Diamond Core Bits ForConstruction/Concrete

Concrete & Construction

Diamond Core Bits

.001" to 48" in Diameter

We offer large variety Diamond core drills, bits and other tooling. Used for drilling large variety of concrete and construction materials. We have large variety of drills in stock and can custom manufacture almost any specification. Contact us for volume pricing.

Our tools provide higher level of performance compared to what is typically available in the market. That's where we excel. When your standard tools fail to meet the cutting requirements, we have the solution you need. As a small American diamond tool manufacturer, we distinguish ourselves through our commitment to quality, high-performance capabilities, excellent value, and the ability to deliver unique and customized solutions.

Construction Materials

- Concrete

- Stone

- Asphalt

- Masonry

- Cement

- Reinforced concrete

- Bricks

- Rebar

- Mortar

- Tile

- Plaster

- Block

- Grout

- Pavers

- Roof Tiles

- Dense Blocks

- Cured Concrete

- Refractory Brocks

- Flint

- Slate

- Soapstone

- Steel

- Quartzsite

- Stucco

- Green Concrete

- Corundum

- Basalt

- High-Performance Concrete

- Dense Fiber Reinforced Materials

- Epoxy & Resin-Based Flooring

- Pre Stressed Concreted

SMART CUT® 140DM DIAMOND CORE BITS / DRILL BITS FOR CONCRETE & ALLIED MATERIALS (WET ONLY)

DRILL ALL TYPES OF CONCRETE AND ALLIED MATERIALS FAST & EASY. Drilling Life: 650+ holes* on most materials. 30% more Diamond than conventional drills. Diamond Drill life will vary depending on material, drilling depth, coolant & drilling equipment used as well as operator experience.

DRY DIAMOND CORE BITS FOR MASONRY & CONCRETE (DRY / WET)

For wet / dry drilling. 9″ tube length with laser-welded individual segments to hold up under extreme heat and cutting pressure. Barrel vents increase air flow to dissipate heat and cool the core bit. Specially formulated professional quality segments provide fast cutting and long life in a variety of materials including concrete, reinforced concrete, brick, block and masonry. Full range of sizes for virtually any job. Use on core drilling machines and hand-held drills. Core Bit intended for Concrete with light to moderate reinforcement, Masonry, Block and Brick. Can be used Dry or Wet

SMART CUT® DIAMOND CORE BITS

Designed for Drilling Hard Materials such as full range of Rocks (granite, marble, quartz, flagstone, sandstone, onyx, amethyst, travertine, garnet. Will also work (agate, jasper, jade, petrified wood, and similar minerals). What sets these core bits apart is high grade of diamond used & advanced bond formulation designed for Hard Material.

DIAMOND CORE DRILLS & OTHER TOOLS

Custom Manufacturing Capabilities

Have a Unique Requierement?

Let Us Make Custom Diamond Drill Or Tool Specifically Designed For Your Application/ Requirements Just About Any Diamond/Cbn Can Be Designed And Manufactured Per Your Drawing Or Specifications

No Minimum

Order Quantity

Fast Lead

Times

Precision Tolerances

Free

Consultation

Limitless

Possibilities

Drilling Accessories

Water Swivel Adapters

Water Swivel Adapters (also known as drill head assemblies) are to supply high water, coolant, or air through the center of your diamond drills. Water Swivel Adapters/Drill Head Assemblies cools both diamond drills and material in zone of drilling.

Dressing Sticks

Dressing Sticks are available from stock to fit all types of diamond, cbn, abrasive wafering & cut off blades and sectiong saws. Such as Buehler.

Shank Adapters

Fits into drill press chuck allows the diamond drill to fit into drilling machine chuck or collets available with 3/8″

Drilling Templates

Drilling templates allow minimize drill vibration, makes sure proper positioning of the drill, insuring accuracy and minimum chipping. These are

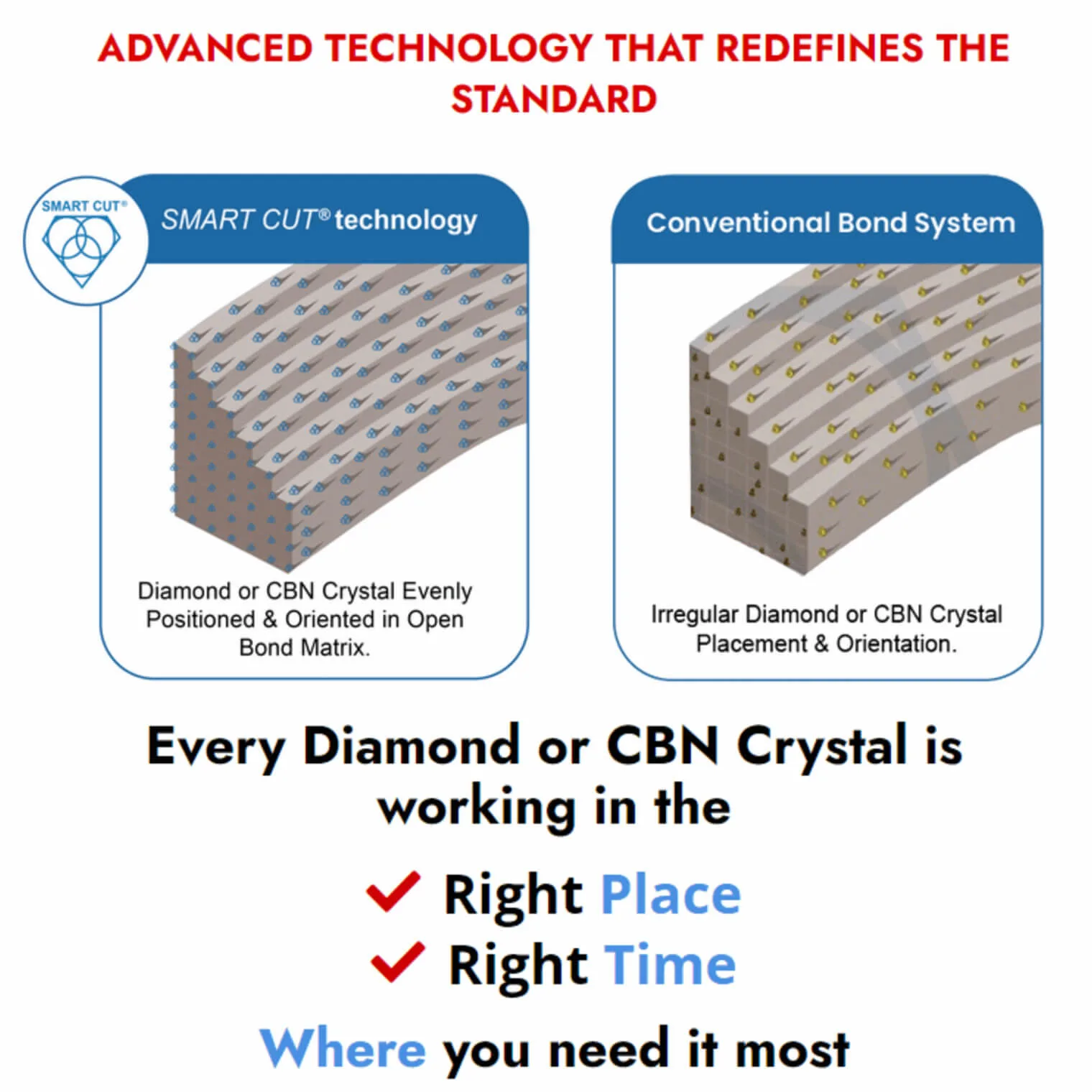

SMART CUT® technology

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

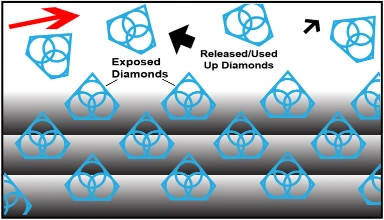

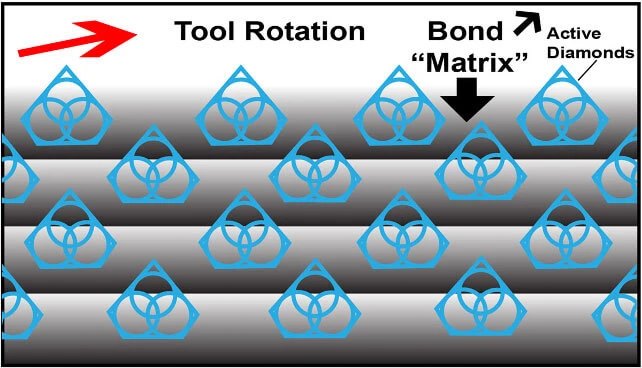

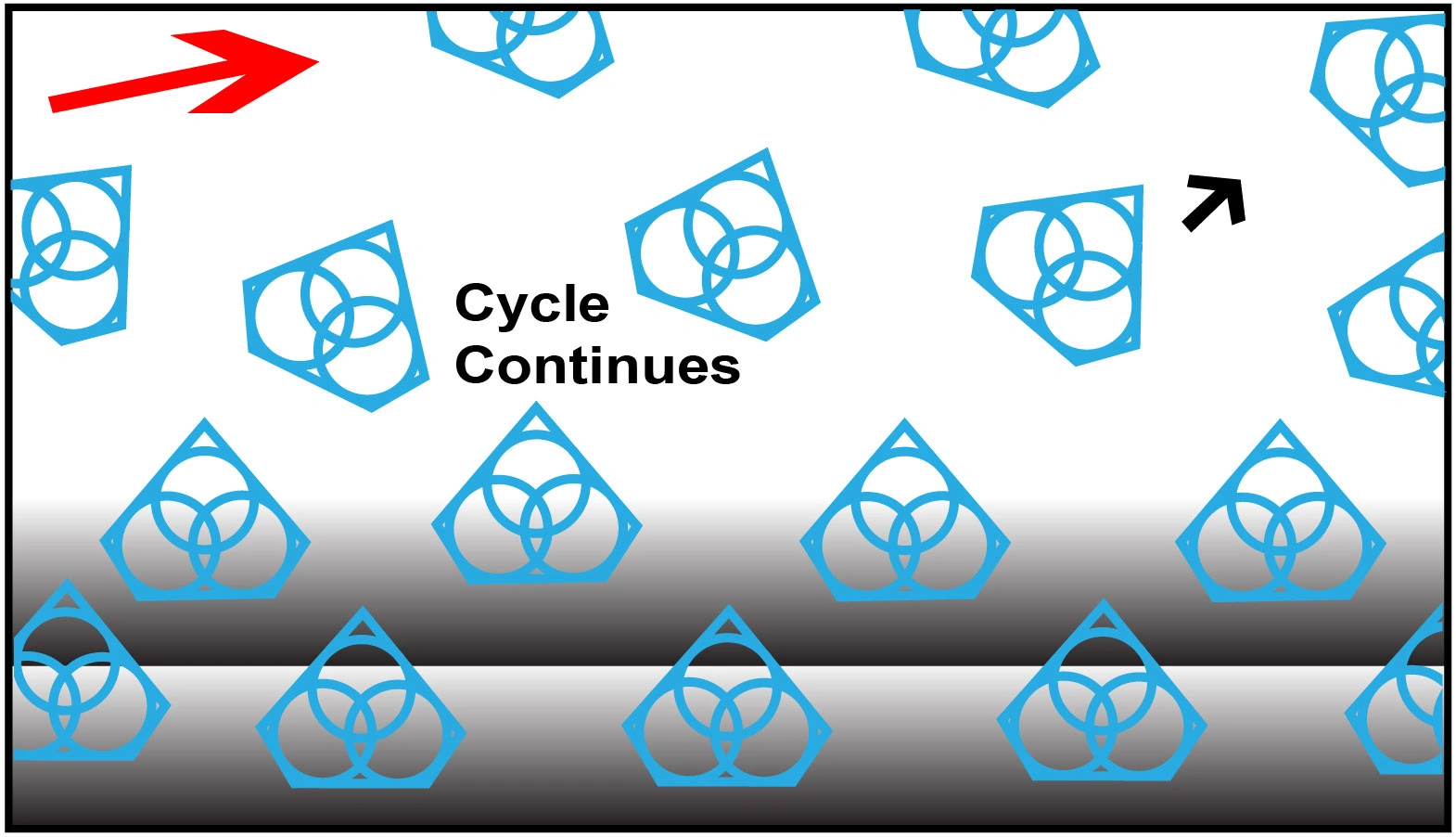

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superiror Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

- Custom Manufacturing

- Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

We understand that your success depends on select the right diamond & CBN blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Diamond Drills & Tools in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary drill chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect drill life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after drilling.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools