Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® 135DB Braised Bond Diamond Core Drills & Non Core Formation Drills with a 5/8-11″ Female Thread – the ultimate solution for precision drilling in a wide range of materials. These high-quality core drills can be used both wet or dry and are designed to meet the demanding needs of professionals and DIY enthusiasts alike, offering exceptional performance and durability.

SMART CUT® 135DB Braised Bond Diamond Core Drills & Non Core Formation Drills with a 5/8-11″ Female Thread. These diamond drills will drill large variety of materials faster and freer then any type of other diamond drills or other types of non diamond drills available.

SMART CUT® 135DB are designed to drill a wide variety of materials, including composites, fiberglass, ceramics, porcelain, various metals, concrete, brick, stone, and more, making them versatile for applications ranging from composites, to construction and even art installations.

The 5/8-11″ female thread ensures seamless integration with a wide variety of equipment such as angle grinders, drilling machines and other power tools commonly used across industries, simplifying setup and interchangeability. These core drills will drill very fast and provide good , surface finish with minimal chipping, ideal for high-quality finishes in both wet and dry conditions.

Tab Content

Yes, Braised Bond Diamond Core Drills can be used for drilling graphite. The diamond segments on these core drills are capable of efficiently drilling through graphite, even though it is a relatively soft material.

Yes, Braised Bond Diamond Core Drills are suitable for drilling composite materials, including fiberglass and carbon fiber composites. They are designed to provide precise and clean holes in these materials.

Yes, Braised Bond Diamond Core Drills can be used for drilling soft and gummy materials. These core drills are versatile and can efficiently drill through a wide range of materials, including those that are softer in nature.

When drilling into concrete and masonry, Braised Bond Diamond Core Bits typically produce a relatively smooth and clean hole with well-defined edges. The quality of the finish can vary based on factors such as the type of aggregate in the concrete and the presence of reinforcing materials.

When drilling into natural or engineered stone surfaces, Braised Bond Diamond Core Bits can provide a clean and precise hole with a smooth surface finish. The final appearance can depend on the hardness and composition of the stone.

When drilling through metal, such as steel or aluminum, Braised Bond Diamond Core Bits can produce a smooth surface finish with minimal burring or distortion. However, metal chips and debris may be generated during the drilling process.

When drilling into composite materials, Braised Bond Diamond Core Bits can produce clean and precise holes with minimal delamination or splintering, resulting in a smooth surface finish.

When drilling into plastics, the surface finish is generally smooth and clean, provided the appropriate drilling speed and technique are used.

It’s important to note that achieving the best surface

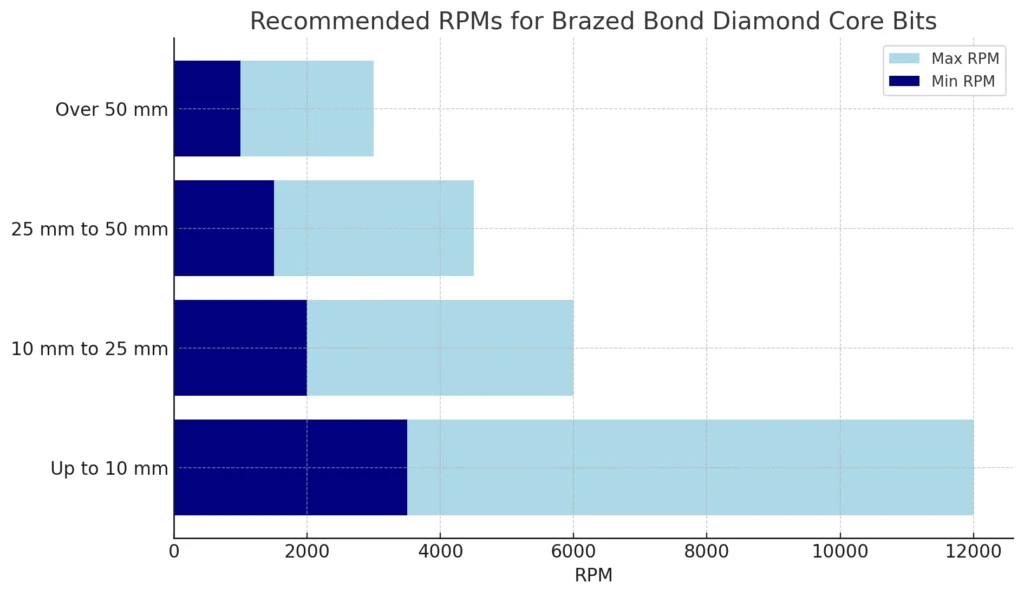

The drilling speed of Braised Bond Diamond Core Bits/Drills can vary based on several factors, including the material being drilled, the specific core bit or drill used, and the drilling equipment. Here are some general guidelines

When drilling into concrete and masonry, Braised Bond Diamond Core Bits/Drills can typically achieve drilling speeds ranging from 300 to 1,000 revolutions per minute (RPM), depending on the hardness of the material and the diameter of the core bit.

Drilling into natural or engineered stone can be done at speeds ranging from 600 to 1,500 RPM, with the specific speed depending on the stone’s hardness and the core bit’s size.

Drilling through metal materials like steel or aluminum can be accomplished at speeds between 500 and 1,500 RPM, with higher speeds often used for thinner metal sheets and lower speeds for thicker materials.

Drilling composite materials typically requires speeds between 800 and 2,500 RPM, depending on the composite’s composition and thickness, as well as the core bit’s size.

When drilling plastics, speeds ranging from 1,500 to 3,000 RPM are commonly employed, with adjustments based on the plastic’s type and thickness.

Braised Bond Diamond Core Bits/Drills are not typically recommended for drilling glass. Glass is a fragile and brittle material, and using braised bond diamond core drills with coarse diamond grit size such as these can lead to chipping, cracking, or shattering of the glass. However if this is chipping and rough surface finish is not important for you then braised bond drills are sufficient.

Yes, Braised Bond Diamond Core Bits/Drills can be used for drilling metal materials, including steel, aluminum, and other non-ferrous metals. However, there are some considerations to keep in mind.

When drilling metal, consider the following factors:

⦁ Select the appropriate core bit or drill bit designed for metal drilling.

⦁ Use lubrication or cutting oil to reduce heat and friction during the drilling process.

⦁ Adjust the drilling speed and pressure based on the specific metal type and thickness.

⦁ Use appropriate safety measures and protective gear, as metal drilling can produce sharp metal chips.

Drilling speeds for metal materials can typically range from 500 to 1,500 revolutions per minute (RPM), depending on the metal’s type and thickness, as well as the core bit’s size.

To achieve clean and precise holes when drilling metal:

⦁ Maintain a steady hand and avoid excessive pressure to prevent drill bit wandering.

⦁ Use a center punch to create a starting point for the drill bit.

⦁ Secure the workpiece firmly to prevent movement during drilling.

Yes, Braised Bond Diamond Core Bits/Drills can be used for drilling abrasive materials. In fact, they are often preferred for drilling through abrasive materials due to their durability and ability to maintain cutting effectiveness in challenging conditions.

Examples of abrasive materials that can be drilled with Braised Bond Diamond Core Bits/Drills include:

⦁ Heavily reinforced concrete with high silica content

⦁ Asphalt

⦁ Refractory materials (e.g., fire bricks)

⦁ Certain types of natural stone with abrasive components

When drilling abrasive materials, consider the following:

⦁ Use core bits specifically designed for abrasive materials to maximize performance and lifespan.

⦁ Maintain the appropriate drilling speed and pressure based on the material’s hardness and abrasiveness.

⦁ Ensure proper lubrication or coolant flow to reduce heat and wear on the core bits.

The lifespan of Braised Bond Diamond Core Bits/Drills in abrasive materials can vary depending on factors such as the quality of the core bit, the specific abrasive material, and the drilling conditions. Premium-quality core bits designed for abrasive materials often offer extended durability and lifespan.

While Braised Bond Diamond Core Bits/Drills can be used for dry drilling in abrasive materials, it’s important to monitor the core bit’s temperature and consider using cutting oil or specialized lubrication to minimize heat generation and wear. Dry drilling in abrasive materials may shorten the core bit’s lifespan compared to wet drilling.

Yes, Braised Bond Diamond Core Bits/Drills can be used for drilling advanced ceramics. However, drilling advanced ceramics requires specialized diamond core bits designed for ultra-hard materials.

When drilling advanced ceramics, consider the following factors:

⦁ Use core bits specifically engineered for ultra-hard materials like advanced ceramics.

⦁ Ensure proper cooling and lubrication to reduce heat and prevent damage to the core bit.

⦁ Start drilling at a low speed and gradually increase it to prevent chipping or cracking.

⦁ Use precise and controlled drilling techniques to maintain accuracy.

The lifespan of core bits when drilling advanced ceramics can vary depending on factors such as the the specific ceramic material hardness, density and other properties, the drilling conditions, and coolant and rpm’s used. Sintered (metal bond) diamond core drills specifically designed for advanced ceramics are recommended for these more challenging applications.

Dry drilling in advanced ceramics is possible with Braised Bond Diamond Core Bits/Drills designed if the ceramics are in green state (have not been fired) or if fired the ceramics are not ultra hard not above 8 on mohes scale of hardness this is materials such as pzt, zirconia, etc. Please note the life span without coolant will be short and frequent dressing required. Also, it’s essential to monitor the core bit’s temperature and consider using appropriate lubrication or coolant to minimize heat generation and wear. Wet drilling with coolant is often recommended for extended diamond drill and better results when drilling advanced ceramics.

Braised Bond Diamond Core Drills generally offer excellent performance when drilling a wide range of materials. They are known for their durability and ability to maintain cutting effectiveness in challenging conditions. Electroplated core drills are well-suited for softer materials, while Sintered (Metal Bond) core drills are often used for harder materials.

The drilling speed of these core drills depends on the material being drilled and the specific core drill used. Braised Bond Diamond Core Drills can provide faster and freer drilling speeds for large variety of materials. Electroplated core drills usually are second in drilling speed after braised bond diamond core drills, followed by sintered (metal bond) core drills. This has to do with diamond exposure ratio, the bonding type and type and specification of diamond used for the three different bonds types.

The lifespan of core drills depends on factors like material hardness, rpm’s, coolant used, specification and quality of the diamond drill used and drilling conditions. Braised Bond Diamond Core Drills are known for their durability and can have a longer lifespan in abrasive and challenging materials. Electroplated core drills may have a shorter lifespan in comparison, while Sintered (Metal Bond) core drills can have a longer lifespan in very hard materials.

Braised Bond Diamond Core Drills typically produce minimal chipping when used correctly, making them suitable for achieving clean holes. Electroplated core drills may produce more chipping in certain materials due to their design. Sintered (Metal Bond) core drills are known for reduced chipping in very hard materials.

The surface finish produced by these core drills can vary based on factors such as material type and drilling technique. Braised Bond Diamond Core Drills are usually very coarse diamond grit size for faster and more aggressive drilling of larger variety of materials. Electroplated core drills can produce a smooth finish in softer materials, while Sintered (Metal Bond) core drills often yield a smooth finish in harder materials.

⦁ Braised Bond Core Drills are versatile and can perform well in a wide range of materials, reducing the need for multiple core bits.

⦁ They offer durability and longevity in challenging drilling conditions.

⦁ Their ability to maintain cutting effectiveness as the diamond wear down can result in cost savings over time.

⦁ Braised Bond Core Drills drill faster and more aggressively

⦁ Can often be used dry without any coolant

Yes, Braised Bond Diamond Core Drills can be used with both water swivel adapters and shank adapters, depending on your specific drilling requirements and equipment setup.

A water swivel adapter is often used to provide a continuous and controlled flow of water or coolant to the core bit’s cutting surface. This helps keep the core bit cool, reduces friction, and flushes away debris during drilling, enhancing both performance and core bit lifespan.

A shank adapter can be used to connect the core drill to the drilling equipment or drill motor. It provides a secure and compatible connection, ensuring that the core bit operates smoothly and efficiently.

When using water swivel adapters or shank adapters, it’s essential to:

⦁ Ensure that the adapters are compatible with the core drill and the drilling equipment.

⦁ Follow manufacturer recommendations for water flow rates and coolant use when using a water swivel adapter.

⦁ Securely attach the shank adapter to the core drill to prevent any wobbling or movement during drilling.

Water swivel adapters are commonly used when wet drilling is required, especially in applications involving hard or abrasive materials like concrete, stone, or masonry. Shank adapters are used to connect the core drill to a drill motor or machine for stability and precision in various drilling applications.

Braised Bond Diamond Core Drills are typically not designed to be dressed or reconditioned in the same way as some other types of diamond tools. They are often used until the diamond section, at which point they are replaced with new core drills. They can be dressed occasionally if needed

Braised Bond Diamond Core Drills have diamond section that are braised (bonded) to the core bit’s body. There is only one or few layers of diamond on the steel body. Frequent dressing can wear away the bond matrix holding the diamonds in place really fast.

When the diamond section on a Braised Bond Diamond Core Drill become worn, it’s recommended to replace the entire core drill with a new one. This ensures that you maintain optimal drilling performance and avoid the risk of poor results or damage to the material being drilled.

To extend the lifespan of Braised Bond Diamond Core Drills, it’s essential to use them with the appropriate drilling parameters, including the correct drilling speed, coolant or lubrication, and feed rate. Regularly inspect the core drill for signs of wear, and replace it when the diamond section is significantly worn down.

Braised Bond Diamond Core Bits are not typically suitable for drilling graphite. It’s recommended to use carbide or high-speed steel drill bits for graphite, which is a relatively soft material.

Braised Bond Diamond Core Bits are not ideal for drilling composite materials like fiberglass or carbon fiber composites. Specialized composite drill bits or carbide bits are more suitable to minimize delamination and splintering.

No, Braised Bond Diamond Core Bits are designed for hard and abrasive materials. For soft and gummy materials, consider using specialized tools such as hole saws, rotary burrs, or auger bits depending on the material’s consistency and thickness.

Always select the appropriate tool for the specific material to achieve the best results and avoid unnecessary wear or damage to your core bits.

Yes, Braised Bond Diamond Core Drills can be used for drilling graphite. The diamond segments on these core drills are capable of efficiently drilling through graphite, even though it is a relatively soft material.

Yes, Braised Bond Diamond Core Drills are suitable for drilling composite materials, including fiberglass and carbon fiber composites. They are designed to provide precise and clean holes in these materials.

Yes, Braised Bond Diamond Core Drills can be used for drilling soft and gummy materials. These core drills are versatile and can efficiently drill through a wide range of materials, including those that are softer in nature.

When drilling into concrete and masonry, Braised Bond Diamond Core Bits typically produce a relatively smooth and clean hole with well-defined edges. The quality of the finish can vary based on factors such as the type of aggregate in the concrete and the presence of reinforcing materials.

When drilling into natural or engineered stone surfaces, Braised Bond Diamond Core Bits can provide a clean and precise hole with a smooth surface finish. The final appearance can depend on the hardness and composition of the stone.

When drilling through metal, such as steel or aluminum, Braised Bond Diamond Core Bits can produce a smooth surface finish with minimal burring or distortion. However, metal chips and debris may be generated during the drilling process.

When drilling into wood, Braised Bond Diamond Core Bits can create a clean and smooth hole, especially when used at lower speeds. The finish will be influenced by the type and quality of the wood.

When drilling into composite materials, Braised Bond Diamond Core Bits can produce clean and precise holes with minimal delamination or splintering, resulting in a smooth surface finish.

When drilling into plastics, the surface finish is generally smooth and clean, provided the appropriate drilling speed and technique are used.

It’s important to note that achieving the best surface finish often requires using the correct core bit or drill for the specific material, along with appropriate drilling speeds, feeds, and techniques. Additionally, regular maintenance and inspection of the core bit’s diamond segments are essential to ensure optimal drilling performance and a desirable surface finish.

The drilling speed of Braised Bond Diamond Core Bits/Drills can vary based on several factors, including the material being drilled, the specific core bit or drill used, and the drilling equipment.

When drilling into concrete and masonry, Braised Bond Diamond Core Bits/Drills can typically achieve drilling speeds ranging from 300 to 1,000 revolutions per minute (RPM), depending on the hardness of the material and the diameter of the core bit.

Drilling into natural or engineered stone can be done at speeds ranging from 600 to 1,500 RPM, with the specific speed depending on the stone’s hardness and the core bit’s size.

Drilling through metal materials like steel or aluminum can be accomplished at speeds between 500 and 1,500 RPM, with higher speeds often used for thinner metal sheets and lower speeds for thicker materials.

Drilling composite materials typically requires speeds between 800 and 2,500 RPM, depending on the composite’s composition and thickness, as well as the core bit’s size.

When drilling plastics, speeds ranging from 1,500 to 3,000 RPM are commonly employed, with adjustments based on the plastic’s type and thickness.

Braised Bond Diamond Core Bits with a 5/8-11″ female thread are specialized tools used in large variety drilling applications. They are designed for drilling holes in hard materials like s concrete, stone, and masonry and soft materials such as composites, fiberglass, graphite, metals, and many others.

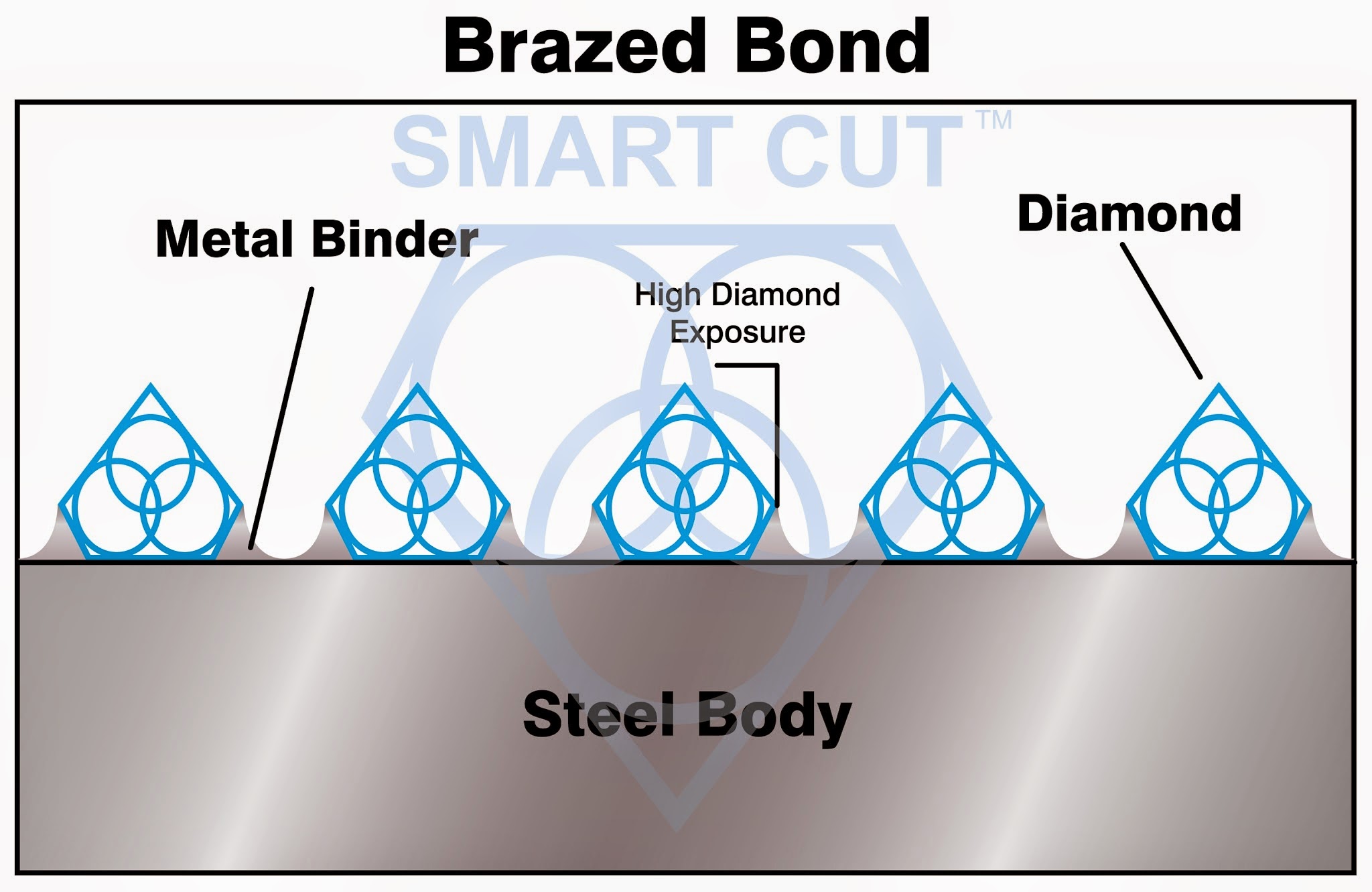

These core bits are equipped with diamond-impregnated coating with high diamond exposure that are braised (bonded) onto the core bit’s steel body. Diamonds are incredibly hard and can cut through tough materials effectively. When the core bit rotates, the diamond grind away the material, creating a hole.

