CBN (Cubic Boron Nitride) Grinding Wheels – Everything you wanted to know

-

Posted by

contactor6

Why Use Cubic Boron Nitride (CBN) Wheels?

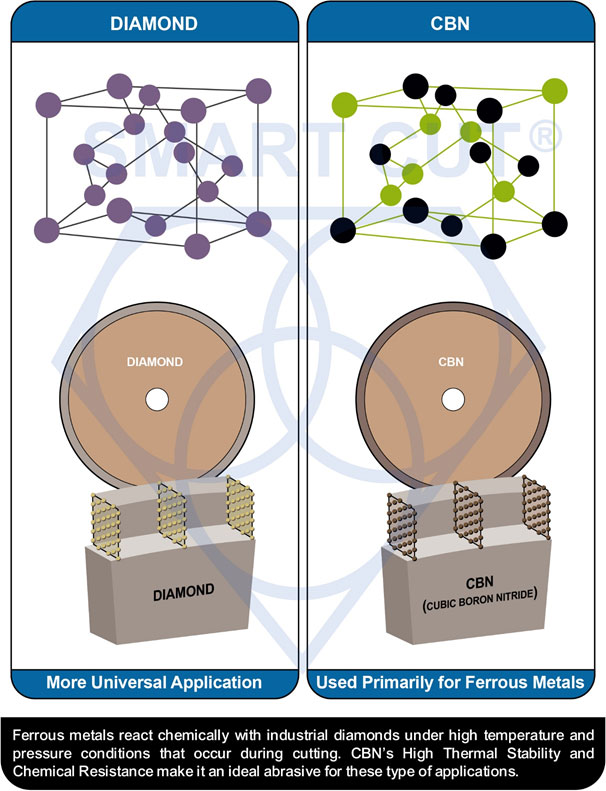

Cubic boron nitride (CBN) grinding wheels are gaining recognition as superior tools for machining difficult metals. Initially used in toolrooms and cutter-grinding applications, CBN wheels are now making a significant impact in production grinding operations, where conventional abrasives would wear out much faster. CBN wheels are versatile, ranging from regrinding high-speed cutting tools to high-speed grinding of hardened steel components in the automotive industry.

Advantages of CBN Grinding Wheels

CBN (Cubic Boron Nitride) grinding wheels offer numerous advantages over conventional abrasive wheels, making them an excellent choice for grinding ferrous metals and other hard materials. Here are the key benefits that highlight why CBN wheels are preferred in many high-precision grinding applications:

Superior Hardness and Toughness

CBN wheels are more than twice as hard as conventional abrasives, such as aluminum oxide and silicon carbide. This exceptional hardness allows them to effectively grind hard ferrous metals, including high-speed steels, tool steels, and other hardened materials. However, hardness alone is not sufficient for efficient grinding; the abrasive must also be tough enough to withstand the high machining pressures and heat generated during the grinding process. CBN crystals meet both requirements, maintaining their cutting edge longer and wearing out much slower than traditional abrasives. This combination of hardness and toughness ensures consistent performance and prolonged wheel life, even in demanding grinding operations.

Enhanced Cutting Efficiency

Conventional grinding wheels tend to break down quickly, leading to high frictional heat and reduced material removal rates as the grains dull. This degradation can compromise part accuracy and geometry, requiring frequent wheel changes and adjustments. In contrast, CBN wheels maintain their sharp cutting edges for extended periods, providing sustained cutting capacity. This prolonged efficiency reduces the frequency of wheel changes and minimizes downtime, contributing to higher productivity.

High Thermal Conductivity

CBN wheels offer high thermal conductivity, which is crucial in managing the heat generated during grinding. Excessive heat can cause uncontrolled thermal expansion, leading to workpiece distortion, surface burns, and metallurgical damage. The superior thermal conductivity of CBN abrasives helps dissipate heat more effectively, preventing heat buildup and reducing the risk of thermal damage. This feature is particularly beneficial in high-speed and high-feed grinding applications, where heat management is critical to maintaining workpiece integrity.

Reduced Wheel Glazing

Wheel glazing occurs when the abrasive grains become dull and the bond material is unable to break down to expose new sharp grains. This results in a smooth, glass-like surface on the wheel that reduces its cutting ability. CBN wheels, with their high thermal conductivity and wear resistance, are less prone to glazing. They continue to cut efficiently without significant loss of performance, ensuring consistent grinding results and extending the wheel's service life.

Thermal and Chemical Stability

CBN abrasives are thermally and chemically stable at temperatures exceeding 1,832°F (1,000°C), much higher than typical grinding temperatures. This stability allows CBN wheels to maintain their integrity and performance under extreme conditions. The high-temperature stability reduces wheel wear and ensures precise workpiece geometry and accuracy, even during prolonged grinding operations. The chemical stability of CBN also means it does not react with iron-based materials, further enhancing its suitability for grinding ferrous metals.

Precision and Accuracy

The prolonged cutting efficiency and stability of CBN wheels contribute to higher precision and accuracy in grinding operations. The consistent performance of CBN abrasives allows for tighter tolerances and better control over part dimensions and surface finishes. This makes CBN wheels ideal for applications requiring high precision, such as in the aerospace, automotive, and tool-making industries.

Cost-Effectiveness

Although CBN wheels may have a higher initial cost compared to conventional abrasive wheels, their longer lifespan and sustained performance result in overall cost savings. The reduced frequency of wheel changes, lower downtime, and improved grinding efficiency contribute to lower operational costs. Additionally, the high-quality finishes and precise geometries achieved with CBN wheels can reduce the need for secondary finishing operations, further enhancing cost-effectiveness.

-

Alloy steels (45-68 RC)

Alloy steels (45-68 RC)

-

Carbon tool steels (45-68 RC)

Carbon tool steels (45-68 RC)

-

Die steel (45-68 RC)

Die steel (45-68 RC)

-

High speed steel (45-68 RC)

High speed steel (45-68 RC)

-

Chilled cast iron

Chilled cast iron

-

Ni Hard

Ni Hard

-

Forged steel

Forged steel

-

Meehanite iron

Meehanite iron

-

Moly chrome steel rolls

Moly chrome steel rolls

-

Inconel 600

Inconel 600

-

Rene

Rene

-

Incoloy

Incoloy

-

Monel

Monel

-

Stellite

Stellite

-

Colmonoy

Colmonoy

-

Waspoloy

Waspoloy

-

Tool Steels

Tool Steels

-

Alloy Steels

Alloy Steels

-

Hardening Steels

Hardening Steels

-

Stainless Steels

Stainless Steels

-

Bearing Steels

Bearing Steels

-

Heat-Resistant Alloys

Heat-Resistant Alloys

-

Super Heat-Resistant Alloys

Super Heat-Resistant Alloys

-

Sintered Metals

Sintered Metals

-

Ferrous Metals (Ferrous and other)

Ferrous Metals (Ferrous and other)

-

Copper Alloys

Copper Alloys

-

Hard Ferrous (steel) parts over 45 Rockwell C

Hard Ferrous (steel) parts over 45 Rockwell C

-

Iron

Iron

-

Cobalt Alloys

Cobalt Alloys

-

Nickel Superalloys

Nickel Superalloys

-

Lead Alloys

Lead Alloys

CBN Wheel Manufacturing and Applications

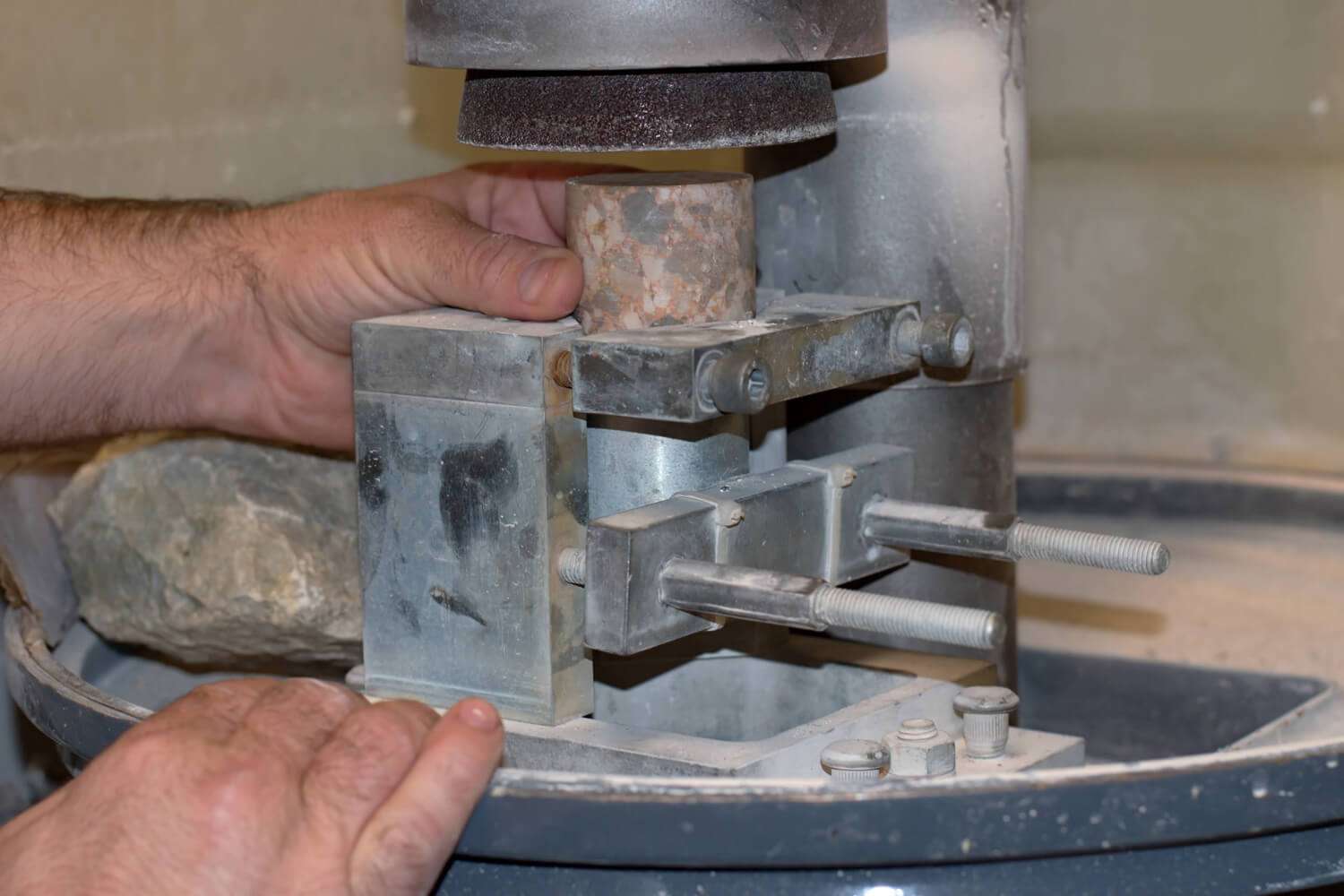

Grinding wheels are essential tools in metalworking, composed of abrasive grains held together by a suitable bond material. Cubic boron nitride (CBN) wheels, in particular, are engineered to meet the high demands of precision, durability, and efficiency in various grinding applications. In metalworking, grinding wheels serve three primary purposes: generating flat, cylindrical, and formed surfaces; removing stock from hard metals; and producing high-quality surface finishes.

Generating Flat, Cylindrical, and Formed Surfaces

CBN wheels excel in creating flat, cylindrical, and formed surfaces with high precision. The superior hardness and thermal stability of CBN abrasive grains allow these wheels to maintain their shape and integrity during intensive grinding processes. This makes CBN wheels ideal for applications that require accurate and consistent geometries, such as:

-

Flat Surfaces: CBN wheels are used in surface grinding operations to produce perfectly flat surfaces on workpieces. This is crucial in industries where flatness and parallelism are critical, such as in the production of machine components and precision tools.

Flat Surfaces: CBN wheels are used in surface grinding operations to produce perfectly flat surfaces on workpieces. This is crucial in industries where flatness and parallelism are critical, such as in the production of machine components and precision tools.

-

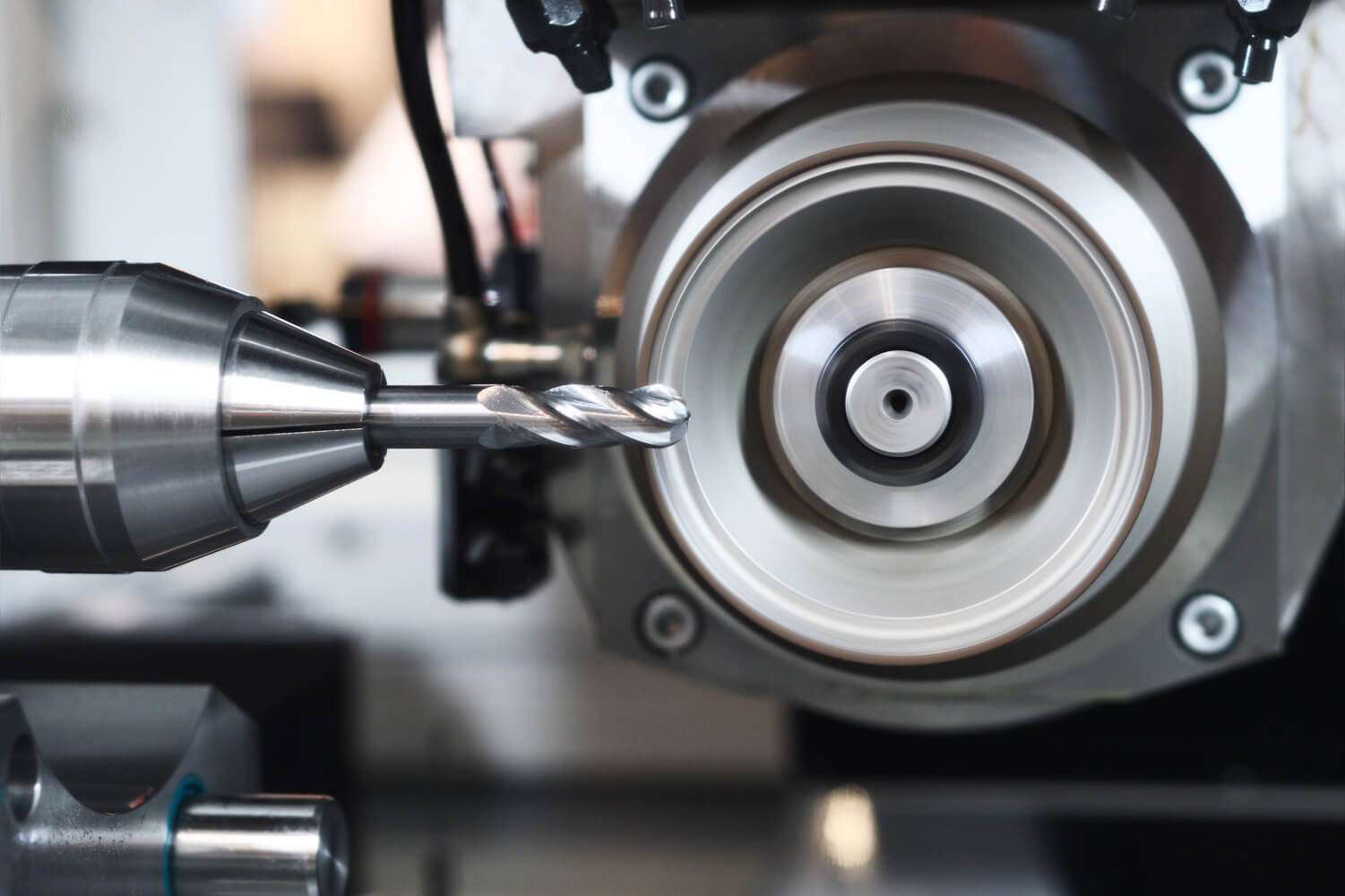

Cylindrical Surfaces: In cylindrical grinding, CBN wheels are employed to grind the external or internal surfaces of cylindrical workpieces. This includes applications like the finishing of shafts, bearings, and other rotational parts where roundness and concentricity are essential.

Cylindrical Surfaces: In cylindrical grinding, CBN wheels are employed to grind the external or internal surfaces of cylindrical workpieces. This includes applications like the finishing of shafts, bearings, and other rotational parts where roundness and concentricity are essential.

-

Formed Surfaces: For grinding complex shapes and profiles, CBN wheels can be custom-engineered to match the specific contours of the workpiece. This capability is particularly valuable in the aerospace, automotive, and tool-making industries, where intricate shapes and tight tolerances are required.

Formed Surfaces: For grinding complex shapes and profiles, CBN wheels can be custom-engineered to match the specific contours of the workpiece. This capability is particularly valuable in the aerospace, automotive, and tool-making industries, where intricate shapes and tight tolerances are required.

Removing Stock from Hard Metals

CBN wheels are specifically designed to remove material from tough metals, providing an effective solution for difficult-to-grind substances. The exceptional hardness of CBN makes it suitable for grinding hard metals such as hardened steel, high-speed steel, and superalloys. These wheels are capable of:

-

Efficient Stock Removal: The high cutting efficiency of CBN wheels allows for rapid material removal, reducing cycle times and increasing productivity. This is particularly beneficial in applications involving high-volume production or large workpieces.

Efficient Stock Removal: The high cutting efficiency of CBN wheels allows for rapid material removal, reducing cycle times and increasing productivity. This is particularly beneficial in applications involving high-volume production or large workpieces.

-

Minimizing Tool Wear: Due to their durability, CBN wheels exhibit lower wear rates compared to conventional abrasive wheels. This reduces the frequency of wheel changes and maintenance, leading to cost savings and improved operational efficiency.

Minimizing Tool Wear: Due to their durability, CBN wheels exhibit lower wear rates compared to conventional abrasive wheels. This reduces the frequency of wheel changes and maintenance, leading to cost savings and improved operational efficiency.

-

Grinding Tough Materials: CBN wheels can effectively grind materials that are challenging for traditional abrasives, such as nickel-based superalloys and hardened tool steels. This makes them indispensable in industries like aerospace, where components are often made from these tough materials.

Grinding Tough Materials: CBN wheels can effectively grind materials that are challenging for traditional abrasives, such as nickel-based superalloys and hardened tool steels. This makes them indispensable in industries like aerospace, where components are often made from these tough materials.

Producing High-Quality Surface Finishes

Due to their durability and stability, CBN wheels are ideal for achieving smooth surface finishes. The uniformity and sharpness of CBN grains contribute to the wheel's ability to produce high-quality finishes on workpieces, which is essential in applications that demand superior surface integrity and appearance. The benefits include:

-

Consistent Surface Quality: The hardness and resilience of CBN ensure that the abrasive grains remain sharp and effective throughout the grinding process. This consistency results in uniform surface finishes, which are critical for components that require precise fits and smooth interfaces.

Consistent Surface Quality: The hardness and resilience of CBN ensure that the abrasive grains remain sharp and effective throughout the grinding process. This consistency results in uniform surface finishes, which are critical for components that require precise fits and smooth interfaces.

-

Reduced Thermal Damage: CBN wheels generate less heat during grinding compared to conventional abrasives, reducing the risk of thermal damage to the workpiece. This is particularly important in applications where maintaining the metallurgical properties of the material is crucial.

Reduced Thermal Damage: CBN wheels generate less heat during grinding compared to conventional abrasives, reducing the risk of thermal damage to the workpiece. This is particularly important in applications where maintaining the metallurgical properties of the material is crucial.

-

Enhanced Performance: The ability of CBN wheels to maintain their form and cutting efficiency over extended use leads to improved performance in grinding operations. This results in higher-quality end products with minimal surface defects.

Enhanced Performance: The ability of CBN wheels to maintain their form and cutting efficiency over extended use leads to improved performance in grinding operations. This results in higher-quality end products with minimal surface defects.

Grinding Wheel Structure and Components

A grinding wheel is a fundamental tool in many machining and material processing applications, known for its ability to cut, shape, and finish workpieces with precision. To perform effectively, a grinding wheel must be both durable enough to withstand high pressures and designed to gradually break down to expose new sharp cutting edges. The structure of a grinding wheel is meticulously engineered to balance these requirements. The main components of a grinding wheel are the abrasive grain and the bond material that holds the grains together. Each component plays a crucial role in the wheel’s overall performance and efficiency.

Types of Abrasive Grain

There are seven different types of cubic boron nitride (CBN) abrasives, each designed to optimize performance for specific wheel types and bond systems. These types are grouped into three categories:

1. Medium Toughness, Single-Crystal (Monocrystalline) Abrasive:

-

Ideal for general grinding operations with a balance between toughness and hardness.

Ideal for general grinding operations with a balance between toughness and hardness.

2. High Toughness, Single-Crystal (Monocrystalline) Abrasive:

-

Designed for applications requiring greater durability and resistance to breakage.

Designed for applications requiring greater durability and resistance to breakage.

3. Tough Microcrystalline Abrasive:

-

Suited for grinding operations needing high toughness and resistance to wear.

Suited for grinding operations needing high toughness and resistance to wear.

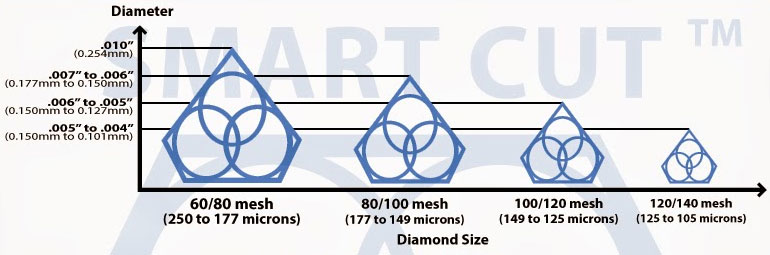

Abrasive grains come in various mesh sizes to suit different grinding applications, ranging from coarse grains to fine micron powders (20 to 800 grit). These are tailored for specific stock removal needs.

