-

0 items in quote

No products in the Quote Basket.

DESCRIPTION

SPECIFICATIONS

FEATURES

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

DESCRIPTION

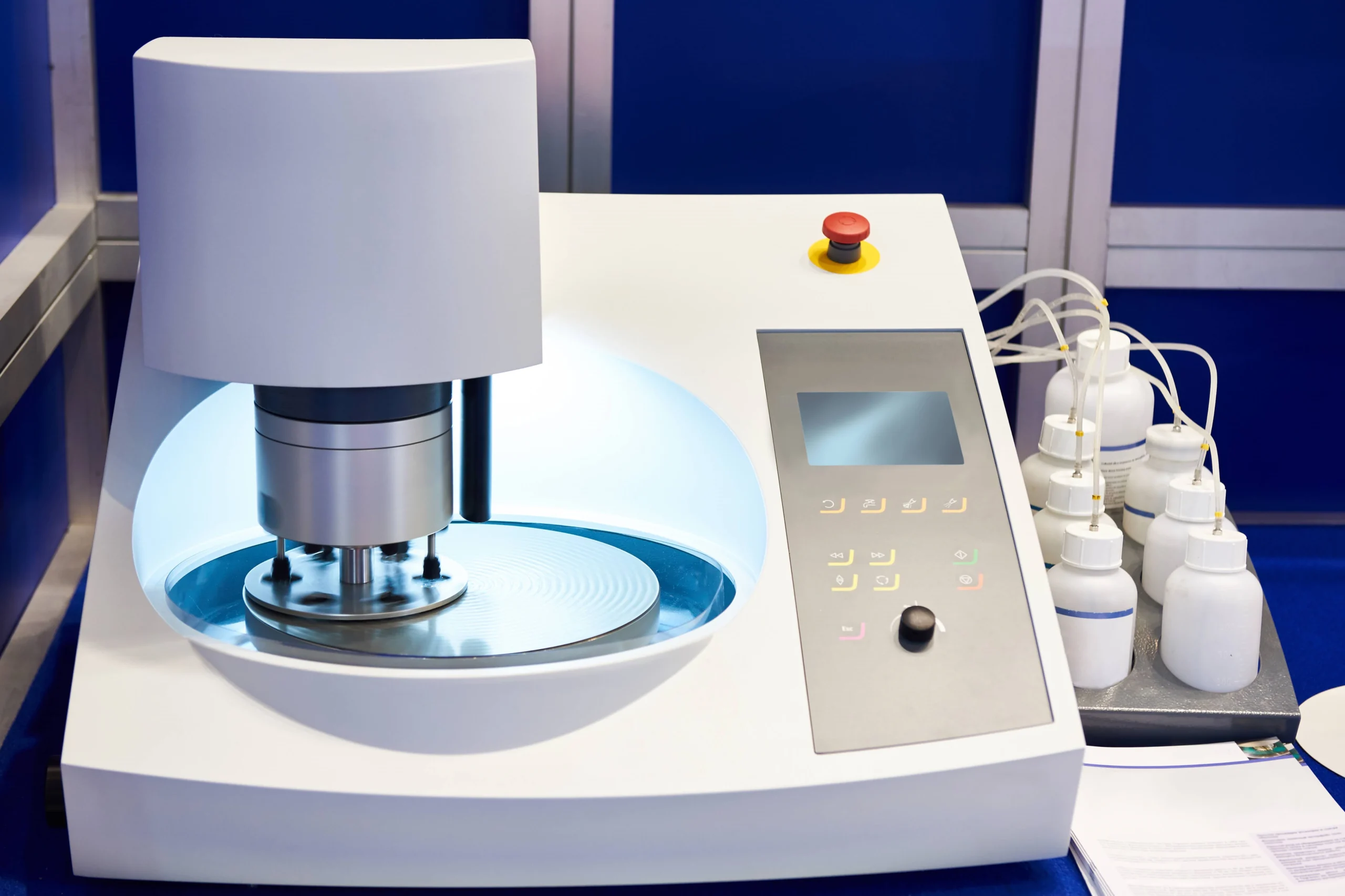

SMART CUT® LG Bench Top Metallurgical Grinder/Polisher with Single Wheel offers an economical solution to your metallographic sample preparation needs. Available in 8” (200mm), 10” (250mm), and 12” (300mm) wheel size and comes with single wheel version with variable rotating wheel speed of 50-600 RPM OR 50-1,000 rpm. Detachable water sprayer for easy cleaning.

A feather touch digital control panel as well as a fully molded FRP body with easy disc change design. 110V, 1 phase, 50/60 Hz and 230 V / 50Hz. This machine is ideal for fast manual grinding and polishing for small to large samples. This machine is incredibly robust while being easy to use and affordable in price. Perfect for organizations on a budget.

SPECIFICATIONS

- Motor – 1HP (Variable Speed)

- Platen Supports – Quick Release system for changing platens

- Diameter of Platens – 200mm (8″)

- Wheel Direction: Clockwise / Counter Clock Wise

- Water inlet 8mm push fit and outlet 32mm drainpipe

- Flexible tap with flexible hose to direct water to any part of platen

- RPM’s Range: 0-500rpm

- Dimensions – 455mm x765mm x385mm

- Weight – 40Kg

FEATURES

- Speed plate operating from 50 to 600 RPM

- Table Top Design

- Rigid table top corrosion proof FRP cabinet

- 8 in. disc polisher (10 in. and 12 in. disc optional)

- 5 h.p. AC motor

- Corrosion resistant wash bowl

- Free flow drain system

- Flexible water jet with control valve

- Safety Emergency Switch

- Digital Speed Indicator

- Retractable Water Hose for Easy Cleaning Bowl Wash

- Splash Guard Lid

- Illuminated Led Indication Display

- Easy Start Stop Smooth Function

- Variable Time and RPM’s Settings

- Front Control Panel with Feather Touch Buttons

- Aluminum disc 8″ diameter (Interchangeable)

- S holding ring (press type)

- Holding band

- Power supply : 230 V / 50Hz ( 1 + N + E ) or 110V, 1 phase, 50/60 Hz

ADVANTAGES

Tab Content

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

Yes, the SMART CUT LG Bench Top Metallurgical Grinder/Polisher with Single Wheel is designed to be affordable, making it a perfect option for organizations on a budget. It provides results comparable to higher-cost equipment in many applications, making it a cost-effective choice for manufacturing and R&D organizations.

The affordability of this product extends beyond the initial purchase cost. The cost of consumables (replacement diamond discs) is also highly competitive, which can enhance your ROI significantly. You can expect to save on consumables, making this machine a worthwhile investment.

Yes, this machine is versatile and can be used with both fixed (abrasive) diamond discs and felt discs with loose abrasive materials such as diamond powder, diamond paste, diamond slurry, and other abrasive powders. This flexibility allows you to choose the most suitable and economical option for your specific application.

Using “Fixed Abrasive” diamond discs offers several advantages, including consistent application of diamond throughout the machine’s steel plate, longer life in terms of the number of parts that can be processed (resulting in significantly lower consumables costs), and faster results compared to using loose abrasives. Additionally, there’s no need to recycle or clean used-up diamond slurry or abrasive, making it an environmentally friendly option.

The variable rotating wheel speed, ranging from 50 to 600 RPM, provides users with the flexibility to tailor the grinding and polishing process to their specific needs. Different materials and sample sizes may require different wheel speeds for optimal results. This feature allows for precise control and ensures that you can achieve the desired finish on your samples.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher is equipped with a Safety Emergency Switch. This switch is a crucial safety feature that allows users to quickly stop the machine in case of an emergency or if any unexpected situation arises during the sample preparation process, ensuring the safety of operators and preventing accidents.

Yes, the machine is designed for easy cleaning and maintenance. It comes with a detachable water sprayer for convenient cleaning. The corrosion-resistant wash bowl with a free-flow drain system ensures that the machine can be cleaned efficiently. Additionally, the retractable water hose and splash guard lid contribute to the ease of maintenance.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher operates on a 110V, 1 phase, 50/60 Hz power supply. This standard power supply is commonly available, making it convenient for users to set up and operate the machine.

