Dicing Blade Case Studies

-

Posted by

Alexander Schneider

Alexander Schneider

Table of Contents

ToggleThis article provides important guidelines for optimizing the dicing process in semiconductor packaging, focusing on package singulation for various technologies such as BGA, QFN, LED, CMOS, and wafer substrates. It covers key variables such as the recommended blade types, coolant options, RPMs, feed rates, and mounting methods to ensure high-quality results and efficient throughput. By exploring specific material requirements and common concerns, this guide offers valuable insights into selecting the ideal dicing parameters for each application.

Share this Article with Friend or Colleague

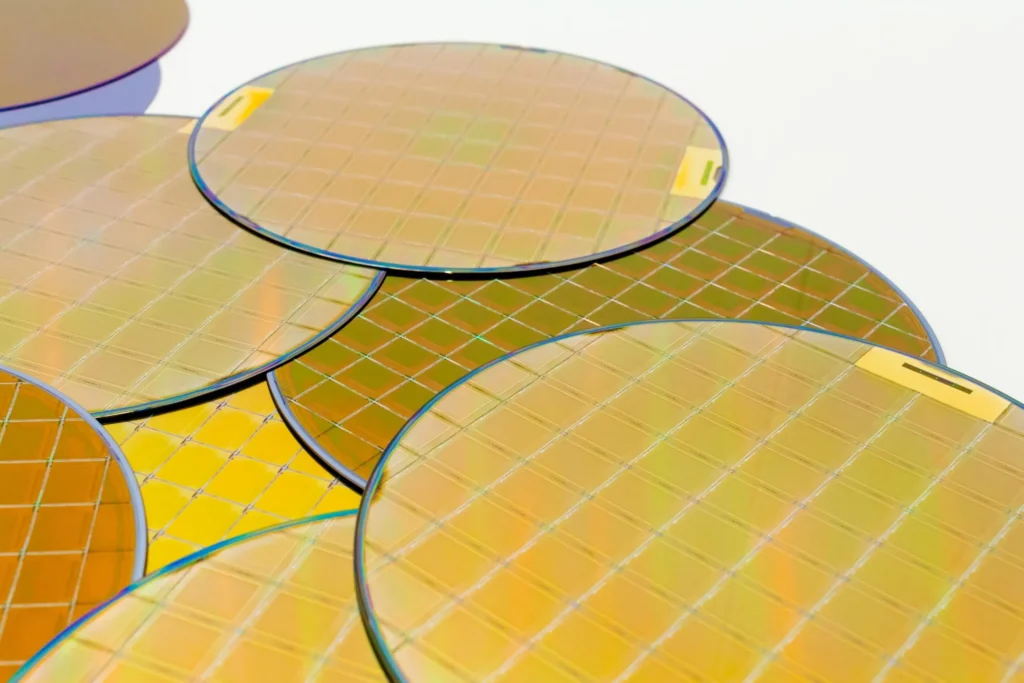

DICING SOLUTIONS FOR PACKAGE SINGULATION

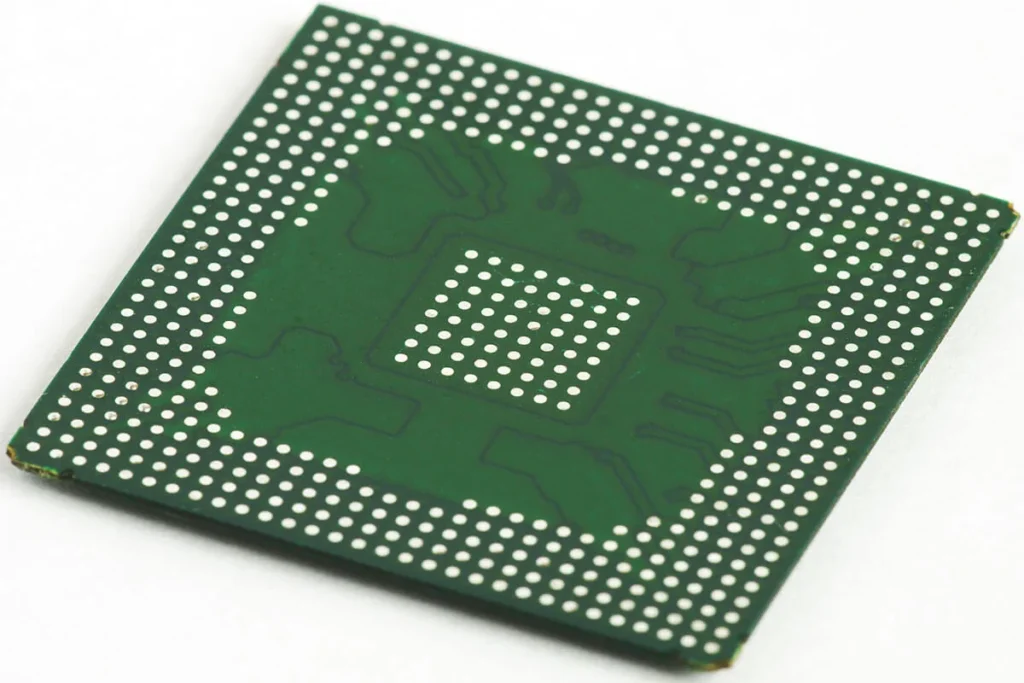

BGA (Ball-Grid Array)

Common Materials: FR4 and epoxy mold compound

Variations:

- LFBGA (Low-Profile Fine-Pitch)

- TFBGA (Thin & Fine-Pitch)

- W-BGA (Window-Type)

- FC-BGA (Flip Chip)

- VFBGA (Very Fine-Pitch)

- POP (Package-on-Package)

- SIP (System-in-Package)

- SD (Secure Digital)

- Micro SD Card

- CBGA (Ceramic)

- PBGA (Plastic)

- UFBG (Ultra-Fine)

- MBGA (Micro)

Typical Concerns:

- Cut quality

- chipping

- burrs

- slivers

- protrusions

- race shorts

- Blade life

Dicing Blade Recommendation:

- SMART CUT HYBRID BOND or sintered (metal bond) series

- Diamond size: 30 – 55 microns

- Blade Thickness: .008” – .014”

Dicing Process Recommendations:

- Feed rate: 50-250 mm/sec

- Spindle speed: 20-40 krpm depending on blade O.D.

- Multi panel mounting on UV tape

- Minimal dressing so as not to create a large radius on the blade edge

Variations:

- HVQFN (Heatsink Very-Thin)

- MLF (Micro Lead Frame)

- FUSION QUADR

- (VQFP: Very Thin Quad Flat Package)

- HQFN (High Power)

Typical Concerns:

- Chipping

- Burrs

- Lead smearing

- Melting

Dicing Blade Recommendation:

- SMART CUT HYBRID BOND or sintered (metal bond) series

- Diamond grit size: 45 – 88 microns

- Thickness: .008” – .020”

Dicing Process Recommendations:

- Feed rate: Half Etched substrates 30-75 mm/sec, Full Copper substrates 15-30 mm/sec

- Spindle speed: 22-35 krpm depending on blade O.D.

- Multi panel mounting on UV tape

- Override process over one substrate to reach final feed rate

LED (Light-Emitting Diode)

Variations:

Chip LED, High Power LED.

