Selecting the Right Dicing Surfactant / Fluid for Your Application

-

Posted by

Brian Farberov

Brian Farberov

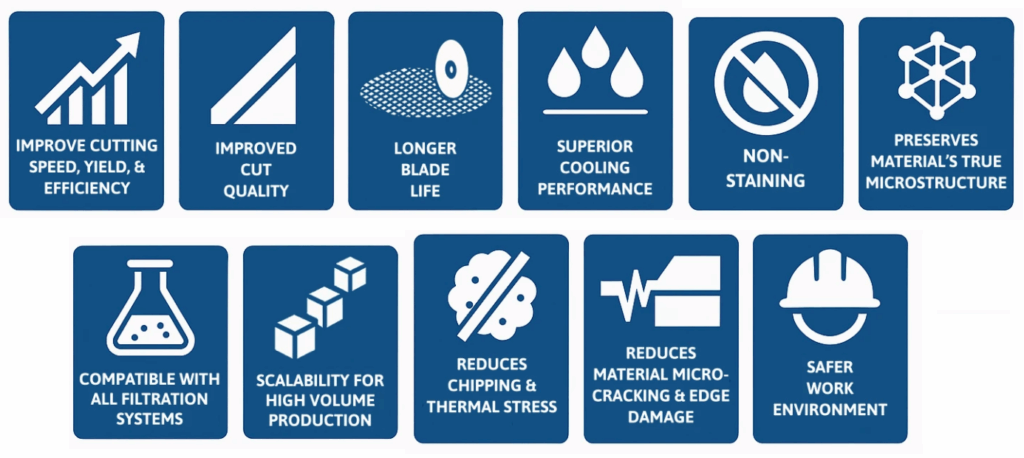

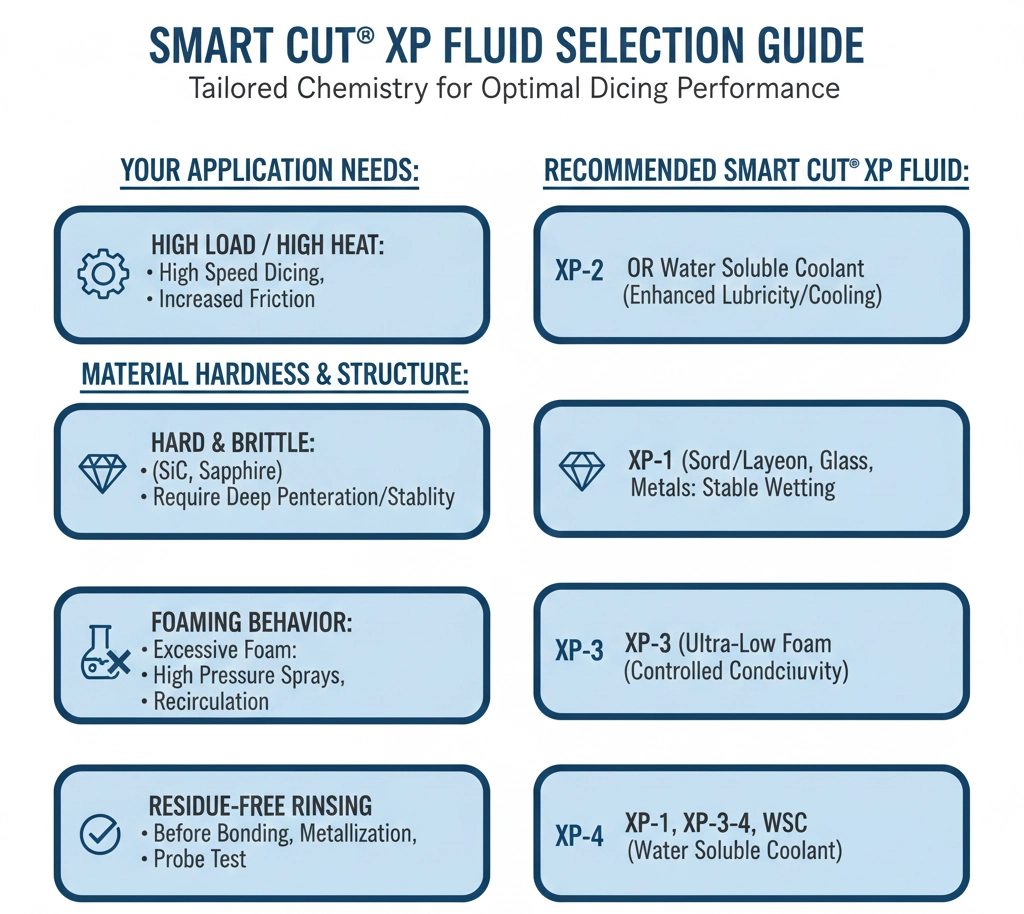

Selecting the correct dicing surfactant / fluid is essential for stable cutting, consistent kerf quality, and long blade life. Each operation places specific demands on lubrication, cooling, foaming control, and electrostatic behavior. You must choose a fluid that matches your material type, blade bond, spindle speed, feed rate, and production environment. The SMART CUT XP series and the SMART CUT Water Soluble Coolant provide targeted solutions for these requirements. Selecting the correct fluid improves yield, reduces defects, and strengthens overall process control.

Table of Contents

Toggle

What Are SMART CUT® XP Series Fluids?

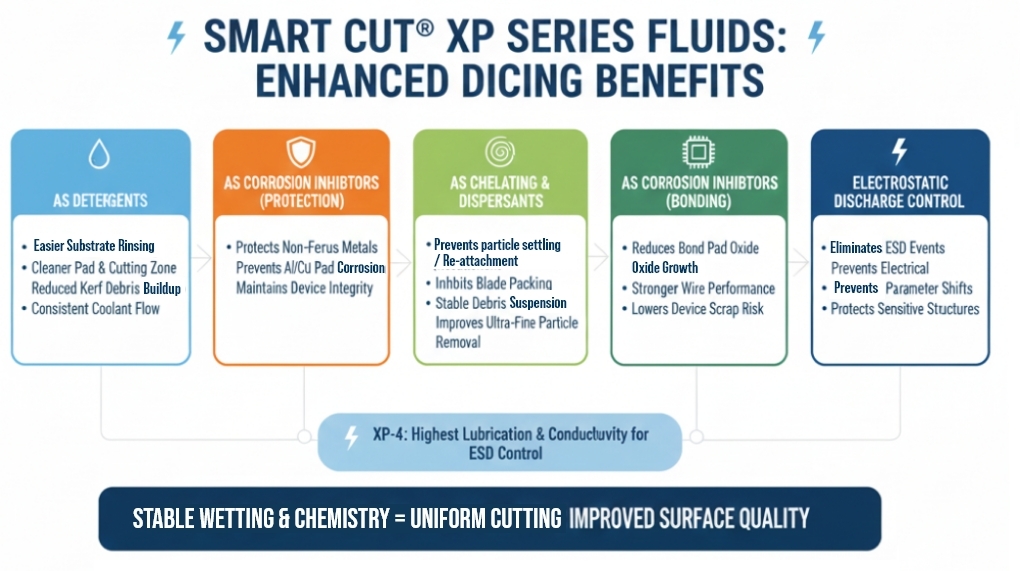

SMART CUT® XP Series fluids are advanced chemical formulations engineered for high precision wafer dicing, back-grinding, MEMS fabrication, optical processing, and advanced ceramic cutting. They enter the process through the saw coolant line and maintain stable performance throughout all stages of cutting and polishing. Each formulation combines the functions of detergent, corrosion inhibitor, chelating agent, and particle dispersant in a single balanced solution. This provides uniform wetting, cleaner blade interaction, and consistent cutting conditions at the blade interface.

The fluids enhance lubrication, stabilize cooling efficiency, and maintain reliable debris transport out of the kerf. This reduces abrasive loading, lowers friction spikes, and limits heat generation. By keeping the interface clean and predictable, they support accurate dimensional control, smooth surface finishes, and stable kerf geometry. SMART CUT® XP formulations are suitable for electronic materials, compound semiconductors, bonded wafers, optical substrates, and engineered ceramics. They maintain chemical stability in DI water, making them well suited for production environments that require repeatable results, low variability, and clean post-cut surfaces.

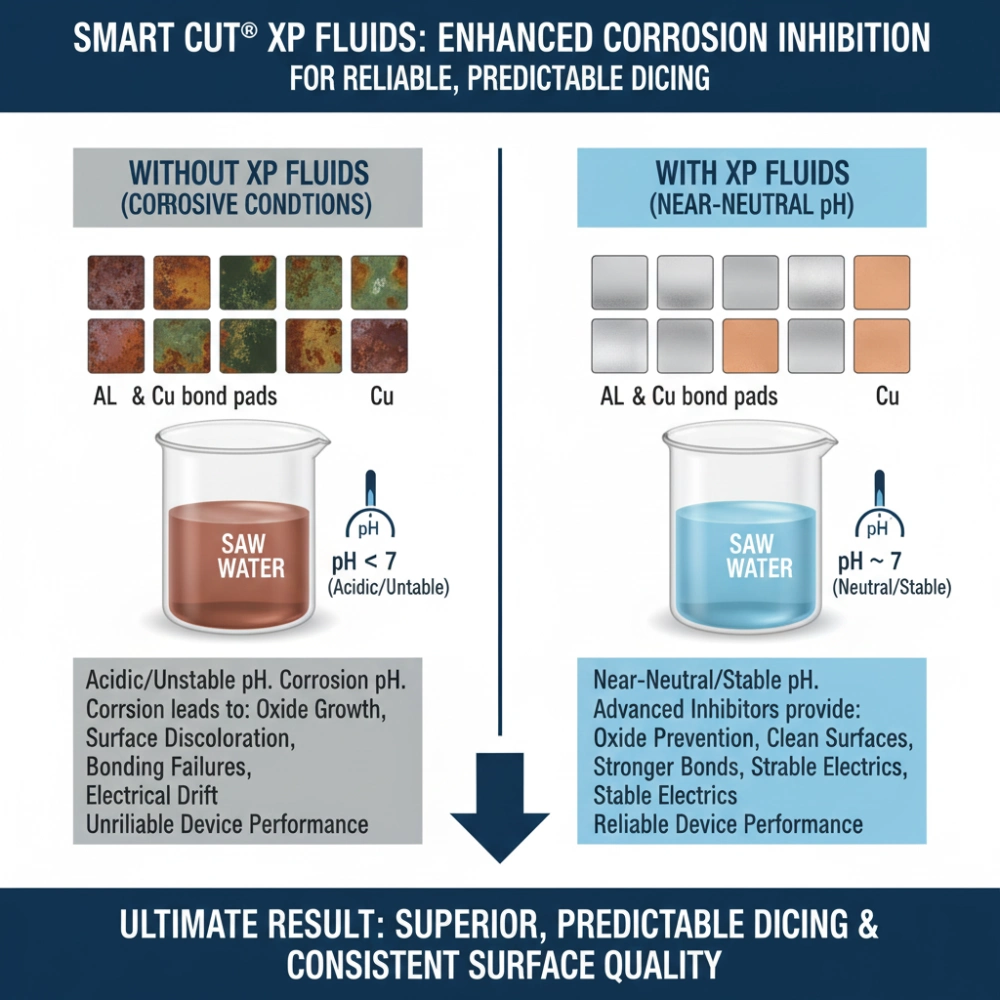

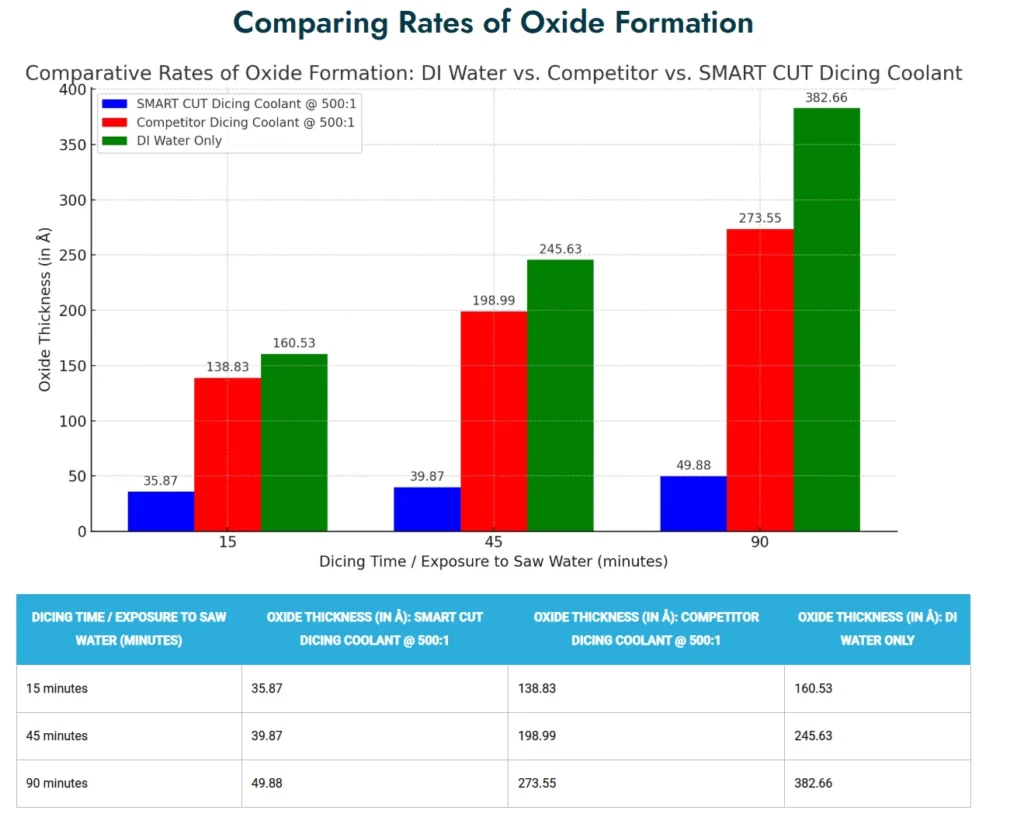

SMART CUT® XP fluids deliver a broad set of critical performance advantages. They make the substrate easier to rinse after cutting and keep the pad, chuck, and cutting zone cleaner from one cycle to the next. They reduce debris accumulation inside the kerf, supporting consistent coolant flow, stronger heat removal, and more stable blade loading. They protect exposed metals by preventing staining and oxidation, including Al and Cu bond pads, where the fluids slow oxide formation and help maintain device integrity during extended or high-temperature operations.

As chelating agents and dispersants, the fluids prevent particles from settling or reattaching to the wafer. They stop debris from packing into the blade matrix and maintain a stable suspension of fine particles, resulting in cleaner kerfs, smoother sidewalls, and improved removal of ultra-fine particles in narrow streets. They also limit oxide growth on metallization, which supports stronger wire bond performance, reduces bonding failures, and lowers the risk of device scrap caused by pad discoloration or chemical residue.

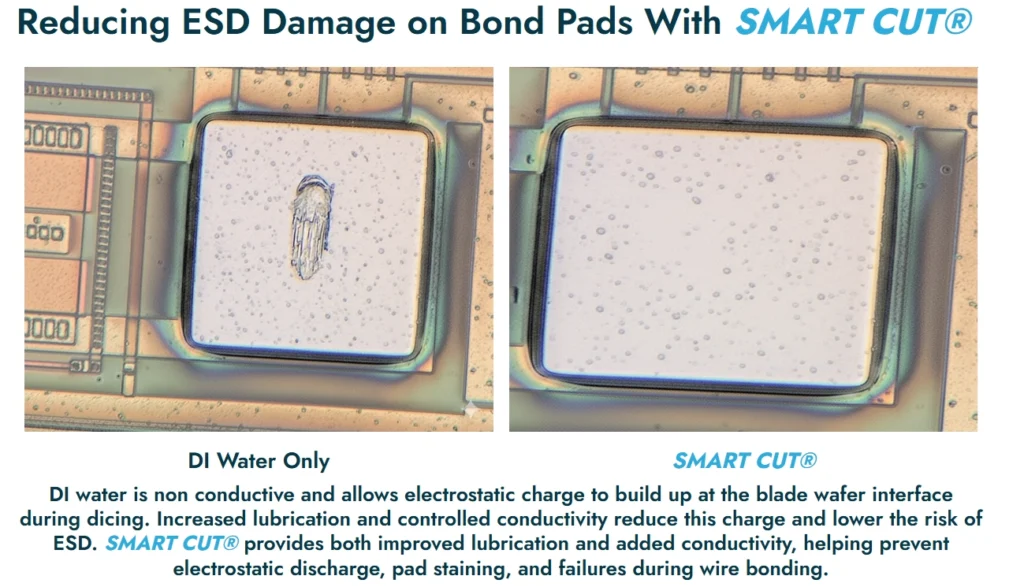

SMART CUT® XP fluids also provide strong electrostatic discharge (ESD) control. They reduce or eliminate ESD events at the blade and wafer interface and prevent electrical parameter shifts that can damage sensitive device structures. This added conductivity protects delicate components during cutting and also during post-processing where charge buildup can occur. SMART CUT® XP-4 delivers the highest lubrication and the strongest conductivity in the series, making it the recommended choice for applications where ESD suppression is critical and process stability must be maintained at all times.

How SMART CUT® Coolant Interacts With Water and Material During Cutting

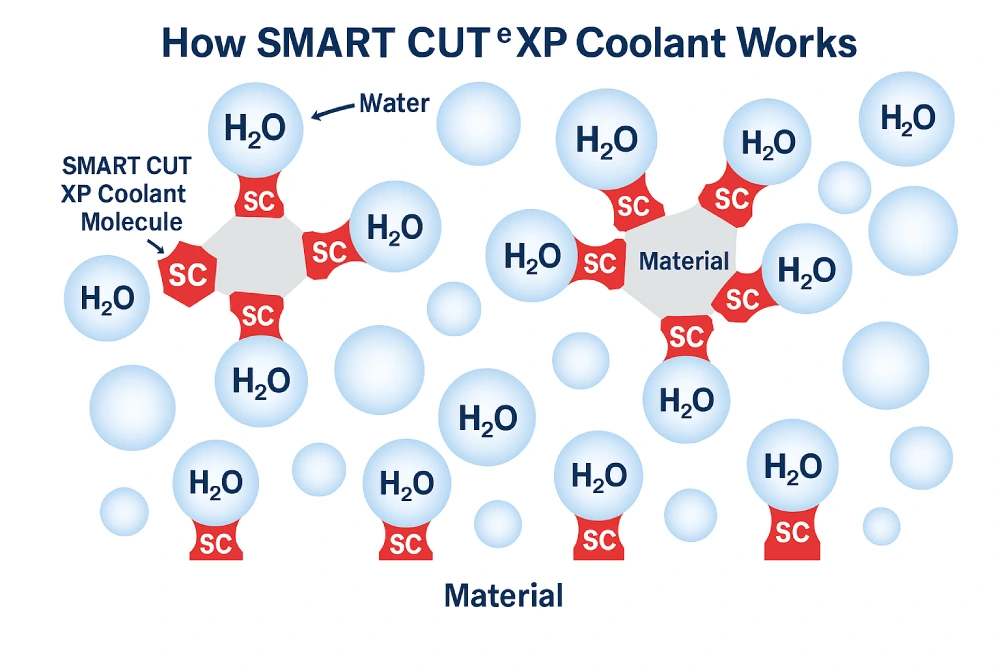

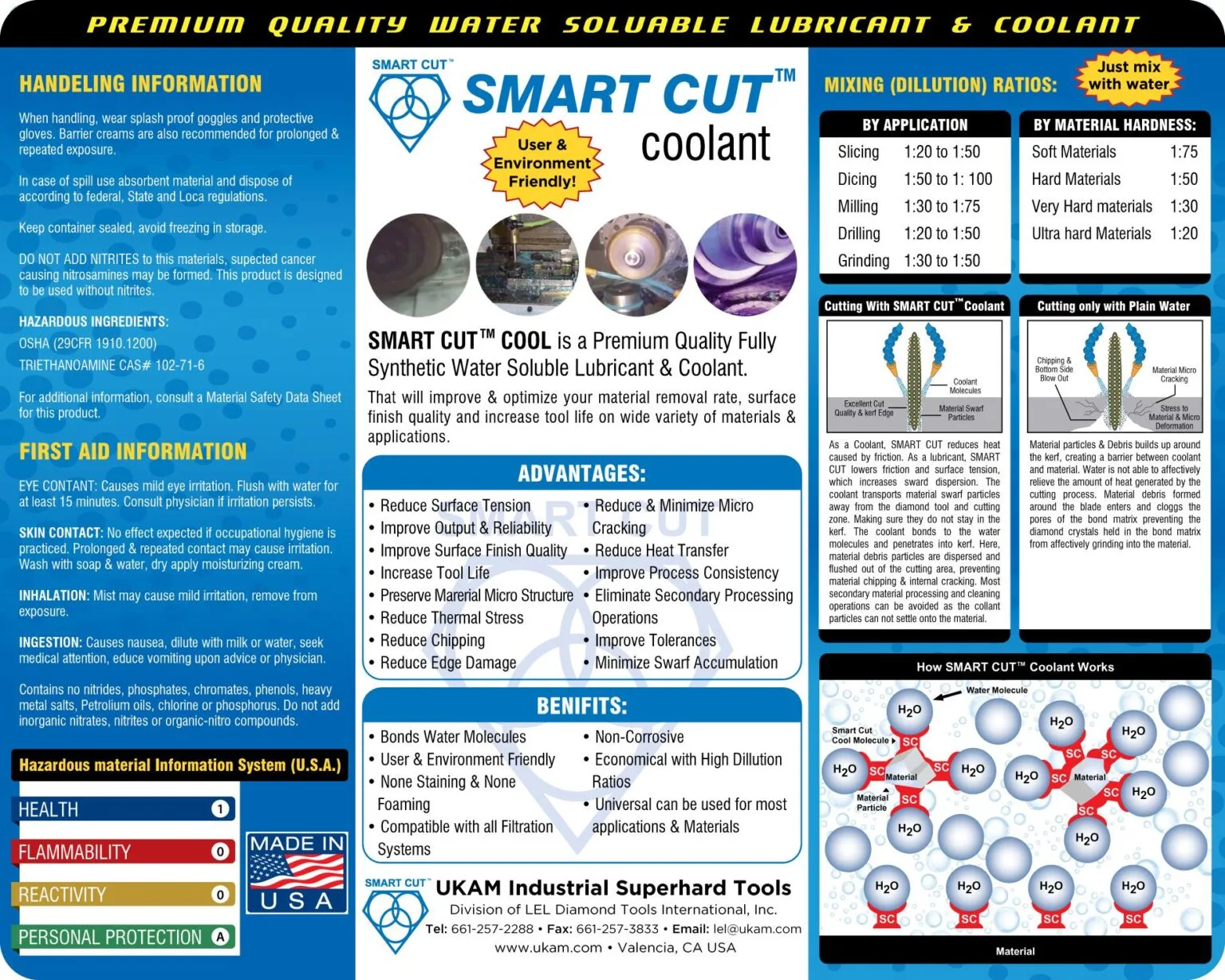

SMART CUT coolant works by attaching to both water molecules and the surface of the material being cut. Each coolant molecule has an affinity for water and for solid surfaces. When mixed with water, the coolant forms a uniform layer that surrounds water clusters and bonds to exposed material particles. This creates a stable interface between the blade, the fluid, and the material.

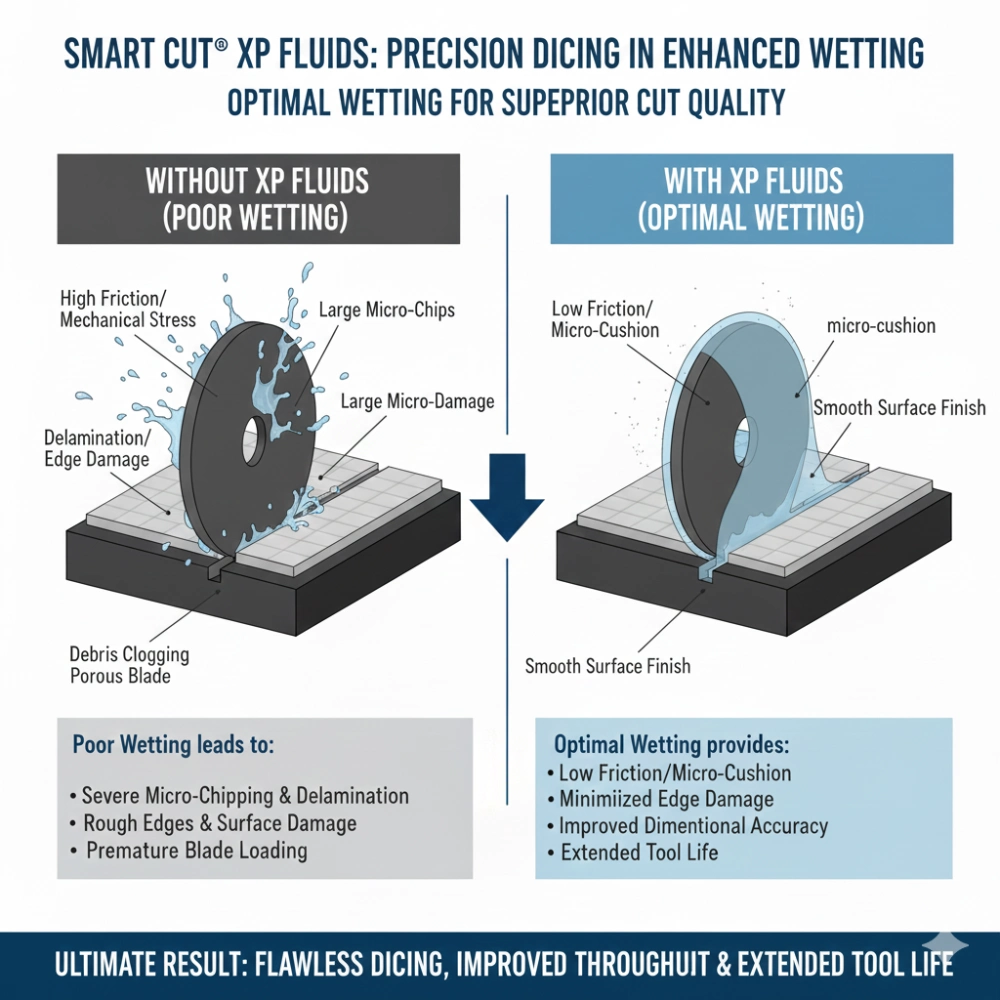

The coolant layer reduces friction at the contact point. It improves wetting so the fluid can reach deep into the kerf and maintain consistent coverage. This helps the blade cut with lower resistance and keeps temperatures under control. The coolant also suspends loose particles. It prevents fines from reattaching to the blade or the material and allows debris to move out of the cutting zone.

This mechanism improves cleaning of the kerf, supports smooth chip evacuation, and promotes steady lubrication. It minimizes heat buildup and reduces micro-chipping. By stabilizing fluid behavior at the point of contact, SMART CUT coolant maintains predictable cutting forces and helps extend tool life.

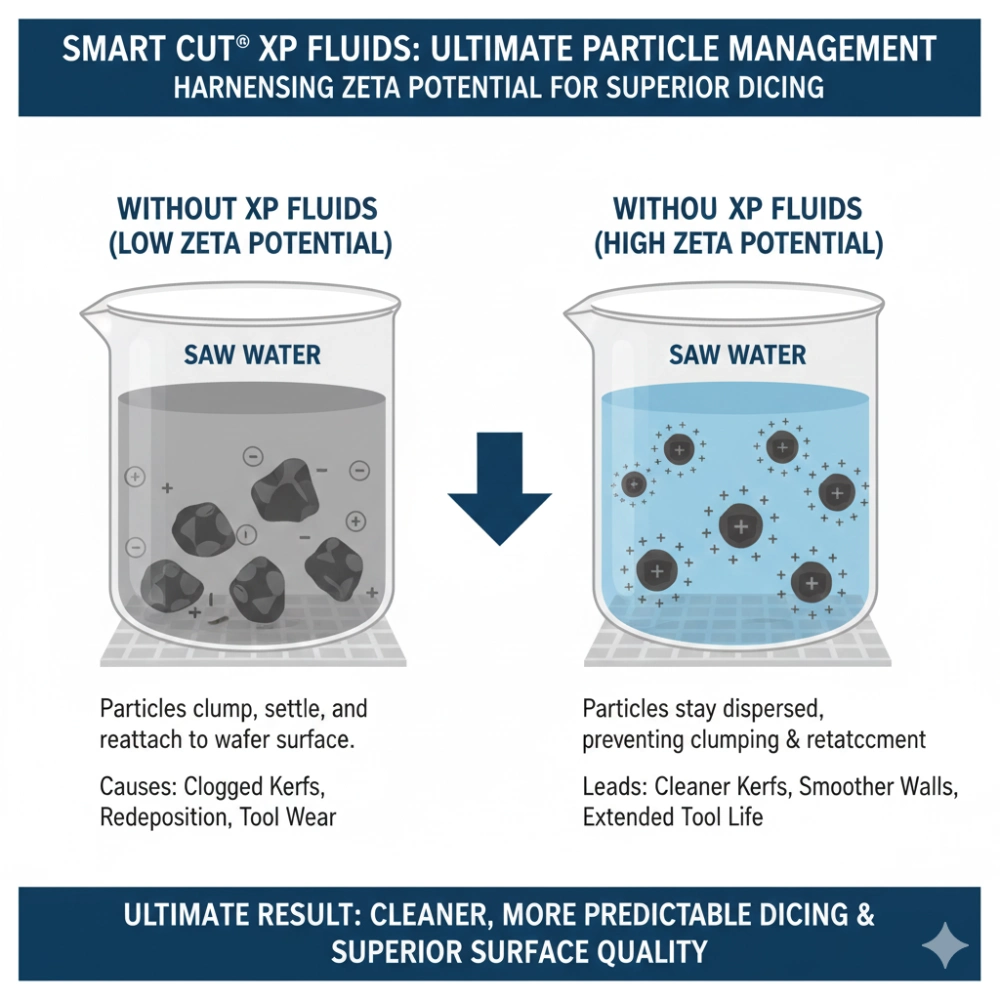

SMART CUT® XP fluids raise the zeta potential of particles suspended in saw water, which increases the natural repulsion between particles. When the zeta potential is high, debris stays dispersed instead of clumping, settling, or reattaching to the wafer surface.

This improves stability inside the cutting zone and keeps the process cleaner and more predictable. A higher zeta potential supports cleaner kerfs, smoother street walls, lower redeposition of ultra-fine particles, and better blade exposure with reduced abrasive loading. These conditions help maintain consistent cutting forces and extend tool life.

The solution maintains a near-neutral pH, protecting delicate materials and ensuring stable chemistry during long cutting runs. SMART CUT® XP fluids contain advanced corrosion inhibitors that make the coolant fully non-corrosive to the metal alloys commonly used in semiconductor packaging. This prevents oxide growth on Al and Cu bond pads, stops surface discoloration, and reduces bonding failures caused by corrosion-driven contamination. Consistent surface protection also limits electrical parameter drift and helps maintain reliable device performance, even under high-temperature or extended recirculation conditions.

The surfactants in SMART CUT® XP fluids are selected for strong wetting of MEMS structures, glass, LEDs, IC materials, and advanced ceramics. Enhanced wetting lowers friction, provides a thin organic micro-cushion at the blade interface, and reduces mechanical stress during cutting. This minimizes micro-chipping, delamination, and other forms of edge damage. Stable wetting also keeps wheels and blades cutting freely, slows loading, and improves the overall smoothness and dimensional accuracy of the finished surface.

SMART CUT® XP fluids also increase the conductivity of DI water to help dissipate electrostatic charge before it accumulates to harmful levels. This reduces the risk of ESD at the blade and wafer interface, prevents shifts in threshold voltage, and minimizes electrical instability during downstream testing. Unlike CO₂ bubblers, the added conductivity does not introduce acids, avoiding corrosion or oxide growth associated with carbonic acid formation.

In addition, SMART CUT® XP fluids have very low Chemical Oxygen Demand (COD) values. This makes them among the cleanest and most environmentally responsible coolants available for precision dicing. Their low COD profile helps reduce waste treatment costs, lowers environmental impact, and supports smoother compliance with facility-level discharge requirements.

How to Select the Right SMART CUT® XP Series Fluids

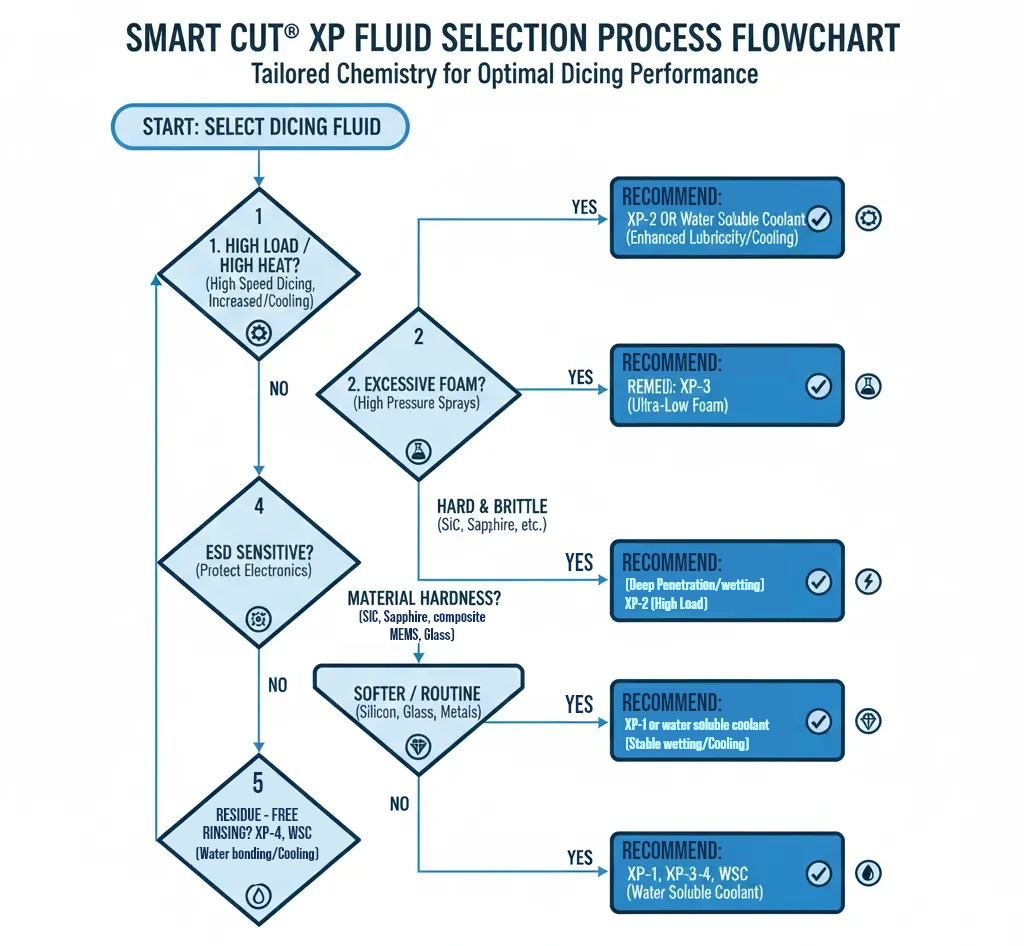

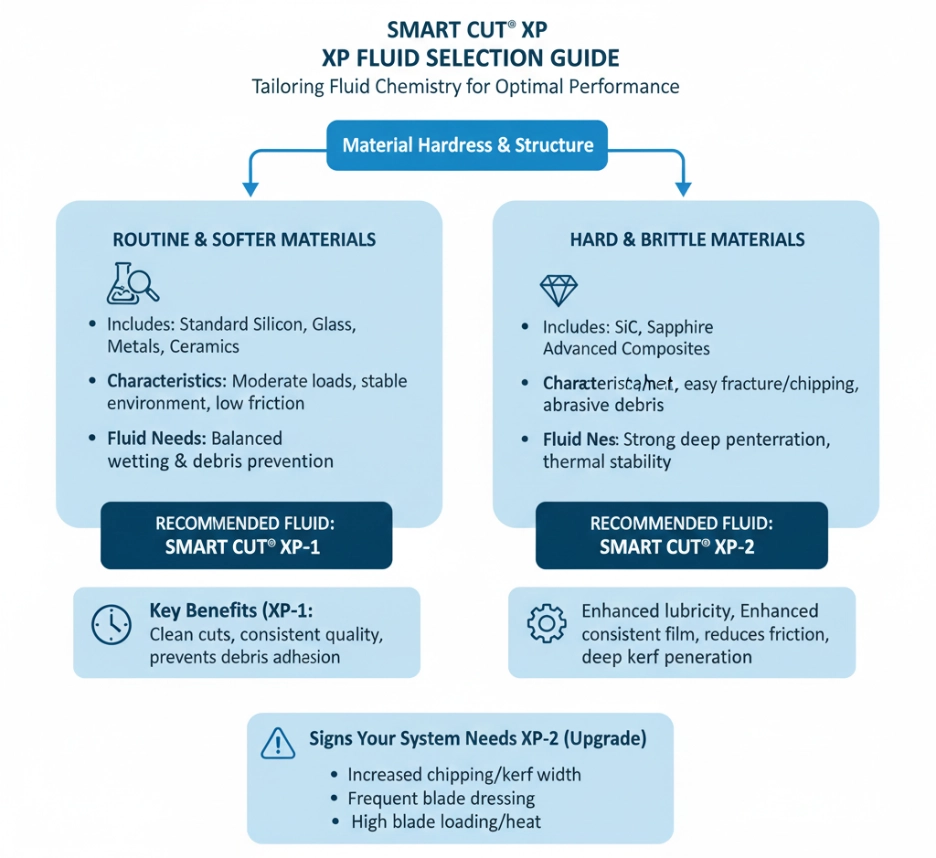

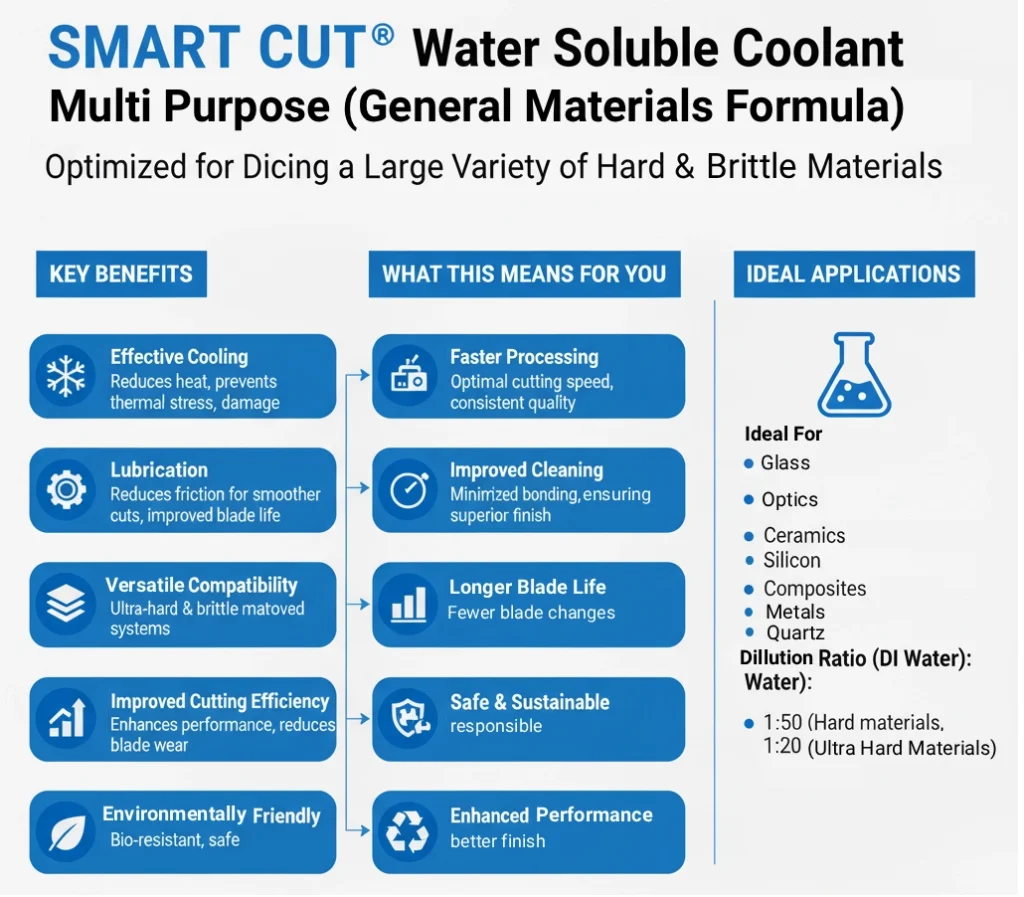

Start by evaluating the cutting load and thermal behavior. High load and high speed cutting generate more friction and heat. These conditions require stronger lubrication and a coolant that can manage temperature at the blade interface. SMART CUT XP-2 is suited for these conditions because it increases lubrication and stabilizes the cutting zone. The SMART CUT Water Soluble Coolant (General Materials Formula) also supports thermal control. It removes heat efficiently, reduces friction, and helps prevent thermal stress, cracking, and edge damage. You use it when you need clean cooling and lubrication on materials such as ceramics, optics, quartz, silicon, composites, and metals.

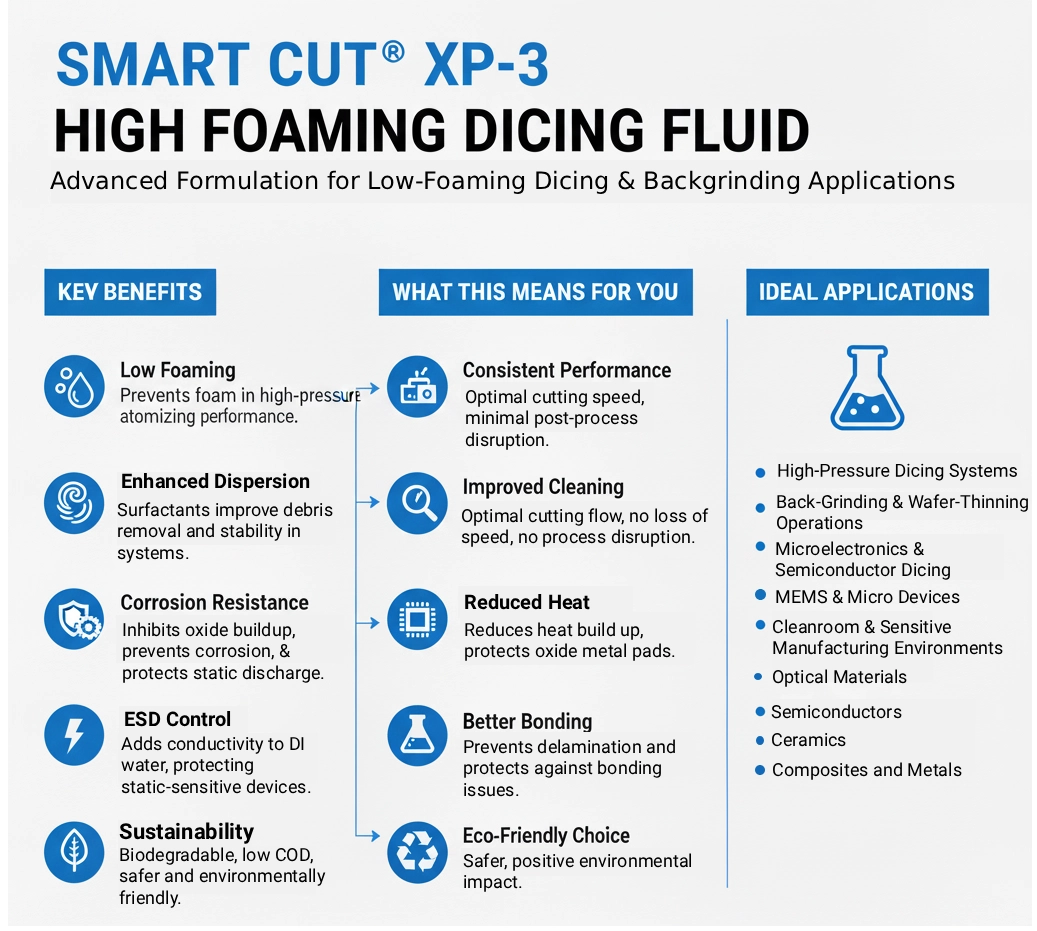

Foaming behavior is also important. Foam disrupts fluid delivery and reduces cooling efficiency. High pressure spray systems and recirculating tanks often generate foam. XP-3 prevents this by providing very low foam. It maintains stable fluid flow into the kerf and supports consistent blade engagement.

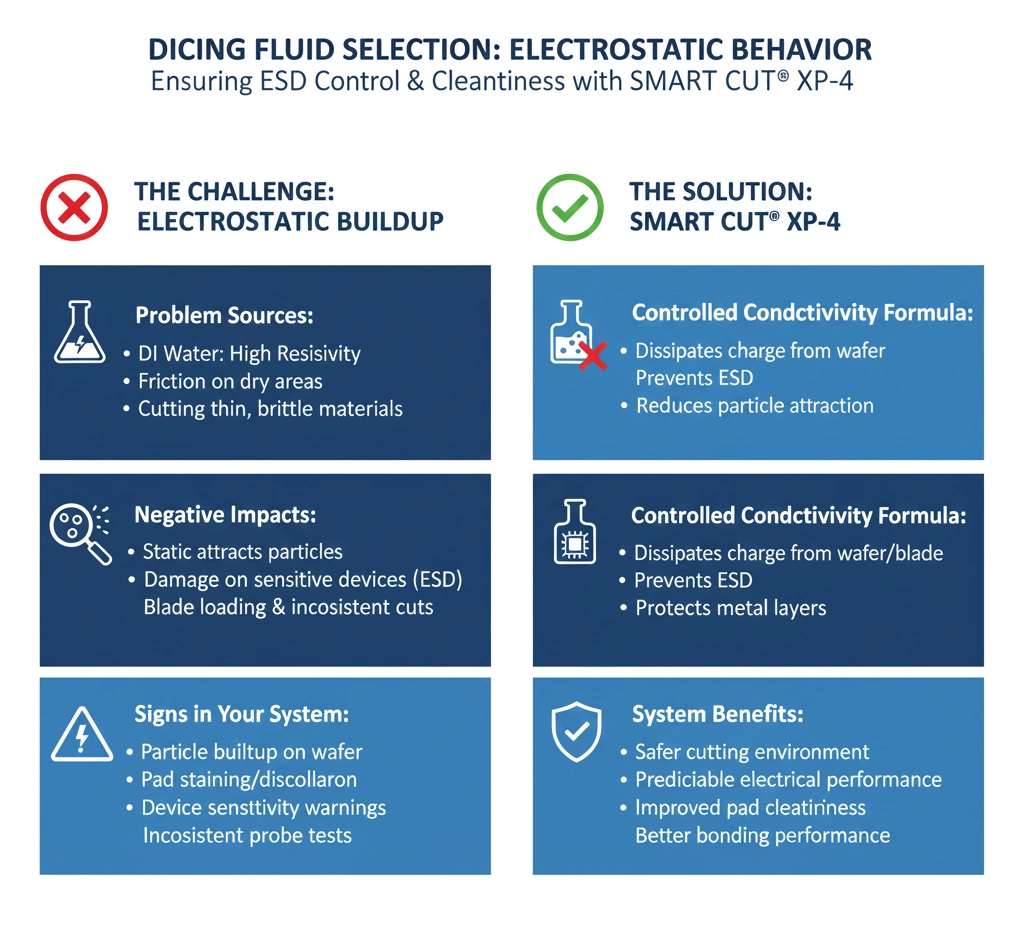

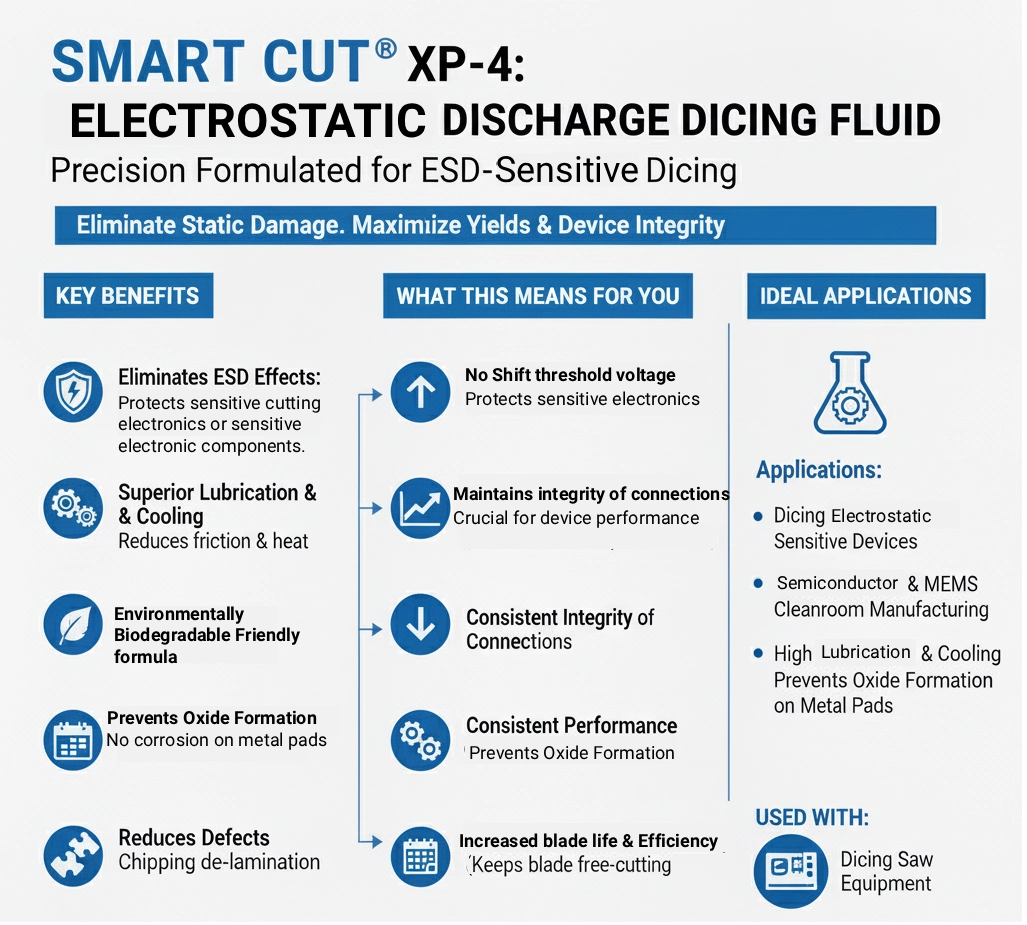

Electrostatic sensitivity is another factor. DI water alone has high resistivity. This allows static charge to build up on wafers, blades, and equipment. Static attracts particles and increases the risk of pad staining and electrical defects. XP-4 corrects this by supplying controlled conductivity. It protects sensitive materials such as semiconductors, ICs, MEMS, and microelectronics.

General materials that do not require enhanced lubrication, foam reduction, or static control perform well with XP-1 or SMART CUT Water Soluble Coolant. XP-1 is suitable for routine dicing of ceramics, glass, semiconductors, and thin metals. SMART CUT Water Soluble Coolant also performs well on these materials. It increases blade life and supports smoother cuts. You mix the coolant with DI water at a dilution ratio of 1:20 to 1:50. Hard materials such as silicon carbide require a ratio near 1:50. Ultra hard materials such as sapphire require a stronger mixture near 1:20.

Material hardness and structure have a direct impact on selection. Hard and brittle materials require strong lubrication and deep fluid penetration to prevent micro chipping and maintain kerf accuracy. Softer or thinner materials require stable wetting and consistent cooling. XP-1 and SMART CUT Water Soluble Coolant meet these needs. XP-2 supports higher friction conditions found in advanced ceramics and composites. XP-3 maintains flow stability in high pressure systems. XP-4 provides static control for electrostatic sensitive devices.

Cutting speed should also be reviewed. High speed dicing increases thermal load and requires a fluid with strong lubrication and stable flow. XP-2 performs best in these conditions. Lower speed or low load cutting works well with XP-1 or SMART CUT Water Soluble Coolant, which maintain clean edges and support predictable flushing.

Downstream cleanliness requirements influence your choice as well. Some operations require a fluid that leaves no residue before bonding, metallization, or probe testing. SMART CUT Water Soluble Coolant, XP-1, and XP-3 rinse clean and support contamination-free surfaces. XP-4 offers the same rinsing behavior with the added benefit of static control.

SMART CUT® Dicing Fluid

Available in 4 Different Formulas to Fit Most Dicing Applications

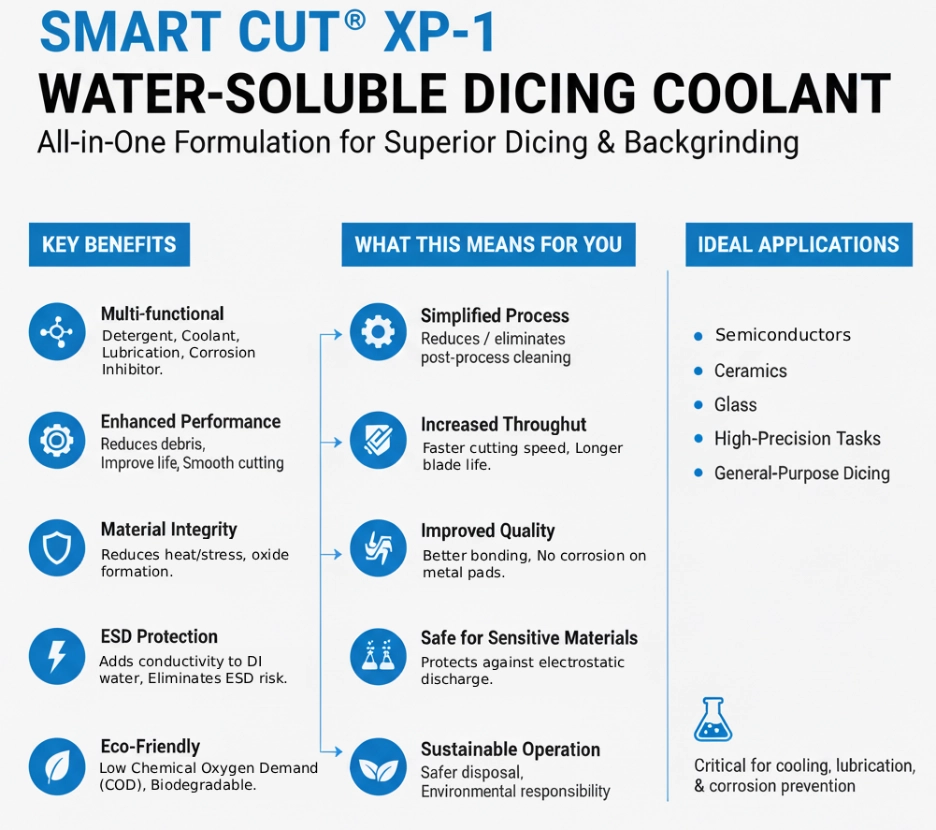

XP-1 is a general-purpose dicing fluid within the SMART CUT® range, designed to reduce debris, improve tool life, and prevent corrosion, while ensuring smooth cutting and protecting sensitive materials from ESD.

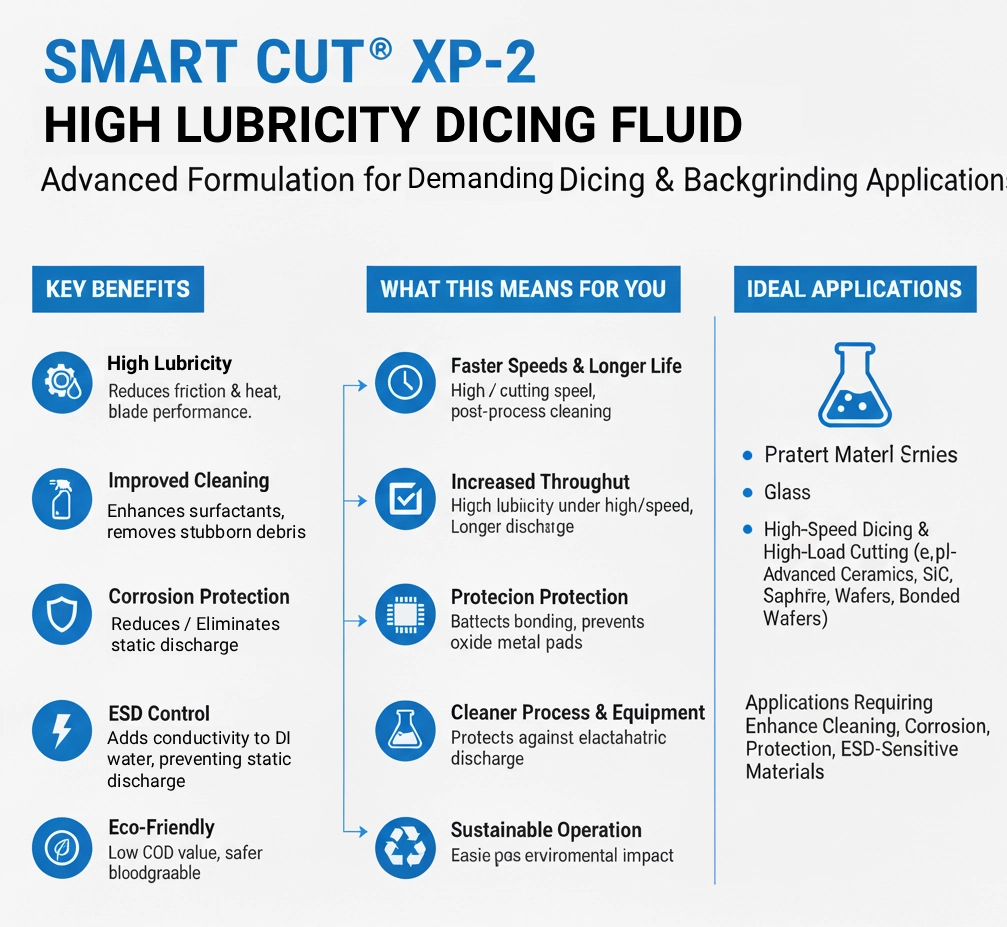

XP-2 enhances lubrication for demanding applications, offering superior cutting speeds, tool longevity, and advanced cleaning capabilities for tough materials like SiC and sapphire.

XP-3 is ideal for high-pressure systems, offering consistent cooling performance without foam buildup.

XP-4 specifically protects electrostatic-sensitive components by eliminating ESD, reducing defects, and extending tool life during the dicing process.

SMART CUT Coolant (General Materials Formula) – versatile, general-purpose coolant, used for dicing ultra hard and brittle materials such as ceramics, optics, quartz, silicon, and other hard materials.

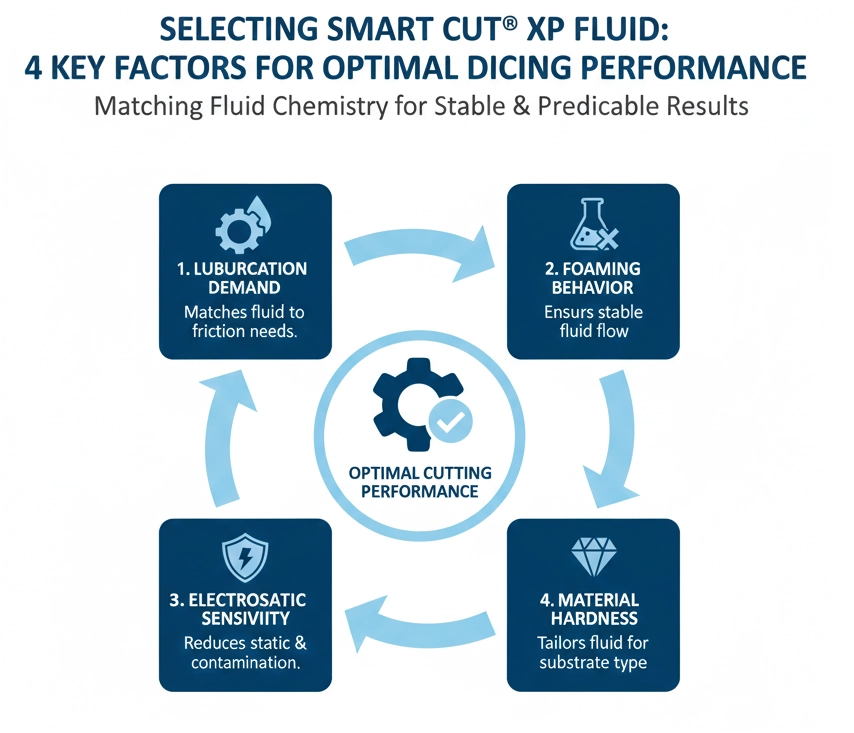

Selecting the correct fluid improves blade life, reduces kerf variation, lowers micro chipping, and stabilizes heat removal. Evaluate lubrication demand, foaming behavior, electrostatic sensitivity, and material hardness. These factors guide you toward the correct SMART CUT dicing fluid for your application.

Selecting the correct dicing fluid requires a clear understanding of your cutting environment. Each operation places different demands on lubrication, foaming behavior, electrostatic control, and material stability. You should evaluate these factors before choosing the proper SMART CUT XP formulation.

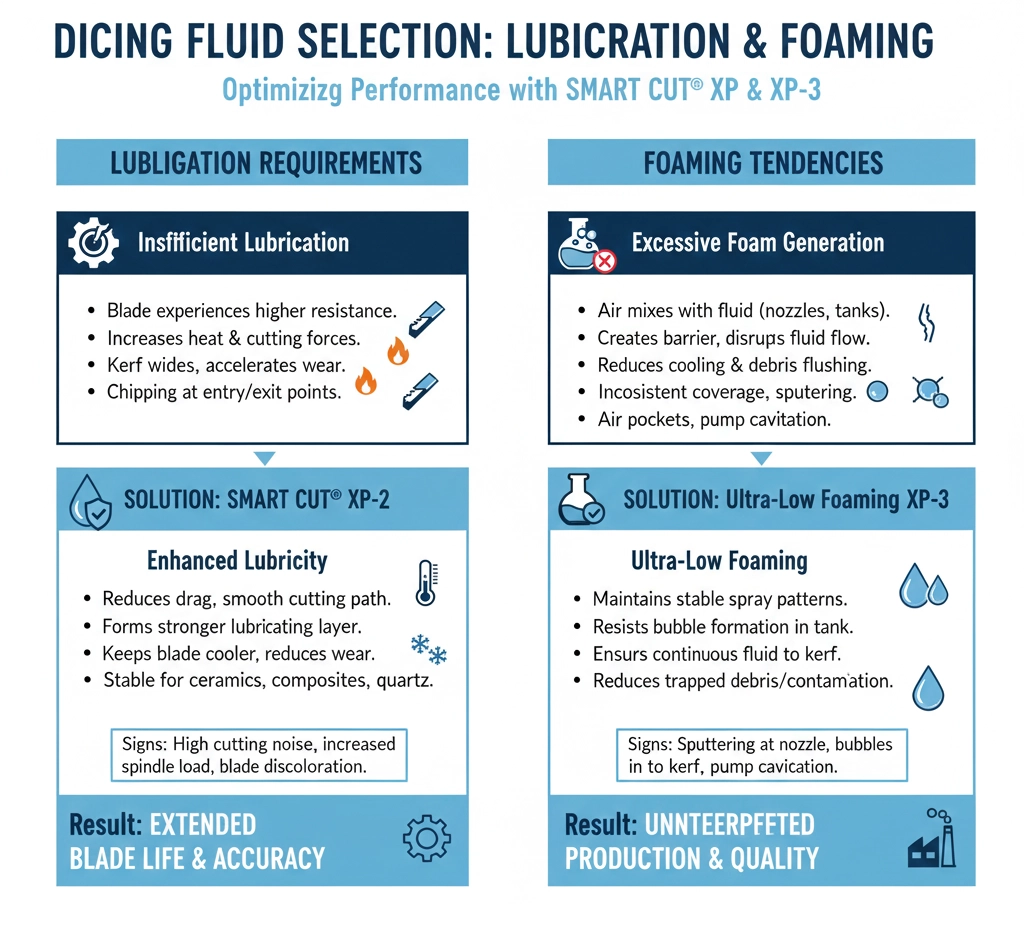

Lubrication Requirements

Begin by reviewing lubrication requirements. Lubrication controls how freely the blade enters the material and how stable the cutting zone remains during operation. When lubrication is insufficient, the blade experiences higher resistance. This increases heat, raises cutting forces, and causes the kerf to widen. Poor lubrication also accelerates blade wear and increases the risk of chipping at the entry and exit points of the cut.

High load cutting places significant stress on the blade. The contact area between the blade and the material becomes larger, and the blade must remove more material per revolution. This produces greater friction and demands a fluid that can maintain a stable film between the blade and the substrate. High speed cutting increases heat even further. At elevated spindle speeds, the blade generates more friction and the temperature rises quickly. Without proper lubrication, thermal stress accumulates and the cut becomes unstable.

These conditions require a fluid with enhanced lubricity to reduce drag on the blade and maintain a smooth cutting path. A high lubricity fluid allows the diamond edge to engage the material cleanly. It limits friction spikes and prevents sudden changes in cutting pressure. It also helps preserve blade geometry, which is essential for maintaining narrow kerf widths and uniform edge quality across long production runs.

When friction increases or the thermal load becomes difficult to manage, XP-2 becomes the correct choice. XP-2 contains additives that reduce resistance at the cutting interface. It forms a stronger lubricating layer, keeps the blade cooler, and reduces wear on the diamond bond. This leads to more uniform cutting forces and more consistent kerf accuracy. XP-2 also stabilizes the cutting interface during heavy slicing of advanced ceramics, composites, quartz, and other difficult materials.

If you observe signs such as higher cutting noise, increased spindle load, blade discoloration, or reduced cut quality, it indicates that the current fluid is not providing enough lubrication. Switching to XP-2 helps restore stable cutting performance. It maintains smoother blade entry, reduces thermal shock, and supports a longer blade life under demanding conditions.

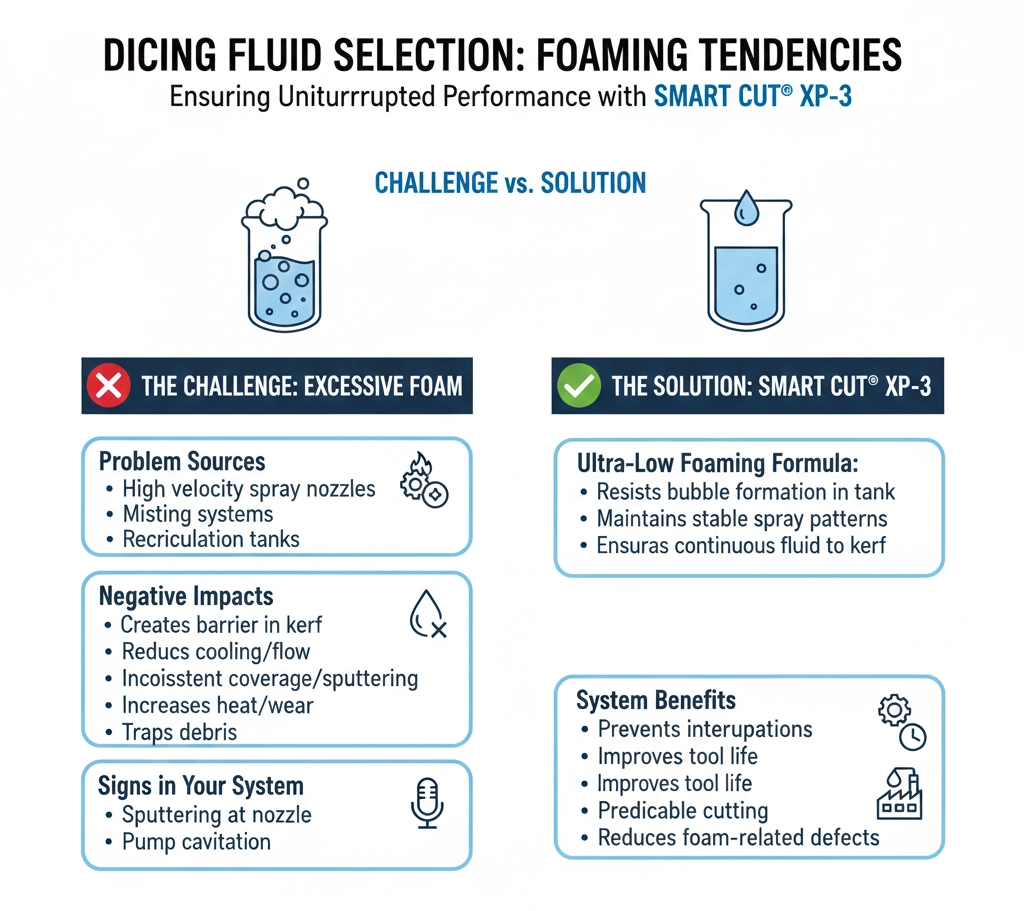

Next, examine foaming tendencies in your system. Foam develops when air mixes with the dicing fluid under high velocity or turbulence. High pressure spray nozzles, fine misting systems, and recirculating tanks are common sources of this problem. When foam forms, it creates a barrier between the fluid and the cutting zone. This barrier prevents the solution from reaching the kerf and reduces its ability to cool and flush debris.

Foam also affects the stability of the cutting process. It changes how the fluid enters the kerf and causes inconsistent coverage. You may see irregular spray patterns, sudden bursts of fluid, or areas where the blade is exposed without adequate cooling. These conditions increase heat, raise cutting forces, and make the blade work harder. Over time, foam contributes to chipping, wider kerfs, and faster blade wear.

In recirculating systems, foam can accumulate inside the tank. This reduces the available volume of usable fluid and causes the pump to draw in air. Air pockets lower flow pressure and reduce the effectiveness of the coolant stream. If you hear pump cavitation, notice sputtering at the nozzle, or see bubbles entering the kerf, your fluid is producing too much foam.

Foam also carries trapped debris. When foam collapses, this debris can fall back onto the wafer surface. This increases contamination and makes downstream cleaning more difficult. High foam levels can also interfere with sensors and fluid level controls in automated dicing equipment.

If you observe unstable flow, air pockets, or inconsistent cooling, you require a fluid with very low foam. XP-3 is formulated for these conditions. It maintains stable spray patterns even at high pressures. It resists bubble formation inside the tank. It keeps the kerf clear and ensures that the fluid reaches the blade continuously. This stability is essential in production environments where long cutting cycles and uninterrupted flow are required.

Using XP-3 reduces interruptions, improves tool life, and maintains predictable cutting performance. It allows your equipment to run at full efficiency and prevents foam-related defects that affect throughput and wafer quality.

Foaming Tendencies

Next, examine foaming tendencies in your system. Foam develops when air mixes with the dicing fluid under high velocity or turbulence. High pressure spray nozzles, fine misting systems, and recirculating tanks are common sources of this problem. When foam forms, it creates a barrier between the fluid and the cutting zone. This barrier prevents the solution from reaching the kerf and reduces its ability to cool and flush debris.

Foam also affects the stability of the cutting process. It changes how the fluid enters the kerf and causes inconsistent coverage. You may see irregular spray patterns, sudden bursts of fluid, or areas where the blade is exposed without adequate cooling. These conditions increase heat, raise cutting forces, and make the blade work harder. Over time, foam contributes to chipping, wider kerfs, and faster blade wear.

In recirculating systems, foam can accumulate inside the tank. This reduces the available volume of usable fluid and causes the pump to draw in air. Air pockets lower flow pressure and reduce the effectiveness of the coolant stream. If you hear pump cavitation, notice sputtering at the nozzle, or see bubbles entering the kerf, your fluid is producing too much foam.

Foam also carries trapped debris. When foam collapses, this debris can fall back onto the wafer surface. This increases contamination and makes downstream cleaning more difficult. High foam levels can also interfere with sensors and fluid level controls in automated dicing equipment.

If you observe unstable flow, air pockets, or inconsistent cooling, you require a fluid with very low foam. XP-3 is formulated for these conditions. It maintains stable spray patterns even at high pressures. It resists bubble formation inside the tank. It keeps the kerf clear and ensures that the fluid reaches the blade continuously. This stability is essential in production environments where long cutting cycles and uninterrupted flow are required.

Using XP-3 reduces interruptions, improves tool life, and maintains predictable cutting performance. It allows your equipment to run at full efficiency and prevents foam-related defects that affect throughput and wafer quality.

Electrostatic Behavior

Electrostatic behavior is another key factor when selecting a dicing fluid. DI water has very high resistivity. This means it does not conduct electrical charge. As a result, static builds up on the wafer surface, blade edge, and surrounding machine components during cutting. This buildup becomes stronger when cutting dry areas, thin structures, or brittle materials that generate friction. Without proper control, these charges accumulate to levels that can damage sensitive devices.

Static attracts fine particles to the wafer surface. These particles adhere to bond pads, channels, and exposed metal layers. Once attached, they can be difficult to remove. This contamination increases the risk of false electrical readings, bonding failures, and defects during probe testing. Static also causes fine debris to cling to the blade, which increases loading and reduces cut consistency.

If you cut ESD-sensitive components, the risks increase further. Semiconductors, ICs, MEMS, image sensors, and microelectronics can suffer electrical damage from even small static discharges. These defects may not appear immediately. They can show up later during packaging, final testing, or field operation. This makes static control essential for modern high-density devices.

To prevent this, you must use a fluid with controlled conductivity. A conductive dicing fluid dissipates charge from the wafer and blade. It creates a safe path for charge to move through the fluid instead of accumulating on device surfaces. This protects delicate structures, reduces particle attraction, and stabilizes the cutting environment.

XP-4 is formulated for these requirements. It provides controlled conductivity while maintaining proper wetting and cooling. It limits charge growth during cutting and prevents sudden electrostatic discharge. XP-4 also protects exposed metal layers from charge-related staining and discoloration. This improves pad cleanliness and supports better bonding performance.

If you observe particle buildup, pad staining, device sensitivity warnings, or inconsistent probe test results, your process may require stronger ESD control. In these cases, XP-4 ensures safer cutting and more predictable electrical performance during and after the cut.

Material Hardness & Structure

You must also consider the hardness and structure of your materials. Material properties determine how much stress the blade experiences during cutting. Hard and brittle substrates generate higher cutting forces. They fracture easily and require stable lubrication, strong wetting, and deep penetration of the dicing solution. Without proper fluid support, these materials chip at the edges, produce irregular kerfs, and place unnecessary load on the blade.

Hard materials such as silicon carbide, sapphire, quartz, advanced ceramics, and technical composites require a fluid that maintains a consistent film on the blade. This film reduces friction, removes heat, and prevents the blade from binding in the kerf. These materials also create fine abrasive debris during cutting. The dicing fluid must reach the full depth of the kerf to flush debris away. Poor penetration causes debris packing, blade loading, and premature wear.

Layered or brittle structures such as MEMS wafers, glass laminates, and thin silicon require careful fluid selection. These materials crack under uneven thermal loads. They also respond poorly to dry spots or inconsistent wetting. A fluid that spreads evenly across the surface and enters narrow geometries helps maintain cleaner edges and prevents micro fractures.

Softer or routine materials place fewer demands on the fluid. Common ceramics, thin metals, glass, and standard silicon wafers need only standard wetting and consistent cooling. These materials do not generate the same friction levels as ultra hard substrates. They respond well to fluids that maintain stable temperature and support predictable flushing. For these situations, XP-1 provides reliable performance. It supports general purpose dicing without the need for special additives or enhanced properties.

SMART CUT® XP-1

Standard Dicing Fluid

SMART CUT® XP-1 is effective when the cutting environment is stable. Use it when you do not observe excessive heat buildup, high blade loading, or debris adhesion. It provides balanced lubrication and wetting for everyday production. It helps maintain clean kerfs and consistent cut quality across a wide range of standard materials.

If you begin cutting harder or more brittle materials and notice increased chipping, wider kerfs, or more frequent blade dressing, you may need a higher performance fluid such as SMART CUT® XP-2 or an alternative formulation. Evaluating the hardness and structure of your materials allows you to choose the correct fluid and maintain stable, repeatable results.

SMART CUT® XP-1 is used when the process is consistent and the cutting load is moderate. XP-2 is selected when friction and heat rise. XP-3 is used when foam disrupts fluid delivery. XP-4 is chosen when static control is necessary. Evaluating these four factors allows you to choose the correct SMART CUT XP fluid and ensures stable, predictable cutting performance.

SMART CUT® XP-1 is a water-soluble dicing coolant engineered to deliver stable, predictable performance in routine semiconductor dicing and backgrinding operations. The formulation provides consistent cooling, balanced lubrication, and clean kerf formation, helping you maintain uniform cut quality from the first wafer to the last. XP-1 keeps cutting forces steady, reduces blade drag, and limits chipping, resulting in smoother edges and extended tool life.

The detergent action is one of the core strengths of SMART CUT® XP-1. The fluid lifts debris from the cutting zone and keeps particles suspended so they can be flushed away effectively. This keeps the blade free-cutting throughout long production runs. A cleaner cutting path produces less heat, less mechanical stress, and fewer micro-fractures in brittle materials. Many users find that XP-1 reduces or eliminates post-process cleaning, improving workflow efficiency. Cleaner wafers also support better downstream results in inspection, bonding, and final device assembly.

XP-1 contains corrosion inhibitors that protect exposed metals during cutting. This prevents oxide growth on bond pads, minimizes discoloration, and maintains reliable electrical connectivity. By reducing oxidation and pad staining, XP-1 helps improve bonding strength and lowers rework rates. The controlled lubricity slows the glazing and polishing of abrasive grains, keeping the blade sharp longer and maintaining consistent cutting performance over extended cycles.

XP-1 also introduces controlled conductivity into DI water. This prevents the buildup of static charge at the blade–wafer interface and eliminates the risk of electrostatic discharge (ESD) during cutting. This benefit is critical for thin wafers, MEMS structures, power devices, and substrates with sensitive dielectric or passivation layers. XP-1 maintains this conductivity without leaving films or residues, making it suitable for high-precision and cleanroom-level processes.

A key environmental advantage of XP-1 is its low Chemical Oxygen Demand (COD). This reduces the environmental load of wastewater streams and supports easier, safer disposal. Facilities with strict environmental guidelines benefit from lower effluent impact and simplified compliance.

XP-1 performs reliably on silicon, ceramics, glass, quartz, composites, and a wide range of microelectronic materials. It remains stable across various spindle speeds, feed rates, and coolant delivery methods, making it suitable for both manual and automated systems. The balanced chemistry ensures repeatable, high-quality results whether you are processing standard wafers or more delicate layered substrates.

SMART CUT® XP-2

High Lubricity Dicing Fluid

SMART CUT XP-2 is the high-lubricity dicing coolant developed for applications that place significant mechanical and thermal stress on both the blade and the workpiece. The formulation delivers VERY HIGH LUBRICITY, SUPERIOR DEBRIS MANAGEMENT, and CONSISTENT THERMAL CONTROL. XP-2 supports reliable cutting at higher spindle speeds and heavier feed loads without loss of stability. This helps you achieve smoother kerfs, fewer defects, and LONGER BLADE LIFE even when processing demanding materials.

The advanced lubricating package forms a stable film at the blade interface. This lowers friction and reduces temperature rise during aggressive cuts. Controlled temperature helps protect brittle, layered, and high-value substrates from thermal shock and micro-fracturing. By slowing abrasive glazing and polishing, XP-2 keeps the blade cutting freely for a longer period. This allows for FASTER CUTTING SPEEDS, STEADIER CUTTING LOADS, and better consistency between the first cut and the last.

XP-2 uses an enhanced surfactant system that delivers STRONGER CLEANING POWER. These surfactants penetrate the kerf quickly, lift debris from the cutting zone, and keep particles suspended so they can be removed efficiently. This is especially beneficial when cutting sapphire, SiC, bonded wafers, quartz, and dense technical ceramics. Cleaner kerfs produce lower cutting forces, improve dimensional accuracy, and reduce the risk of sub-surface damage. Improved debris management also lowers the need for secondary cleaning steps after dicing.

The formulation incorporates HIGH-PERFORMANCE CORROSION INHIBITORS that protect exposed metal features during cutting. These inhibitors suppress oxide formation, preserve metal pad integrity, and prevent discoloration or staining. This improves downstream bonding performance and reduces failures linked to poor surface condition. The stable corrosion protection is important for advanced packaging, thin-wafer processing, MEMS structures, and devices with fine metal features.

XP-2 introduces CONTROLLED CONDUCTIVITY to DI water. This eliminates electrostatic charge at the blade-wafer interface. By preventing ESD events, XP-2 protects sensitive structures that would otherwise fail due to static release. This is important for advanced semiconductor wafers, high-density interconnects, and substrates with delicate dielectric layers. The added conductivity does not leave residue and does not interfere with coating, bonding, or metrology operations.

XP-2 maintains a LOW COD VALUE, reducing the environmental impact of wastewater and simplifying disposal. Facilities with tight environmental controls benefit from the reduced biological and chemical load. XP-2 fits high-volume production lines that require performance, reliability, and environmental compliance at the same time.

XP-2 is intended for high-speed dicing and back-grinding of ADVANCED CERAMICS, SILICON CARBIDE, SAPPHIRE, QUARTZ, BONDED WAFERS, and other challenging substrates. It performs well under varied coolant delivery systems and across a wide range of feed rates and spindle speeds. The chemistry supports HIGH LOAD CUTTING, HIGH SPEED CUTTING, and CLEAN, LOW-DEFECT KERF FORMATION in demanding operations.

DIRECTIONS FOR USE:

This product is designed for once-through delivery during precision dicing of electronic, ceramic, optical, and advanced materials with O.D. diamond blades. Supply the mixed solution directly to the blade contact zone to ensure full wetting and stable lubrication. Maintain a continuous and steady flow to control heat and prevent friction spikes. Verify that the coolant stream reaches both sides of the blade and the entire kerf. Use clean DI water for all dilution steps to maintain chemical purity. Inspect the fluid path to confirm that no backflow, air entrainment, or flow restriction is present. Replace the mixture regularly to maintain consistent cleanliness and performance.

RECOMMENDED DILUTIONS:

For most dicing operations, prepare a working concentration between 0.25 percent and 1.0 percent.

• Use 0.25 percent to 0.40 percent for silicon, fused silica, sapphire, and optical glasses when heat load is moderate.

• Use 0.40 percent to 0.70 percent for harder materials or when higher lubrication is required.

• Use 0.70 percent to 1.0 percent for dense ceramics, metal-bonded substrates, or high-load, high-RPM conditions.

Mix the solution thoroughly before use. Confirm concentration at the start of each shift. Adjust the level if you observe changes in blade load, debris removal, or kerf cleanliness.

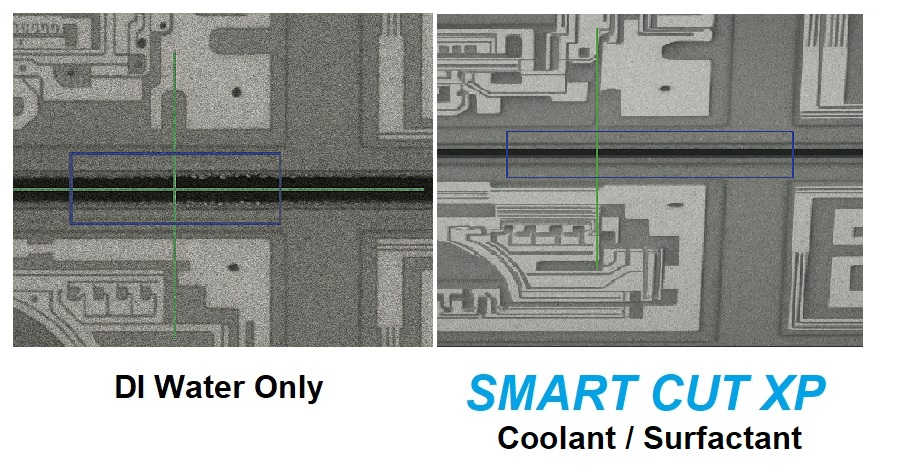

Application Example - Cleaner QFN Package Dicing Results

SMART CUT® XP coolant improves cut cleanliness, reduces contamination, and produces cleaner package edges during QFN package dicing.

Before

QFN Package Before use of SMART CUT® XP Coolant

Before: Dicing QFN packages with DI water resulted in residue, dark contamination, and rough edges. Limited lubrication and weak flushing allowed debris to adhere to the cut surfaces, producing inconsistent kerf quality.

After

QFN Package After use of SMART CUT® XP Coolant

After: Using SMART CUT® XP coolant produced cleaner, brighter edges with reduced debris and no surface smearing. Improved lubrication and flushing created a sharper kerf and more consistent overall dicing quality.

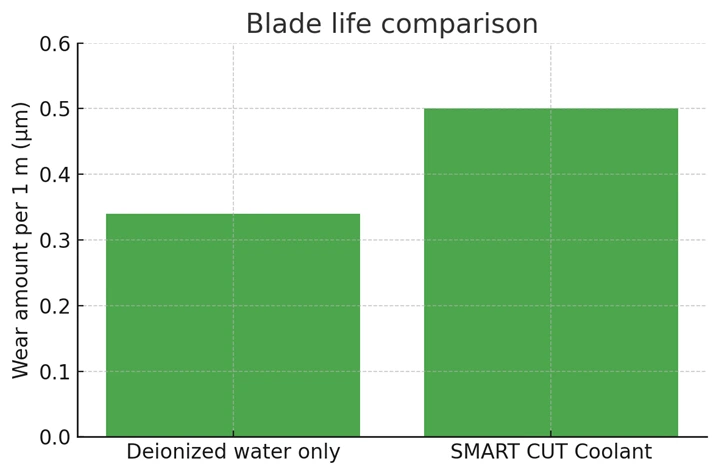

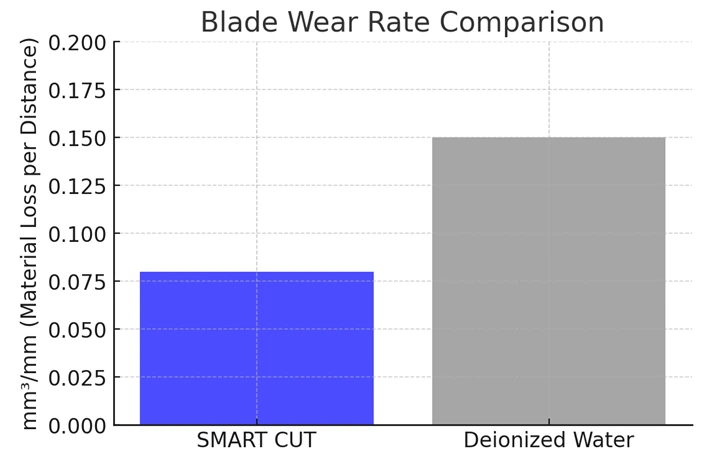

Case Study: Dicing Silicon Wafers

Material: Silicon wafer

Blade: Nickel bond hubless blade

Blade Specifications: 3” (100 mm) diameter × 0.008” (0.203 mm) thickness × 40 mm arbor, 320 grit diamond

Spindle RPM: 30,000 RPM

Feed Speed: 40 mm/s

Objective:

Evaluate the impact of SMART CUT® XP Dicing Coolant / Lubricant on blade longevity and cutting efficiency compared to using only deionized (DI) water.

Results:

- Blade life increased by 48% when using SMART CUT XP Dicing Coolant / Lubricant at a 0.20% concentration compared to DI water alone.

- More consistent cutting performance maintained over extended operation, reducing blade wear rate.

- Lower diamond matrix wear resulted in improved cutting consistency over the entire blade lifespan.

Conclusion:

Using SMART CUT® XP Dicing Coolant / Lubricant significantly extended blade longevity, reduced tool wear, and improved cost efficiency in high-volume silicon wafer dicing applications.

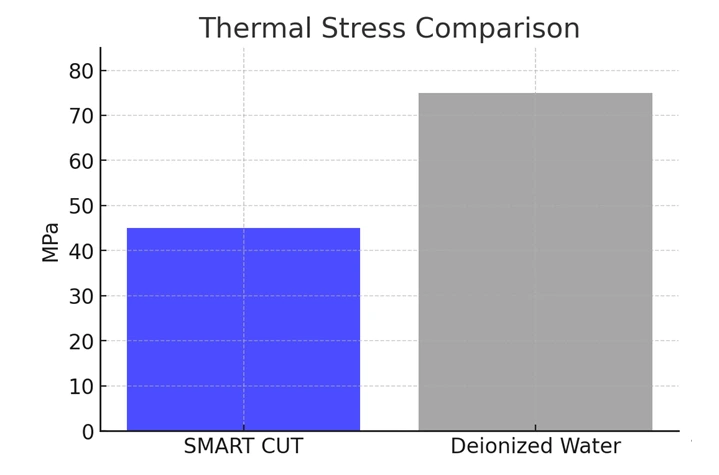

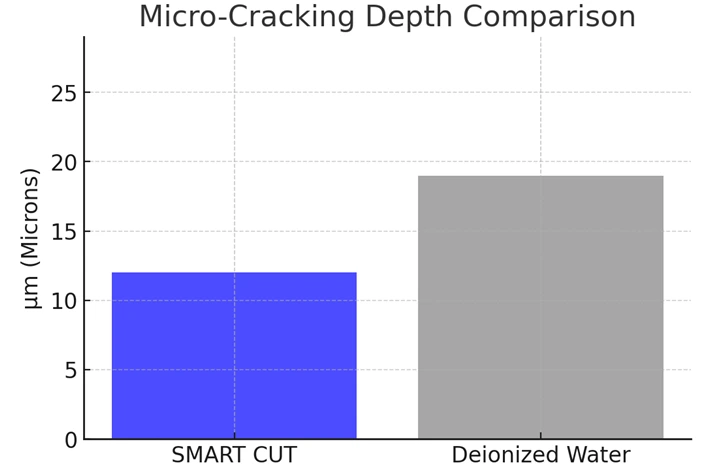

Thermal Stress and Micro-Cracking Reduction in Ceramic Substrate Dicing

Material: Alumina (Al₂O₃) ceramic substrate

Blade: Metal bond dicing blade

Blade Specifications: 4.6” (118 mm) diameter × 0.020” (0.50 mm) thickness × 3.5” (88.9 mm) arbor, 270 grit diamond

Spindle RPM: 6,000 - 8,000 RPM

Feed Speed: 8 - 12 mm/s

Objective:

Determine whether SMART CUT® XP Dicing Coolant / Lubricant reduces thermal stress and micro-cracking during ceramic dicing.

Results:

- Micro-cracking reduced by 38%, improving mechanical strength and final product integrity.

- Lower thermal stress, preventing structural damage in the ceramic and maintaining material properties.

- Blade wear reduced, ensuring longer blade life and consistent cutting performance over extended production runs.

Conclusion:

The use of SMART CUT® XP Dicing Coolant / Lubricant significantly improved cut quality, reduced stress fractures, and enhanced process efficiency for brittle ceramic materials, making it a valuable solution for precision dicing operations.

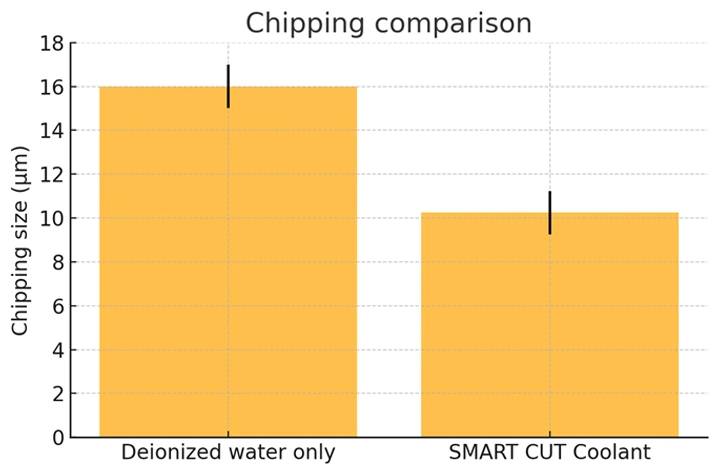

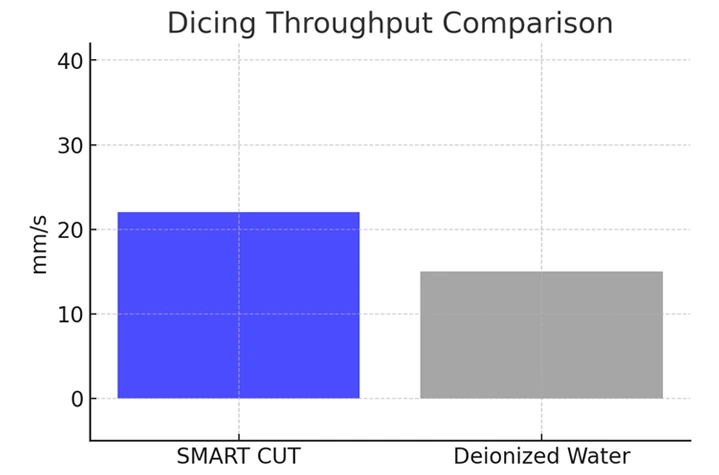

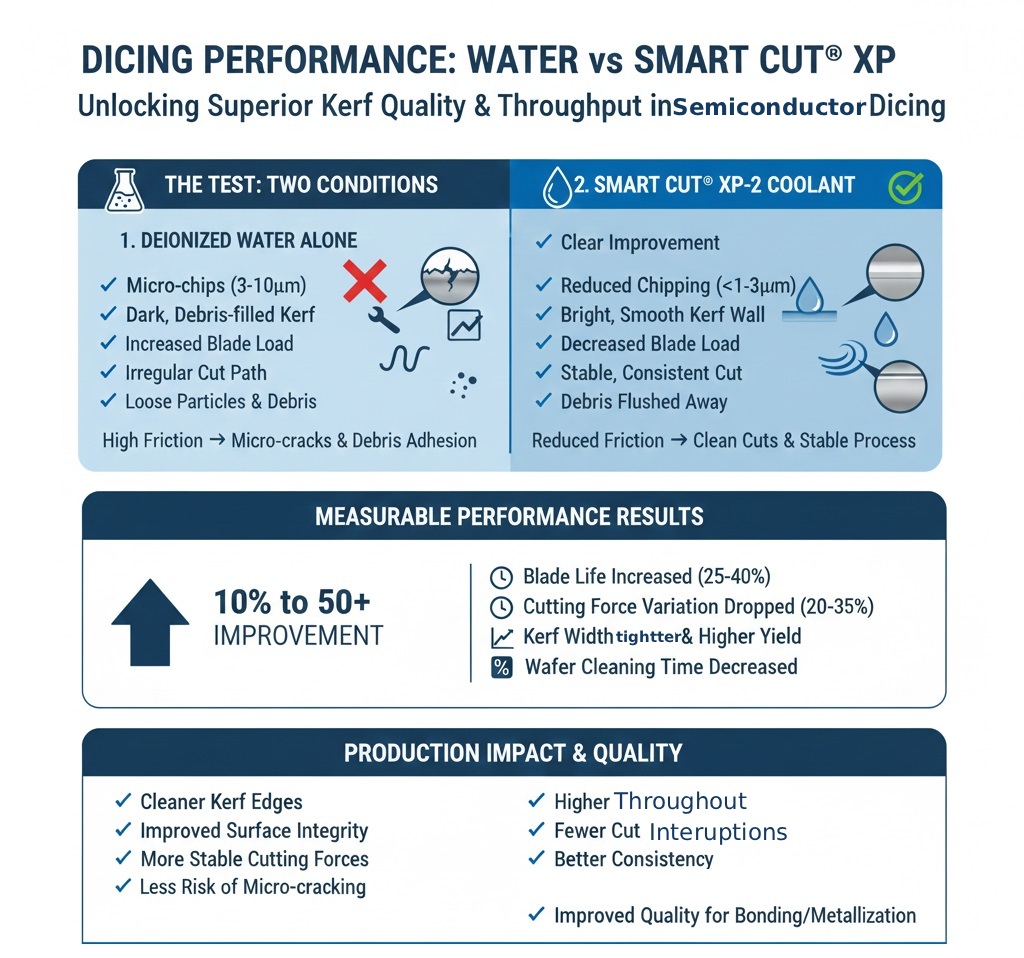

CASE STUDY: Silicon Wafer Dicing: DI Water vs SMART CUT XP SMART CUT®

Two dicking bees were performed on 725 micron silicon wafers using the same hubless resin bond blade and identical machine settings. Only the coolant changed

Di Water Only Cutting showed 3 to 10 micron chipping, friction marks, debris bulldup, and unstable karf geometry.

.SMART CUTO XP-2 Chipping dropped to 1 to 3 microne. Kert edges becanse smooth and clean Blade load and heat decreased. Debris cleared from the street

Result Blade Ble increased Cutting forces stabilized, Kert quality improved, held increased

SMART CUT® XP-3

Low-Foaming Dicing Fluid with Anti-Corrosion & Lubricity Additives

SMART CUT XP-3 is the low-foaming dicing coolant developed for equipment that operates under high pressure or uses atomizing spray systems. The formulation delivers VERY LOW FOAMING BEHAVIOR, STABLE COOLANT FLOW, and CONSISTENT COOLING PERFORMANCE even when exposed to turbulent, high-velocity coolant delivery. XP-3 prevents the foam accumulation that can interrupt flow, reduce cooling efficiency, or contaminate the cutting zone. This makes it suitable for high-precision environments where stable fluid delivery is essential for maintaining quality and repeatability.

The low-foaming chemistry ensures that coolant reaches the blade and kerf reliably. By keeping air entrainment and bubble formation to a minimum, XP-3 maintains steady pressure at the nozzle and stable contact with the cutting interface. This supports accurate dicing performance and prevents sudden changes in cooling or lubrication that can lead to chipping, edge defects, or blade loading. XP-3 provides consistent thermal control across long production runs, helping protect the workpiece from heat-related damage.

XP-3 uses surfactants designed for ENHANCED DISPERSION AND PARTICLE CONTROL. These surfactants keep debris suspended and prevent particles from re-adhering to wafer surfaces. Improved suspension supports cleaner kerfs, lower cutting forces, and more uniform edge quality. Cleaner surfaces also improve downstream processing steps, including inspection, bonding, and packaging. This is especially important in environments where atomizing sprays can otherwise redeposit fine particles on sensitive substrates.

The formulation includes HIGH-EFFICIENCY CORROSION INHIBITORS that protect exposed metal features during cutting. These inhibitors prevent oxide formation on metal pads, leads, and circuitry, helping maintain electrical integrity and reducing the risk of bonding failures. XP-3 also introduces CONTROLLED CONDUCTIVITY into DI water to suppress electrostatic charge at the blade–wafer interface. This eliminates ESD buildup and protects thin wafers, MEMS devices, and structures with delicate dielectric layers.

XP-3 is produced with BIODEGRADABLE COMPONENTS and maintains a LOW COD VALUE, reducing the environmental impact of wastewater and supporting safer disposal. Facilities with strict wastewater controls benefit from the reduced chemical load and improved environmental compliance.

XP-3 is ideal for back-grinding systems and high-pressure dicing platforms that rely on atomizing or high-velocity coolant nozzles. It is suited for LOW-FOAM PRECISION DICING, microelectronics production, MEMS fabrication, and cleanroom operations where foam formation would impact accuracy or cleanliness. The formulation remains stable across wide variations in pressure, flow rate, and spray pattern, ensuring reliable performance during demanding, continuous operation.

Typical Properties:

pH: 6.5

Conductivity: 0.3 mS

Specific Gravity: 1.01

Directions for Use:

Mix SMART CUT® XP-3 with DI water at a concentration between 0.25 percent and 1.0 percent using an injection pump. Deliver the solution as a once-through coolant during precision dicing of electronic, ceramic, optical, and advanced materials. Apply the mixture directly to the blade contact zone to ensure proper wetting, steady lubrication, and full kerf coverage. Maintain a continuous flow to control heat and avoid friction spikes. Confirm that the coolant stream reaches both sides of the blade and flows cleanly through the kerf. Use only DI water to maintain purity. Inspect the entire fluid line for air, backflow, or flow restrictions. Replace the mixture on a routine schedule to maintain stable performance.

Recommended Dilutions:

Prepare the working concentration within the 0.25 percent to 1.0 percent range.

• Use 0.25 percent to 0.40 percent for silicon, fused silica, sapphire, and optical glass.

• Use 0.40 percent to 0.70 percent for harder materials that require higher lubrication.

• Use 0.70 percent to 1.0 percent for dense ceramics, metal-bonded substrates, and high-RPM cutting.

Mix thoroughly before operation. Verify concentration at the start of each shift. Adjust the mixture if blade load, debris removal, or kerf cleanliness changes.

SMART CUT® XP-4

Electrostatic Discharge Sensitive Dicing Fluid

SMART CUT XP-4 is the dicing coolant developed specifically for applications where ELECTROSTATIC DISCHARGE (ESD) poses a serious risk to device integrity. The formulation provides FULL ESD SUPPRESSION, HIGH LUBRICITY, EFFECTIVE COOLING, and CORROSION PROTECTION, combining all critical performance functions into a single, stable fluid. XP-4 is intended for use with advanced semiconductor wafers, MEMS structures, and any device where static discharge during dicing could cause irreversible electrical or structural damage.

The defining capability of XP-4 is its ability to create a CONTROLLED CONDUCTIVE ENVIRONMENT at the blade–wafer interface. This prevents static charge buildup and stops ESD events before they occur. By maintaining charge stability throughout the cut, XP-4 protects threshold voltages, electrical pathways, and delicate component structures. This is important for ultra-thin wafers, high-density ICs, MEMS sensors, power devices, and micro-scale electronic components where even minor charge fluctuations can compromise performance.

XP-4 also provides HIGH LUBRICITY to reduce friction between the blade, abrasive matrix, and material. Lower friction limits temperature rise in the cutting zone and prevents thermal damage in brittle materials. By keeping the blade FREE-CUTTING, XP-4 helps maintain steady cutting forces, smoother kerf walls, and improved dimensional accuracy. Reduced abrasion and glazing extend blade life and improve cutting efficiency, especially in materials that are sensitive to heat or mechanical stress.

The formulation contains ADVANCED CORROSION INHIBITORS that protect exposed metal surfaces and bond pads during the cutting process. These inhibitors prevent the formation of oxides that can cause discoloration, bonding failures, or electrical instability. XP-4 preserves the surface quality of metal pads, improves reliability in downstream bonding processes, and supports stable device performance after assembly.

XP-4 includes components that form a THIN ORGANIC MICRO-LAYER at the blade–material interface. This micro-layer acts as a controlled cushioning film that reduces mechanical impact, helping to prevent chipping, cracking, layer separation, and de-lamination. This contributes to cleaner cuts and higher yields, especially in fragile layered structures and microelectronic substrates.

With a LOW COD VALUE, XP-4 reduces environmental impact and supports safer disposal. The biodegradable composition helps facilities meet strict wastewater and environmental guidelines without compromising cutting performance.

XP-4 is recommended for dicing ESD-SENSITIVE SEMICONDUCTORS, MEMS DEVICES, and other high-value substrates where static discharge cannot be tolerated. It performs well in cleanroom and high-precision manufacturing environments and supports operations requiring strong lubrication, stable cooling, and full ESD protection throughout the entire cutting cycle.

Eliminate ESD Effects

Testing confirms no measurable threshold-voltage shift after dicing when using SMART CUT® XP-4. This indicates stable electrical performance and effective suppression of ESD-related damage during the dicing process.

A previous evaluation performed with SMART CUT® XP-1 showed a noticeable shift in threshold voltage. That shift was attributed to ESD-induced pad damage, caused by insufficient lubrication and low conductivity at the blade-to-wafer interface.

SMART CUT® Water Soluble

Coolant (General Materials Formula)

SMART CUT Water Soluble Coolant (General Materials Formula) is formulated to give you stable thermal control and smooth cutting performance across a wide range of materials. The coolant removes heat quickly from the cutting zone, which protects the workpiece from thermal stress and prevents micro-cracking, edge flaking, and distortion. By lowering friction, it helps you maintain a steady cutting load and produces cleaner, more uniform kerfs. This improves dimensional accuracy and reduces the risk of hidden subsurface damage.

The coolant supports high spindle speeds and extended cutting cycles. It helps prevent glazing on the blade surface and slows abrasive wear, which keeps the blade free-cutting for a longer period. This improves consistency from cut to cut and reduces the number of blade changes required during production. A cleaner cutting environment also lowers the amount of debris that can accumulate on the blade edge or on the wafer surface. This supports better inspection, fewer downstream defects, and improved yield.

The balanced formulation works well with ceramics, optics, quartz, silicon, composites, and metals. It maintains stable behavior across different coolant delivery methods including drip, flood, spray, and recirculating systems. The coolant mixes easily with DI water, allowing operators to adjust concentration based on the hardness and brittleness of the material. Ratios near 1:50 provide the right performance for materials like silicon carbide, which require controlled cooling without excess lubrication. Ratios near 1:20 provide stronger lubrication for ultra-hard or brittle materials such as sapphire, which benefit from extra friction reduction and thermal control.

SMART CUT Water Soluble Coolant supports higher cutting efficiency by reducing heat, lowering friction, and maintaining steady blade performance. It improves surface finish, reduces edge chipping, and minimizes vibration-related defects. The coolant also extends tool life, reduces downtime, and improves process stability, especially during continuous production.

The formula is bio-resistant, which helps prevent bacterial growth in recirculating systems. This keeps the coolant fresh, clear, and odor-free for longer periods. It is safe for operators, compatible with most machine materials, and suitable for cleanroom environments. It offers a dependable solution for both high-volume production and precision laboratory work where consistency and control are essential.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

ARE YOU USING RIGHT

DICING SURFACTANTS FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING SURFACTANTS?

Knowledge Center

Dicing Surfactants Guide

How to Use SMART CUT XP Dicing Surfactants

Selecting the Right Dicing Surfactant / Fluid for Your Application

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

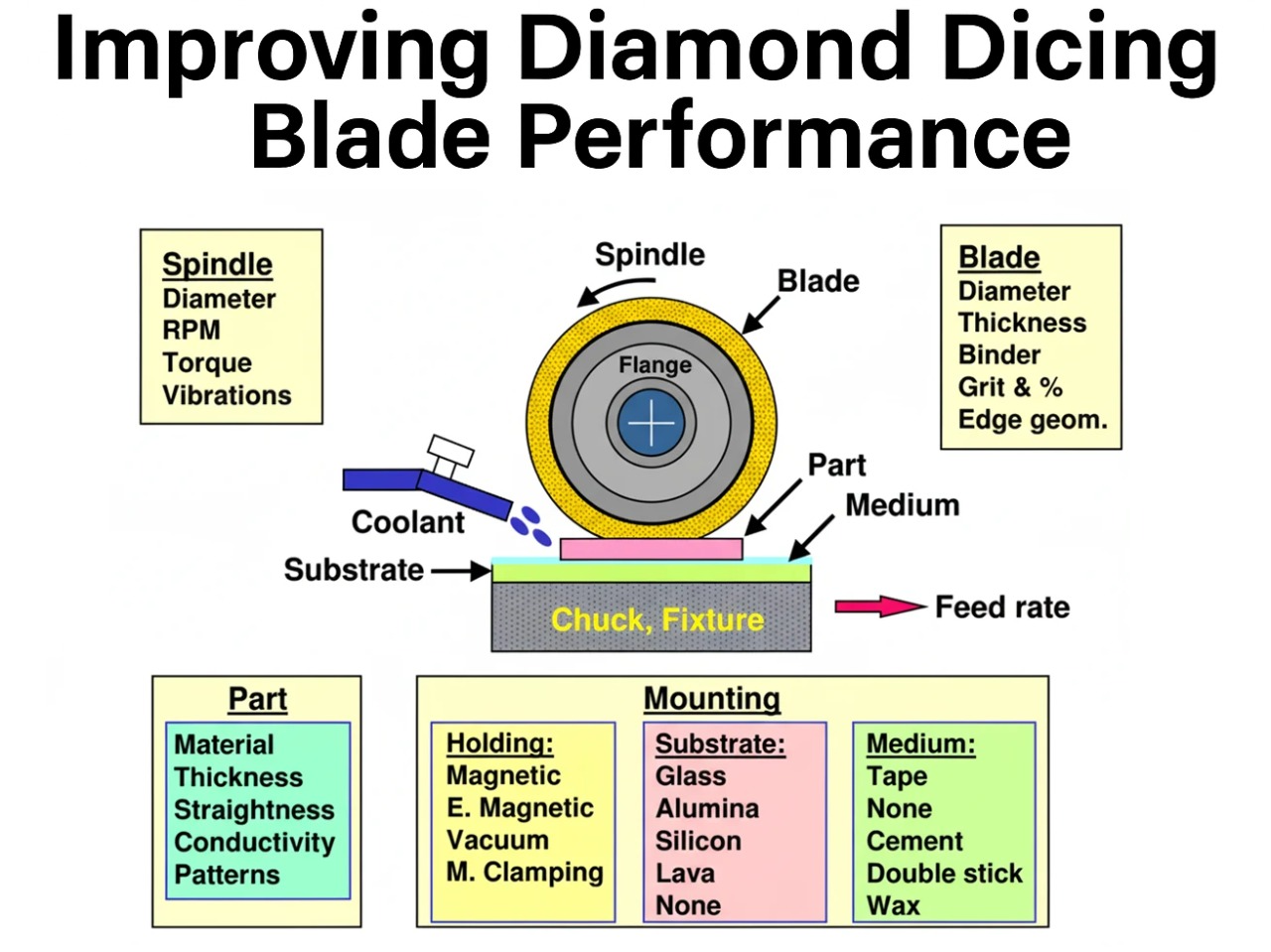

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

Selecting the Right Wafer Dicing Saw Practical Guide

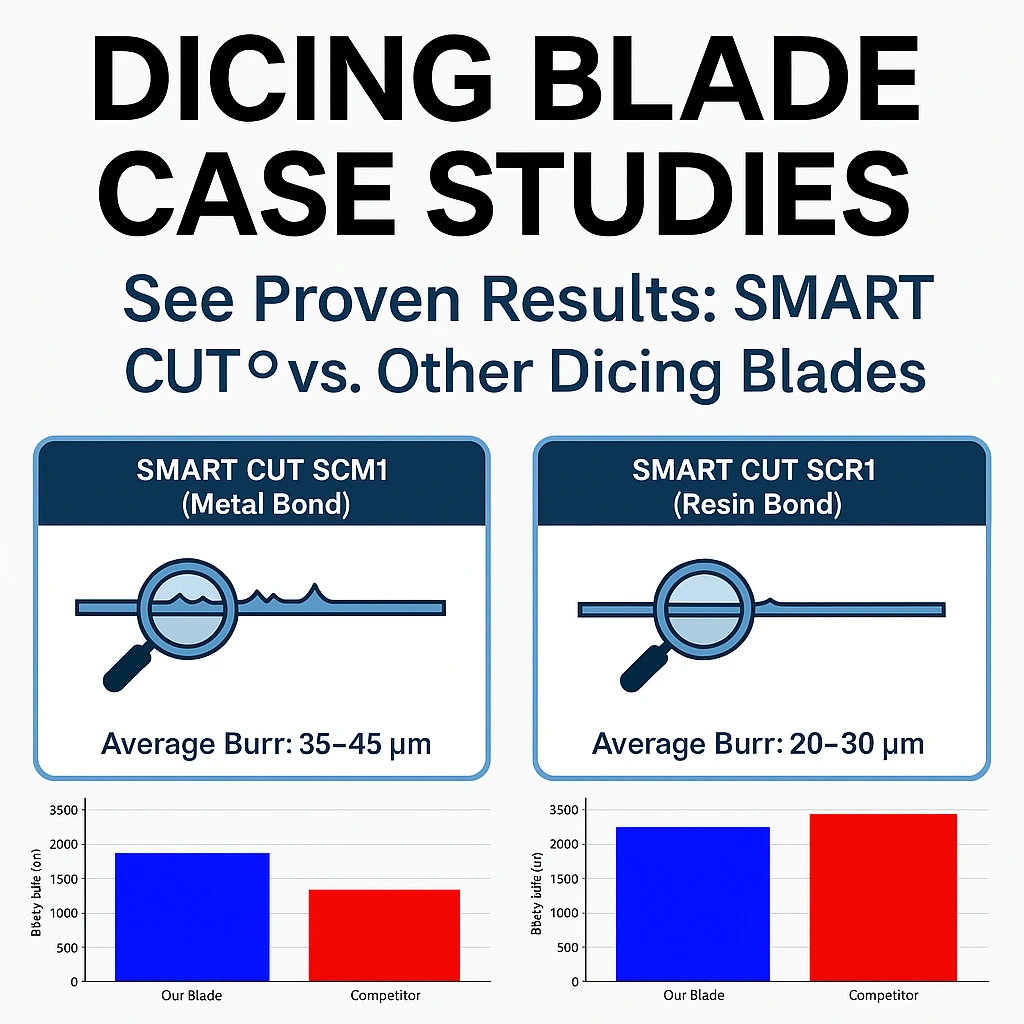

Dicing Blade Case Studies

Application Recommendations

Trouble Shooting Dicing Problems

Optimizing your Diamond Dicing Performance

Dicing Blade Operations Recommendations

Select right Diamond Dicing Blade for your application

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.