Dicing Surfactants Guide

-

Posted by

Brian Farberov

Brian Farberov

Dicing surfactants support stable and consistent wafer dicing. You use them as part of a complete dicing fluid designed to cool the blade, flush debris, and protect exposed device surfaces. Modern semiconductor wafers contain smaller features, thinner metallization, and deeper structures. These conditions require a fluid that can clean effectively and control damage during cutting.

Table of Contents

ToggleDicing fluids serve three main purposes. They remove silicon and metal particles produced during sawing. They cool the blade and the wafer. They reduce friction at the contact point between the blade and the substrate. A dicing operation cannot perform well without a fluid that manages these tasks.

Surfactants are required because DI water alone cannot meet advanced cutting requirements. DI water has high surface tension, which prevents the liquid from wetting the wafer surface and deep structures. Poor wetting leads to weak particle removal, higher contamination, and debris trapped on bond pads. DI water also has very high resistivity, which increases electrostatic charge on the wafer. This charge attracts particles, increases contamination, and raises the risk of ESD damage. At neutral pH, DI water can also cause aluminum corrosion during long exposure.

Advanced dicing operations need a fluid that meets specific performance requirements. The fluid must provide low surface tension for improved wetting. It must remain stable at high dilution. It must control foam to maintain a clear cutting zone. It must support charge dissipation through higher conductivity. It must maintain a pH that protects aluminum and copper metallization. It must provide consistent lubrication to reduce kerf width and support clean edges. A dicing surfactant helps the fluid meet these requirements and supports higher device yield.

Role of Surfactants in Wafer Dicing

A dicing surfactant is a functional additive mixed with deionized water to improve how the cutting fluid behaves during wafer singulation. Its purpose is to help the fluid reach the cutting zone consistently, support blade performance, and stabilize the process when cutting brittle semiconductor materials.

Surfactants reduce surface tension by changing how the fluid spreads on the wafer. Water alone beads and resists entering narrow kerfs. A surfactant lowers this resistance, allowing the fluid to spread evenly and penetrate tight gaps. This improves contact with the cutting interface.

Wetting is important during dicing because uniform coverage ensures that the blade, wafer surface, and debris remain surrounded by fluid. Strong wetting maintains a consistent kerf environment, prevents dry spots, and supports stable blade engagement. It also reduces the chance of micro fractures that occur when the fluid does not reach the full depth of the kerf.

Surfactants influence lubrication, cooling, and flushing. Lubrication reduces friction at the cutting edge. Cooling controls temperature and protects the wafer from thermal effects. Flushing removes debris from the kerf to prevent particle buildup. Together, these functions support cleaner cuts, lower blade wear, and higher yield.

Challenges in Wafer Dicing That Surfactants Address

Particle adhesion and silicon residue buildup are common issues in wafer dicing. Fine particles tend to cling to the wafer surface and remain inside the kerf, which interferes with blade performance and affects downstream cleaning. A surfactant reduces particle adhesion and helps lift and suspend debris so it can be flushed away more easily.

Corrosion of aluminum and copper pads can occur when the dicing environment lacks proper protection. Certain surfactants include corrosion inhibitors that protect metal layers from oxidation. This protection is important for maintaining pad integrity and preventing connectivity failures during later assembly steps.

Electrostatic charge accumulation creates further complications. Dry surfaces and high friction conditions can generate a charge that attracts particles and increases wafer handling risks. Surfactants that add controlled conductivity help reduce electrostatic charge, lowering the chance of ESD-related defects and contamination.

Foam formation disrupts the flow of dicing fluid. Excessive foam prevents the solution from entering the kerf and reduces cooling efficiency. Low foaming surfactants prevent foam buildup, ensuring stable fluid delivery and reliable cutting conditions.

Wider kerf and increased burr formation are often related to poor lubrication and insufficient cooling. When a surfactant improves wetting and reduces friction, the blade maintains sharper engagement with the material. This helps reduce kerf widening and keeps burr formation under control, resulting in cleaner, more consistent cuts.

Key Properties of Effective Dicing Surfactants

Effective dicing surfactants require low surface tension and improved wetting. Low surface tension allows the solution to enter narrow kerfs and coat the wafer surface completely. Improved wetting ensures stable fluid coverage and reliable penetration into the cutting zone, which supports consistent blade performance and clean kerf formation.

