-

0 items in quote

No products in the Quote Basket.

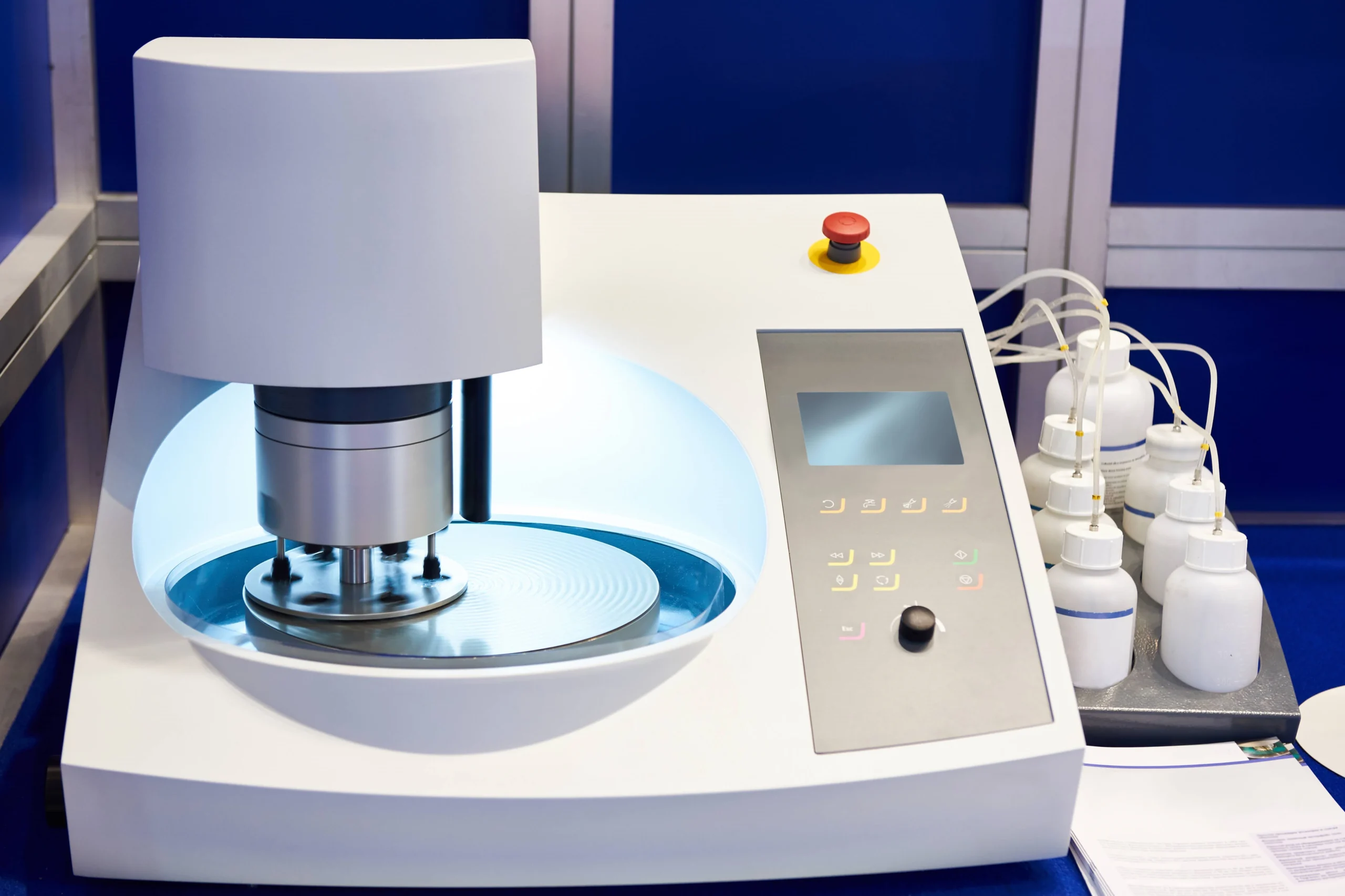

SMART CUT® LP – 12” (300MM)

SMART CUT® LP is most affordable, entry level Laboratory Variable Speed Polishing, Grinding, Lapping Machine. Designed for Mechanical Sample Preparation.

SMART CUT® LP – 12” (300mm)is Perfect for coarse & fine grinding and polishing of large variety of materials. Including: Ultra Hard & Brittle, Metals, Ceramics, Refractories, Cement, and Petrographic thin sections. As well as full range of optical materials, such as: Bk7, Fused Silica, Zeroder, Quartz, Soda Lime Glass, Yag, Sapphire, and Many Others.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

Its Variable Speed allows the operator the flexibility to move from high speed rough grinding to low speed final polishing.

It’s molded plastic housing will never rust. Capable of withstanding more exploitation, requires less maintenance, and much easier to use that Fully Automatic Polishing, Lapping, & Grinding Equipment. Preferred by thousands of Universities, Government Research Laboratories, Commercial Laboratories & Advanced Material fabrication facilities.

Precision steel plate accepts magnetic backed accessories for quick and easy changing of discs. This unit comes with a water manifold including overhead loc-line, a water pump, 1/4″ tubing, and a drain to ensure ample water coolant reaches to the machine and drains away properly.

SPECIFICATIONS

- Weight:44.00 LBS

- Width:23.00 (in)

- Height:23.00 (in)

- Depth:15.00 (in)

ADVANTAGES

- Can be used for almost any Application

- Variable Speed from 25 to 1,800 RPM

- Very Easy to Use

- Runs Quietly and Cleanly

- Can withstand more exploitation &

- Requires less maintenance

- Most Affordable Entry Level Solutions Available Today

- Perfect for Manufacturing and R & D organizations on a Budget

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

Tab Content

OPERATING MANUALS

Tab Content

ACCESSORIES

Tab Content

Compare to Brand Name Grinding / Polishing Machines for Sample Preparation & Materials Research. Perfect for Manufacturing and R & D facilities on a Budget.

What you will save on cost of Consumables will more than pay for SMART CUT® LP in short period of time

VARIABLE SPEED

from 25 to 1,800 RPM. The SMART CUT® LP– 12” (300mm)has a large range of speeds to accommodate a wide variety of materials and applications. Operator can adjust the RPM as needed. High RPM setting is recommended for grinding and lower RPM setting is recommended for final polishing. Runs very quietly – Perfect for laboratory or production Environment.

Runs cleanly

No plastic aprons and cold, coolant soaked hands are required. Specially designed coolant spray shield keeps coolant in the work area and not on you. The finishing process uses a modest supply of coolant – in most cases, a quart of coolant will last all day.

Clean up is easy

Just remove the coolant spray shield and tray, wash, and you are ready to work again. Versatile & Easy to Use By changing to the appropriate disc/lap, your machine can be used for grinding, lapping, or polishing operation. Your machine has been designed to use a variety of diamond, felt, and abrasive discs/films depending on your individual technique or desired results.

Versatile & Easy to Use

By changing to the appropriate disc/lap, your machine can be used for grinding, lapping, or polishing operation. Your machine has been designed to use a variety of diamond, felt, and abrasive discs/films depending on your individual technique or desired results.

INTERCHANGABLE PSA BACKED DISCS

SMART CUT® (Fixed Abrasive) diamond discs are interchangeable. Each Disc has magnetic backing and attached to the machine steel plate. It takes only seconds to change discs. The operator can go from rough finish to final polish on same machine. By changing to the appropriate disc, your machine can be used for grinding, lapping, or polishing operation. SMART CUT® LP has been designed to use a variety of diamond, felt, and abrasive discs/films depending on your individual technique or desired results

MOST AFFORDABLE MACHINE ON THE MARKET & HIGHEST QUALITY LOW COST CONSUMABLES

What really sets these machines apart is their AFFORDIBILITY. For many applications SMART CUT® LP provide equal results and in less time, then many other much higher cost equipment. Which makes them a Perfect option for organizations of all sizes (manufacturing, R & D) that are on a Budget.

Compare to any brand name Grinding, & Polishing Machines on market today. Your ROI (RETURN ON INVESTMENT) will also be enhanced by affordable cost of consumables (replacement) diamond discs. Which are amount the most competitively prices in the world. What you will save on cost of Consumables will more than pay for these machines short period of time.

MADE IN USA

SMART CUT® LP Machines are made with pride 100% in USA from all parts made in USA. Including all of the consumables diamonds discs (metal bond, resin bond, and felt), diamond paste, slurry, abrasive powders also Made in USA

CAN BE USED WITH BOTH FIXED (ABRASIVE) DIAMOND DISCS & FELT DISCS WITH LOOSE ABRASIVE

These machines can use both Fixed (abrasive) Diamond Discs & Felt discs with loose abrasive (diamond powder, diamond paste, diamond slurry, and all abrasive powders). Allowing you to select the most optimum and economic option for you application. Fixed Abrasive diamond discs (have diamond impeded on the surface of the disc (metal bond) or diamond impregnated inside the disc (resin bond). Advantages of using “Fixed Abrasive” System includes: consistent application of diamond through the entire machine steel plate. Life in number of parts that can be processed (significantly lower consumables cost, and in much shorter time it would take to achieve same results with loose abrasives.

AFFORDABLE - Perfect for Organizations on a Budget

What really sets these machines apart is their AFFORDIBILITY. For many applications SMART CUT® LP provide equal results and in less time, then many other much higher cost equipment. Which makes them a Perfect option for organizations of all sizes (manufacturing, R & D) that are on a Budget. Compare to any brand name Grinding, & Polishing Machines on market today. Your ROI (RETURN ON INVESTMENT) will also be enhanced by affordable cost of consumables (replacement) diamond discs. Which are amount the most competitively prices in the world.

Diamond

Grinding & Polishing Consumables

- Abrasive Belts

- Abrasive Powders

- Abrasive Suspensions

- Abrasive Pastes

- Polishing Pads

- Diamond Suspensions

- Diamond Paste

- Diamond Cup Powders

- Abrasives Discs

- Abrasive Rolls/Strips

- Diamond Belts

- Diamond film

- Grinding/Polishing Machines

- Diamond grinding/polishing strips/foils

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Related Products

SMART CUT® MP-A Manual Grinder / Polishing Machine

SMART CUT® NP Dual Manual Grinder / Polisher

SMART CUT® NP Single Wheel Metallographic Grinder and Polisher

SMART CUT® LG Manual Metallurgical Grinder/Polisher with Single Wheel

SMART CUT® LP – Grinding/Polishing Machine

Recently Viewed Products

ARE YOU USING RIGHT CONSUMABLES?

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT METALLOGRAPHIC CONSUMABLES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....