This product offers comparable performance and features to well-known brands like BUEHLER, STRUERS, and LECO, but at a more affordable price point. It provides a cost-effective alternative without compromising on quality or functionality, making it an attractive option for organizations seeking budget-friendly equipment for their metallographic sample preparation needs.

Certainly! The SMART CUT LG Bench Top Metallurgical Grinder/Polisher has the following dimensions: 455mm x 765mm x 385mm (height x width x depth). It weighs 40 kilograms, making it relatively compact and easy to transport or install in various laboratory or industrial settings.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher comes with an 8-inch diameter aluminum disc that is interchangeable. This feature allows users to replace the disc as needed or switch to different disc types for specific applications. Interchangeable discs can be a cost-effective way to adapt the machine to various sample preparation requirements.

The machine features a flexible water jet with a control valve, which allows users to direct water to any part of the platen as needed. The water inlet is an 8mm push fit, and the outlet is a 32mm drainpipe. This water management system helps ensure efficient cooling and lubrication during the grinding and polishing processes.

Yes, the SMART CUT LG Bench Top Metallurgical Grinder/Polisher is designed to accommodate both clockwise and counterclockwise wheel directions. This versatility is beneficial for users who have specific requirements or preferences for the direction of wheel rotation.

Users can easily adjust the RPM of the wheel using the digital control panel. The machine allows for variable RPM settings, ranging from 0 to 500 RPM, or 50 to 1,000 rpm providing precise control over the speed of the grinding and polishing process to achieve the desired results.

Regular maintenance is essential to keep the machine in optimal working condition. While specific maintenance requirements may vary, it’s generally advisable to follow the maintenance guidelines provided in the user manual. This may include routine cleaning, lubrication of moving parts, and periodic inspections to ensure that the machine operates smoothly and safely.

The use of “Fixed Abrasive” diamond discs, as mentioned in the product description, can be considered a greener option compared to loose abrasives. It reduces the need for recycling or cleaning used-up diamond slurry or abrasive, making the sample preparation process more environmentally friendly. Additionally, the machine’s efficient design and materials contribute to its eco-friendliness.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher is versatile and can be used for a wide range of materials commonly encountered in metallographic sample preparation. It is suitable for preparing samples made of metals, ceramics, and other materials commonly used in industrial and research applications.

Optional accessories, such as additional platens, different disc sizes, or specialized tools, may be available depending on the manufacturer or distributor. Users interested in expanding the capabilities of the machine should inquire with the seller or manufacturer about the availability of optional accessories and their compatibility with the SMART CUT LG Bench Top Metallurgical Grinder/Polisher.

When operating the SMART CUT LG Bench Top Metallurgical Grinder/Polisher, users should adhere to standard safety practices, including wearing appropriate personal protective equipment (PPE) such as safety glasses and gloves. It’s essential to follow the safety guidelines provided in the user manual and ensure that the Safety Emergency Switch is easily accessible in case of an emergency.

Yes, this product is suitable for use in both research and industrial settings. Its versatility, cost-effectiveness, and ease of use make it a valuable tool for organizations of various sizes and purposes, including research and development laboratories and manufacturing facilities.

The installation and setup of the SMART CUT LG Bench Top Metallurgical Grinder/Polisher are typically straightforward. Users should ensure that the machine is placed on a stable and level surface, connect it to the appropriate power supply, and follow the instructions in the user manual for any specific setup procedures. In most cases, it can be quickly integrated into the workspace.

Replacement parts are available

Yes, the SMART CUT LG Bench Top Metallurgical Grinder/Polisher is designed for versatility and can be used for both rough grinding and fine polishing applications. Users can adjust the parameters, such as wheel speed and abrasives, to achieve the desired finish and quality for their specific samples.

The machine’s design allows for flexibility in accommodating samples of varying sizes and shapes. Users can adjust the sample placement and positioning to ensure effective grinding and polishing regardless of the sample’s size or shape. The versatile nature of the product makes it suitable for a wide range of sample types.

Yes, users can customize the RPM settings to meet the requirements of specific applications or materials. The variable rotating wheel speed, with a range of 50 to 600 RPM, offers precise control and flexibility for achieving optimal results, whether for different materials or sample preparation techniques.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher is designed to manage sample cooling through the use of water. The machine features a detachable water sprayer, a corrosion-resistant wash bowl, and a flexible water jet with a control valve. These components ensure that samples are effectively cooled and lubricated during the grinding and polishing operations.

Yes its possible attach additional fixtures or clamping mechanisms to secure irregularly shaped samples during processing. This feature can be especially useful for maintaining sample consistency and precision during grinding and polishing.

The suitability of the SMART CUT LG Bench Top Metallurgical Grinder/Polisher for controlled environments or cleanrooms may depend on the specific requirements of the facility. Users should assess whether the machine meets cleanliness and contamination control standards for their particular application and environment.

The machine’s dimensions and weight make it relatively portable and easy to relocate within a laboratory or workspace. Users can move it to different workstations or areas as required, provided that a suitable power supply is available. However, it’s essential to handle the machine with care and follow safety precautions when relocating it.

Proper disposal of consumables, such as used diamond discs or abrasive materials, is important. Users should follow local regulations and guidelines for the disposal of these materials, which may include recycling or disposing of them in a manner that is environmentally responsible and compliant with local laws.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher is primarily designed for wet grinding and polishing processes that involve the use of water or coolant. While it may be possible to adapt the machine for some dry grinding applications, users should exercise caution and follow our recommendations to ensure safe and effective operation in different modes.

Depending on its compatibility with automation interfaces and requirements, the SMART CUT LG Bench Top Metallurgical Grinder/Polisher may be suitable for integration into automated or robotic sample preparation systems. Users interested in automation should inquire with the manufacturer or a systems integrator to explore the possibilities and necessary adaptations.

Users can typically purchase replacement consumables and accessories directly from the manufacturer or authorized distributors. This ensures that users have access to genuine replacement parts and accessories that are compatible with the machine.

The machine is designed to handle abrasive materials commonly used in sample preparation. To minimize wear and tear on components, users should follow best practices for sample preparation, including using appropriate abrasives, ensuring proper lubrication, and periodically inspecting and replacing worn components, such as platens and diamond discs, as recommended in the user manual.

The versatility of the SMART CUT LG Bench Top Metallurgical Grinder/Polisher makes it suitable for various applications, including preparing samples for electron microscopy, spectroscopy, and other analytical techniques. Users should consult the manufacturer or distributor for guidance on adapting the machine to specific sample preparation requirements for such applications.

Proper storage and maintenance of consumables are essential to maximize their lifespan and performance. Users should store consumables in a dry, clean, and controlled environment to prevent contamination and degradation.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher is designed to handle a wide range of materials, including advanced materials like ceramics, composites, and advanced alloys. Users should choose appropriate abrasives and settings to match the specific properties and requirements of these materials.

Users encountering technical challenges or operational issues should have access to technical support from the manufacturer or distributor. This support may include remote assistance, troubleshooting guidance, or on-site service if necessary. Users should inquire about the available support options and response times.

The machine is designed to handle the use of water or coolants during sample preparation. Safety considerations may include proper water supply and drainage, ensuring that electrical components are well-protected, and following safety guidelines for the use of water or coolants to minimize the risk of electrical hazards.

The quality of water or coolants used with the machine may affect its performance and longevity. Users should refer to the ourrecommendations for the type and quality of water or coolants suitable for use with the machine. This may include considerations such as deionized water or specific coolant formulations.

Proper handling and disposal of waste generated during the sample preparation process are important for environmental and safety reasons. Users should follow local regulations and guidelines for the disposal of waste materials, including used abrasive materials.

Routine calibration checks are essential for ensuring the accuracy of RPM and other settings. Some manufacturers may provide calibration tools and instructions with the machine.

The SMART CUT LG Bench Top Metallurgical Grinder/Polisher offers an economical solution for metallographic sample preparation.

The SMART CUT LG provides comparable performance and features to these renowned brands but at a more affordable price point. It offers a cost-effective alternative without compromising on quality or functionality.

. The SMART CUT LG features a variable rotating wheel speed (50-600 RPM), a digital control panel, and versatile water management. Its affordability, combined with competitively priced consumables, enhances the return on investment. This machine is designed to be a budget-friendly choice without sacrificing performance.

The SMART CUT LG is positioned as an affordable option for organizations on a budget. It aims to provide equal results in less time compared to higher-cost equipment from Buehler, Struers, and Leco, making it an attractive choice for cost-conscious buyers.

Yes, the SMART CUT LG is versatile and can use both fixed (abrasive) diamond discs and felt discs with loose abrasives, similar to machines from Buehler, Struers, and Leco. This flexibility allows users to select the most suitable and cost-effective option for their specific application.

The SMART CUT LG’s use of “Fixed Abrasive” diamond discs can be considered a greener option compared to machines using loose abrasives. It reduces the need for recycling or cleaning used-up diamond slurry or abrasive, making it a more environmentally friendly choice. This aligns with environmentally conscious practices.

How does the SMART CUT LG’s ease of maintenance compare to machines from Buehler, Struers, and Leco?

The SMART CUT LG is designed for easy maintenance with features such as a detachable water sprayer, corrosion-resistant wash bowl, and retractable water hose. While machines from Buehler, Struers, and Leco may also offer ease of maintenance, the SMART CUT LG’s user-friendly design contributes to its accessibility for routine cleaning and upkeep.

Yes, the SMART CUT LG is versatile and can be used with a wide range of materials commonly encountered in metallographic sample preparation, including metals, ceramics, and more. This versatility aligns with the capabilities of machines from Buehler, Struers, and Leco, making it suitable for various sample types and applications.

The SMART CUT LG’s variable wheel speed (50-600 RPM) provides users with precise control, similar to machines from Buehler, Struers, and Leco. This feature allows for tailored sample preparation, ensuring optimal results for different materials and sample sizes.

OPERATING MANUALS

Tab Content

AFFORDABLE - Perfect for Organizations on a Budget

What really sets these machines apart is their AFFORDIBILITY. For many applications SMART CUT® LP provide equal results and in less time, then many other much higher cost equipment. Which makes them a Perfect option for organizations of all sizes (manufacturing, R & D) that are on a Budget. Compare to any brand name Grinding, & Polishing Machines on market today. Your ROI (RETURN ON INVESTMENT) will also be enhanced by affordable cost of consumables (replacement) diamond discs. Which are amount the most competitively prices in the world.

Diamond

Grinding & Polishing Consumables

- Abrasive Belts

- Abrasive Powders

- Abrasive Suspensions

- Abrasive Pastes

- Polishing Pads

- Diamond Suspensions

- Diamond Paste

- Diamond Cup Powders

- Abrasives Discs

- Abrasive Rolls/Strips

- Diamond Belts

- Diamond film

- Grinding/Polishing Machines

- Diamond grinding/polishing strips/foils

What you will save on cost of Consumables will more than pay for these machines short period of time

Compare to BUEHLER, STRUERS, & LECO

Why pay more?

CAN BE USED WITH BOTH FIXED (ABRASIVE) DIAMOND DISCS & FELT DISCS WITH LOOSE ABRASIVE

These machines can use both Fixed (abrasive) Diamond Discs & Felt discs with loose abrasive (diamond powder, diamond paste, diamond slurry, and all abrasive powders). Allowing you to select the most optimum and economic option for you application. Fixed Abrasive diamond discs (have diamond impeded on the surface of the disc (metal bond) or diamond impregnated inside the disc (resin bond). Advantages of using “Fixed Abrasive” System includes: consistent application of diamond through the entire machine steel plate. Life in number of parts that can be processed (significantly lower consumables cost, and in much shorter time it would take to achieve same results with loose abrasives. No used up diamond slurry or abrasive having to recycle or clean, makes this much cleaner and greener option that is friendly to the environment.

Front Control Panel with feather touch buttons

Variable time and rpm settings

Corrosion Resistant wash bowl free flow drain

Flexible water jet with control valve

Retractable water hose for easy cleaning bowl wash

COMPARE SMART CUT LG vs BUEHELR Eco Met 30

| Feature | Buehler EcoMet 30 | SMART CUT LG |

| Platen Size Options | 8, 10, 12 inches | 8 inches (10 and 12 inches optional) |

| Speed Range | 50-500 rpm | 50-600 rpm |

| Motor Power | 0.4 hp (300W) for single, 0.6 hp (440W) for twin | 0.5 hp AC motor |

| Water Supply System | 0.25 inch OD tube, 40-100 psi | Flexible water jet with control valve |

| User Interface | Basic control panel | Digital speed indicator, retractable water hose, splash guard lid, LED display, feather touch control panel |

| Weight | Single: 101.5 lbs, Twin: 154 lbs | 40 Kg |

| Power Supply | 100-240VAC, 50/60Hz, 1 phase | 230V / 50Hz |

| Additional Features | Quiet operation, robust design | Economical, user-friendly, suitable for various organizations |

| Feature | Buehler EcoMet 30 | SMART CUT LG |

| Platen Size Options | 8, 10, 12 inches | 8 inches (10 and 12 inches optional) |

| Speed Range | 50-500 rpm | 50-600 rpm |

| Motor Power | 0.4 hp (300W) for single, 0.6 hp (440W) for twin | 0.5 hp AC motor |

| Water Supply System | 0.25 inch OD tube, 40-100 psi | Flexible water jet with control valve |

| User Interface | Basic control panel | Digital speed indicator, retractable water hose, splash guard lid, LED display, feather touch control panel |

| Weight | Single: 101.5 lbs, Twin: 154 lbs | 40 Kg |

| Power Supply | 100-240VAC, 50/60Hz, 1 phase | 230V / 50Hz |

| Noise Level | 65dB at 500rpm | Not specified |

| Additional Features | Quiet operation, robust design | Economical, user-friendly, suitable for various organizations |

| Design Focus | Flexibility in sample size, ease of use | Affordability, robustness, ease of use |

| Construction Material | Not specified | Fully molded FRP body |

| Emergency Safety Feature | Not specified | Safety Emergency Switch |

| Digital Indicators | Not specified | Illuminated LED Indication Display |

| Cleaning Features | Rinse and spin feature for cleaning | Detachable water sprayer, retractable water hose |

| Control Panel Design | Knob switch | Front Control Panel with Feather Touch Buttons |

| Disc Change Design | Not specified | Easy disc change design |

| Drain System | Not specified | Free flow drain system |

| Platen Direction | Counter-Clockwise | Clockwise / Counter Clock Wise |

| Compatibility with Abrasives | Compatible with CarbiMet grinding paper and MetaDi diamond suspension fluid | Can be used with both fixed (abrasive) diamond discs & felt discs with loose abrasive |

| Additional Features | Quiet operation, robust design | Economical, user-friendly, suitable for various organizations |

| Design Focus | Flexibility in sample size, ease of use | Affordability, robustness, ease of use |

| Construction Material | Not specified | Fully molded FRP body |

| Emergency Safety Feature | Not specified | Safety Emergency Switch |

| Digital Indicators | Not specified | Illuminated LED Indication Display |

| Cleaning Features | Rinse and spin feature for cleaning | Detachable water sprayer, retractable water hose |

| Control Panel Design | Knob switch | Front Control Panel with Feather Touch Buttons |

| Disc Change Design | Not specified | Easy disc change design |

| Drain System | Not specified | Free flow drain system |

| Platen Direction | Counter-Clockwise | Clockwise / Counter Clock Wise |

Why Choose Us?

Optimize Your Application To Ultimate Level Of Efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Related Products

SMART CUT® MP-A Manual Grinder / Polishing Machine

SMART CUT® NP Dual Manual Grinder / Polisher

SMART CUT® NP Single Wheel Metallographic Grinder and Polisher

SMART CUT® LP – 12” (300MM)

SMART CUT® LP – Grinding/Polishing Machine

Recently Viewed Products

ARE YOU USING RIGHT CONSUMABLES?

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT METALLOGRAPHIC CONSUMABLES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Choosing the correct diamond suspension, whether monocrystalline or polycrystalline, significantly impacts the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can help you...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....