-

0 items in quote

No products in the Quote Basket.

02

Nov

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

10

Oct

Everything You Wanted to Know About Cutting Glass with Diamond Blades

Cutting glass is a delicate process that requires the right set up, technique and process to avoid cracks, chips, or fractures. The inherent brittleness and hardness of glass make it challenging to work...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools facilitate detailed tasks such as engraving and finishing, offering precise control and enabling you to work...

12

Sep

Drilling Composite Materials Using Diamond Drills & Hole Saws

Drilling composite materials presents a unique set of challenges due to their heterogeneous nature, which combines different materials with varying properties. To achieve precision and maintain the integrity of both the tool and the workpiece,...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

30

Jul

Load Feed Rate

SPINDLE SPEED / RPM’S

Spindle speed (RPM) is a critical factor for diamond and CBN wafering blades in metallography and sample preparation. Optimal speeds vary based on the blade's outside diameter (OD), the specific application, the...

08

Jul

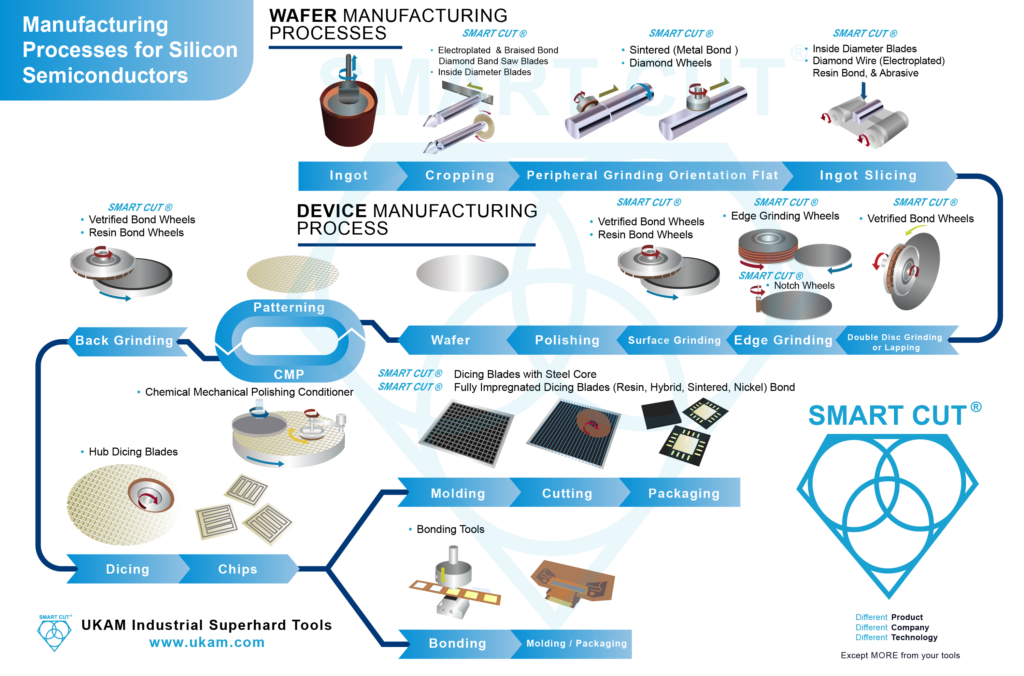

Manufacturing Processes for Silicon Semiconductors From Ingot to Integrated Circuit

Share this Article with Friend or Colleague

1. Ingot Production

The journey begins with the creation of silicon ingots, which are pure silicon cylinders produced through methods like the Czochralski process. Once formed, these ingots undergo a...

08

Jul

Low Speed Saw Case Studies

Share this Article with Friend or Colleague

Introduction

In the realm of precision cutting, the SMART CUT® 6005 Low Speed Diamond Saw stands out for its capability to handle a variety of materials with high...