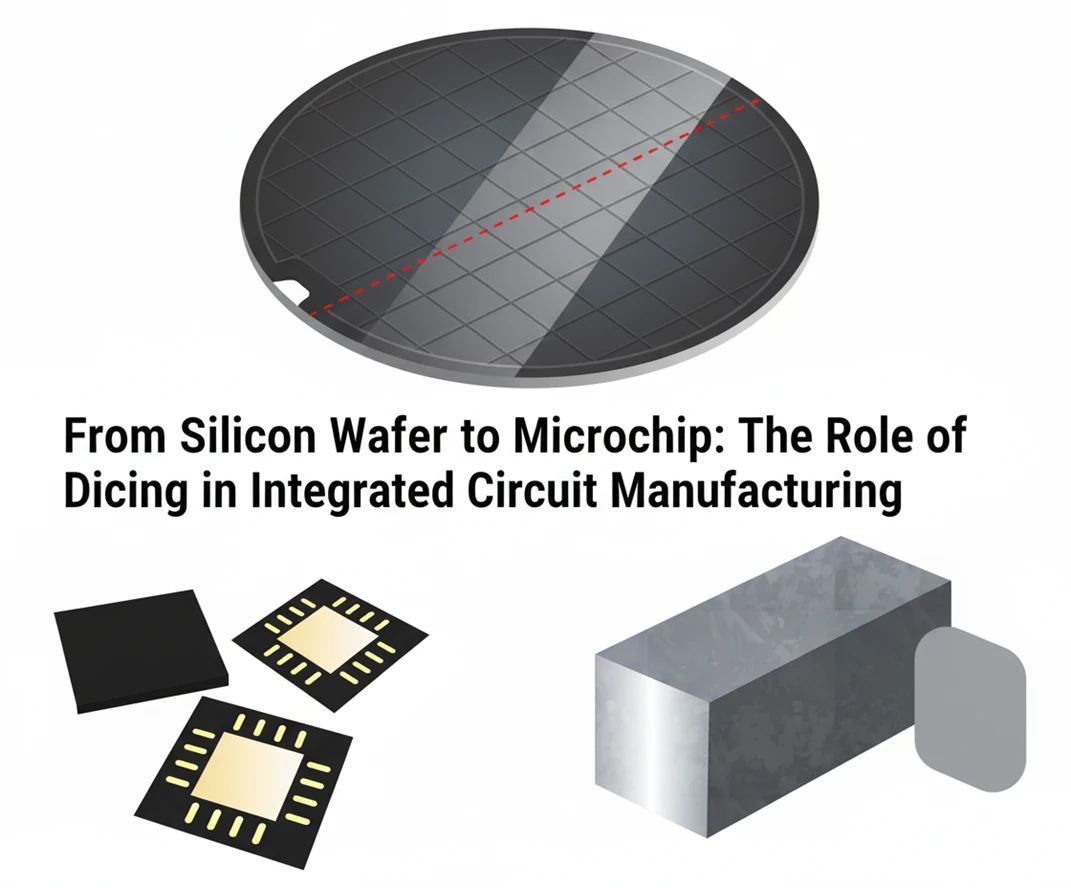

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

-

Posted by

contactor6

The making of the integrated circuit is a long and complex process that involves many critical steps. In most cases, the wafer travels to multiple facilities before it is completed and turned into the final product. A 6, 8, or 12 inch diameter wafer can contain thousands of tiny devices, each serving as part of a larger system or as key components in scientific and technological breakthroughs.

Table of Contents

ToggleWafer designs vary in complexity and may use multiple materials such as gold, copper, germanium, or gallium arsenide. Some wafers include solder bumps, intricate channels, and cavities. Others are made of waveguides or contain moving parts such as MEMS. The range of possibilities in wafer design is virtually limitless.

The microchip has become one of humanity’s greatest achievements, driving progress in the modern technological era. It embodies our desire to improve and innovate. The following overview will explain the main stages of integrated circuit manufacturing, with a focus on how dicing plays a critical role and why it is essential to the final outcome.

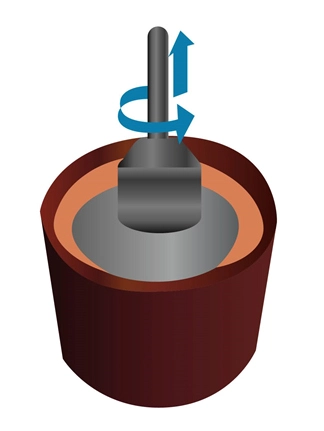

Making the silicon ingot

This step is carried out in a crystal pulling furnace, where high-purity silicon is melted in a controlled environment. A single-crystal silicon seed is then introduced, rotated, and slowly pulled upward. During this process, silicon atoms attach to the seed, forming a single-crystal ingot. It is a slow and highly precise process, requiring tight temperature control, as well as the use of dopants and pure gases to meet the desired specifications. The furnace itself is a complex system designed for accuracy. This environment is the birthplace of the silicon wafer, the fundamental base of most integrated circuits. Once the ingot is grown, it is polished, and the crystal orientation is marked by making a notch or cutting a flat on its surface.

Slicing and polishing

The silicon ingot is sliced into thin wafers using a wire saw or inside diameter saw. The wafers are then subjected to lapping and polishing to achieve uniform thickness and to remove imperfections from the surface. Depending on the application, wafers may be single-sided or double-sided polished. The polished side becomes the active surface for circuitry fabrication. To improve durability, the edges of the wafer are rounded and polished to prevent breakage. Finally, wafers undergo rigorous cleaning with special solvents and deionized water, and are carefully dried to prepare them for the next stage of processing.

Oxidation

Oxidation is an essential step in integrated circuit manufacturing. While silicon naturally oxidizes over time, the process is deliberately accelerated in production. This is achieved by exposing the wafer to oxygen or water vapor at very high temperatures inside an oxidation or diffusion furnace.

The reaction between the silicon and these elements forms a thin, uniform layer of silicon dioxide (SiO₂) on the wafer surface. This oxide layer serves as a protective barrier, an electrical insulator, and a foundation for subsequent photolithography and etching steps. The exact method—dry oxidation using oxygen or wet oxidation using water vapor—is chosen depending on the thickness and quality of oxide required for the device design.

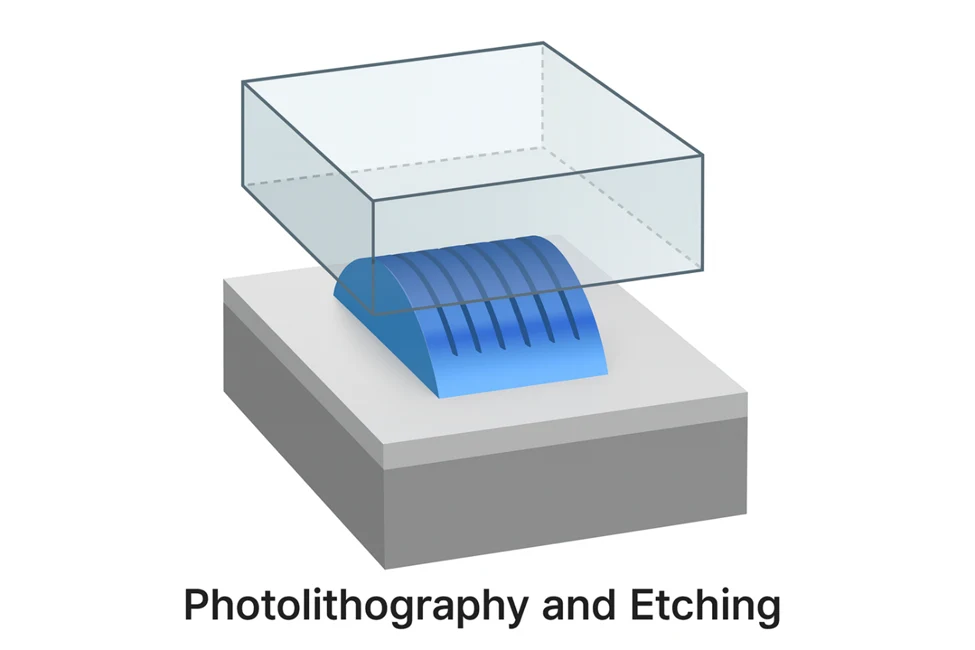

Photolithography and the Etching Process

At this stage, the circuitry of the integrated circuit including transistors, capacitors, resistors, and connectors is created. These features are built on a microscopic scale, and with every generation of technology, they continue to become smaller and more complex.

The process borrows methods from photography and lithography. The wafer is first coated with photoresist, a light-sensitive liquid applied while the wafer spins to ensure a uniform layer. After coating, the wafer undergoes a soft bake to cure the resist.

A mask, typically made from soda lime or fused silica, contains the circuit pattern at a larger scale. The coated wafer acts as photographic film, while the mask serves as the negative. Ultraviolet light shines through the transparent areas of the mask, causing the photoresist beneath to chemically react.

The wafer is then developed with chemicals to remove the exposed photoresist. Next, the wafer undergoes etching, where the unprotected oxide layer is removed, leaving the desired pattern intact. Once the patterning step is complete, the remaining photoresist is stripped away.

This photolithography and etching cycle is repeated multiple times, layer by layer, until the full circuitry is formed. When fabrication is complete, the wafer is tested to identify working and defective devices. A wafer map is generated to mark the locations of nonfunctional components, ensuring only good devices move forward in the process.

The Dicing Process

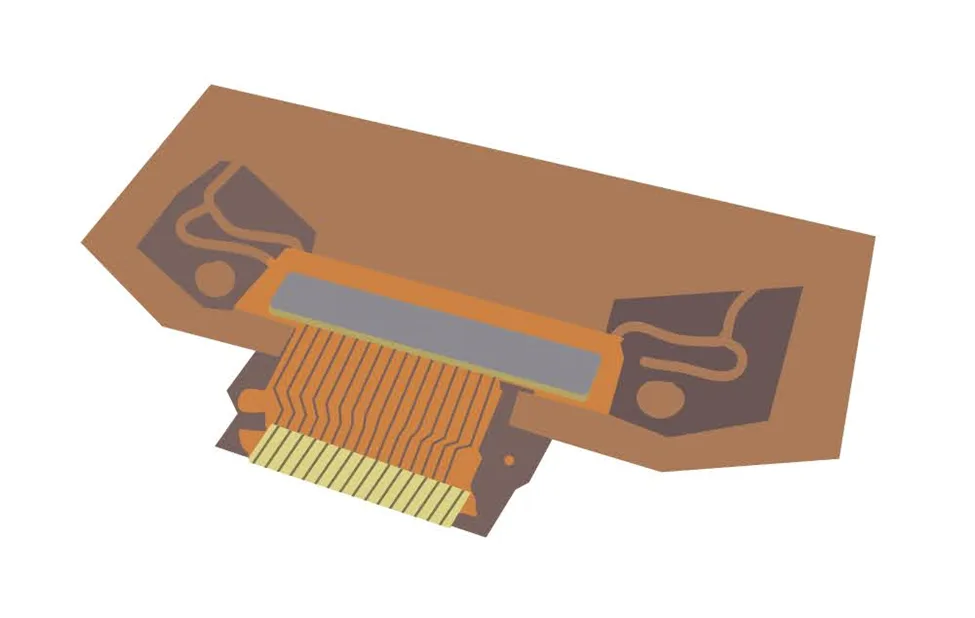

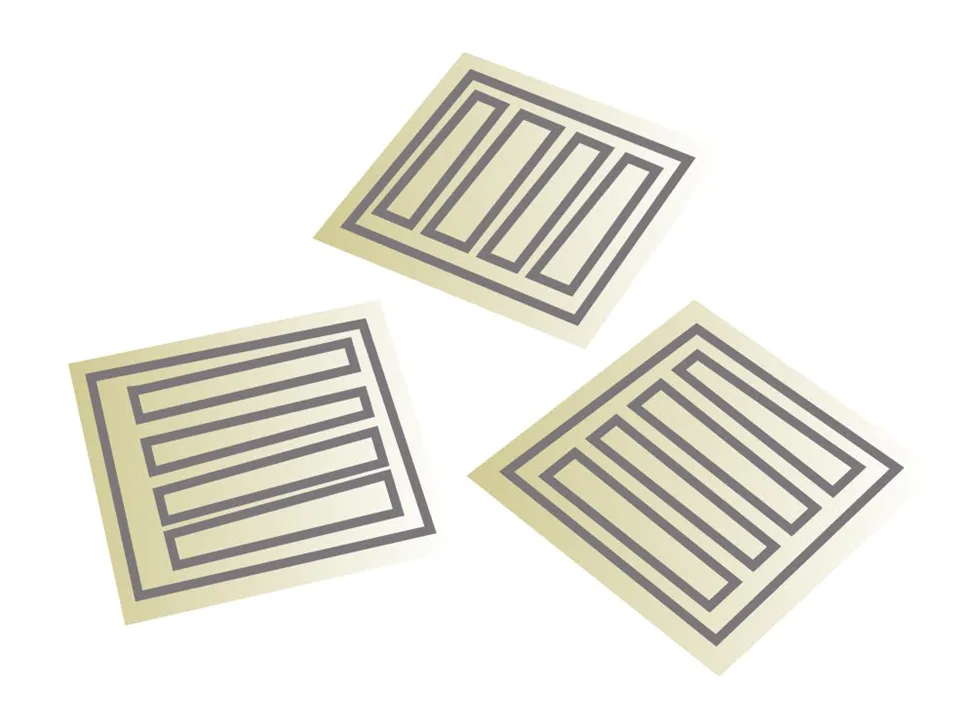

At this stage, a wafer contains hundreds or thousands of microchips, and the next step is to separate each device into individual dies. This is achieved through the dicing process.

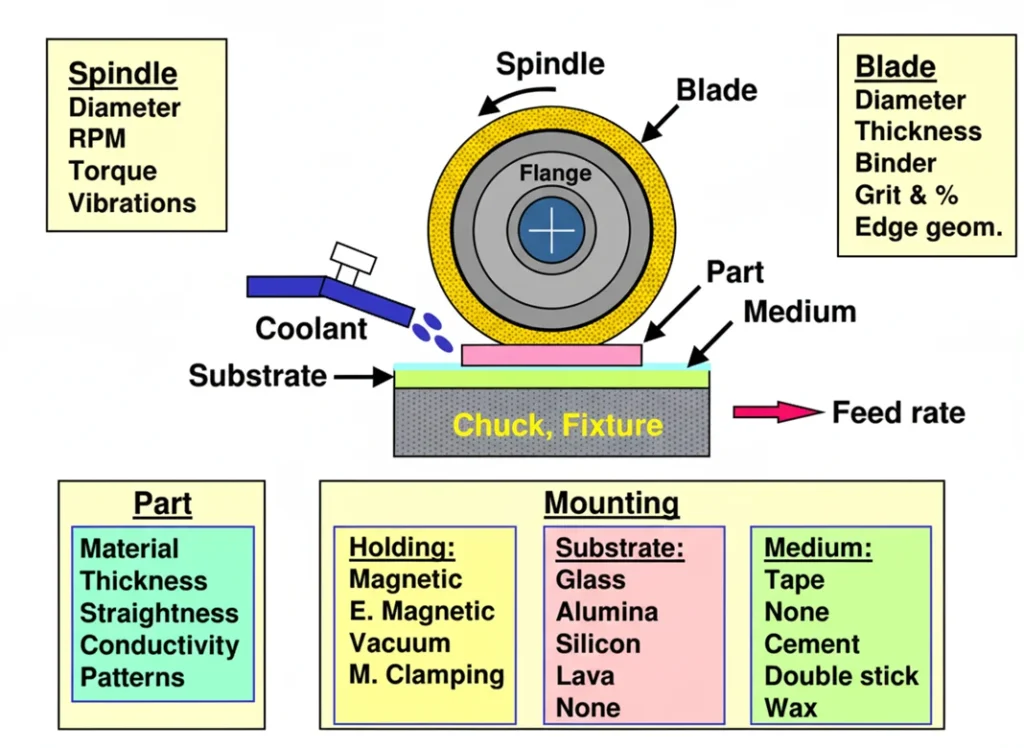

Dicing involves cutting the wafer with a diamond dicing blade bonded with nickel, resin, or metal. The blade spins at very high RPM, while the wafer is advanced into it at a controlled feed rate. The process is often described as violent and abrasive, but it delivers extreme precision when performed correctly.

To protect the devices, wafer layouts include narrow regions known as streets, which act as cutting lanes. A typical street width is around 80 microns, though advanced designs continue to push for smaller and smaller streets. With nickel bond dicing blades, the industry standard for silicon wafers, it is possible to achieve blade thicknesses as small as 15 microns (0.0006″).

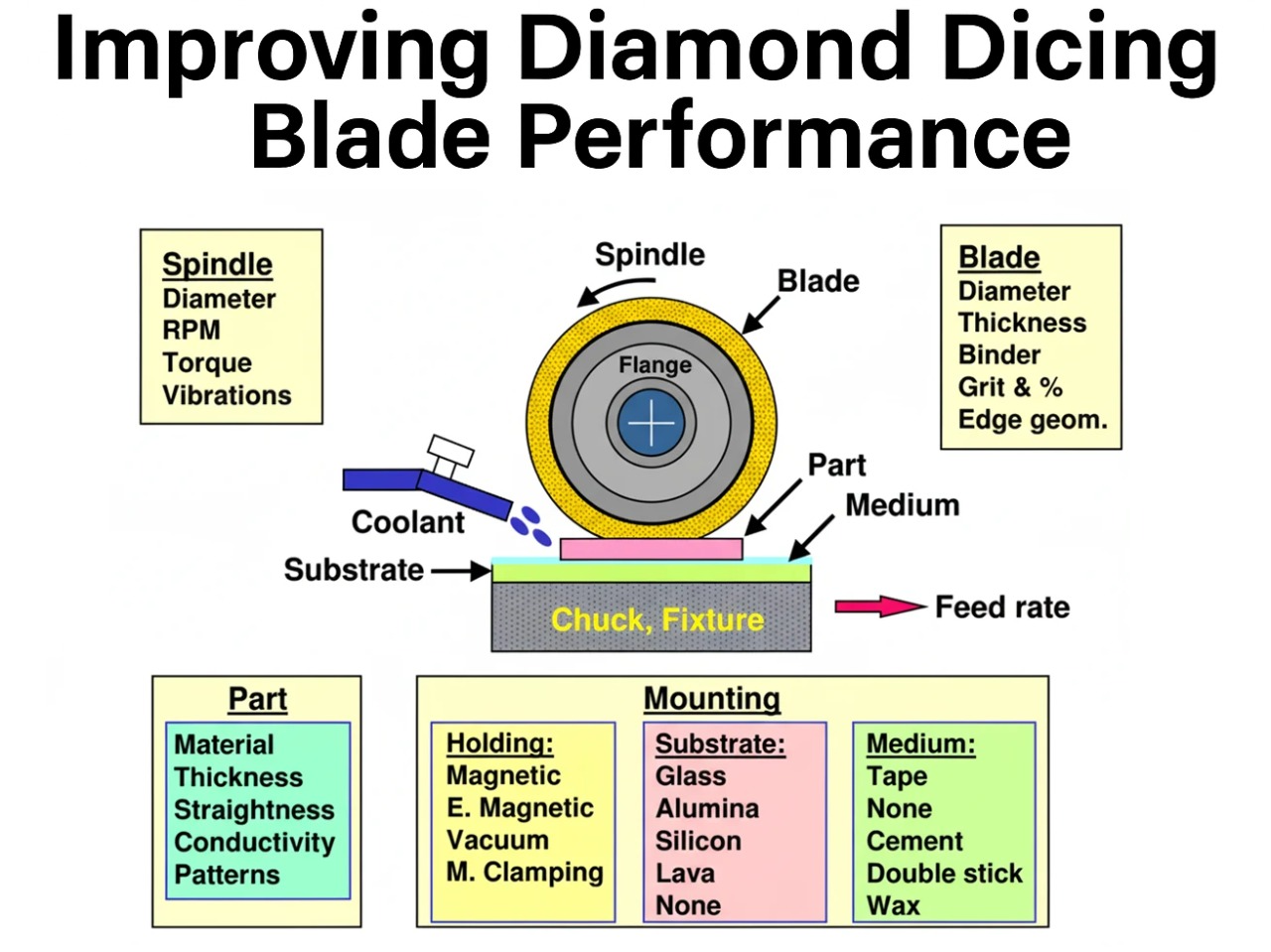

The three most critical elements of dicing are the blade, the dicing machine, and the operating parameters. Selecting the right combination of these factors determines cut quality, yield, and overall device reliability.

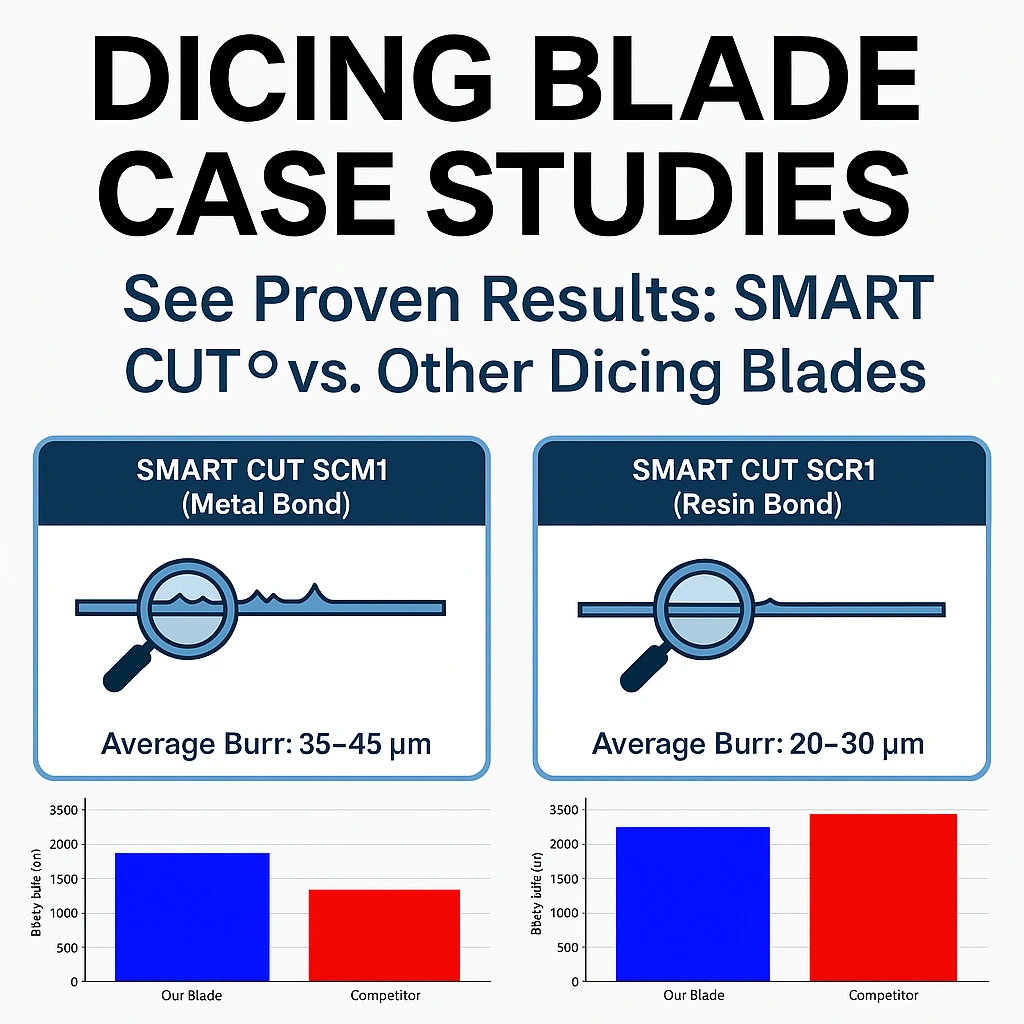

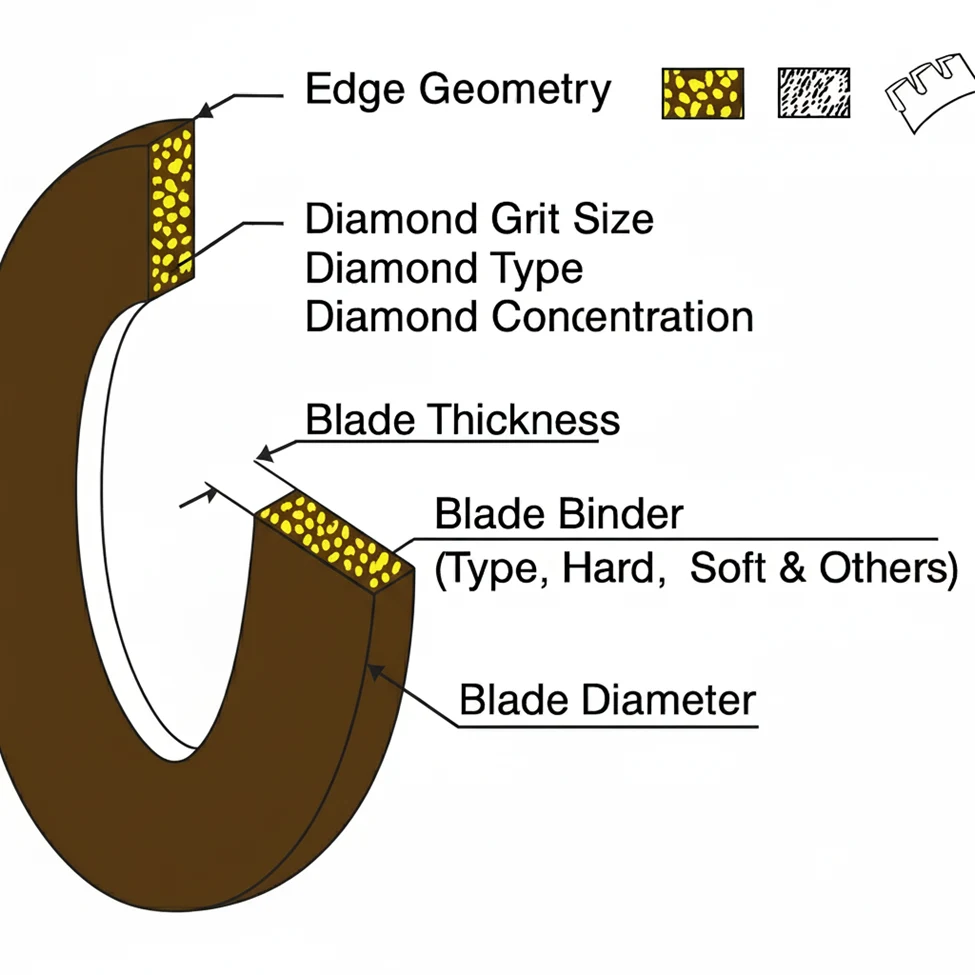

The Dicing Blade

Selecting the right dicing blade for a given application is critical to achieving accuracy, yield, and blade life. Dicing blades are available in a range of sizes, bond types, grit sizes, and configurations. They are produced in both hubbed and hubless forms, each suited for specific equipment and applications.

Bond types determine how the blade interacts with the material:

- Resin bond blades are typically used for glass, quartz, sapphire, and other brittle materials.

- Nickel bond blades are the standard for silicon, gallium arsenide, germanium, and indium phosphide.

- Metal sintered blades are best suited for plastics, QFN packages, printed circuit boards (PCB), and FR4 materials.

All dicing blades use diamond abrasive particles, most often synthetic diamond as the cutting medium. The diamond grit size must be carefully chosen to match the material’s hardness, thickness, and the desired cut quality.

