-

0 items in quote

No products in the Quote Basket.

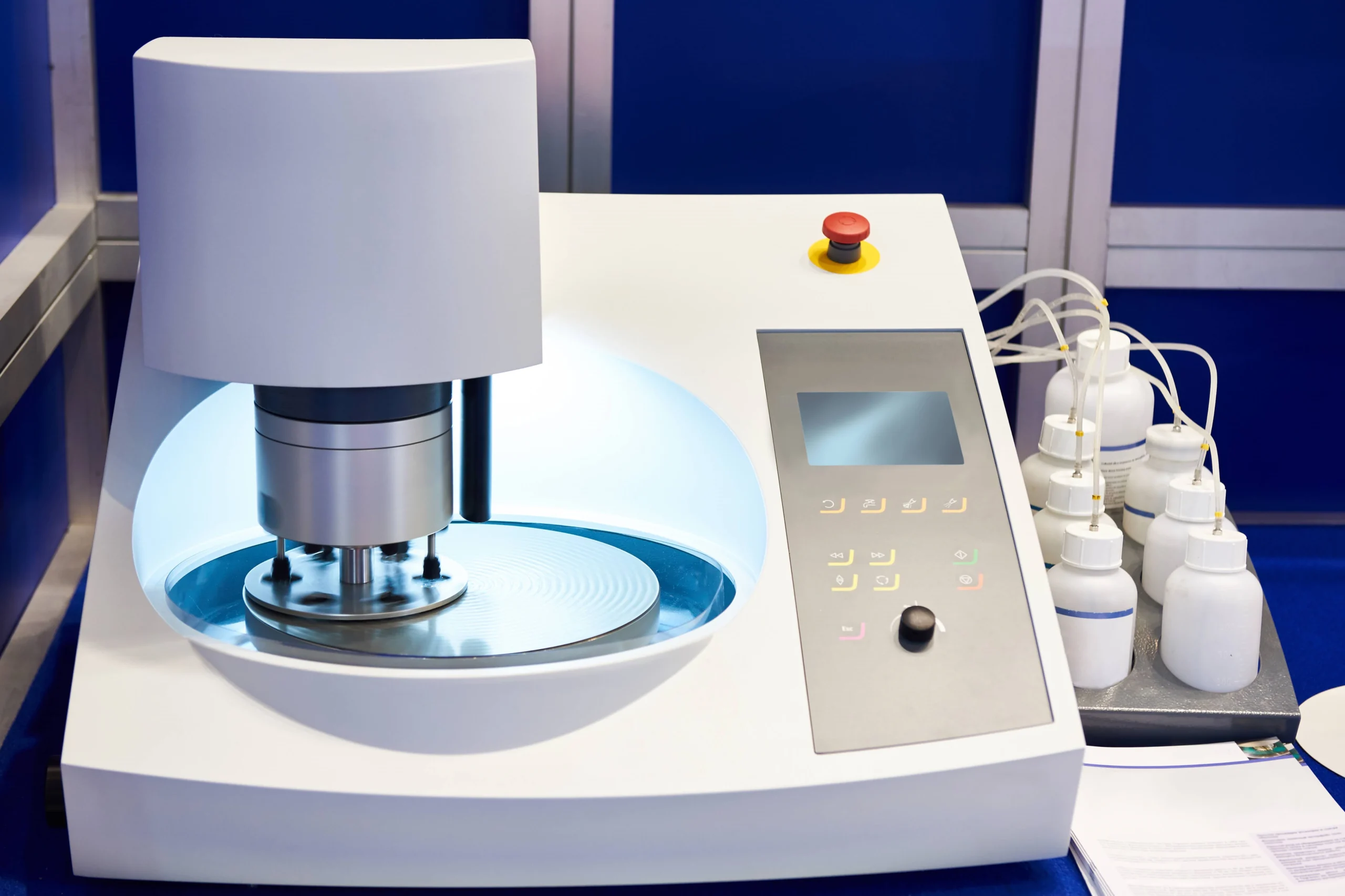

SMART CUT® RP 4000YX / 5000YX

Precision Grinding & Polishing Machine

SMART CUT® RP 4000YX / 5000YX Precision Grinding & Polishing Machine is a next-generation semi-automatic system engineered for high-precision sample preparation in applications involving semiconductor wafers, advanced ceramics, metallographic specimens, and other hard or brittle materials requiring stringent surface finish tolerances and material removal accuracy.

This system offers vacuum adsorption to securely hold samples in place during the grinding and polishing process. The 4000YX model is specifically designed to accommodate samples up to 4 inches in diameter, while the 5000YX model supports wafers up to 6 inches.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

FEATURES

INDUSTRIES USED IN

FAQ

ACCESSORIES

OPERATING MANUALS

DESCRIPTION

Both models allow for adjustable sample tilt ranging from 0 to 10 degrees, enabling users to optimize contact uniformity and achieve superior polishing results across uneven or variably shaped surfaces.

To enhance control over the process, the machine utilizes a gravity-based pressurization mechanism, allowing users to continuously adjust the sample loading force between 0 and 4 kilograms. The polishing head incorporates a programmable oscillation mechanism, swinging the sample left and right to simulate the manual polishing motion, which improves the evenness of surface finishing. The swing amplitude can be adjusted between 0 and 15 degrees, while the swing speed of the arm remains stable and can be fine-tuned to match the specific polishing requirements of different materials.

A powerful 1-kilowatt independent motor drives the polishing disc, ensuring consistent torque across the entire speed range. This system maintains performance regardless of the rotational speed or the pressure applied during the operation. The grinding and polishing disc operates within a wide rotational speed range from 5 to 100 revolutions per minute, enabling operators to tailor the process to both coarse and fine grinding requirements.

Users interact with the system through an intuitive full-touchscreen interface that simplifies parameter setup and process control. All operational settings—including disc rotation speed, duration, direction, and swing parameters—are digitally programmable and can be saved for future use. The system supports up to 64 user-defined polishing programs, which allow repeatable processes and efficient transitions between different sample types or preparation protocols.

An integrated four-station droplet dispensing system is included to facilitate the precise application of different abrasives or polishing fluids. Each droplet channel supports a flow rate adjustable between 1 and 100 milliliters per minute, enabling tailored control of fluid delivery to each polishing station.

Both models are powered by a standard AC220V 50Hz power supply and come housed in a compact, durable frame with physical dimensions of 760 × 430 × 360 mm (L × W × H) and a net weight of approximately 30 kg. The system includes all necessary standard accessories such as grinding/polishing platens, vacuum trays, abrasive dispensers, and a maintenance tool kit.

this system combines engineering precision, user-centric design, and process automation to meet the rigorous demands of material research, quality assurance, semiconductor fabrication, and petrographic analysis. It offers a high degree of flexibility, making it ideal for laboratories and facilities requiring precise, repeatable, and customizable grinding and polishing performance.

SPECIFICATIONS

Technical Specifications:

|

Specification |

SMART CUT® RP 4000YX |

SMART CUT® RP 5000YX |

|---|---|---|

|

Number of Grinding/Polishing Heads |

1 |

2 |

|

Max Sample Diameter |

3” (optional: 4”) |

5” (optional: 6”) |

|

Resolution |

1 micron |

1 micron |

|

Sample Tilt Angle Range |

0° to 10° |

0° to 10° |

|

Adjustable Sample Loading Force |

0 – 4 kg (continuous) |

0 – 4 kg (continuous) |

|

Arm Swing Amplitude |

0° to 15° adjustable |

0° to 15° adjustable |

|

Arm Swing Speed |

Variable & adjustable |

Variable & adjustable |

|

Disc Diameter |

Ø300 mm |

Ø400 mm |

|

Disc Drive Motor |

1.0 kW |

1.0 kW |

|

Disc Speed Range |

5 – 100 RPM |

5 – 100 RPM |

|

Rotation Direction |

Clockwise/Counterclockwise with auto switching |

|

|

Manual Speed Settings |

V1 = 5, V2 = 15, V3 = 25, V4 = 50 (User-defined) |

|

|

Stored Process Parameters |

64 programmable modes |

64 programmable modes |

|

Droplet Dispensing Units |

4 |

4 |

|

Droplet Speed |

1 – 100 mL/min |

1 – 100 mL/min |

|

Power Supply |

AC 220V, 50 Hz |

AC 220V, 50 Hz |

|

Dimensions (L × W × H) |

760 × 430 × 360 mm |

760 × 430 × 360 mm |

|

Weight |

30 kg |

30 kg |

FEATURES

Key Features:

- High-Precision Material Removal:

Engineered for precision grinding and polishing applications requiring sub-micron level accuracy. - Vacuum Sample Fixation:

Secure sample holding through vacuum adsorption.- 4000YX: Compatible with wafers up to 4 inches

- 5000YX: Supports wafers up to 6 inches

- Adjustable Sample Tilt:

Enables fine-tuning of sample angle from 0° to 10°, improving polishing uniformity on uneven surfaces. - Gravity-Based Sample Loading:

Provides adjustable and stable loading force, continuously variable between 0 – 4 kg for optimal sample contact. - Semi-Automatic Sample Swing Functionality:

The sample stage oscillates laterally to simulate manual movement, improving polishing uniformity. - Programmable Swing Arm Speed and Amplitude:

- Swing amplitude adjustable from 0° to 15°

- Uniform and user-defined swing speed for repeatable results

- High-Powered Drive System:

Integrated 1KW independent motor ensures constant torque across all speeds for consistent performance, even under load. - Wide Speed Range:

Grinding/polishing disc speed adjustable from 5 to 100 RPM to suit various materials and process stages. - Touchscreen User Interface:

Full digital interface with intuitive controls for setting and saving process parameters. - Advanced Parameter Management:

Up to 64 programmable grinding and polishing modes, including:- Speed

- Time

- Rotation direction (clockwise/counterclockwise, forward/reverse switching)

- Abrasive Dispensing System:

- Integrated 4-station droplet control system

- Drip speed adjustable from 1 – 100 mL/min

- Allows different abrasives to be used at each polishing station

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

ACCESSORIES

Tab Content

OPERATING MANUALS

Tab Content

Advantages:

High-Precision Performance

Delivers sub-micron level grinding and polishing accuracy, ideal for advanced materials and critical applications.

Vacuum-Based Sample Holding

Ensures stable and secure sample fixation without mechanical clamping, minimizing deformation or slippage.

Supports Multiple Wafer Sizes

AUTOPOL100YX accommodates up to 4″ wafers; AUTOPOL200YX supports up to 6″ wafers, offering flexibility across sample sizes.

Adjustable Sample Tilt

Sample tilt angle adjustable from 0° to 10°, enhancing contact uniformity and improving surface finish consistency.

Continuously Adjustable Loading Force

Gravity-based pressure system allows continuous adjustment of sample force from 0 to 4 kg for optimal polishing conditions.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Semi-Automatic Oscillating Motion

Swinging sample arm simulates manual motion to produce uniform results while reducing operator fatigue.

Adjustable Swing Amplitude and Speed

Swing amplitude customizable from 0° to 15°, with uniformly controlled swing speed for repeatable polishing motion.

Independent High-Torque Motor (1KW)

Maintains consistent torque across all RPMs, ensuring reliable performance even under heavy loading conditions.

Wide Speed Range (5 – 100 RPM)

Accommodates both rough grinding and final polishing through variable disc speeds, enabling a full range of operations.

Touchscreen Control Interface

User-friendly full-color touchscreen simplifies parameter input, control, and monitoring for efficient operation.

Process Memory and Automation

Stores up to 64 user-defined programs including speed, time, and direction—ensuring repeatability and process optimization.

Four-Channel Abrasive Dispenser

Integrated droplet system supports four different abrasive fluids, each with individually controlled flow rates (1–100 mL/min).

Compact Footprint with Low Operating Noise

Ideal for laboratory environments requiring quiet, compact, and efficient equipment.

Multi-Application Versatility

Suitable for semiconductor, petrographic, metallographic, ceramic, optical, and materials science sample preparation.

Robust Construction and Reliable Operation

Built for continuous use in research, quality control, and production environments with minimal maintenance required

Related Products

SMART CUT® NP-1A

SMART CUT® NP-2A Automatic Metallographic Grinder & Polisher

SMART CUT® AP Automatic Grinder/Polisher with Single Wheel

Recently Viewed Products

ARE YOU USING RIGHT CONSUMABLES?

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT METALLOGRAPHIC CONSUMABLES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....