How to Use SMART CUT XP Dicing Surfactants

-

Posted by

Brian Farberov

Brian Farberov

SMART CUT® XP dicing surfactants should be introduced into the saw water supply in a controlled and consistent manner to ensure proper dilution, stable chemical performance, and uniform delivery to the cutting zone. Correct dosing equipment and proper setup help achieve full dissolution, predictable surfactant behavior, and maximum cleaning, lubrication, and ESD-control performance.

Table of Contents

ToggleA chemical metering system is the most reliable method of feeding SMART CUT® XP Series solutions into dicing saws. The system must maintain the selected dilution ratio, compensate for changes in water pressure, and mix the surfactant thoroughly before it reaches the blade.

Below are the recommended components and their functions.

- Chemical Metering Pump

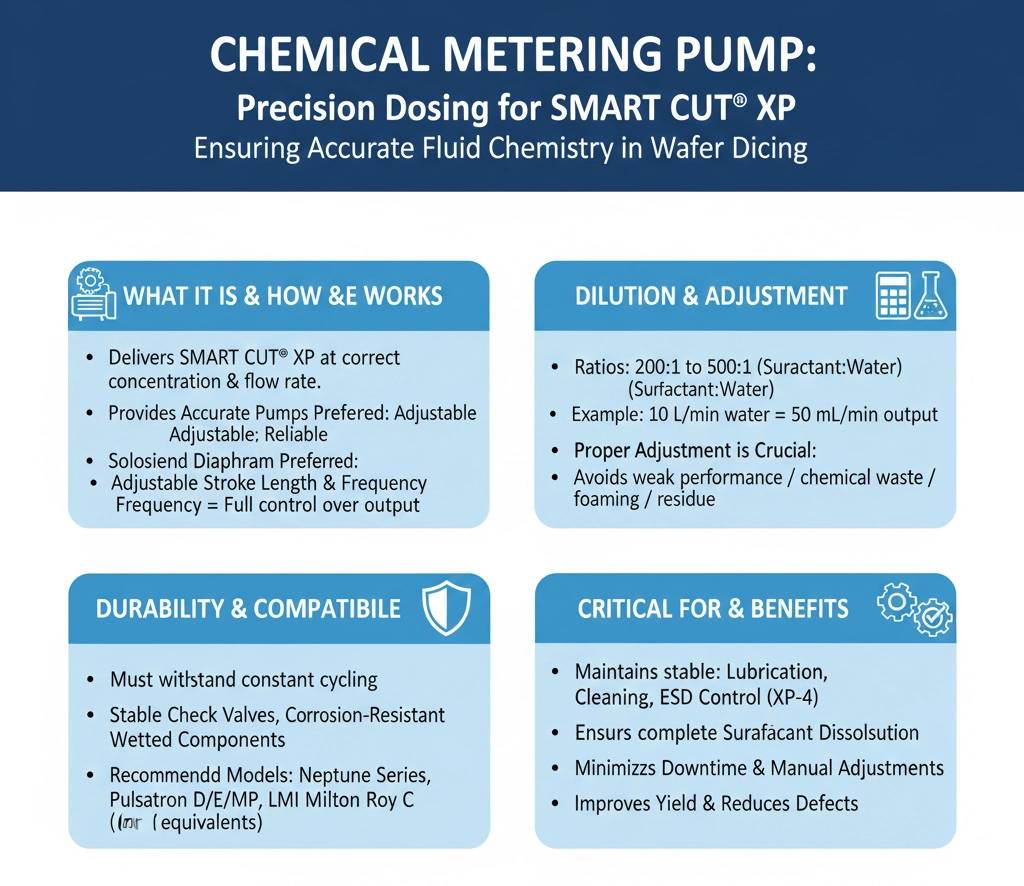

A chemical metering pump plays a central role in delivering SMART CUT® XP surfactants at the correct concentration and flow rate. The pump provides accurate, repeatable dosing, which is essential for maintaining stable lubrication, cleaning action, and ESD control during dicing. Solenoid diaphragm metering pumps are preferred because they provide precise displacement, simple adjustability, and reliable operation under continuous use. Adjustable stroke length and stroke frequency give the operator full control over chemical output, making it possible to fine-tune the system for different materials, blade types, and cutting parameters.

The metering pump must be able to deliver SMART CUT XP fluids at dilution ratios between 200:1 and 500:1. These ratios ensure proper wetting and chemical activation without overuse of surfactant. When setting up the system, operators should first determine the water consumption rate of each saw. For example, a saw using 10 liters of water per minute requires a pump capable of feeding 50 ml per minute to maintain a 200:1 ratio. Operators can adjust the stroke amplitude to increase or decrease the volume per stroke and can modify stroke frequency to set the number of doses delivered each minute.

Proper adjustment is important for ensuring complete dissolution of the surfactant in the saw water before it reaches the blade. If the dose is too low, lubrication and cleaning performance will weaken. If the dose is too high, chemical waste increases, and excessive foaming or residue may occur. A correctly sized metering pump allows the operator to maintain balance and ensures that the surfactant components activate as intended.

The pump must also be able to withstand constant cycling. SMART CUT® XP surfactants are used in continuous production environments, often running for many hours without interruption. A reliable pump minimizes downtime and reduces the need for manual adjustments. The pump should include a durable diaphragm, stable check valves, and corrosion-resistant wetted components.

Neptune Series PZiA, Pulsatron Series D, Series E, Series MP, and LMI Milton Roy Series C all provide appropriate capacity and chemical compatibility. These models offer adjustable controls, stable output, and compatibility with a wide range of installation configurations. Users may choose based on available mounting space, preferred control interfaces, and integration needs with existing water supply systems. Equivalent pumps from other reputable manufacturers can also be used as long as they meet the required flow capacity, material compatibility, and adjustability.

- Back Pressure Control Valve

A back-pressure control valve is an important component in maintaining accurate and reliable dosing of SMART CUT® XP surfactants. When the saw water line operates below 20 psi, or when pressure varies due to equipment cycling or multiple tools drawing from the same supply, the metering pump cannot deliver a stable chemical feed. Low or inconsistent pressure allows the pump discharge to fluctuate, which leads to uneven surfactant concentration, reduced lubrication performance, and inconsistent cleaning behavior at the blade.

The back-pressure control valve creates a constant, regulated pressure against which the metering pump can deliver its stroke. This ensures that each stroke of the pump dispenses the correct amount of surfactant and that the fluid enters the saw water line with predictable force. Without this back pressure, the discharge check valves inside the pump may not reseat properly after each stroke, leading to partial dosing, air entrainment, or erratic chemical injection.

A stable back-pressure condition also prevents siphoning, which occurs when water flow stops or slows, and the pump line unintentionally draws in or pushes out chemical due to pressure imbalance. Siphoning can result in overdosing, underdosing, or chemical backflow. By maintaining consistent downstream resistance, the back-pressure valve eliminates these risks and ensures that the surfactant only moves when the pump is actively stroking.

Back-pressure valves also contribute to long-term pump reliability. The check valves inside solenoid-driven metering pumps are sensitive to inconsistent pressure conditions. When pressure is too low or fluctuates, the check valves may cycle irregularly, impacting the pump’s ability to maintain its rated output. Over time, this leads to premature wear of the check valve components, reduced pump accuracy, and the need for more frequent maintenance. The back-pressure valve prevents these issues by ensuring that the pump operates in a stable environment.

In multi-saw installations or systems with long plumbing runs, a back-pressure valve becomes even more important. Line pressure may vary widely as different saws turn on and off. The valve absorbs these variations, protecting the chemical injection system and ensuring that every saw receives the correct surfactant concentration. This helps maintain consistent cutting performance, predictable cooling behavior, and uniform lubrication across all equipment.

- Calibration Cylinder

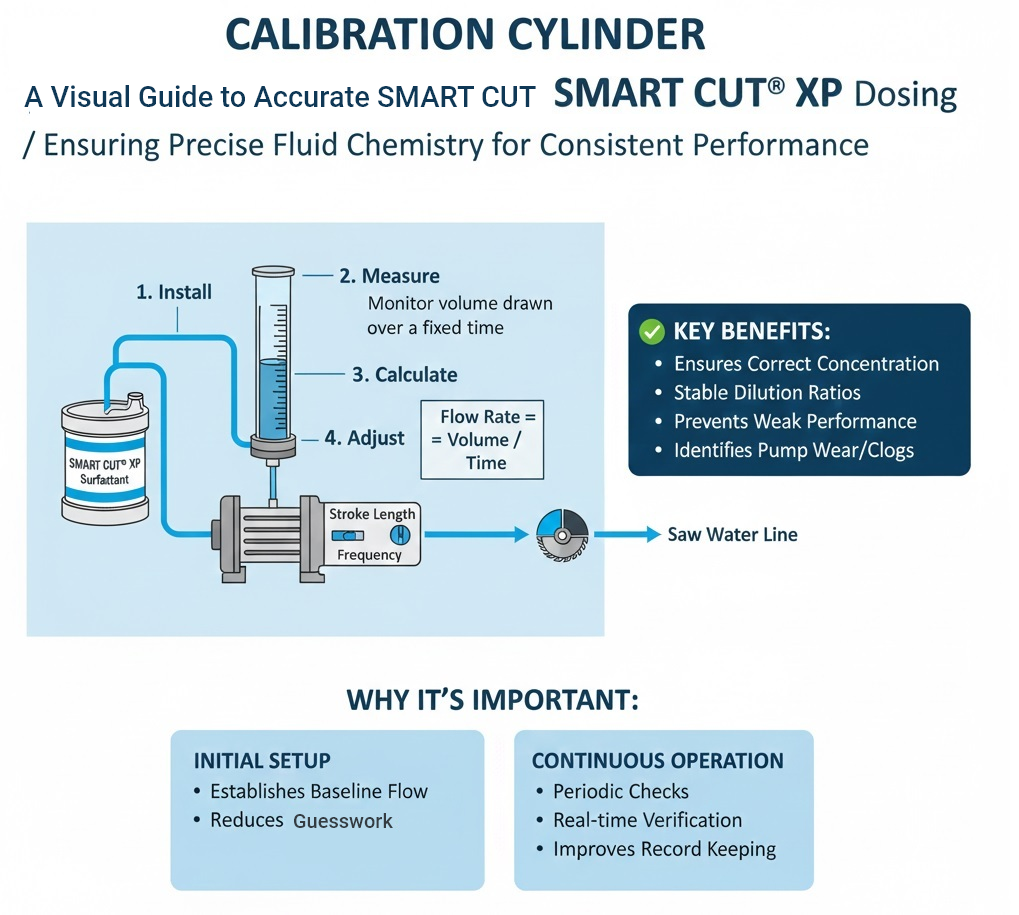

A calibration cylinder provides a simple and accurate way to verify that the metering pump is drawing the correct volume of SMART CUT® XP surfactant into the system. It is installed on the pump suction line and serves as a direct measurement device, allowing operators to visually confirm flow rate and make precise adjustments. Because the cylinder is graduated, operators can monitor chemical draw over a fixed period of time and calculate exact delivery rates. This ensures that dilution ratios remain stable and that the surfactant is being introduced into the saw water line at the proper concentration.

A calibration cylinder is also valuable during initial system setup. It allows the operator to establish a baseline flow rate, adjust the pump’s stroke length and frequency, and reach the desired output before the system is placed into production. This reduces guesswork and ensures that the surfactant reaches full performance from the start. During operation, periodic checks with the cylinder confirm that the pump continues to deliver the correct volume. This helps identify changes caused by worn diaphragms, clogged suction lines, or air leaks in the pump head.

Calibration cylinders improve operational control by providing real-time verification without shutting down the system. Operators can monitor chemical consumption trends, confirm accuracy after maintenance, and quickly diagnose dosing irregularities. They also help maintain consistent dilution ratios across multiple saws, especially in facilities that use centralized surfactant supply systems.

Many modern pumps now offer automatic flow calibration, which electronically measures output and adjusts pump settings without manual measurement. However, a calibration cylinder remains a reliable and practical tool for manual verification. It offers a clear visual reference, requires no electronics, and provides confirmation even when pump sensors or control electronics fail. Using a cylinder also standardizes measurement procedures between operators, helping maintain consistency in performance and record keeping.

- Injection Valve

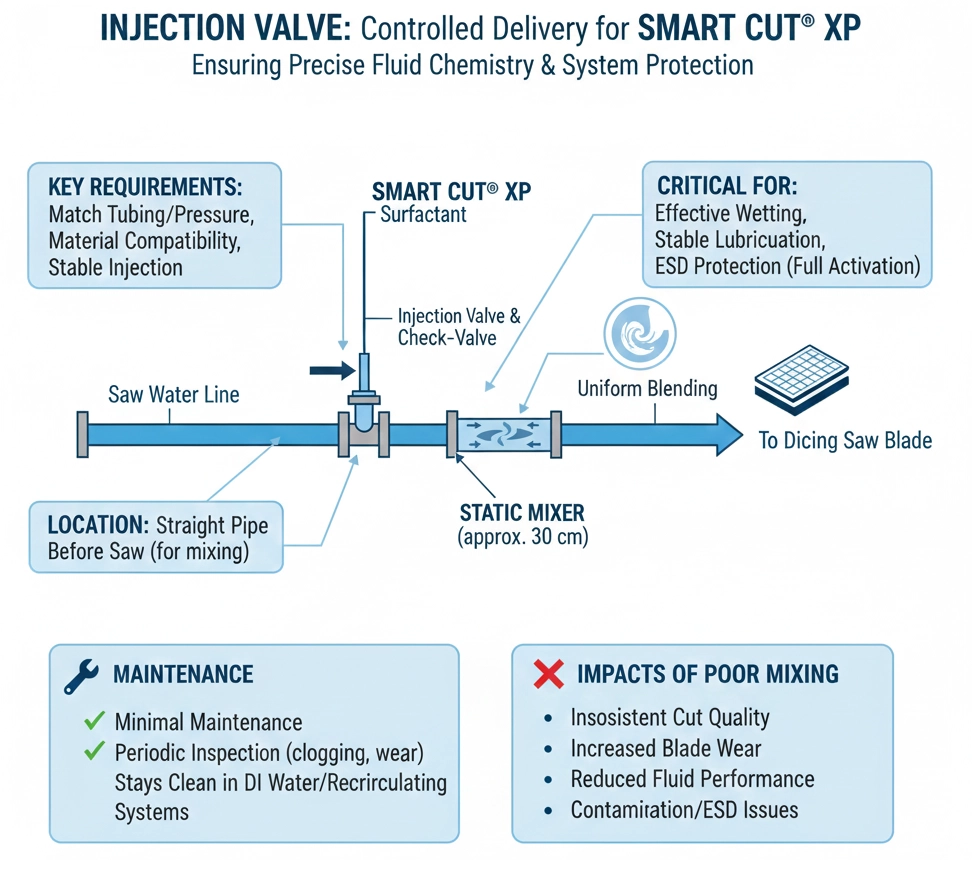

An injection valve provides the controlled entry point for introducing SMART CUT® XP surfactants into the saw water line. It ensures that the surfactant is delivered smoothly and consistently at the correct point in the system. The valve must match the tubing size, material compatibility, and pressure rating of the water line to guarantee proper flow and prevent leaks. A properly selected injection valve ensures that the surfactant stream enters the water line with enough force and stability to promote complete mixing downstream.

Most high-quality metering pumps include an injection valve that also functions as a check-valve assembly, allowing chemical flow in only one direction. The check valve protects the pump and chemical supply tank by preventing water from flowing backward into the pump head. Backflow can dilute the chemical, contaminate the reservoir, or damage pump components. The one-way flow feature also ensures that dosing remains accurate and that each stroke of the pump delivers a controlled amount of surfactant.

A well-installed injection valve maintains stable injection even when pressure fluctuates, which is common in multi-saw configurations or systems with variable water demand. It ensures that the surfactant enters the water stream in a uniform pattern, minimizing pulsation, air entrainment, or delayed delivery. This helps maintain steady dilution ratios, reduces variability in lubrication and cleaning performance, and ensures that SMART CUT® XP surfactants activate fully before reaching the blade.

The location of the injection valve is also important. It should be installed at a point where water flow is steady and where there is enough straight pipe length downstream to allow full chemical mixing before the fluid reaches the saw. This ensures predictable surfactant activity, consistent cooling, stable lubrication, and reliable ESD protection at the cutting interface.

Injection valves require minimal maintenance, but operators should periodically check for mineral buildup, clogging, or wear on the check-valve components. These issues can affect dosing accuracy and lead to irregular surfactant delivery. A simple inspection schedule keeps the valve performing reliably over long periods of operation.

