-

0 items in quote

No products in the Quote Basket.

SMART CUT® DIAMOND CORE BITS

SINTERED (METAL BOND) SUPER PREMIUM QUALITY – Pointed Segments

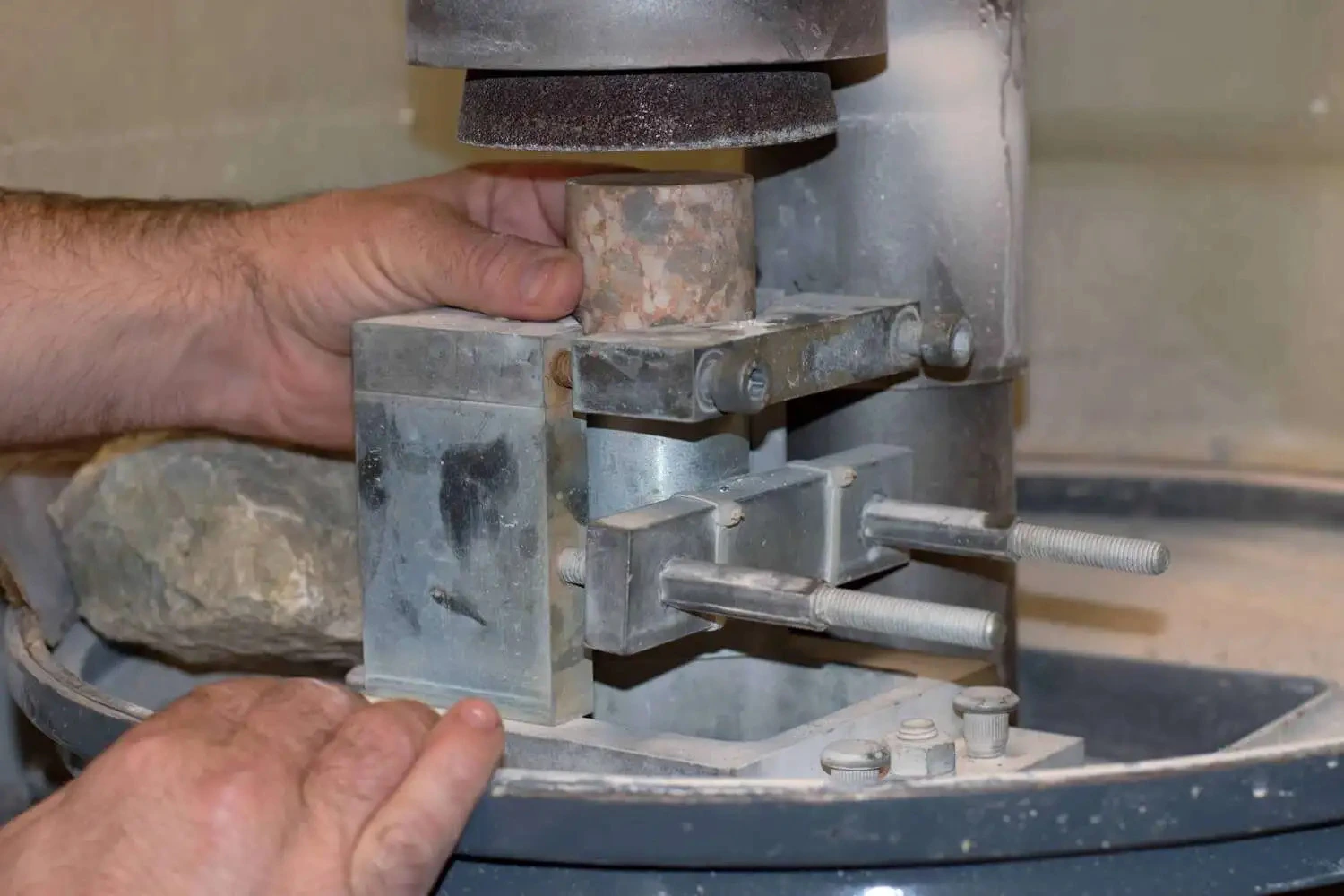

Designed for Drilling Hard Materials such as full range of Rocks (granite, marble, quartz, flagstone, sandstone, onyx, amethyst, travertine, garnet. Will also work (agate, jasper, jade, petrified wood, and similar minerals). What sets these core bits apart is high grade of diamond used & advanced bond formulation designed for Hard Material. The diamond segment is shaped in a U form, has double-pointed tips penetrate quickly and hold a straight drilling path to reduce side drag, and also increases coolant flow to reduce heat and removal slurry more efficiently. Diamond Segments are Laser Welded to precision machined steel body by automatic process that is very highly consistent and error free. Must use with Mineral Oil or water soluble coolant to drill these harder materials. Also very highly recommended to use with water swivel adapter to run high pressure of coolant through center of drill and frequent dressing for these harder materials.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Double pointed core bits have specially formulated diamond segments that allows it to drill through cured concrete with hard aggregate and heavy steel quickly and smoothly.

SPECIFICATIONS

Drilling Depth: 14.5″

Overall Length: 17.5″

Diamond Depth (Height): 10mm

Used On:

- Core Rings

- Hand Held Core Drill Machines

- Hydraulic Drilling Machines

- Pneumatic Core Drilling

- Other Drilling Equipment

FREQUENTLY ASKED QUESTIONS

SMART CUT™ Diamond Core Bits are premium-quality, sintered (metal bond) core bits designed for drilling hard materials, including concrete with hard aggregate and heavy steel. What sets them apart is the high-grade diamond used and an advanced bond formulation specifically designed for hard materials. These core bits feature double-pointed diamond segments for quick and smooth drilling.

