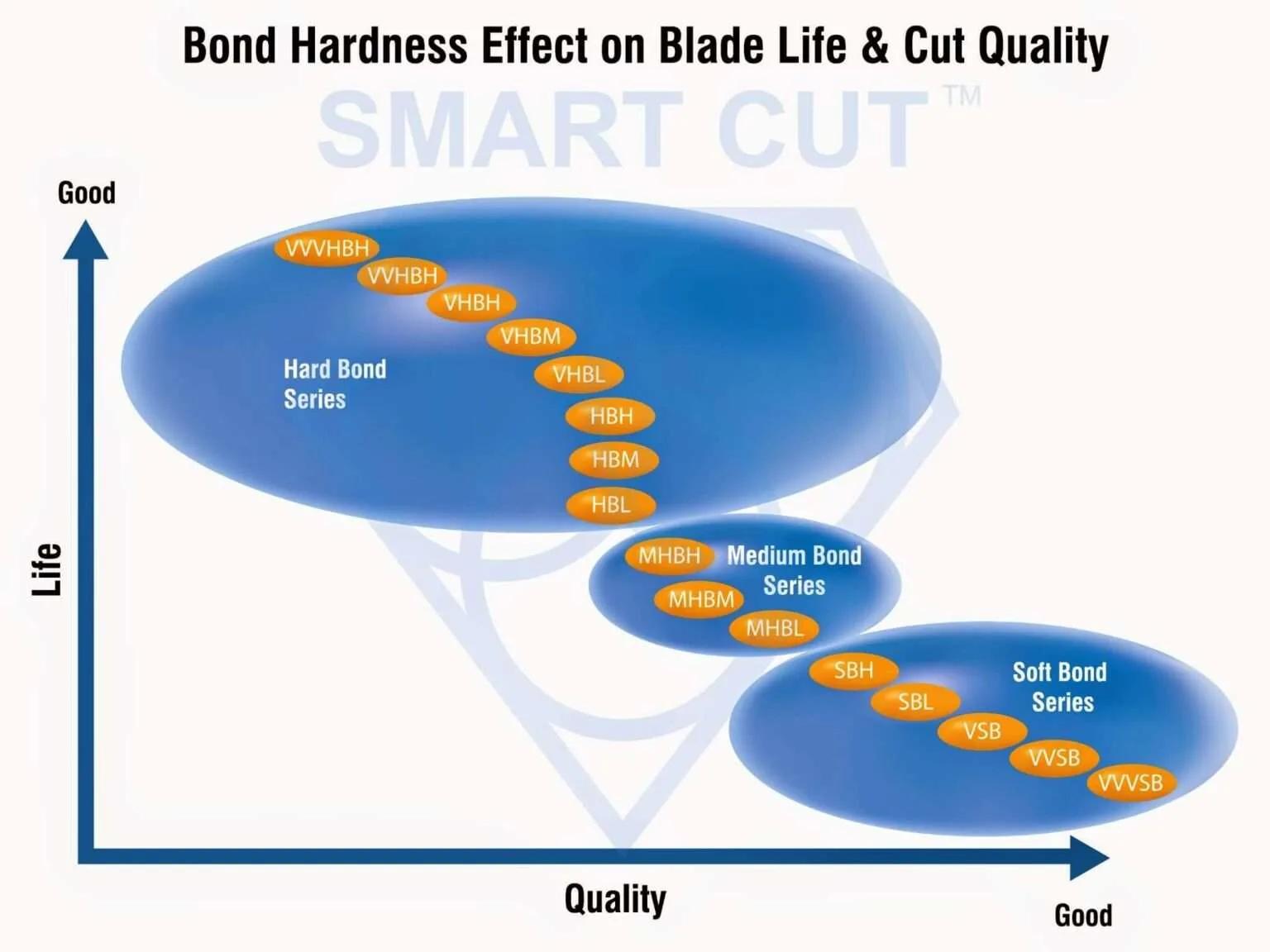

Influence of Blade Bond Hardness on Performance

The hardness of the blade bond determines how quickly diamonds are exposed during cutting. A softer bond wears faster, exposing fresh diamond particles more frequently, which improves cutting efficiency but shortens blade lifespan. A harder bond lasts longer but may lead to diamond dulling before new abrasive particles are exposed, increasing cutting forces and smearing.

For applications requiring extended production runs, metal bond blades with moderate hardness provide a good balance between wear resistance and diamond exposure. For high-precision or delicate materials, using a softer resin bond blade helps maintain low cutting forces and minimizes chipping. Hybrid bond formulations can also be tailored to specific material compositions, offering an intermediate solution between wear resistance and cut quality.

Automation and Data-Driven Optimization

In modern manufacturing environments, automated cutting systems and real-time process monitoring allow for greater precision and consistency in QFN cutting. By integrating sensor-based monitoring of blade wear, cutting force, and temperature, manufacturers can optimize cutting parameters dynamically, ensuring consistent performance throughout the blade’s life cycle. AI-driven analytics, based on real-time data collection, can help predict optimal blade replacement times, reducing unexpected downtime and improving overall production efficiency.

Balancing Cost, Performance, and Quality in Blade Selection

The decision between resin and metal bond blades should not be made in isolation but rather as part of an overall process cost-benefit analysis. While resin bond blades offer superior cut quality, they require more frequent replacement, leading to higher consumable costs. Metal bond blades, despite their durability, may introduce additional post-processing expenses due to increased burr formation and smearing.

