Understanding & Calculating Return on Investment for Diamond & CBN Blades

-

Posted by

Carlos Sanchez

Carlos Sanchez

Table of Contents

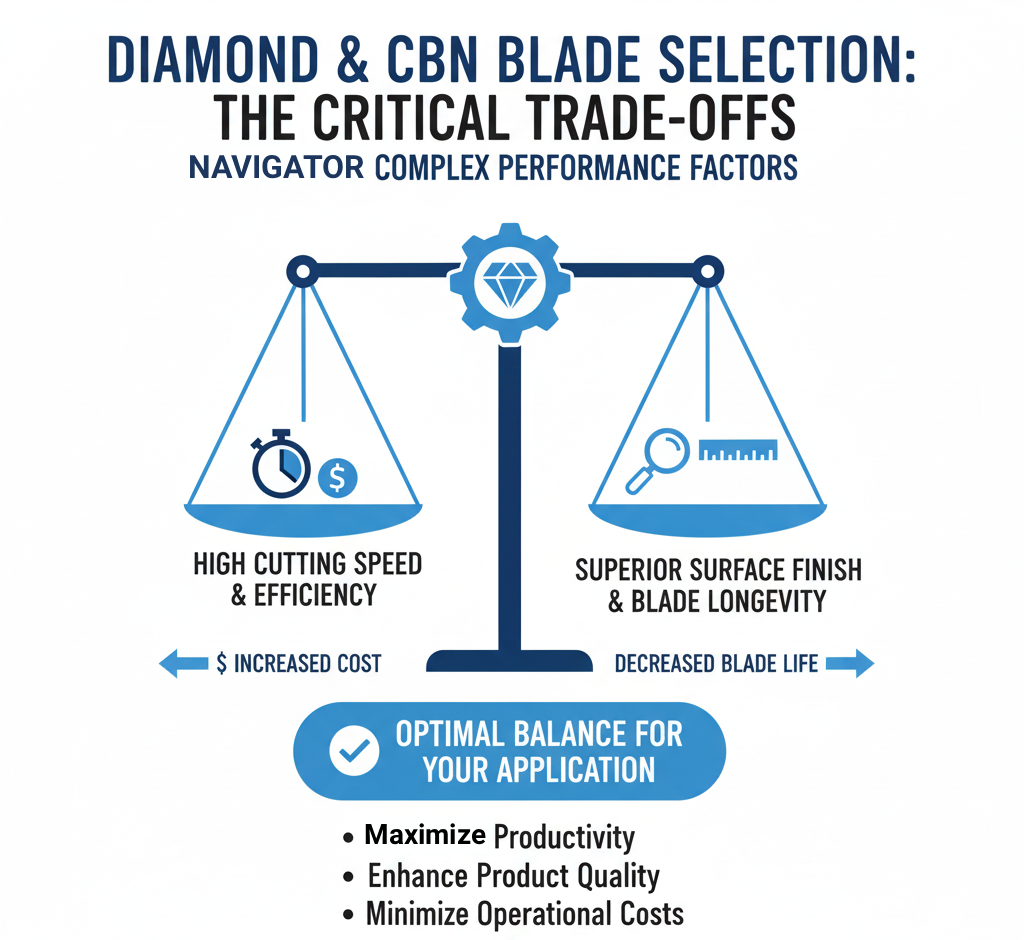

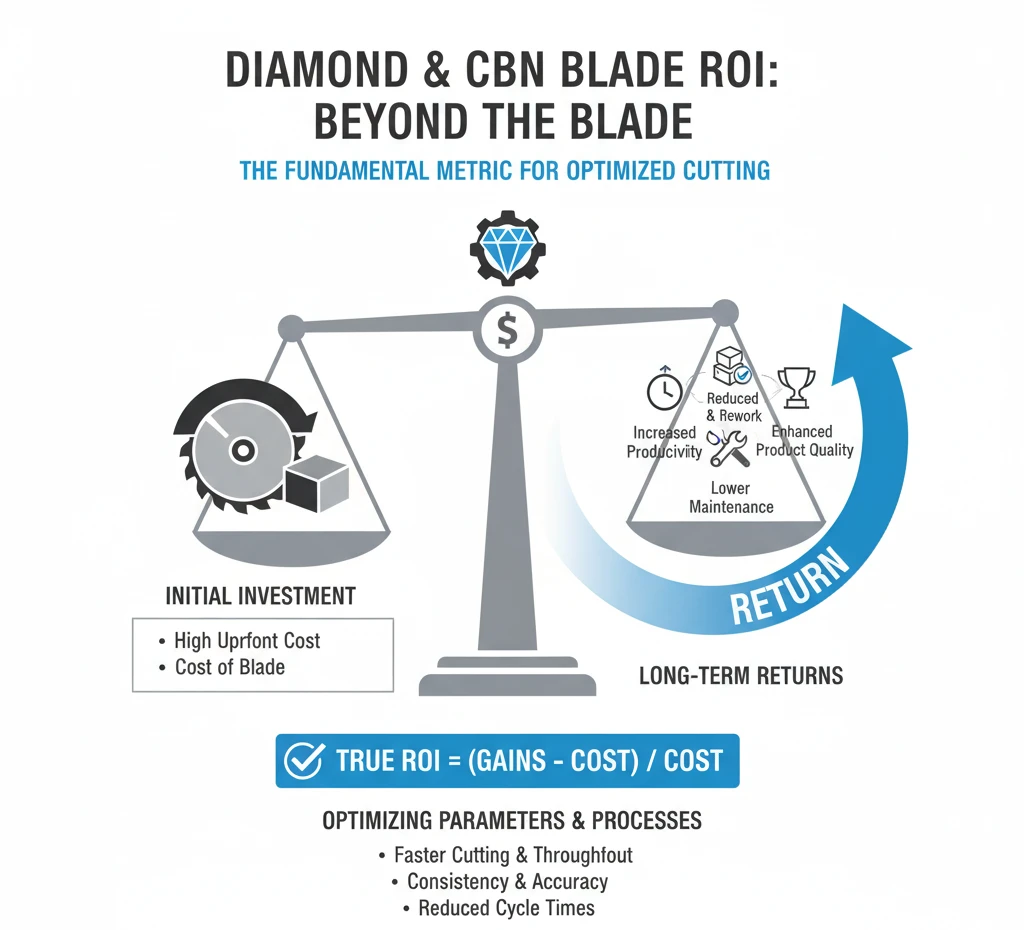

ToggleThe term "ROI" (Return On Investment) is frequently mentioned across various industries, often with different interpretations depending on the context. However, few take the time to thoroughly understand what ROI truly represents and its specific implications for their application, especially in the context of diamond and CBN blades. At the same time, the correct calculation of ROI is often overlooked. ROI is one of the most fundamental and critical metrics when it comes to evaluating and comparing diamond and CBN blades for any application.

Many people may not realize that ROI goes beyond selecting the most optimized diamond or CBN blade for your needs. It also encompasses the optimization of all cutting parameters and processes to achieve the best possible results.

Considering and calculating Return on Investment (ROI) is important for making informed, cost-effective decisions. While high-quality diamond and CBN cutting blades have a higher upfront cost, their durability, performance, and efficiency often lead to significant long-term savings. Evaluating ROI highlights financial benefits such as increased productivity, reduced waste, and lower maintenance costs..

High-quality diamond & cbn cutting blades improve productivity through faster cutting speeds and greater efficiency, with improved throughput, less secondary finishing operations, higher level of consistency, higher accuracy, and reduced cycle times justifying the initial cost. Generally requiring less maintenance and having longer lifespans, these blades contribute to uninterrupted production schedules and operational efficiency. Producing superior cut quality with minimal defects, they reduce the need for secondary finishing processes and rework, ultimately leading to better product quality and higher customer satisfaction.

This article shows which variables are important part of Return on Investment equation that you should consider and how to calculate this important and fundamental metric. Along with a number of examples of Return on Interment calculations for different industries an applications.

What does ROI (Return On Investment) mean for Diamond and CBN Blades?

Increased Productivity:

High-quality diamond and cubic boron nitride (CBN) blades are designed for optimal performance, enabling faster cutting speeds and higher level of cut quality efficiency. This directly translates to increased output, as more material can be processed in a shorter amount of time. The cutting speed, abrasive exposure and durability of these blades reduce the need for frequent changes, minimizing interruptions in the cutting process. The net result is a significant boost in productivity, allowing you to get more work done faster and potentially expand your operational capacity without additional labor costs.

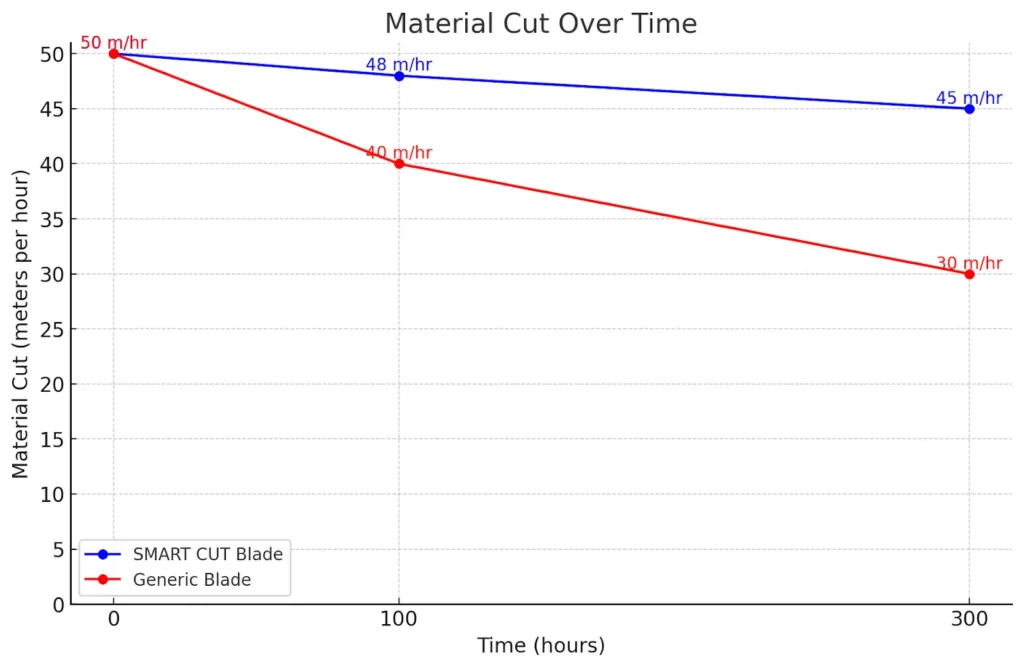

Cutting Speed

The cutting speed of a diamond or CBN blade is a crucial factor in determining the overall productivity of cutting operations, making it a key consideration in calculating the return on investment (ROI) for these tools. The effectiveness of a blade in maintaining high cutting speeds directly influences how efficiently materials are processed, minimizing downtime and maximizing throughput. This not only speeds up task completion but also enhances the cost-effectiveness of the operation.

An exceptional blade’s ability to sustain high cutting speeds without bogging down ensures that materials are cut swiftly and consistently, reducing the need for frequent maintenance or blade replacement. This continuity allows for uninterrupted cutting operations, leading to higher output and better resource utilization. As a result, the operation experiences fewer delays, translating into more completed tasks within the same timeframe.

The advanced technology behind diamond and CBN blades, including optimized bond formulations and superior material composition, plays a significant role in sustaining these high cutting speeds. High-grade diamond or CBN crystals embedded in a carefully designed bond matrix ensure that the blade remains sharp and effective throughout its use. This design continuously exposes fresh cutting edges, allowing the blade to maintain high speeds even as it wears down, further contributing to efficient material removal.

The relationship between cutting speed and ROI is evident: faster cutting speeds lead to more efficient operations, reducing labor costs and increasing the number of completed projects. As the blade maintains its high performance over time, the cost per cut decreases, resulting in a more favorable ROI. Thus, cutting speed is not just a measure of a blade’s performance but a critical factor in maximizing the economic benefits of using diamond and CBN blades. By enabling quicker and more efficient cutting, these blades contribute significantly to long-term gains in productivity and cost savings.

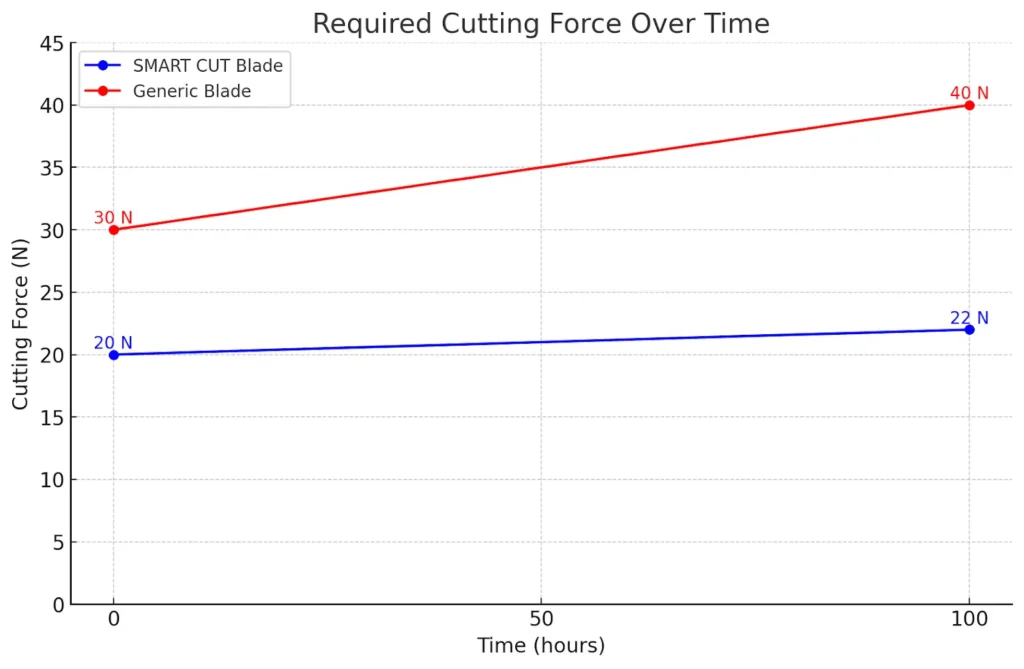

Required Force

The amount of force required to penetrate material during cutting operations is an important variable of a diamond or CBN cutting blade's efficiency. Superior blades are engineered to cut through materials with minimal force, a feature that displays their advanced design and the high quality of the materials used in their construction. This efficiency not only enhances the cutting process but also plays a significant role in improving productivity, which directly impacts the return on investment (ROI) for these blades.

In cutting operations, the force required to cut through various materials is influenced by factors such as the hardness and structural characteristics of the material. Superior diamond and CBN cutting blades are designed to optimize this cutting force, ensuring that even the hardest materials can be sliced with minimal effort. This optimization is critical for maintaining the integrity of the material being cut and for maximizing the blade's efficiency and lifespan.

Diamond & cbn Blades that require less force to cut reduce the mechanical stress on both the material and the cutting equipment. This reduction in stress not only preserves the quality of the material but also decreases wear and tear on the blade, leading to a longer blade life and fewer replacements. This durability contributes to a lower cost per cut, which is a key factor in calculating ROI.

At the same time, diamond & cbn blades that operate efficiently with lower force allow for faster cutting speeds, further enhancing productivity. By minimizing the force needed, these blades enable operators to work more quickly and with greater precision, leading to higher output in less time. The combination of reduced downtime, longer blade life, and faster cutting translates to significant cost savings, making these blades a smart investment.

Using blades that require minimal cutting force also offers ergonomic benefits for operators, reducing physical strain and the risk of accidents. This not only improves safety but also allows operators to maintain high levels of focus and accuracy over extended periods, contributing to consistent, high-quality results.

Here is the line chart comparing the required cutting force over time for the SMART CUT® blade and the generic blade. The chart clearly illustrates how the cutting force increases over 100 hours, with the SMART CUT® blade showing a much smaller increase compared to the generic blade. This visual representation highlights the superior performance of the SMART CUT® blade in maintaining lower cutting forces over time.

