Diamond Blades For Lapidary Industry

lapidary industry

Diamond Blades

Leading Manufacturer of High Precision & Ultra Thin Diamond Blades 0.5" (12.7mm) to 48 (1219mm) in Outside Diameter, starting from 004 (0.1mm) Thick.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

Established in 1990

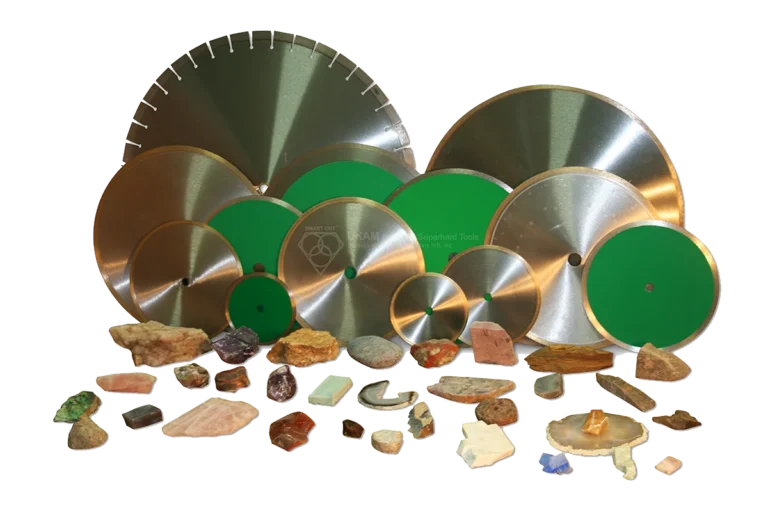

Diamond blades for

Lapidary Industry

Shop Diamond Lapidary Blades

SMART CUT® 310m

Lapidary Blades

Available 6" (150mm) to 16" (400mm) Diameter. SMART CUT 310M Sintered (metal bond) Lapidary Blades provide unmatched performance for cutting Precious & Semi Precious Stones and also used in art glass application. These are the best blades in the industry. Offer fastest cutting speed and 40% to 80% longer life then any other lapidary blade.

SMART CUT® 300M

Lapidary Blades

Available from 4" to 36" OD. Series 300M will provide smooth surface finish and is designed for cutting all types of lapidary materials. This blades provides longer life and faster cutting speeds then ordinary notched rim, plated diamond blades. This is the most inexpensive & popular sintered (metal bond) blades & most wide used on market today.

SMART CUT® 305M

Lapidary Blades

Available 4" to 36" Diameter. Series 305M provide unmatched performance on a very wide variety of ultra hard to soft lapidary materials. This sintered (metal bond) lapidary blade is known for their aggressive, fast, and rough cutting capability.

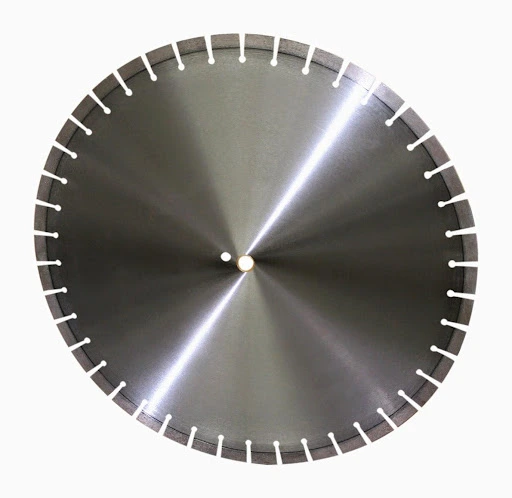

SMART CUT® 301M

Lapidary Blades

SMART CUT® SERIES 301M blades feature a cutting- edge turbo design that accelerates the cutting process, offering a faster and freer cutting speed, compared to notched diamond cutting blades.

SMART CUT® 315M

Lapidary Blades

SMART CUT® SERIES 315M sintered (metal bond) diamond lapidary blades are specially designed to efficiently cut a wide range of hard lapidary materials

SMART CUT® 405M

Lapidary Blades

SMART CUT® Series - 405M DIAMOND CUT OFF BLADES FOR VERY ABRASIVE MATERIALS SMART CUT® Series 405M are Designed for...

Minature Diamond Cutting Wheels

Use for cutting, slotting, grooving, grinding, & shaping a large spectrum of materials. Ranging from ultra hard & brittle materials (such as A1203, sapphire, etc), Ultra Hard Metals, Glass, Composites.

Lapidary Slabbing Blades 16"(406mm) to 48"(1,219)mm

SMART CUT® 320MS Segmented Lapidary Blade

Available 16" to 36" Diameter, these Narrow Slot Segment Design, sintered (metal bond) Lapidary blades. Designed for smooth cutting of ultra hard to soft lapidary materials. This is one of the most popular slabbing lapidary blades.

SMART CUT® 330MS Segmented Lapidary Blade

Available 18" to 36" Diameter, Wide Slot Segment Design. spacing between segments. Designed for fast and more aggressive cutting, where chipping and very smooth cut loss is not essential.

SMART CUT® 325M Continuous Lapidary Blade

Available 18" (450mm) to 20" (500mm) Diameter Continuous rim, Sintered (Metal Bond) 325M blade is designed for delicate cutting and minimum chipping of wide variety of natural stone, semi precious stone, glass, and related materials.

Larger Diameter Slabbing Lapidary Blades

Large Diamond Diamond Lapidary Slabbing Blades larger then 36" (914mm) to 72" (1,828mm) are used for cutting large variety of materials on specialized cutting machines. These are typically made to order.

other

Blade Types

Diamond Wire Blades

Diamond Wire for almost all laboratory and larger diamond wire saws. Used for cutting large variety of ultra hard to soft materials. Available in...

Diamond Band Saw Blades

Diamond Band Saw Blades are used for cutting large variety of ultra hard to soft materials wet or dry. Available to fit just about any type of Band Saw Blades.

Accessories

Dressing Sticks

Dressing Sticks are available from stock to fit all types of diamond, cbn, abrasive wafering & cut off blades and sectiong saws. Such as Buehler.

Blade Stiffeners

Wheel Stiffeners provide stability, rigidity & additional support for your blades. They help in prventing the blade from loosing wobbling

Precision Arbors

Precision arbors ½” (12.7mm) and 5/8” (15.75mm) diameter to fit many different type of cutting machines and cutting blades. Use in conjunction...

Precision Cutting Service & Process Development

We offer large variety of of services including: Dicing, Slicing, Sectioning, Drilling, Coring, Micro Drilling, Grinding, Polishing, & Machining

Why Work With Us?

Comprehensive Source of Information on Diamond Lapidary Blades

We understand that your success depends on select the right diamond lapidary blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Diamond Lapidary Blades in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary lapidary blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect lapidary blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools