-

0 items in quote

No products in the Quote Basket.

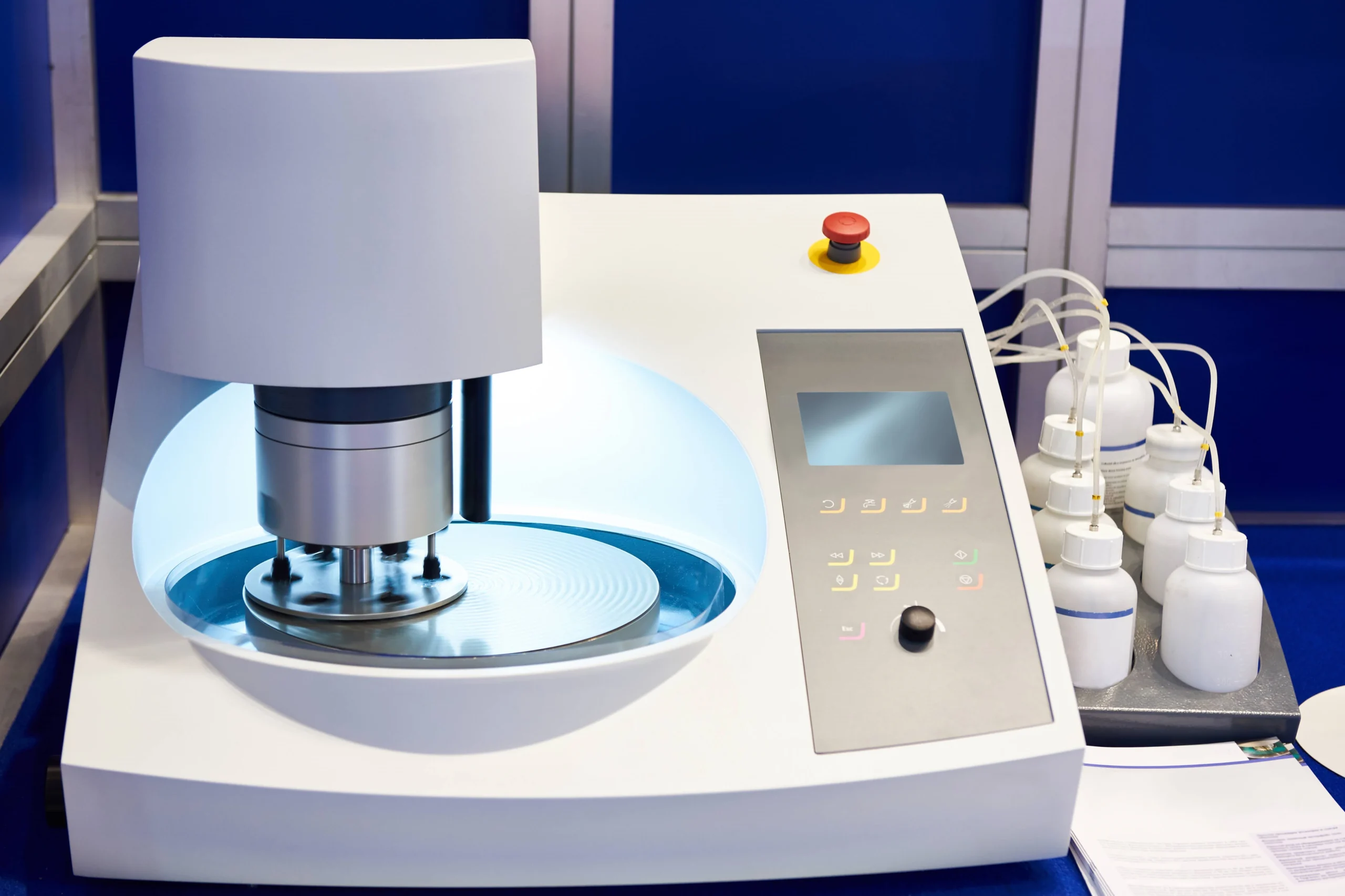

SMART CUT® NP Wheel Metallographic Grinder and Polisher

SMART CUT® NP Wheel Metallographic Grinder and Polisher embodies sophistication and precision engineering for metallographic specimen preparation. This robust unit is tailored to support the needs of both novice and expert technicians by simplifying complex grinding and polishing tasks through a user-friendly interface and superior design features.

Equipped with a variable speed drive, the SMART CUT® NP allows for precise control over the grinding and polishing actions. It boasts three preset speed selections to optimize the preparation process for various types of samples. Its flexibility is further enhanced with direction control, offering both clockwise and counterclockwise rotation, which is critical for achieving uniform specimen surfaces.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

FEATURES

INDUSTRIES USED IN

FAQ

ACCESSORIES

DESCRIPTION

Ease of maintenance and operation is at the forefront of the SMART CUT® NP design. It features a pull-out water hose with a universal direction nozzle, facilitating straightforward and effective cleaning of the basin. Additionally, the inclusion of a plastic disposable bowl liner ensures hassle-free and hygienic maintenance after each use.

Durability is important in the construction of the SMART CUT® NP. The working wheel is crafted from hard-anodized aluminum, which not only extends the life of the machine but also maintains its aesthetic quality. The body is made from a high-strength composite material that resists corrosion and wear, encapsulated by a powder-coated aluminum housing for added protection against harsh environments.

This single wheel grinder and polisher is an ideal choice for laboratories seeking a reliable and efficient solution to prepare high-quality metallographic samples. Its design ensures long-lasting reliability and consistent performance, setting a new standard in specimen preparation equipment.

SPECIFICATIONS

- Number of stations: Single wheel

- Drive Mechanism: 1 hp (750 W) dynamic torque servo motor

- Speed: Variable 100-1000 rpm

- Electrical Specifications: 110V or 220V 50/60 Hz

- Dimensions (WxDxH): 16.5 x 21 x 8.5-inch (420 x 530 x 220 mm)

- Weight: 29 kg (63 lbs)

- Working wheels: 8 and 10-inch diameter

ADVANTAGES

- User-Friendly Interface: Simplifies the operation, making it accessible for both novice and experienced users.

- Variable Speed Settings: Includes three preset fast speed buttons, allowing for precise control over the grinding and polishing process.

- Directional Control: Offers both counterclockwise and clockwise rotation, enhancing the versatility and effectiveness of sample preparation.

- Easy Maintenance: Equipped with a pull-out water hose with universal direction for easy basin cleaning and a plastic disposable bowl liner for hassle-free cleaning.

- Durability: Features a hard anodized aluminum working wheel and a durable composite body that resists rust, extending the lifespan of the equipment.

- Robust Construction: Built with powder-coated aluminum housing for enhanced durability and long-lasting reliability in demanding laboratory environments.

- Efficient Design: Streamlined construction minimizes physical strain and maximizes efficiency in specimen preparation.

FEATURES

Tab Content

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

Tab Content

ACCESSORIES

Tab Content

|

Wheel (mm) |

●Ø203○Ø254 |

|

Speed (rpm) |

100-1000 |

|

Motor |

550W |

|

Power |

110/220V |

|

Paper Ring |

● |

|

Splash Guard |

● |

|

Cover |

● |

|

Grinding Paper |

● |

|

Polishing Cloth |

● |

|

Diamond Spary |

○ |

|

Diamond Slurry |

○ |

|

Alumina Powder |

○ |

|

Recirculating Tank |

○ |

Related Products

SMART CUT® MP-A Manual Grinder / Polishing Machine

SMART CUT® NP Dual Manual Grinder / Polisher

SMART CUT® LG Manual Metallurgical Grinder/Polisher with Single Wheel

SMART CUT® LP – 12” (300MM)

SMART CUT® LP – Grinding/Polishing Machine

Recently Viewed Products

ARE YOU USING RIGHT CONSUMABLES?

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT METALLOGRAPHIC CONSUMABLES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected diamonds...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

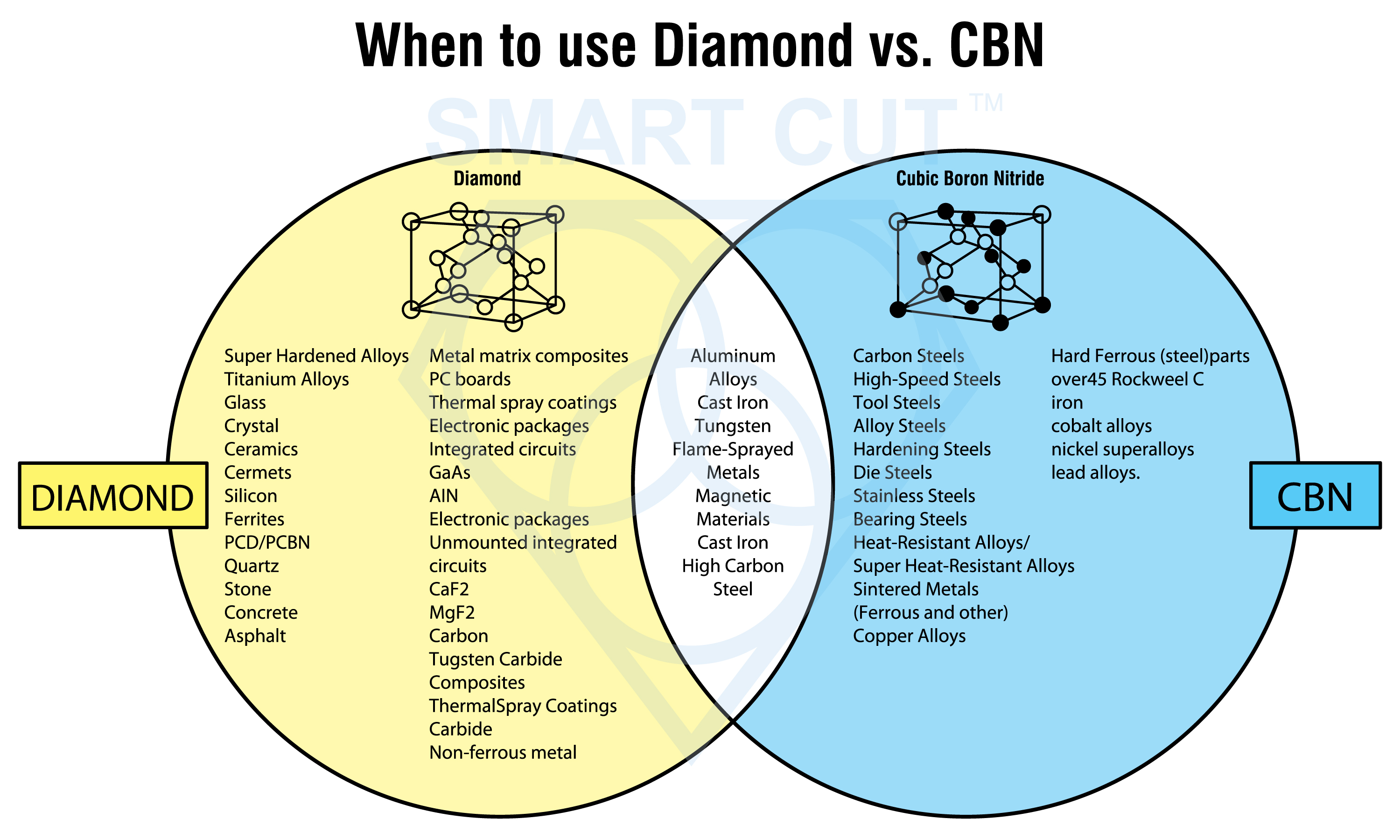

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

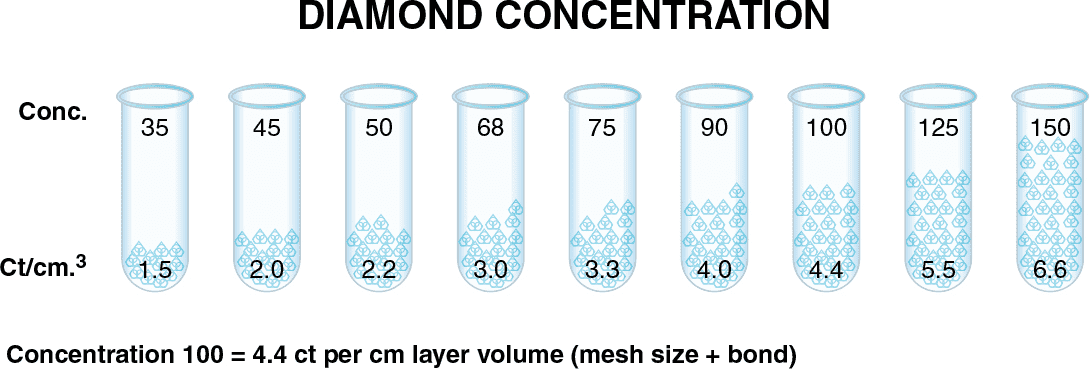

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Choosing the correct diamond suspension, whether monocrystalline or polycrystalline, significantly impacts the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can help you...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

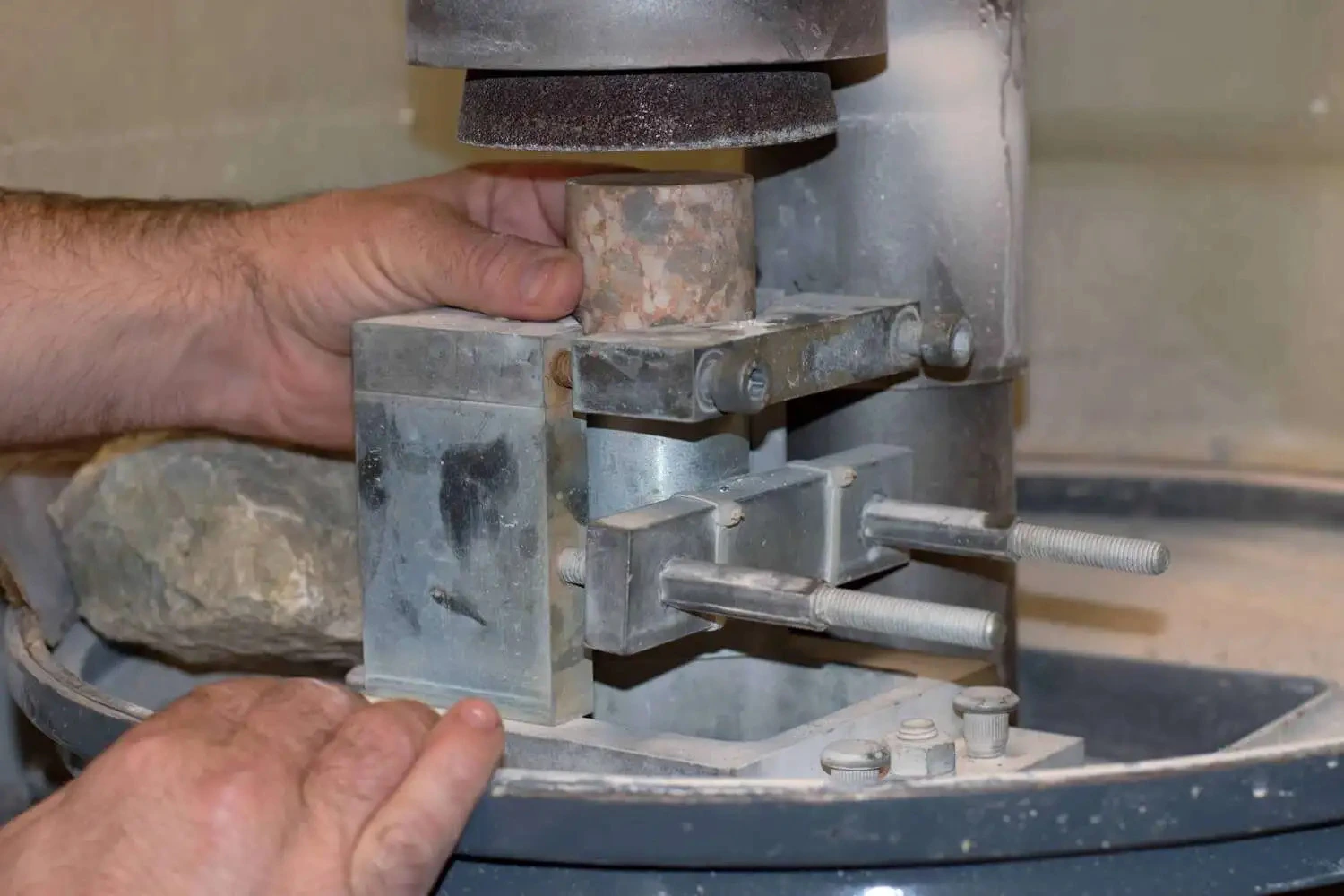

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Selecting Right Silicon Carbide Paper / Discs for Metallography / Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use