Dressing Frequency

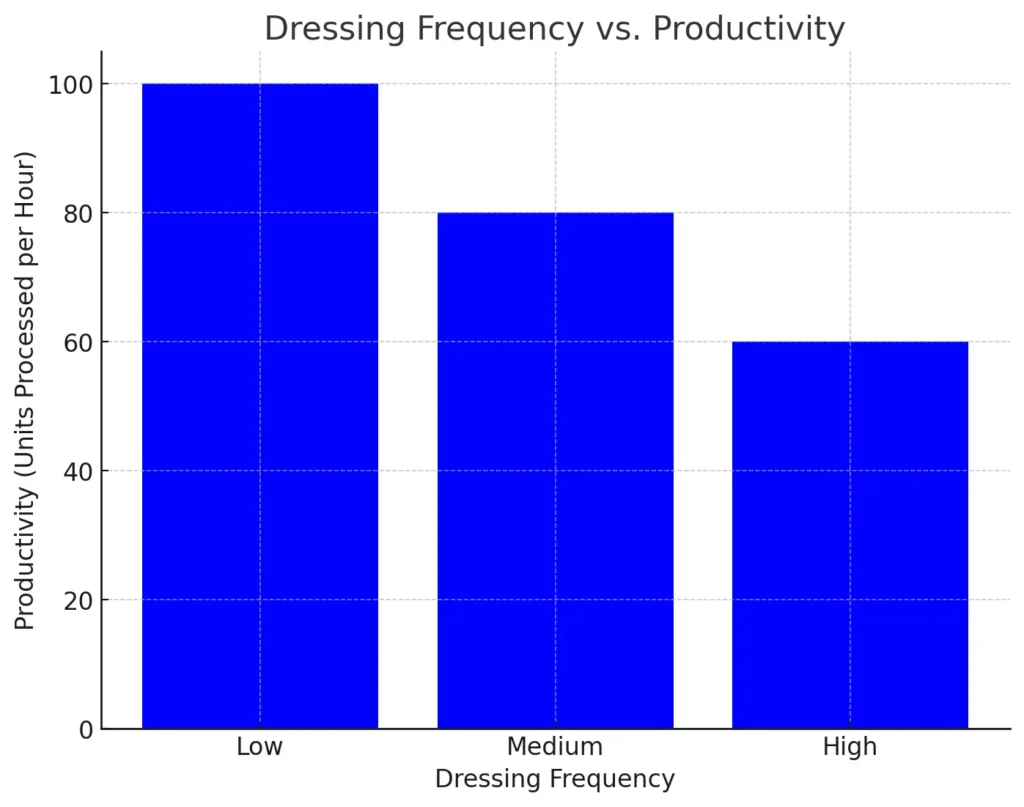

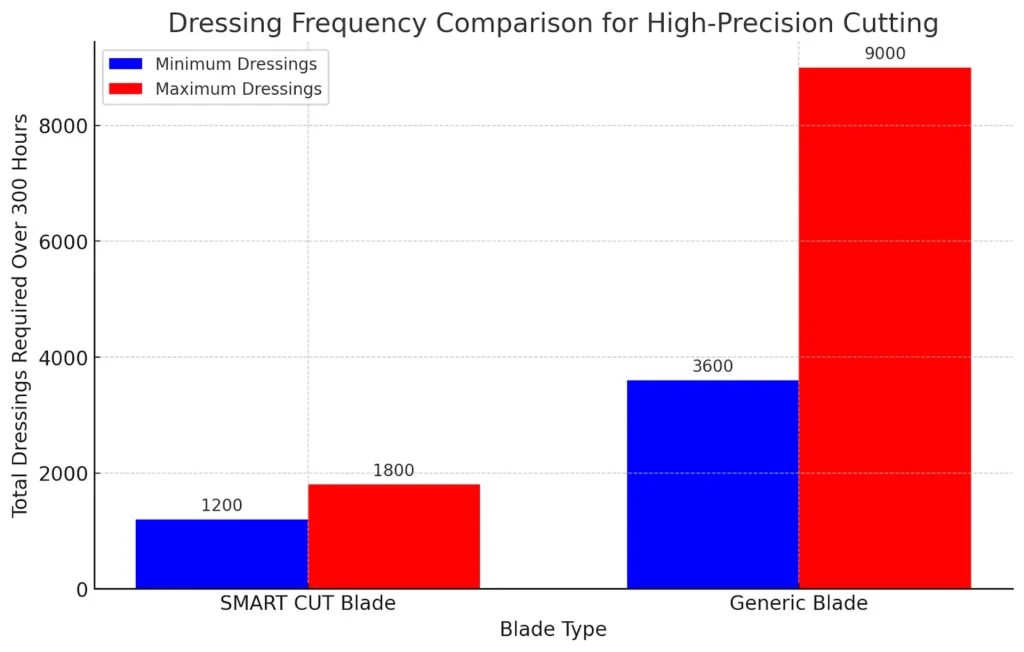

The frequency with which a diamond or CBN blade requires dressing significantly impacts productivity and plays a crucial role in calculating return on investment (ROI). Dressing refreshes the blade's cutting surface by removing worn material and exposing new diamond or CBN crystals, essential for maintaining optimal cutting performance. However, frequent dressing can indicate inefficiencies that disrupt workflow and increase costs.

Diamond & CBN Blades that require less frequent dressing maintain their cutting efficiency longer, reducing downtime and allowing for continuous operation. This boosts productivity, as more material can be processed without interruptions. Fewer dressing cycles also mean lower maintenance costs, less wear on the blade, and reduced overall operating expenses. This leads to a lower cost per cut, directly improving ROI.

Consistent cutting performance with less frequent dressing contributes to a stable production process, minimizing variability and ensuring high-quality results. By reducing maintenance needs and extending blade life, superior diamond and CBN blades enhance productivity and cost-effectiveness, resulting in a stronger return on investment.

Here is the bar chart comparing the dressing frequency for the SMART CUT®

blade and the generic blade over 300 hours of operation. The chart clearly illustrates the significant difference in the total number of dressings required, highlighting the efficiency of the SMART CUT® blade compared to the generic blade.

Material Compatibility

Material compatibility is a crucial feature of superior diamond and CBN blades, directly impacting their versatility and efficiency in various cutting applications. These blades are meticulously designed to adapt to a wide range of materials, from the hardest metals to more delicate composites, showcasing a performance level that surpasses more specialized cutting blades. The ability of a blade to transition seamlessly between different material types without frequent adjustments or blade changes is a testament to the advanced technology and thoughtful design behind diamond and CBN blades. This versatility streamlines workflows and significantly enhances operational efficiency.

The development of versatile diamond and CBN blades involves rigorous testing across a spectrum of materials, ensuring that they can handle the unique challenges posed by different materials, such as varying hardness, abrasiveness, and thermal sensitivity. By fine-tuning factors like diamond grit size, bond hardness, and blade geometry, these blades are optimized to deliver consistent performance across diverse materials.

This material compatibility not only improves productivity by reducing downtime for blade changes or adjustments but also contributes to calculating a better return on investment (ROI). The fewer the interruptions and the broader the range of materials a single blade can effectively cut, the higher the productivity and the lower the operational costs. This efficiency translates into a stronger ROI, as the blade's versatility maximizes its utility across multiple applications, reducing the need for additional blades or processes and lowering overall costs.

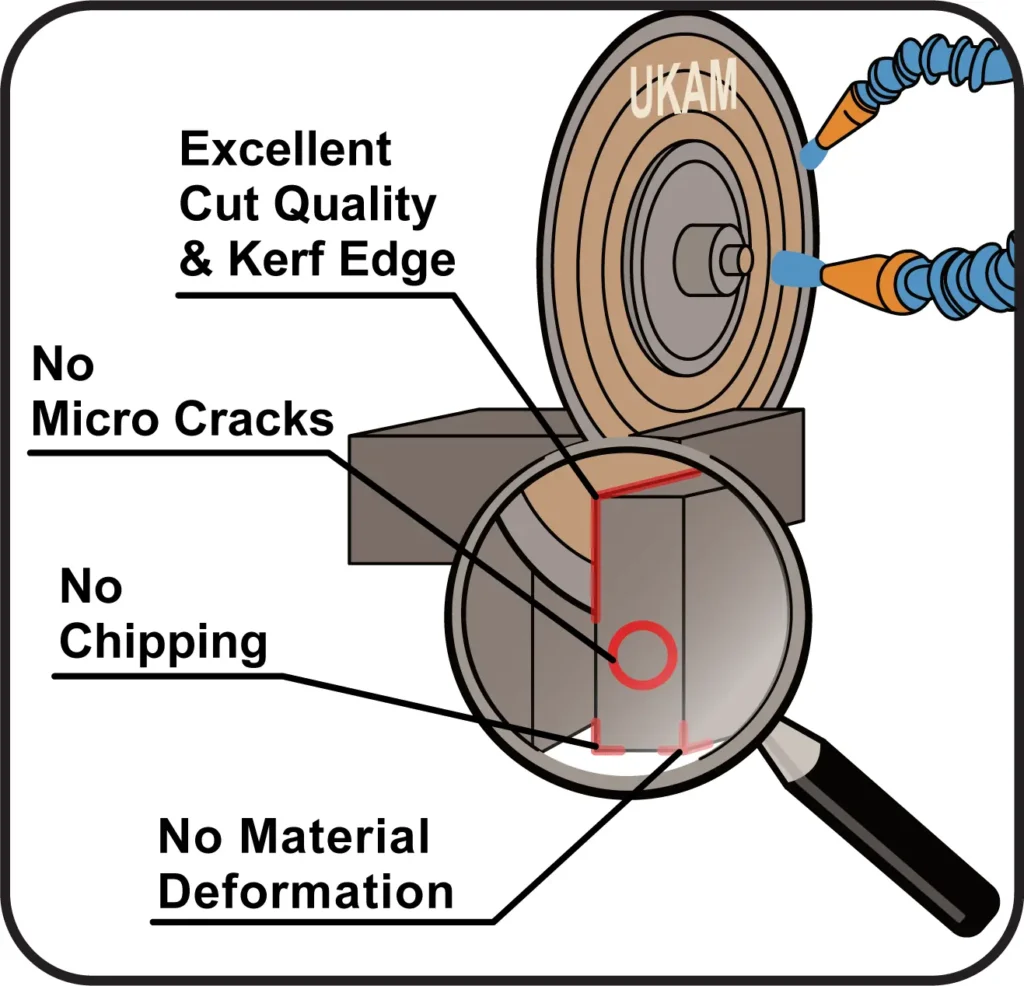

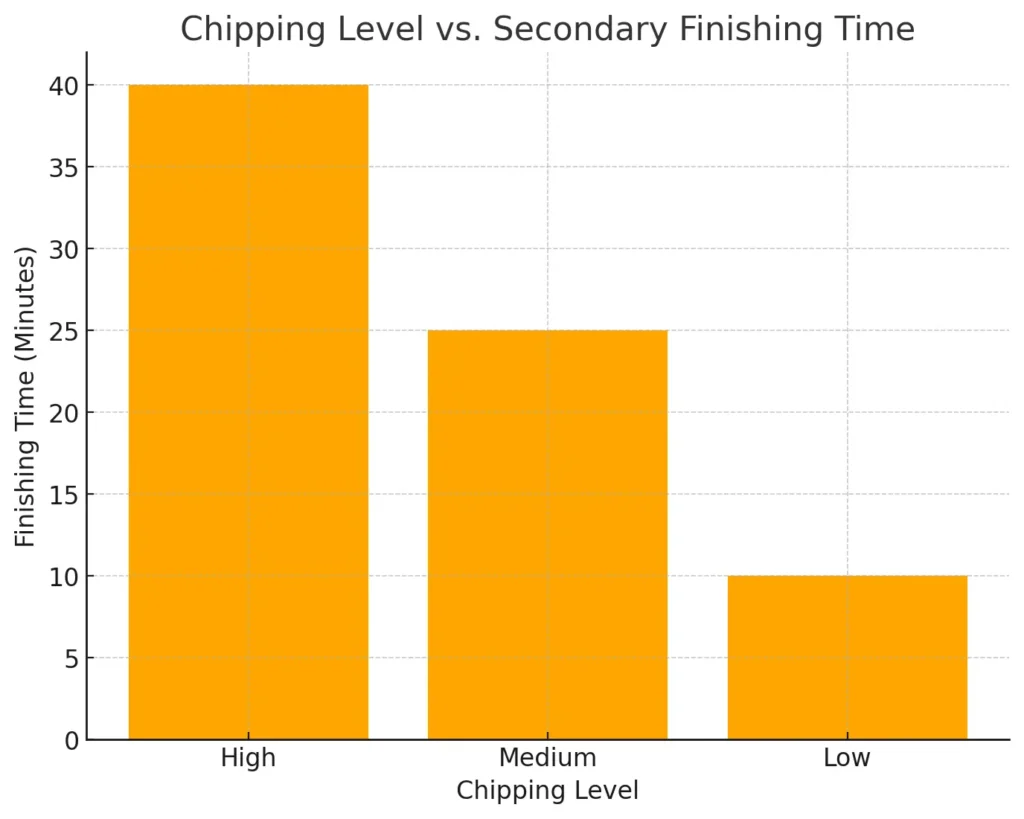

Cut Quality / Chipping Level

The quality of the cut, particularly the smoothness of the edges, is a crucial measure of a diamond or CBN blade's performance. Superior diamond and CBN blades are distinguished by their ability to produce chip-free edges, which significantly improves both the precision and finish of the cut. This high level of cut quality not only improves the aesthetic appeal of the material but also streamlines the fabrication process by reducing or even eliminating the need for secondary finishing operations.

Achieving a clean, chip-free cut is essential for maintaining the integrity of the material and ensuring that it meets the required specifications right from the initial cut. This capability is particularly important when working with materials where edge quality directly impacts the final product's performance or appearance. By minimizing chipping and other defects, these blades reduce waste and rework, leading to greater efficiency in the cutting process.

In terms of productivity and return on investment (ROI), the ability to produce high-quality cuts with minimal chipping translates to significant cost savings. Less time spent on secondary finishing operations means more time devoted to cutting, increasing overall throughput. Additionally, reducing material waste and ensuring that each cut meets the necessary standards the first time around lowers the overall cost per piece, thereby improving ROI.

Here is the grouped bar chart that compares the cut quality and chipping levels for the SMART CUT® blade and the generic blade, both initially and after 100 hours of operation. The chart visually highlights the differences in performance, showing how the SMART CUT® diamond cut off wheel / blade maintains lower chipping levels over time compared to the generic blade, which experiences a more significant increase in chipping

Durability and Longevity

Durability and longevity are important attributes that define the overall value and effectiveness of a diamond or CBN blade. These qualities go beyond mere resistance to physical wear, including the blade's ability to maintain cutting precision, speed, and efficiency over an extended period of use. Superior diamond and CBN blades are designed to withstand the rigors of extensive cutting operations without significant degradation, making them not only cost-effective but also reliable for delivering consistent, high-quality performance.

The longevity of these blades is a product of the superior materials and R & D, and engineering that go into their design and manufacturing. High-quality diamond or CBN crystals, paired with optimized bond formulations, ensure that the blade remains sharp and efficient even after prolonged use. This resistance to wear and tear reduces the frequency of blade replacements, leading to lower maintenance costs and less downtime, both of which are critical for improving productivity.

Longevity directly impacts return on investment (ROI) by extending the blade's operational life. A blade that lasts longer while maintaining its performance reduces the overall cost per cut, making each operation more economically efficient. Fewer replacements and less frequent maintenance translate into higher uptime and sustained productivity, which in turn leads to greater profitability.

Here is the line chart illustrating the material cut over time for both the SMART CUT blade and the generic blade. The chart shows the initial cutting rate and how it decreases over 100 and 300 hours of operation, reflecting the wear and performance differences between the two blades. The SMART CUT® diamond cut off wheel / blade maintains higher efficiency with a slower decline in material cut rate compared to the generic blade, which shows a more significant reduction over time.

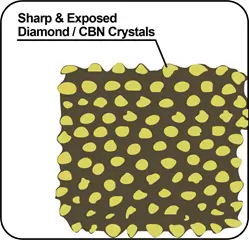

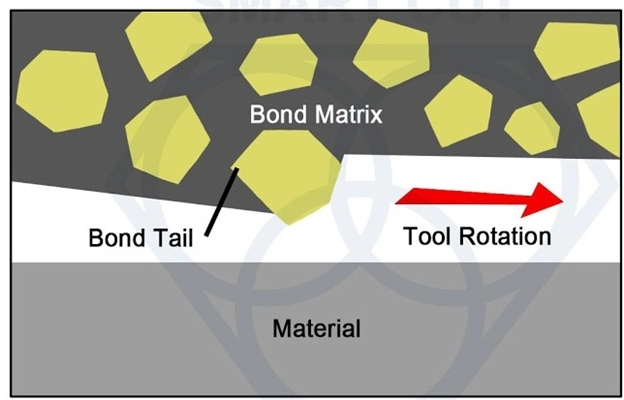

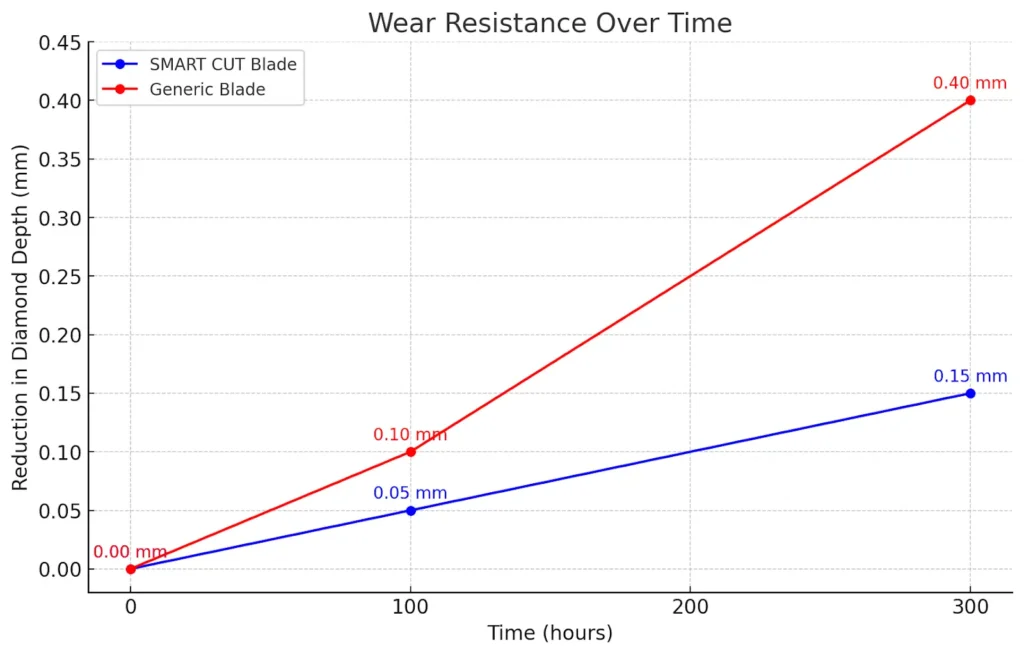

Wear Resistance

Wear resistance is a critical attribute that directly affects the longevity and cost-effectiveness of a diamond or CBN blade. A blade that can endure the demands of intensive use without significant degradation in its cutting capabilities ensures consistent performance and provides greater value over its lifespan. High-quality diamond and CBN blades are characterized by their ability to retain their cutting edge and diameter over extended periods, showcasing resilience against the wear and tear that typically accompanies demanding cutting tasks.

The wear resistance of these blades is largely determined by the advanced technology and bond matrix composition used in their design. High-grade, synthetic diamonds or CBN crystals, optimized for toughness and thermal resistance, ensure that the cutting edges remain sharp and effective through repeated use.

The bond matrix plays a crucial role as well; it must be hard enough to keep the abrasive crystals exposed while wearing down at a rate that continuously reveals new, sharp edges. Achieving this balance involves sophisticated material formulations and precise manufacturing processes that extend the blade's cutting life.

In terms of productivity and return on investment (ROI), superior wear resistance translates directly into longer blade life and fewer replacements. This reduces overall operating costs by minimizing downtime for blade changes and maintaining consistent cutting performance throughout the blade’s life. The extended durability allows operators to complete more work with fewer interruptions, increasing throughput and efficiency.

Ultimately, the wear resistance of a diamond or CBN blade enhances productivity and improves ROI by ensuring that the blade delivers reliable, long-lasting performance in even the most demanding applications. This makes these blades a cost-effective investment, providing sustained value over time.

line chart illustrating the wear resistance over time for the SMART CUT® blade and the generic blade. The chart shows how each blade's diamond depth reduces over 300 hours of operation, with theSMART CUT® blade exhibiting significantly better wear resistance compared to the generic blade. This visual representation highlights the durability and longer effective life of the SMART CUT® diamond cut off wheel / blade in high-precision cutting operations.

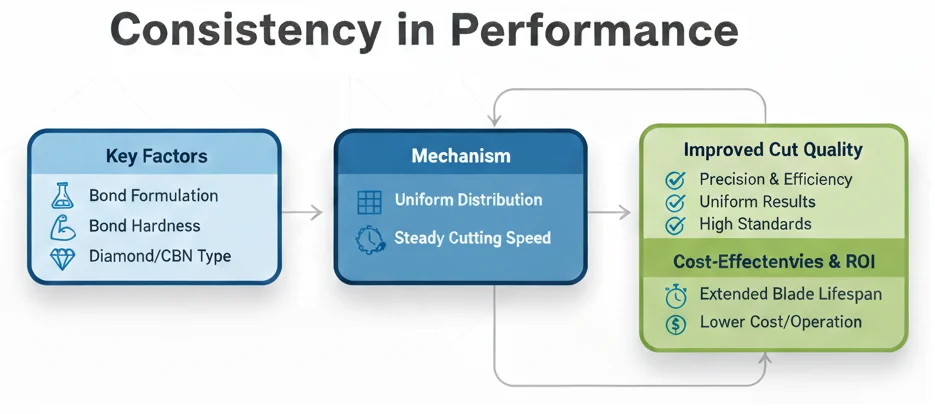

Consistency in Performance

Consistency in performance is a defining characteristic of an exceptional diamond or CBN blade, setting it apart from others. The ability to deliver uniform results across a wide range of materials is what truly distinguishes a high-quality blade. Achieving this consistency requires the right bond formulation, appropriate bond hardness, and the optimal diamond or CBN type. These factors ensure that the abrasive particles are exposed evenly throughout the bond matrix, providing consistent cutting performance every time the blade makes contact with the material.

This uniform distribution of diamonds or CBN within the blade is crucial for maintaining a steady cutting speed, which in turn supports precision and efficiency with each pass. A blade that consistently performs well not only enhances productivity by reducing the need for adjustments or rework but also improves the overall quality of the cut, ensuring that each operation meets the desired standards.

High-quality blades also offer freer cutting capabilities, which reduce resistance when slicing through various materials. This not only extends the blade's lifespan by minimizing wear but also ensures that the cut quality remains high, even over extended use. The reduced resistance and consistent performance allow operators to work more efficiently, completing tasks faster and with greater accuracy.

In terms of productivity and return on investment (ROI), consistency in performance translates to fewer interruptions, less downtime for adjustments, and more reliable results. This means more work can be completed in less time, lowering the overall cost per operation and enhancing the blade's value. By delivering dependable, high-quality performance across a range of materials, these blades ensure that cutting operations remain efficient and cost-effective, making them a smart investment for any application.

Higher Accuracy & Straightness of the Cut

The straightness of the cut is a key measure of a diamond or CBN blade's performance, indicating its precision and construction quality. A blade that consistently produces straight cuts shows exceptional engineering and a uniform distribution of diamond or CBN particles. This precision is essential for accurate, high-quality cutting.

A well-designed blade, with geometric accuracy and balance, ensures minimal deviation during cutting. Even distribution of abrasive particles prevents uneven wear, keeping the blade on a straight path. Blade stiffness also plays a crucial role, as a rigid blade resists bending and maintains accuracy, while effective vibration control prevents deviations.

Achieving straight cuts reliably reduces the need for rework, saving time and material, which directly impacts productivity and return on investment (ROI). By ensuring consistent accuracy, high-quality diamond and CBN blades enhance efficiency and deliver better ROI, making them a smart choice for precision cutting tasks.

How to Calculate Return on Investment (ROI) for diamond and cubic boron nitride (CBN) blades

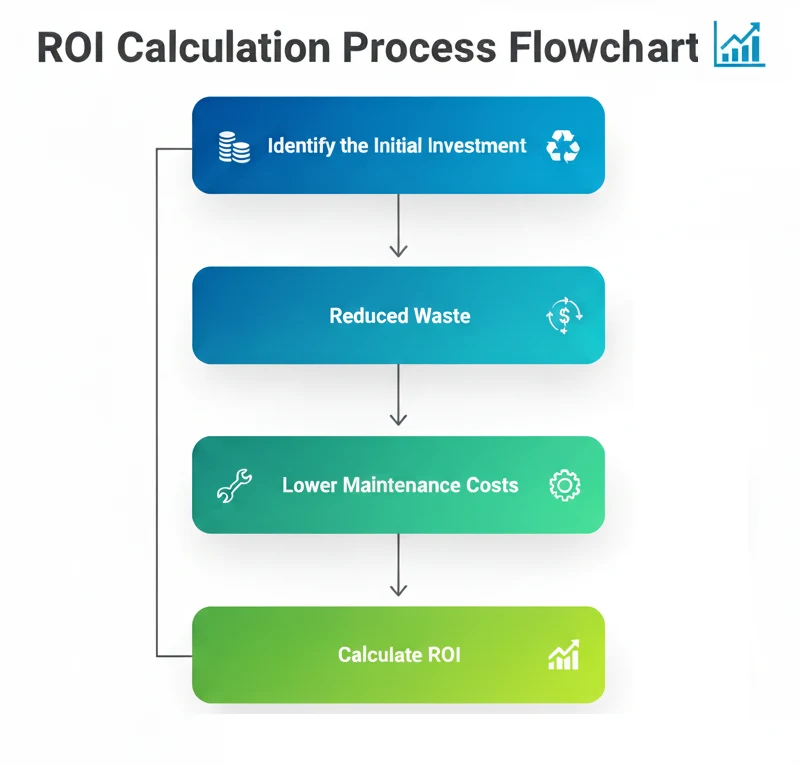

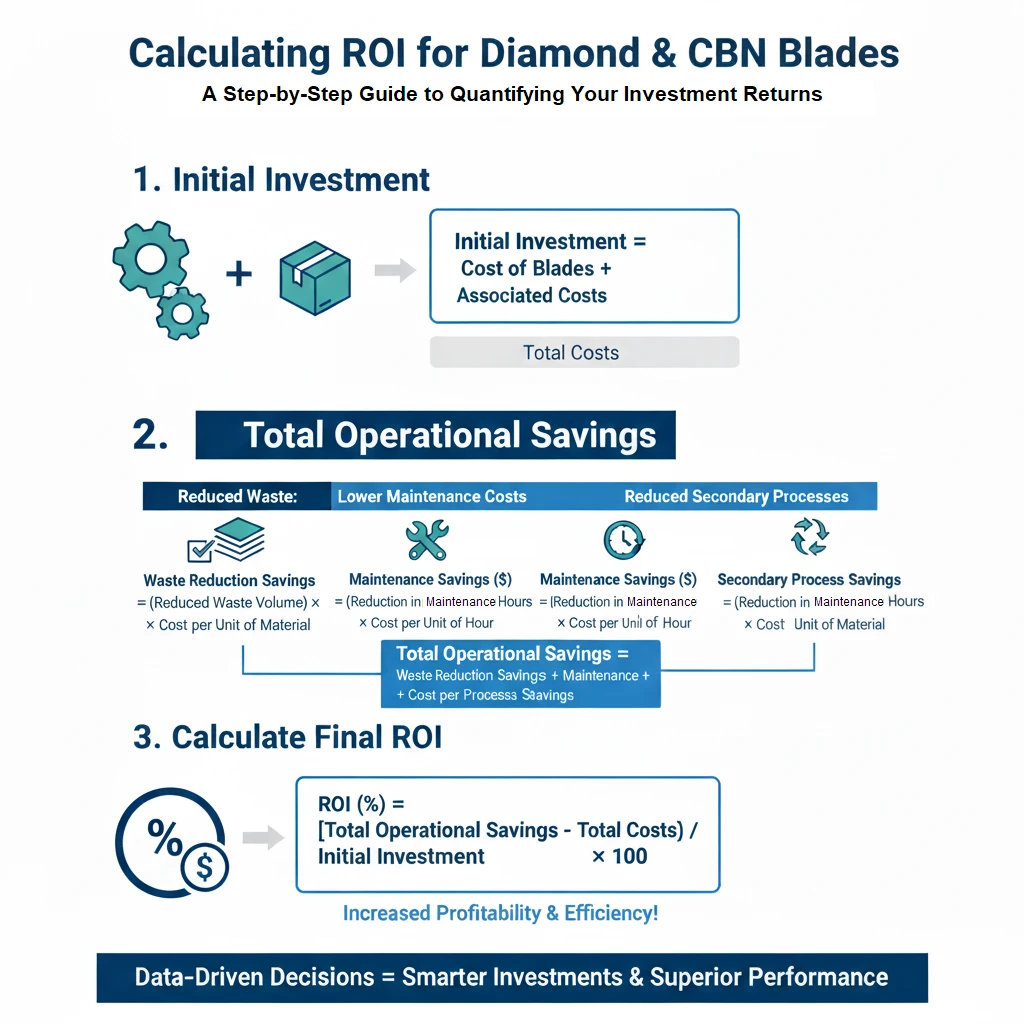

Calculating the Return on Investment (ROI) for diamond and cubic boron nitride (CBN) blades involves evaluating both the costs and benefits associated with using these high-quality cutting tools. Here's a step-by-step guide on how to calculate ROI:

1. Identify the Initial Investment

Determine the initial cost of purchasing the diamond or CBN blades. This includes the purchase price and any associated costs such as shipping or installation.

Initial Investment = Cost of Blades + Associated Costs

2. Reduced Waste:

Estimate the cost savings from reduced material waste due to cleaner, more accurate cuts.

Waste Reduction Savings ($) = (Reduced Waste Volume) × (Cost per Unit of Material)

3.Lower Maintenance Costs:

Determine the savings from reduced maintenance and blade replacement frequency.

Maintenance Savings ($) = (Reduction in Maintenance Hours) × (Cost per Hour) + (Fewer Blades Purchased) × (Cost of Each Blade)

4. Reduced Secondary Processes:

Estimate the savings from minimized secondary finishing processes such as grinding or polishing.

Secondary Process Savings ($) = (Reduction in Secondary Process Hours) × (Cost per Hour)

Total Operational Savings = Productivity Gain + Waste Reduction Savings + Maintenance Savings + Secondary Process Savings

5. Calculate ROI

The ROI is calculated by comparing the net benefits (total operational savings minus total costs) to the initial investment.