The 5/8-11″ female thread refers to the thread size on the core bit, which allows it to be easily attached to compatible tools like angle grinders and drilling machines, water swivel adapters, shank adapters with a corresponding 5/8-11″ male thread. This thread size ensures a secure and stable connection during the drilling process.

These core bits are commonly used in construction and renovation projects for tasks like creating holes for plumbing and electrical installations, anchoring bolts, and sampling materials for testing purposes, drilling holes in composites, graphite, metals, porcelain, and counter tops.

Yes, these core bits come in various sizes to accommodate different hole diameter requirements. Common sizes range from 1/2 inch to several inches in diameter, depending on the specific application.

Selecting the right core bit depends on the material you need to drill through and the size of the hole you want to create. Consider the hardness and thickness of the material, as well as the diameter of the hole required, to determine the appropriate core bit.

Proper maintenance includes ensuring the core bit is kept cool during operation by using water or a suitable coolant. Additionally, periodically inspect the core bit for wear and replace it if the diamond segments become too worn down. Using the correct drilling speed and pressure is also essential to maximize the core bit’s lifespan.

Yes, many Braised Bond Diamond Core Bits with 5/8-11″ female thread are designed for both wet and dry drilling applications. However, it’s crucial to check the product specifications and recommendations from the manufacturer to ensure compatibility with your intended drilling method.

You can find these core bits at construction supply stores, online retailers, and specialized tool suppliers. Make sure to choose a reputable supplier to ensure the quality and authenticity of the product.

The lifespan of these core bits can vary depending on several factors, including the quality of the core bit, the hardness of the material being drilled, and the operating conditions. On average, they can last for several hundred drilling cycles with proper care and maintenance.

While some Braised Bond Diamond Core Bits are designed for dry drilling, it’s generally recommended to use water or a suitable coolant for wet drilling. Dry drilling can generate excessive heat, which may reduce the core bit’s lifespan and affect drilling performance.

Safety is paramount when working with these core bits. Always wear appropriate personal protective equipment (PPE), including safety goggles, ear protection, and gloves. Follow the manufacturer’s instructions and guidelines for safe operation, and be aware of potential hazards like flying debris and kickbacks.

Braised Bond Diamond Core Bits are typically not designed to be recoated once the diamond section wear down. It’s more cost-effective to replace them with new core bits when they become dull or worn.

Store these core bits in a cool, dry place away from direct sunlight and moisture. Make sure they are stored in a way that prevents damage to the diamond segments, such as in a protective case or rack.

If your core bit becomes stuck during drilling, stop the operation immediately. Attempting to force it may damage the core bit or the drilling equipment. Try gently rocking the bit back and forth to release it, and if that doesn’t work, seek professional assistance to avoid potential hazards.

Braised Bond Diamond Core Bits with a 5/8-11″ female thread can be used with handheld power tools such as angle grinders and drilling machines that have a compatible 5/8-11″ male thread. This versatility makes them suitable for a wide range of applications.

When drilling deep holes, it’s essential to periodically withdraw the core bit to clear debris and allow coolant to flow into the hole. This helps maintain drilling efficiency and prevents overheating.

Braised Bond Diamond Core Bits can be used for both vertical and horizontal drilling applications. However, proper support and stabilization are crucial when drilling horizontally to ensure accuracy and safety.

Some Braised Bond Diamond Core Bits are designed for both dry and wet drilling, offering versatility. However, it’s important to check the product specifications to confirm if a particular core bit is suitable for your intended drilling method.

Segmented core bits have diamond segments separated by gaps, which allows for faster drilling and better debris removal. Continuous rim core bits, on the other hand, provide a smoother, cleaner cut but may drill more slowly. The choice between them depends on your specific drilling needs, surface finish requirements, preferred drilling speed, coolant use and material you are drilling.

When using water coolant for wet drilling, it’s essential to capture and dispose of the wastewater responsibly to prevent environmental contamination. Some local regulations may govern the disposal of wastewater from construction and drilling activities, so be sure to comply with any applicable laws and guidelines.

Yes, Braised Bond Diamond Core Bits are suitable for precision drilling applications, including creating holes for anchors, dowels, and other fasteners. They offer excellent control and accuracy when used correctly.

When drilling through concrete that may contain rebar or other metal objects, it’s essential to use core bits designed for such applications. Core bits with diamond segments specifically engineered for metal reinforcement can help you drill through these obstacles without damaging the core bit.

When changing or replacing core bits, make sure the equipment is turned off and disconnected from the power source. Follow the manufacturer’s instructions for safely securing and tightening the core bit to avoid accidents or injury.

While dry drilling is possible with some Braised Bond Diamond Core Bits, it’s generally not recommended due to the risk of overheating and reduced core bit lifespan. Whenever possible, use water or a suitable coolant to keep the core bit cool during drilling.

Regularly inspect the core bit for signs of wear and replace it when the diamond segments become worn down. Clean the core bit after each use to remove debris and extend its lifespan. Lubricate the threaded connection to prevent corrosion, and store it properly to prevent damage.

Braised Bond Diamond Core Bits are designed for hard materials like concrete, stone, and masonry. Using them on softer materials may cause excessive wear and reduce their effectiveness. For softer materials, consider using specialized core bits designed for those applications.

To maximize efficiency and reduce vibration, ensure that the core bit is properly centered on the drilling surface. Use a steady and controlled drilling speed, and avoid excessive pressure. Periodically withdraw the core bit to clear debris and maintain a smooth drilling process.