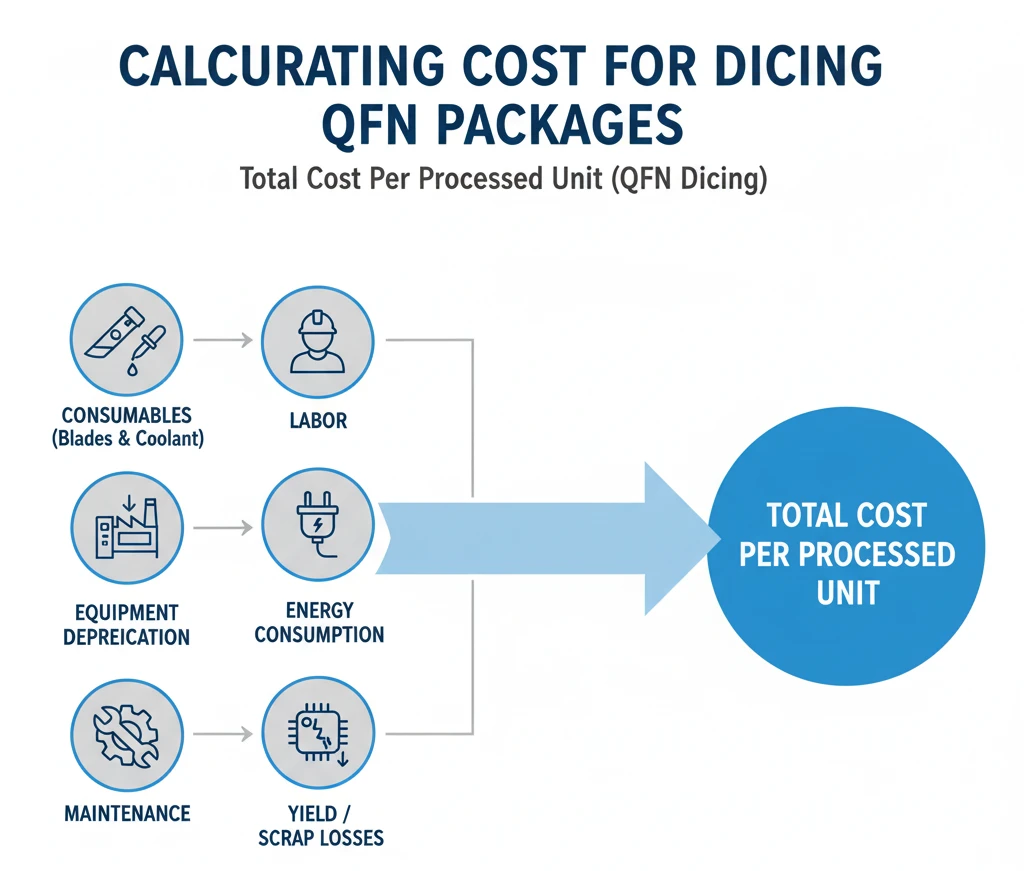

Calculating total cost per processed unit, rather than just blade cost, provides a clearer picture of which option is more economical in the long run. Factors such as reduced material waste, lower rework rates, improved process efficiency, and overall yield improvement should be considered when evaluating blade selection.

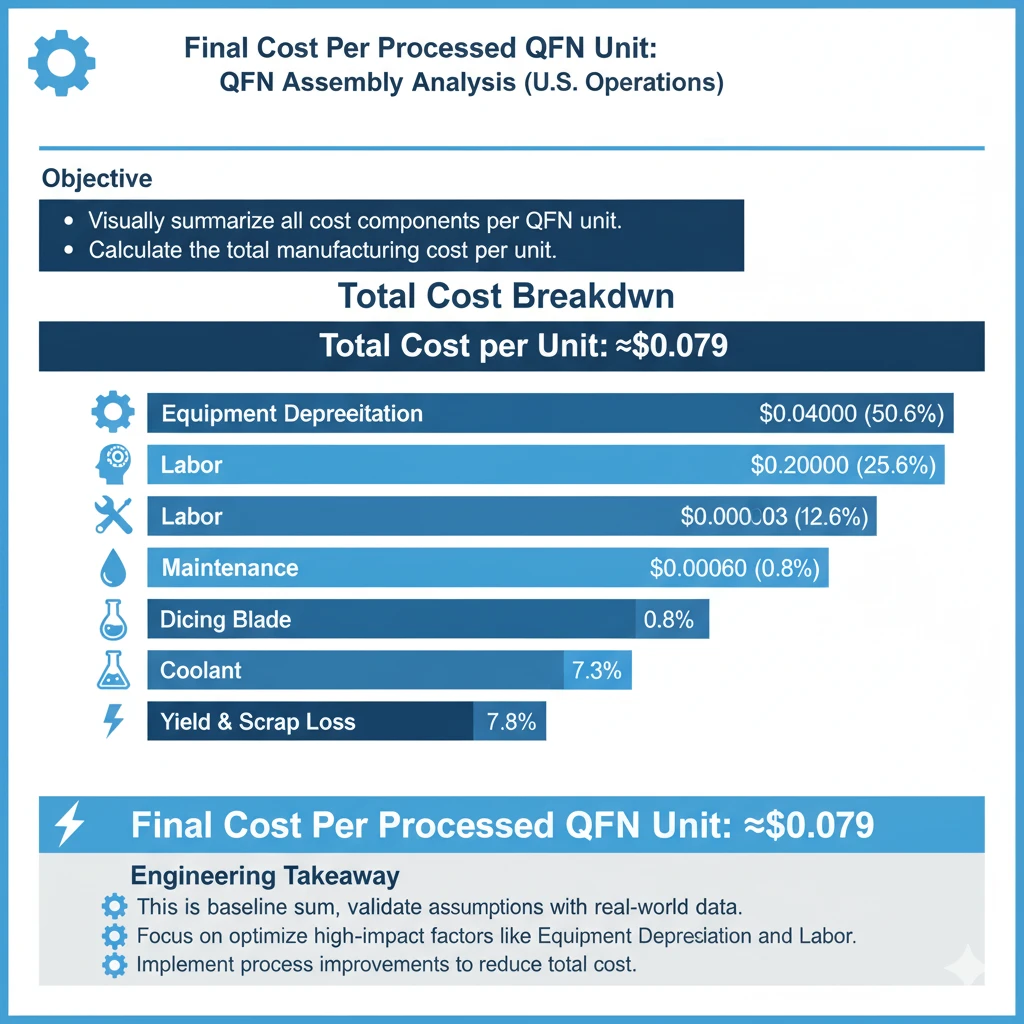

Calculating Cost for Dicing QFN Packages

The total cost per processed unit in QFN dicing consists of several key cost factors, including

-

Consumables (dicing blades and coolant)

Consumables (dicing blades and coolant)

-

Equipment depreciation

Equipment depreciation

-

Maintenance

Maintenance

-

Labor

Labor

-

Energy consumption

Energy consumption

-

Yield/scrap losses

Yield/scrap losses

Below is the detailed breakdown of each cost component. Please note this is just for example purposes only and the cost is based on U.S. (American Operations). Costs factors will significantly vary based on the Region/Country and other factors.

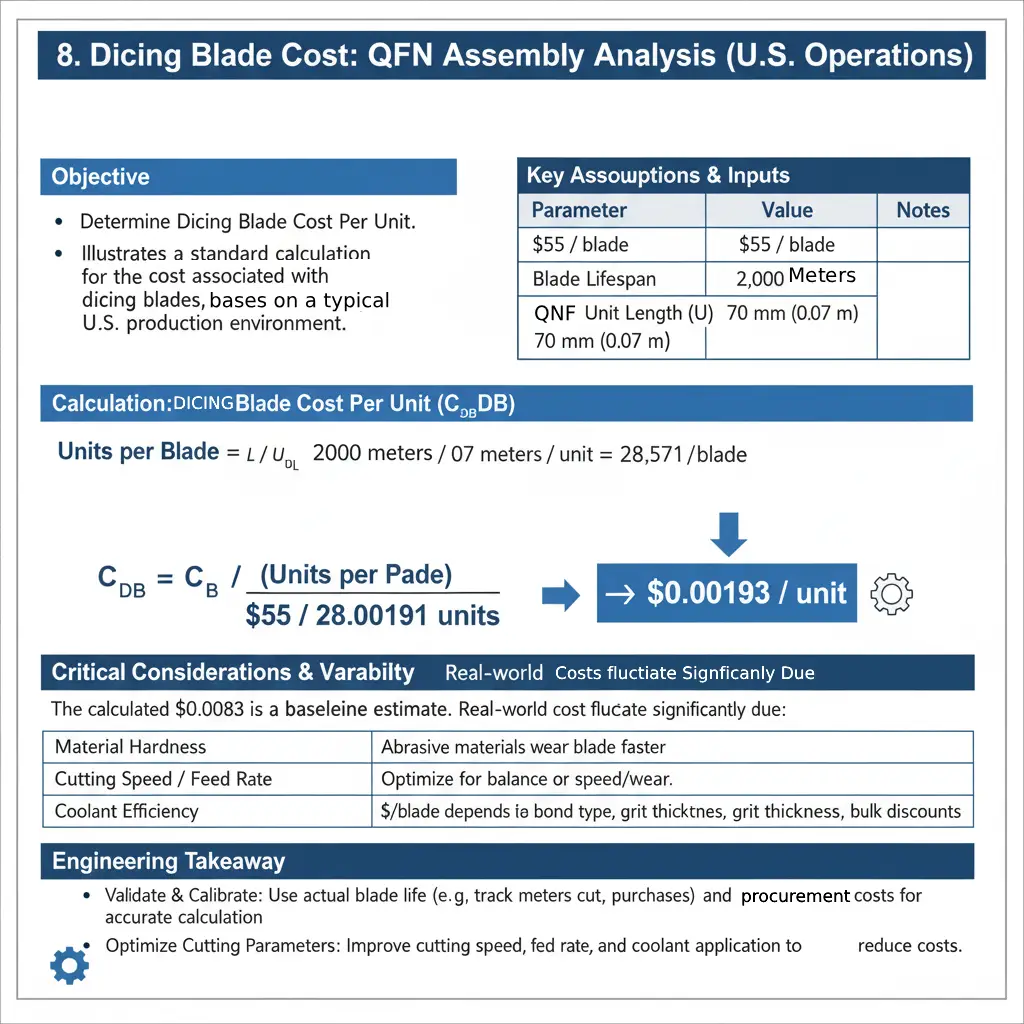

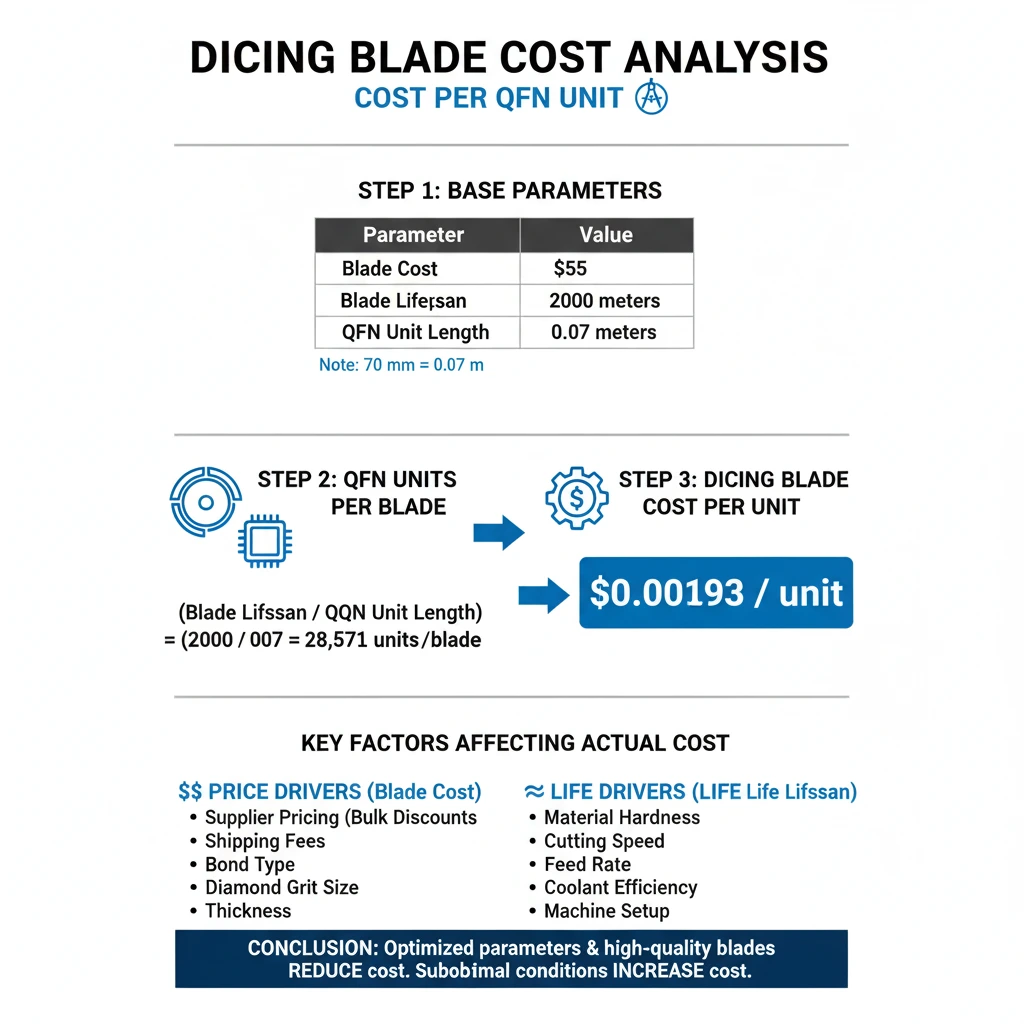

1. Dicing Blade Cost

Each dicing blade costs $55 and has a cutting life of 2,000 meters. Given that each QFN unit is approximately 70 mm (0.07 m), we calculate the total number of QFN units processed per blade:

(2000/0.07)=28,571 QFN units per blade

The cost per unit for the dicing blade: (55/28,571)=0.00193

The Dicing Blade Cost calculation assumes a blade price of $55 and an estimated blade lifespan of 2,000 meters before replacement. Actual blade costs may vary depending on supplier pricing, bulk purchase discounts, shipping fees, and blade specifications such as bond type, diamond grit size, and thickness.

The blade lifespan of 2,000 meters is an estimate and may differ based on material hardness, cutting speed, feed rate, coolant efficiency, and machine setup. If cutting particularly abrasive materials or operating under suboptimal conditions, blade life may be shorter, increasing the cost per unit. Conversely, optimized cutting parameters and high-quality blade selection can extend lifespan, reducing overall costs.

Users should verify their actual blade life and procurement costs to adjust the calculation for a more accurate cost-per-unit estimate based on their specific dicing process and material conditions.

2. Coolant Cost

The Coolant Cost calculation assumes a price of $30.91 per gallon and an estimated coolant usage rate of 5,000 QFN units per gallon. This estimate is based on typical dicing operations but does not account for variations in coolant consumption due to machine settings, cutting parameters, or recirculation efficiency.

The cost of coolant is $1,7000 per 55-gallon drum. Since each gallon costs: (1,700/55)=30.91 USD per gallon

We assume One gallon of coolant processes 5,000 QFN. The cost per unit for coolant: (30.91/5,000)=0.0062

Thus, the coolant cost per unit is $0.0062

Actual coolant costs may vary depending on coolant type, evaporation rate, filtration system efficiency, disposal costs, and specific machine flow rate settings. A once-through coolant system will result in higher consumption and increased costs, while a recirculating system can significantly reduce per-unit expenses.

Users should monitor their actual coolant usage and system efficiency to refine cost estimates and adjust calculations based on real-world consumption rates and operational conditions.

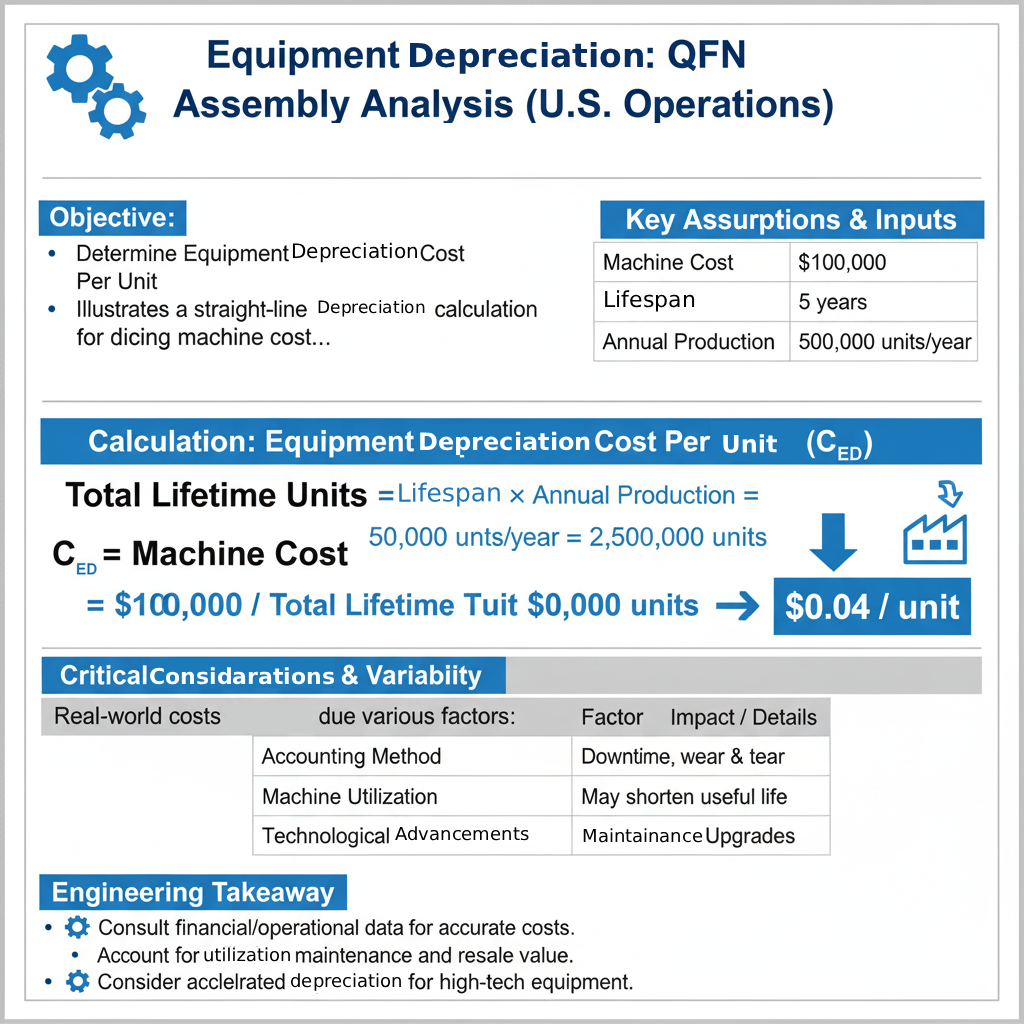

3. Equipment Depreciation

The Equipment Depreciation calculation assumes a dicing machine cost of $100,000 and an estimated lifespan of 5 years, processing 500,000 QFN units per year. These values are based on straight-line depreciation and do not account for factors such as resale value, machine efficiency degradation over time, or potential upgrades and maintenance costs.

The dicing machine cost of $100,000 and an estimated lifespan of 5 years, processing 500,000 QFN units per year. The total number of units processed in its lifetime:

(5*500,000) = 2,500,000

The cost per unit for equipment depreciation: (100,000/2,500,000) = 0.04

Thus, the equipment depreciation cost per unit is $0.04

Actual depreciation costs may vary depending on accounting methods used (e.g., straight-line vs. accelerated depreciation), machine downtime, wear and tear, technological advancements, and shifts in production volume. Additionally, unforeseen maintenance expenses or component replacements may increase the overall cost of ownership.

Users should consult their financial and operational data to determine the most accurate depreciation cost per unit, considering actual machine utilization, maintenance expenses, and potential resale or scrap value at the end of its useful life.

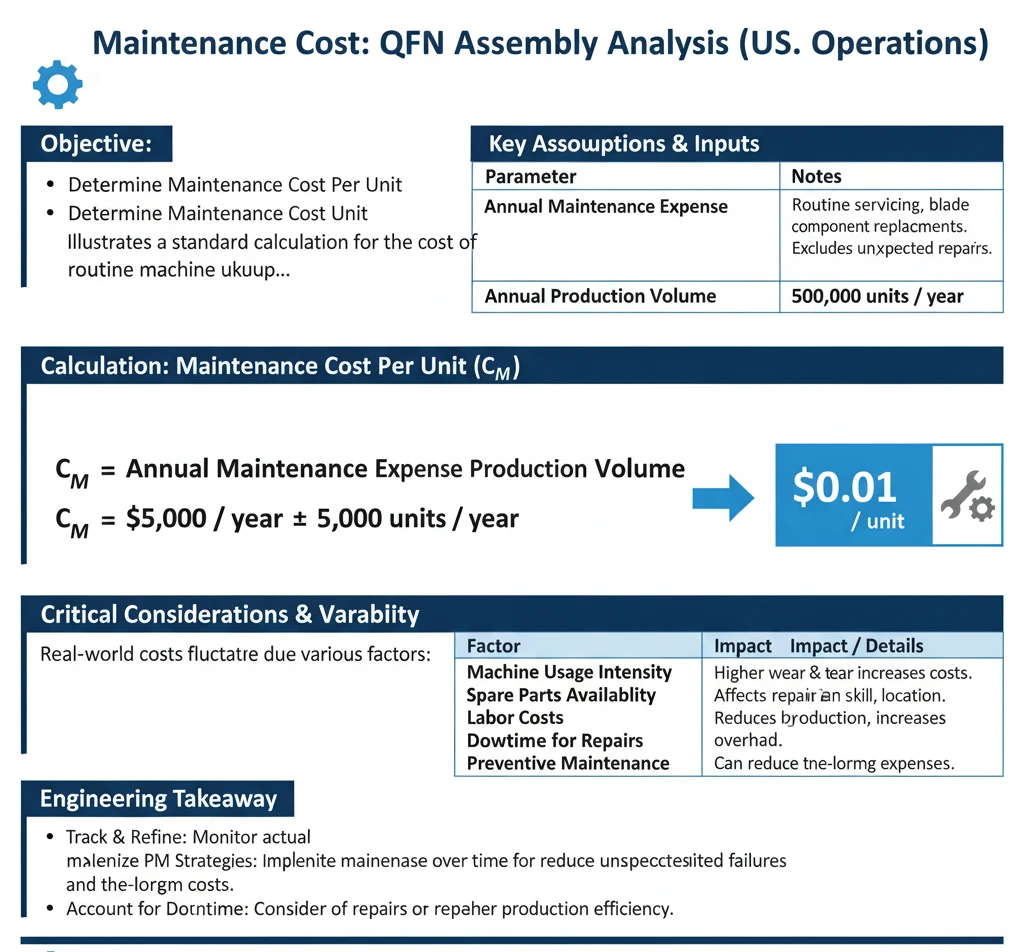

4. Maintenance Cost

Routine servicing, blade dressing, and component replacements cost approximately $5,000 per year. Since the machine processes 500,000 QFN units per year, the maintenance cost per unit is:

Annual maintenance expenses (routine servicing, blade dressing, and component replacements) are estimated at $5,000 per year. With 500,000 QFN units processed annually, the cost per unit for maintenance: (5,000/500,000) = 0.01

Thus, the maintenance cost per unit is $0.01.

The Maintenance Cost calculation assumes an annual maintenance expense of $5,000 and a processing volume of 500,000 QFN units per year. This estimate includes routine servicing, blade dressing, and component replacements, but does not account for unexpected repairs, major equipment failures, or variations in maintenance frequency.

Actual maintenance costs may fluctuate due to machine usage intensity, wear and tear on critical components, availability of spare parts, labor costs for servicing, and potential machine downtime for repairs. Additionally, preventive maintenance strategies and optimized operating conditions can reduce long-term maintenance expenses, while higher-than-expected operational stress can increase them.

Users should track actual maintenance expenses over time to refine cost estimates and adjust calculations based on real-world machine performance and service requirements.

5. Labor Cost

The hourly wage for an operator is $20 per hour *, and they process 1,000 QFN units per hour. The labor cost per unit is:

The operator's hourly wage is $20, and they process 1,000 QFN units per hour. The cost per unit for labor: (20/1,000) = 0.02

Thus, the labor cost per unit is $0.02.

The Labor Cost calculation assumes an hourly wage of $20 per hour and a processing rate of 1,000 QFN units per hour. Actual labor costs may vary significantly depending on geographic location, labor laws, employee experience, overtime pay, and additional benefits such as health insurance, bonuses, or training expenses.

The processing rate of 1,000 QFN units per hour is an estimate and can be affected by machine efficiency, operator skill level, setup time, downtime for maintenance, and overall workflow optimizations. In real-world production environments, variations in batch sizes, shift structures, and operator fatigue may impact productivity.

Users should validate these assumptions with their actual labor rates and production efficiency data to determine more accurate labor costs per unit based on their specific operational conditions. This example here is given for U.S. / American Operations.

6. Energy Cost

The Energy Cost calculation is based on an assumed machine power consumption of 2 kWh per hour and an electricity rate of $0.12 per kWh, which may vary depending on location, energy provider, and industrial contract rates. Actual power consumption can fluctuate based on machine efficiency, operational settings, cooling system load, and additional auxiliary equipment usage.

The dicing machine consumes 2 kWh per hour and an electricity rate is $0.12 per kWh, If the machine processes 1,000 QFN units per hour, the cost per units for energy: ((2*0.12)/1,000) = 0.00024

Thus, the energy cost per unit is $0.00024.

Furthermore, the unit processing rate of 1,000 QFN units per hour is an estimate and may differ depending on production speed, dicing parameters, blade wear, and material properties. Variations in uptime, maintenance schedules, and downtime for blade changes can also impact the actual energy cost per unit.

Users should verify their actual machine power consumption and electricity costs to obtain a more precise estimate and adjust calculations accordingly to reflect real-world conditions.

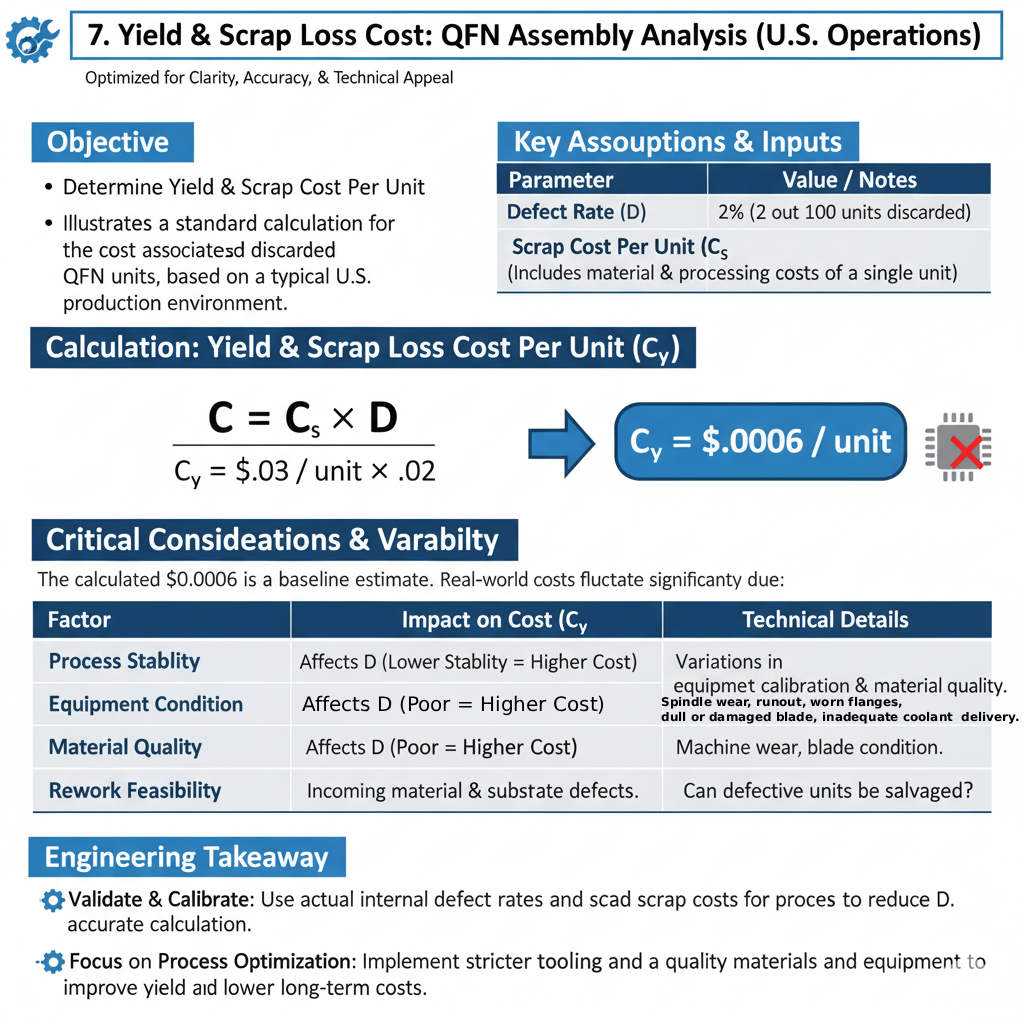

7. Yield & Scrap Loss Cost

The Yield & Scrap Loss Cost calculation is based on an assumed 2% defect rate, which may vary depending on process stability, equipment condition, material quality, and operator expertise. The actual defect rate could be higher or lower based on specific production environments, quality control measures, and cutting parameters.

A 2% defect rate means 2 out of every 100 QFN units are discarded. If the scrap cost per unit is $0.03,

then the effective cost per unit due to yield loss: (0.03*0.02) = 0.0006

Thus, the yield & scrap loss cost per unit is $0.0006.

Additionally, the scrap cost per unit is an estimate and may differ due to fluctuations in material costs, rework feasibility, and recovery processes. This calculation does not account for potential process optimizations, such as improved dicing parameters, enhanced blade selection, or better coolant application, which could reduce defect rates and lower overall costs.

Users should validate these assumptions with real production data and adjust calculations accordingly to reflect actual manufacturing conditions.

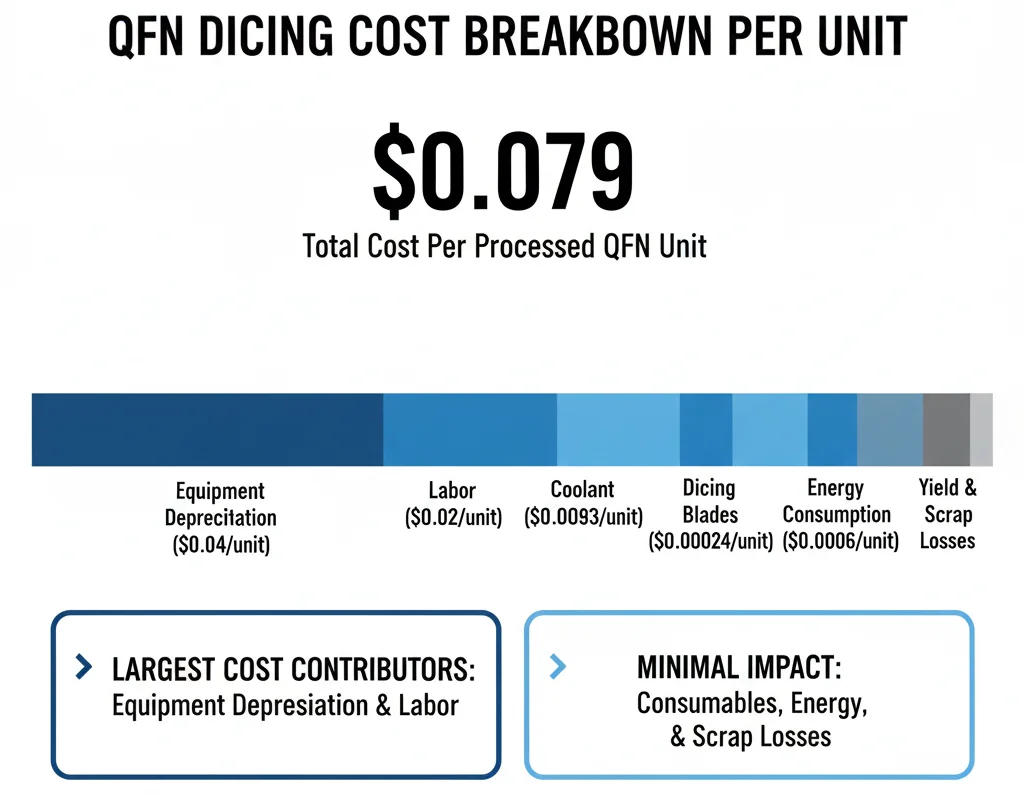

Final Cost Per Processed QFN Unit

Summing up all cost components:

|

Cost Component |

Cost per Unit (USD) |

|---|---|

|

Dicing Blade |

$0.00193 |

|

Coolant |

$0.00620 |

|

Equipment Depreciation |

$0.04000 |

|

Maintenance |

$0.01000 |

|

Labor |

$0.02000 |

|

Energy |

$0.00024 |

|

Yield & Scrap Loss |

$0.00060 |

|

Total Cost per Unit |

$0.07897 (~$0.079) |

-

The total cost per processed QFN unit is approximately $0.079.

The total cost per processed QFN unit is approximately $0.079.

-

The largest cost contributors are equipment depreciation ($0.04/unit) and labor ($0.02/unit).

The largest cost contributors are equipment depreciation ($0.04/unit) and labor ($0.02/unit).

-

Consumables such as dicing blades ($0.00193/unit) and coolant ($0.0062/unit) have a relatively low impact on total cost.

Consumables such as dicing blades ($0.00193/unit) and coolant ($0.0062/unit) have a relatively low impact on total cost.

-

Energy consumption ($0.00024/unit) and scrap losses ($0.0006/unit) contribute minimally to overall expenses.

Energy consumption ($0.00024/unit) and scrap losses ($0.0006/unit) contribute minimally to overall expenses.

Cost Breakdown:

Ayan Sadyk is a materials scientist and process engineer with over two decades of experience in the industrial diamond tooling sector. His expertise lies in integrating ultra-thin diamond blades, CBN wheels, and advanced cutting systems into precision manufacturing workflows for applications in optics, semiconductors, and technical ceramics.

With a background in materials behavior and surface integrity, Mr. Sadyk brings a data-driven, application-specific approach to cutting and grinding process development. He has worked closely with manufacturers and R&D facilities across Eastern Europe, North America, and the Middle East, helping optimize tool life, surface finish, and process stability.

As an author, he focuses on bridging materials science with tooling innovation—writing on topics such as blade wear mechanisms, thermal effects in hard material sectioning, and adaptive process design.

ARE YOU USING RIGHT DICING BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING BLADES?

Knowledge Center

Select right Diamond Dicing Blade for your application

Dicing Blade Operations Recommendations

Optimizing your Diamond Dicing Performance

Trouble Shooting Dicing Problems

Application Recommendations

Dicing Blade Case Studies

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Selecting the Right Wafer Dicing Saw Practical Guide

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

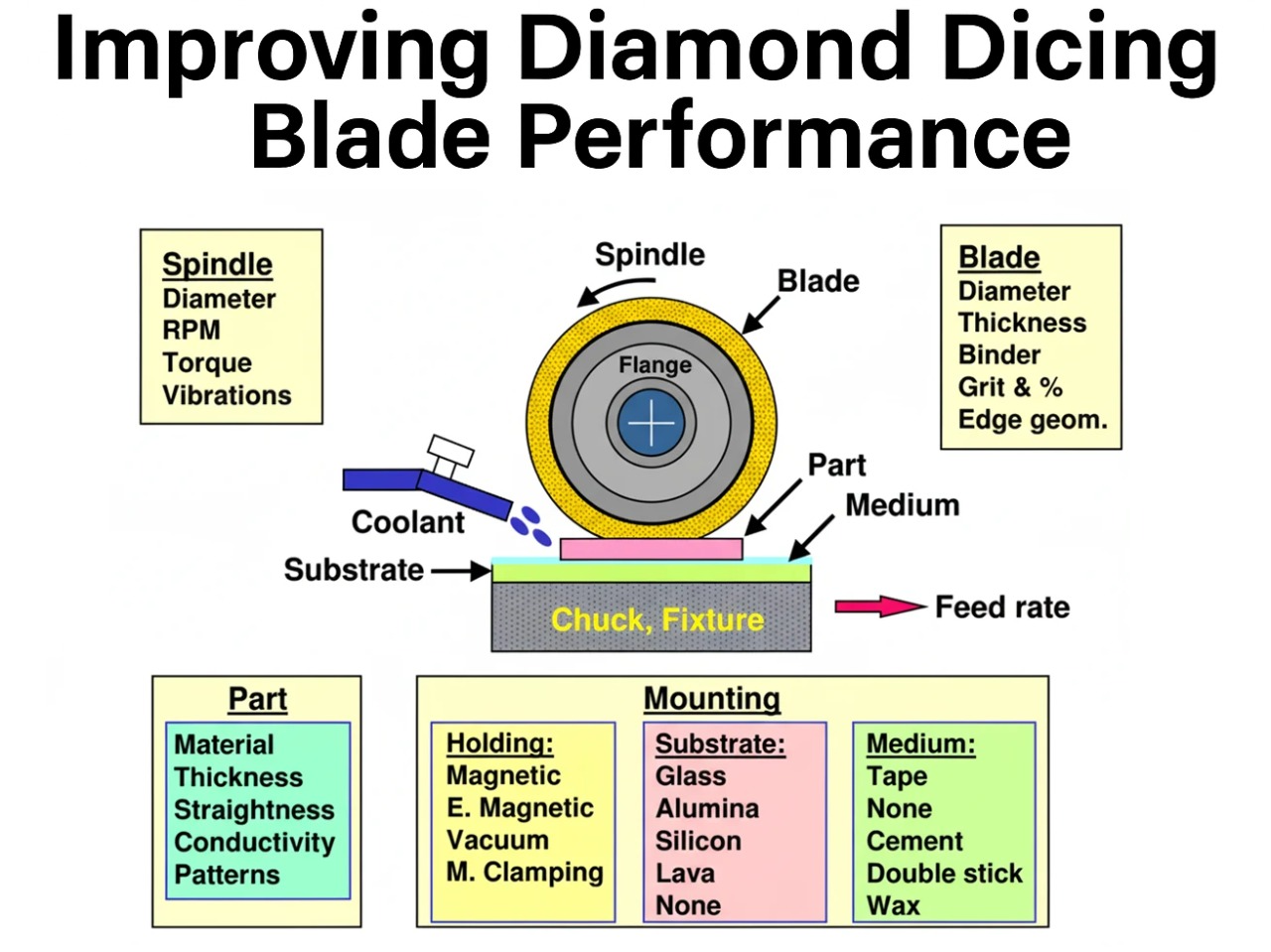

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Diamond vs CBN (cubic boron nitride) Tools

Choosing The Correct Diamond Bond Type

Selecting the Right Coolant Method for your Diamond & CBN Tools

Ayan Sadyk is a materials scientist and process engineer with over two decades of experience in the industrial diamond tooling sector. His expertise lies in integrating ultra-thin diamond blades, CBN wheels, and advanced cutting systems into precision manufacturing workflows for applications in optics, semiconductors, and technical ceramics.

With a background in materials behavior and surface integrity, Mr. Sadyk brings a data-driven, application-specific approach to cutting and grinding process development. He has worked closely with manufacturers and R&D facilities across Eastern Europe, North America, and the Middle East, helping optimize tool life, surface finish, and process stability.

As an author, he focuses on bridging materials science with tooling innovation—writing on topics such as blade wear mechanisms, thermal effects in hard material sectioning, and adaptive process design.