Typical Concerns:

- Copper burrs

- End of blade life due to limited exposure

- Throughput (maximize UPH)

Dicing Blade Recommendation:

- SMART CUT HYBRID BOND or Nickel Bond series

- Diamond size: 10,13 & 17 microns

- Thickness: .003” – .008”

Dicing Process Recommendations:

- Feed rate: 80-150 mm/sec

- Spindle speed: 25-30 krpm

- Multi panel mounting on UV tape

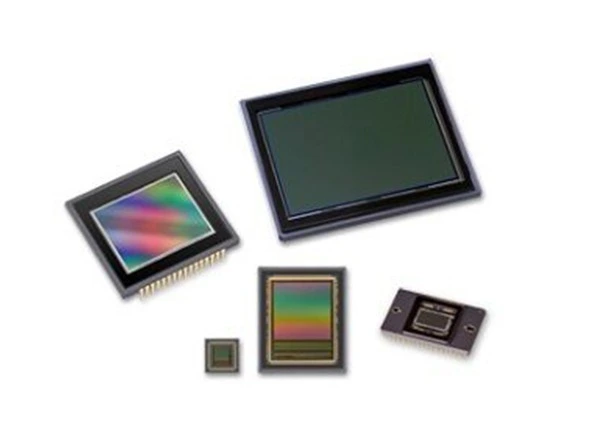

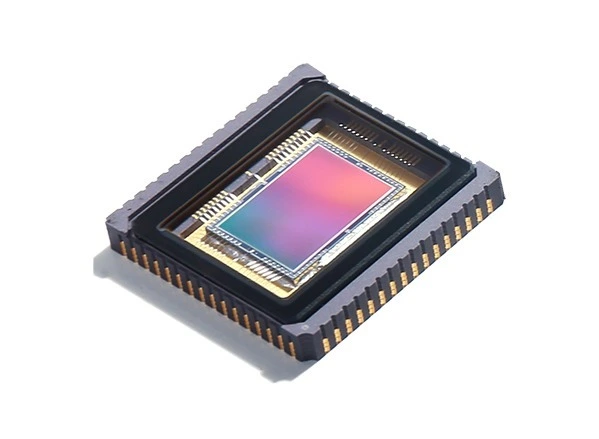

CMOS (Complementary Metal-Oxide Semiconductor)

Common Materials - Borosilicate Glass, HTCC (High Temperature Co-fired Ceramics).

Variations:

CIS (CMOS Image Sensor) Glass Lid, CIS (CMOS Image Sensor) Substrate.

Typical Concerns:

- Chip Damage and Breakage

- Cutting Precision and Kerf Control

- Heat Dissipation

- Surface Quality

- Blade Life & Consistency

Dicing Blade Recommendation:

- Bond Type: Resin Bond, Sintered (Metal Bond), Hybrid Bond, Nickel bond

- Diamond Size: 2 to 30 microns

- Kerf Thickness:10 to 30 microns

Dicing Process Recommendations:

- Feed rate: 80-150 mm/sec

- Spindle speed: 25-30 krpm

- Multi panel mounting on UV tape

DWDM (Dense Wavelength Division Mulitplexing) Filters

Variations:

SAW (Surface Acoustic Wave) Filter devices, Beam Splitters, Passive Components

Typical Concerns:

- Top-side and back-side chipping

- Cut perpendicularity

- Kerf side surface finish

Dicing Blade Recommendation:

- SMART CUT series Resin, HYBRID, & Sintered (metal bond) blades

- Diamond size: 30 – 45 microns (resin) and 7 – 15 microns (sintered)

- Thickness: .006″ – .012”

Dicing Process Recommendations:

- Feed rate: 4 – 20 mm/sec

- Spindle speed: 20 – 30 krpm (2″) 10 – 15 krpm (4″)

- SMART CUT® XP Dicing Coolant Lubricant Surfacant may reduce chipping and improve surface finish

HDD (Hard Disk Drive)

Typical Concerns:

- High Mechanical (internal) stress

- burrs

- large kerf width

- lack of accuracy

Dicing Blade Recommendation:

- Bond Type: Resin Bond, Sintered (Metal Bond)

- Diamond Size: 1 to 25 microns

- Kerf Thickness: 15 to 100 microns

Dicing Process Recommendations:

- Feed Rates: 1 mm/s to 5 mm/s

- RPM’s: 15,000 RPM to 30,000 RPM

- Mounting Type: Vacuum chucks or magnetic chucks

- Coolant Used: Water-soluble coolants

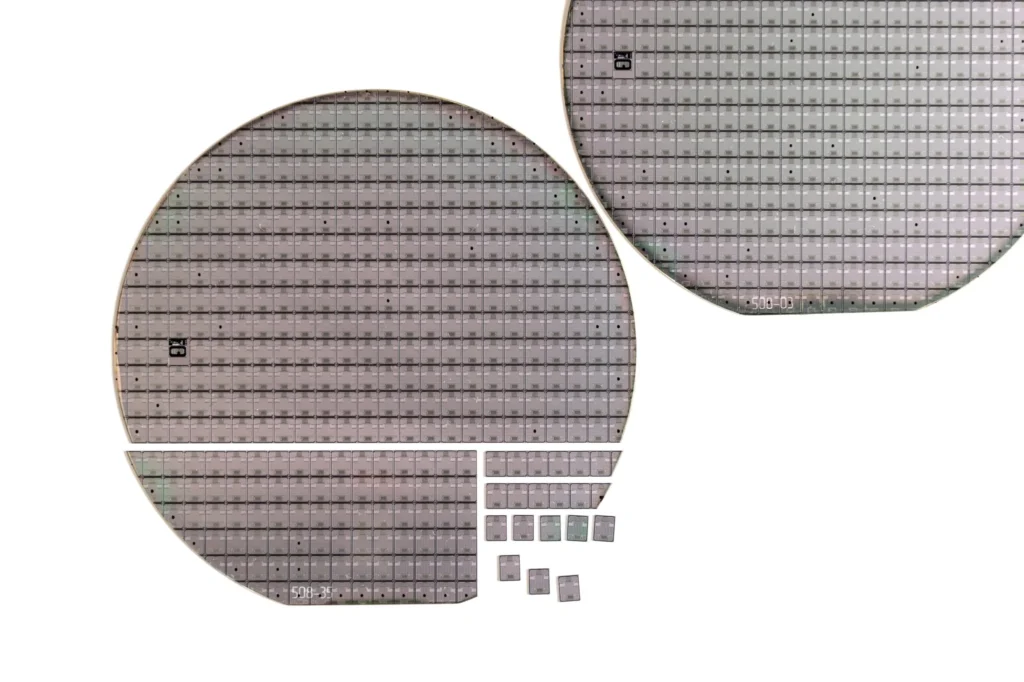

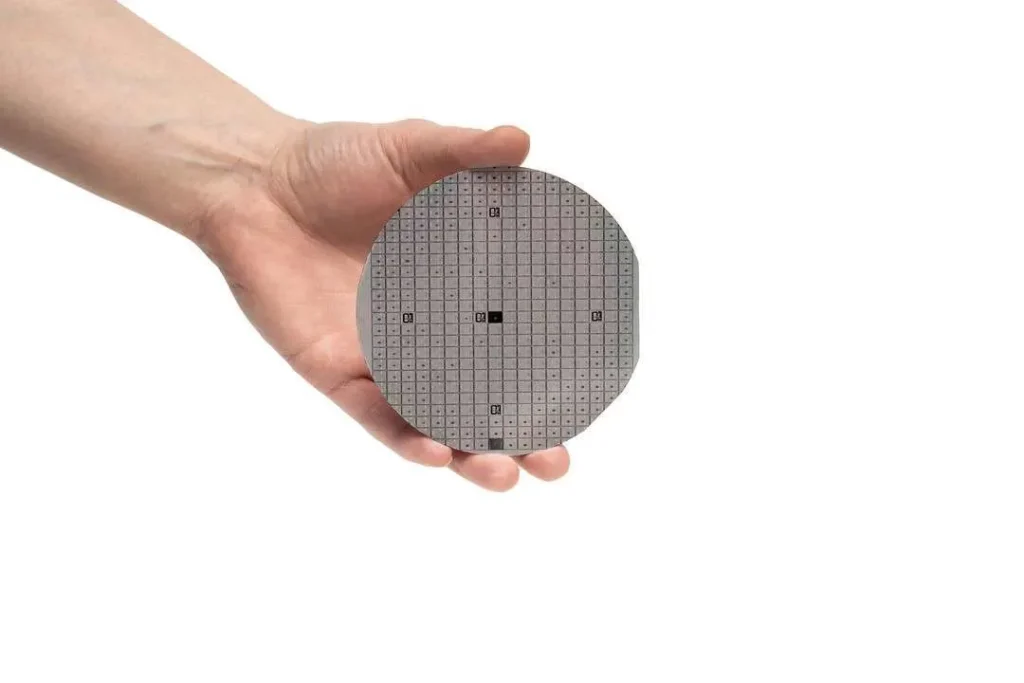

Semiconductor Wafer

Typical Concerns:

- Feed Rates: 1 mm/s to 5 mm/s

- RPM’s: 15,000 RPM to 30,000 RPM

- Mounting Type: Vacuum chucks or magnetic chucks

- Coolant Used: Water-soluble coolants

Dicing Blade Recommendation:

- SMART CUT Nickel Bond or HYBRID series

- Diamond size: 4 – 6 microns

- Thickness: .0008” – .0016”

Dicing Process Recommendations:

- Feed rate: 25 – 75 mm/sec

- Spindle speed: 30 – 50 krpm

- Mounting: Blue or UV tape

- Cooling type: DI water with and without additives

- Carbon dioxide bubbler is optional

Alexander Schneider is a senior applications engineer and leading authority in the industrial diamond tooling industry, with over 35 years of hands-on experience in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels. His work spans a wide range of advanced materials including ceramics, glass, composites, semiconductors, and high-performance metals.

Throughout his career, he has collaborated with leading R&D institutions, national laboratories, and high-tech manufacturing companies across Europe, North America, and Asia, providing technical expertise and tailored solutions for demanding cutting and surface preparation applications.

Mr. Schneider has played a pivotal role in advancing precision cutting, sectioning, dicing, and grinding technologies used in research, production, and failure analysis. He is widely respected for his ability to optimize tool design and cutting parameters to meet exacting industry standards—balancing factors such as cut quality, blade life, material integrity, and process consistency.

As an author, Mr. Schneider is known for delivering practical, application-focused insights that translate complex technical challenges into clear, actionable strategies. His articles and technical guides serve as trusted resources for engineers, researchers, and manufacturers seeking to improve precision, reduce process variability, and enhance tool performance in critical applications.