The recommended drilling speed or RPM can vary depending on the specific core bit and the material being drilled. Always refer to the manufacturer’s guidelines for the optimal drilling speed to achieve the best results and prolong the core bit’s life.

Dry drilling in cold weather can be challenging as it may increase the risk of overheating due to reduced lubrication and cooling. If you need to drill in cold conditions, consider using a suitable coolant or water to help maintain an appropriate operating temperature.

When handling core bits with exposed diamond segments, use caution to avoid accidental contact with the sharp edges. It’s advisable to wear gloves and handle the core bit with care to prevent injury.

Yes, Braised Bond Diamond Core Bits are suitable for drilling holes in reinforced concrete. However, it’s essential to use the appropriate core bit specifically designed for reinforced concrete to ensure efficient drilling and avoid premature wear.

While Braised Bond Diamond Core Bits with a 5/8-11″ female thread are designed to be compatible with various drilling equipment, it’s always a good practice to ensure that the thread size and connection are compatible with your specific machine. In most cases, 5/8-11″ female-threaded core bits should work with standard drilling equipment.

Yes, Braised Bond Diamond Core Bits can be used for drilling in vertical or overhead positions. However, proper safety measures, such as securing the drilling equipment and using appropriate support structures, should be taken to prevent accidents or injuries.

The lifespan of the diamond segments can vary widely based on factors such as the quality of the core bit, the hardness of the material being drilled, and the drilling conditions. On average, diamond segments can last for several hours of continuous drilling before they require replacement.

Some manufacturers recommend a break-in procedure for new core bits to help seat the diamond segments and optimize performance. This procedure typically involves drilling through a soft material like asphalt or brick for a few minutes before starting the main drilling operation.

While it’s generally recommended to use water or a suitable coolant for wet drilling, in some situations, you can use an added lubricant or cutting oil as a substitute to minimize heat generation and extend the core bit’s life. However, this approach may not be as effective as using water.

If your core bit becomes jammed or stuck, stop drilling immediately to avoid damage to the core bit or the drilling equipment. Attempt to gently rock the core bit back and forth to release it. If the core bit remains stuck, seek professional assistance to avoid potential hazards and equipment damage.

When disposing of used core bits, take care to ensure that they are properly secured and do not pose any safety hazards. You should also consider recycling or disposing of them in accordance with local regulations and guidelines for construction and drilling waste.

Some Braised Bond Diamond Core Bits are designed for underwater drilling applications, but it’s essential to check the product specifications and ensure they are suitable for the specific underwater drilling conditions you are facing.

Generally, Braised Bond Diamond Core Bits are not designed to be re-tipped or re-segmented once the diamond segments wear down. Attempting to re-tip them may not provide satisfactory results and could affect drilling performance.

When drilling near edges or corners, use a slower drilling speed and exercise caution to prevent chipping or damaging the material. You may also consider starting the hole slightly away from the edge and gradually moving toward it to reduce the risk of chipping.

Yes, Braised Bond Diamond Core Bits can be used for precision drilling tasks, including creating holes for decorative fixtures. They provide the control and accuracy needed for such applications.

It’s generally not recommended to attempt to re-sharpen diamond segments on core bits. Diamond segments are typically brazed onto the core bit’s body during manufacturing, and attempting to sharpen them may damage the core bit and affect drilling performance.

Braised Bond Diamond Core Bits are typically designed for drilling through harder materials like concrete, stone, and masonry. For drilling into ceramic tiles, it’s better to use specialized tile drill bits that are specifically designed for this purpose to prevent cracking or chipping of the tiles.

If a core bit becomes stuck, stop drilling immediately. Use caution when attempting to remove it, as it may be under pressure. Follow safe removal procedures, and consider seeking professional assistance if necessary to avoid accidents or injury.

Braised Bond Diamond Core Bits are typically used for drilling in flat surfaces. Drilling in curved or rounded surfaces may be challenging and may require specialized equipment or techniques to achieve the desired hole shape.

To maintain the threaded connection, periodically inspect it for signs of wear or damage. Lubricate the threads as needed to prevent corrosion. Ensure that the core bit is securely tightened onto the drilling equipment before each use to prevent slippage during drilling.

Braised Bond Diamond Core Bits can be used with handheld drills that have a compatible 5/8-11″ female thread. This versatility allows for both handheld and larger machine-based drilling, depending on your needs.

Common signs of core bit wear include reduced drilling speed, decreased cutting efficiency, increased heat generation, and visible damage to the diamond segments. If you notice any of these signs, it’s time to replace the core bit for optimal performance.

After each use, it’s essential to clean the core bit thoroughly to remove debris and prevent diamond segments from clogging. Use a wire brush or specialized cleaning tools to clear the segments and ensure they remain sharp.

For extremely dense or heavily reinforced materials, it’s advisable to use premium-quality core bits specifically designed for such applications. These core bits often have advanced diamond segments and specialized features to handle the toughest drilling conditions.

Drilling speed can vary depending on factors such as the core bit size, the material being drilled, and the drilling equipment. Generally, core bits with larger diameters may drill more slowly, while smaller core bits can achieve faster drilling speeds. Always refer to the manufacturer’s recommendations for specific drilling speed guidelines.

Yes, Braised Bond Diamond Core Bits are commonly used for drilling holes in concrete slabs to install anchor bolts, structural elements, and other fasteners. They provide precision and accuracy for such applications.

If you encounter unexpected resistance while drilling, stop the operation immediately. Resistance could indicate a hidden obstacle, such as rebar or a hard aggregate, which may damage the core bit. Investigate the cause of resistance before continuing.

Braised Bond Diamond Core Bits are not suitable for drilling holes in delicate materials like glass, as they may cause chipping or cracking. For such materials, specialized glass or tile drill bits should be used.

When removing the core from the core bit, use caution to prevent injury. Gently tap the core from the backside to release it, taking care not to damage the core or the diamond segments. Always wear appropriate safety gear, including gloves, when handling the core.

Yes, Braised Bond Diamond Core Bits can be used with precise depth control to create holes with specific depths. Many drilling machines have depth adjustment features that allow for accurate drilling to the desired depth for anchor installation and other applications.

Braised Bond Diamond Core Bits offer several advantages, including faster drilling in hard materials, longer lifespan, and the ability to maintain cutting effectiveness even as the diamond segments wear down. They are preferred for demanding drilling applications.

Braised Bond Diamond Core Bits are suitable for drilling holes in refractory materials, including fire bricks and kiln linings. Their diamond segments are designed to withstand the high temperatures generated when drilling through such materials.

When drilling deep holes, it’s essential to maintain a consistent drilling speed, use an adequate coolant flow, and periodically withdraw the core bit to clear debris and allow for proper cooling. Proper cooling is crucial to prevent overheating and core bit damage.

Common challenges include overheating, reduced drilling speed, and encountering hidden obstacles. To address these issues, follow manufacturer recommendations for cooling, ensure proper drilling techniques, and use specialized core bits for challenging materials.

Braised Bond Diamond Core Bits are primarily designed for drilling round holes. Creating square or rectangular holes typically requires specialized tools or techniques, such as sawing or cutting.

Re-tipping or re-segmenting Braised Bond Diamond Core Bits can be a challenging and specialized process that is typically performed by professionals or specialized tool manufacturers. It may not always be cost-effective compared to replacing the core bit.

When dry drilling outdoors with Braised Bond Diamond Core Bits, it’s important to consider environmental factors such as wind and temperature variations that can affect cooling. Using a suitable coolant or water may be necessary to ensure consistent performance.

When drilling holes in delicate stone materials, use lower drilling speeds and light pressure to minimize the risk of chipping or cracking. Additionally, consider using specialized core bits designed for soft or decorative stone.

While Braised Bond Diamond Core Bits are primarily designed for drilling round holes, they can be used creatively to create unique shapes by drilling a series of closely spaced holes and then connecting them.

When drilling in hazardous or confined spaces, ensure proper ventilation, use respiratory protection if needed, and have emergency rescue procedures in place. Additionally, consider using compact and maneuverable drilling equipment suitable for tight spaces, if available. Always follow safety guidelines and regulations for such environments.

Certainly, here are some additional frequently asked questions (FAQ) about Braised Bond Diamond Core Bits.

To achieve precise diameter control, use a Braised Bond Diamond Core Bit with the desired diameter, and ensure that the drilling equipment is stable and properly aligned. Pilot holes or templates can also help achieve accurate hole diameters.

Yes, Braised Bond Diamond Core Bits can be used for drilling holes in historical or delicate architectural materials like sandstone or limestone. However, it’s crucial to use the appropriate core bit with a lower drilling speed to prevent damage to these softer stones.

Core bit overheating can result from factors such as excessive drilling speed, inadequate coolant flow, or too much pressure applied during drilling. To prevent overheating, ensure that you follow the recommended drilling speed, maintain proper coolant flow, and use the correct drilling pressure.

For extremely abrasive materials, it’s advisable to use specialized core bits designed for such applications. These core bits often have diamond segments specifically engineered to withstand the high abrasion of materials with high silica content.

Drilling in curved surfaces may require specialized equipment or techniques to maintain accuracy. Consider using flexible shaft core drilling machines or adapting the drilling equipment to the curved surface for precise hole creation.

In situations where water or coolant access is limited, you can use a suitable lubricant or cutting oil to reduce heat generation during dry drilling. However, be mindful of the core bit’s temperature to prevent overheating.

The lifespan of Braised Bond Diamond Core Bits in heavy-duty drilling applications can vary widely depending on factors like the quality of the core bit and the drilling conditions. Premium-quality core bits are designed for extended continuous use and may have a longer lifespan than standard core bits.

Braised Bond Diamond Core Bits are not typically used for drilling holes in composite materials like fiberglass or carbon fiber. For such materials, specialized cutting tools like carbide or high-speed steel drill bits are more suitable to avoid delamination or damage.

Dispose of used core bits in accordance with local regulations for construction and drilling waste. Some regions may have specific disposal requirements for diamond-tipped tools, so it’s essential to follow local guidelines and environmentally responsible disposal practices.

When drilling near or through existing structural elements, it’s crucial to ensure that the drilling operation does not compromise their integrity. Seek the guidance of a structural engineer or a professional experienced in drilling near existing structures to ensure safety and structural stability.

If you cannot re-tip or re-segment a worn core bit, it’s best to dispose of it and replace it with a new one. Attempting to sharpen or recondition it may lead to decreased drilling performance and potential safety hazards.

When drilling near walls or floors that may contain electrical or plumbing lines, use a wall or floor scanner to locate and mark the positions of these utilities. Drilling cautiously and at a controlled speed will help minimize the risk of accidental damage.

When drilling into materials with irregular shapes or varying thicknesses, it may be necessary to adapt the drilling technique and use specialized support structures to maintain stability and accuracy during the drilling process.

