-

0 items in quote

No products in the Quote Basket.

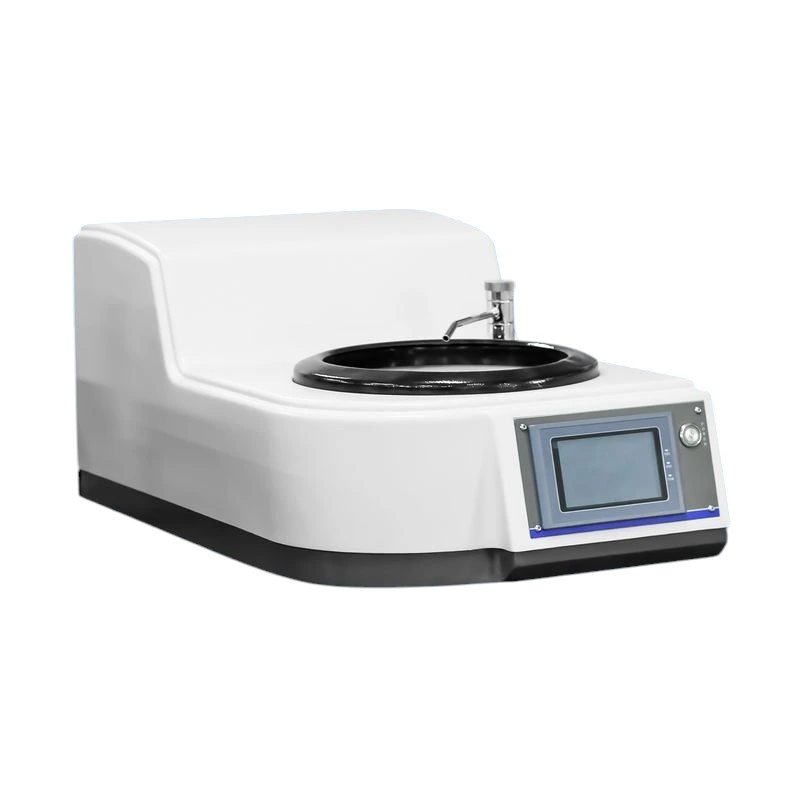

SMART CUT® RP

Automatic Grinder/Polisher – Single Wheel

SMART CUT® RP is a state-of-the-art, multi-functional machine designed to handle all stages of metallographic specimen preparation, including coarse grinding, fine grinding, and both coarse and fine polishing. This versatile system combines exceptional performance, ease of use, and advanced automation to streamline the preparation process while delivering consistent, high-quality results.

At the heart of the SMART CUT® RP is a 1000W high-power, high-torque motor, ensuring reliable operation across a wide range of applications. Its variable speed control ranges from 5 RPM to 1500 RPM, enabling precise adjustments to meet specific preparation requirements. The quick start and stop function allows the working plate to halt in just two seconds, improving efficiency and safety during operation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

FEATURES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

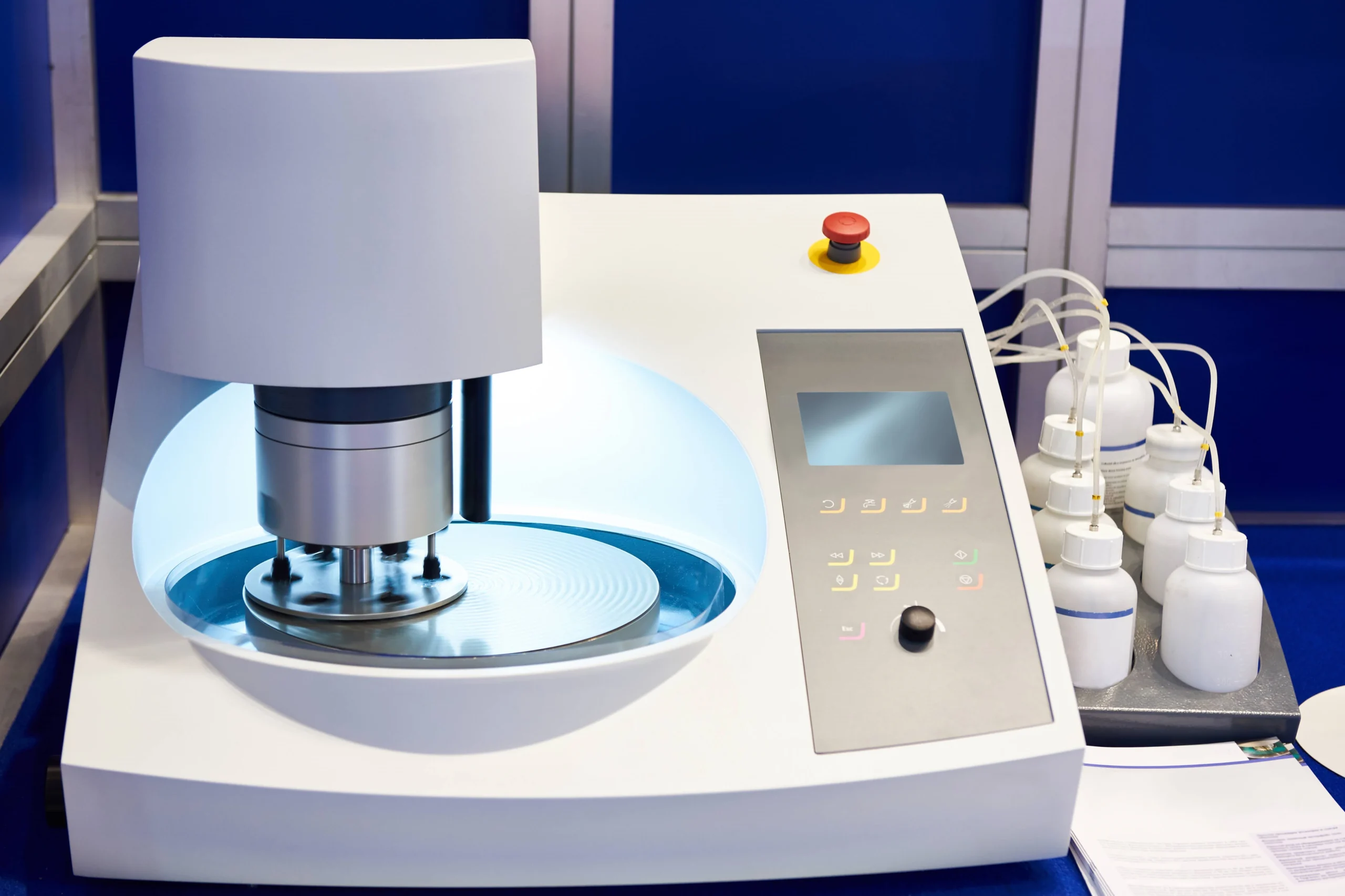

The machine is equipped with a DELTA PLC control system that automates critical parameters such as speed, rotation direction, grinding and polishing time, and water valve management. All settings are saved for future use, ensuring consistent results with minimal effort. A newly designed large touch screen interface provides an intuitive platform for setting and monitoring grinding and polishing parameters, enhancing user convenience and control.

Both manual and automatic operating modes are available, offering flexibility to suit diverse workflows. In manual mode, users can select from four preset speeds or customize them for specific tasks such as pre-grinding, grinding, or polishing. The automatic mode supports up to 64 programmable production processes, enabling precise, repeatable operations for consistent specimen preparation.

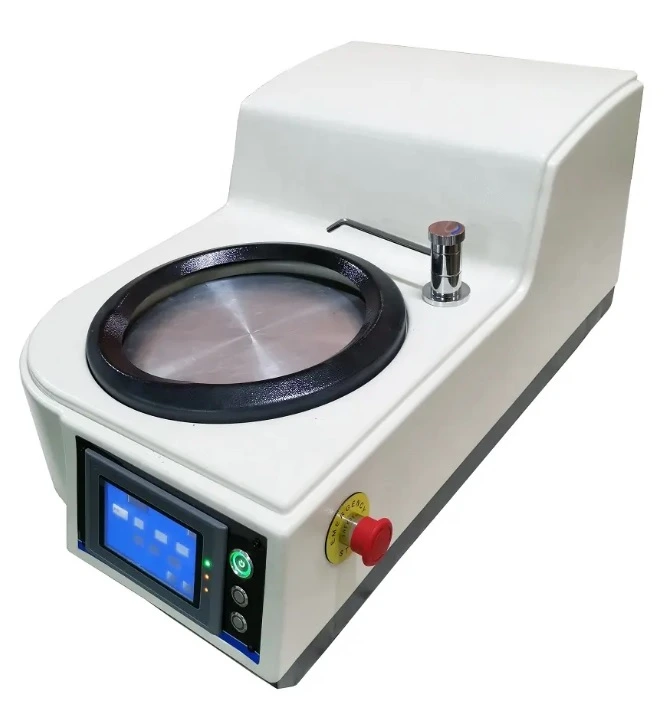

The SMART CUT® RP features an advanced water flow management system, allowing users to adjust the water drop position and flow rate with precision. Water flow starts and stops automatically at the beginning and end of each process, reducing waste and ensuring optimal cooling during operation. The inclusion of a magnetic anti-sticking disc makes replacing abrasive paper and polishing cloths fast and effortless, further improving operational efficiency.

This machine is upgradeable, with the option to add an automatic grinding head that can simultaneously process up to six samples. Additionally, it supports the integration of a polishing liquid dispenser for automated liquid application, providing even greater efficiency and precision. Safety features such as an emergency switch and the ability to switch the rotation direction of the grinding and polishing disc enhance user confidence during operation.

The SMART CUT® RP offers reliable performance with stable operation, low noise levels, and a sleek, modern design. Its compact and durable construction ensures long-term usability in laboratory, research, and industrial environments. With a comprehensive set of standard accessories, including grinding paper, polishing cloths, and diamond polishing liquid, the machine is ready for immediate use. Optional accessories, such as additional grinding paper and polishing liquids in various micron sizes, further expand its capabilities to meet specialized needs.

This advanced machine combines cutting-edge technology with user-centric design, making the SMART CUT® RP the ultimate solution for precision metallographic specimen preparation.

SPECIFICATIONS

Technical Specifications

- Grinding & Polishing Disc Diameter:254 mm (Optional: 230 mm, 203 mm).

- Variable Speed Range: 5–1500 RPM, with forward and reverse rotation directions.

- Four-Level Constant Speed Settings: V1 = 300 RPM, V2 = 500 RPM, V3 = 600 RPM, V4 = 800 RPM (user customizable).

- Automatic Mode: Supports up to 64 programmable production processes.

- Motor Power: 1000 W high-torque motor (1.34 HP)

- Power Supply: 110V 60Hz and Single-phase, 220 V, 50 Hz.

- Overall Dimensions: 760 mm × 430 mm × 360 mm.

- Weight: 35 kg (77.16 lbs)

- Quick Start/Stop Time: Working plate stops rotating in 2 seconds.

- Control System: DELTA PLC for automated grinding and polishing parameter management.

- Water Flow Control: Adjustable water drop position and flow rate; automated start/stop at process beginning and end.

- Safety Features: Emergency switch and reversible rotation for grinding and polishing disc.

- Direction: Clockwise, counterclockwise adjustable

- Upgradeable Options: Automatic grinding head for processing up to six samples and polishing liquid dispenser integration.

FEATURES

High-Performance Motor

- Equipped with a 1000W high-power, high-torque motor for superior performance across a wide range of

applications.

Variable Speed Control

- Wide rotation speed range from 5 RPM to 1500 RPM for customizable grinding and polishing operations.

- Quick start/stop feature with a working plate that halts in just 2 seconds.

Advanced Automation & Control

- Powered by an imported DELTA PLC control system, enabling automatic parameter

saving for speed, rotation direction, grinding and polishing time, and water valve operation.

User-Friendly Interface

- Large, newly designed touch screen interface for intuitive control and easy parameter

adjustments.

Customizable Operating Modes

- Manual Mode: Four preset constant speeds (V1=300 RPM, V2=500 RPM, V3=600 RPM, V4=800 RPM)

customizable for pre-grinding, grinding, and polishing. - Automatic Mode: 64 programmable production processes for consistent and efficient operation.

Precision Water Flow Management

- Adjustable water drop position and flow rate, with automatic start/stop at the

beginning and end of the grinding and polishing process.

Magnetic Disc System

- Magnetic anti-sticking disc for quick and easy abrasive paper or polishing cloth

replacement.

Upgradeable to Automatic Processing

- Compatible with an optional automatic grinding head for processing up to 6 samples simultaneously.

- Polishing liquid dispenser can be connected for automated liquid application (optional).

Exceptional Build Quality

- Runs with stable operation, low noise, and a sleek, professional design.

Safety Features

- Includes an emergency switch for quick operation shutdown.

- Grinding & polishing disc rotation direction can be easily switched between clockwise and counterclockwise.

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

The SMART CUT® RP is a versatile automatic grinder/polisher designed for all stages of metallographic specimen preparation. It is capable of coarse grinding, fine grinding, and both coarse and fine polishing. This machine is used to prepare metal, ceramic, composite, and other hard material samples for microscopic analysis in laboratories, research institutions, and industrial environments.

The SMART CUT® RP is powered by a 1000W high-torque motor (1.34 HP), ensuring reliable and consistent performance across a wide range of grinding and polishing applications.

The machine features a variable speed control that ranges from 5 RPM to 1500 RPM, allowing users to fine-tune the speed to match the specific grinding or polishing requirements. Additionally, it includes four preset constant speeds:

- V1 = 300 RPM

- V2 = 500 RPM

- V3 = 600 RPM

- V4 = 800 RPM

Users can also customize the speed settings for specific tasks such as pre-grinding, grinding, or polishing.

Yes, the SMART CUT® RP is suitable for grinding and polishing a wide range of materials, including metals, ceramics, glass, and composites. The machine can accommodate various abrasive materials and polishing cloths to achieve high-quality finishes for different workpieces.

The SMART CUT® RP offers two operating modes:

- Manual Mode: Allows users to select from four preset speeds or customize them for specific applications like pre-grinding, grinding, or polishing.

- Automatic Mode: Supports up to 64 programmable production processes for consistent, repeatable operations. This mode automates key parameters like speed, rotation direction, and grinding/polishing time.

The SMART CUT® RP includes an advanced water flow management system:

- Users can adjust the water drop position and flow rate with precision.

- Water flow starts and stops automatically at the beginning and end of each grinding or polishing process, optimizing cooling and reducing waste.

- This system helps ensure optimal lubrication during the grinding and polishing phases, enhancing performance and preventing overheating.

Yes, the SMART CUT® RP features a magnetic anti-sticking disc, which makes the replacement of abrasive paper and polishing cloths quick and effortless. This system minimizes downtime and increases operational efficiency.

The SMART CUT® RP is equipped with several important safety features:

- Emergency Switch: In case of an emergency, the machine can be quickly turned off for safety.

- Reversible Rotation: The grinding and polishing disc can be rotated in both clockwise and counterclockwise directions, providing flexibility for different types of material processing.

Yes, the SMART CUT® RP is upgradeable with the following options:

- Automatic Grinding Head: You can add an automatic grinding head that allows for simultaneous processing of up to six samples.

- Polishing Liquid Dispenser: The machine supports the integration of a polishing liquid dispenser for automated liquid application, which can further enhance efficiency and precision.

- Dimensions: The machine measures 760 mm x 430 mm x 360 mm.

- Weight: The SMART CUT® RP weighs 35 kg (77.16 lbs), making it compact and easy to integrate into laboratory or research environments.

The SMART CUT® RP is equipped with a quick start/stop feature, allowing the working plate to halt in just two seconds. This feature improves operational efficiency and enhances safety by reducing the time it takes for the machine to come to a complete stop.

The SMART CUT® RP comes with a comprehensive set of standard accessories, including:

- Grinding paper (various grits)

- Polishing cloths (canvas, flocking)

- Diamond polishing liquid

- Water inlet pipe and drainage components

Optional accessories include additional grinding paper, polishing liquids in various micron sizes, and other specialized tools for specific tasks.

The SMART CUT® RP is designed with user-friendly features:

- A large, intuitive touch screen interface allows easy parameter adjustments and real-time status monitoring.

- The machine offers both manual and automatic modes, providing flexibility to accommodate various workflows and experience levels.

The SMART CUT® RP is ideal for use in a variety of industries, including:

- Metallography and Materials Science

- Electronics and Semiconductor Manufacturing

- Automotive and Aerospace Engineering

- Academia and Research Institutions

- Manufacturing of Composite Materials

Regular maintenance includes:

- Cleaning the machine after each use, especially the work plate, grinding discs, and water system.

- Checking the water system for leaks or blockages.

- Lubricating moving parts, such as the motor and bearings, according to the user manual.

- Replacing worn abrasive materials such as grinding paper or polishing cloths as needed.

The SMART CUT® RP is designed to handle single-sample processing by default. However, you can upgrade the machine with an automatic grinding head that can process up to six samples simultaneously. This upgrade is ideal for high-throughput applications and labs requiring faster processing times for multiple specimens.

In automatic mode, the machine can be programmed to perform up to 64 different production processes. This includes setting parameters like speed, rotation direction, grinding time, and polishing time. Here’s how to program the machine:

- Select Automatic Mode from the main interface on the touch screen.

- Use the touch screen interface to input or modify the parameters for each process. These can include preset speeds (V1, V2, V3, V4), rotation direction, water flow rate, and time.

- Once the parameters are set, press “Save” to store the settings for future use.

- Start the programmed process, and the machine will automatically carry out the sequence, adjusting settings as per the stored parameters.

Yes, the SMART CUT® RP is compatible with polishing liquids. You can connect the machine to an automated polishing liquid dispenser (optional) for consistent and even liquid application during the polishing process. The liquid dispenser ensures a smooth application, improving surface finish quality and efficiency.

The SMART CUT® RP features a magnetic anti-sticking disc system that allows for easy replacement of grinding paper or polishing cloths:

- Turn off the machine and ensure it is unplugged.

- Gently remove the old grinding paper or polishing cloth from the magnetic disc.

- Clean the work plate and the disc surface to remove any residual materials or adhesives.

- Place the new abrasive paper or polishing cloth onto the magnetic disc and press down firmly to secure it in place.

- Ensure the disc is properly aligned before resuming operation.

Accordion ContentIf the SMART CUT® RP produces unusual noises or excessive vibrations, follow these troubleshooting steps:

- Turn off the machine and unplug it for safety.

- Inspect the grinding disc and work plate for any loose components or worn parts.

- Check that the abrasive paper or polishing cloth is securely mounted and not causing imbalances.

- Ensure that the motor and bearings are properly lubricated and functioning smoothly.

- If the issue persists, contact customer support for further diagnosis.

The SMART CUT® RP features an adjustable water flow management system:

- The water flow can be controlled via the touch screen interface, allowing users to adjust the flow rate and drop position.

- Use the interface to increase or decrease the flow rate for optimal cooling during grinding and polishing.

- The system also includes an automatic water start/stop feature, which ensures water flow begins when the grinding or polishing process starts and stops when it ends, reducing waste.

Yes, the SMART CUT® RP can be connected to a water filtration system to ensure the water used is clean and free from impurities. This is particularly important if you are working with materials that are sensitive to contamination or require ultra-clean polishing results. Using filtered water helps prevent clogging in the drainage system and improves the overall quality of the preparation process.

To maintain the SMART CUT® RP’s water system:

- Clean the water inlet and drainage pipes regularly to prevent blockages. Debris buildup can affect water flow and cause backflow.

- Periodically flush the system to remove any accumulated residues from the grinding or polishing processes.

- Inspect the water valve and connections for leaks or damage. Replace seals and fittings as needed to maintain a secure connection.

- Make sure the water filter (if used) is cleaned or replaced regularly to ensure a steady flow of clean water into the system.

The frequency of replacement depends on the amount of use and the material being processed:

- Grinding Paper: Replace when the abrasive surface shows signs of wear, damage, or when the paper becomes clogged with material.

- Polishing Cloths: Replace when they become too worn or lose their effectiveness in achieving a smooth surface finish. Polishing cloths are typically changed after several polishing cycles.

Always inspect abrasives and cloths before each operation to ensure that they are in good condition and suitable for use.

Yes, with the optional automatic grinding head, you can process up to six samples simultaneously. This feature is particularly beneficial for labs or environments that require high throughput and efficiency. The automatic head allows precise, simultaneous grinding or polishing of multiple specimens, reducing the overall processing time.

To adjust the speed:

- Select the manual mode on the touch screen interface.

- Choose from one of the preset speeds (V1, V2, V3, V4) or enter a custom speed within the range of 5 RPM to 1500 RPM.

- The speed can be adjusted in real-time, so you can make changes based on the task at hand, whether you’re doing coarse grinding, fine grinding, or polishing.

- For more precise control, customize the speed settings to match specific material properties or desired outcomes.

Yes, the SMART CUT® RP comes equipped with a DELTA PLC control system that automatically saves the grinding and polishing parameters, such as speed, rotation direction, grinding time, and water flow rate. These settings can be reused for future operations, ensuring consistent results with minimal effort. In automatic mode, you can save up to 64 different programmable production processes for easy recall.

The SMART CUT® RP offers high versatility for different materials:

- Grinding Materials: The variable speed control allows you to select the appropriate speed for various abrasive materials, depending on the material hardness and size.

- Polishing Materials: The machine supports the use of polishing liquids, cloths, and pads that can be selected based on the material being polished. Adjustable water flow and position ensure proper cooling and lubrication, leading to superior surface finishes.

Using the correct combination of abrasives, polishing liquids, and cloths ensures optimal results across a wide range of materials, including metals, ceramics, and composites.

If the SMART CUT® RP encounters an error during operation:

- Stop the machine immediately using the emergency switch.

- The machine’s touch screen interface will typically display an error message or code, helping you identify the issue.

- Common causes may include issues with the motor, water system, or PLC control system.

- Refer to the user manual for troubleshooting steps or contact customer support if the error cannot be resolved.

Always check for issues such as loose connections, clogs in the water system, or incorrect parameter settings.

No, the SMART CUT® RP can handle grinding and polishing operations, but only one process can be done at a time. However, the machine is designed for quick transitions between these tasks:

- In automatic mode, after completing grinding, the machine can automatically switch to polishing once the grinding process is complete.

- Users can easily select from preset speeds for coarse grinding (low speeds) and fine polishing (higher speeds), allowing for a seamless workflow between tasks.

The SMART CUT® RP is built for extended use, but it is always recommended to give the machine periodic breaks, especially during high-intensity operations such as coarse grinding. Extended operation without cooling periods can cause motor overheating.

As a guideline:

- For normal operations (e.g., fine grinding or polishing), running the machine for 2-3 hours at a time should be fine, followed by a short break to allow the motor and other components to cool.

- For heavy grinding operations, consider taking breaks every 1 hour to prevent overheating.

If you experience any signs of overheating or excessive noise, turn off the machine and allow it to cool before resuming.

If you notice that the polishing result is inconsistent or not as smooth as expected, the following factors may be the cause:

- Incorrect Polishing Cloth: Ensure that the appropriate polishing cloth (canvas, flocking, etc.) is being used for the material and desired finish.

- Excessive Pressure: Avoid applying too much pressure during polishing, as this can cause uneven results. Let the machine and the abrasive materials do the work.

- Water Flow: Ensure that the water flow is properly adjusted. Insufficient water can cause the polishing process to be ineffective, while too much water can lead to slippage or reduced pressure.

- Worn Polishing Cloth: Replace the polishing cloth if it has become worn or damaged. A worn cloth may not provide consistent polishing results.

- Incorrect Speed Settings: Adjust the speed according to the material and the level of polish you are aiming to achieve. Too high a speed can reduce the effectiveness of the polishing.

Yes, the SMART CUT® RP is designed to meet the needs of both manual and automated production environments:

- Manual Mode: Ideal for smaller batches, research, or specific projects where precise control and customization are necessary. Operators can adjust speed, time, and other settings based on specific needs.

- Automatic Mode: Suitable for high-volume or repetitive tasks, where 64 programmable production processes can be saved and recalled for consistent results. The machine automatically adjusts parameters, streamlining the preparation process and ensuring uniformity across multiple samples.

The flexibility of these two modes allows the SMART CUT® RP to be integrated into varied production workflows.

To ensure consistent and repeatable results:

- Use automatic mode to store and recall settings for specific processes, reducing the chance of human error.

- Regularly inspect the abrasive paper or polishing cloth for wear, and replace it when necessary to avoid inconsistent results.

- Calibrate the machine periodically, especially the water flow system, to ensure consistent application during each cycle.

- Use the same materials (abrasives, cloths, liquids) consistently to avoid variability in preparation.

- Monitor the machine during operation to ensure that there are no mechanical issues such as vibrations or imbalances.

By using the machine as recommended and regularly maintaining it, you will achieve precise and repeatable metallographic specimen preparation.

The SMART CUT® RP operates with low noise levels due to its well-engineered motor and design. Under normal operating conditions, the noise produced by the machine is typically below 70 dB. This makes it suitable for use in laboratory environments where noise levels must be kept to a minimum.

If you notice any unusual loud noises or vibrations during operation, it may indicate an issue with the motor, work plate, or grinding/polishing disc. It is advised to turn off the machine and perform a quick inspection.

The SMART CUT® RP typically comes with a one-year warranty covering manufacturing defects on parts and labor. The warranty excludes damages caused by misuse, improper maintenance, or third-party modifications. For extended warranty options or specific details, please refer to the warranty terms provided with the machine or consult the supplier directly.

The processing time for each sample varies based on the material, the type of abrasive used, and the required finish. As a general guideline:

- Coarse grinding may take 5–10 minutes per sample.

- Fine grinding typically takes 10–20 minutes per sample.

- Polishing generally takes 15–30 minutes, depending on the material and the level of smoothness required.

Using the automatic mode and programmable processes can help speed up repetitive operations and maintain consistent sample preparation times.

Yes, the SMART CUT® RP allows you to program up to 64 different production processes in automatic mode. This feature is ideal for applications requiring sequential tasks such as:

- Pre-grinding

- Grinding

- Polishing

Each process can be individually configured with specific parameters like speed, time, water flow rate, and rotation direction. Once programmed, the machine will automatically execute the tasks in the defined order, reducing operator input and ensuring repeatable, consistent results.

When working with materials that are sensitive to heat or prone to overheating (e.g., certain plastics or delicate ceramics):

• Use lower grinding speeds (e.g., V1 or V2 speed settings) to reduce heat generation.

• Make sure to adjust the water flow rate to provide additional cooling to the work surface.

• If necessary, operate in short bursts, allowing the machine to cool down between cycles.

• Consider using coarse abrasives for the initial stages of grinding to reduce the heat produced during the process.

Excessive heat can distort materials or affect the quality of the finish, so it’s important to monitor temperature and adjust settings as needed.

The SMART CUT® RP is designed primarily for wet grinding and polishing. The inclusion of the water flow system helps cool the workpiece and lubricate the grinding surface, ensuring optimal performance and preventing overheating. For dry grinding, it’s important to consider:

- The increased heat buildup during dry operations, which can damage both the sample and the machine’s components.

- Dust control: Dry grinding produces dust that can clog the machine’s filters and damage sensitive parts.

If you must perform dry grinding, ensure that the machine is equipped with proper dust collection and air filtration systems to protect the motor and control systems from debris.

The SMART CUT® RP is compatible with an external polishing liquid dispenser to automate liquid application during the polishing process. Here’s how to integrate the dispenser:

- Connect the dispenser to the designated connection port on the machine.

- Set the flow rate and dispensing timing via the machine’s touch screen interface.

- The system will automatically apply polishing liquids during the polishing process, ensuring even and consistent liquid distribution across the polishing cloth.

This integration ensures a controlled application of polishing fluids, improving surface quality and consistency, especially for fine polishing tasks.

Yes, the SMART CUT® RP can handle a variety of sample sizes. The standard grinding and polishing disc diameter is 254 mm (with optional sizes such as 230 mm or 203 mm available).

- Small specimens: The machine can easily accommodate smaller specimens for precise and accurate grinding or polishing. Use the appropriate abrasive material for fine or coarse preparation as required.

- Large specimens: Larger specimens can be processed by adjusting the grinding settings or using multiple sessions to handle larger surface areas.

For processing multiple specimens at once, the automatic grinding head upgrade allows the machine to handle up to six samples simultaneously, improving throughput in a high-volume setting.

To ensure optimal performance of the SMART CUT® RP, calibration is typically required after extended use or following significant maintenance. Steps for calibration:

- Check alignment: Ensure the grinding or polishing disc is correctly aligned and mounted.

- Adjust water flow: Calibrate the water flow rate and drop position for efficient cooling and lubrication during operation.

- Test speed settings: Verify the speed range of the grinding or polishing disc by testing it at each preset speed (V1, V2, V3, V4).

- Run sample tests: Perform test runs with sample specimens to ensure that the machine is operating smoothly and producing the desired results. Adjust settings if necessary.

Calibration may need to be performed periodically, depending on machine usage and material processing needs. Refer to the user manual for specific calibration instructions.

Yes, the SMART CUT® RP can be used in clean rooms or controlled environments, provided the following conditions are met:

• Low dust environment: Since grinding and polishing can produce debris, ensure the room is equipped with adequate air filtration or dust collection systems.

• Stable power supply: Ensure the machine is connected to a stable and clean power supply to avoid any electrical issues.

• Temperature control: Ensure that the machine is used in an environment with a controlled temperature to avoid overheating of sensitive components.

• The compact design and low noise levels of the SMART CUT® RP make it suitable for such environments.

Replacement parts, accessories, and consumables (such as grinding paper, polishing cloths, polishing liquids, and replacement motor parts) can be ordered directly from us.

OPERATING MANUALS

Download Operating Manuals

ACCESSORIES

Tab Content

Advantages

- Versatility: Combines coarse grinding, fine grinding, and both coarse and fine polishing into one machine, streamlining the specimen preparation process.

- High Power and Performance: Equipped with a 1000W high-torque motor for reliable and consistent operation across various applications.

- Wide Speed Range: Adjustable speeds from 5 RPM to 1500 RPM for precision in grinding and polishing.

- Advanced Automation: Features DELTA PLC control for automatic parameter saving and process repeatability.

- User-Friendly Interface: Large touch screen for intuitive operation, quick adjustments, and real-time status monitoring.

- Flexible Operating Modes: Offers both manual and automatic modes with customizable speed settings and up to 64 programmable processes.

- Magnetic Disc System: Enables quick and easy replacement of abrasive paper and polishing cloths, minimizing downtime.

- Upgradeable Design: Optional automatic grinding head for simultaneous processing of up to six samples and compatibility with a polishing liquid dispenser.

- Safety Features: Includes an emergency switch and reversible disc rotation for added safety and versatility.

- Compact and Durable: Stable operation with low noise, sleek design, and robust construction for long-term use.

- Comprehensive Accessories: Comes with a complete set of standard accessories for immediate operation, with optional add-ons for specialized tasks.

- Precise and Repeatable Results: Automation and customizable settings ensure consistent, high-quality specimen preparation every time.

AFFORDABLE - Perfect for Organizations on a Budget

What really sets these machines apart is their AFFORDIBILITY. For many applications SMART CUT® RP provide equal results and in less time, then many other much higher cost equipment. Which makes them a Perfect option for organizations of all sizes (manufacturing, R & D) that are on a Budget. Compare to any brand name Grinding, & Polishing Machines on market today. Your ROI (RETURN ON INVESTMENT) will also be enhanced by affordable cost of consumables (replacement) diamond discs. Which are amount the most competitively prices in the world.

Diamond

Grinding & Polishing Consumables

- Abrasive Belts

- Abrasive Powders

- Abrasive Suspensions

- Abrasive Pastes

- Polishing Pads

- Diamond Suspensions

- Diamond Paste

- Diamond Cup Powders

- Abrasives Discs

- Abrasive Rolls/Strips

- Diamond Belts

- Diamond film

- Grinding/Polishing Machines

- Diamond grinding/polishing strips/foils

Standard Package (included with machine)

|

Name |

Quantity |

Name |

Quantity |

|---|---|---|---|

|

Grinding & polishing machine |

1 set |

Anti-sticky disc (254mm) |

1 pc. |

|

Magnetic working plate (254mm) |

1 pc. |

Waterproof ring |

1 pc. |

|

One side sticky polishing cloth (250mm), velvet & canvas |

10 pcs./each |

One side sticky polishing cloth (250mm), velvet & canvas |

2 pcs./each |

|

Diamond polishing liquid, 6 micron, 200ml |

1 bottle |

Input-water pipe Φ8mm |

1 pc. |

|

Output-water pipe Φ25mm |

1 pc. |

Input-water pipe adapter |

1 pc. |

|

Touch pen |

1 pc. |

Power cable |

1 pc. |

|

Filter screen (60#) |

4 pcs. |

Triangle valve |

1 pc. |

|

PTFE tape |

1 pc. |

Rubber washer with filter screen |

1 pc. |

|

Pipe clamper 18-32 |

1 pc. |

Machine certificate |

1 share |

Related Products

SMART CUT® NP-3A

SMART CUT® NP-1A

SMART CUT® AP Automatic Grinder/Polisher with Single Wheel

Recently Viewed Products

ARE YOU USING RIGHT CONSUMABLES?

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT METALLOGRAPHIC CONSUMABLES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....