- Static Mixer

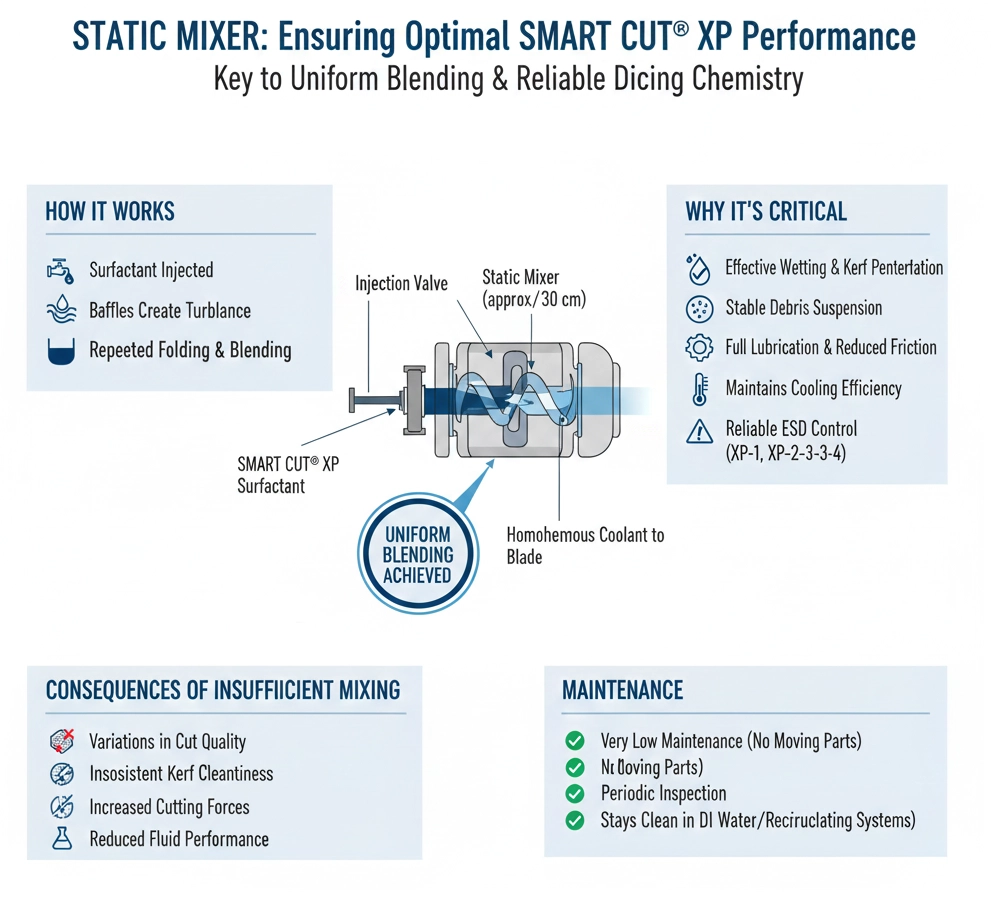

A static mixer is an essential component for achieving complete and uniform blending of SMART CUT XP surfactants with the saw water before the fluid reaches the dicing blade. Once the surfactant is injected through the injection valve, the static mixer provides the turbulence needed to fully disperse the chemical throughout the water stream. This controlled mixing process ensures that every portion of coolant delivered to the blade contains the correct concentration of surfactant.

The static mixer should be installed immediately downstream of the injection valve, with a recommended length of approximately 30 cm. This length provides enough internal turbulence to break up the surfactant stream and distribute it evenly across the flow. Inside the mixer, fixed baffles or elements redirect the water in alternating directions. This creates repeated folding and blending of the fluid, allowing the surfactant to dissolve rapidly and uniformly. The result is a consistent, homogenous coolant solution that performs reliably in high-speed and high-precision cutting environments.

Proper mixing is critical for maintaining the key functions of SMART CUT® XP products. Complete activation ensures effective wetting, which helps coolant penetrate narrow kerfs and reach the blade edge. It ensures stable debris suspension, preventing particles from redepositing onto wafer surfaces or causing blade loading. It guarantees full lubrication, which reduces friction and temperature rise at the cutting interface. It also maintains cooling efficiency, protecting sensitive materials from thermal stress. For XP-1, XP-2, XP-3, and XP-4, consistent mixing is necessary to achieve reliable ESD control, especially when processing electrostatic-sensitive devices.

When mixing is insufficient, chemical performance becomes uneven. Operators may see variations in cut quality, inconsistent kerf cleanliness, increased blade wear, or unstable cutting forces. Incomplete mixing also reduces the benefits of each SMART CUT® XP formula, preventing the surfactant from reaching its full potential. The static mixer prevents these problems by ensuring that the coolant arriving at the blade has the correct concentration profile in every cycle.

Static mixers require very little maintenance. They contain no moving parts and rely entirely on flow-induced turbulence. Periodic inspection is recommended to check for mineral buildup or contamination that could reduce flow or mixing efficiency. In systems that use DI water or recirculating coolant loops, the mixer typically remains clean for long periods.

SMART CUT® XP Coolant Metering System

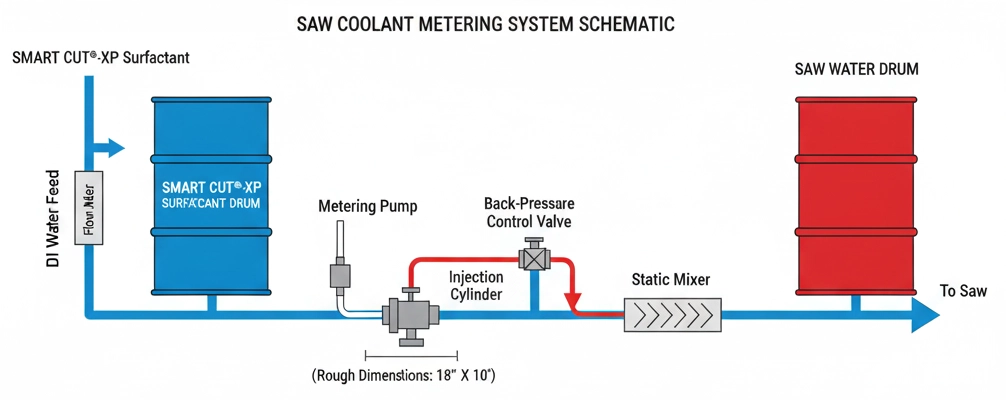

This schematic shows how the SMART CUT® XP coolant metering system delivers a controlled mixture of surfactant and DI water to the saw. The setup maintains a stable concentration, protects the equipment, and ensures the coolant reaches the blade with proper lubrication, wetting, and cleaning performance. It provides a reliable method for keeping dicing conditions consistent during production.

The DI water line feeds directly into the system and passes through a flow meter. This confirms a consistent supply of clean water before any chemical addition. The SMART CUT® XP surfactant drum is connected in parallel. The metering pump draws the surfactant from the drum and pulls it into the injection cylinder. The cylinder allows operators to check pump accuracy, verify stroke volume, and confirm that the correct dose is delivered during each cycle.

A back pressure control valve stabilizes pump operation. It prevents siphoning, pulsing, and uncontrolled flow. It also protects the injection point from pressure fluctuations that occur when the saw water demand changes. Stable back pressure keeps dosing accurate even during long production shifts.

The injection valve serves as the entry point for SMART CUT® XP into the water stream. It includes a check mechanism that prevents reverse flow and protects the surfactant drum from contamination. Proper placement of the injection valve ensures the surfactant enters at the correct velocity for reliable mixing.

After injection, the solution passes through a static mixer. The mixer creates turbulence that blends the surfactant into the water. This ensures proper wetting, lubrication, and cleaning effect by the time the coolant reaches the blade. Complete mixing helps prevent streaking, uneven chemistry, and changes in cut quality.

The blended coolant flows into the saw water drum and maintains a uniform concentration while feeding the dicing saw. This setup supports consistent heat removal, lower cutting forces, improved debris suspension, and longer blade life. It also reduces oxidation, staining, and contamination on sensitive wafer surfaces.

A metering system built in this configuration helps maintain process stability and supports predictable dicing results during high volume production.

The system delivers coolant through a chemical metering pump that injects SMART CUT® XP Series fluid directly into the DI water supply feeding the saw blade. This method provides controlled dosing and ensures the coolant reaches the cutting zone at the correct chemical strength.

The metering pump must maintain a stable and repeatable dilution ratio between 200:1 and 2000:1. This range supports a wide set of materials, blade types, and cutting loads. The pump must also operate with DI water flow rates of up to 10 liters per minute without interruption. A stable flow prevents fluctuations in lubrication, wetting, and cooling.

For reliable operation, set the stroke frequency and stroke length at the mid-range of the pump’s available settings. This provides a strong balance between output stability and mechanical durability. Mid-range operation also reduces the risk of pulsing, backflow, or irregular injection. These conditions can occur when pumps run at the extremes of their range.