Drilling into brittle materials like terracotta or porcelain tiles with Braised Bond Diamond Core Bits requires careful control of drilling speed, light pressure, and the use of appropriate support materials to minimize the risk of cracking or breakage.

When drilling into materials with embedded aggregate or highly abrasive components, use a core bit designed for abrasive materials and maintain a proper drilling speed to extend the core bit’s life. Frequent inspections and replacement of worn segments are also recommended.

It is not advisable to use Braised Bond Diamond Core Bits for drilling into materials that produce toxic or harmful dust or fumes, such as asbestos-containing materials. Specialized equipment and procedures are required for working with hazardous materials, and proper safety precautions must be taken.

Warranty periods or guarantees for Braised Bond Diamond Core Bits can vary by manufacturer and product. It’s essential to review the manufacturer’s documentation and terms of sale to understand the warranty coverage and duration.

Braised Bond Diamond Core Bits can be used for high-precision applications, but achieving precise results may require advanced drilling techniques, precision drilling equipment, and meticulous attention to detail.

When drilling in confined spaces with limited ventilation, ensure adequate respiratory protection and follow strict safety protocols. Proper ventilation systems or exhaust fans may also be necessary to maintain a safe working environment.

Image | Name | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $15.39 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $15.99 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $39.47 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $39.47 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 |

Image | Name | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $154.87 | Max: Min: 1 Step: 1 | |||

$154.87 | Max: Min: 1 Step: 1 | ||||

105DE, 135DB, 115DM, 125DM, 130DMN, 140DM (up to 1-5/8″ OD) | $235.00 | Max: Min: 1 Step: 1 |

Tab Content

Image | New Item No | Diameter | Drill Depth | Drill Type | Thread Size | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|

1070014 | 6mm(1/4") | 1.5” | Non core Formation | 5/8-11” | $64.85 | Max: Min: 1 Step: 1 | ||

1070516 | 8mm(5/16") | 1.5” | Non core Formation | 5/8-11” | $66.98 | Max: Min: 1 Step: 1 | ||

1070038 | 10mm(3/8") | 1.5” | Non core Formation | 5/8-11” | $68.75 | Max: Min: 1 Step: 1 | ||

1070012 | 12mm(1/2") | 1.5” | Non core Formation | 5/8-11” | $70.89 | Max: Min: 1 Step: 1 | ||

1070058 | 15mm(5/8") | 1.5” | Non core Formation | 5/8-11” | $74.83 | Max: Min: 1 Step: 1 | ||

1070034 | 3/4"(20mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $79.81 | Max: Min: 1 Step: 1 | ||

1070010 | 1"(25mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $84.99 | Max: Min: 1 Step: 1 | ||

1070114 | 1-1/4"(32mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $87.89 | Max: Min: 1 Step: 1 | ||

1070138 | 1-3/8"(35mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $91.05 | Max: Min: 1 Step: 1 | ||

1070120 | 1-1/2"(38mm) | 2.36” (60mm) | Non core Formation | 5/8-11” | $105.86 | Max: Min: 1 Step: 1 | ||

1070158 | 1-5/8"(41mm) | 2.36” (60mm) | Non core Formation | 5/8-11” | $110.53 | Max: Min: 1 Step: 1 | ||

1070134 | 1-3/4"(45mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $117.65 | Max: Min: 1 Step: 1 | ||

1070200 | 2"(51mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $132.40 | Max: Min: 1 Step: 1 | ||

1070214 | 2-1/4"(57mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $142.25 | Max: Min: 1 Step: 1 | ||

1070238 | 2-3/8"(60mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $150.82 | Max: Min: 1 Step: 1 | ||

1070212 | 2-1/2"(64mm) | 2.36” (60mm) | Non core Formation | 5/8-11” | $162.40 | Max: Min: 1 Step: 1 | ||

1070278 | 2-7/8"(70mm) | 2.36” (60mm) | Non core Formation | 5/8-11” | $173.65 | Max: Min: 1 Step: 1 | ||

1070300 | 3"(76mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $189.90 | Max: Min: 1 Step: 1 | ||

1070314 | 3-1/4"(83mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $228.30 | Max: Min: 1 Step: 1 | ||

1070312 | 3-1/2"(88mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $242.85 | Max: Min: 1 Step: 1 | ||

1070400 | 4"(101mm) | 2.36” (60mm) | Hollow (Slotted) | 5/8-11” | $259.72 | Max: Min: 1 Step: 1 |

Brazed Diamond Tools are produced using and process that creates a fusion between the diamonds and the metal bond. While they may appear similar to electroplated (nickel bond) diamond tools. They are produced utilizing completely different process. Brazed Bond Diamond Tools are produced inside vacuum oven at a high temperature, single layer of diamond crystal bonded to steel body with very high diamond exposure. Not only does it promote high diamond exposure, but it also eliminates the loss of diamond particles through pull-out. The diamond section will not strip or peel from the steel body. This translates into multiple benefits, including: aggressive tools that last longer, cut faster, run cooler and load less, providing increased productivity and part consistency.

Diamond drills made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional nickel bonded diamond CBN Drills SMART CUT® diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

SMART CUT® Braised Bond Diamond Core Drill have diamonds fused to the steel body. Unlike Many Other drill Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process.The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

SMART CUT® Diamond Drills are the best investment you can make! Although they may cost more than Diamond drills . They Will more than pay for themselves in terms of overall performance and provide best Return on investment.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales