-

0 items in quote

No products in the Quote Basket.

SMART CUT® Diamond Lapping Film

SMART CUT® Diamond Lapping Film is expertly designed for precise sample preparation in metallography and a variety of analytical applications. This high-performance product boasts superior finishing capabilities suitable for a wide range of materials, such as metals, ceramics, and composites. It serves as a crucial tool for achieving outstanding outcomes in both research and industrial settings.

The film features diamond particles that are uniformly distributed to ensure a consistent scratch pattern, which facilitates even material removal. A high-quality resin bond is incorporated to enhance the film's durability and longevity, allowing for multiple uses without a decline in performance. Supported by a robust polyester film backing, SMART CUT® Diamond Lapping Film provides exceptional stability and simplifies the lapping process. The product is available in a wide array of micron sizes, enabling precise customization to meet specific surface finish requirements.

DESCRIPTION

SPECIFICATION

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

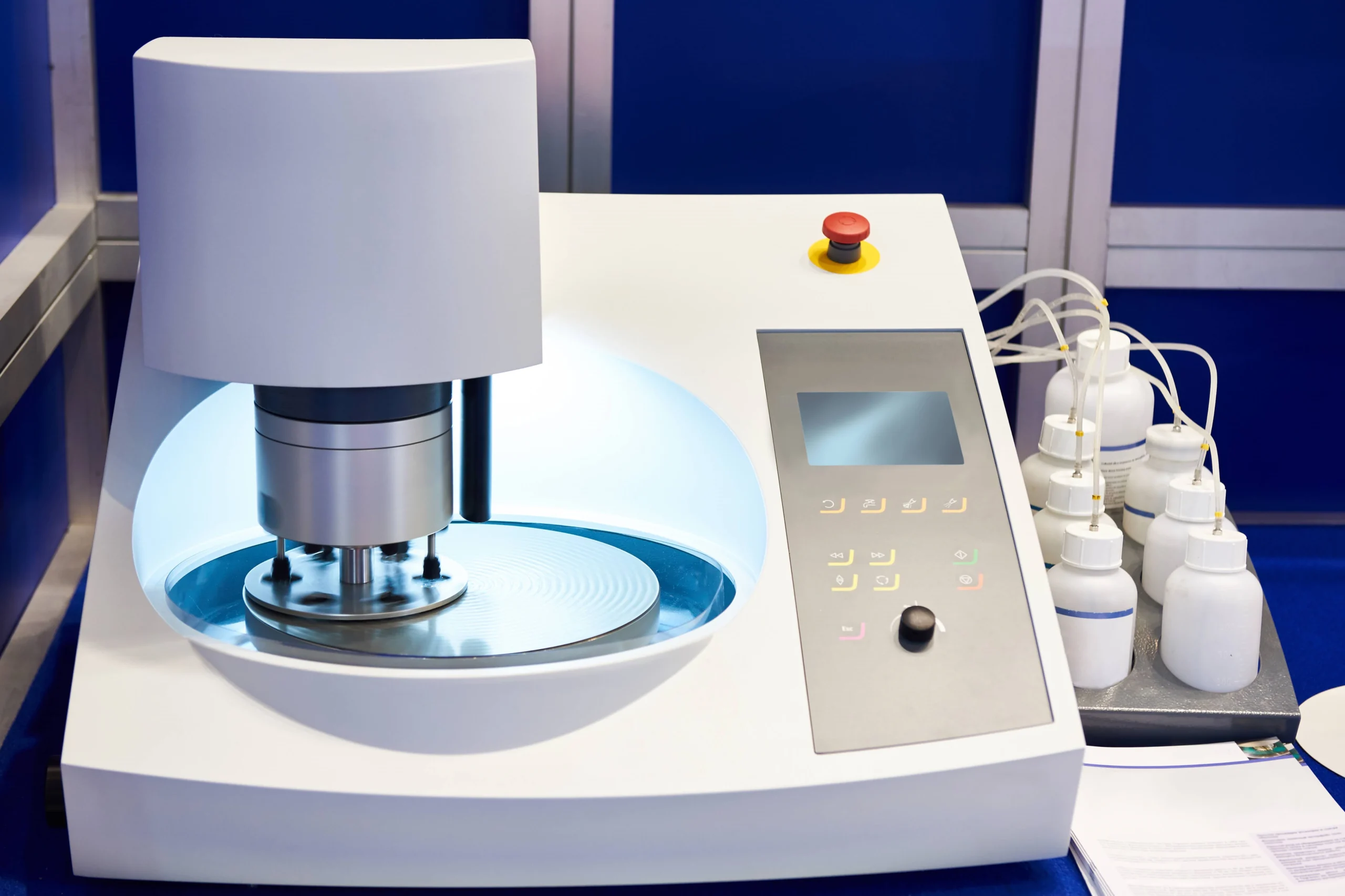

SMART CUT® Diamond Lapping Film utilizes micron-graded diamond particles resin-bonded to a uniform 3-mil polyester backing. This configuration offers a cleaner and more consistent alternative to traditional diamond compounds or slurries. It is particularly effective for finishing and polishing hard-to-grind materials such as glass, ceramics, hardened metals, fiber optics, optical components, composites, and micro-electronic materials, making it ideal for SEM and TEM analysis. The film can be used either wet or dry.

Available in grit sizes from 0.1 µm to 30 µm, SMART CUT® Diamond Lapping Film can be supplied in standard sheet or roll formats. These formats are customizable to suit specific application needs and are compatible with most lapping machines or suitable for hand lapping applications.

SPECIFICATION

Tab Content

FREQUENTLY ASKED QUESTIONS

Tab Content

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Advantages

- Sample Preparation: Ideal for preparing samples for microscopic analysis, ensuring a smooth, flat surface without introducing artifacts.

- Metallography: Perfect for the precise preparation of metallurgical specimens, facilitating detailed examination of the microstructure of metals and alloys.

- Quality Assurance: Provides consistent and repeatable results, crucial for quality control in manufacturing and material sciences.

Features

- Reduced Processing Times: The high cutting efficiency of diamond particles reduces the time needed for sample preparation, increasing throughput in busy labs and production environments.

- Superior Finish Quality: Achieve superior surface finishes with minimal subsurface damage, crucial for accurate analysis in scientific and industrial settings.

- Cost-Effective: The durability and reusability of our lapping films make them a cost-effective solution for high-volume testing and analysis.

Showing 1 – 35 of 35 results Showing all 35 results Showing the single result No results found

Sort by Name A - Z

Filters Sort results

Reset Apply

Image | ITEM NO | NAME | QUANTITY | Get Quote |

|---|---|---|---|---|

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 | ||||

Max: Min: 1 Step: 1 |

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Read More

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

Related Products

SMART CUT® Resin Bond Diamond Discs for Grinding & Polishing Machines

SMART CUT® Metal Bond Diamond Discs for Large Grinding / Polishing Machines

Resin Bond Diamond Discs

Resin Bond Discs are designed removal of material/sample scratches, chips. high spots, & as well as pre-polishing on a larger variety of materials. Using a propriety technique, a high concentration of premium diamond is loaded onto each disc to provide an extremely aggressive grinding rate yet leaves an exceptionally smooth surface finish. Each disc is color coded to easily determine the diamond size of the disc. These resin bond diamond discs are guaranteed to out-perform many cloth polishing discs using loose conventional abrasive or diamond compound/slurry finishing systems. Depending on the application and process these discs on average will last for 100-200 parts/samples & maintain consistent level of performance. These are perfect for hard materials such as metals, ceramics, refractories, cement, geological rocks, glass, optics, composites, and many other materials 35 and up Rockwell C scale of hardness. All discs come with a 3M pressure-sensitive adhesive backing that bonds to backing plates, or with magnetic backing to attach to steel plates. Must be used with coolant. Not recommended for heavy stock material removal

DIAMOND LAPS

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond laps & polishing discs. Below you will find information, specifications & prices on all laps & polishing discs we offer for this application. Contact us for volume pricing. We can also produce any custom diamond wheel per your specification. Contact us Today for Free Quote!

Recently Viewed Products

ARE YOU USING RIGHT Diamond Lapping Film

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT Diamond Lapping Film?

Knowledge Center

02

Jun

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Diamond is the hardest material known to man kind....

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

Discover the Right Diamond Powder for Your Application: Choosing Between Monocrystalline and Polycrystalline Diamonds

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Which to use for your application?

Diamond shape plays a significant role...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Trusted by Tens of Thousands of...

11

Jun

Selecting the Right Diamond Suspension for your Application – Monocrystalline or Polycrystalline?

Selecting the correct diamond suspension, whether monocrystalline or polycrystalline, has a significant impact on the quality and efficiency of the polishing and material removal processes. Understanding the properties and applications of both types of suspensions can...

17

Jun

Improve Sample Quality & Optimize your Polishing Operating for Metallography & Sample Preparation

Polishing is important step in metallography & sample preparation for revealing the true microstructure of materials, including grain boundaries, phases, and inclusions, which provide insights into material properties and history. This guide is designed to...

26

Jun

Optimize your Grinding Operation for Metallography & Sample Preparation

Share this Article with Friend or Colleague

Grinding is a fundamental mechanical process in metallography that involves removing material from a specimen using hard, abrasive particles. This process is essential for preparing specimens for microscopic...

11

Sep

What is the difference between Lapping, Grinding, & Polishing

Some of the major differences include the type and diamond mesh size of diamond discs used, type and size of abrasives used and their holding method. Other factors include RPM’s (speed) used and pressure applied...