-

0 items in quote

No products in the Quote Basket.

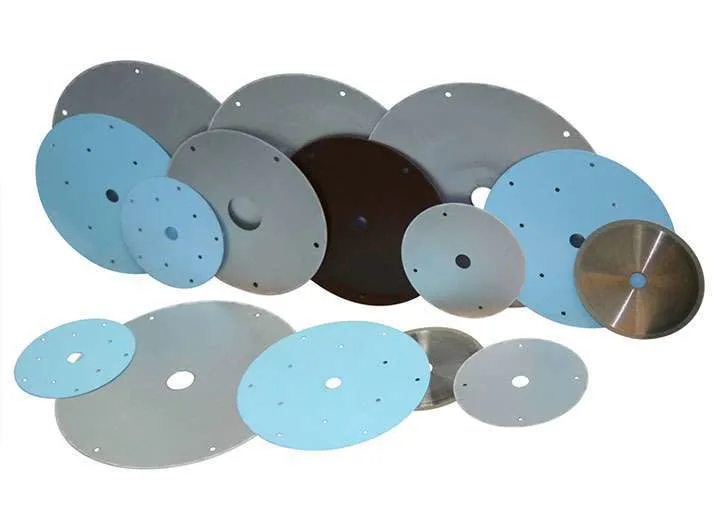

Diamond Rotary Dressers

Diamond Rollers are used to form grinding wheels for many different kinds of mass production. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method. Dressing rollers can be classified under Diamond profile dressing rollers and Diamond form dressing rollers. Diamond profile dressing rollers are ued to share grinding wheels in shortest amount of time. Profile form dressing rollers are used to from simple and high complex profile contours.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Diamond Rollers are used to form grinding wheels for many different kinds of mass production. Shorter dressing time and long tool life leads to high productivity and consistent process conditions. Many kinds of conventional grinding wheels, and in special cases super-hard grinding wheels, can be dressed with this dressing method. Dressing rollers can be classified under Diamond profile dressing rollers and Diamond form dressing rollers. Diamond profile dressing rollers are ued to share grinding wheels in shortest amount of time. Profile form dressing rollers are used to from simple and high complex profile contours.

SPECIFICATIONS

Tab content

FREQUENTLY ASKED QUESTIONS

Tab content

INDUSTRIES USED IN

Tab content

ACCESSORIES

Tab content

USAGE RECOMMENDATION

Tab content

Diamond Rotary Dressers

are used for manufacture of components for:

-

Automotive

Automotive

-

Aerospace

Aerospace

-

Power Generation

Power Generation

-

Machine Tool

Machine Tool

-

Precision Engineering Industries.

Precision Engineering Industries.

-

Threads

Threads

-

Turbine Blades

Turbine Blades

-

Bearing Jornals

Bearing Jornals

-

Bearings Races

Bearings Races

-

Engine Valves

Engine Valves

-

Fuel Injector Components

Fuel Injector Components

-

Shearing Blades

Shearing Blades

-

Gears

Gears

-

Engine Components

Engine Components

-

Transmission Components

Transmission Components

Used to dress and shape grinding wheels, particularly in applications where complex profiles or specific geometries are required.

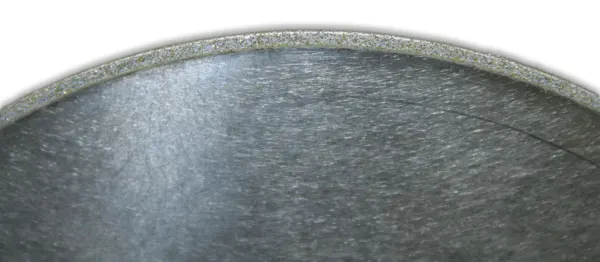

Dressing rollers are typically cylindrical in shape and are made up of a metal core with a layer of diamond grains bonded to its surface. The diamond grains provide the necessary hardness and abrasive properties to effectively dress grinding wheels. The size and arrangement of the diamond grains on the roller's surface determine the profile or shape that can be achieved.

When a grinding wheel needs to be dressed or shaped, the dressing roller is brought into contact with the rotating wheel. The abrasive action of the diamond grains on the roller's surface removes material from the grinding wheel, effectively dressing it to the desired shape or profile. This process helps to restore the grinding wheel's cutting efficiency and maintain the desired precision in the finished workpiece.

Contact Us for FREE Quote & Recommendation

Let Us Help You:

-

Improve Tool Life

Improve Tool Life

-

SAVE TIME & MONEY

SAVE TIME & MONEY

-

Obtain More Consistent Results

Obtain More Consistent Results

-

Improve Surface Finish

Improve Surface Finish

-

Preserve True Material Microstructure

Preserve True Material Microstructure

-

Reduce & eliminate Material Deformation

Reduce & eliminate Material Deformation

-

Improve Tool Lite & Overall Performance

Improve Tool Lite & Overall Performance

Why Work With Us?

Read More

We understand that your success depends on select the right diamond lapidary blade, and optimizing your parameters to best fit your applications/needs.

Largest Inventory of Diamond Lapidary Blades in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

We Are a Partner In Your Success

American Manufacturer

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Comprehensive Source of Information on Diamond Lapidary Blades

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Experience makes all the Difference

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary lapidary blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect lapidary blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

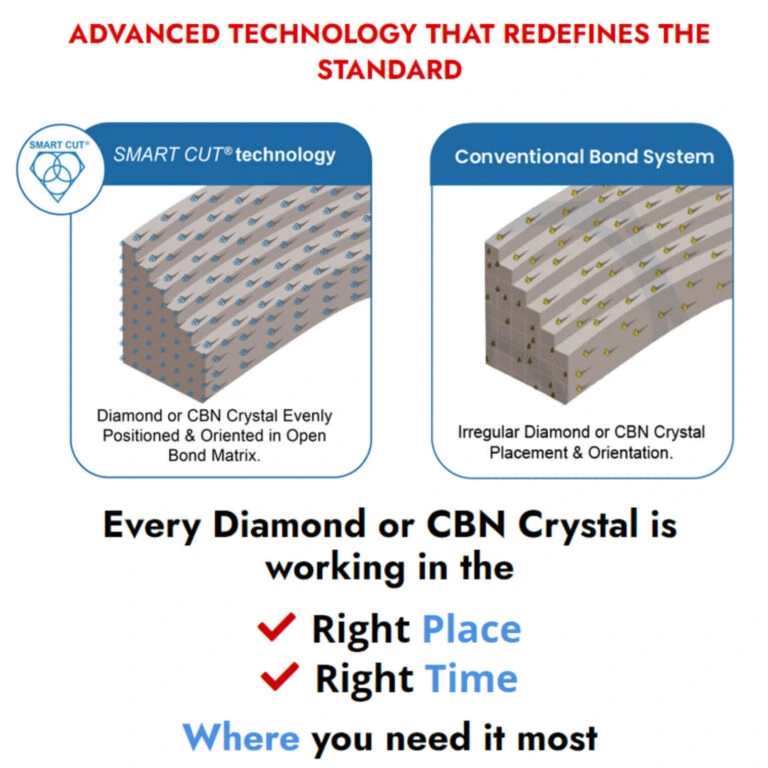

Advanced Technology

Superior Quality &

Consistency

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

Related Products

SMART CUT® Series 400 Wafering Blade, Resin Bond

Resin Bond Diamond Wafering Blades for use on Precision & Laboratory type Cut off Saws

SMART CUT® Series 400 are Designed for Precision, Chip Free cutting of wide variety of materials These are very thin kerf blades and are very delicate. Must be used on high precision specialized laboratory cutting saws (not tile saws, trim saws, etc) The diamond section can be easily broken if the material moves while cutting, blade is dropped, material is feed to fast into the blade, material is not fed consistently straight into the blade (shifts position) etc. Diamond Size is Medium providing faster cutting speed, while still providing surface quality unmatched by 95% of other blades.SMART CUT 105N Diamond, Nickel Bond Wafering Blades INTERRUPTED RIM

SMART CUT™ Series 105N more freer cutting & aggressive than continuous rim nickel bond wafering blades. Best Suited for cutting larger variety of micro-electronics packages, pcb boards, plastics, composites, soft and precious metals, fish and human bones, graphite, GRP, FR4. Core steel with memory. Always snaps back to its original shape no matter how much bent.

Standard arbor size inside diameter is ½” (12.7mm) (* we can modify arbor size of any blade to anything you want same day for a small additional fee, if needed)

SMART CUT® Series 100N Wafering Blade, Nickel Bond

NICKEL BOND, DIAMOND CONTINUOUS RIM

SMART CUT® Series 100N will provide finer cut quality than interrupted rim nickel bond wafering blades. Best suited for cutting soft and fragile crystals, silicon wafers & substrates, fiberglass, glass fibers. made with stainless steel core Standard arbor size inside diameter is ½” (12.7mm) (* we can modify arbor size of any blade to anything you want same day for a small additional fee, if needed) Nickel Bond Diamond Cut off blades Blades usually have a single layer of diamonds, held by a tough durable nickel alloy. diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.Diamond, Nickel Bond Cut Off Blades for Laboratory & Other Saws

SMART CUT® Series 600 RCBN CBN, Resin Bond Cut Off Blades

SMART CUT® Series 600 RCBN CBN, Cut Off blades are designed for cutting of extremely hard ferrous metals (HV 500 - 1400) used on large variety of high speed & abrasive cut off saws.

Resin bond CBN Cut Off Blades offer superior cut quality than any type diamond wafering blade available. Recommended for applications where cut quality and surface finish is very important. Compared to their sintered (metal bond) wafering blade counterparts. Resin Bond CBN Cut Off Blades offer far superior cut quality than the finest size metal bond (sintered) bade. Recommended for cutting Tool Steels, Heat-sensitive Materials, Hard Alloys, Soft Ferrous Alloys, Titanium Alloys where low heat generation or improved surface finish is desired. Most commonly used at higher speeds.SMART CUT® 320MS

Narrow Slot Segment Design - Diamond Depth (Height): 5mm - 16" to 36" Diameter

SMART CUT® Series slabbing sintered (metal bond) diamond cut off blades, are Segmented Design with (narrow spacing between the segments). Designed for smooth cutting of ultra hard materials. Such as soft rocks & minerals, advanced ceramics, glass, composites, and some metals. Perfect for users who wish to minimizes loss of valuable material. This is a popular slabbing blade used among geological laboratories. Most widely used blade for cutting precious & semi precious stones / rocks. SMART CUT® Series slabbing sintered (metal bond) diamond cut off blades, are Segmented Design with (narrow spacing between the segments). Designed for smooth cutting of ultra hard materials. Such as soft rocks & minerals, advanced ceramics, glass, composites, and some metals. Perfect for users who wish to minimizes loss of valuable material. This is a popular slabbing blade used among geological laboratories. Most widely used blade for cutting precious & semi precious stones / rocks.SMART CUT Series 300M

SMART CUT® 325M Continuous Slabbing Blade

SMART CUT® Series - 325M Continuous Rim - Diamond Depth (Height): 8mm

The SMART CUT® Series 330MS Continuous Rim, Sintered (Metal Bond) blade is an excellent choice for manufacturing, and R & D organizations, and professionals who need precise and clean cuts with very little chipping. This blade is specially designed to work with delicate materials like natural stone, semi-precious stone, glass, ceramics and other ultra hard and brittle materials.SMART CUT® Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

SMART CUT® Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...