Confirm that the injection point is clean and unobstructed. Verify that the check valve on the pump discharge line is functioning. A working check valve prevents backflow into the chemical supply and protects the accuracy of the concentration.

Monitor the DI water line pressure. Changes in line pressure can affect injection performance. A back-pressure control valve is recommended to stabilize the system and support uniform delivery of the SMART CUT® XP fluid.

Inspect the metering pump and tubing on a regular schedule. Replace worn components to maintain consistent dosing. Ensure that all connections are tight and that there are no air bubbles in the line. Air pockets can interrupt injection and weaken coolant performance.

This setup ensures that the SMART CUT® XP Series coolant is delivered at a controlled concentration, with consistent flow, and with full chemical activation before reaching the blade. This improves lubrication, reduces heat, enhances debris flushing, and supports the performance of all SMART CUT® XP products.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

ARE YOU USING RIGHT

DICING SURFACTANTS FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING SURFACTANTS?

Knowledge Center

Dicing Surfactants Guide

How to Use SMART CUT XP Dicing Surfactants

Selecting the Right Dicing Surfactant / Fluid for Your Application

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

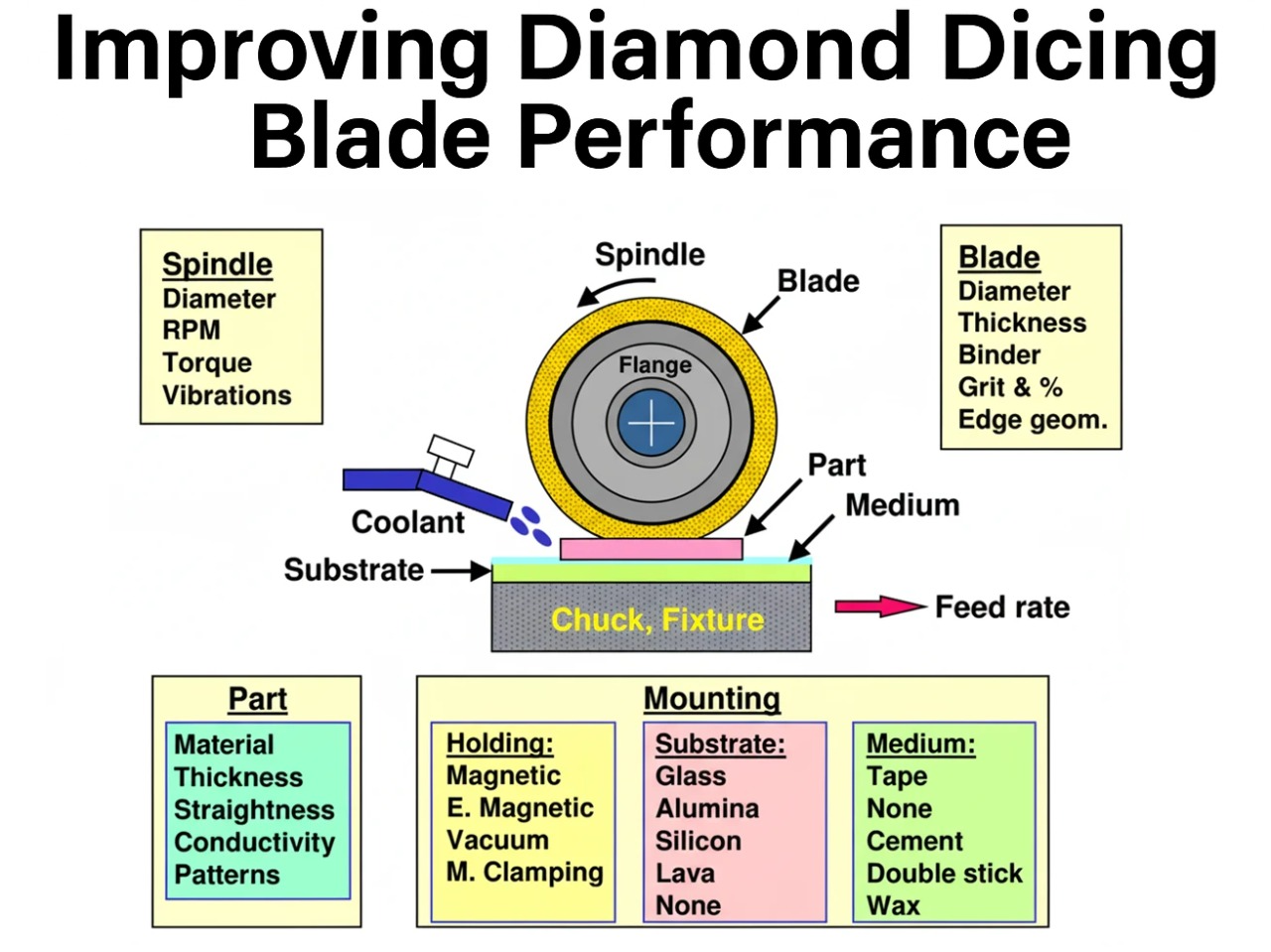

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

Selecting the Right Wafer Dicing Saw Practical Guide

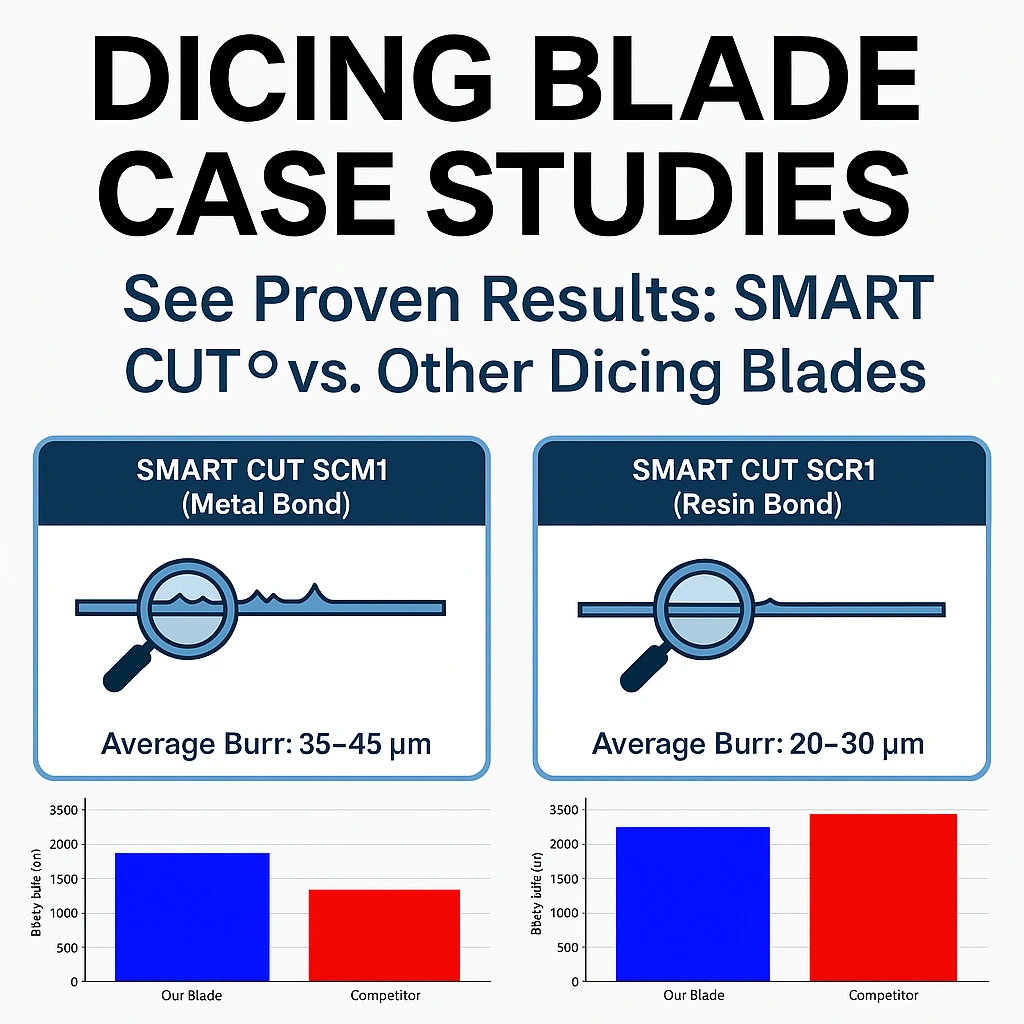

Dicing Blade Case Studies

Application Recommendations

Trouble Shooting Dicing Problems

Optimizing your Diamond Dicing Performance

Dicing Blade Operations Recommendations

Select right Diamond Dicing Blade for your application

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.