SMART CUT™ Diamond Core Bits are designed for a wide range of hard materials, including granite, marble, quartz, flagstone, sandstone, onyx, amethyst, travertine, garnet, concrete, agate, jasper, jade, petrified wood, and many other minerals.

Yes, you can use SMART CUT™ Diamond Core Bits with hand-held drills for diameters up to 1.5″. However, they are not suitable for use with drill presses or milling machines.

SMART CUT™ Diamond Core Bits have double-pointed diamond segments that provide faster drilling, reduced vibration, improved cooling, and efficient slurry removal. They are specially formulated with high-quality diamonds and advanced bond materials, making them almost indestructible when used with coolant.

Sintered (metal bond) diamond tools have multiple layers of diamonds impregnated inside the metal matrix, offering superior performance in cutting hard materials. Unlike other types, sintered diamond tools wear evenly and consistently, resulting in longer life and more reliable performance.

SMART CUT™ Diamond Core Bits offer numerous advantages, including longer life, more consistent performance, minimized chipping, and improved surface finish. They are manufactured using the highest quality raw materials, ensuring the best performance and value.

To maximize the lifespan and performance, follow recommended RPMs (speed) based on core bit diameter, and consider factors like drilling depth, drilling pressure, material abrasiveness, material hardness, and aggregate size. Using coolant and proper maintenance will also help extend their life.

Yes, these core bits are suitable for industrial applications and are compatible with various drilling equipment, including core drilling machines, hydraulic drilling machines, and more.

SMART CUT™ Diamond Core Bits are designed for wet drilling. It is highly recommended to use them with mineral oil or a water-soluble coolant to ensure optimal cooling and lubrication during the drilling process.

Yes, these core bits are rebuildable, which means you can replace worn-out or damaged segments, extending their usable life and cost-effectiveness.

The double-pointed segments provide faster drilling speeds, reduced vibration, and improved cooling and slurry removal. They also help maintain a straight drilling path, reducing side drag and increasing drilling efficiency.

Yes, SMART CUT™ Diamond Core Bits are designed to handle concrete with heavy steel reinforcements. Their advanced bond formulation and high-quality diamonds allow them to drill through concrete with hard aggregate and heavy steel efficiently.

Core bit bond hardness can vary. Softer bond hardness provides faster drilling but may result in shorter core bit life. Harder bond hardness offers longer core bit life but may drill more slowly. The choice depends on the specific drilling requirements and materials.

SMART CUT™ Diamond Core Bits are suitable for both DIY enthusiasts and professionals. Their ease of use and superior performance make them a valuable tool for a wide range of projects.

To select the right core bit, consider factors such as the type of material you are drilling, the diameter of the hole needed, drilling depth, and the drilling equipment you are using. Our specifications tab provides guidance on RPM, core bit life, and drilling speed based on these factors.

These core bits are primarily designed for straight drilling paths. While they can be used on slightly curved surfaces, their optimal performance is achieved on flat and straight surfaces.

Always follow safety guidelines and wear appropriate protective gear when operating drilling equipment. Additionally, ensure the work area is well-ventilated when using coolant. Familiarize yourself with the safety recommendations provided by your equipment manufacturer.

SMART CUT™ Diamond Core Bits can be used for underwater drilling with the proper equipment and precautions. However, ensure that the drilling equipment and electrical components are suitable for underwater use and follow all safety guidelines for underwater operations.

While SMART CUT™ Diamond Core Bits are designed for hard materials, cutting glass or ceramics may not be their primary application. They are better suited for materials like granite, marble, concrete, and others mentioned in the product description.

Dry drilling with SMART CUT™ Diamond Core Bits is not recommended. Using them without proper lubrication and cooling can significantly reduce their lifespan and may result in less effective drilling.

SMART CUT™ Diamond Core Bits are recommended for materials with a hardness range of 30 to 65 on the Rockwell scale (4 to 8.00 on Mohs scale). For drilling tempered steel or industrial ceramics, specialized diamond tools may be required.

Regularly inspect the core bit for wear and damage. Keep the segments clean and free of debris. Follow recommended RPMs and use coolant as advised. When segments show signs of wear, consider rebuilding or replacing them for optimal performance.

SMART CUT™ Diamond Core Bits are versatile and can handle a variety of materials, including both hard and soft. However, for optimal performance, you may consider having specific core bits for each material type.

When handling core bits, wear protective gloves and follow proper lifting techniques to avoid injury. Store them in a dry, cool place away from direct sunlight and corrosive substances to prevent damage to the segments or bond.

Cutting speeds can vary depending on the material and specific project requirements. Refer to our specifications tab for RPM recommendations based on core bit diameter, and adjust the cutting speed as needed for different materials.

Yes, these core bits can be used for drilling holes in walls made of materials like concrete, granite, or marble for plumbing or electrical installations. Always follow safety guidelines and use the appropriate equipment for wall drilling.

SMART CUT™ Diamond Core Bits are designed to be compatible with drilling rigs from different manufacturers. However, always ensure that the core bit thread size matches the drilling rig’s specifications for a secure fit.

Yes, you can use SMART CUT™ Diamond Core Bits with a standard hand-held electric drill for smaller diameters (up to 1.5″). Ensure that the drill’s chuck can accommodate the core bit’s thread size for a secure fit.

While SMART CUT™ Diamond Core Bits are designed for hard materials, including some ceramics, they may not be the best choice for delicate ceramic tiles or porcelain. Specialized ceramic tile core bits are available for such applications.

Yes, SMART CUT™ Diamond Core Bits can be used for drilling holes in concrete or masonry walls to install anchor bolts or fasteners. They are well-suited for these applications, providing efficient and precise drilling.

SMART CUT™ Diamond Core Bits are primarily designed for hard natural materials, such as stone and concrete. While they may cut composite materials, it’s advisable to use specialized core bits designed for composites to achieve the best results.

After each use, clean the core bit’s segments of debris and slurry, and inspect for any signs of wear or damage. Dress the diamond core bit by drilling into dressing stick when needed. Store them in a dry, cool place. If segments are wornout, consider rebuilding or replacing them before the next use.

SMART CUT™ Diamond Core Bits can be used for drilling holes in refractory materials and firebricks. Their advanced design and high-quality diamonds make them effective in such applications, ensuring precision and durability.

When using SMART CUT™ Diamond Core Bits indoors or in confined spaces, ensure proper ventilation to dissipate any coolant fumes. Use appropriate personal protective equipment, and follow all safety guidelines for the equipment and materials being drilled.

Yes, SMART CUT™ Diamond Core Bits are suitable for creating holes in concrete slabs or floors for plumbing or electrical conduits. They offer efficient and precise drilling in these applications.

SMART CUT™ Diamond Core Bits are designed to operate at room temperature. Avoid exposing them to extreme temperatures or sudden temperature changes, as this can affect their performance and lifespan.

Yes, these core bits are ideal for drilling holes in natural stone countertops to accommodate faucets, appliances, or other fixtures. They provide clean and precise cuts in stone materials.

SMART CUT™ Diamond Core Bits can be used for drilling holes in engineered quartz countertops. However, for optimal results, ensure that the core bit is compatible with the specific type of engineered quartz you are working with.

To ensure proper alignment and stability, use a drill guide or template to mark the drilling location and maintain a straight drilling path. Secure the material to be drilled firmly to prevent shifting during the drilling process.

Yes, SMART CUT™ Diamond Core Bits are suitable for drilling holes in reinforced concrete walls and structures. Their design and advanced materials make them effective for such applications.

While SMART CUT™ Diamond Core Bits are designed for use with drilling rigs and hand-held drills, they are not typically used with rotary hammers or hammer drills. These core bits are better suited for standard drill systems. If using on rotary hammer drill use on rotation mode only

SMART CUT™ Diamond Core Bits can be used for drilling holes in terrazzo flooring or tiles. However, it’s essential to use the appropriate core bit size and RPM settings for the best results.

Yes, SMART CUT™ Diamond Core Bits are suitable for making holes in outdoor concrete or stone surfaces like patios or walkways. They are versatile and can be used in various outdoor applications.

Yes, these core bits can be used for making holes in concrete blocks or bricks. They provide efficient and precise drilling in these materials, making them suitable for a range of construction and masonry projects.

SMART CUT™ Diamond Core Bits may come with basic operating instructions. However, it’s advisable to refer to our website or contact our customer support for comprehensive guidance on proper usage and maintenance.

Yes, these core bits are suitable for creating holes in rock formations for geological exploration or sampling. Their advanced design and high-quality diamonds make them effective for such scientific applications. We offer extensions to extend their drilling depth.

Disposal of worn-out or damaged core bits should follow local regulations and guidelines for handling and disposing of diamond tools. Depending on your location, there may be specific waste disposal facilities or recycling options for such materials.

While SMART CUT™ Diamond Core Bits are versatile, they may not be the best choice for extremely fragile materials like porcelain tiles or ceramic pots. Specialized core bits designed for ceramics may provide better results in these cases.

INDUSTRIES USED IN

Concrete & Construction

Natural Stone

Lapidary

ACCESSORIES

Showing 1 – -1 of 16 results Showing all 16 results Showing the single result No results found

Sort by Name A – Z

Filters Sort results

Reset Apply

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $26.72 | Max: Min: 1 Step: 1 | |||

Color: 5/8″-11″ thread. Fits into drill press chuck. Shank adapter threads into 5/8″-11″ female thread of diamond drill. Can be used with any other tool with 5/8″-11″ thread. | $22.46 | Max: Min: 1 Step: 1 | |||

1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 | |||

$154.87 | Max: Min: 1 Step: 1 | ||||

$154.87 | Max: Min: 1 Step: 1 | ||||

$235.00 | Max: Min: 1 Step: 1 |

Showing 1 – -1 of 4 results Showing all 4 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Name | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

$154.87 | Max: Min: 1 Step: 1 | ||||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $235.00 | Max: Min: 1 Step: 1 |

USAGE RECOMMENDATION

02

Jun

Diamond Core Bits for Concrete & Construction are available in countless of specifications. Diamond core bits, known for their unmatched durability and cutting ability, are a necessity for professionals needing to drill through reinforced concrete,…

02

Jun

Concrete Drilling Metrics – Optimizing your Diamond Core Bit

Recommendations on speeds, feed rates and equipment to use to obtain best return on investment for using diamond core bits for drilling concrete and related materials

Share this Article with Friend or…

02

Jun

Optimal Drilling Performance – How to Properly Use Diamond Core Bits

To achieve the best drilling results, it’s important to know the right techniques and tips for using diamond core bits. Whether you’re experienced or new to construction and drilling, using these bits properly can make…

02

Jun

Select right Diamond Drill for your application

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will…

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided…

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind…

02

Jun

Diamond Tools Guide – Selecting Right Drills & Tools for your application

These tools are used for many different industries grinding and shaping material into different forms, expanding exiting inside diameters, grinding, finishing and polishing existing material. Grinding different angles and radius, creating cavities of various forms,…

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency….

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide…

Concrete & Construction Drilling: https://ukam.com/concrete-construction-drilling/

Recommended RPM’s (Speed)

| Core Bit Diameter | Max/Min RPM* | |

|---|---|---|

| 1″ – 2″ | (25mm – 51mm) | 1,200 – 1,000 |

| 2.25 ” – 5″ | (57mm – 127mm) | 1,000 – 500 |

| 5.25″ – 12″ | (134mm – 305mm) | 500 – 250 |

Diamond Core Bit Variables affecting Bit Life & Performance

| Diamond Core Bit Characteristics | Core Bit Life | Drilling Speed | |

|---|---|---|---|

| Core Bit Bond Hardness | Softer Harder | Shorter Longer | Faster Slower |

| Diamond Quality | Lower Higher | Shorter Longer | Slower Faster |

| Diamond | Lower | Shorter | Slower |

| Concentration | Higher | Longer | Faster |

| Segment Thickness | Thinner Thicker | Shorter Longer | Faster Slower |

Application Variables affecting Diamond Core Bit Specification Selection & Performance

| The Job | Core Bit Life | Drilling Speed | |

|---|---|---|---|

| Drilling Depth | Shallow Deep | Usually Shorter Usually Longer | Faster Slower |

| Drilling Pressure | Lower Higher | Longer Shorter | Slower Faster |

| Abrasiveness of Material | More Less | Shorter Longer | Faster Slower |

| Material Harness | Higher Softer | Shorter Longer | Slower Faster |

| Aggregate Size | Larger Smaller | Shorter Longer | Slower Faster |

Advantages

- Will Not Lose Segments

- Different Design (Proven & Tested)

- Rebuildable

- Almost Indestructible (when used with coolant)

- Fast Drilling

- Super Long Life / Consistent Performance

- Works on concrete, allied, & ultra hard materials

- Longer Life

- More Consistent Performance

Features

- Faster drilling with the pointed segments provide incredibly fast drilling speeds

- Fast seating and reduced vibration, the pointed tips penetrate quickly, and hold a straight drilling path to reduce side drag

- Reduced vibration improves drilling efficiency and bit life

- Improved cooling and slurry removal the double pointed segments increases water flow to reduce heat and removed slurry more efficiently

- Specially formulated segments contain high concentrations of quality diamonds combined with a special blend of metal powders to deliver maximum performance with lowest drilling costs

- Wide spaced segment design with tall segments, (.420")

Equipment Used on:

These core bits are designed to be used on drilling rigs and for smaller diameters up to 1.5" can also be used on hand held drills (not to be used on drill press or milling machine, we can produce other type of diamond core drills for that equipment).

Materials Used on

- Granite

- Marble

- Quartz

- Flagstone

- Sandstone

- Onyx

- Amethyst

- Travertine

- Garnet

- Concrete

- Agate

- Jasper

- Jade

- Petrified wood

- Many other minerals

Showing 1 – -1 of 24 results Showing all 24 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No | Old Item No. | Outside Diameter | Segment Width | Segment Length | Number of Segments | Thread Size | Online Special | Item No for 3 pcs | 3 PCS Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

1048101 | 50CA10SG | 1.0" | 3.3mm | 16mm | 3 | 5/8-11" | $69.30 | 1048183 | $60.98 | Max: Min: 1 Step: 1 | ||

1048121 | 50CA12SG | 1/2" | Crown | 5/8-11" | $73.15 | 1048180 | $65.83 | Max: Min: 1 Step: 1 | ||||

1048118 | 50CA11SG | 1-1/8" | 3.3mm | 16mm | 3 | 5/8-11" | $80.40 | 1048184 | $70.75 | Max: Min: 1 Step: 1 | ||

1048580 | 50CA58SG | 5/8" | Crown | 5/8-11" | $85.47 | 1048181 | $75.21 | Max: Min: 1 Step: 1 | ||||

1048114 | 50CA14SG | 1-1/4" | 3.3mm | 16mm | 4 | 5/8-11" | $90.30 | 1048185 | $79.46 | Max: Min: 1 Step: 1 | ||

1048340 | 50CA34SG | 3/4" | Crown | 5/8-11" | $97.79 | 1048182 | $86.05 | Max: Min: 1 Step: 1 | ||||

1048138 | 50CA145SG | 1-3/8" | 3.3mm | 16mm | 4 | 5/8-11" | $99.79 | 1048186 | $87.81 | Max: Min: 1 Step: 1 | ||

1048112 | 50CA15SG | 1-1/2" | 3.3mm | 20mm | 4 | 5/8-11" | $105.35 | 1048187 | $92.70 | Max: Min: 1 Step: 1 | ||

1048134 | 50CA17SG | 1-3/4" | 3.5mm | 20mm | 5 | 5/8-11" | $108.71 | 1048188 | $95.66 | Max: Min: 1 Step: 1 | ||

1048200 | 50CA20SG | 2.0" | 3.5mm | 20mm | 6 | 5/8-11" | $116.41 | 1048189 | $102.44 | Max: Min: 1 Step: 1 | ||

1048214 | 50CA21SG | 2-1/4" | 3.5mm | 20mm | 7 | 1-1/4-7" | $133.07 | 1048190 | $117.10 | Max: Min: 1 Step: 1 | ||

1048212 | 50CA22SG | 2-1/2" | 3.5mm | 20mm | 8 | 1-1/4-7" | $149.70 | 1048191 | $131.74 | Max: Min: 1 Step: 1 | ||

1048300 | 50CA30SG | 3.0" | 3.5mm | 20mm | 9 | 1-1/4-7" | $175.18 | 1048192 | $154.15 | Max: Min: 1 Step: 1 | ||

1048312 | 50CA32SG | 3- 1/2" | 3.5mm | 20mm | 10 | 1-1/4-7" | $182.94 | 1048193 | $160.98 | Max: Min: 1 Step: 1 | ||

1048400 | 50CA40SG | 4.0" | 3.8mm | 20mm | 12 | 1-1/4-7" | $227.94 | 1048194 | $200.58 | Max: Min: 1 Step: 1 | ||

1048412 | 50CA42SG | 4-1/2" | 4.2mm | 20mm | 13 | 1-1/4-7" | $260.57 | 1048195 | $229.30 | Max: Min: 1 Step: 1 | ||

1048500 | 50CA50SG | 5.0" | 4.2mm | 20mm | 15 | 1-1/4-7" | $288.71 | 1048196 | $254.06 | Max: Min: 1 Step: 1 | ||

1048600 | 50CA60SG | 6.0" | 4.5mm | 24mm | 16 | 1-1/4-7" | $365.89 | 1048197 | $321.98 | Max: Min: 1 Step: 1 | ||

1048700 | 50CA70SG | 7.0" | 4.5mm | 24mm | 17 | 1-1/4-7" | $454.61 | 1048198 | $400.05 | Max: Min: 1 Step: 1 | ||

1048800 | 50CA80SG | 8.0" | 4.5mm | 24mm | 18 | 1-1/4-7" | $476.00 | 1048199 | $418.88 | Max: Min: 1 Step: 1 | ||

1048900 | 50CA90SG | 9.0" | 5.0mm | 24mm | 20 | 1-1/4-7" | $547.00 | 1048200 | $492.3 | Max: Min: 1 Step: 1 | ||

1048100 | 51CA10SG | 10.0" | 5.0mm | 24mm | 22 | 1-1/4-7" | $845.00 | 1048201 | $760.50 | Max: Min: 1 Step: 1 | ||

1048120 | 51CA12SG | 12.0" | 5.5mm | 24mm | 27 | 1-1/4-7" | $951.00 | 1048202 | $855.90 | Max: Min: 1 Step: 1 | ||

1048140 | 51CA14SG | 14.0" | 5.0mm | 24mm | 30 | 1-1/4-7" | $998.00 | 1048203 | $898.72 | Max: Min: 1 Step: 1 |

1048101,1048121,1048118,1048580,1048114,1048340,1048138,1048112,1048134,1048200,1048214,1048212,1048300,1048312,1048400,1048412,1048500,1048600,1048700,1048800,1048900,1048100,1048120,1048140,

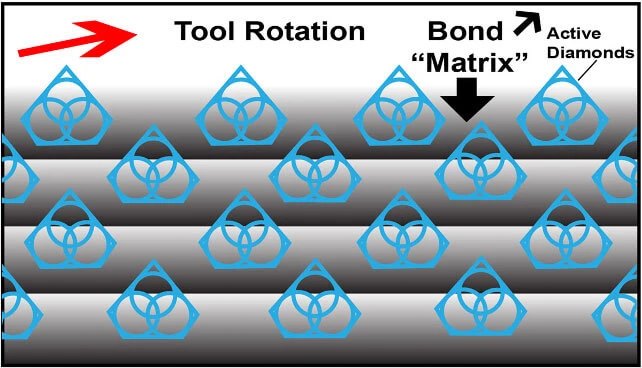

About Sintered (Metal Bond)

Sintered (metal bonded) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are “impregnated” with diamonds. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, advanced ceramics, optics, glass, granite, tile and etc. The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting. Sintered (metal bonded) diamond tools are recommended for machining hard materials from 45 to 75 on rockwell scale (5 to 9.5 on mohe’s scale of hardness).

SMART CUT® Difference

How SMART CUT® Diamond Core Bits are Different in comparison to other Diamond Core Bits.

Faster Drilling Action

Diamond drills made utilizing SMART CUT technology are much more aggressive than your conventional drills. They can drill faster, while still leaving behind a smooth finish free of material deformation.

Longer Life

In most cases tools manufactured utilizing SMART CUT technology, will outlast other conventional nickel bonded diamond & CBN drills. SMART CUT diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

More Consistent Performanc

SMART CUT Multi Layered Electroplated Diamond Drills have three diamond layers impregnated inside the bond matrix. Unlike Many Other drill Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Manufactured Using The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Best Performance & Value on the Market

SMART CUT Multi Layered Electroplated Diamond Drills are the best investment you can make! Although they may cost more than electroplated (nickel bond), Diamond Drills. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

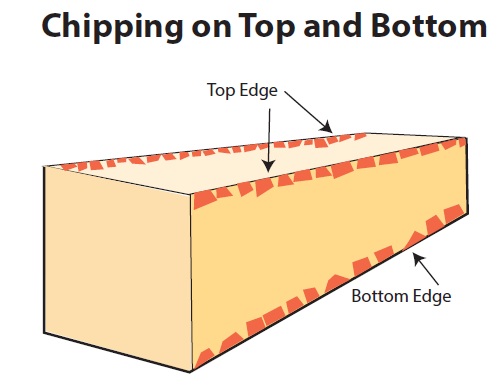

Minimize Chipping & Improve Surface Finish

SMART CUT Multi Layered Electroplated Diamond Drills have diamonds oriented and evenly distributed in a bond matrix. Providing faster, freer cutting action with minimum heat generation. This translates in improved surface finish and minimum chipping.

Its what you cant see that makes all the Difference

How SMART CUT ® Bond Works?

Step 1

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

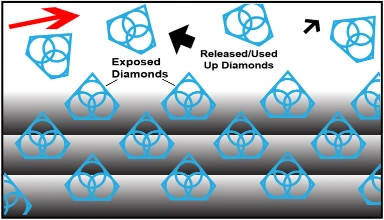

Step 2

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

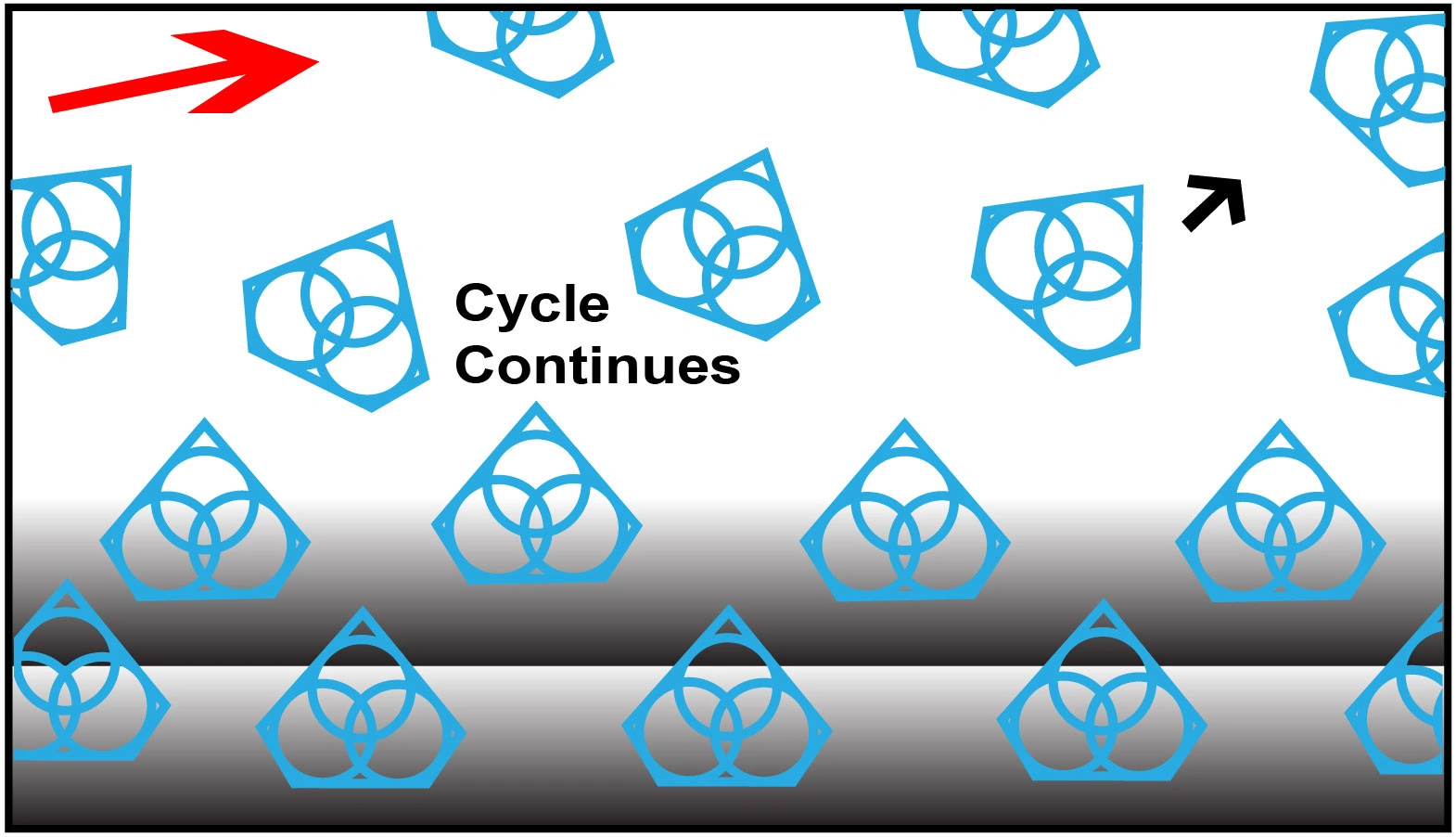

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

DIMOND CORE BIT FOR CONSTRUCTION

Custom Manufacturing Capabilities

In addition to the standard SMART CUT series Diamond Core Bits typically available from stock. We can produce large variety of custom diamond Core Bits and tools per your specification or drawing

- Almost any diameter

- Almost any (anygle/radius) Segments

- Almost Any Wall/kerf Thickness

- Custom drill lengths

- Custom Mounting Types

- Almost any diamond size

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Related Products

SMART CUT Diamond Counter Sinks Multi Layered Electroplated

SMART CUT® Diamond Counter Sinks are precision-engineered tools designed for creating countersink holes, expanding existing holes, breaking sharp corners, chamfering edges, and polishing pre-existing holes across a wide range of materials. These high-performance tools deliver exceptional accuracy and consistency, making them ideal for a variety of precise hole modification tasks.