ROI (%) = [(Total Operational Savings - Total Costs) / Initial Investment] × 100

Example of Return on Investment (ROI) Calculation

|

Parameter |

SMART CUT™ Series Diamond Blade |

Generic Diamond Blade |

|---|---|---|

|

Blade Specifications |

10" x .060" x 1.25", sintered (metal bond), diamond depth: 10 mm, high concentration |

10" x .060" x 1.25", sintered (metal bond), diamond depth: 10 mm, high concentration |

|

Material |

Alumina Oxide 99% (100 mm x 100 mm x 10 mm slabs) |

Alumina Oxide 99% (100 mm x 100 mm x 10 mm slabs) |

|

Cutting Speed |

2,000 RPM |

2,000 RPM |

|

Feed Rate |

0.5 mm/sec |

0.5 mm/sec |

|

Coolant Used |

SMART CUT™ Water-Soluble Coolant |

Generic Water-Soluble Coolant (metalworking) |

|

Cutting Machine |

Surface grinder with diamond cutting capabilities |

Surface grinder with diamond cutting capabilities |

|

Cutting Time per Part |

Reduced by 20% |

Standard |

|

Number of Parts Cut per Shift |

Increased by 25% |

Standard |

|

Tool Life |

Extended due to optimized blade-coolant synergy |

Standard |

|

Cost per Part |

Reduced due to higher productivity and fewer blade replacements |

Higher due to standard productivity and more frequent blade replacements |

|

Overall ROI |

Superior |

Standard |

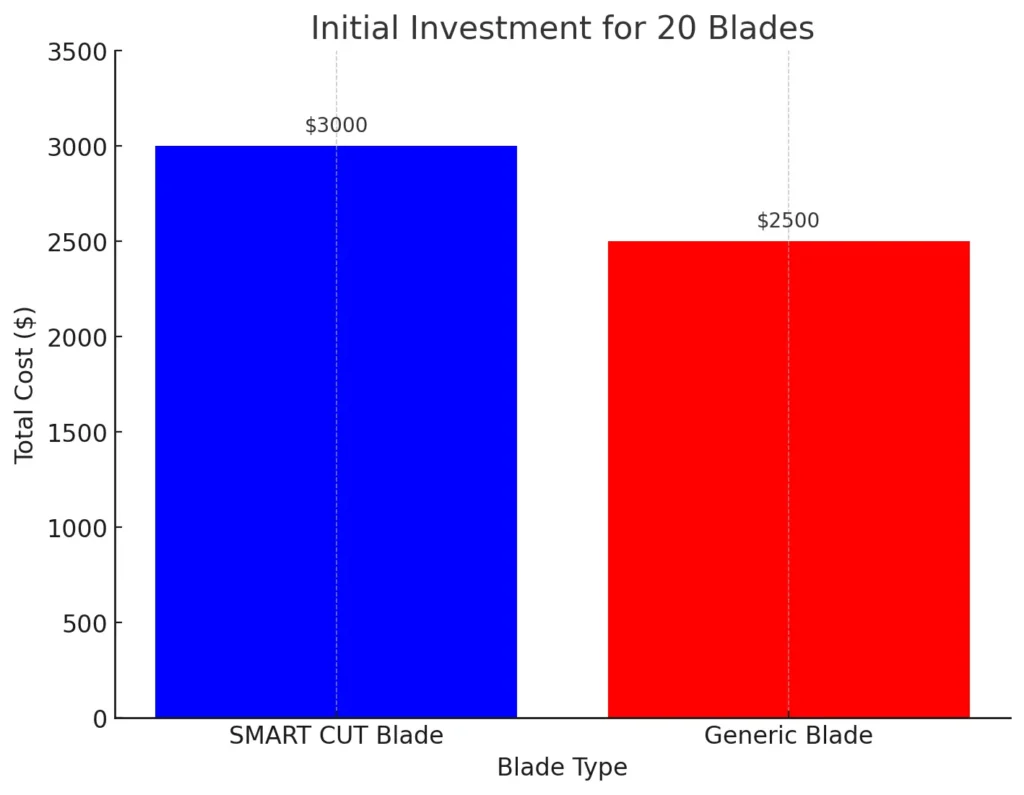

Identify the Initial Investment

Determine the initial cost of purchasing the diamond or CBN blades. This includes the purchase price and any associated costs such as shipping or installation.

Initial Investment = Cost of Blades + Associated Costs

Cost Comparison

|

Parameter |

SMART CUT™ Blade |

Generic Blade |

|---|---|---|

|

Cost per Blade |

$150.00 |

$125.00 |

|

Number of Blades |

20 |

20 |

|

Total Cost of Blades |

$3,000.00 |

$2,500.00 |

Calculate Operational Savings

Estimate the savings generated by using these blades over a specific period. This can include various factors:

Increased Productivity:

Calculate the value of increased production due to faster cutting speeds and more efficient processes.

Productivity Gain ($) = (Increased Units Produced per Hour) × (Value per Unit) × (Number of Hours in Period)

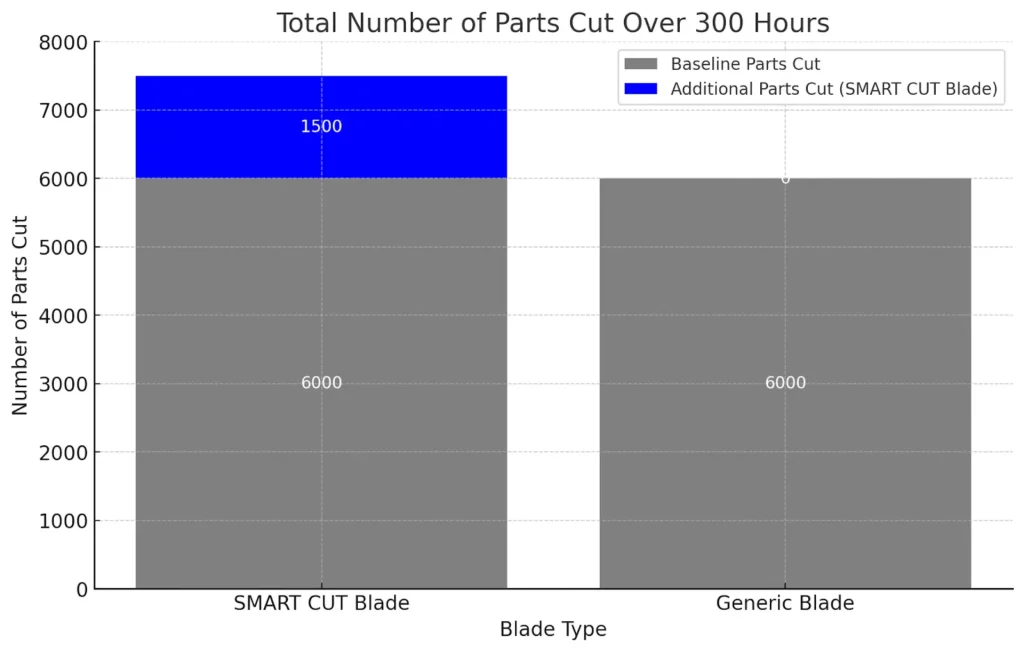

Productivity Comparison

|

Parameter |

Generic Blade |

SMART CUT™ Blade |

|---|---|---|

|

Baseline Cutting Rate |

20 parts/hour |

20 parts/hour |

|

Increase in Cutting Rate |

N/A |

Additional 5 parts/hour |

|

Total Cutting Rate |

20 parts/hour |

25 parts/hour |

|

Total Parts Cut Over 300 Hours |

6,000 parts |

7,500 parts |

Example of Calculation:

1. Baseline Cutting Rate with the Generic Blade:

-

Number of parts cut per hour: 20 parts/hour

Number of parts cut per hour: 20 parts/hour

-

Additional parts cut per hour: 5 parts/hour

Additional parts cut per hour: 5 parts/hour

Number of Parts Cut per Hour:

-

Generic Blade:

Generic Blade:

Parts per Hour = 20 parts/hour

-

SMART CUT Blade:

SMART CUT Blade:

Parts per Hour = 20 parts/hour + 5 parts/hour = 25 parts/hour

Total Number of Parts Cut Over 300 Hours:

SMART CUT Blade:

Total Parts Cut = 25 parts/hour × 300 hours = 7,500 parts

Generic Blade:

Total Parts Cut = 20 parts/hour x 300 hours = 6,000 parts

-

Increased Units Produced per Hour: 5 units/hour

Increased Units Produced per Hour: 5 units/hour

-

Value per Unit: $100

Value per Unit: $100

-

Number of Hours in Period: 300 hours

Number of Hours in Period: 300 hours

Productivity Gain Formula:

Productivity Gain ($) = (Increased Units Produced per Hour) × (Value per Unit) × (Number of Hours in Period)

Calculation:

Productivity Gain = 5 units/hour $100 per unit × 300 hours

Productivity Gain = 1,500 (units) × $100 per unit

Productivity Gain = $150,000

Result:

The total Productivity Gain is $150,000 over the 300-hour period.

stacked bar chart that illustrates the total number of parts cut over 300 hours for both the SMART CUT® blade and the generic blade. The chart clearly shows the baseline number of parts cut by both blades (6,000 parts) and highlights the additional parts cut due to the increased efficiency of the SMART CUT® blade (1,500 additional parts).