When working with hubbed blades, exposure must be considered, ensuring that enough blade extends beyond the hub to cut through the material while leaving sufficient allowance for wear. With hubless blades, the flange becomes a critical factor. The flange holds the blade in place and sets it on the spindle. To select the correct hubless blade, the inside diameter (ID) and outside diameter (OD) of the flange must be matched to the blade. Exposure for a hubless blade is calculated by subtracting the flange OD from the blade OD and dividing the result by two.

The essential specifications for any dicing blade are size (OD, ID), bond type (resin, nickel, or sintered), hub style (hubbed or hubless), thickness, grit size, and exposure. Some manufacturers also offer blades with different diamond concentrations, which influence both blade life and cutting performance.

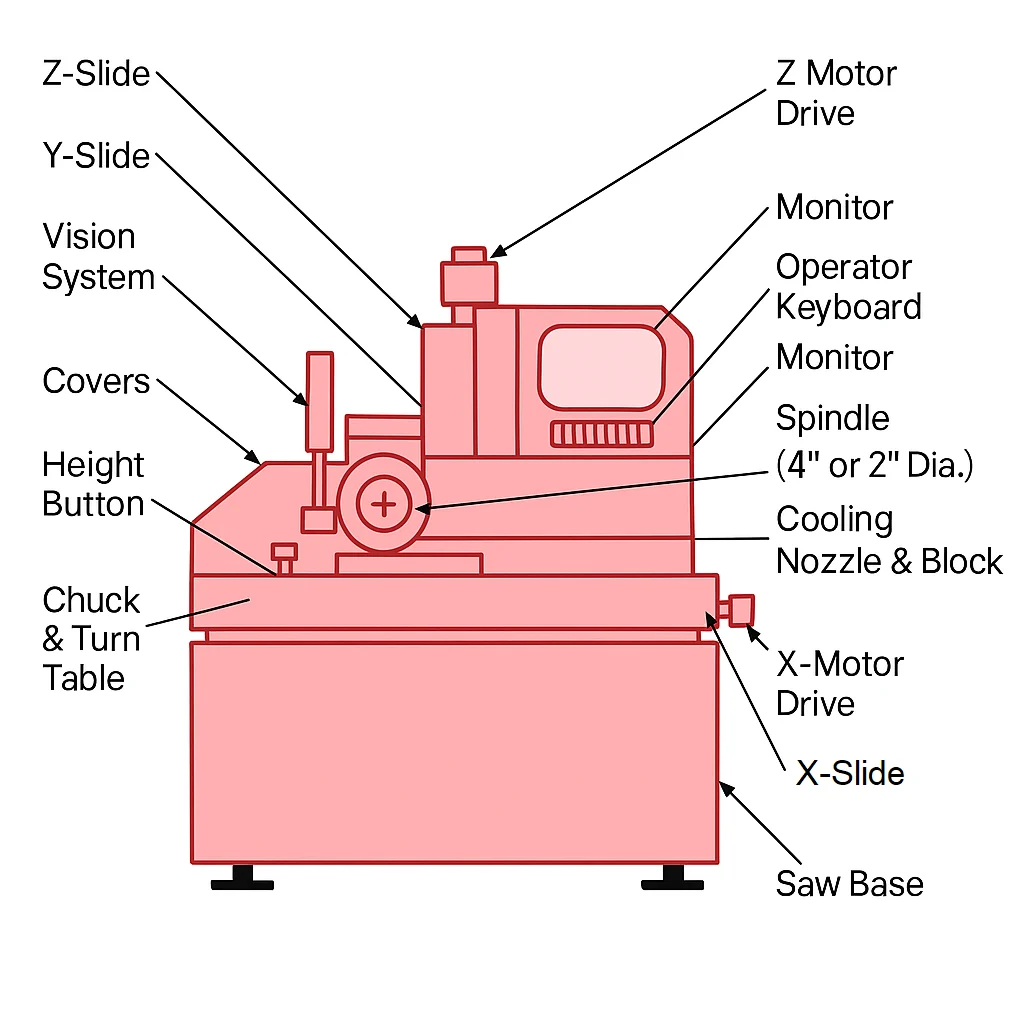

The Dicing Machine

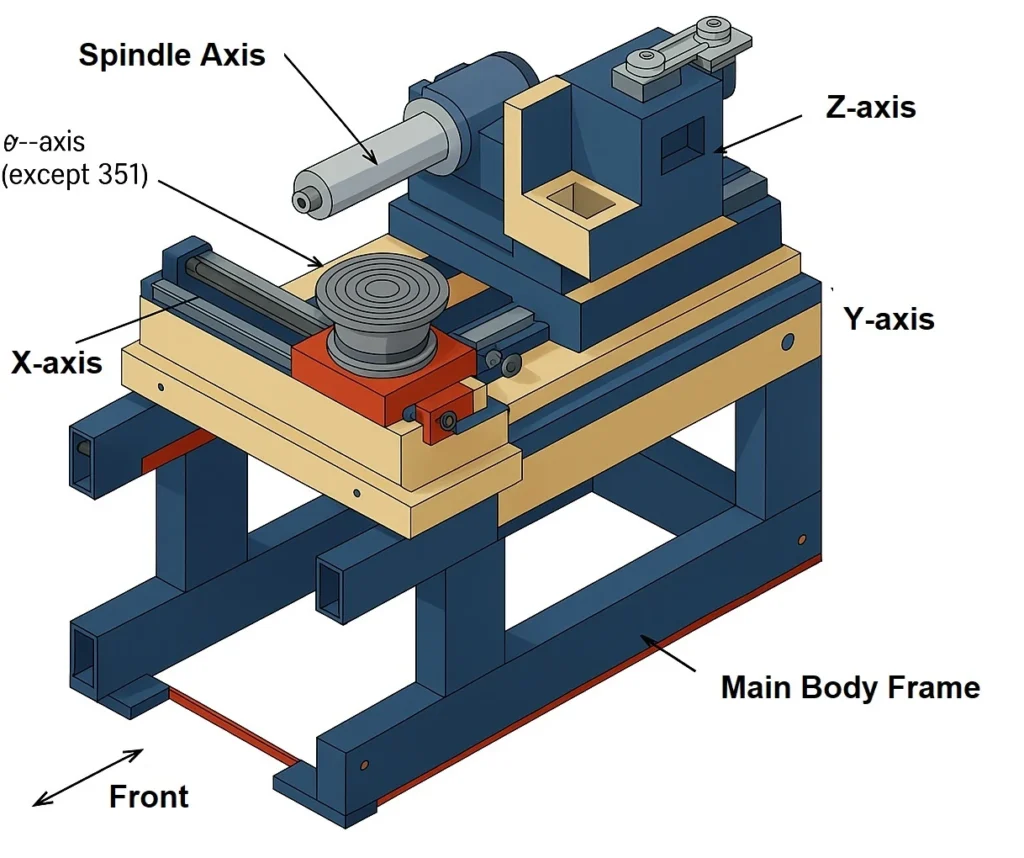

Modern dicing machines are highly sophisticated and precise, capable of maintaining tolerances as tight as 2 to 5 microns. They are built with multiple components that work together to achieve both accuracy and repeatability.

At the center is the spindle, available in 2, 3, or 4 inch sizes, with the 2-inch spindle being the most common. The spindle is mounted on a lead screw, which allows controlled movement in the Y-axis, while also moving vertically in the Z-axis.

The chuck, typically made of metal or ceramic, serves as the wafer platform. It uses a vacuum system to securely hold the wafer in place. The chuck moves in the X-axis, which controls the feed rate, and can also rotate for alignment. Before dicing, wafers are mounted on a ring or film frame with dicing tape. The vacuum secures the wafer, preventing any movement during cutting. The blade is calibrated to cut slightly into the tape without piercing it, ensuring complete separation of the dies while leaving the tape intact.

To further improve accuracy, dicing machines are equipped with optics for pattern observation and software for programmable control. These systems allow operators to define cut positions, parameters, and sequences.

Advanced dicing machines now include features such as pattern recognition, automated wafer loading and unloading, and real-time sensors. These sensors can automatically adjust blade height and compensate for wear, ensuring consistent cut depth and extended blade life.

The Parameters

In wafer dicing, process parameters are critical. The most important include spindle speed (RPM), feed rate, blade type, grit size, cooling water flow, and number of passes. These settings must be carefully matched to the material type, material thickness, street width, die size, and chipping tolerances.

The choice of dicing tape is also essential, since it directly affects wafer stability, adhesion, and ease of die separation. Using the wrong tape or settings can compromise the entire process.

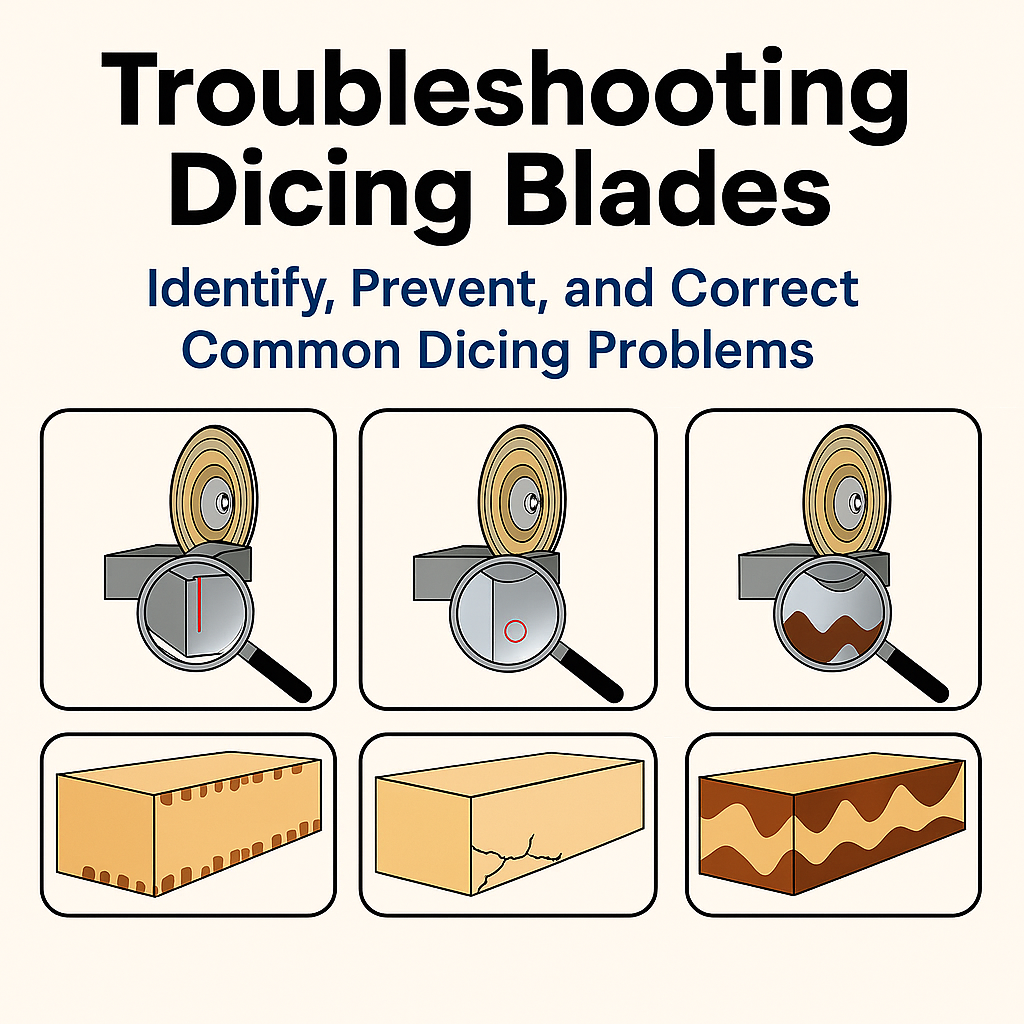

As wafer designs advance, streets become narrower, specifications tighter, and accuracy requirements higher. This leaves very little margin for error. If any parameter is incorrect, the consequences can be severe, including unacceptable front-side or back-side chipping, improper cut profile, incomplete depth, wafer cracks, contamination, or miscuts.

The right combination of parameters ensures consistent cut quality, high yield, and device reliability, making parameter control one of the most important aspects of dicing.

Cleanliness

The dicing process generates large amounts of saw residue, which can contaminate the wafer surface and settle in critical areas. To maintain device cleanliness and reliability, one of two cleaning methods is typically used.

- Photoresist coating before dicing: The wafer is coated with photoresist, then baked at 100°C for 30 minutes. During dicing, any residue that lands on the wafer surface adheres to the photoresist. Afterward, the photoresist layer is removed, taking the residue with it and leaving the wafer clean.

- High-pressure deionized water cleaning: After dicing, the wafer can be placed in a specialized pressure washer. This system shoots high-pressure deionized water at the wafer while it spins, effectively flushing away saw residue trapped in wafer crevices.

In most cases, this cleaning step is the final operation after dicing, ensuring the wafer is ready for the next process stage. If the photoresist method was used, the final step includes stripping the resist to fully clean the wafer.

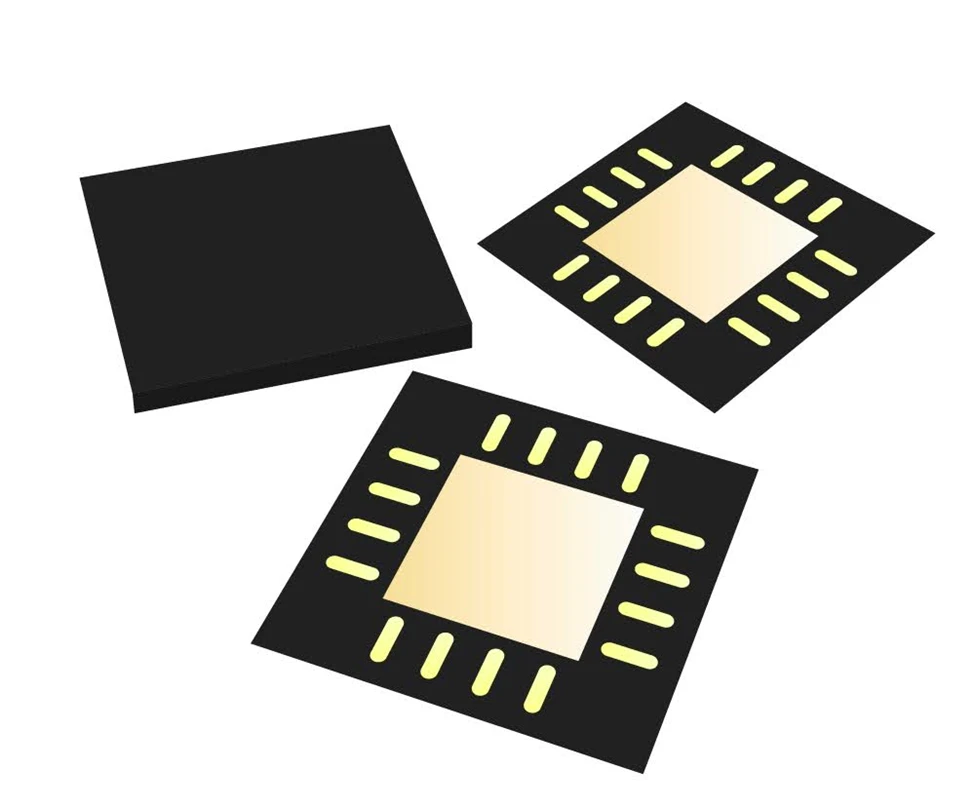

Pick and Place; Final Packaging

After all previous processes are complete, the wafer has been fabricated, tested, and diced into individual microchips. At this stage, the chips remain attached to dicing tape on a ring or film frame, and the final step is to separate and package them for sale or assembly.

This is done through the pick and place process, which can be carried out manually or automatically.

- In the manual method, a vacuum wand—a pen-like tool that uses suction—lifts individual dies from the tape. The wand includes a release mechanism that allows the operator to place each die into its container. Dies are typically placed in either a gel pack or a waffle pack.

- A gel pack contains a sticky membrane that holds the die in place during transport. Different levels of tackiness are available depending on the application.

- A waffle pack has precisely sized cavities to hold each die without adhesives, suitable for handling delicate or contamination-sensitive devices.

- In the automated method, a pick and place machine is programmed to remove dies from the tape in a specific sequence. These machines can process large quantities efficiently and with higher repeatability.

Regardless of the method, operators rely on the wafer map created earlier to identify working dies and separate them from defective ones. Once picked and placed, the dies are ready for final packaging or integration into electronic assemblies.

The integrated circuit, born from a silicon ingot and refined through countless precise steps has become a cornerstone of modern life. It powers our phones, computers, automobiles, communications, defense systems, and medical devices. It is a key driver of technological progress, and it continues to evolve toward greater efficiency and complexity. Looking back at how far this technology has come in just fifty years, and forward to what it may achieve in the next century, the microchip stands as one of humanity’s most significant achievements.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990