ARE YOU USING RIGHT DICING BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING BLADES?

Knowledge Center

Select right Diamond Dicing Blade for your application

Dicing Blade Operations Recommendations

Optimizing Dicing Blade Performance

Trouble Shooting Dicing Problems

Application Recommendations

Dicing Blade Case Studies

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Selecting the Right Wafer Dicing Saw Practical Guide

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Diamond vs CBN (cubic boron nitride) Tools

Choosing The Correct Diamond Bond Type

Alexander Schneider is a senior applications engineer and leading authority in the industrial diamond tooling industry, with over 35 years of hands-on experience in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels. His work spans a wide range of advanced materials including ceramics, glass, composites, semiconductors, and high-performance metals.

Throughout his career, he has collaborated with leading R&D institutions, national laboratories, and high-tech manufacturing companies across Europe, North America, and Asia, providing technical expertise and tailored solutions for demanding cutting and surface preparation applications.

Mr. Schneider has played a pivotal role in advancing precision cutting, sectioning, dicing, and grinding technologies used in research, production, and failure analysis. He is widely respected for his ability to optimize tool design and cutting parameters to meet exacting industry standards—balancing factors such as cut quality, blade life, material integrity, and process consistency.

As an author, Mr. Schneider is known for delivering practical, application-focused insights that translate complex technical challenges into clear, actionable strategies. His articles and technical guides serve as trusted resources for engineers, researchers, and manufacturers seeking to improve precision, reduce process variability, and enhance tool performance in critical applications.