Available in a range of standard specifications, SMART CUT® Diamond Counter Sinks can also be custom-manufactured to meet almost any unique application or requirement. The multi-layered electroplated diamond coating provides superior wear resistance, enhancing both tool life and cutting efficiency.

SMART CUT® 005DME MCDU

SMART CUT® 005DME diamond micro drills are produced using electroplated (nickel bond) galvanic plating process. These tools can be used for drilling and machining large variety of materials such as Precision Optics, Silicon Carbide, Boron Nitride, Boron Carbide, Alumina Ceramics, Silicon, Sapphire & Yag, Glass, Quartz, & Pyrex Tubing & Many Other Applications.

Small diameter below .020” (0.5mm) are made using diamond plating (galvanic) method, where the diamond crystals are deposited evening on the tip evenly over time. The steel body using is usually high speed steel ranging in hardness from 40 to 50 Rockwell scale C. Precision tolerances are maintain on diameter.

SMART CUT® 015DSE

SMART CUT Series 015DSE Multi Layered Electroplated solid drills are flat cylinder shape with transition angle. These miniature diamond drills have high diamond concentration and give a smother, faster drilling action with minimum heat generation. The multiple layers of diamond coating which provides best diamond adhesion in the bond matrix. This provides longer life span, compared to standard and comparable electroplated miniature drills. Higher level of consistency and better surface finish. Most popular type of diamond drills for drilling small holes for jewelry (stone, glass, & many other materials). Multiple layers of diamond provide longer drilling life, faster & freer drilling. Available from stock from 0.75mm to 2.5mm

115DE SMART CUT® Series

Thin Wall Diamond Core Drills, Sintered (Metal Bond)

SMART CUT® 115DE Series Thin Wall Diamond Core Drills from UKAM Industrial Superhard Tools are engineered to provide exceptional performance in the most demanding drilling applications. Designed for tough, abrasive materials such as glass, alumina, quartz, ruby, YAG, silica, silicon, graphite, composites, and other non-metallic ceramics, these drills feature a sintered metal matrix bond that securely holds the diamond, ensuring high durability and consistent performance. With a wall thickness of 1.2mm (.047”), these core drills are optimized for long-lasting performance, faster drilling speeds, and minimal heat generation. Each drill is precision-machined from a single piece of steel using high-precision CNC equipment, ensuring tight tolerances, accuracy, and consistency. The diamond depth (height) of 10mm provides the longest possible tool life and ensures the highest performance standards in the industry. The 5/8-11" female thread ensures compatibility with most standard drilling equipment, offering flexibility and easy integration into existing setups. The medium diamond grit size offers an ideal balance between cutting speed and surface finish quality, making these drills highly versatile for various drilling applications.Water Swivel Adapters

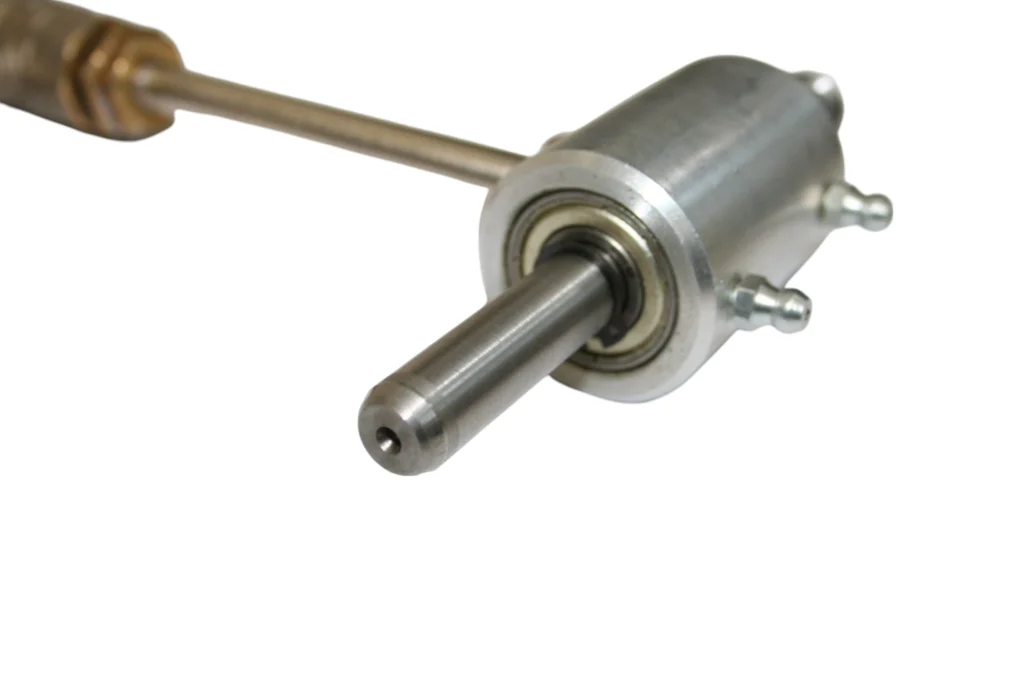

SMART CUT® Water Swivel Adapters, also known as drill head assemblies, are precision-engineered components essential for delivering a continuous, pressurized flow of water, coolant, or air directly through the center of your diamond core drills and other hollow-shaft rotary tools. This internal coolant delivery method provides direct lubrication at the cutting interface, ensuring the most effective heat dissipation and friction reduction where it matters most—at the point of contact between the tool and the material.

By channeling coolant through the core of the tool, these adapters help maintain stable cutting temperatures, reduce thermal expansion, and significantly minimize the risk of cracking, delamination, burning, and tool loading. This results in dramatically extended tool life—in some in many cases over 350% +—as well as faster drilling speeds, reduced downtime, and superior material finish and dimensional accuracy. The integration of SMART CUT® Water Swivel Adapters into your operation will substantially enhance process efficiency and consistency, particularly when working with heat-sensitive, brittle, or high-precision materials.

Universally compatible, these adapters are designed to seamlessly fit a wide range of drilling systems, CNC machines, manual drill presses, and automated drilling equipment. They are available in multiple shaft diameters, thread types, and mounting configurations, and are engineered to mate precisely with diamond drill collets and chuck systems.

SMART CUT® 140DM Diamond Core Bits / Drill Bits for Concrete & Allied Materials (wet only)

SMART CUT® DIAMOND CORE BITS

SINTERED (METAL BOND) SUPER PREMIUM QUALITY – Pointed Segments

Designed for Drilling Hard Materials such as full range of Rocks (granite, marble, quartz, flagstone, sandstone, onyx, amethyst, travertine, garnet. Will also work (agate, jasper, jade, petrified wood, and similar minerals). What sets these core bits apart is high grade of diamond used & advanced bond formulation designed for Hard Material. The diamond segment is shaped in a U form, has double-pointed tips penetrate quickly and hold a straight drilling path to reduce side drag, and also increases coolant flow to reduce heat and removal slurry more efficiently. Diamond Segments are Laser Welded to precision machined steel body by automatic process that is very highly consistent and error free. Must use with Mineral Oil or water soluble coolant to drill these harder materials. Also very highly recommended to use with water swivel adapter to run high pressure of coolant through center of drill and frequent dressing for these harder materials.Recently Viewed Products

ARE YOU USING RIGHT DIAMOND CORE BITS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND CORE BITS?

02

Jun

Diamond Core Bit Ultimate Guide

Diamond Core Bits for Concrete & Construction are available in countless of specifications. Diamond core bits, known for their unmatched durability and cutting ability, are a necessity for professionals needing to drill through reinforced concrete,...

02

Jun

Concrete Drilling Metrics – Optimizing your Diamond Core Bit

Recommendations on speeds, feed rates and equipment to use to obtain best return on investment for using diamond core bits for drilling concrete and related materials

Share this Article with Friend or...

02

Jun

Select right Diamond Drill for your application

Learn important diamond drill methodology. understand diamond drill specifications and their differences Selecting the right Diamond Drills/Bits for your application is key to obtaining desired diamond drilling results. Using the Right Diamond Drill will...

02

Jun

How to Properly Use Precision Diamond Drills

Step by step guide on how to properly use and care for your diamond drills. Selecting the right diamond drill/diamond drill bit parameters, often involves a trial and error process. Many which can be avoided...

02

Jun

Diamond Drills Guide

Diamond are used across large variety of industries and applications. This guide explores the wide range of diamond drill types, including hollow core drills designed for removing a cylindrical core, non-core formation drills that grind...

02

Jun

Optimizing your Diamond Drilling Operation

There are numerous factors that influence the performance of diamond drills. Understanding these factors helps users select the appropriate diamond drill specifications for their specific applications, optimizing drilling operations to achieve maximum efficiency....

02

Jun

Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

Share this Article with Friend or Colleague

There are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the...

03

May

Diamond Core Drill & Drill Trouble Shooting Guide

Learn the most common problems most people have in using diamond drills. How to resolve them and avoid them in first place

https://ukam.com/wp-content/uploads/2024/07/diamond-drill-troublehsooting-guide.mp4

Troubleshooting Drilling Problems

Having issues with your diamond drilling operation? This Illustrated Guide...

09

Sep

Understanding & Calculating Return on Investment for Diamond Core Drills & Other Tools

The term "ROI" (Return On Investment) is widely used across industries, often interpreted differently depending on the context. However, few truly understand what ROI represents and its specific implications, particularly in the context of diamond...

09

Sep

Understanding Tradeoffs – Searching for Perfect Diamond Drill & Tool

Choosing the right diamond drill or tool can significantly impact efficiency, cost, and quality. However, this is not a simple and clear-cut process. Selecting the optimal drill or tool involves navigating a complex landscape of...

20

Sep

Diamond Drill Terminology

How to fine tune each of these variables to improve and optimize your drilling operation in the success of your diamond drilling operation

Share this Article with Friend or Colleague

DIAMOND DRILL /...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use