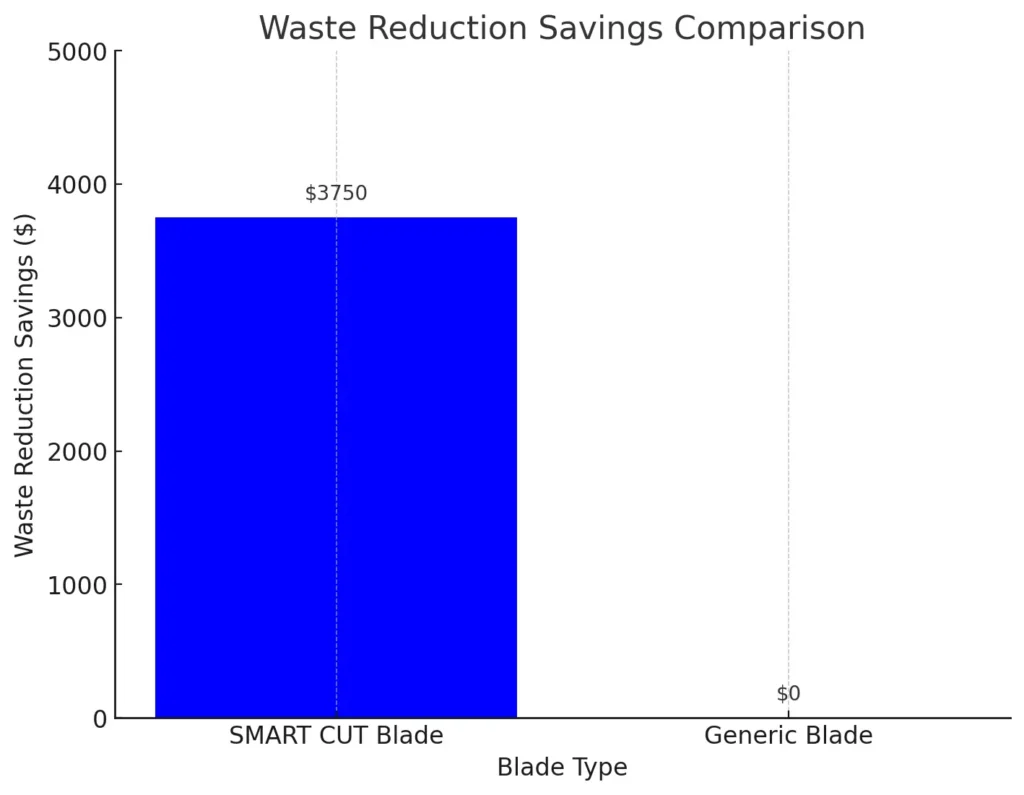

Reduced Waste:

Estimate the cost savings from reduced material waste due to cleaner, more accurate cuts.

Waste Reduction Savings ($) = (Reduced Waste Volume) × (Cost per Unit of Material)

-

Number of Parts: 7,000

Number of Parts: 7,000

-

Reduced Waste Volume per Part: 0.066 cubic centimeters per part.

Reduced Waste Volume per Part: 0.066 cubic centimeters per part.

-

Cost per Unit of Material: $1 per cubic centimeter

Cost per Unit of Material: $1 per cubic centimeter

Waste Reduction Savings=7,000 parts × 0.066cc / part × $1 per cc = $462

Waste Reduction Savings is $462.00

bar chart that compares the waste reduction savings between the SMART CUT® blade and the generic blade. The chart shows the $3,750 in savings achieved by using the SMART CUT® diamond cut off wheel / blade, with minimal or no savings represented for the generic blade.

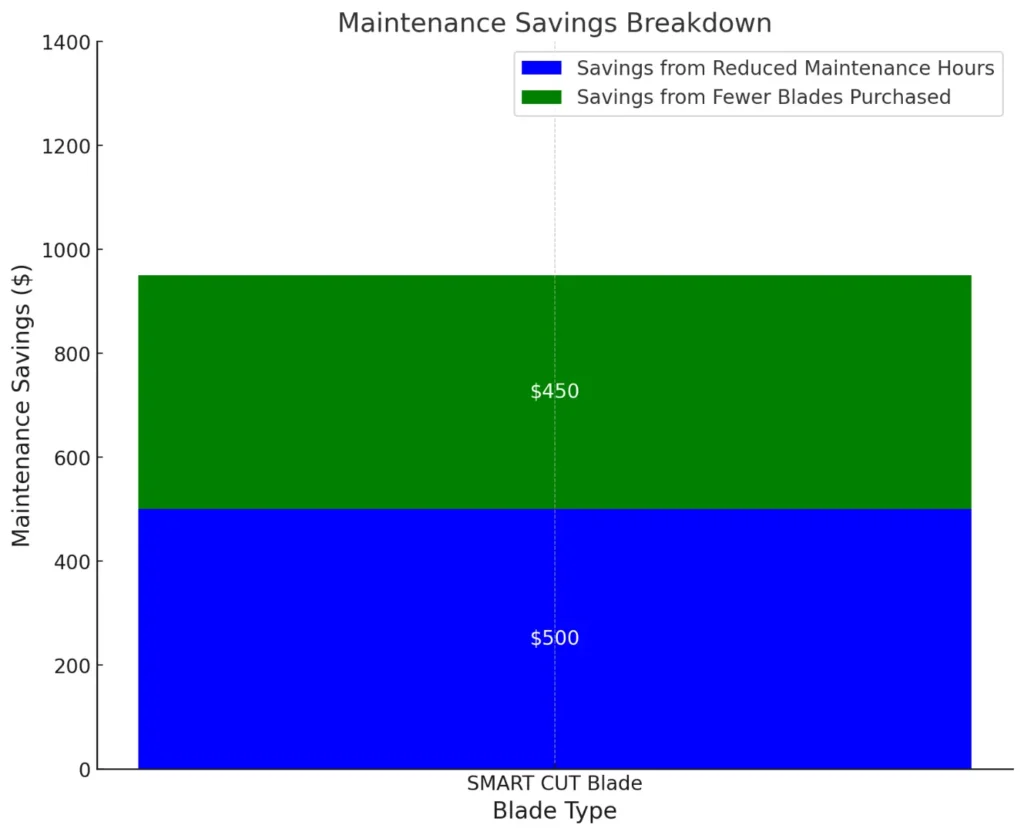

Lower Maintenance Costs:

Determine the savings from reduced maintenance and blade replacement frequency.

Maintenance Savings ($) = (Reduction in Maintenance Hours) × (Cost per Hour) + (Fewer Blades Purchased) × (Cost of Each Blade)

Reduction in Maintenance Hours: 10 hours (using the SMART CUT® blade reduces maintenance time by 10 hours over a 300-hour period).

Cost per Hour: $50 per hour (cost of maintenance labor).

Fewer Blades Purchased: 5 fewer SMART CUT® blades.

Cost of Each Blade:

-

SMART CUT®

Blade: 7,000

SMART CUT®

Blade: 7,000

-

Generic Blades$125 per blade

Generic Blades$125 per blade

Calculation:

Savings from Reduced Maintenance Hours:

Savings from Maintenance Hours=10 hours×50 $ per hour = 500

Savings from Fewer Blades Purchased:

Savings from Fewer Blades=5 blades×150 $ per blade = $750

Total Maintenance Savings:

Maintenance Savings= $500 + $750 = $1,250

This savings calculation includes:

-

$500 : from a reduction in maintenance hours (10 hours saved at $50 per hour).

$500 : from a reduction in maintenance hours (10 hours saved at $50 per hour).

-

$750from purchasing 5 fewer SMART CUT® blades at $150 each.

$750from purchasing 5 fewer SMART CUT® blades at $150 each.

Reduction in Maintenance Hours: 10 hours

Cost per Hour: $50 per hour

Fewer Blades Purchased: 3 fewer blades are needed.

Cost of Each Blade: $150 per blade.

Calculation:

Savings from Reduced Maintenance Hours:

Savings from Maintenance Hours = 10 hours × $50 per hour = $500

Savings from Fewer Blades Purchased:

Savings from Fewer Blades=3 blades× $150 per blade = $450

Total Maintenance Savings = $500 + $450 = $950

stacked bar chart that illustrates the maintenance savings breakdown for the SMART CUT® blade. The chart shows the total savings of $1,250, divided into $500 from reduced maintenance hours and $750 from purchasing fewer blades.

Reduced Secondary Processes:

Estimate the savings from minimized secondary finishing processes such as grinding or polishing.

Secondary Process Savings ($) = (Reduction in Secondary Process Hours) × (Cost per Hour)

Reduction in Secondary Process Hours: SMART CUT® diamond cut off wheel / blade reduces secondary finishing time by 20 hours over a given period.

Cost per Hour: cost of labor for secondary processes (e.g., grinding or polishing) is $60 per hour.