Bonding Systems for CBN Wheels

CBN wheels utilize two main types of bonding systems: impregnated-bond wheels and electroplated wheels.

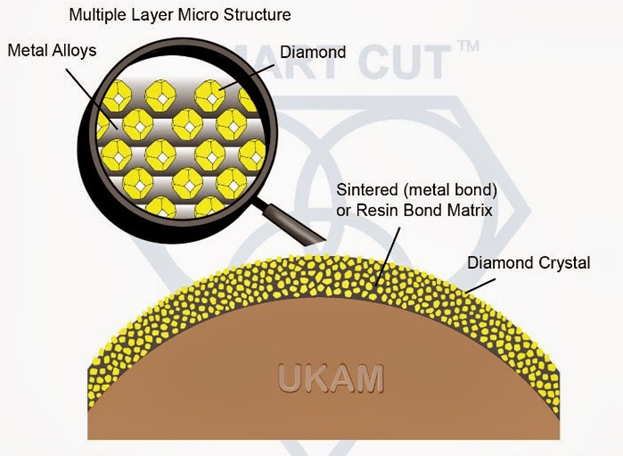

Impregnated Bond Wheels

These wheels have CBN abrasive mixed with the bond material (resin, metal, or vitrified) throughout the thickness of the rim section. The bond must have properties that complement the abrasive, wearing at a similar rate to maintain consistent grinding performance.

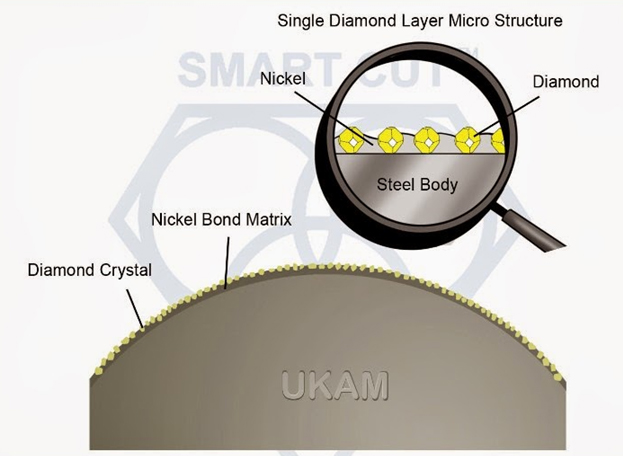

Electroplated CBN Wheels

These wheels have a single layer of CBN abrasive bonded to the machined surface of a metal wheel core through a nickel electroplating bath. This electroplated nickel matrix provides excellent retention of the abrasive, ensuring durability and longevity.

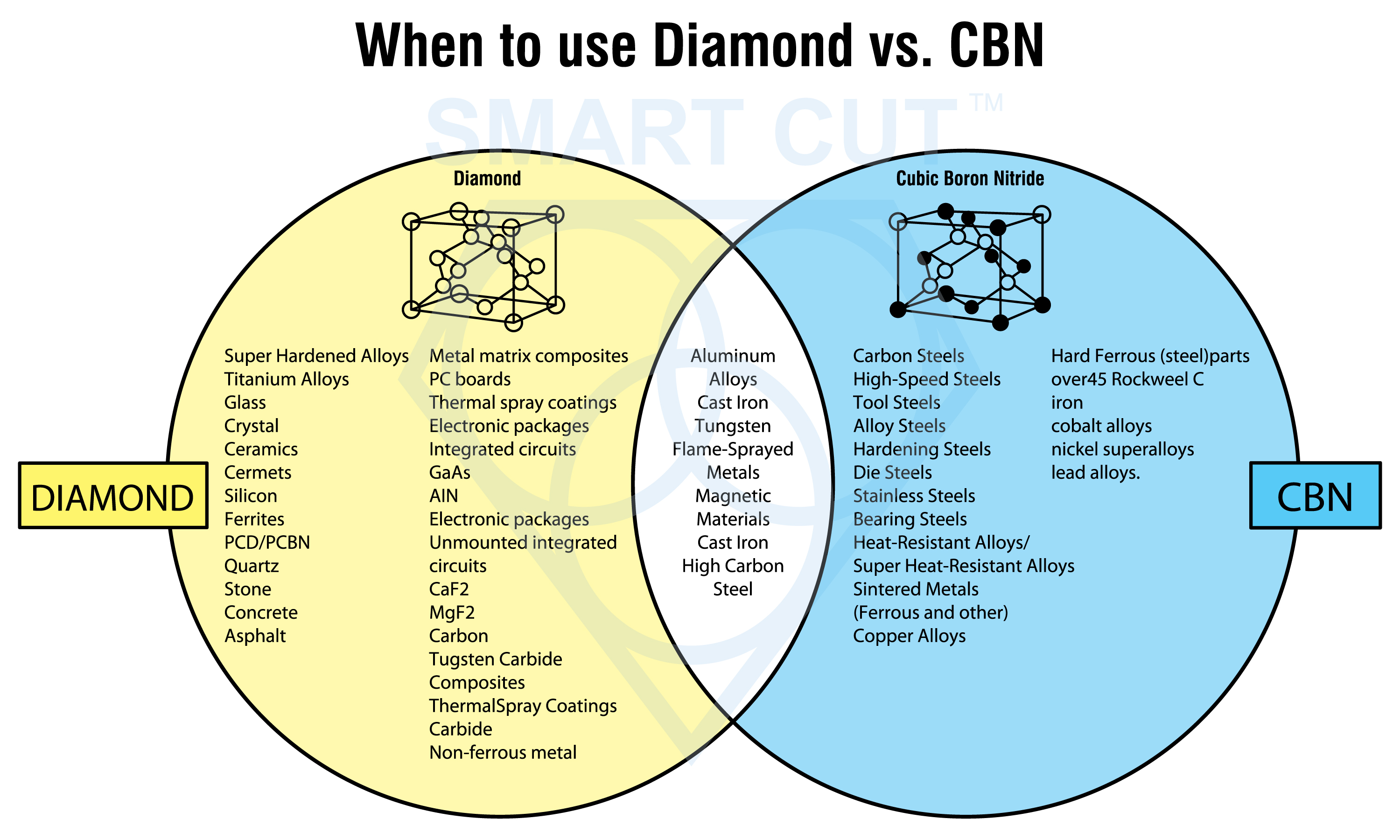

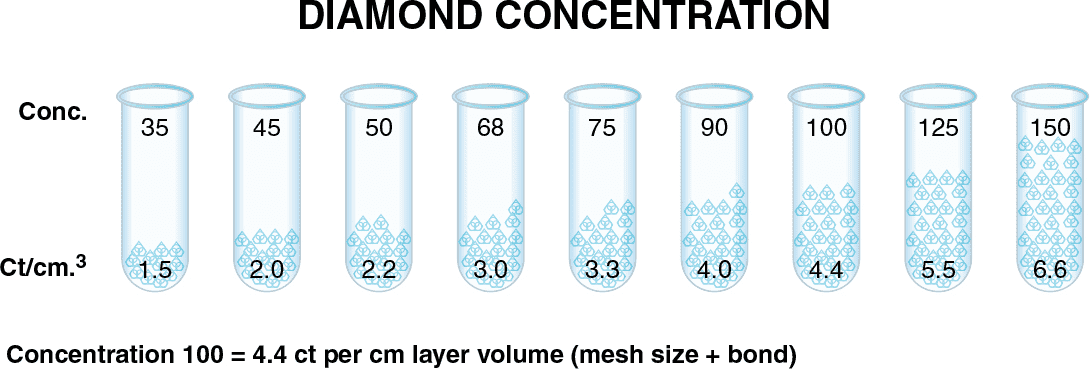

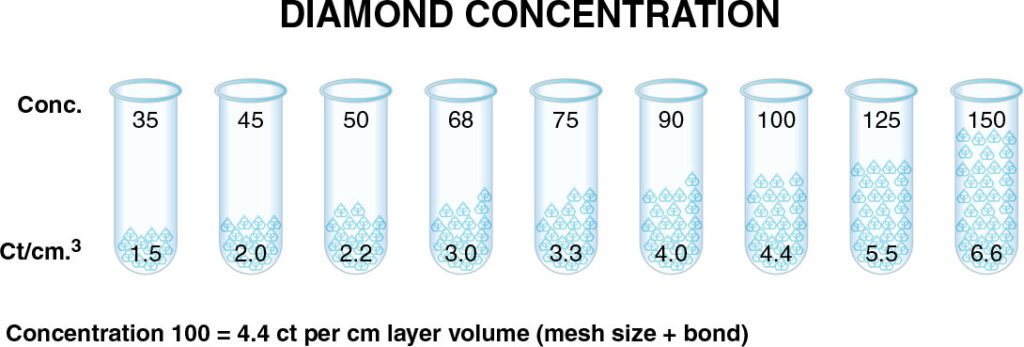

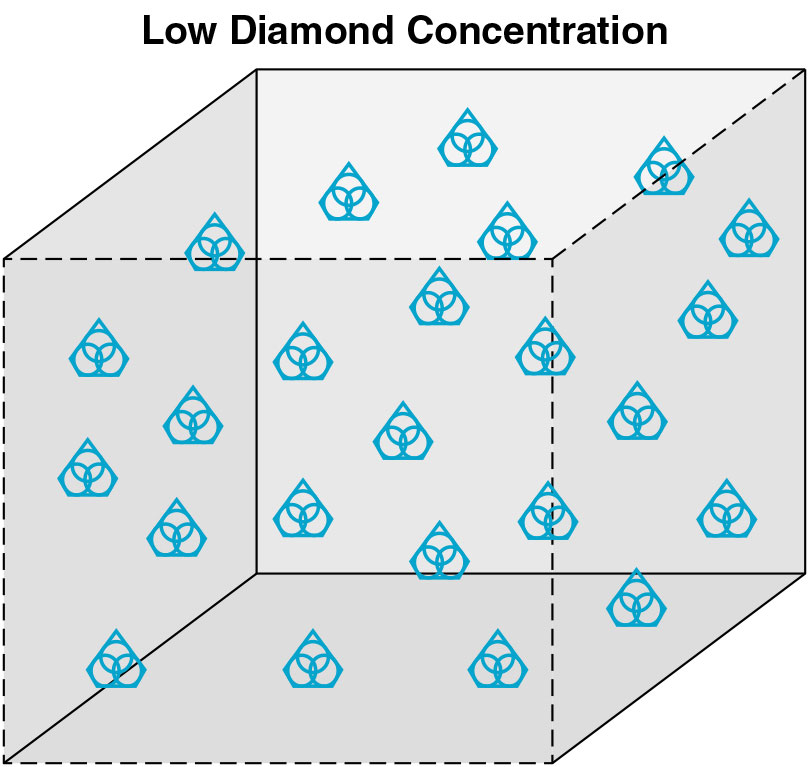

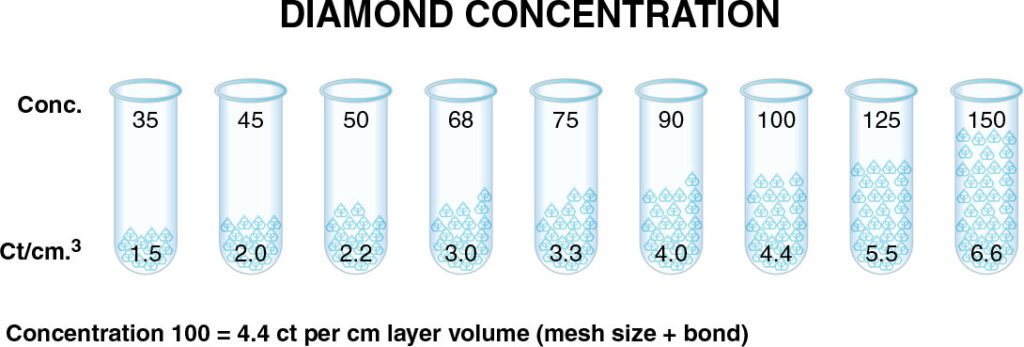

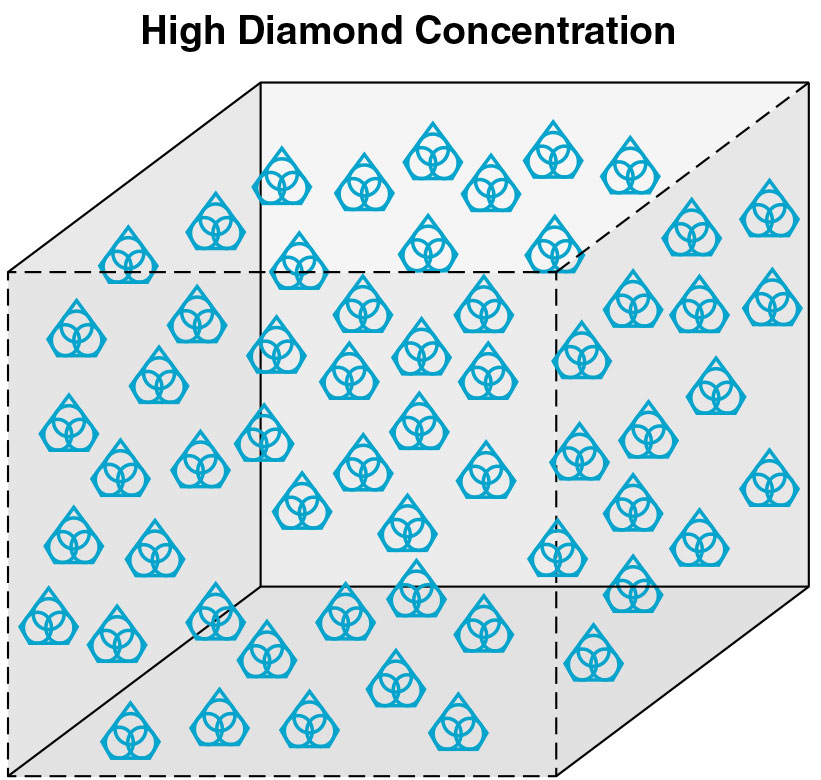

Understanding Concentration in CBN Wheels

Concentration refers to the amount of superabrasive CBN material contained in the rim of a grinding wheel. A 100-concentration wheel has 72 carats of superabrasive per cubic inch (72 carats/in³) or 4.4 carats per cubic centimeter (4.4 carats/cm³), representing 25% of the rim's volume. A 50-concentration wheel has half the superabrasive content of a 100-concentration wheel, or 12.5% by volume.

Concentration is a key factor that affects the performance of CBN (cubic boron nitride) wheels. Generally, higher concentrations lead to longer tool life, while lower concentrations may lead to reduced durability. Below are some guidelines for understanding the impact of abrasive concentration:

High Concentration

-

Increased Tool Life: More superabrasive content leads to longer-lasting wheels.

Increased Tool Life: More superabrasive content leads to longer-lasting wheels.

-

Less Force Per Abrasive Particle: Higher concentration spreads the grinding force across more particles.

Less Force Per Abrasive Particle: Higher concentration spreads the grinding force across more particles.

-

Improved Surface Finish: More abrasive particles result in smoother grinding.

Improved Surface Finish: More abrasive particles result in smoother grinding.

Low Concentration

-

Decreased Tool Life: Fewer abrasive particles lead to shorter-lasting wheels.

Decreased Tool Life: Fewer abrasive particles lead to shorter-lasting wheels.

-

More Force Per Abrasive Particle: Lower concentration focuses more force on each particle, causing them to wear out faster.

More Force Per Abrasive Particle: Lower concentration focuses more force on each particle, causing them to wear out faster.

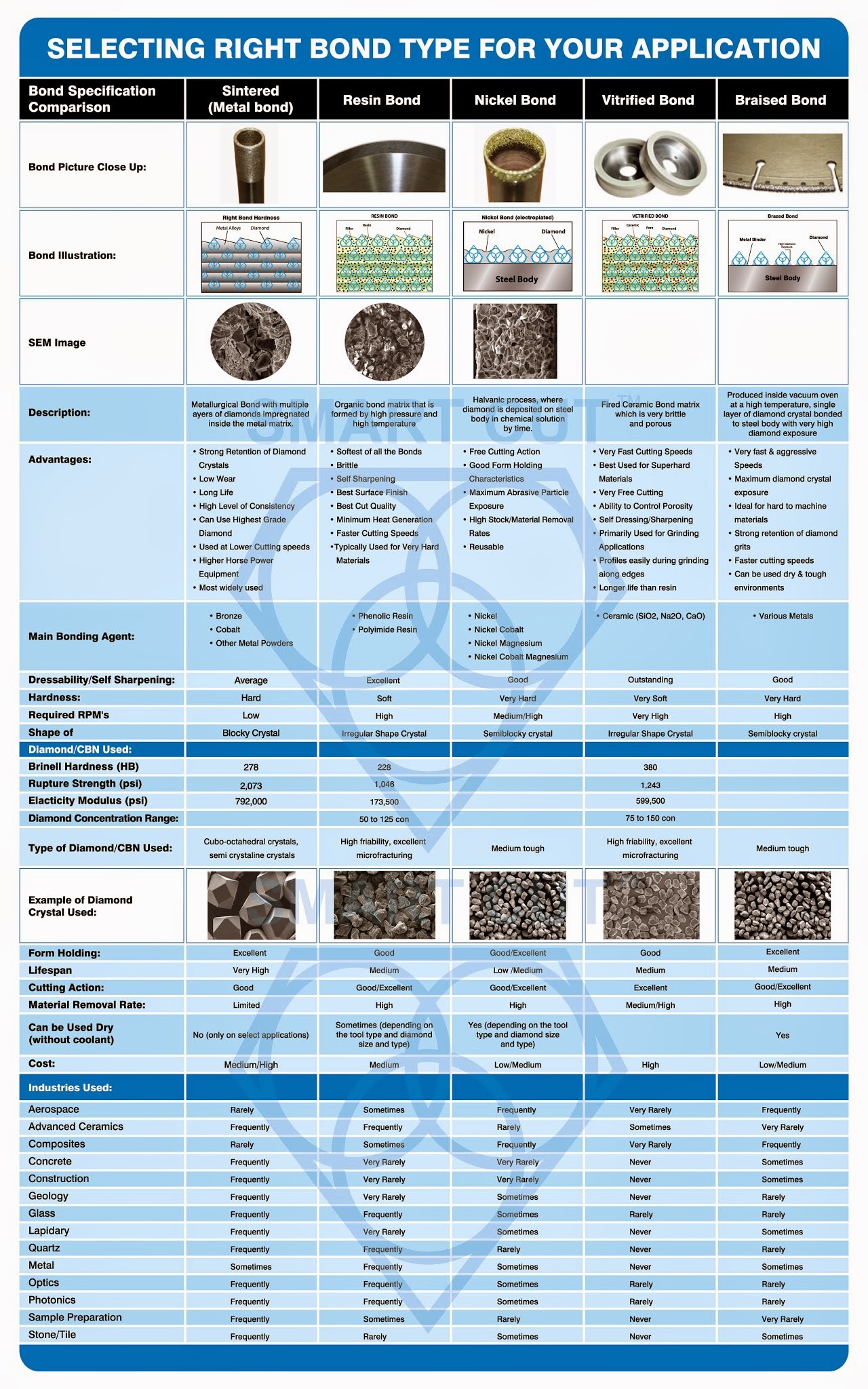

Bond Types in CBN Grinding Wheels

To effectively grind a wide range of materials, CBN grinding wheels use different bonding systems to hold the abrasive grains to the wheel's core. The four most common bonding systems used in CBN superabrasive grinding wheels are resinoid, vitreous, metal, and electroplated. Each bond type has specific manufacturing processes that impact the wheel's properties, affecting wheel truing and dressing procedures. These procedures are critical in determining the effectiveness of a wheel.

Resinoid Bonded Wheels

Resinoid-bonded wheels are a popular choice due to their flexibility and adaptability. These wheels use a resin-based bond to hold the abrasive grains in place. The properties of this bond type determine the wheel's behavior during grinding and its truing and dressing requirements.

What Are Resin-Bonded Wheels?

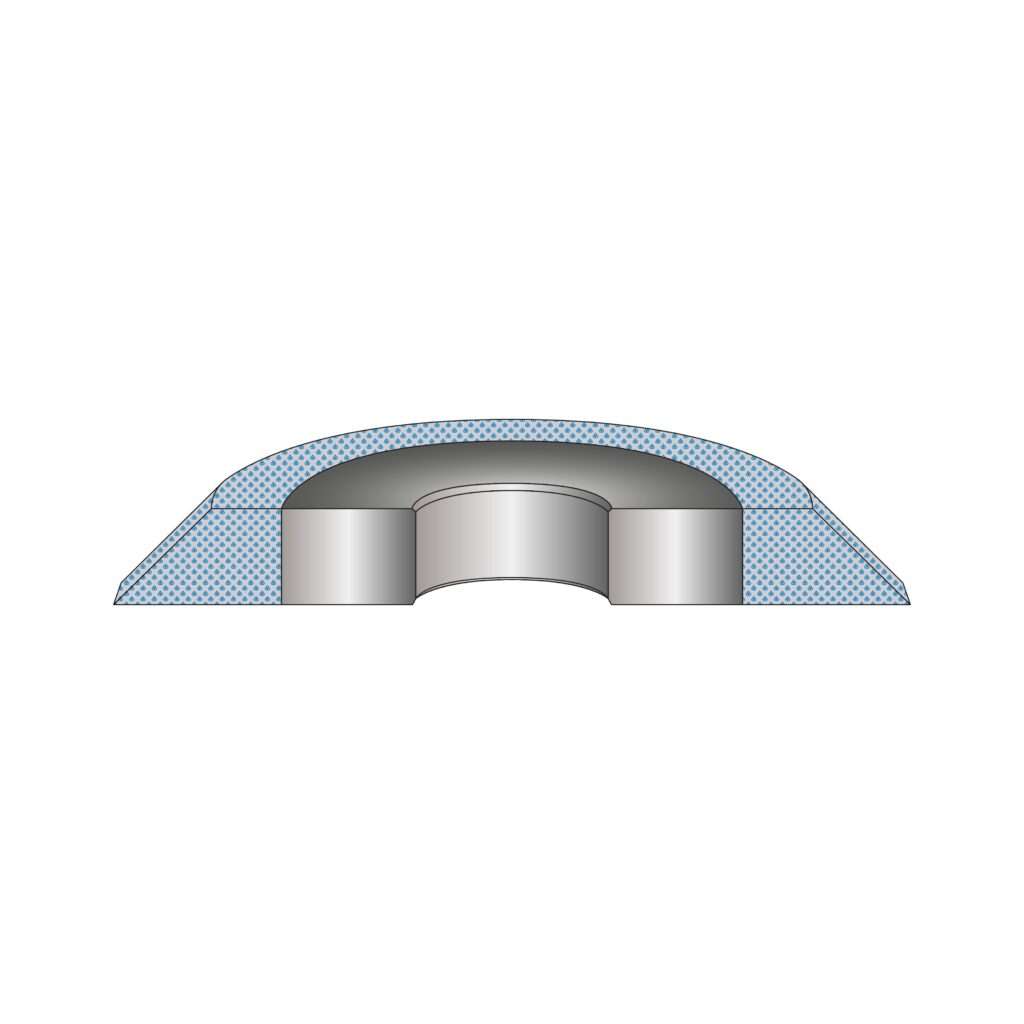

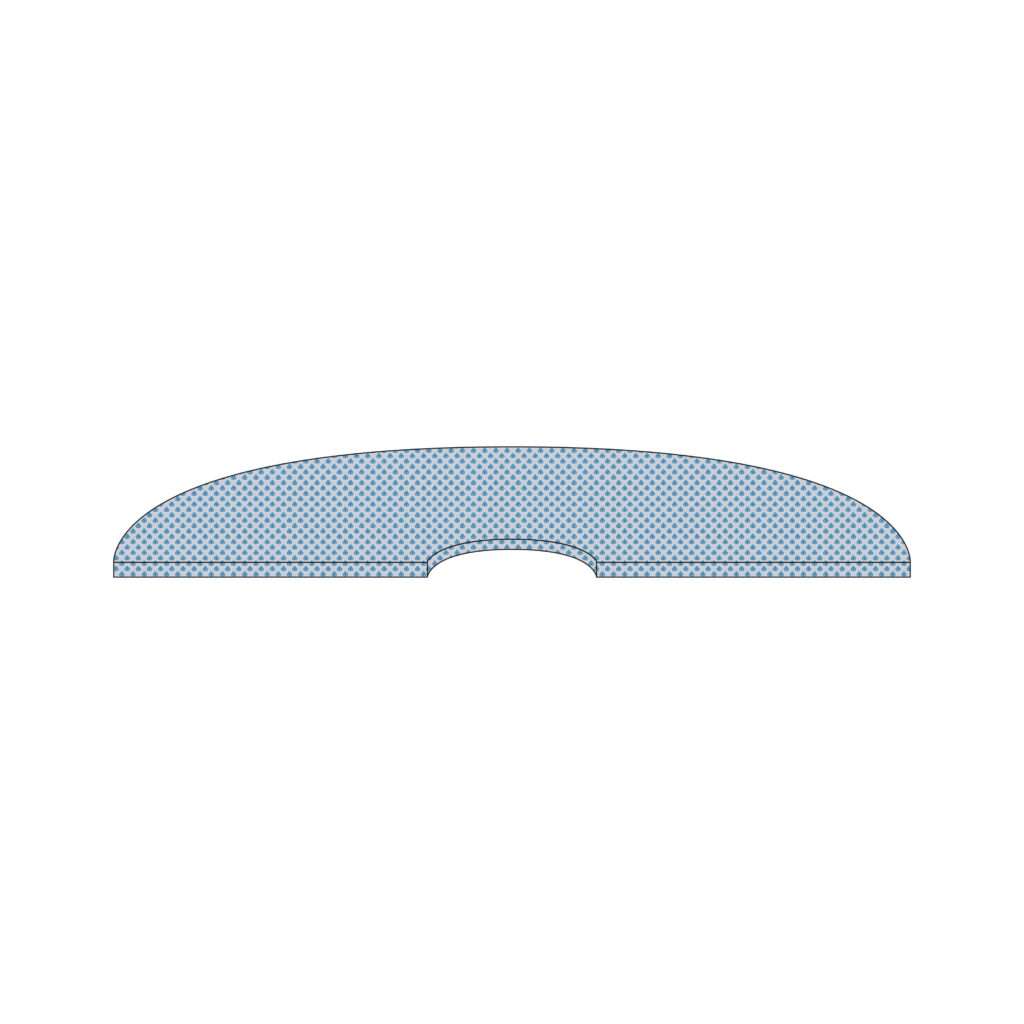

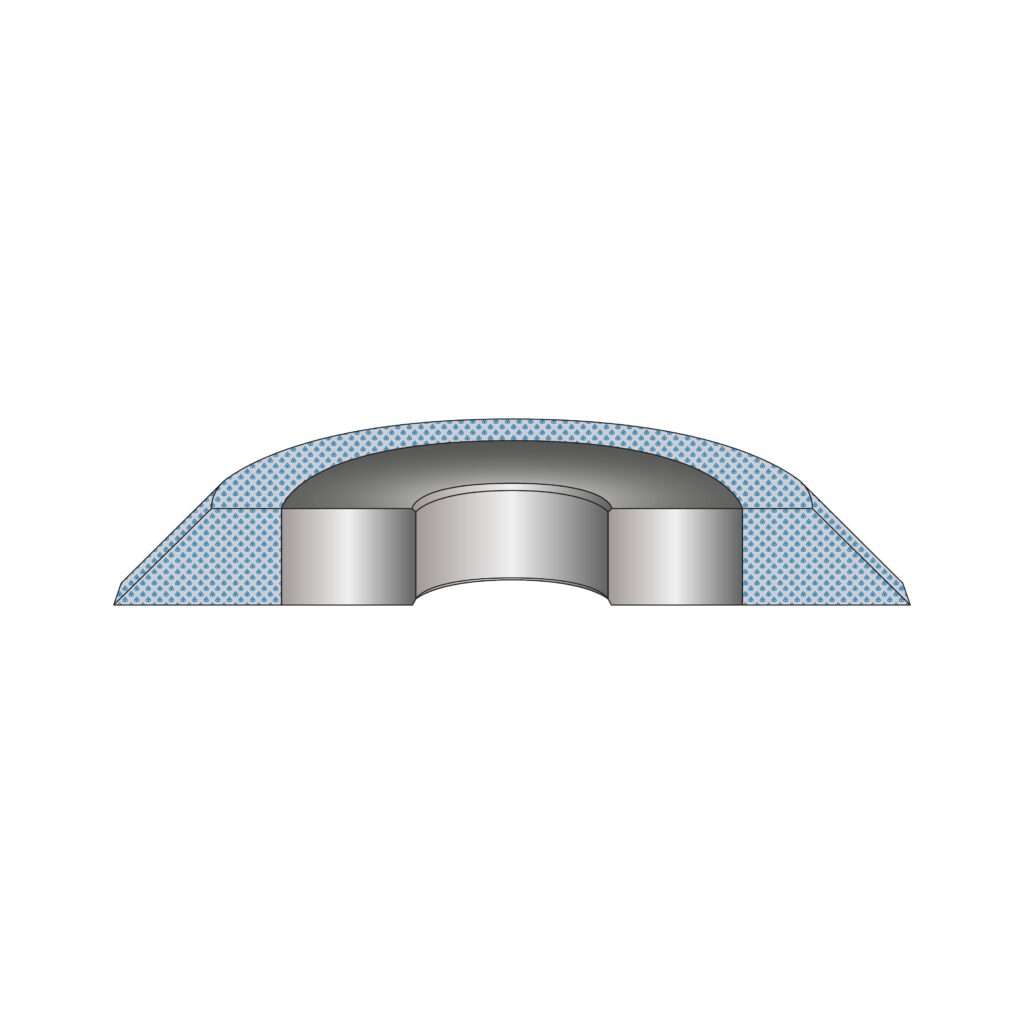

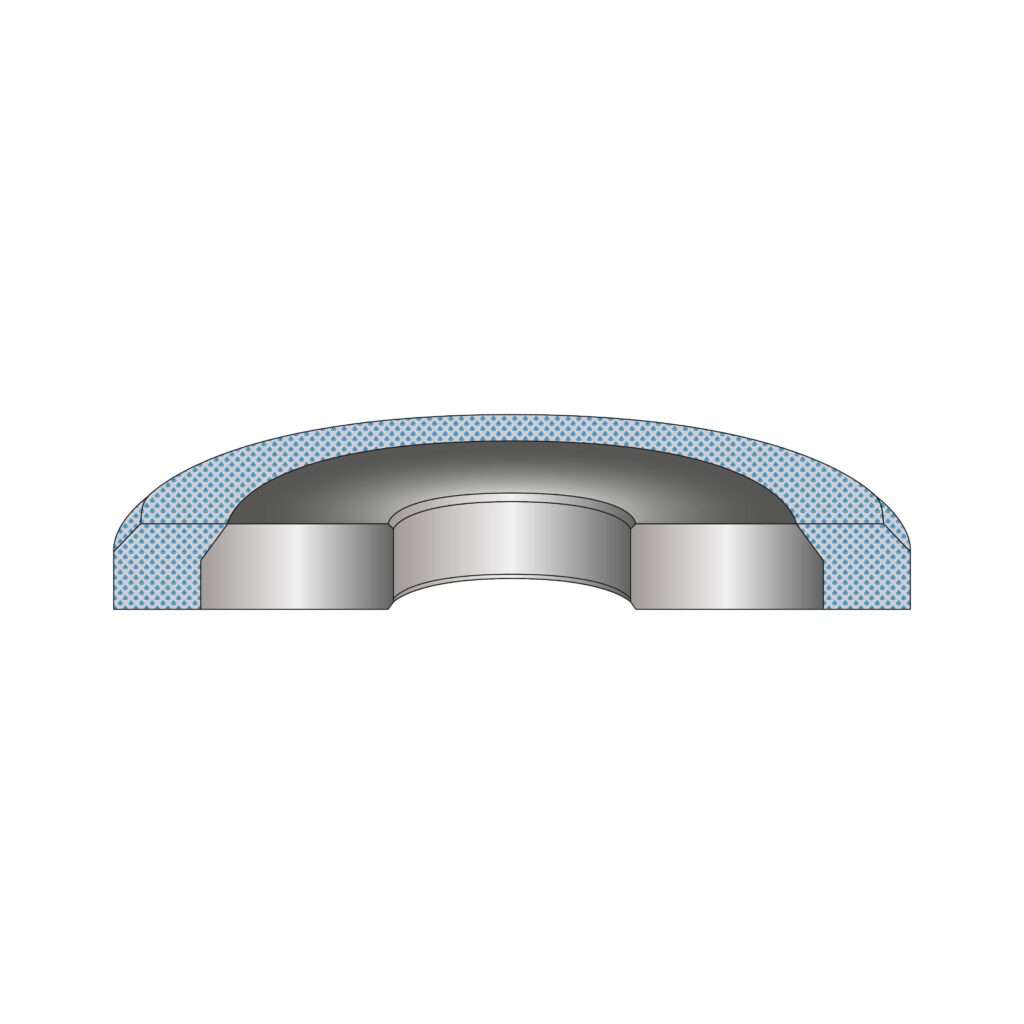

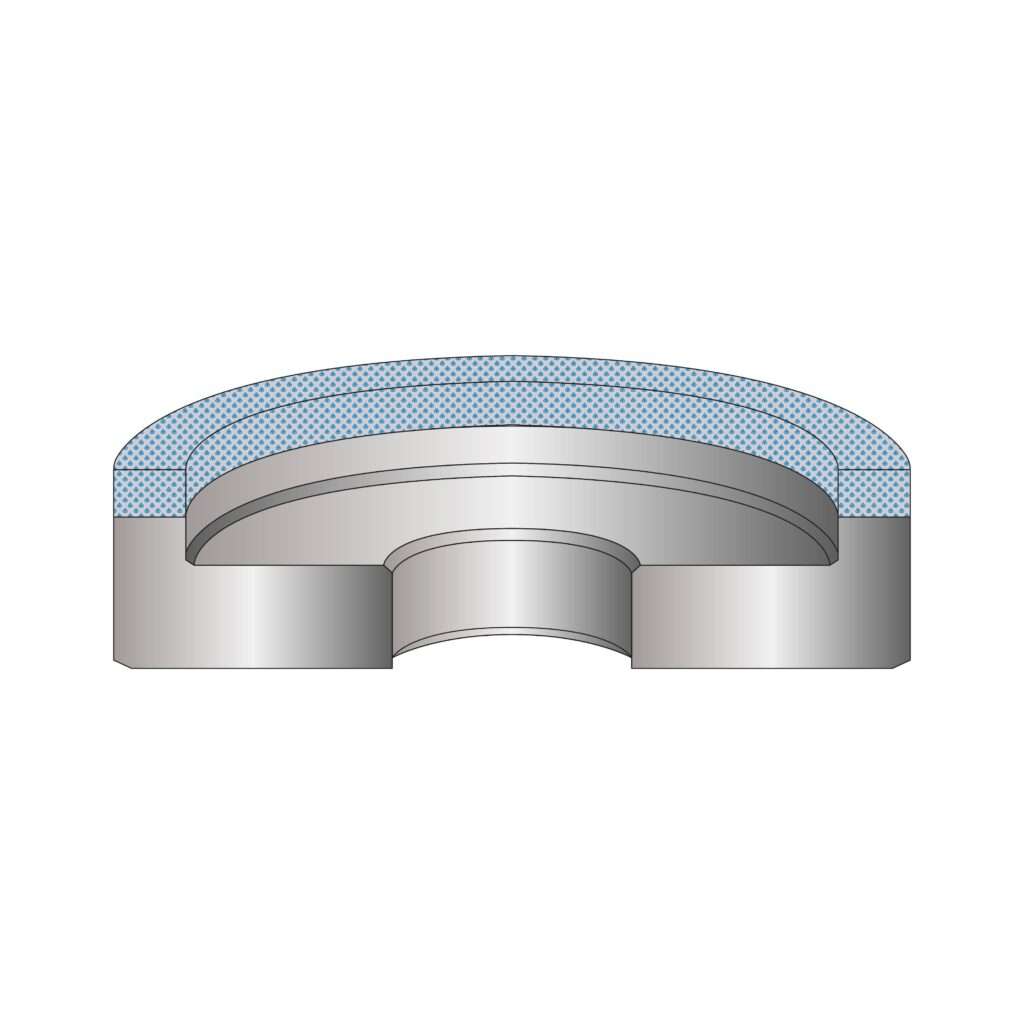

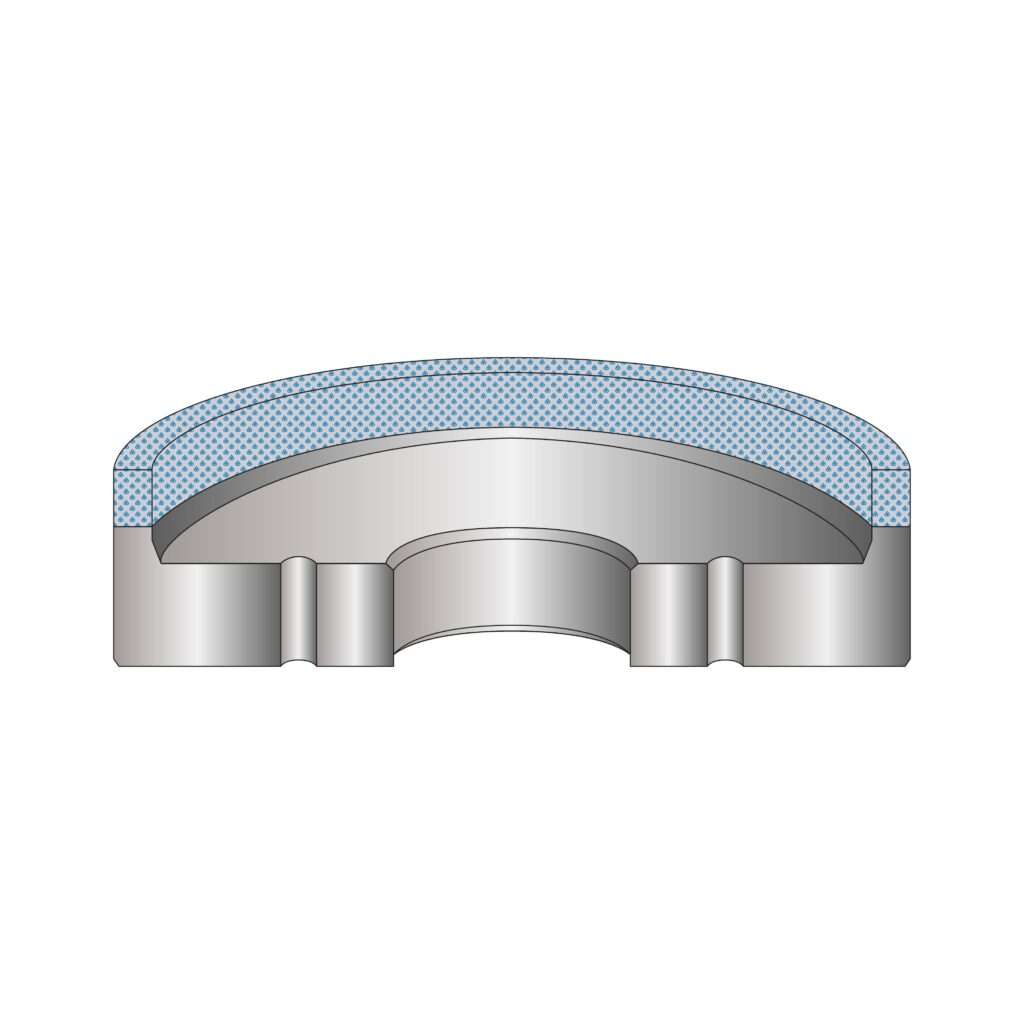

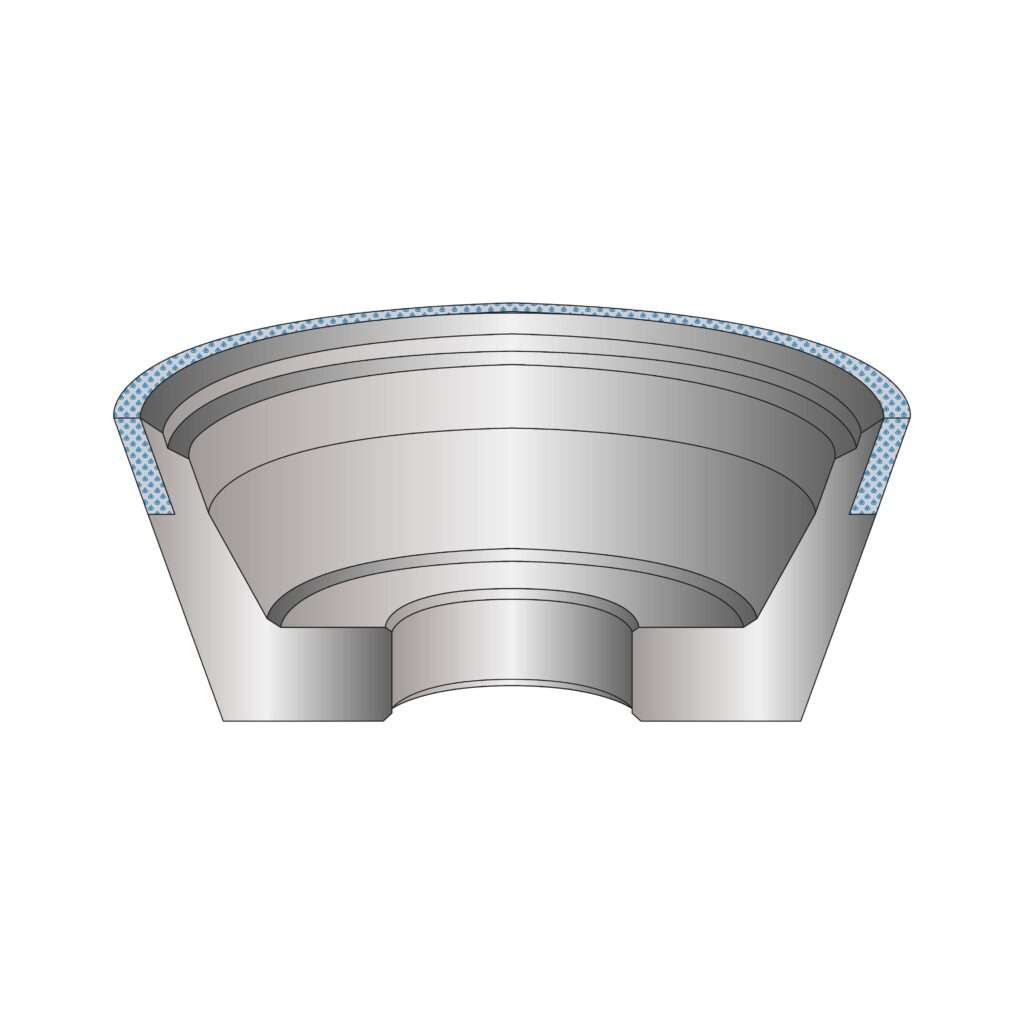

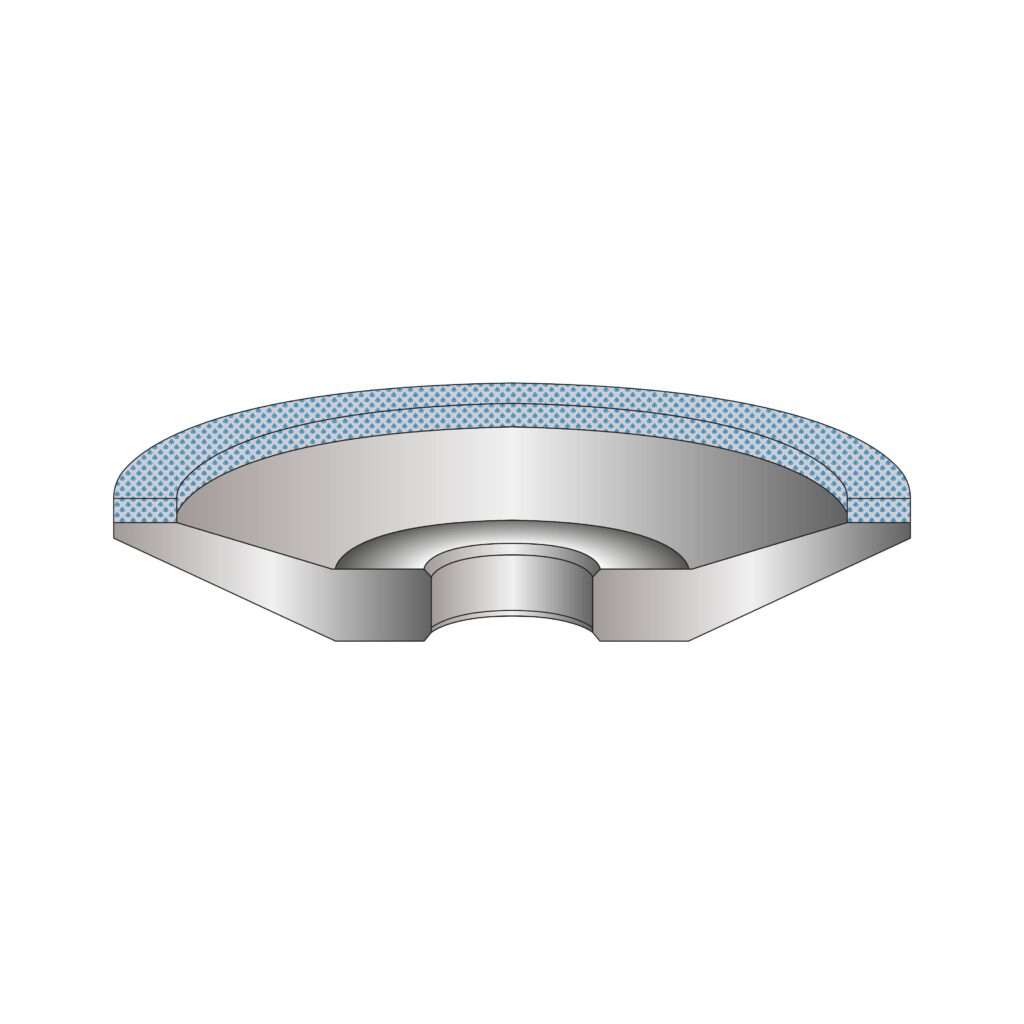

Resin-bonded wheels are created by mixing measured amounts of phenolic or polyimide resin with filling agents and metal-coated cubic boron nitride (CBN) abrasive. This mixture is then used to fill a mold cavity, forming the grinding rim section around the wheel core (Figure 4-4). Once the cavity is filled, the mixture is subjected to pressure and temperatures up to 750°F (399°C), which bonds the abrasive to the wheel core. After removal from the mold, a further temperature curing cycle polymerizes and strengthens the resin bond.

Variations in Resin-Bonded Wheels

Depending on the grinding application, a resin-bonded wheel may contain concentrations ranging from 50 to 125 of abrasive grains. Most resin-bonded CBN wheels have between 75 and 100 concentration of abrasive. Because the resin bond is relatively weak, it generally supports a maximum concentration of 100 to 125.

Characteristics of Resin-Bonded Wheels

Resin-bonded wheels are known for their free-cutting qualities. They can remove material quickly but have limited form-holding ability and shorter life spans compared to other bond types. Resin-bonded CBN wheels are commonly used in toolrooms and production applications for grinding tool steels, other hardened steels, and superalloys.

Key Features of Resin-Bonded CBN Wheels

-

Versatility: Can be effectively used in a wide range of applications.

Versatility: Can be effectively used in a wide range of applications.

-

Variety: Available in many shapes and sizes.

Variety: Available in many shapes and sizes.

-

Mechanical Bonding: Offers a fair degree of mechanical bonding.

Mechanical Bonding: Offers a fair degree of mechanical bonding.

-

Abrasion Resistance: Provides reasonable abrasion resistance.

Abrasion Resistance: Provides reasonable abrasion resistance.

-

Compatibility: Can be designed for both wet and dry grinding.

Compatibility: Can be designed for both wet and dry grinding.

-

Free-Cutting: Known for good free-cutting qualities, allowing for faster material removal.

Free-Cutting: Known for good free-cutting qualities, allowing for faster material removal.

Understanding these key features helps explain why resin-bonded CBN wheels are a popular choice for various grinding applications, especially where fast material removal is required. Despite their limited form-holding capabilities, these wheels are adaptable and versatile, offering a range of options to suit different grinding needs.

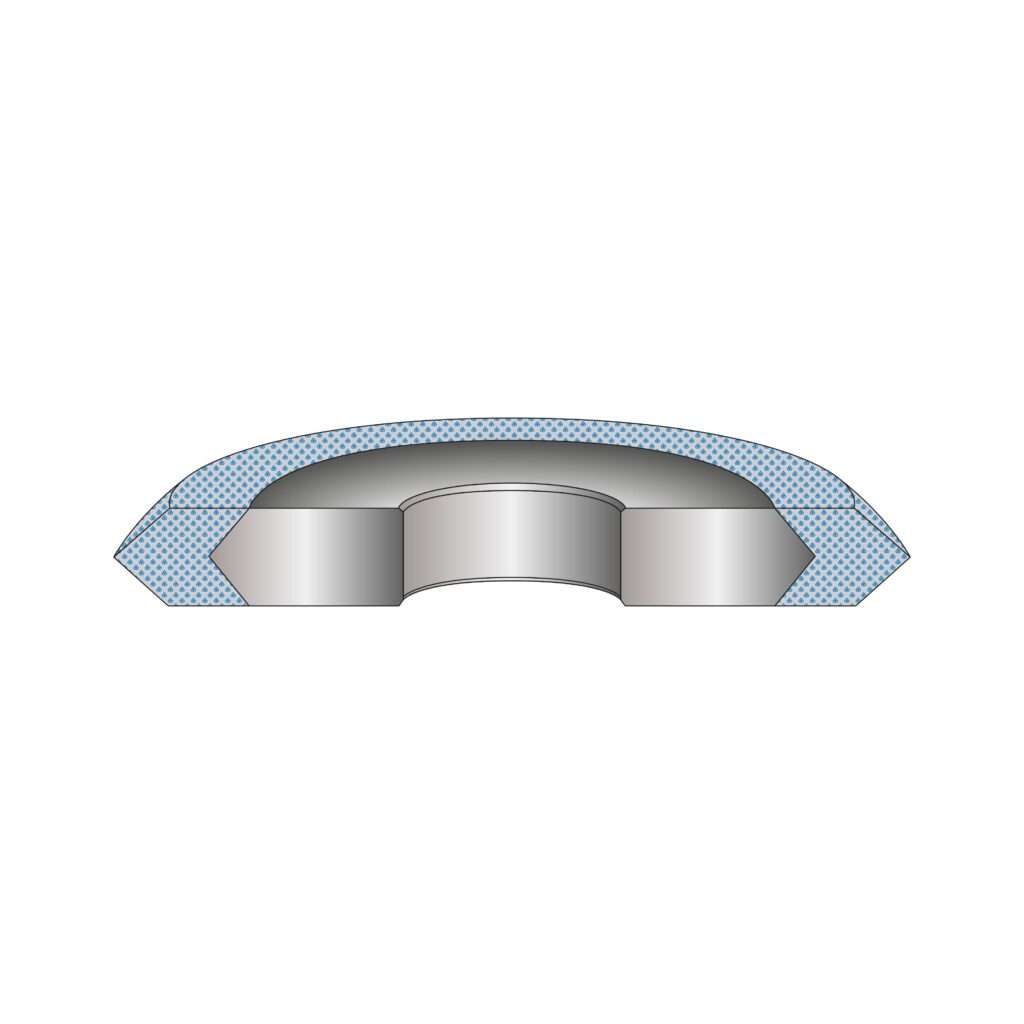

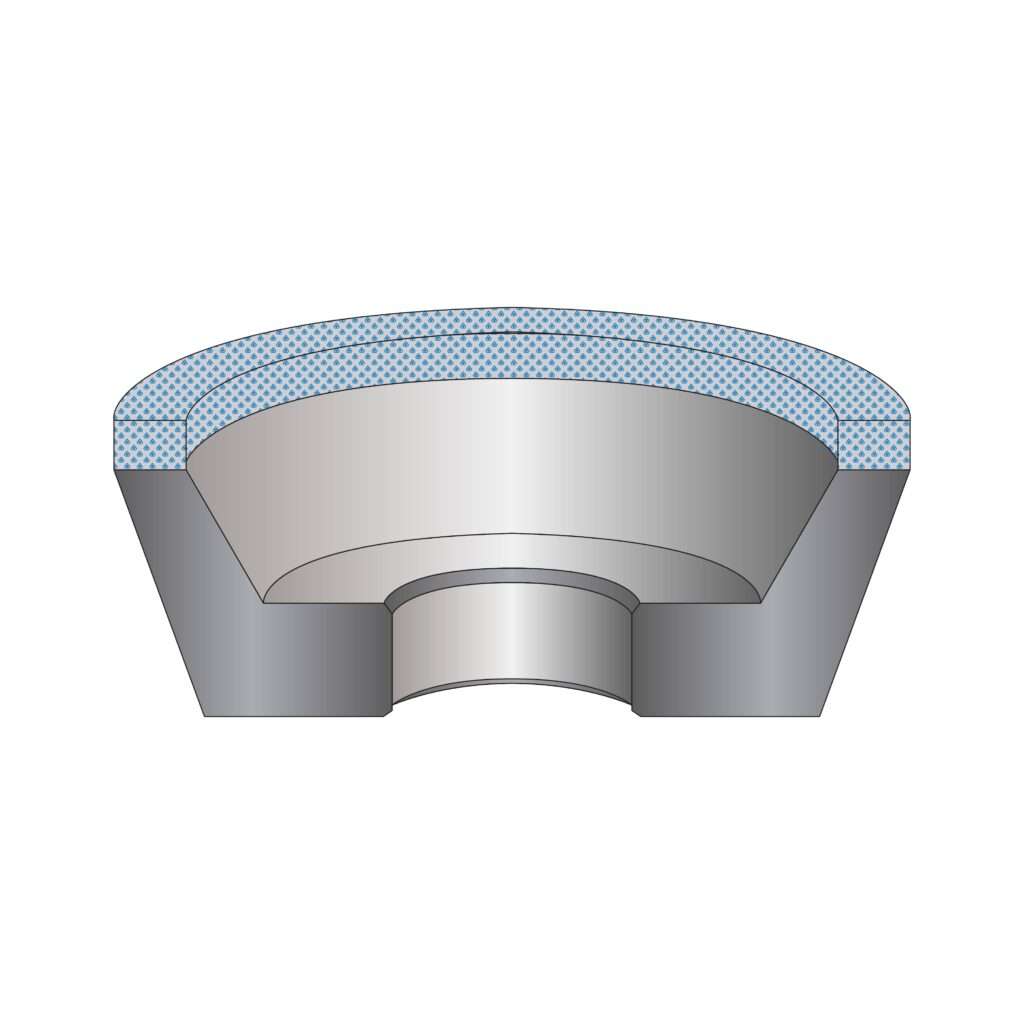

Understanding Vitreous-Bonded CBN Wheels

Vitreous-bonded CBN (cubic boron nitride) wheels offer greater bonding strength than resin-bonded wheels. This increased strength allows manufacturers to adjust the porosity and structure of the wheel, giving them more control over the basic strength and chip clearance.

Vitreous bonds are versatile enough to accommodate wheels with varying concentrations of CBN abrasive, ranging from 50 to 200 concentration (12.5 to 50% by volume). This flexibility provides manufacturers with a wide range of options when designing wheels for different applications.

One advantage of vitreous-bonded wheels is the ability to condition the surface to meet specific requirements. This adaptability allows for more precise control over the wheel's performance, making it suitable for a broader range of grinding tasks.

Overall, vitreous-bonded CBN wheels offer a balance of strength and flexibility, providing a more robust bonding system compared to resin bonds. The ability to vary concentration and customize the wheel's structure makes these wheels suitable for a variety of grinding operations, from light to heavy-duty applications.

The Versatility of Vitreous-Bonded CBN Wheels

Vitreous-bonded CBN (cubic boron nitride) wheels are gaining popularity in production grinding applications due to their ability to achieve a wide range of metal removal rates (MRR) and surface finishes. This versatility makes them suitable for various industrial applications.

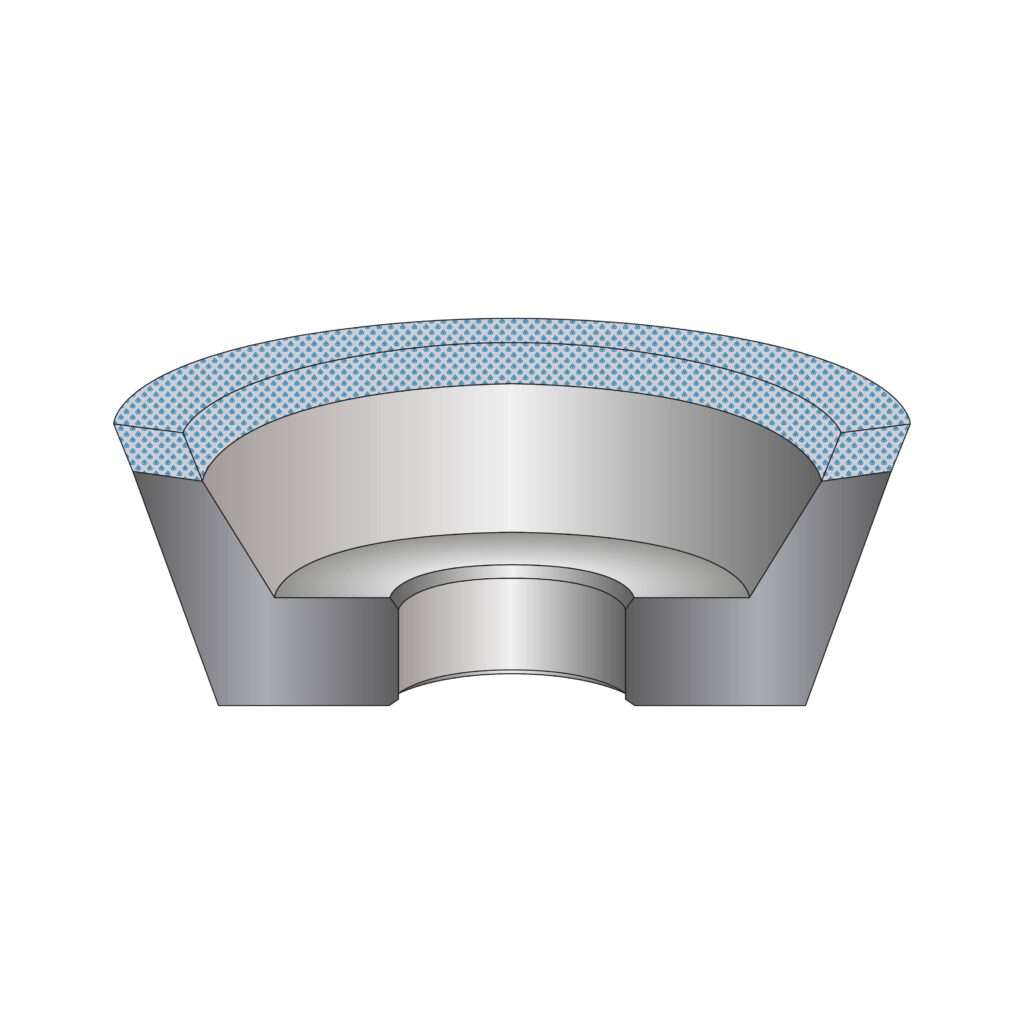

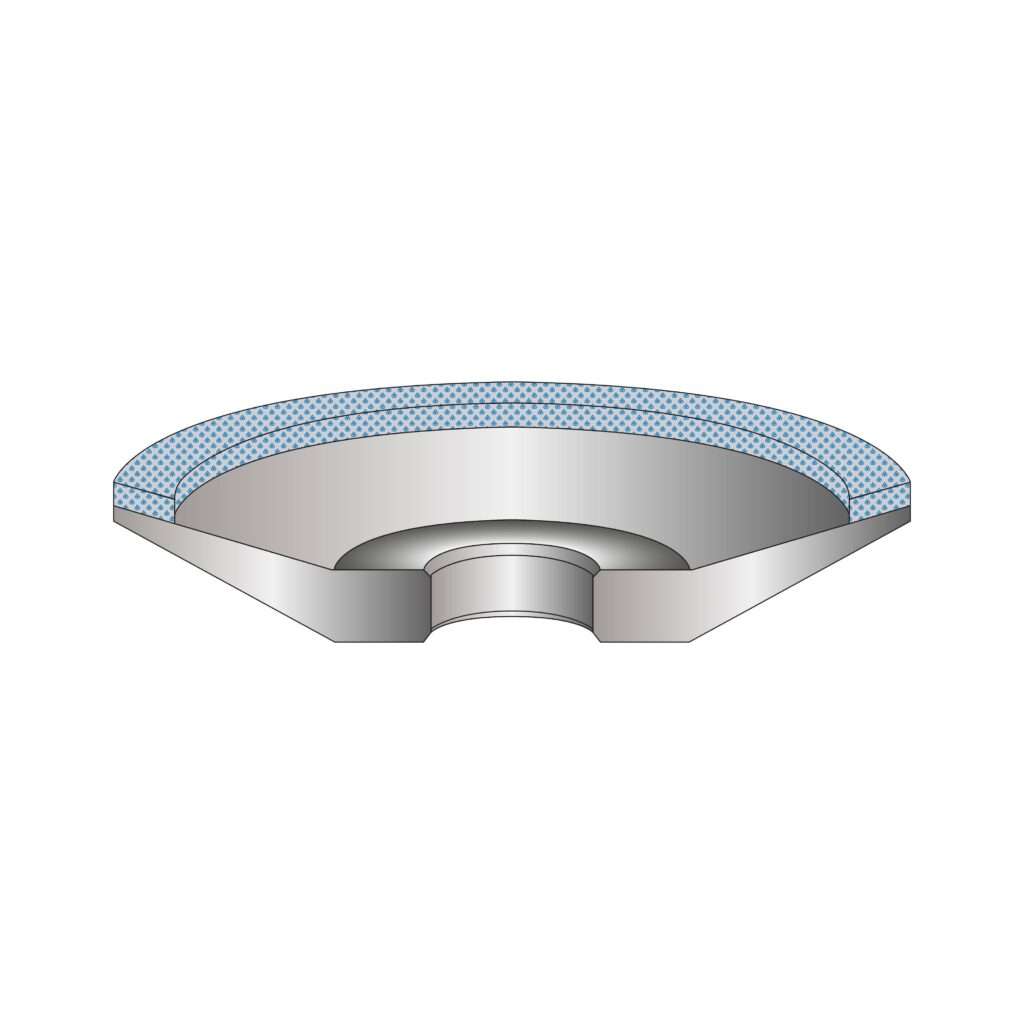

The Manufacturing Process of Vitreous-Bonded Wheels

Manufacturing vitrified-bond wheels involves several critical steps:

1. Mixing the Frit with CBN Abrasive:

-

The proper amount of powdered vitreous material, known as frit, is mixed with the desired type, weight, and grain size of CBN abrasive.

The proper amount of powdered vitreous material, known as frit, is mixed with the desired type, weight, and grain size of CBN abrasive.

2. Filling the Mold

-

This mixture is carefully placed into a mold cavity surrounding a wheel core made of ceramic material, capable of withstanding temperatures as high as 1,832°F (1,000°C).

This mixture is carefully placed into a mold cavity surrounding a wheel core made of ceramic material, capable of withstanding temperatures as high as 1,832°F (1,000°C).

3. Creating the "Green Wheel":

-

The newly formed "green wheel" is carefully removed from the mold and placed in a furnace with precisely controlled temperature and atmosphere conditions.

The newly formed "green wheel" is carefully removed from the mold and placed in a furnace with precisely controlled temperature and atmosphere conditions.

4. Bond Formation:

-

During the furnacing cycle, a chemical reaction occurs that causes the bonding material to form a hard, vitreous bond, securing the CBN abrasive to the wheel core.

During the furnacing cycle, a chemical reaction occurs that causes the bonding material to form a hard, vitreous bond, securing the CBN abrasive to the wheel core.

5. Making Larger Wheels

-

Large vitrified wheels may consist of smaller individual radial segments, carefully fitted and cemented to the periphery of the wheel core.

Large vitrified wheels may consist of smaller individual radial segments, carefully fitted and cemented to the periphery of the wheel core.

Advantages of Vitreous-Bonded Wheels

Vitreous-bonded wheels are known for their free-cutting capabilities, good surface finishes, wear resistance, and ability to retain straightness and form. The porosity or open structure can be adjusted to provide chip clearance, allow coolant in, and prevent wheel loading.

These wheels can also be crush-formed and rotary diamond dresser-formed, making them suitable for creep-feed grinding of hardened steel.

Key Characteristics of Vitreous-Bonded Superabrasive Wheels

-

Free-Cutting: They cut smoothly, reducing the risk of wheel glazing.

Free-Cutting: They cut smoothly, reducing the risk of wheel glazing.

-

Good Surface Finishes: These wheels deliver consistent, high-quality finishes.

Good Surface Finishes: These wheels deliver consistent, high-quality finishes.

-

Wear Resistance: The bond's durability helps extend wheel life.

Wear Resistance: The bond's durability helps extend wheel life.

-

Retain Straightness and Form: Vitreous-bonded wheels maintain their shape well during grinding.

Retain Straightness and Form: Vitreous-bonded wheels maintain their shape well during grinding.

-

Porosity Control: The open structure helps with chip clearance and coolant flow, preventing wheel loading.

Porosity Control: The open structure helps with chip clearance and coolant flow, preventing wheel loading.

These characteristics make vitreous-bonded CBN wheels an attractive choice for a wide range of grinding applications, offering a good balance of performance, durability, and flexibility.

Key Features of Vitreous-Bonded CBN Wheels

Vitreous-bonded CBN (cubic boron nitride) wheels have several characteristics that make them appealing for grinding operations:

-

Abrasion Resistance: They offer strong resistance to wear.

Abrasion Resistance: They offer strong resistance to wear.

-

Form-Holding Capabilities: Vitreous-bonded wheels maintain their shape well.

Form-Holding Capabilities: Vitreous-bonded wheels maintain their shape well.

-

Long Life: Their durability contributes to extended wheel life.

Long Life: Their durability contributes to extended wheel life.

-

Easier to True and Dress: Compared to other systems, they're generally simpler to maintain.

Easier to True and Dress: Compared to other systems, they're generally simpler to maintain.

-

Versatility in Surface Finishes: They can generate a wide range of finishes.

Versatility in Surface Finishes: They can generate a wide range of finishes.

-

High Concentrations: Concentrations of 150 to 200 produce the best surface finishes.

High Concentrations: Concentrations of 150 to 200 produce the best surface finishes.

-

Least Resistance to Damage: Vitreous-bonded wheels are less prone to damage from mishandling or setup issues.

Least Resistance to Damage: Vitreous-bonded wheels are less prone to damage from mishandling or setup issues.

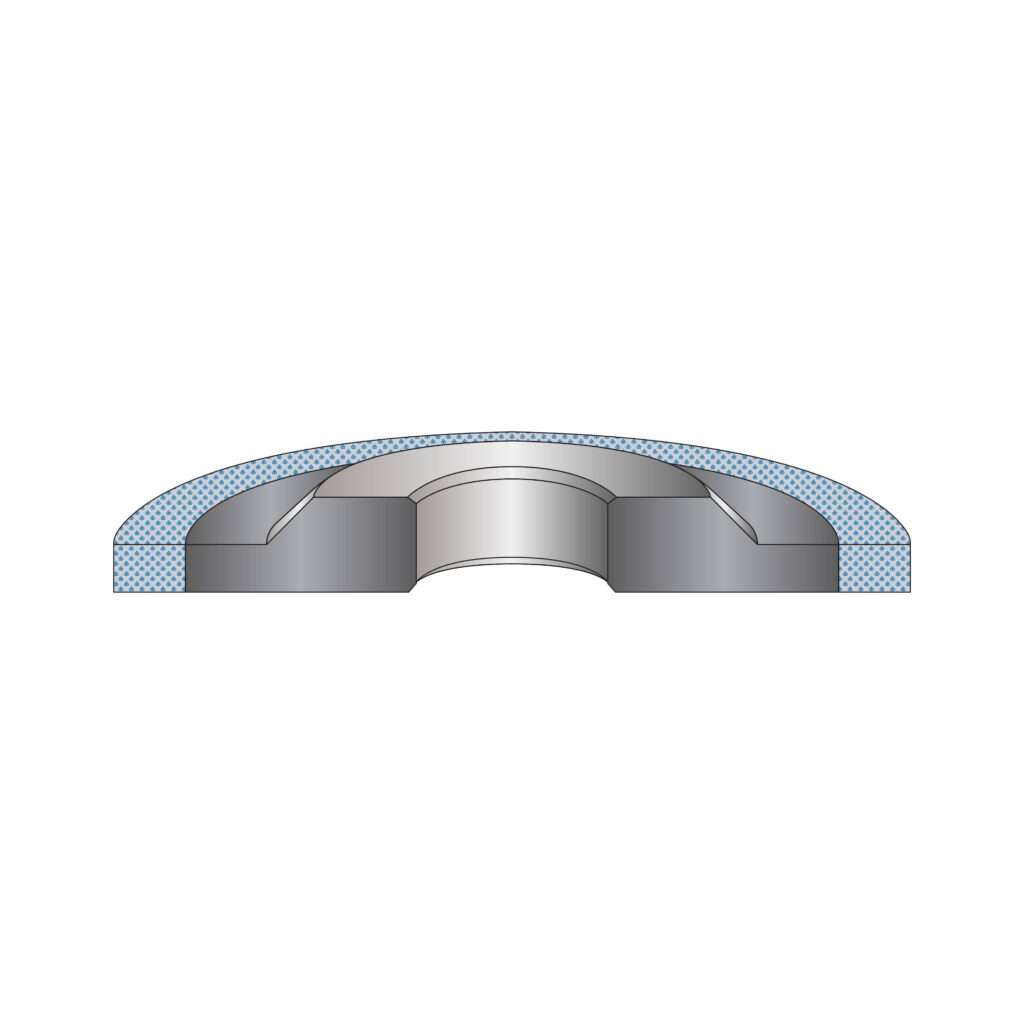

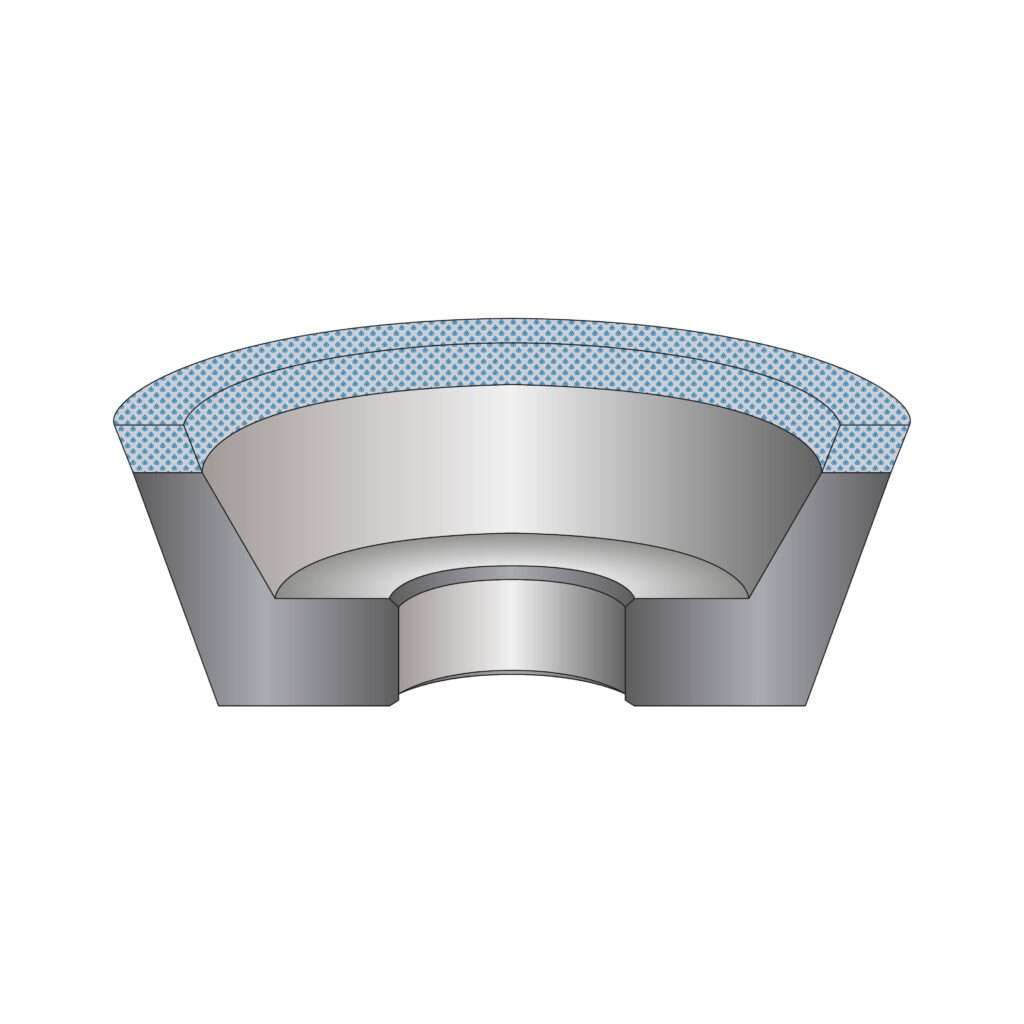

Metal-Bonded Wheels: Manufacturing Process and Benefits

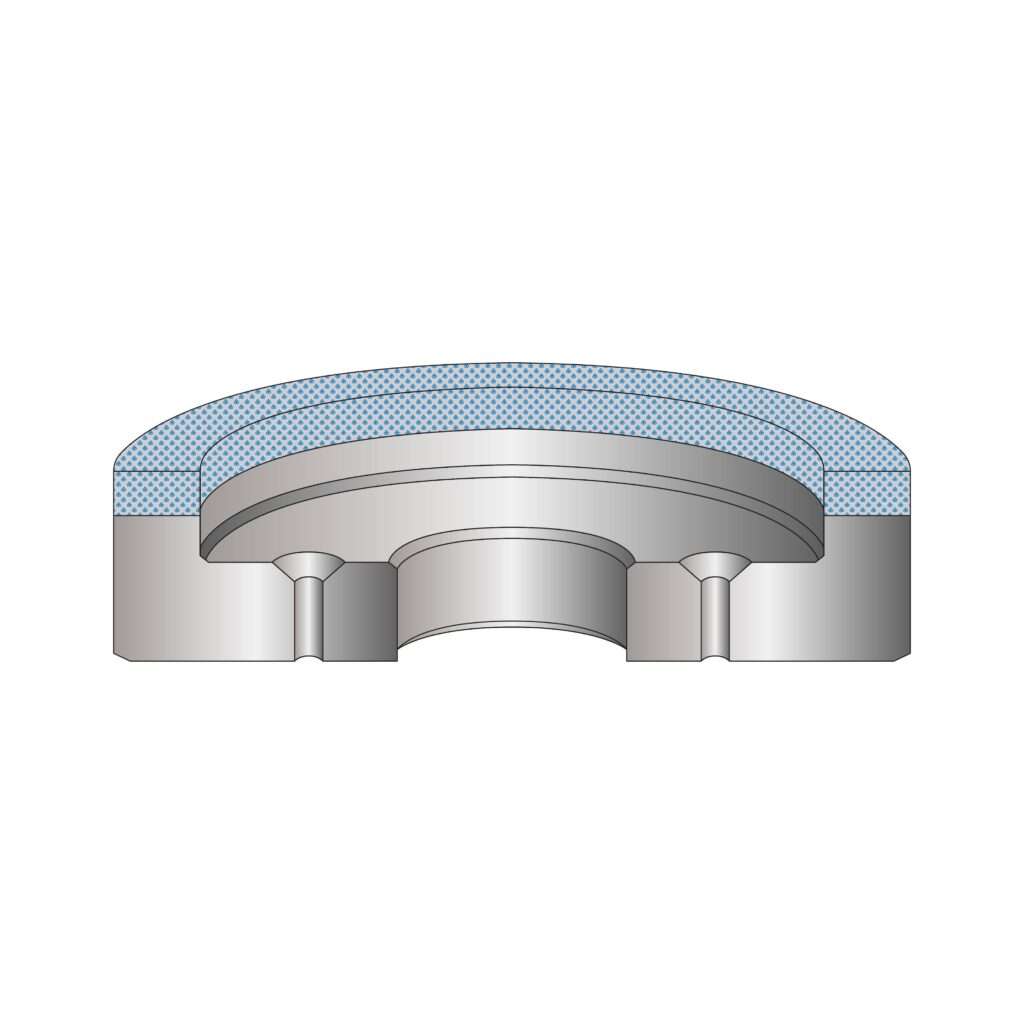

Metal-bonded CBN wheels make up a smaller percentage of CBN wheels used today, but they offer distinct advantages:

1. Mixing Metals and CBN Abrasive:

-

A measured amount of powdered metals, typically bronze or a derivative, is mixed with the appropriate type, weight, and size of CBN abrasive.

A measured amount of powdered metals, typically bronze or a derivative, is mixed with the appropriate type, weight, and size of CBN abrasive.

2. Placement in the Mold

-

This mixture is carefully placed into a mold cavity surrounding the high-temperature wheel core.

This mixture is carefully placed into a mold cavity surrounding the high-temperature wheel core.

3. Controlled Furnace Process

-

The entire assembly is placed in a precise temperature- and atmosphere-controlled furnace. During the cycle, the powdered metal partially melts and fuses to form a high-strength bond, securing the CBN abrasive.

The entire assembly is placed in a precise temperature- and atmosphere-controlled furnace. During the cycle, the powdered metal partially melts and fuses to form a high-strength bond, securing the CBN abrasive.

Metal-bonded wheels are commonly used for internal, form, and creep-feed grinding applications due to their toughness and heat resistance.

Find out more about sintered (metal bond) diamond & cbn wheels >>>

Characteristics of Metal-Bonded Grinding Wheels

-

Tough Bond: Metal is a tough bonding material, offering high abrasion and heat resistance.

Tough Bond: Metal is a tough bonding material, offering high abrasion and heat resistance.

-

Excellent for Interrupted Grinding: They perform well in operations with inconsistent grinding patterns.

Excellent for Interrupted Grinding: They perform well in operations with inconsistent grinding patterns.

-

Long Tool Life: These wheels last longer due to their robust structure.

Long Tool Life: These wheels last longer due to their robust structure.

-

Higher Power Requirement: They typically need more power to operate.

Higher Power Requirement: They typically need more power to operate.

-

Excellent Form-Holding Capabilities: Metal-bonded wheels maintain their shape during use.

Excellent Form-Holding Capabilities: Metal-bonded wheels maintain their shape during use.

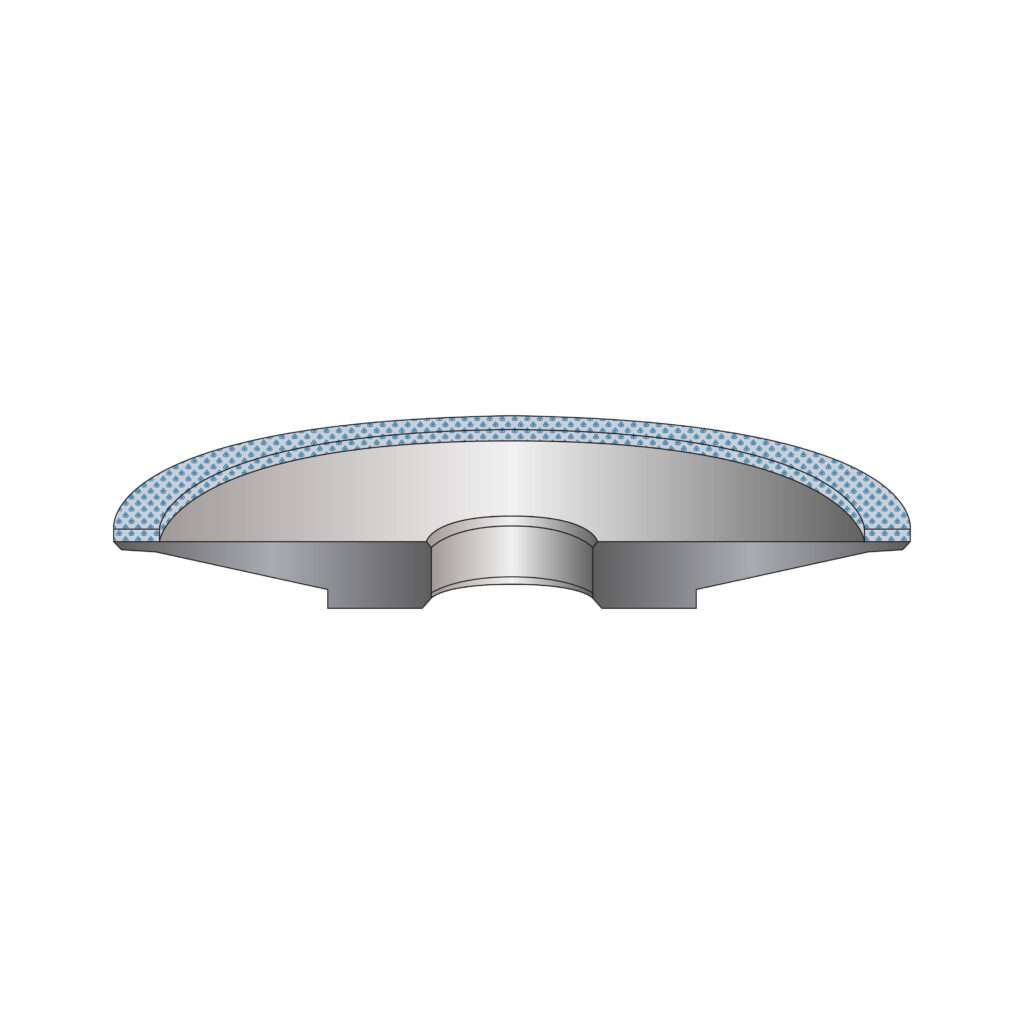

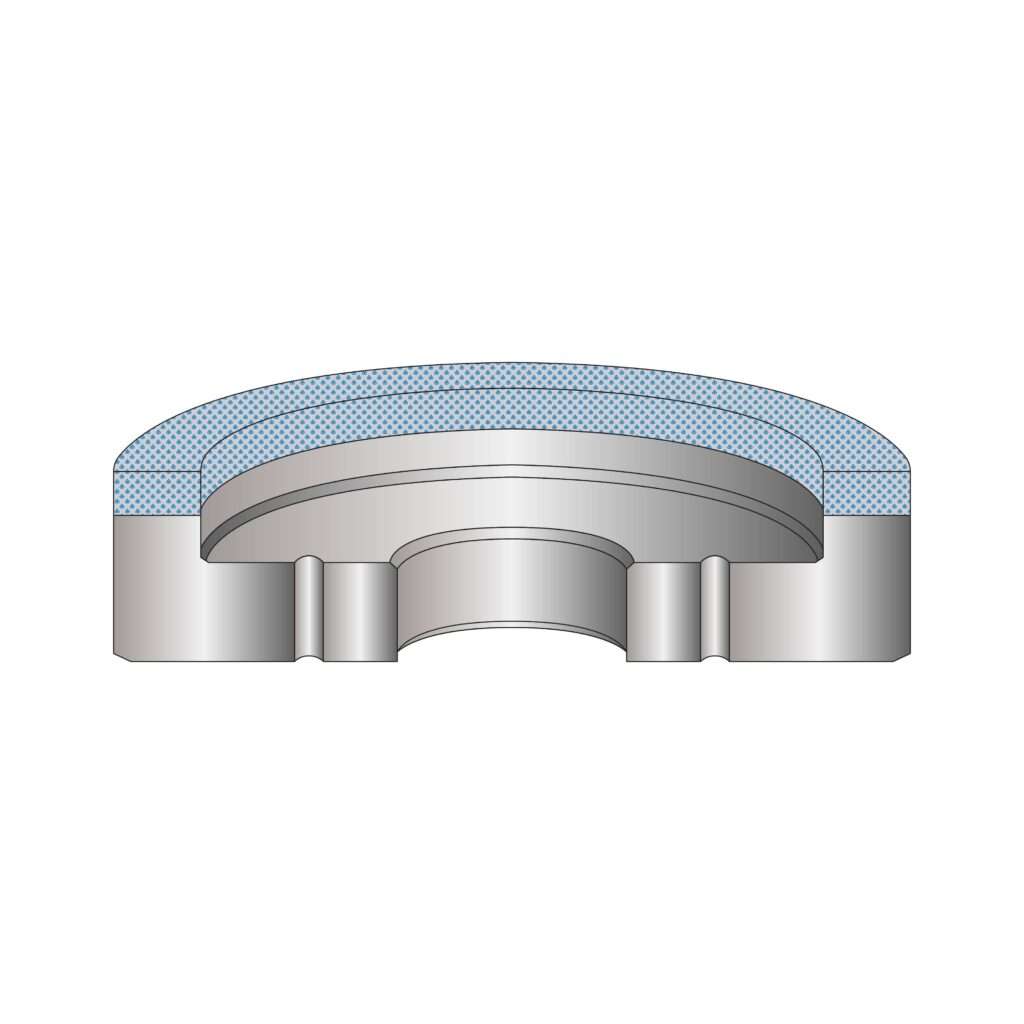

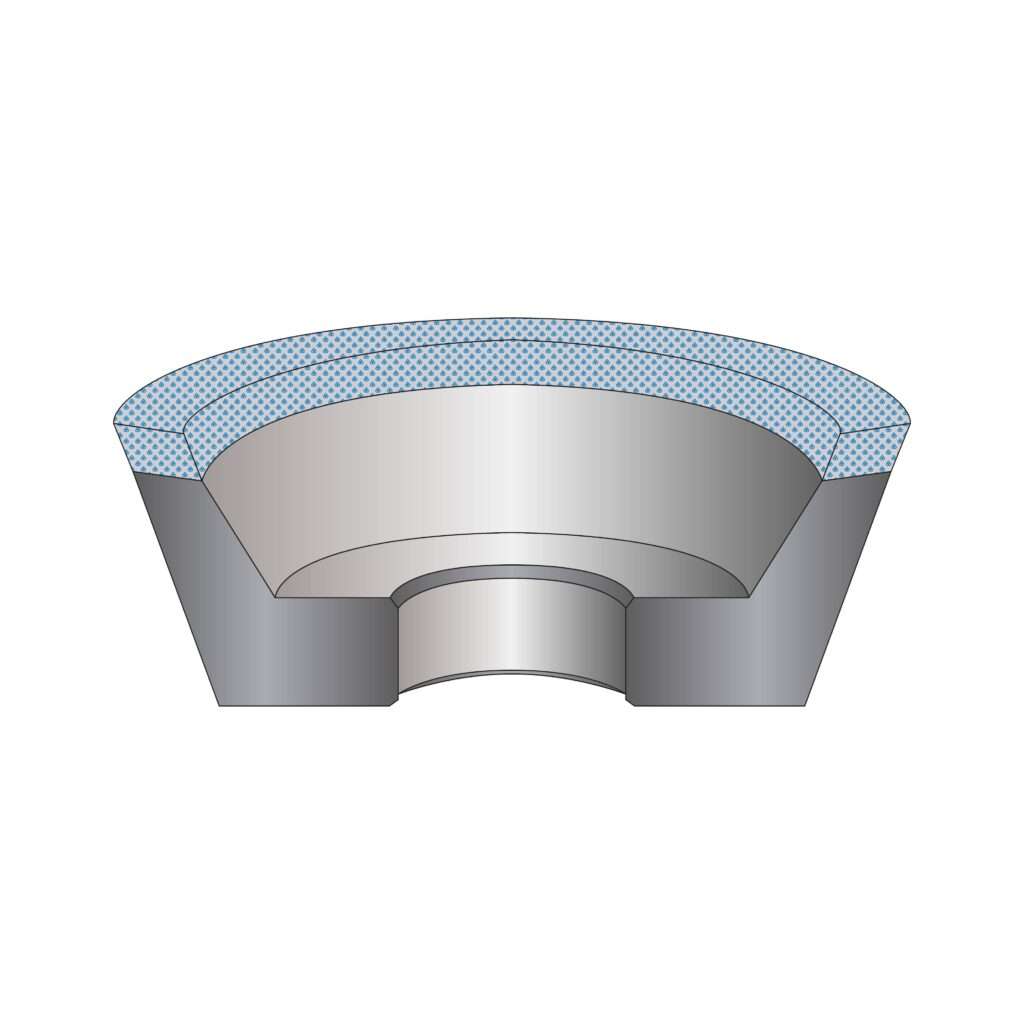

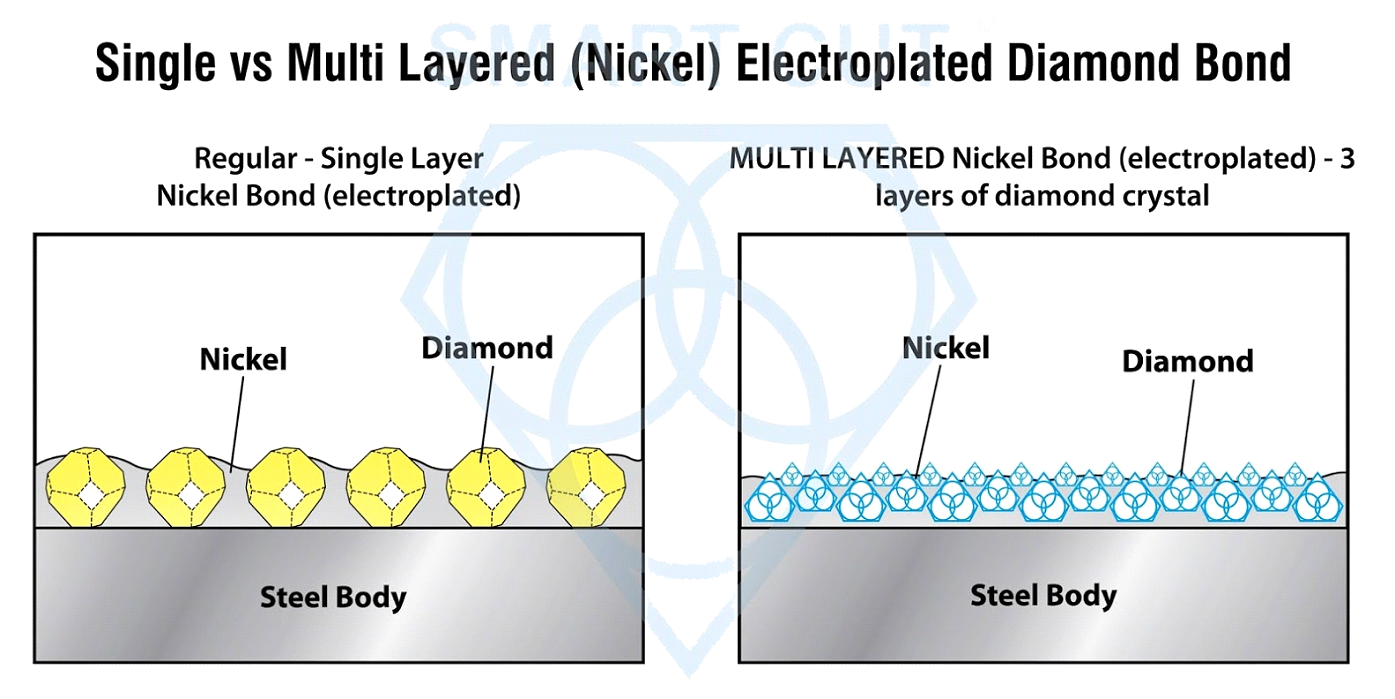

Electroplated CBN Wheels: Composition and Applications

Electroplated wheels have a single layer of CBN abrasive particles bonded to the wheel surface in a nickel electroplating bath. Nickel is chosen for its excellent bonding strength and ease of plating. Electroplated wheels are ideal for high stock-removal rates and are particularly useful for grinding deep forms like gear teeth, splines, and deep grooves.

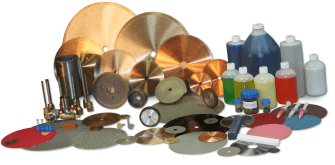

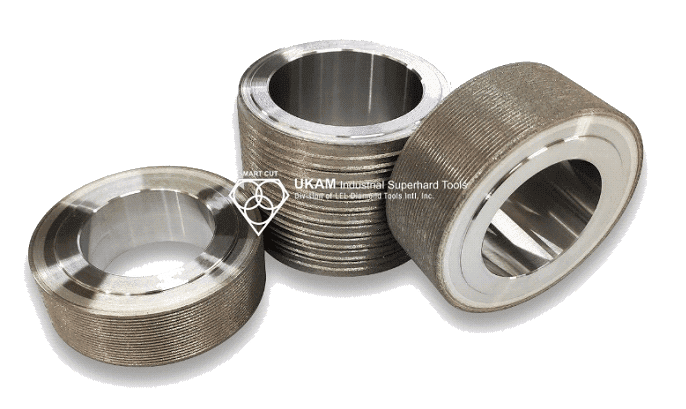

DIAMOND & CBN WHEELS

ELECTROPLATED (NICKEL BOND)

SMART CUT® Electroplated (Nickel Bond) Bond Diamond & CBN Wheels Our top-of-the-line diamond & CBN whels are meticulously crafted with the finest diamonds, ranging from 0.5 microns to 20 grit diamond mesh size, available in Synthetic, Natural Diamond, or CBN (cubic boron nitride) to suit a diverse array of applications, materials, and industries.

They have several layers of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration, better diamond crystal retention and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster cutting action with minimum heat generation.

Advantages of this type of technology include: longer tool life, more uniformity in performance, less stress to material being worked on, minimum material deformation, and better preservation of true material micro structure. This is specially important for more delicate, sensitive applications such as: glass, crystals, silicon wafers, carbon composites, sapphire, etc.

Why Electroplated (Nickel Bond) Diamond & CBN Wheels?

Electroplating is the only bond that allows different diamond crystal rotrusion/exposure through use of different coating thicknesses.

Usually the exposure ratio is based on the application (materials to be cut) The final specification depends primarily on the machining task and the associated necessary chip clearance space. For high-speed grinding the coating thickness should be about 30 to 40% of the grit particle diameter, when grinding or cutting glass fibre-reinforced plastics 30 to 50%, when machining ceramic material and cemented carbide 60 to 70%, and when machining stone up to 100%.

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside.

Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Electroplated Diamond Products Manufactured by UKAM Industrial are Multi Layered. They have 3 layers of diamonds, not just 1 layer of diamonds like conventional electroplated diamond tools.

CHARACTERISTICS OF Electroplated (Nickel Bond) Diamond & CBN Wheels

-

Main Boding Agent : Nickel, Nickel Cobalt, Nickel Magnesium, Nickel Cobalt Magnesium

Main Boding Agent : Nickel, Nickel Cobalt, Nickel Magnesium, Nickel Cobalt Magnesium

-

Dressability: Good

Dressability: Good

-

Hardness : Very Hard

Hardness : Very Hard

-

Required RPM's: Medium/Hight

Required RPM's: Medium/Hight

-

Shape of Diamond & CBN Used: Semi blocky Crystal

Shape of Diamond & CBN Used: Semi blocky Crystal

-

Form Holding: Good / Excellent

Form Holding: Good / Excellent

-

Lifespan: Low / Medium

Lifespan: Low / Medium

-

Cutting Action: Good / Excellent

Cutting Action: Good / Excellent

-

Can be Used Dry: Yes (depending on tool type, diamond size and type)

Can be Used Dry: Yes (depending on tool type, diamond size and type)

-

Cost: Low/Medium

Cost: Low/Medium

Key Characteristics of Electroplated Diamond & CBN Grinding Wheels

-

Lowest-Cost Tool Form: Electroplated wheels are generally more affordable.

Lowest-Cost Tool Form: Electroplated wheels are generally more affordable.

-

Complex Forms Easily Manufactured: They can be shaped into a variety of forms and contours.

Complex Forms Easily Manufactured: They can be shaped into a variety of forms and contours.

-

Good Form-Holding Capability: Despite their single-layer structure, they retain their shape well during grinding.

Good Form-Holding Capability: Despite their single-layer structure, they retain their shape well during grinding.

|

Wheel Bond Type |

Rim Depth |

Wheel Life |

G-Ratio |

Cutting Action |

Metal-Removal Rate |

Form Holding |

Precautions for Use |

Grinding |

|---|---|---|---|---|---|---|---|---|

|

Resin |

>0.079 in. (2 mm) |

Limited Long |

Medium High |

Good to Excellent |

High Limited |

Good |

None recommended |

Wet or Dry |

|

Metal |

>0.079 in. (2 mm) |

Long |

Medium |

Excellent |

Medium to High |

Good |

None recommended; Least resistance to damage |

Wet |

|

Electroplated |

One abrasive layer |

Limited |

N/A |

Good to Excellent |

High |

Good |

None |

Wet preferred; Can be used dry |

Grinding Characteristics and Performance

The grinding characteristics and performance of different wheel bond systems are outlined below:

-

Maximum Abrasive Particle Exposure: These wheels offer the highest level of abrasive particle exposure.

Maximum Abrasive Particle Exposure: These wheels offer the highest level of abrasive particle exposure.

-

Highest Stock-Removal Capability: They excel in stock removal, making them ideal for heavy-duty grinding tasks.

Highest Stock-Removal Capability: They excel in stock removal, making them ideal for heavy-duty grinding tasks.

-

Limited Finish Capabilities and Shorter Wheel Life: However, they may have limitations in achieving fine finishes and typically have a shorter lifespan.

Limited Finish Capabilities and Shorter Wheel Life: However, they may have limitations in achieving fine finishes and typically have a shorter lifespan.

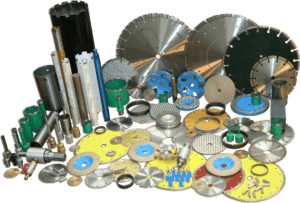

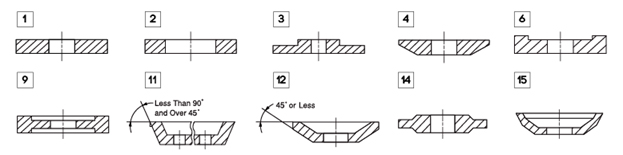

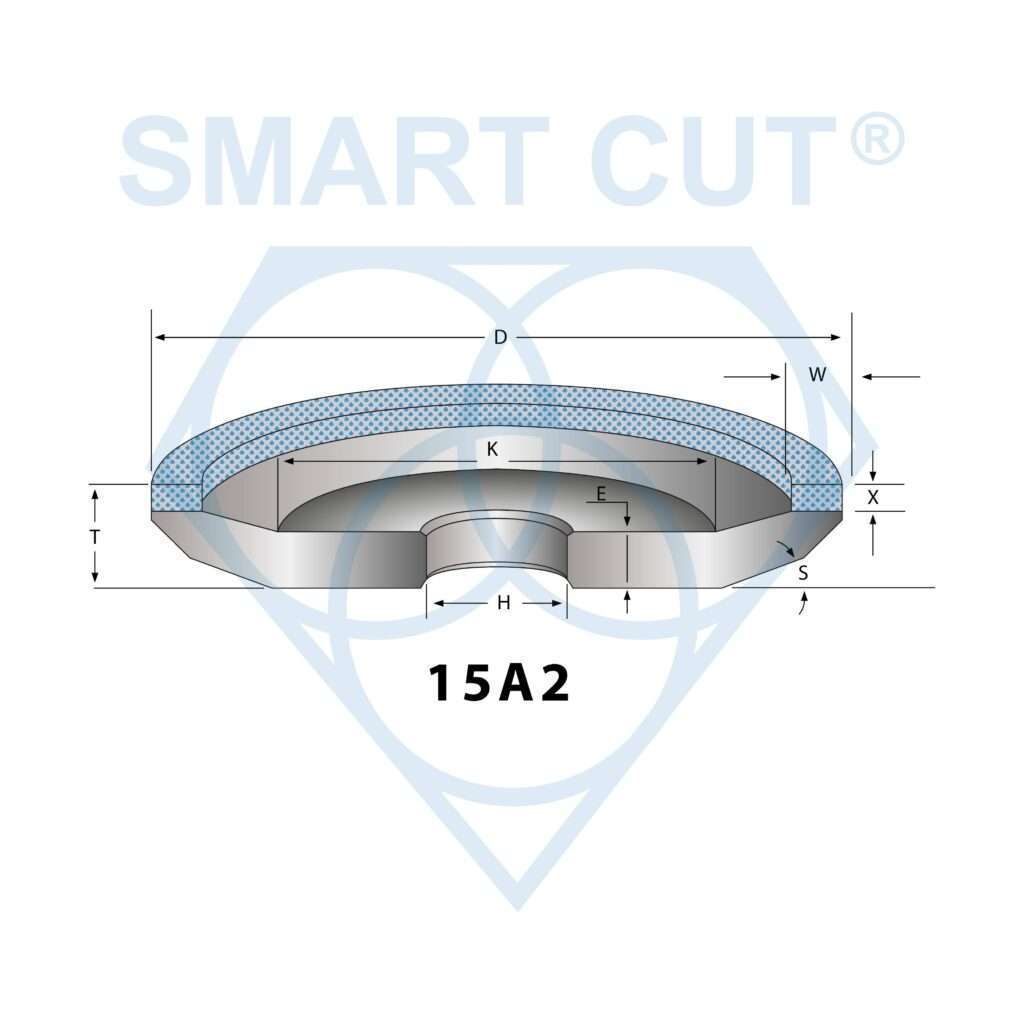

Wheel Shapes and Identification

A diverse range of shapes and sizes of superabrasive grinding wheels are manufactured to accommodate specific grinding equipment needs.

Wheel Shapes and Sizes

In the industrial grinding environment, there are nine standard wheel shapes available in various standardized dimensional sizes. These shapes, established by the American National Standards Institute (ANSI), are widely adopted by superabrasive wheel manufacturers. Additionally, manufacturers produce variations of these shapes to suit specific grinding needs.

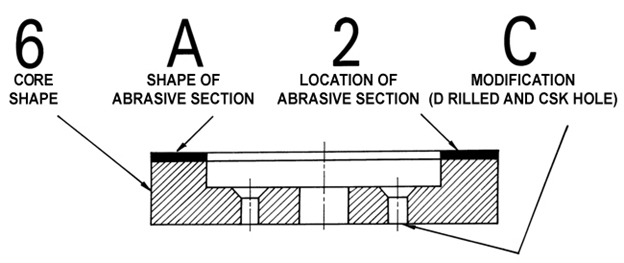

Wheel Identification

Superabrasive grinding wheels are identified by a code comprising four characteristics: the core shape, abrasive section shape, abrasive section location, and wheel modifications. This code system, utilized in the United States (ANSI) and Europe (FEPA), is straightforward and aids in understanding the wheel's specifications.

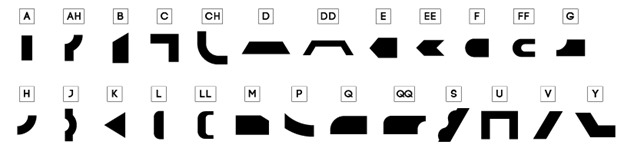

Basic Core Shapes

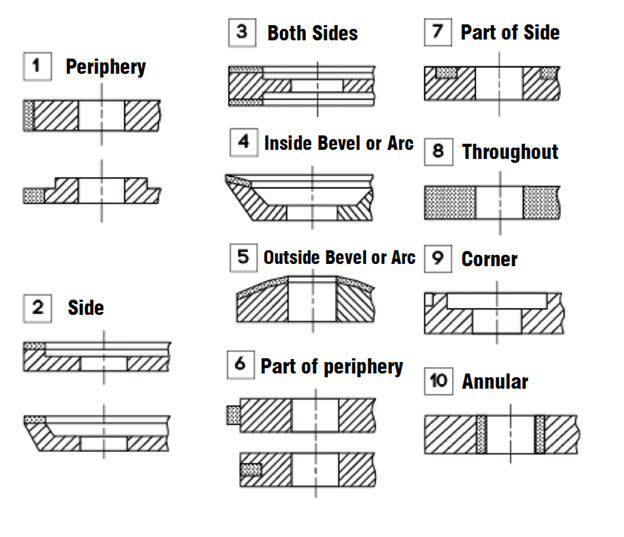

Abrasive Selection Location

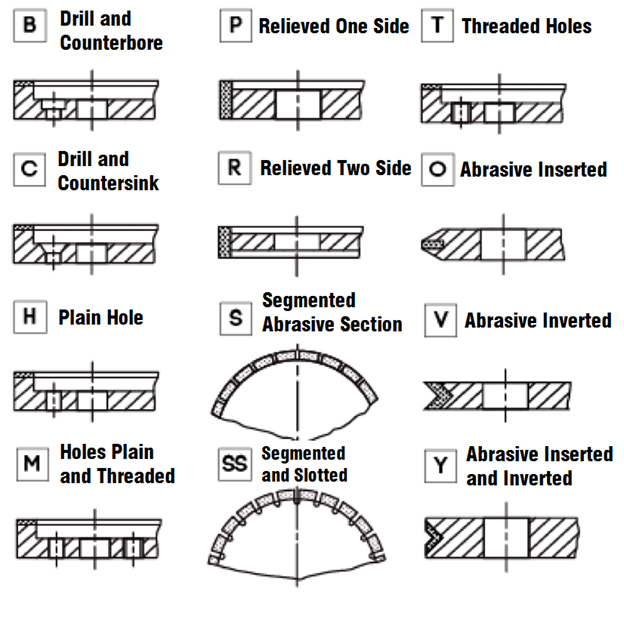

Wheel Modifications

Shape of Abrasive Section

Wheel Markings

-

United States Standard (ANSI): American manufacturers follow the ANSI marking system, which assigns a symbol to each key characteristic of a superabrasive grinding wheel. This system facilitates detailed identification and future orders.

United States Standard (ANSI): American manufacturers follow the ANSI marking system, which assigns a symbol to each key characteristic of a superabrasive grinding wheel. This system facilitates detailed identification and future orders.

-

European Standard (FEPA): European manufacturers adhere to the FEPA marking system. Similar to ANSI, it provides clear identification of superabrasive grinding wheels.

European Standard (FEPA): European manufacturers adhere to the FEPA marking system. Similar to ANSI, it provides clear identification of superabrasive grinding wheels.

Wheel Selection

When selecting a grinding wheel, understanding its shape, size, and markings according to ANSI or FEPA standards is essential. This knowledge ensures compatibility with grinding equipment and optimal performance in specific applications.

Importance of Wheel Selection

Choosing the right grinding wheel is crucial for a successful grinding operation. The type of wheel and its usage directly impact the metal removal rate (MRR) and the wheel's lifespan. Manufacturers provide valuable recommendations based on their expertise, guiding users to select the most suitable wheel for each task.

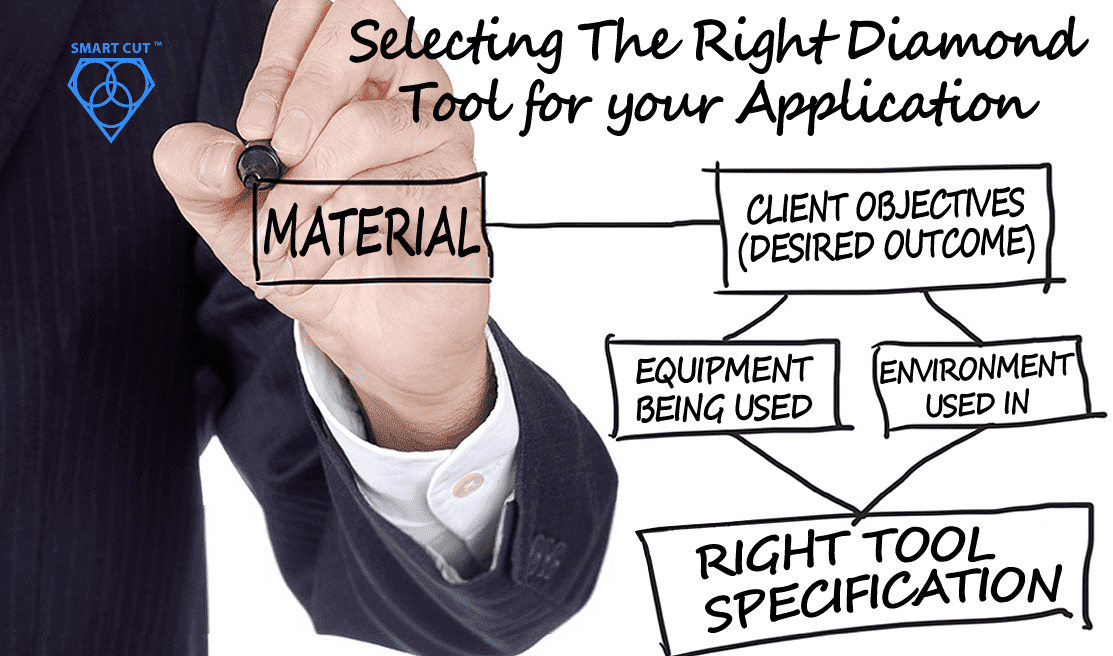

Factors Affecting CBN Wheel Selection

Selecting the appropriate cubic boron nitride (CBN) wheel for your grinding application is crucial for achieving optimal performance and desired outcomes. Several factors must be considered to ensure that the chosen wheel matches the specific requirements of the grinding task. This section discusses the key factors that influence CBN wheel selection, including the type of grinding operation, grinding conditions, surface finish requirements, workpiece shape and size, and workpiece material.

Type of Grinding Operation

The nature of the grinding task significantly impacts the choice of CBN wheel. Different operations demand specific wheel types to achieve the desired results. Rough grinding involves the rapid removal of large amounts of material. Coarse grit sizes and high-concentration wheels are typically used for these applications to enhance efficiency and speed. Precision grinding, on the other hand, requires high accuracy and fine surface finishes. Fine grit sizes and wheels with lower concentrations are preferred to achieve the necessary precision and minimize surface imperfections. Tool and cutter grinding involves sharpening or reshaping tools, requiring CBN wheels with specific profiles and high precision to maintain the tool's geometry and ensure a sharp edge. Surface grinding focuses on producing a smooth, flat surface, with fine grit wheels chosen to achieve the desired surface finish with minimal defects.

Grinding Conditions

The conditions under which grinding takes place also influence the selection of CBN wheels. The rotational speed of the grinding wheel affects its cutting performance, so wheels must be selected based on their rated speed to prevent safety hazards and ensure efficient grinding. The force applied during grinding impacts wheel wear and performance; high-pressure applications may require more durable wheels with higher concentrations to withstand the load. Additionally, the presence and type of coolant used can affect the wheel's performance, as coolants help reduce heat generation and improve surface finish, making them essential for certain applications.

Surface Finish Requirements

The desired surface smoothness plays a crucial role in determining the appropriate CBN wheel type. Applications requiring a smooth, polished finish necessitate the use of fine grit wheels with lower abrasive concentrations to achieve the necessary level of detail. Standard finishing tasks may use wheels with medium grit sizes and concentrations to balance material removal and surface quality. When surface finish is not critical, coarser grit wheels with higher concentrations can be used for rapid material removal without focusing on smoothness.

Workpiece Shape and Size

The geometry of the workpiece influences the selection of the CBN wheel. Workpieces with intricate shapes or profiles require wheels with specific profiles or electroplated CBN wheels that can maintain sharp edges and precise forms. Grinding larger workpieces may demand wheels with higher durability and material removal capabilities to handle the extensive surface area. For small or delicate workpieces, precision and care are necessary. Fine grit wheels with lower concentrations are suitable for these tasks to prevent damage and ensure accuracy.

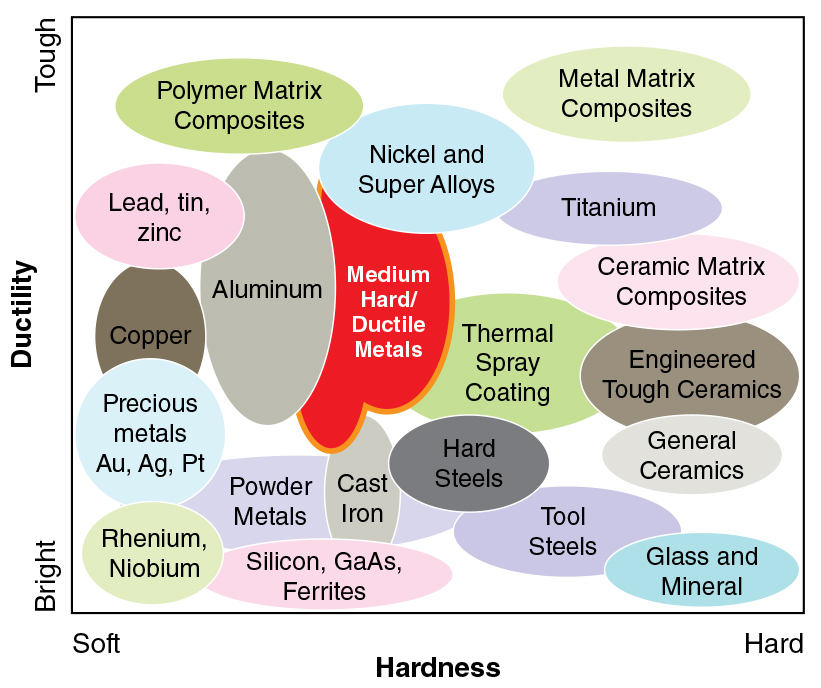

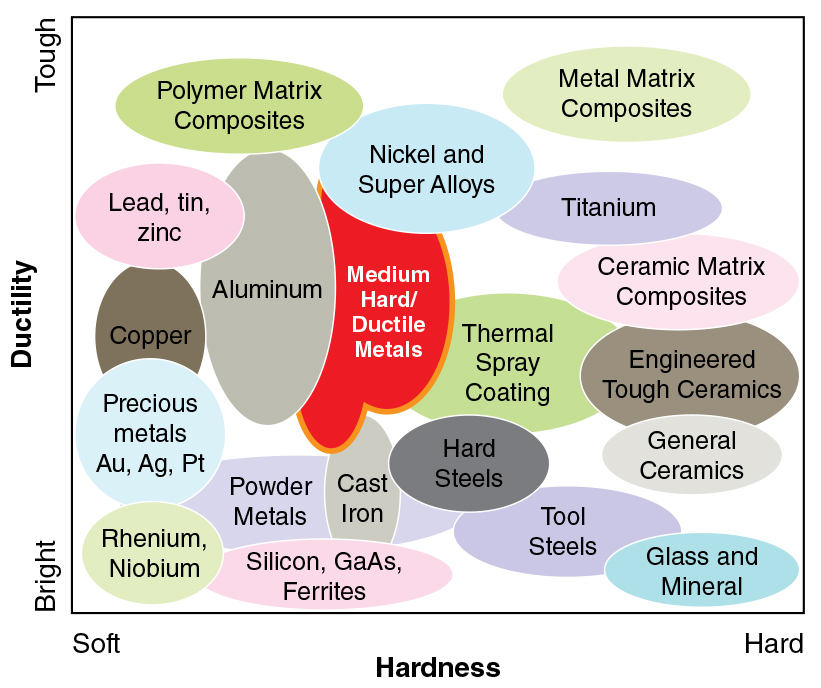

Workpiece Material

The material being ground is perhaps the most critical factor in selecting the appropriate CBN wheel. Hard materials such as hardened steels, high-speed steels, and superalloys require wheels with high concentrations of CBN and appropriate bond types (e.g., metal or vitrified bonds) to effectively cut and maintain durability. Softer materials can be effectively ground using wheels with lower concentrations and resin bonds to achieve the desired surface finish without excessive wear on the wheel. Materials like ceramics and glass, which are brittle, necessitate wheels that can minimize chipping and cracking, often using fine grit sizes and specific bond types to achieve a smooth finish without causing damage.

Matching Wheel Types to Applications

CBN wheels come in four types: resin, vitrified, metal, and electroplated. Each type is designed for particular applications and must be chosen accordingly. No single type suits all grinding needs. Thus, selecting the best wheel involves matching the abrasive's characteristics, including concentration and size, to the specific requirements of the grinding task.

Find out more about selecting the right bond type for your application >>>

Comparison table summarizing the characteristics, applications, advantages, and limitations of different abrasive concentrations and sizes for CBN wheels:

|

Abrasive Characteristics |

High Concentration (75% and above) |

Low Concentration (50% and below) |

Coarse Grit Sizes (80/100 mesh) |

Fine Grit Sizes (320/400 mesh) |

|---|---|---|---|---|

|

Characteristics |

Greater number of abrasive particles, increased cutting points |

Fewer abrasive particles, softer cutting action |

Larger abrasive particles, rougher grinding surface |

Smaller abrasive particles, smoother grinding surface |

|

Applications |

Grinding hard and dense materials (e.g., hardened steels, superalloys) |

Grinding softer materials, precision and finishing applications |

Rough grinding, deburring, high stock removal |

Precision grinding, achieving fine surface finishes |

|

Heavy-duty grinding tasks |

Finishing applications, tool sharpening, delicate component grinding |

Heavy-duty machining, tool grinding |

Tool and cutter grinding, aerospace component finishing |

|

|

Advantages |

Superior cutting performance, longer tool life, maintains form well |

Smoother surface finish, reduces overheating, lower initial cost |

High material removal rate, effective on tough materials |

Smooth, polished surface finish, less heat generation |

|

Limitations |

Higher initial cost, more heat generation |

Shorter wheel life, more frequent wheel changes |

Rougher surface finish, higher heat generation |

Lower material removal rate, more frequent dressing |

Abrasive Concentration

-

High Concentration Benefits: Increased concentrations typically lead to higher material removal rates, extended wheel lifespan, and enhanced surface finishes.

High Concentration Benefits: Increased concentrations typically lead to higher material removal rates, extended wheel lifespan, and enhanced surface finishes.

-

Grinding Power: Higher concentrations require more grinding power because of increased abrasive contact with the workpiece.

Grinding Power: Higher concentrations require more grinding power because of increased abrasive contact with the workpiece.

-

Vitrified-Bond Wheel Advantage: Vitrified-bond wheels can handle higher abrasive concentrations better than resin bonds due to their stronger grip on abrasive grains.

Vitrified-Bond Wheel Advantage: Vitrified-bond wheels can handle higher abrasive concentrations better than resin bonds due to their stronger grip on abrasive grains.

-

Application Considerations: In applications like ID grinding with small-diameter wheels, high abrasive concentrations result in prolonged wheel life and superior surface finishes.

Application Considerations: In applications like ID grinding with small-diameter wheels, high abrasive concentrations result in prolonged wheel life and superior surface finishes.

The concentration of CBN abrasive within the bond-matrix material significantly affects the performance of impregnated-bond wheels.

Abrasive Grit Sizes

-

Coarse CBN Grain: Enhances material removal capabilities while reducing wheel wear rate.

Coarse CBN Grain: Enhances material removal capabilities while reducing wheel wear rate.

-

Surface Finish: Coarser CBN grains typically result in rougher surface finishes. Microcrystalline CBN abrasives, such as Borazon 550, 560, and 570, offer smoother finishes compared to monocrystalline CBN abrasives.

Surface Finish: Coarser CBN grains typically result in rougher surface finishes. Microcrystalline CBN abrasives, such as Borazon 550, 560, and 570, offer smoother finishes compared to monocrystalline CBN abrasives.

-

Replacement Considerations: When substituting an aluminum oxide wheel with a CBN wheel, the abrasive grit size can be reduced by up to three sizes without sacrificing the metal removal rate. This allows for the combination of fine surface finishes with high productivity. For instance, a 46-grit aluminum oxide wheel can be replaced with a 100-grit CBN wheel.

Replacement Considerations: When substituting an aluminum oxide wheel with a CBN wheel, the abrasive grit size can be reduced by up to three sizes without sacrificing the metal removal rate. This allows for the combination of fine surface finishes with high productivity. For instance, a 46-grit aluminum oxide wheel can be replaced with a 100-grit CBN wheel.

The size of the abrasive grain plays a vital role in determining the metal removal rate and the surface finish quality.

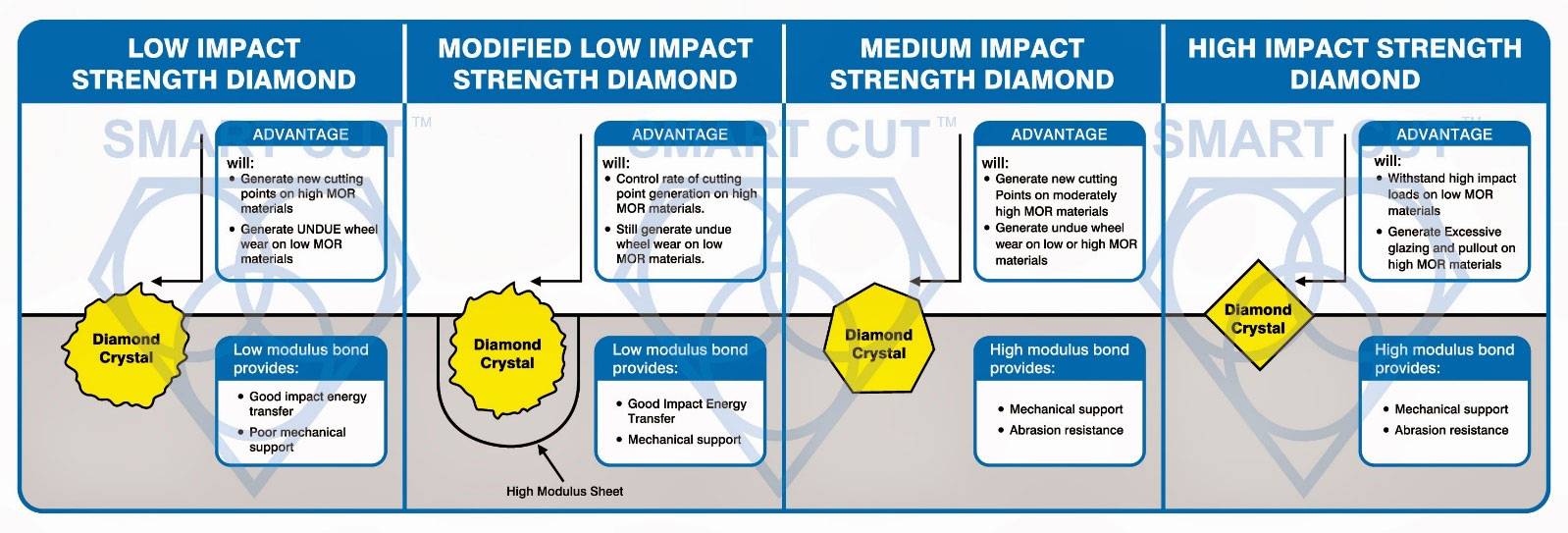

Abrasive Toughness

The toughness of an CBN abrasive plays a crucial role in selecting the right wheel for a grinding operation. It directly impacts factors such as metal removal rates, wheel longevity, and surface finish. Wheel manufacturers possess deep knowledge of CBN abrasive types and can recommend the most appropriate option.

-

Self-Sharpening Characteristics: Although CBN crystals are highly wear-resistant, their sharp edges may dull over time if the abrasive, bond system, and grinding conditions are not appropriately matched.

Self-Sharpening Characteristics: Although CBN crystals are highly wear-resistant, their sharp edges may dull over time if the abrasive, bond system, and grinding conditions are not appropriately matched.

-

Controlled Fracturing: Ideally, the crystal should fracture in a controlled manner to expose fresh and sharp cutting edges, ensuring consistent grinding performance.

Controlled Fracturing: Ideally, the crystal should fracture in a controlled manner to expose fresh and sharp cutting edges, ensuring consistent grinding performance.

Crystal Toughness Considerations

Crystal toughness is crucial for optimal grinding performance. Here are the key considerations:

-

Crystal Too Tough: If the crystal is overly tough for the application, it may resist fracturing. This can lead to the formation of a polished wear flat on the crystal, rendering it ineffective in cutting efficiently.

Crystal Too Tough: If the crystal is overly tough for the application, it may resist fracturing. This can lead to the formation of a polished wear flat on the crystal, rendering it ineffective in cutting efficiently.

-

Crystal Not Tough Enough: Conversely, if the crystal lacks toughness for the application, it may fracture prematurely. This results in wasted abrasive, shortened wheel life, and a rougher surface finish.

Crystal Not Tough Enough: Conversely, if the crystal lacks toughness for the application, it may fracture prematurely. This results in wasted abrasive, shortened wheel life, and a rougher surface finish.

-

Medium-Toughness Crystals Recommended: For most grinding jobs, medium-toughness crystals are suitable.

Medium-Toughness Crystals Recommended: For most grinding jobs, medium-toughness crystals are suitable.

-

Higher-Toughness Crystals: Recommended for operations with higher grinding forces.

Higher-Toughness Crystals: Recommended for operations with higher grinding forces.

-

Microcrystalline CBN Types: Recommended for exceptionally severe grinding conditions.

Microcrystalline CBN Types: Recommended for exceptionally severe grinding conditions.

Wheel Selection Guidelines

Cubic boron nitride (CBN) grinding wheels are designed in various shapes and sizes to accommodate a wide range of grinding operations, ensuring that there is an appropriate wheel for almost any task. The selection of the right CBN wheel is essential to achieving optimal grinding performance, efficiency, and quality. This section provides detailed guidelines on selecting the appropriate CBN wheel based on its range of shapes and sizes, the availability of individually engineered wheels, construction features, and overall availability.

Range of Shapes and Sizes

CBN grinding wheels come in a diverse array of shapes and sizes, each tailored to specific grinding applications. This variety ensures that the wheels can effectively meet the requirements of different grinding tasks. The available shapes and sizes include:

-

Straight Wheels: These are the most common type, used for cylindrical, surface, and internal grinding operations. They are versatile and can handle a wide range of applications.

Straight Wheels: These are the most common type, used for cylindrical, surface, and internal grinding operations. They are versatile and can handle a wide range of applications.

-

Formed Wheels: Designed with a specific profile or shape to match the contour of the workpiece. These wheels are used for precision grinding operations where maintaining the shape of the workpiece is critical.

Formed Wheels: Designed with a specific profile or shape to match the contour of the workpiece. These wheels are used for precision grinding operations where maintaining the shape of the workpiece is critical.

-

Ring Wheels: These are used for large-scale grinding operations and are often employed in the manufacturing of large components where a substantial grinding surface is needed.

Ring Wheels: These are used for large-scale grinding operations and are often employed in the manufacturing of large components where a substantial grinding surface is needed.

-

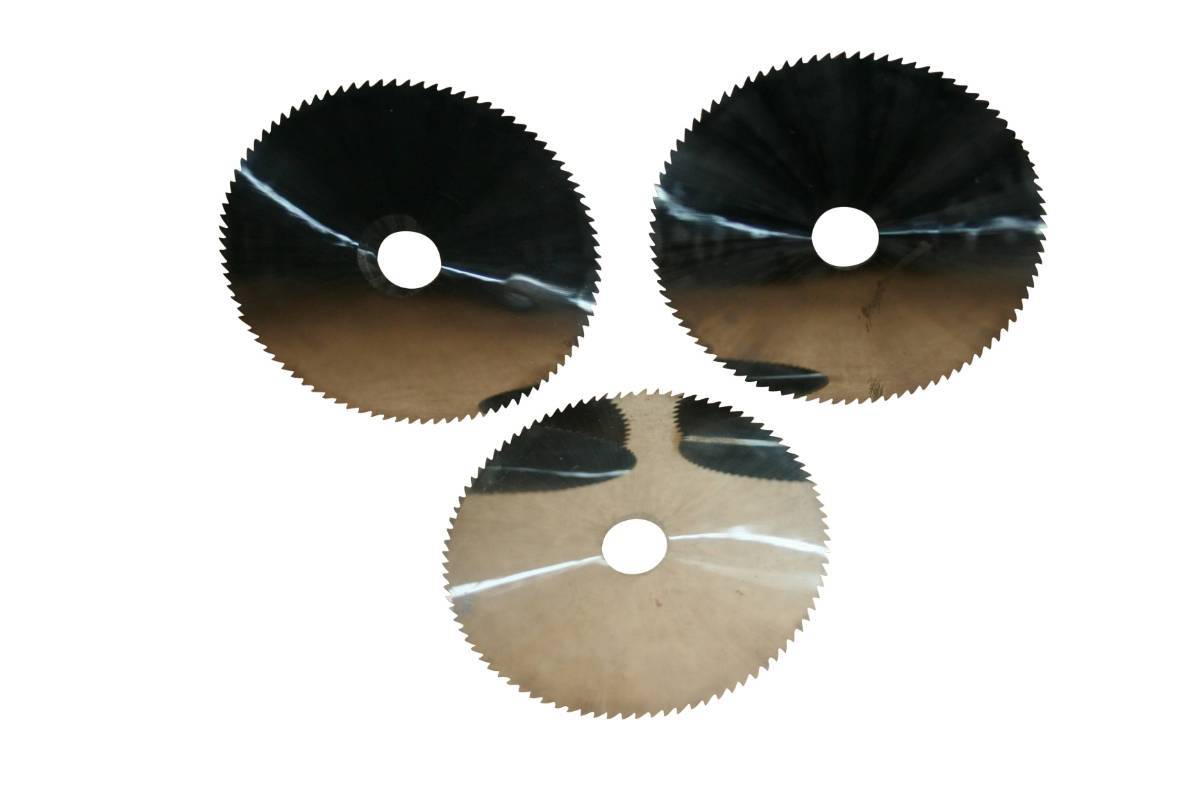

Disk Wheels: Flat, circular wheels used for surface grinding. They are ideal for achieving a smooth, flat finish on the workpiece.

Disk Wheels: Flat, circular wheels used for surface grinding. They are ideal for achieving a smooth, flat finish on the workpiece.

-

Microcrystalline CBN Types: Recommended for exceptionally severe grinding conditions.

Microcrystalline CBN Types: Recommended for exceptionally severe grinding conditions.

-

Flaring Cup Wheels: These have a flared cup shape and are commonly used for grinding larger surfaces and for applications requiring a larger contact area.

Flaring Cup Wheels: These have a flared cup shape and are commonly used for grinding larger surfaces and for applications requiring a larger contact area.

-

Mounted Wheels: Smaller wheels mounted on a spindle or mandrel, used for precision grinding in hard-to-reach areas or for detailed work.

Mounted Wheels: Smaller wheels mounted on a spindle or mandrel, used for precision grinding in hard-to-reach areas or for detailed work.

-

Mandrels and Hones: These are used for internal grinding and honing operations, providing precision and control for finishing internal surfaces.

Mandrels and Hones: These are used for internal grinding and honing operations, providing precision and control for finishing internal surfaces.

Custom Engineered Wheels

In addition to standard shapes and sizes, CBN wheels can be individually engineered to meet the specific needs of superabrasive grinding systems or particular grinding operations. These custom-engineered wheels are designed to optimize performance for specialized tasks, ensuring that the grinding process is efficient and effective. Custom wheels can be tailored in terms of size, shape, grit size, concentration, and bond type to meet the unique requirements of a given application.

Construction Features

CBN grinding wheels are constructed with a high level of precision to ensure durability and performance. The construction typically involves a preformed core, which provides the structural foundation of the wheel, and an abrasive portion on the grinding face. The depth of the abrasive portion usually ranges between 1.5 and 10 mm, depending on the application. This construction ensures that the wheel can maintain its shape and integrity during grinding operations, providing consistent performance and a high-quality finish.

Availability

One of the key advantages of CBN wheels is their availability. There is usually a CBN wheel suitable for any grinding operation, given the wide range of standard and custom options. Whether the task involves heavy-duty material removal, precision finishing, or working with hard-to-grind materials, there is a CBN wheel designed to meet those specific needs. The extensive variety ensures that users can find the right wheel to optimize their grinding processes, improve efficiency, and achieve the desired outcomes.

Guidelines for CBN Wheel Selection

Selecting the appropriate cubic boron nitride (CBN) grinding wheel is essential for achieving optimal performance and desired results in various grinding operations. Here are some essential guidelines to follow when choosing CBN grinding wheels:

1. Choose the Right Bond

The bond type of the CBN wheel plays a critical role in determining its performance for specific grinding processes. Different bonds are suited to different applications, and selecting the correct one ensures efficient and high-quality grinding. Here is a guide to the recommended wheel bonds for various grinding processes:

|

Grinding Process |

Recommended Wheel Bonds |

|---|---|

|

Surface grinding (wet) |

Resin |

|

Horizontal spindle, reciprocating table |

Resin |

|

Horizontal spindle, rotary table |

Resin |

|

Vertical spindle, rotary table |

Resin, metal |

|

Tool and cutter grinding (dry) |

Resin |

|

Jig grinding (dry) |

Electroplated (small IDs) |

|

Cylindrical grinding (wet) |

Resin |

|

Internal grinding (wet) |

Vitreous (best finishes) |

|

Form grinding (wet) |

Resin |

|

Centerless grinding (wet) |

Vitreous |

|

Double-disk grinding (wet) |

Resin |

|

Internal grinding (dry) |

Vitreous (shallow forms) |

|

Double-disk grinding (dry) |

Resin |

|

Specialized Applications |

Metal, vitreous, resin |

2. Specify Wheel Dimensions

Selecting the correct dimensions for your CBN wheel is crucial for maintaining performance and efficiency.

-

Diameter and Width: When replacing an aluminum oxide wheel with a CBN wheel, maintain the same diameter but consider reducing the width by 25 to 50 percent, depending on the application. This adjustment can help optimize the grinding process.

Diameter and Width: When replacing an aluminum oxide wheel with a CBN wheel, maintain the same diameter but consider reducing the width by 25 to 50 percent, depending on the application. This adjustment can help optimize the grinding process.

-

Avoid Undersize Wheels: Using undersize wheels can lead to faster wear and increased cost per ground piece. If you need to make size adjustments, it is preferable to reduce the width rather than the diameter to maintain effective performance.

Avoid Undersize Wheels: Using undersize wheels can lead to faster wear and increased cost per ground piece. If you need to make size adjustments, it is preferable to reduce the width rather than the diameter to maintain effective performance.

Selecting the correct dimensions for your CBN wheel is crucial for maintaining performance and efficiency in grinding operations. The dimensions of the wheel, including its diameter and width, play a significant role in determining the effectiveness and longevity of the grinding process.

When replacing an aluminum oxide wheel with a CBN wheel, it is generally recommended to maintain the same diameter. This consistency ensures that the wheel fits properly on the grinding machine and can operate at the same rotational speed, providing stability and maintaining performance standards. However, there are specific adjustments that should be considered regarding the width of the wheel. Keeping the diameter constant when switching from aluminum oxide to CBN wheels helps to preserve the machine's balance and ensures compatibility with existing setups and safety guards. This also allows the wheel to utilize the same surface area for grinding, ensuring consistent contact with the workpiece. Depending on the application, reducing the width of the CBN wheel by 25 to 50 percent compared to the aluminum oxide wheel can be beneficial. CBN wheels are generally more efficient at material removal, meaning they can achieve the same or better results with a narrower profile.

Reducing the width of the CBN wheel can help optimize grinding performance by providing more precise control over the grinding process, especially in applications requiring fine tolerances and high precision. A narrower wheel also generates less heat, reducing the risk of thermal damage to the workpiece and extending the wheel's lifespan. Additionally, using a narrower wheel can lower material costs, as less abrasive material is required for manufacturing the wheel.

Using undersize wheels, which are significantly smaller in diameter than the original specifications, can lead to several issues that negatively impact the grinding process and overall cost-efficiency. Undersize wheels have less abrasive material available for grinding, leading to faster wear. This results in more frequent wheel replacements, increasing downtime and maintenance costs. The shorter lifespan of undersize wheels means that the cost per unit of material ground increases, as more wheels are consumed over the same period. Moreover, smaller diameter wheels may not provide the same level of stability and cutting efficiency, potentially leading to poorer surface finish and increased risk of defects in the workpiece.

If adjustments to the wheel size are necessary, it is generally preferable to reduce the width rather than the diameter. This approach maintains the wheel's structural integrity and ensures that the wheel can still operate effectively at the intended rotational speeds. A wheel with the original diameter but reduced width can still offer high cutting efficiency and maintain effective contact with the workpiece. Maintaining the original diameter ensures that the wheel remains compatible with the existing machine setup, including spindle speed, mounting fixtures, and safety guards.

Specifying the correct dimensions for your CBN wheel is vital for optimizing the grinding process. By maintaining the original diameter and considering a reduction in width, you can enhance the performance, efficiency, and cost-effectiveness of your grinding operations. Avoiding undersize wheels helps to ensure longevity and consistent quality in your grinding results. Carefully considering these factors will allow you to select the most suitable CBN wheel dimensions for your specific application, ultimately leading to improved productivity and reduced operational costs.

3. Optimize Abrasive Mesh Size

The mesh size of the CBN abrasive affects the wheel's performance and the finish quality of the workpiece.

-

Choose Coarse Abrasive: For longer wheel life, opt for wheels with coarse (large mesh size) CBN abrasive. Coarse abrasives are more durable and suitable for high material removal rates.

Choose Coarse Abrasive: For longer wheel life, opt for wheels with coarse (large mesh size) CBN abrasive. Coarse abrasives are more durable and suitable for high material removal rates.

-

Fine Abrasive: Fine abrasive produces better surface finishes with lower downfeed rates. This is ideal for applications requiring high precision and smooth surface quality.

Fine Abrasive: Fine abrasive produces better surface finishes with lower downfeed rates. This is ideal for applications requiring high precision and smooth surface quality.

Selecting the appropriate mesh size ensures that the grinding process meets specific application requirements, balancing material removal rates, surface finish quality, and wheel longevity. Understanding the differences between coarse and fine abrasives can help in optimizing the grinding process for various applications.

Coarse Abrasive

Coarse abrasives, characterized by large mesh sizes, are designed for high material removal rates and longer wheel life. These abrasives are more durable and can withstand the rigors of heavy-duty grinding tasks.

Performance and Durability: Coarse CBN abrasives are robust and capable of removing substantial amounts of material quickly. Their large particle size provides a more aggressive cutting action, making them ideal for rough grinding operations. The durability of coarse abrasives ensures that the wheel maintains its cutting efficiency over longer periods, reducing the frequency of wheel changes and minimizing downtime. Coarse abrasive wheels are particularly suitable for applications that require significant material removal in a short amount of time. This includes operations such as rough grinding, deburring, and initial shaping of workpieces. Industries such as automotive, aerospace, and heavy machinery manufacturing often utilize coarse abrasives for their ability to handle tough materials and demanding grinding tasks.

Benefits: Using coarse abrasives can lead to higher productivity due to their fast material removal rates. They are also cost-effective in applications where surface finish is not the primary concern, as the robust nature of coarse abrasives extends wheel life and reduces operational costs.

Fine Abrasive

Fine abrasives, with smaller mesh sizes, are designed to produce better surface finishes and are ideal for applications requiring high precision and smooth surface quality.

Surface Finish Quality: Fine CBN abrasives excel in providing superior surface finishes. The smaller particle size allows for finer grinding, resulting in a smoother and more refined surface on the workpiece. This makes fine abrasives the preferred choice for finishing operations where surface quality is critical. Fine abrasive wheels are commonly used in precision grinding tasks such as tool and cutter grinding, finishing of aerospace components, and manufacturing of medical devices. These applications demand high levels of accuracy and surface integrity, which fine abrasives are well-suited to deliver.

Fine abrasives require lower downfeed rates, which means they grind more delicately, reducing the risk of damaging the workpiece. This precision is essential in applications that involve intricate details and tight tolerances.

Benefits: The use of fine abrasives leads to excellent surface quality and precision in the finished product. Although fine abrasives may have a shorter lifespan compared to coarse abrasives, their ability to produce high-quality finishes can eliminate the need for additional finishing processes, ultimately saving time and costs in the long run.

Balancing Coarse and Fine Abrasives

Choosing the appropriate abrasive mesh size depends on the specific requirements of the grinding task. Coarse abrasives are beneficial for tasks that prioritize material removal and wheel longevity, while fine abrasives are essential for achieving high surface quality and precision. In some cases, a combination of both coarse and fine abrasives may be used within a grinding operation to balance efficiency and quality.

4. Optimal Abrasive Concentration

The concentration of cubic boron nitride (CBN) abrasive within a grinding wheel is a critical factor that influences its cutting ability and durability. Higher concentrations of abrasive particles generally result in better cutting performance and longer wheel life. However, the optimal concentration level must be carefully selected based on the specific grinding application and the capabilities of the grinding machine. Here are some essential guidelines to follow for selecting the optimal abrasive concentration:

Select Highest Concentration

Choosing the highest concentration that the grinding machine can effectively drive is crucial for maximizing cutting performance and wheel longevity. Higher concentrations provide more abrasive particles per unit volume, enhancing the wheel's cutting efficiency and extending its lifespan. This increased density of abrasive particles allows for more effective material removal and better overall performance. To ensure optimal performance, refer to specific grinding application recommendations for concentration levels. Different grinding tasks may require different concentrations to achieve the best results. Consulting with wheel manufacturers or technical guides can provide valuable insights into the appropriate concentration levels for various applications. For example, high-precision tasks might benefit from higher concentrations, while less demanding applications might require lower concentrations.

Resin Bond Wheels

For surface grinding, resin-bond wheels with a concentration of 100 are recommended. Resin-bond wheels offer a good balance between cutting efficiency and surface finish, making them suitable for a wide range of surface grinding applications. The 100 concentration level ensures that there are enough abrasive particles to provide effective cutting action while maintaining a smooth surface finish on the workpiece. This concentration level is ideal for achieving high-quality results in surface grinding tasks.

Consider Machine Power

When using large-diameter wheels or grinding machines with limited horsepower, a 75-concentration CBN wheel may be necessary to prevent spindle slowdown. Higher concentrations require more power to drive effectively, and machines with limited horsepower might struggle to maintain optimal performance with very high concentrations. By selecting a slightly lower concentration, such as 75, the wheel can operate efficiently without overloading the spindle. This consideration ensures that the grinding machine runs smoothly and maintains consistent cutting performance.

Factors Affecting Efficiency

Efficiency in grinding operations is crucial for maximizing productivity, achieving high-quality results, and minimizing operational costs. Several factors influence the efficiency of grinding processes. Understanding and optimizing these factors can lead to significant improvements in performance. Here are key considerations to enhance grinding efficiency:

Speed, Feed, and Workpiece Material

The parameters of speed, feed rate, and the material being worked on are fundamental to grinding efficiency. Adjusting these parameters appropriately can significantly impact the effectiveness of the grinding operation.

The rotational speed of the grinding wheel (measured in RPM) directly affects the cutting action and material removal rate. Higher speeds can improve material removal rates but may also increase heat generation, which can lead to thermal damage. It is essential to find the optimal speed that balances cutting efficiency and thermal control.

The feed rate, or the rate at which the workpiece is fed into the grinding wheel, influences the grinding force and surface finish. Higher feed rates can enhance productivity but may compromise surface quality. Conversely, lower feed rates can achieve better surface finishes but may slow down the process. Optimizing the feed rate for the specific material and desired outcome is crucial.

Different materials respond differently to grinding. Harder materials require more robust and harder abrasives, while softer materials may need less aggressive abrasives to avoid excessive wear. Understanding the properties of the workpiece material and selecting the appropriate grinding parameters is vital for efficient grinding.

Grinding Machine Condition

The condition of the grinding machine itself plays a significant role in the efficiency of the grinding process. Ensuring that the grinder is in optimal condition can prevent issues that lead to inefficiencies.

Regular maintenance of the grinder, including checking for wear and tear, ensuring proper lubrication of moving parts, and replacing worn-out components, helps maintain the machine's performance. Proper alignment and calibration of the grinder are essential for precise and efficient grinding. Misalignment can lead to uneven wear of the grinding wheel and suboptimal grinding results.

Minimizing vibrations in the grinding machine can enhance the surface finish and prolong the life of the grinding wheel. Ensuring that the machine is stable and properly mounted can help reduce vibrations.

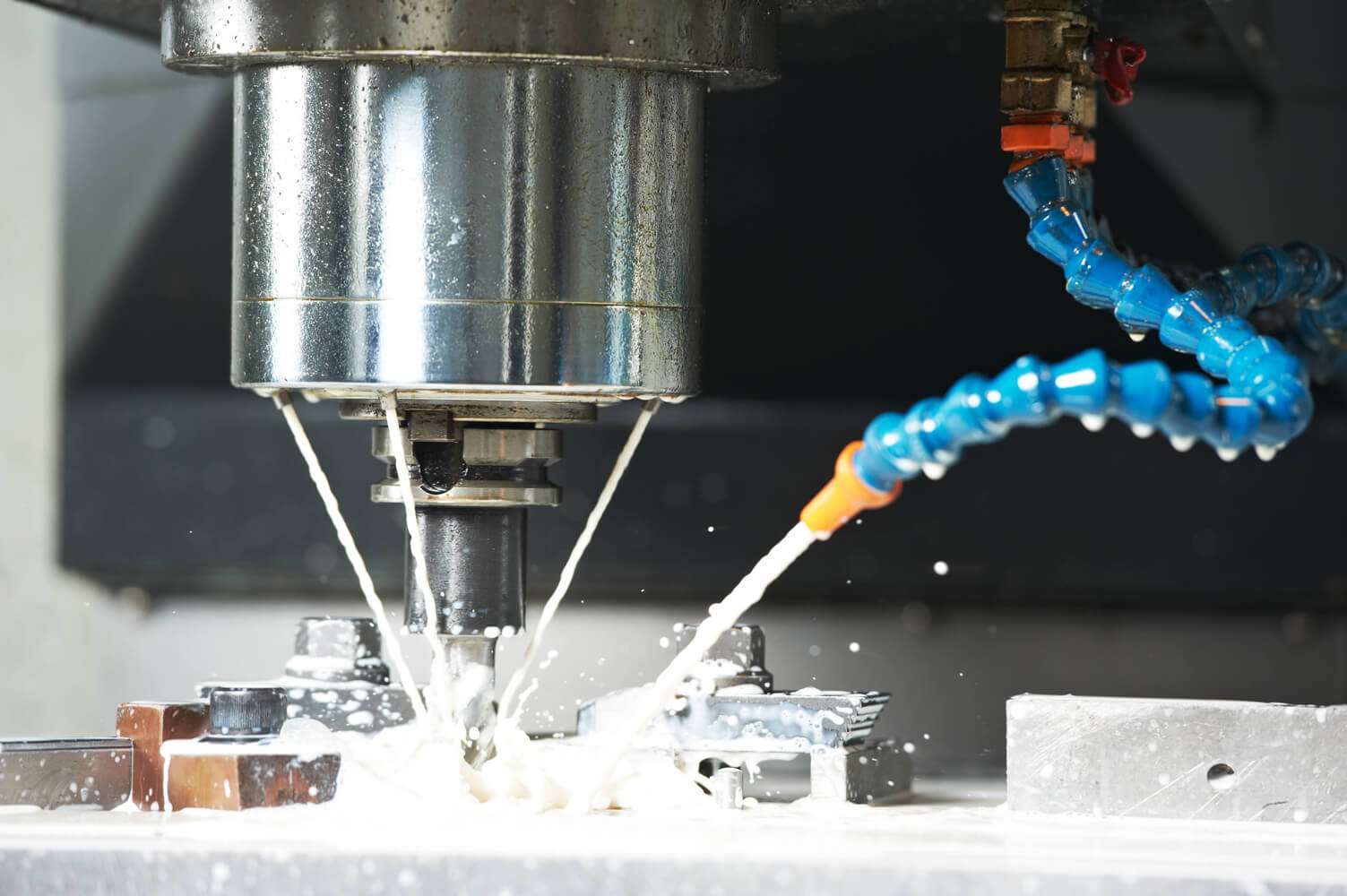

Cutting Fluids

Using appropriate cutting fluids is crucial for cooling and lubrication during the grinding process. Cutting fluids help manage heat generation, reduce friction, and remove grinding debris, thereby improving efficiency and surface quality.

Cutting fluids help dissipate the heat generated during grinding, preventing thermal damage to the workpiece and extending the life of the grinding wheel. Selecting a cutting fluid with good cooling properties is essential for high-speed and high-feed grinding operations. Proper lubrication reduces friction between the grinding wheel and the workpiece, enhancing cutting efficiency and surface finish. Cutting fluids with excellent lubrication properties are particularly beneficial in operations requiring high precision and fine surface finishes.

Choosing the right grinding wheel for the specific application is crucial for cost-effective operations. Factors such as wheel type, abrasive material, bond type, and wheel dimensions should be carefully considered to match the requirements of the grinding task. Implementing best practices in grinding operations, such as optimizing grinding parameters, maintaining the grinder, and using appropriate cutting fluids, can enhance efficiency and reduce operational costs.

Monitoring and managing the life of the grinding wheel can prevent premature wear and replacement. Using wheels with higher durability and maintaining them properly can reduce the frequency of wheel changes and associated downtime. Optimizing the grinding process to reduce energy consumption can contribute to cost savings. Efficient use of machine power, appropriate selection of grinding parameters, and minimizing idle times can all help in achieving energy-efficient grinding operations.