-

0 items in quote

No products in the Quote Basket.

SMART CUT® HIGH PRECISION GRINDING / POLISHING HEAD

HIGH PRECISION & CONTROL OF MATERIAL REMOVAL

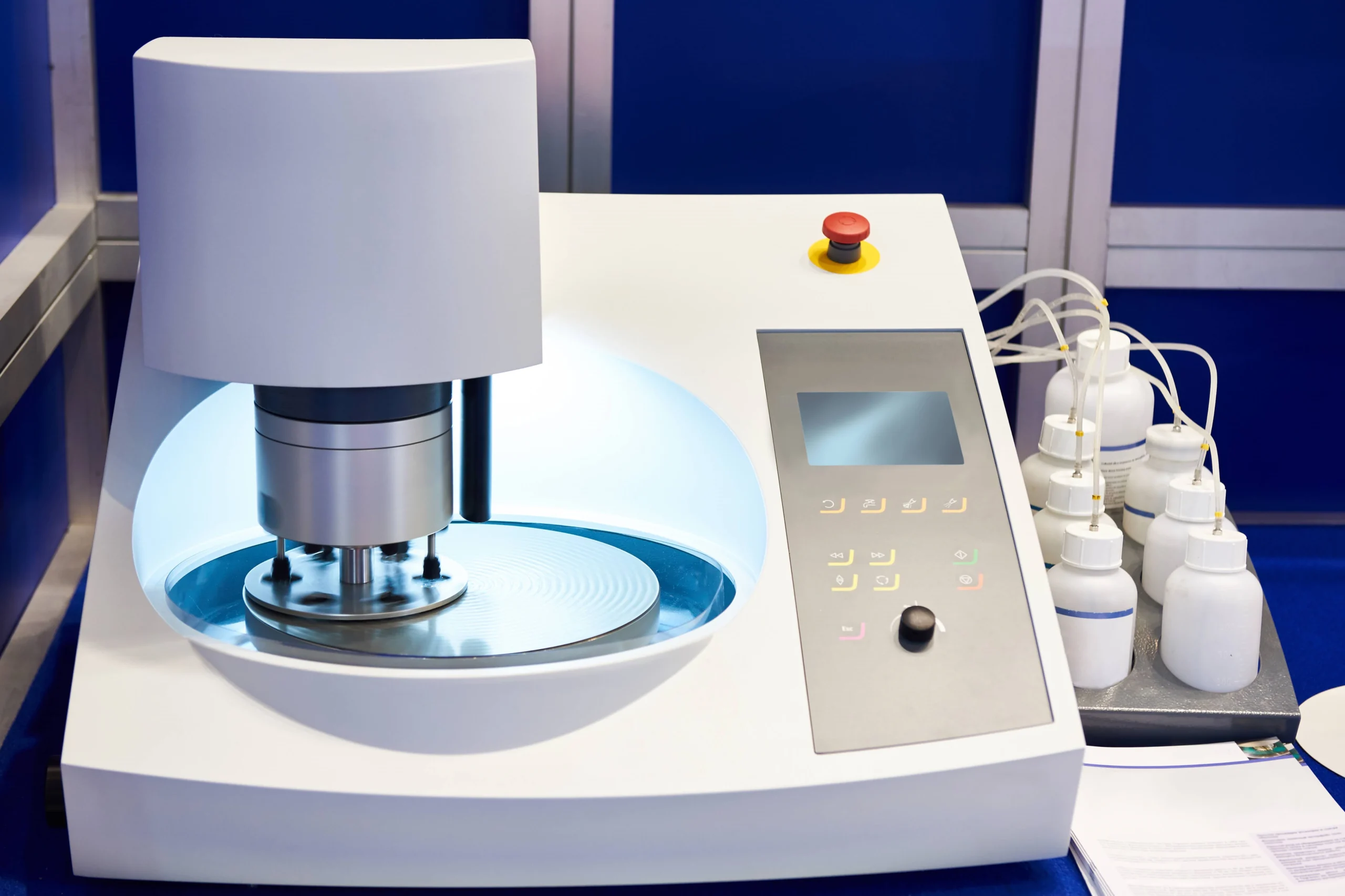

Unlock the next level of precision with the SMART CUT® High Precision Grinding/Polishing Head, a state-of-the-art tool designed to elevate the quality and consistency of sample preparation. This high-performance system offers unrivaled control over material removal, making it the ideal solution for a wide range of applications, including microscopic evaluation (optical, SEM, TEM, AFM, and more) in research, quality control, and failure analysis.

Versatile and Precise Sample Preparation

The SMART CUT® High Precision Grinding/Polishing Head excels in a variety of polishing techniques, offering capabilities such as parallel polishing, precise angle polishing, and site-specific polishing. Whether working with metals, ceramics, semiconductors, or composites, this versatile tool ensures that each sample is prepared to exact specifications for subsequent analysis. By utilizing this system, you can achieve repeatable, high-quality results, eliminating variability and reducing the need for manual intervention.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

FEATURES

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

DESCRIPTION

The consistent performance provided by the SMART CUT® head eliminates inconsistencies that often arise from different operators’ handling, ensuring high-quality preparation no matter who is operating the system.

Unmatched Control Over Material Removal

One of the standout features of the SMART CUT® system is its ability to give users full control over the material removal process. Unlike traditional handheld polishing jigs, the SMART CUT® head allows only the sample to come into contact with the abrasive surface, ensuring that the material is removed in a highly controlled and uniform manner. This system offers adjustable pressure settings, which means that operators can precisely define the amount of pressure to apply and the exact material removal required for each sample.

The fine spring mechanism within the grinding/polishing head, coupled with an intuitive fine adjustment knob, allows for extremely accurate pressure regulation, ensuring that the amount of material removed aligns perfectly with the preset parameters. This results in a more controlled, repeatable process that reduces the potential for errors and ensures more consistent outcomes.

Automatic Precision for Optimal Results

Once the pre-set pressure is reached, the SMART CUT® Grinding/Polishing Head automatically ceases material removal when the defined objective is achieved. This built-in precision control ensures that the desired material has been removed, preventing over-polishing and minimizing the risk of sample damage. The automatic stop feature adds an extra layer of convenience for operators, making it easier to obtain high-quality, reproducible results without manual monitoring.

Ideal for High-Precision Applications

The SMART CUT® High Precision Grinding/Polishing Head is an essential tool for industries that demand consistent, high-quality sample preparation. Its ability to deliver uniform pressure and flatness ensures even material removal across all types of samples. Whether you’re working with fragile materials for failure analysis or precise specimens for R&D, this system guarantees that every sample is prepared with the utmost precision.

The SMART CUT® system is particularly beneficial for applications in failure analysis, yield analysis, quality control, and research and development (R&D). By providing consistent, controlled polishing and grinding, the SMART CUT® Grinding/Polishing Head is indispensable for any laboratory or production environment where accuracy and reproducibility are paramount.

Industries That Benefit from SMART CUT® :

- Semiconductor and Microelectronics Manufacturing

- Materials Science and Metallurgy

- Ceramics and Composites Engineering

- Aerospace and Automotive Industries

- Failure Analysis and Quality Control Labs

- Research and Development Laboratories

Elevate your material preparation processes with the SMART CUT® High Precision Grinding/Polishing Head, a reliable, efficient, and precise solution that delivers consistent, high-quality results every time.

FEATURES

- Large variety of samples can be uniformly ground and polished

- can work with unencapsulated samples

- Front Digital Indicator displays real-time material removal/sample

- advancement, 1 micron resolution

- operator can pre-set exact amount of material to be removed

- operator can adjust the amount of pressure to be applied in real time, without stopping the operation

- Very easy to use with no operator training required

SPECIFICATIONS

Tab Content

ADVANTAGES

- Exceptional Precision: Provides precise, reproducible material removal with full control over the polishing rate.

- Consistent Results: Eliminates user inconsistencies, ensuring uniform material removal and high-quality sample preparation.

- Automated Functionality: Automatically stops once the desired material removal is achieved, preventing over-polishing.

- Increased Efficiency: Streamlines the sample preparation process, reducing time and minimizing errors.

- Versatile Application: Suitable for a wide range of materials and polishing techniques (parallel, angle-specific, site-specific).

- User-Friendly: Easy-to-use controls allow for quick adjustments of pressure and material removal settings.

- Reduced Risk of Damage: Prevents over-polishing, ensuring the integrity of delicate samples.

- Durable and Reliable: Built to last with robust materials, ensuring long-term performance and reliability.

- Ideal for Research & Quality Control: Perfect for R&D, failure analysis, and quality control processes where precision is critical.

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

Tab Content

OPERATING MANUALS

Tab Content

Benefits:

- Unmatched Precision and Control: The SMART CUT® system provides exceptional control over material removal, allowing for precise, reproducible results. It ensures that only the sample interacts with the abrasive, eliminating inconsistencies and variability typically introduced by manual processes.

- Consistent Material Removal: The system applies a uniform pressure, ensuring even and controlled material removal across the sample. The adjustable pressure settings allow operators to specify the exact amount of material to be removed, providing high precision for various sample types.

- Automatic Stop for Optimal Results: Once the desired material removal is achieved, the SMART CUT® Grinding/Polishing Head automatically halts, preventing over-polishing and reducing the risk of sample damage. This automation guarantees consistency and ensures the highest quality results every time.

- Increased Efficiency: By eliminating the need for handheld polishing jigs and manual monitoring, the SMART CUT® system improves operational efficiency. It reduces preparation time and minimizes the potential for errors, speeding up the sample preparation process while maintaining high quality.

- Elimination of User Inconsistencies: Unlike manual polishing, which can vary depending on the operator's skill, the SMART CUT® Grinding/Polishing Head eliminates user-induced inconsistencies, ensuring that every sample is prepared to the same high standard, regardless of who is operating the system.

- Wide Application Range: The SMART CUT® system is versatile and can be used for a variety of materials, including metals, ceramics, semiconductors, and composites. It offers capabilities for parallel polishing, angle-specific polishing, and site-specific polishing, making it suitable for different evaluation methods, including optical, SEM, TEM, and AFM.

- Increased Reproducibility: The ability to set specific pressure levels and material removal amounts ensures that each preparation is consistent and repeatable, making the SMART CUT® system ideal for applications in failure analysis, yield analysis, quality control, and research & development.

- User-Friendly Operation: The system features a fine spring mechanism and easy-to-adjust control knobs that allow operators to precisely set the pressure and removal parameters. This intuitive design ensures that even less experienced users can achieve high-quality results.

- Reduced Risk of Sample Damage: The automated stop feature prevents over-polishing, minimizing the potential for sample degradation or damage. This ensures that delicate materials are treated with care, enhancing the longevity and integrity of your samples.

- Enhanced Flatness and Uniformity:The SMART CUT® Grinding/Polishing Head ensures uniform flatness across the material, providing uniform results that meet high standards for microscopic analysis and material characterization.

- Durable and Long-Lasting: Built with robust materials and engineered for precision, the SMART CUT® Grinding/Polishing Head offers long-term durability, making it a reliable investment for high-precision sample preparation in various industries.

- Ideal for R&D and Quality Control: The SMART CUT® system is a valuable tool in research and development as well as quality control processes, where accuracy and reproducibility are critical. Its precise control helps ensure that experimental data or production-quality assessments are based on consistent sample preparations.

SMART CUT™ GP grinding/polishing head is an excellent tool for precision cross sectioning of a wide variety of materials. Applications that can benefit from is use include failure analysis, yield analysis, quality control, and R & D.

The SMART CUT GP grinding/polishing head provides consistent level of pressure, flatness to insure uniform material removal. The operator set exactly the amount of pressure to apply and amount of material they wish to remove. The grinding/polishing head will apply the level of pressure pre set by the operator until the desired amount of material has been removed, automatically stopping when the objective has been achieved.

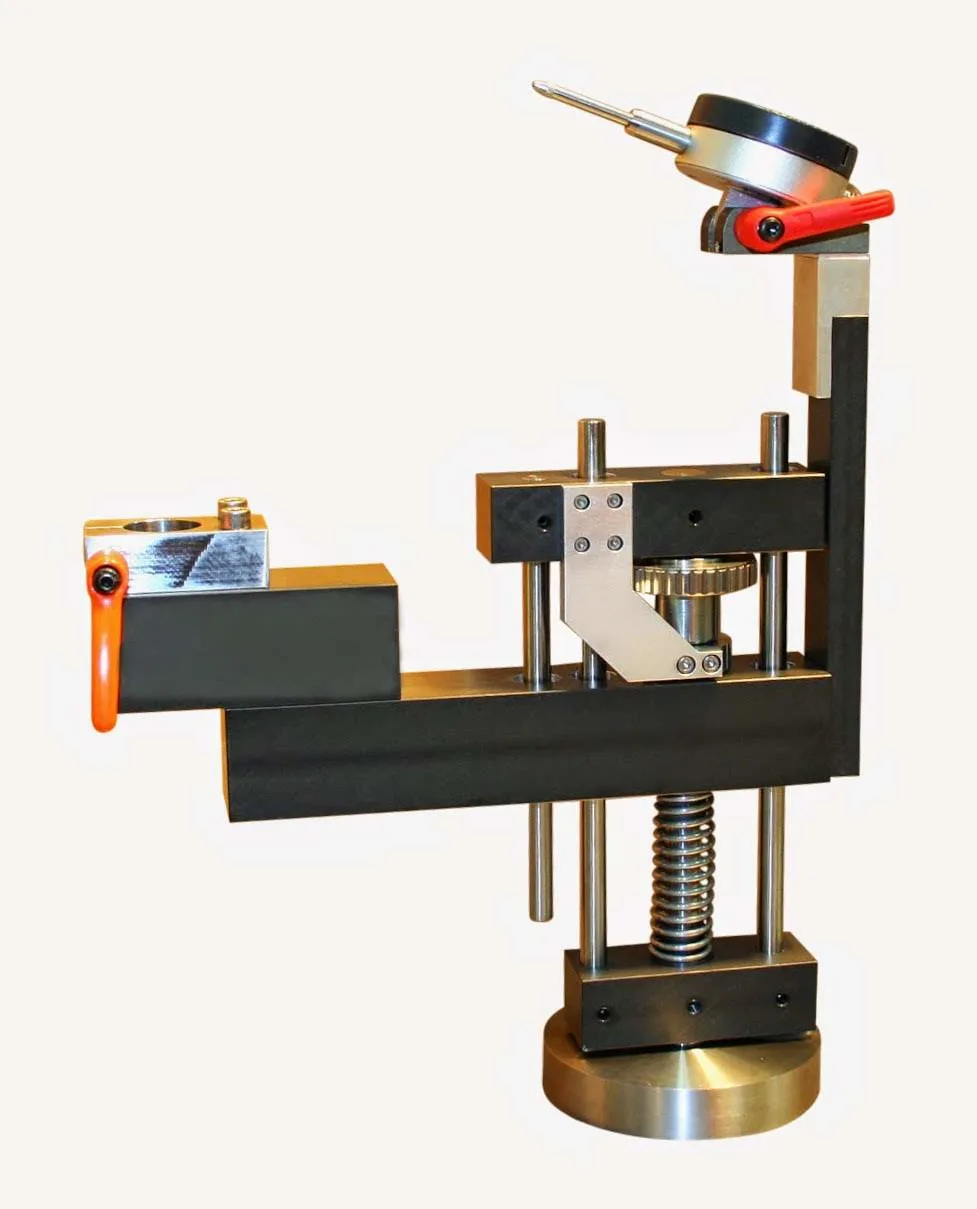

material/sample is placed in a ring a show above.

Pressure is applied to the grinding/polishing head by fine spring mechanism. Controlled by fine adjustment knob above.

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Related Products

Silicon Carbide Paper new

SMART CUT® Silicon Carbide Abrasive Paper is meticulously designed for preparing metallographic specimens, incorporating superior silicon carbide grains embedded in a resilient, waterproof backing for both dry and wet grinding. This versatile paper transitions smoothly from coarse cutting to fine polishing, ensuring that specimens are precisely prepared for microscopic analysis.

Recently Viewed Products

ARE YOU USING RIGHT CONSUMABLES?

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT METALLOGRAPHIC CONSUMABLES?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Share this Article...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Which to use for your application?

Diamond shape plays a significant role in the effectiveness of polishing solutions, affecting both the polishing rate and the quality of the final finish. Understanding the differences between monocrystalline and...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...

29

Jan

Guide to Selecting the Right SMART CUT® Metallographic / Metallurgical Polishing Cloth & Pads for Your Application

Proper selection of SMART CUT® Metallographic / Metallurgical Polishing Cloths and Pads is important to achieving best results in metallography and sample preparation. These products are specially designed for precision, durability, and compatibility with various...

30

Jan

Select the Right Silicon Carbide Paper Discs for Metallography Sample Preparation

Selecting the right silicon carbide paper for metallographic sample preparation is important for achieving accurate and reliable results in material analysis. The grinding and polishing process plays a fundamental role in preparing specimens for microscopic...

30

Jan

Upgrading Metallography Grinding with Silicon Carbide Paper

This guide covers the best practices for using silicon carbide paper in metallography. It includes tips on proper grit progression, optimizing pressure and speed settings, preventing common issues, and extending the life of the abrasive....