Secondary Process Savings = 20 hours × $60 per hour = $1,200

Calculation of Secondary Process Savings: $1,200

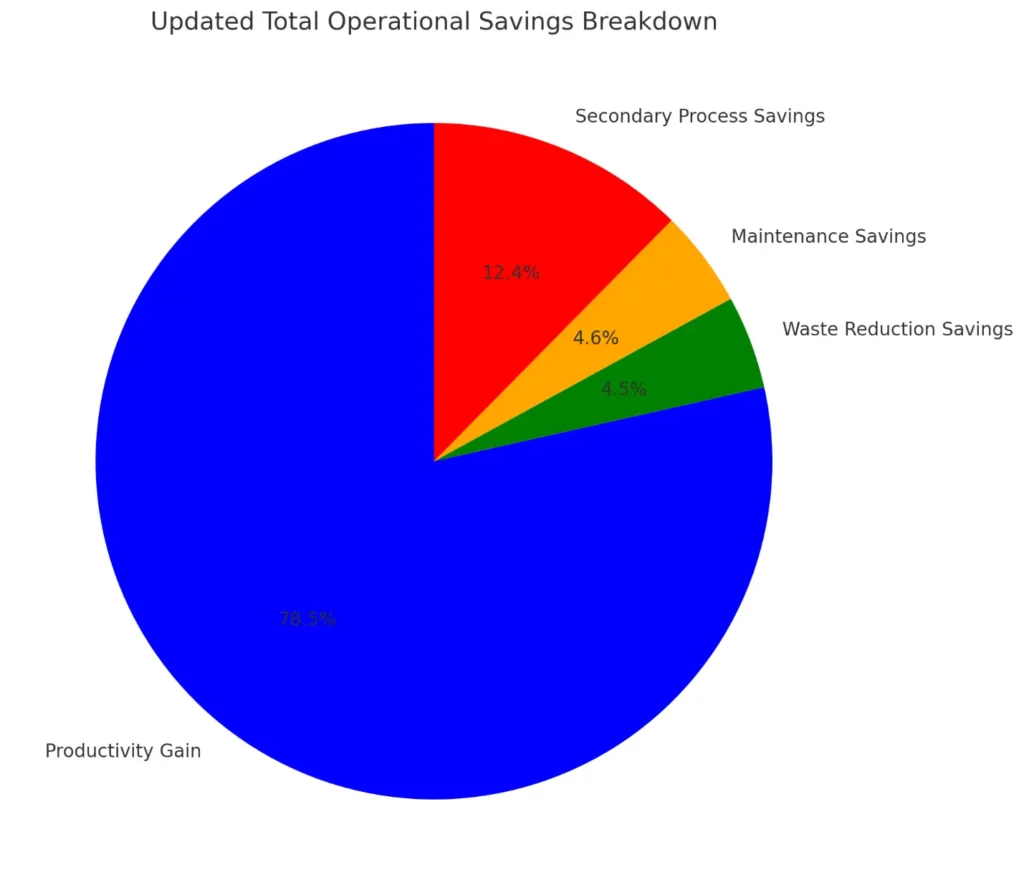

Total Operational Savings = Productivity Gain + Waste Reduction Savings + Maintenance Savings + Secondary Process Savings

Total Operational Savings:

|

Cost Component |

SMART CUT Blades |

Conventional Blades |

|---|---|---|

|

Initial Investment |

$3,000 |

$2,500 |

|

Maintenance Costs |

$2,000 |

$3,500 |

|

Replacement Costs |

$1,500 |

$3,000 |

|

Downtime Costs |

$500 |

$1,000 |

|

Total Costs |

$7,000 |

$10,000 |

|

Total Operational Savings |

$10,360 |

$0 |

|

Net Gain / (Total Operational Costs) |

$3,360 |

$10,000 |

Total Operational Savings = $8,134 + $462 + $481 + $1,283

Calculation of Total Operational Savings = $10,360

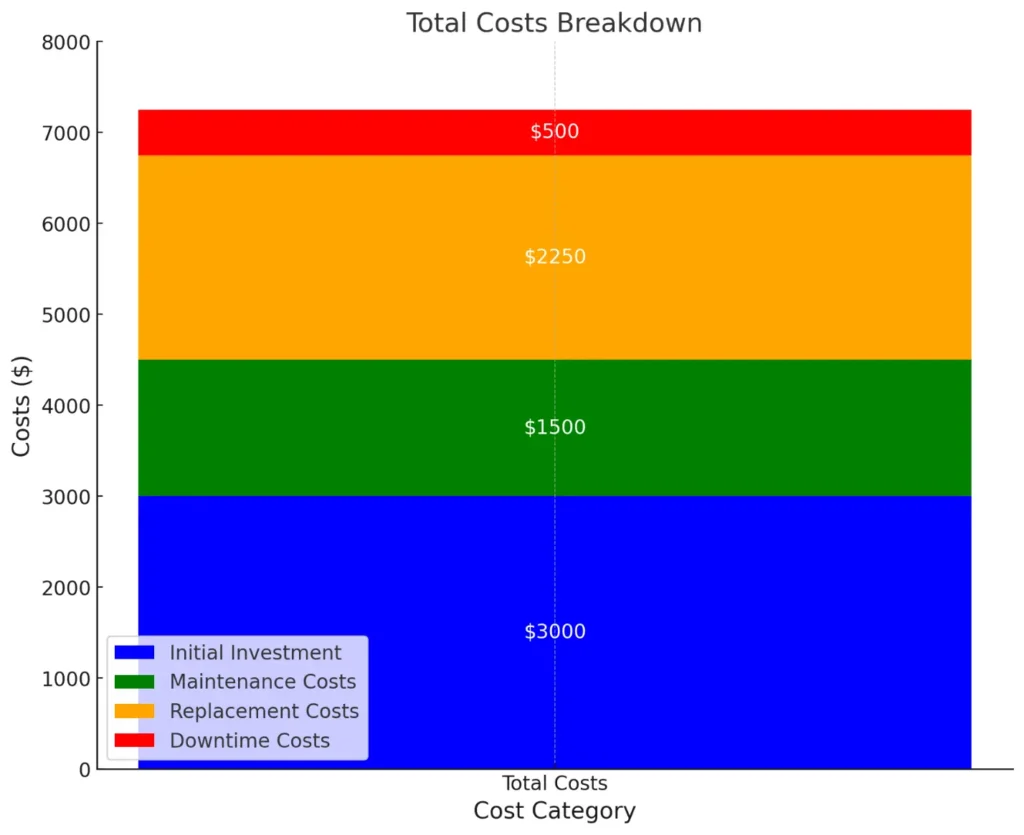

Calculate Total Costs

Determine the total costs associated with the new blades, including maintenance, replacements, and downtime over the evaluation period.

Total Costs = Initial Investment + Ongoing Costs (Maintenance, Replacements, Downtime)

|

Cost Component |

SMART CUT Blades |

Conventional Blades |

|---|---|---|

|

Initial Investment |

$3,000 |

$2,500 |

|

Maintenance Costs |

$2,000 |

$3,500 |

|

Replacement Costs |

$1,500 |

$3,000 |

|

Downtime Costs |

$500 |

$1,000 |

|

Total Costs |

$7,000 |

$10,000 |

Initial Investment: $3,000 for 20 SMART CUT®

diamond cut off wheel / blade

Maintenance Costs: $1,250, so let’s assume maintenance costs without the savings would be $1,500 (i.e., $1,500 - $1,250 = $250 maintenance cost).

Replacement Costs: to purchase 15 additional SMART CUT®

blades over the evaluation period (replacing the initial 5 savings).

Replacement Cost = 15 blades × $150 per blade = $2,250.

Downtime Costs: downtime costs are based on lost production and are $500 over the evaluation period.

Total Costs = $3,000 + $1,500 + $2,250 + $500 = $10,000

stacked bar chart that breaks down the Total Costs associated with the new blades, showing the contributions from the Initial Investment, Maintenance Costs, Replacement Costs, and Downtime Costs. This chart clearly illustrates how each cost component contributes to the overall total of $7,250

Calculate ROI

The ROI is calculated by comparing the net benefits (total operational savings minus total costs) to the initial investment.

ROI (%) = [(Total Operational Savings - Total Costs) / Initial Investment] × 100

ROI Formula:

ROI (%) = [(Total Operational Savings - Total Costs) / Initial Investment] × 100

Given Data:

-

Initial Investment: $3,000

Initial Investment: $3,000

-

Total Operational Savings: $10,360

Total Operational Savings: $10,360

-

Total Costs:$7,000

Total Costs:$7,000

Step-by-Step Calculation:

1. Calculate the Net Savings:

Net Savings = Total Operational Savings - Total Costs

Substituting the values:

Net Savings 10, 360 7,000 =3, 360

2. Calculate ROI:

ROI (%) = [(3, 360) / 3000] × 100

Simplifying the equation:

ROI (%) [1.12] × 100 = 112%

ROI for SMART CUT® Blade = 112%

ROI Calculator

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

Carlos Sanchez is a senior technical specialist and field applications trainer with more than 17 years of experience in the use and optimization of industrial diamond tools, including ultra-thin diamond blades, core drills, and CBN grinding wheels. With a foundation in industrial engineering and technical operations, Mr. Sanchez has worked extensively with manufacturers and laboratories around the world, providing hands-on support and practical training for a wide range of cutting, grinding, and sample preparation applications.

Fluent in both English and Spanish, Carlos is known for his ability to translate complex tooling concepts into clear, actionable procedures for engineers, technicians, and production staff. His approach emphasizes real-world process improvement, tool longevity, and operator education—ensuring clients get the most out of their diamond tooling investments.

As an author, Mr. Sanchez shares field-tested insights on tool performance optimization, defect prevention, training methodologies, and troubleshooting common cutting issues.

ARE YOU USING RIGHT DIAMOND & CBN BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN BLADES?

Knowledge Center

How to Properly Use Precision Diamond & CBN Blades

Precision & Ultra Thin Diamond Blade Guide

How to Improve & Optimize Your Diamond Sawing Operation

Evaluating & Comparing Diamond Blades

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Total Cost of Ownership & Why its Important

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Carlos Sanchez is a senior technical specialist and field applications trainer with more than 17 years of experience in the use and optimization of industrial diamond tools, including ultra-thin diamond blades, core drills, and CBN grinding wheels. With a foundation in industrial engineering and technical operations, Mr. Sanchez has worked extensively with manufacturers and laboratories around the world, providing hands-on support and practical training for a wide range of cutting, grinding, and sample preparation applications.

Fluent in both English and Spanish, Carlos is known for his ability to translate complex tooling concepts into clear, actionable procedures for engineers, technicians, and production staff. His approach emphasizes real-world process improvement, tool longevity, and operator education—ensuring clients get the most out of their diamond tooling investments.

As an author, Mr. Sanchez shares field-tested insights on tool performance optimization, defect prevention, training methodologies, and troubleshooting common cutting issues.