Low foam generation is essential at the nozzle and in the recirculation system. Excess foam disrupts fluid flow, reduces cooling efficiency, and causes unstable cutting conditions. A well-formulated surfactant produces minimal foam, allowing the fluid to reach the blade and wafer without interruption.

Chemical stability at dilutions up to 1:10000 is important for process control. Many dicing operations use highly diluted solutions to protect sensitive devices and reduce chemical load. A stable surfactant maintains consistent performance even at extreme dilution, without separating, degrading, or losing wetting capability.

Compatibility with organic acids and bases is another key requirement. Dicing lines often include multiple cleaning chemistries, and the surfactant must behave predictably with these solutions. A compatible additive prevents unexpected reactions and maintains fluid integrity across different process steps.

Suitable performance across pH 4 to 13 ensures versatility in a wide range of dicing environments. Wafer materials, blade bonds, and equipment conditions can vary. A surfactant that performs reliably across a broad pH range offers process flexibility and supports stable results in both acidic and alkaline systems.

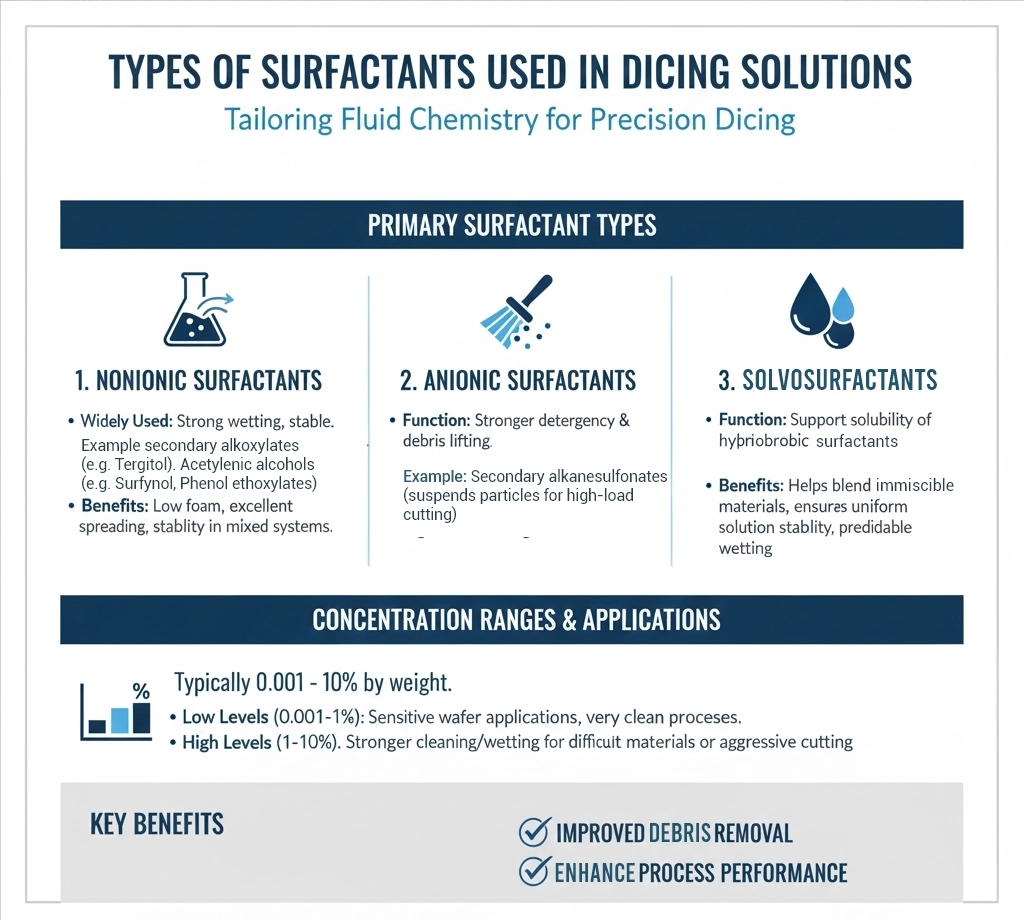

Types of Surfactants Used in Dicing Solutions

Nonionic surfactants are widely used because they provide strong wetting and stable performance under different chemical conditions. Secondary alcohol ethoxylates, such as Tergitol 15 S 7, offer effective wetting and work well in highly diluted dicing solutions. Acetylenic alcohol surfactants, such as Surfynol S 61, improve spreading and reduce surface tension without creating excess foam. Phenol ethoxylates from the Triton series provide good cleaning strength and maintain stability in mixed chemical systems.

Anionic surfactants are used when stronger detergency or debris lifting is required. Secondary alkanesulfonates, such as Hostapur SAS, deliver high cleaning efficiency and help keep silicon particles suspended for improved flushing. They work well when stronger particle removal is needed during high load cutting.

Solvosurfactants support the solubility of hydrophobic surfactants. They help blend materials that normally separate in water. This ensures uniform solution stability and maintains predictable wetting behavior across long production runs.

Recommended concentration ranges are typically between 0.001 and 10 percent by weight. Low levels support sensitive wafer applications that require very clean processes. Higher levels provide stronger cleaning and wetting for difficult materials or aggressive cutting conditions.

Interaction Between Surfactants and Organic Acids

Organic acids are combined with surfactants to improve cleaning strength during wafer dicing. Acids alone dissolve oxides and residues, but they do not always reach the full depth of the kerf. When blended with a surfactant, the solution gains better wetting and improved access to the cutting zone. This combination strengthens the cleaning action and supports more stable dicing performance.

Cu oxide removal is a primary function of these acid-surfactant blends. Copper pads can form oxide layers during processing. Organic acids dissolve these layers, while the surfactant keeps dissolved oxides suspended for removal. This supports cleaner copper surfaces and protects pad integrity for later assembly steps.

Al corrosion control is also achieved through controlled acid formulations. Aluminum pads are sensitive to aggressive chemistry. Organic acids provide mild and selective cleaning, and the surfactant helps distribute the solution evenly so no area is exposed to excessive acid concentration. This reduces the risk of pitting or surface damage.

Common organic acids used in these systems include citric, oxalic, and fumaric acids. These acids provide controlled oxide removal and are suitable for sensitive wafer materials. They dissolve unwanted films without attacking underlying metal layers.

Surfactants support acid penetration and cleaning by improving fluid flow into the kerf. Lower surface tension allows the acid solution to reach tight gaps, micro cracks, and debris-packed regions. This ensures uniform chemical contact, better flushing, and more predictable oxide removal throughout the cut path.

Performance Benefits of Surfactant Containing Dicing Solutions

Improved particle removal is achieved through low surface tension. When the solution spreads easily across the wafer, it lifts and suspends particles that would otherwise remain trapped in the kerf. This supports cleaner surfaces and reduces contamination during downstream processing.

Reduced kerf width is especially important when working with BGA, ceramic, and silicon substrates. A surfactant improves wetting and keeps the blade running smoothly. This allows the blade to follow a tighter cutting path and helps maintain narrower kerfs with more consistent dimensional accuracy.

Lower burr and chip formation results from better lubrication and cooling. A surfactant stabilizes the fluid film between the blade and the material. This lowers friction, reduces heat, and supports cleaner edges with fewer defects.

Reduction of galvanic corrosion on aluminum pads occurs when the surfactant works with inhibitors in the solution. This combination limits oxidation on metal layers and provides stronger corrosion control during and after cutting.

Better dissipation of electrostatic charge is another key benefit. Certain surfactants add controlled conductivity to the fluid. This helps remove charge from the wafer surface and reduces static related contamination.

Lower risk of false electrical failures at probe testing follows from cleaner pads and reduced particle buildup. When the dicing solution leaves fewer residues and minimizes corrosion, probe contact becomes more stable. This supports more reliable electrical testing and reduces the chance of intermittent or false failures.

Practical Guidelines for Selecting a Dicing Surfactant

Selection criteria depend on the substrate being cut. Hard and brittle materials such as silicon, SiC, and ceramics require strong wetting and low surface tension. This ensures full kerf penetration and reliable debris removal. Composite materials and BGA substrates need balanced detergency and gentle chemistry to protect sensitive layers. The surfactant must provide stable wetting without leaving residues that interfere with downstream cleaning.

Matching the surfactant type to cutting conditions is essential. High load or high speed cutting benefits from additives that provide strong lubrication to lower friction at the blade edge. Light load or low speed operations may require milder surfactants to prevent over cleaning or changes in wafer surface behavior. The surfactant must support the expected cutting forces, spindle speeds, and cooling requirements.

Foaming must be evaluated for high flow recirculation systems. Excess foam reduces fluid delivery, affects spray patterns, and lowers cooling efficiency. In these environments, the surfactant must generate very low foam at the nozzle and in the tank. This ensures stable fluid supply to the blade and prevents interruptions during sustained production.

Impact on blade life and lubrication quality should be considered. Surfactants that improve wetting and reduce friction help the blade cut more freely. This reduces blade loading and supports longer blade life with more consistent performance. Poor lubrication leads to higher temperatures and faster wear, which negatively affects cut quality and tool cost.

Mixed metal metallization, especially copper and aluminum, requires careful chemical selection. The surfactant must work with mild organic acids and corrosion inhibitors to provide balanced protection for both metals. A suitable formulation prevents copper oxide buildup while avoiding aggressive conditions that could damage aluminum pads. This ensures stable pad surfaces for later bonding and electrical testing.

Practical Guidelines for Selecting a Dicing Surfactant

|

Selection Factor |

What You Must Consider |

Practical Requirement |

|---|---|---|

|

Substrate Type |

Material hardness and structure influence wetting needs. Hard and brittle materials need deeper penetration of the fluid. Composites and BGA layers need gentle cleaning. |

Use strong wetting and low surface tension for silicon, SiC, and ceramics. Use balanced detergency and mild chemistry for composites and BGA substrates. Avoid residues that interfere with downstream cleaning. |

|

Cutting Conditions |

Cutting force, blade speed, and load determine lubrication demand. Heavy loads need stronger lubricity. Low loads need milder behavior. |

Use higher lubricity surfactants for high speed or high load cutting. Use milder surfactants for low speed or light load cutting to avoid over cleaning or surface alteration. |

|

Foaming Behavior |

High flow and recirculation systems produce foam more easily. Foam causes unstable fluid delivery, weak spray patterns, and poor cooling. |

Select low foam surfactants for recirculated systems. Surfactant must maintain low foam at the nozzle and in the tank to support stable, continuous spraying. |

|

Blade Life and Lubrication Quality |

Surfactants influence friction, heat generation, and blade loading. Good wetting improves blade performance and stability. Poor lubrication reduces blade life. |

Choose surfactants that reduce friction and improve wetting to extend blade life. Avoid chemistries that increase heat, wear, or load on the blade. |

|

Mixed Metal Metallization |

Copper and aluminum require controlled chemical environments. Surfactant must support protective acids and inhibitors. |

Use surfactants compatible with mild organic acids and corrosion inhibitors. Formulation must prevent copper oxide buildup while avoiding aluminum damage to maintain stable bonding surfaces. |

Recommended Application Conditions

Typical dilution ratios range from 1:0 to 1:1,000. Full strength solutions are used when difficult materials produce heavy residue or when stronger detergency is needed for aggressive cutting. Highly diluted solutions support sensitive semiconductor devices where minimal chemistry contact is required. You should determine the correct dilution by evaluating substrate hardness, blade bond type, kerf width targets, and the level of wetting and detergency needed for consistent cutting. Establishing a controlled dilution protocol helps maintain repeatability from lot to lot.

Flow rate and temperature conditions affect both blade performance and chemical stability. A steady flow ensures constant delivery of fresh solution into the kerf, allowing debris to be carried out before it binds to the blade. Higher flow rates are recommended for thick substrates and wide kerfs to maintain strong flushing action. Temperature control is equally important. Most operations hold the fluid near room temperature to prevent thermal shock and to keep lubrication performance consistent. Elevated temperatures can accelerate chemical activity, while cooler temperatures may increase viscosity and reduce wetting efficiency.

Compatibility with DI water, CO₂ treated water, and mixed chemistries is essential for predictable behavior. DI water provides the cleanest environment, but some facilities use CO₂ treated water to control pH and reduce static. The surfactant must remain chemically stable in each of these environments, without separating, foaming excessively, or reacting with other additives. Mixed chemistries, such as organic acids or corrosion inhibitors, also require a stable surfactant that maintains wetting and cleaning strength across the full operating pH range.

Post dicing cleaning steps determine how the surfactant behaves during rinse. A high quality surfactant should rinse completely, leaving no film or residue on the wafer surface. You should verify rinsability in both single wafer and batch cleaning systems. Proper rinse behavior improves pad cleanliness, prevents contamination during packaging, and avoids interference with probe testing. Inadequate rinsing can trap chemistry in micro recesses, leading to false electrical failures or unpredictability in downstream bonding. Establishing a cleaning and rinse sequence that matches the surfactant’s behavior ensures stable results across all device types.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

ARE YOU USING RIGHT

DICING SURFACTANTS FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DICING SURFACTANTS?

Knowledge Center

Dicing Surfactants Guide

How to Use SMART CUT XP Dicing Surfactants

Selecting the Right Dicing Surfactant / Fluid for Your Application

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

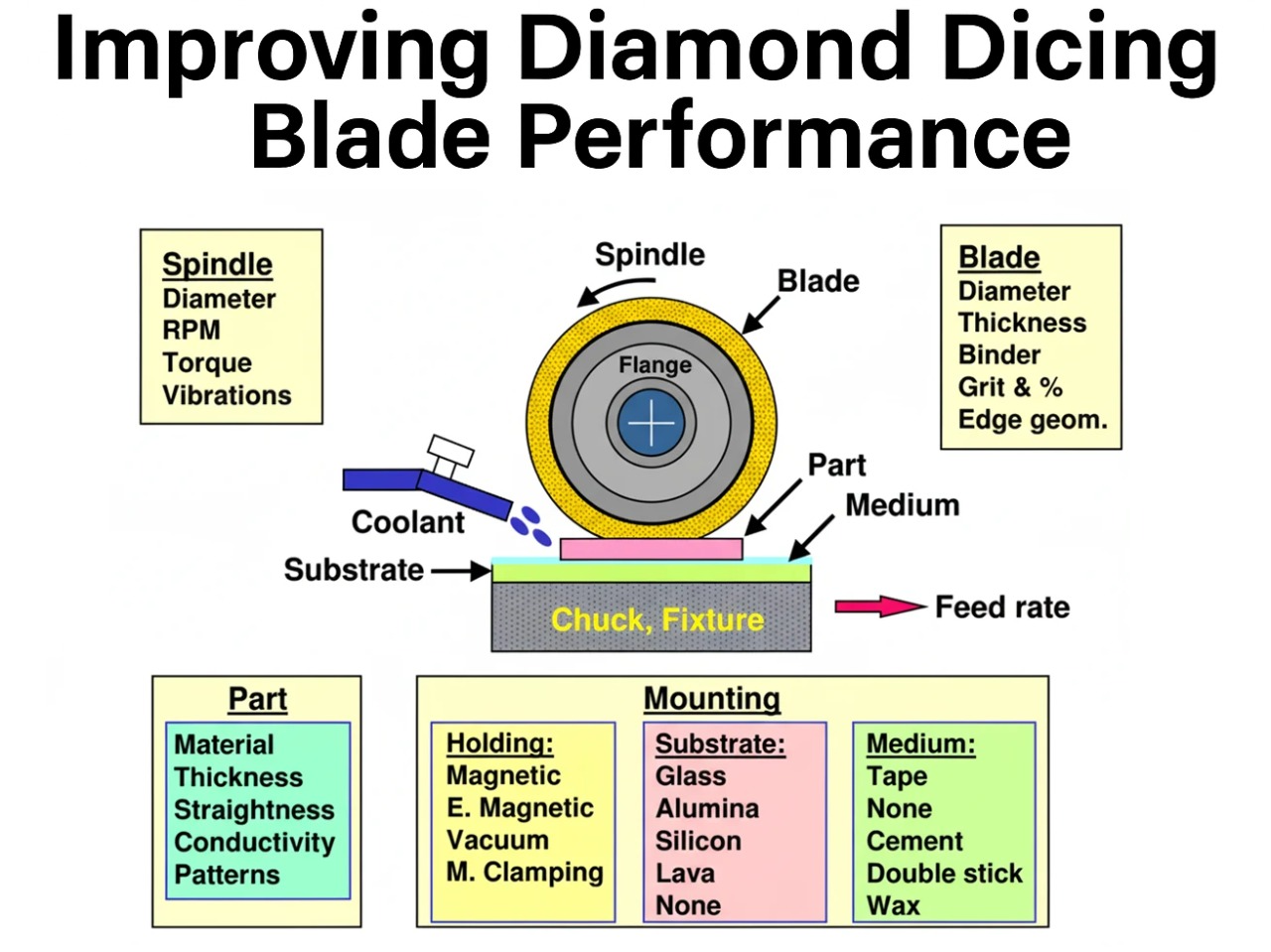

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

Selecting the Right Wafer Dicing Saw Practical Guide

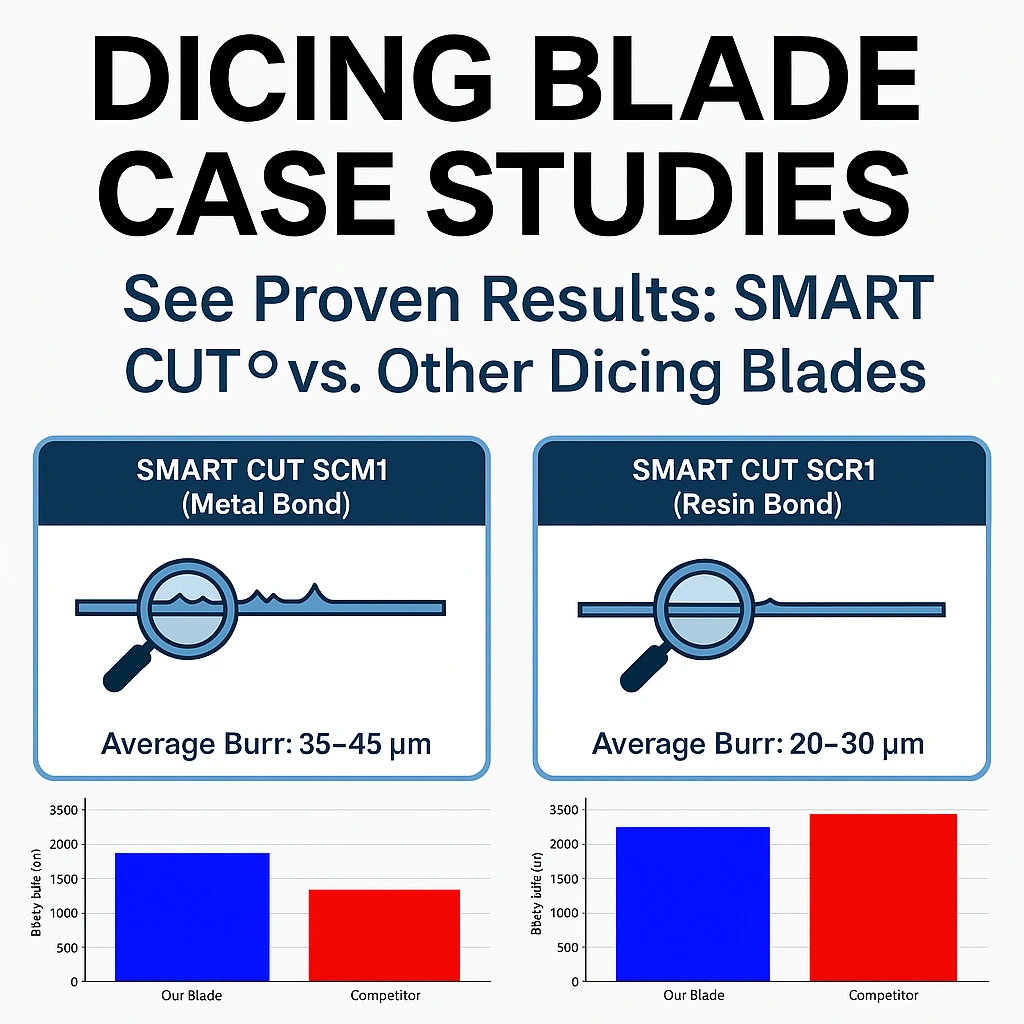

Dicing Blade Case Studies

Application Recommendations

Trouble Shooting Dicing Problems

Optimizing your Diamond Dicing Performance

Dicing Blade Operations Recommendations

Select right Diamond Dicing Blade for your application

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.