Sample Preparation Consumables for Metallography: Selection, Function, and Best Practices

-

Posted by

Brian Farberov

Brian Farberov

Table of Contents

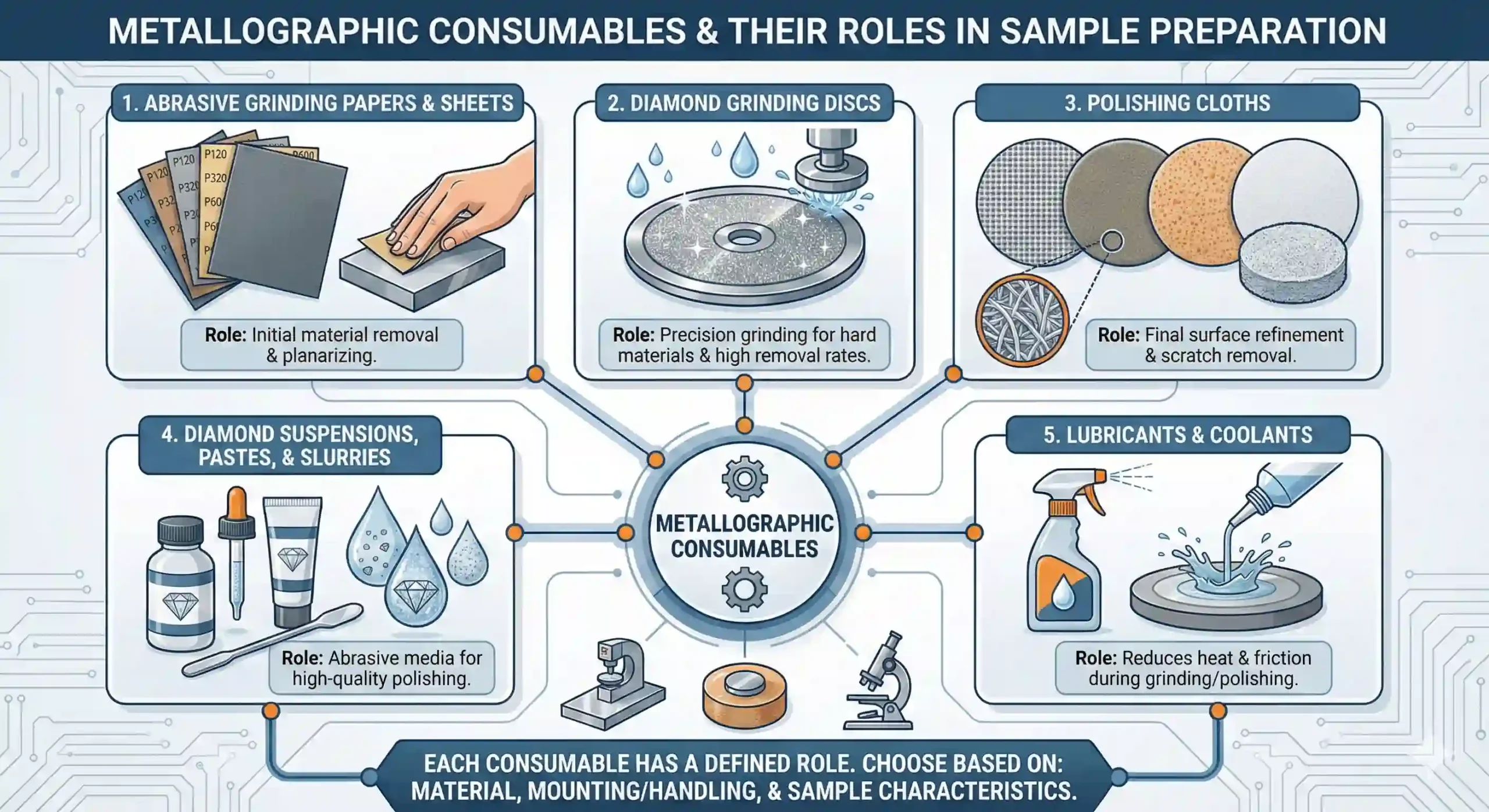

ToggleCareful sample preparation is the key to good metallographic analysis. Although equipment features and process conditions are significant factors, the impact of sample preparation consumables is equally crucial for surface quality, reproducibility, and trustworthiness in microstructural assessment. Consumables for many sample types are the constituents that interact directly with the surface of a specimen, and choice can have a significant influence on final results and preparation efficiency.

Grinding papers, polishing cloths, diamond abrasives, suspensions, and lubricants all influence material removal behavior, surface deformation, and edge retention. If, however, consumables are improperly chosen or not properly applied in a consistent fashion, defects can arise even if the machines and their parameters are well controlled. This article is intended to review sample preparation consumables utilized in metallography, discussing the role they play in each stage of preparation and providing best practices for reliable and reproducible results.

What Are Sample Preparation Consumables?

Common metallographic consumables include:

- Abrasive grinding papers and sheets

- Diamond grinding discs

- Polishing cloths with varying surface structures

- Diamond suspensions, pastes, and slurries

- Lubricants and coolants used during grinding and polishing

Each consumable has its defined role during the preparation process and needs to be chosen depending on material, mounting/handling, and sample characteristics.

Role of Consumables Across the Preparation Stages

Coarse Grinding

The coarse grinding stage is intended to remove cutting damage, surface irregularities, or deformation introduced during sectioning. At this stage, higher material removal rates are required, and surface finish is a secondary consideration.

Consumables commonly used include:

- Coarse grit silicon carbide grinding papers

- Rigid metal bond diamond grinding discs

- Rigid resin bond diamond grinding discs

Key factors at this stage include abrasive size, disc flatness, and consistent pressure application. Excessive force or worn consumables can introduce deep scratches and deformation that are difficult to remove in later stages.

Fine Grinding

Fine grinding bridges the gap between material removal and surface refinement. The objective is to reduce deformation depth while preparing the surface for polishing.

Typical consumables include:

Polishing

Polishing consumables include:

- Polishing cloths with defined hardness and nap characteristics

- Diamond suspensions or colloidal abrasives

- Compatible lubricants to control friction and heat

The interaction between polishing cloth, abrasive size, and lubricant determines whether the surface is polished uniformly or suffers from smearing, pull-out, or relief between phases.

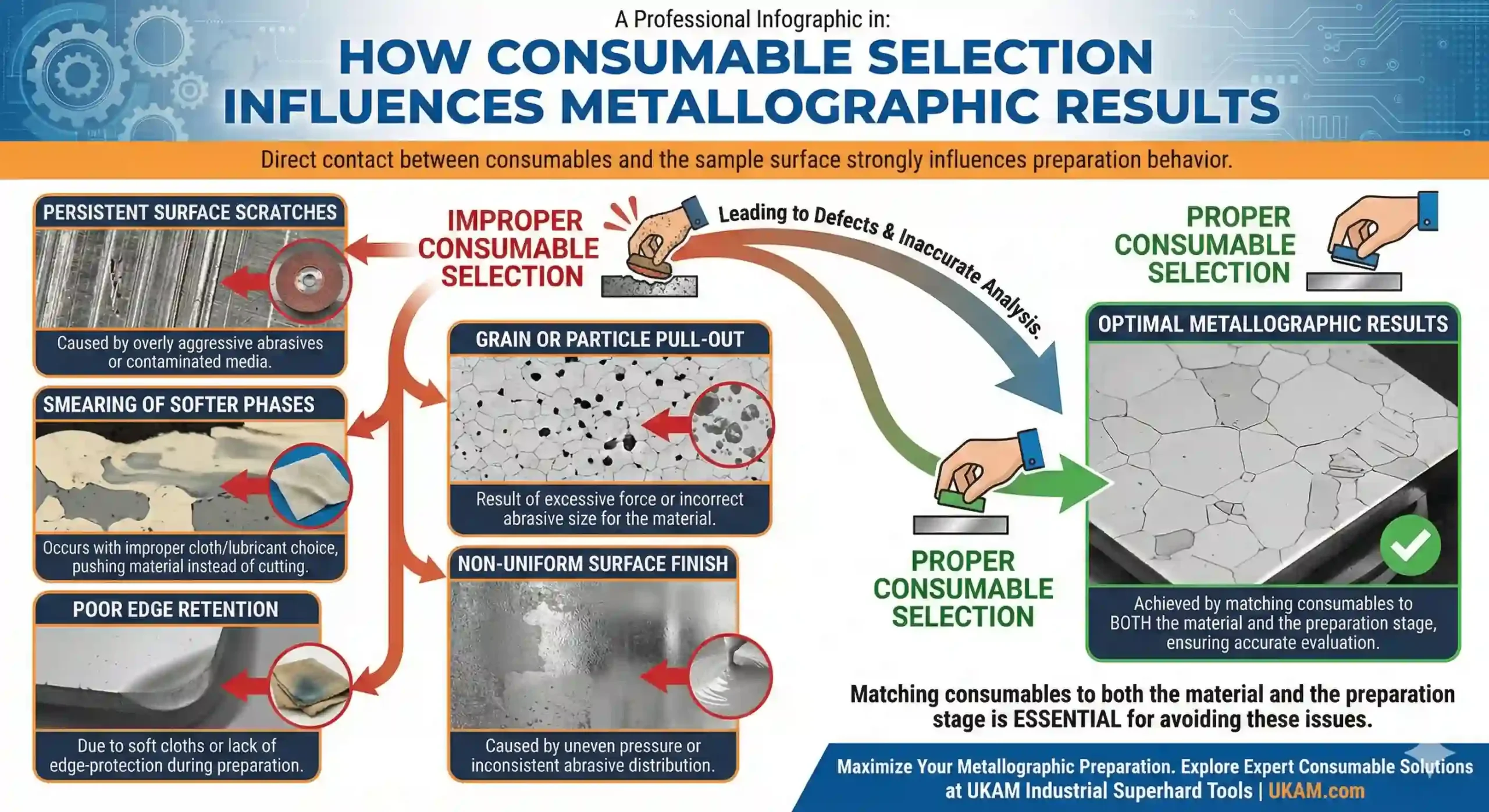

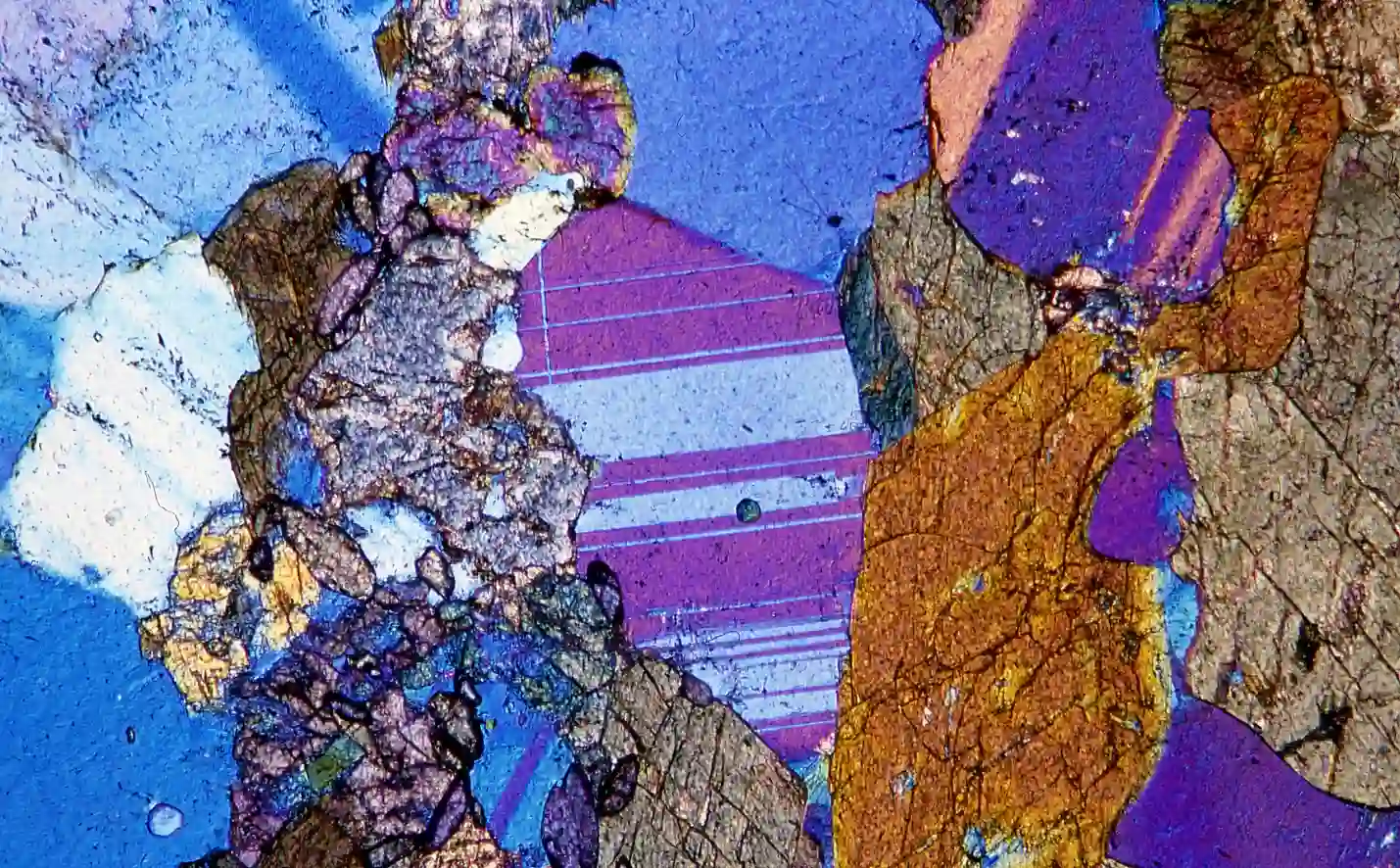

How Consumable Selection Influences Metallographic Results

Many preparation defects are attributed to equipment or operator technique when the underlying cause is actually a consumable mismatch. Because consumables directly contact the sample surface, their properties strongly influence preparation behavior.

Improper consumable selection may lead to:

● Persistent surface scratches

● Smearing of softer phases

● Grain or particle pull-out

● Poor edge retention

● Non-uniform surface finish

Matching consumables to both the material and the preparation stage is essential for avoiding these issues.

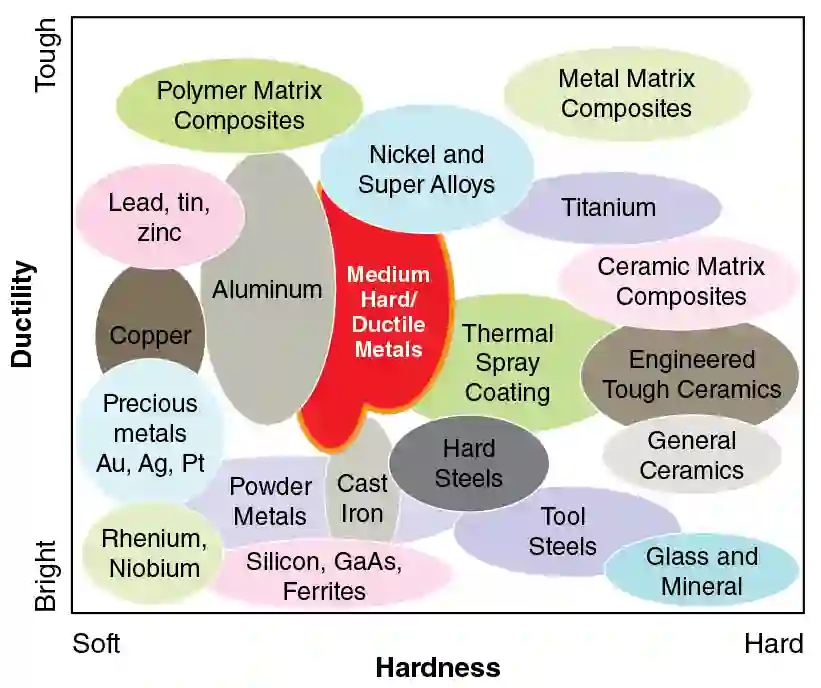

Material-Specific Considerations for Consumables

Ferrous Materials

Steels and iron-based alloys generally respond well to diamond-based grinding and polishing systems. However, excessive pressure or incorrect cloth selection during polishing can result in smearing, particularly in softer microstructural phases.

Non-Ferrous Metals

Materials such as aluminum, copper, and their alloys are more susceptible to deformation and smearing. Consumables with controlled cutting action and appropriate lubrication are necessary to minimize surface distortion.

Ceramics and Hard Materials

Ceramics, carbides, and other hard materials require rigid grinding surfaces and diamond abrasives to achieve effective material removal. Fine abrasive progression is especially important to avoid subsurface damage.

Composites and Multi-Phase Materials

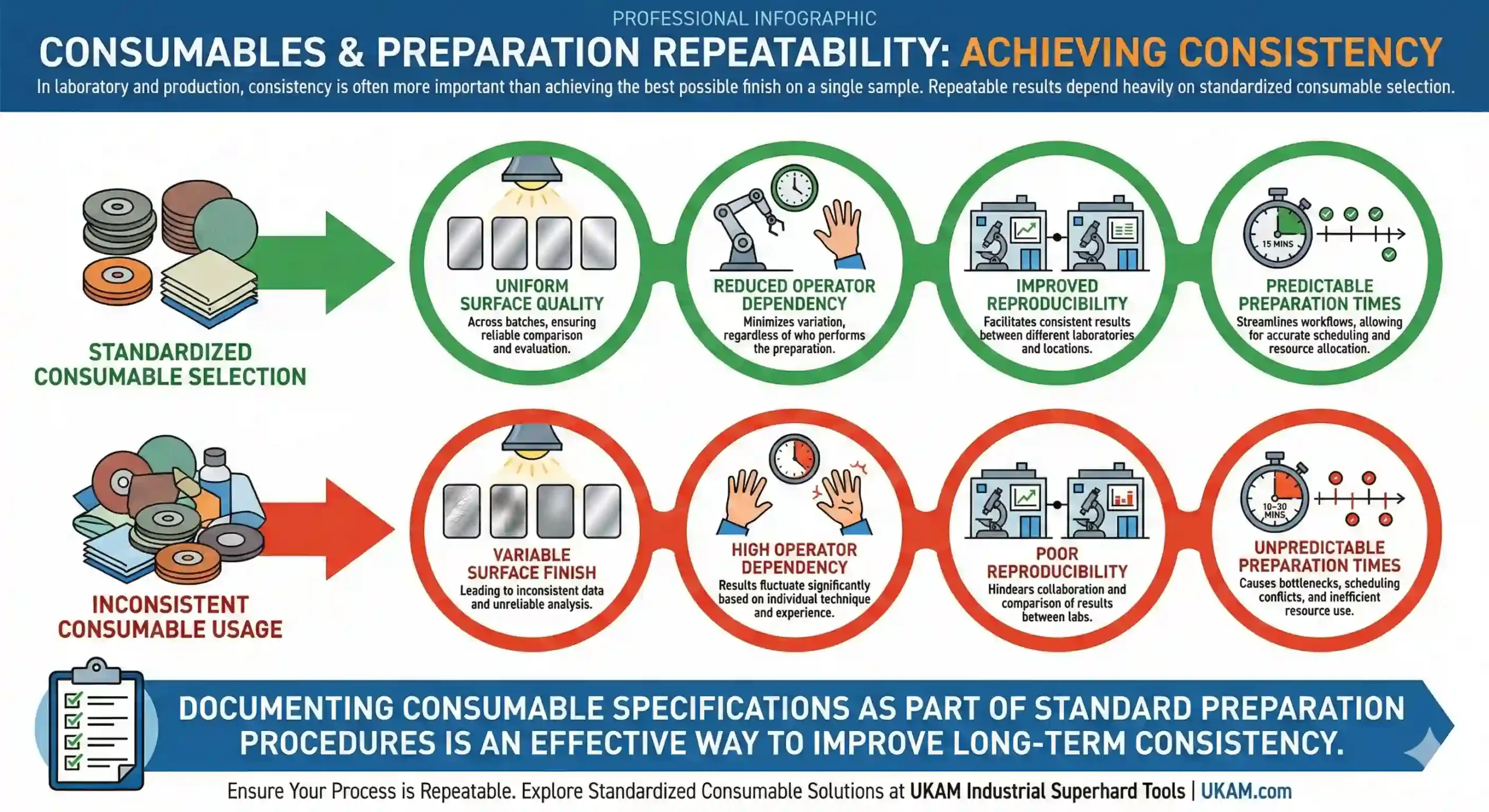

Consumables and Preparation Repeatability

In laboratory and production environments, consistency is often more important than achieving the best possible finish on a single sample. Repeatable results depend heavily on standardized consumable selection.

Consistent consumable usage supports:

- Uniform surface quality across batches

- Reduced operator dependency

- Improved reproducibility between laboratories

- Predictable preparation times

Documenting consumable specifications as part of standard preparation procedures is an effective way to improve long-term consistency.

Common Consumable-Related Preparation Issues

|

Issue |

Likely Consumable-Related Cause |

|---|---|

|

Deep scratches |

Worn or incorrect abrasive size |

|

Smearing |

Incompatible polishing cloth or lubricant |

|

Poor edge retention |

Cloth too soft or excessive pressure |

|

Rapid consumable wear |

Incorrect abrasive bond or material mismatch |

|

Inconsistent finish |

Mixing consumable types between runs |

Best Practices for Managing Sample Preparation Consumables

Effective consumable management is essential for maintaining preparation quality over time.

Recommended practices include:

- Storing consumables in clean, dry, and controlled environments

- Using dedicated consumables for each preparation stage

- Replacing consumables before excessive wear affects results

- Maintaining consistency in consumable selection across operators

These practices help ensure that consumables perform as intended throughout their service life.

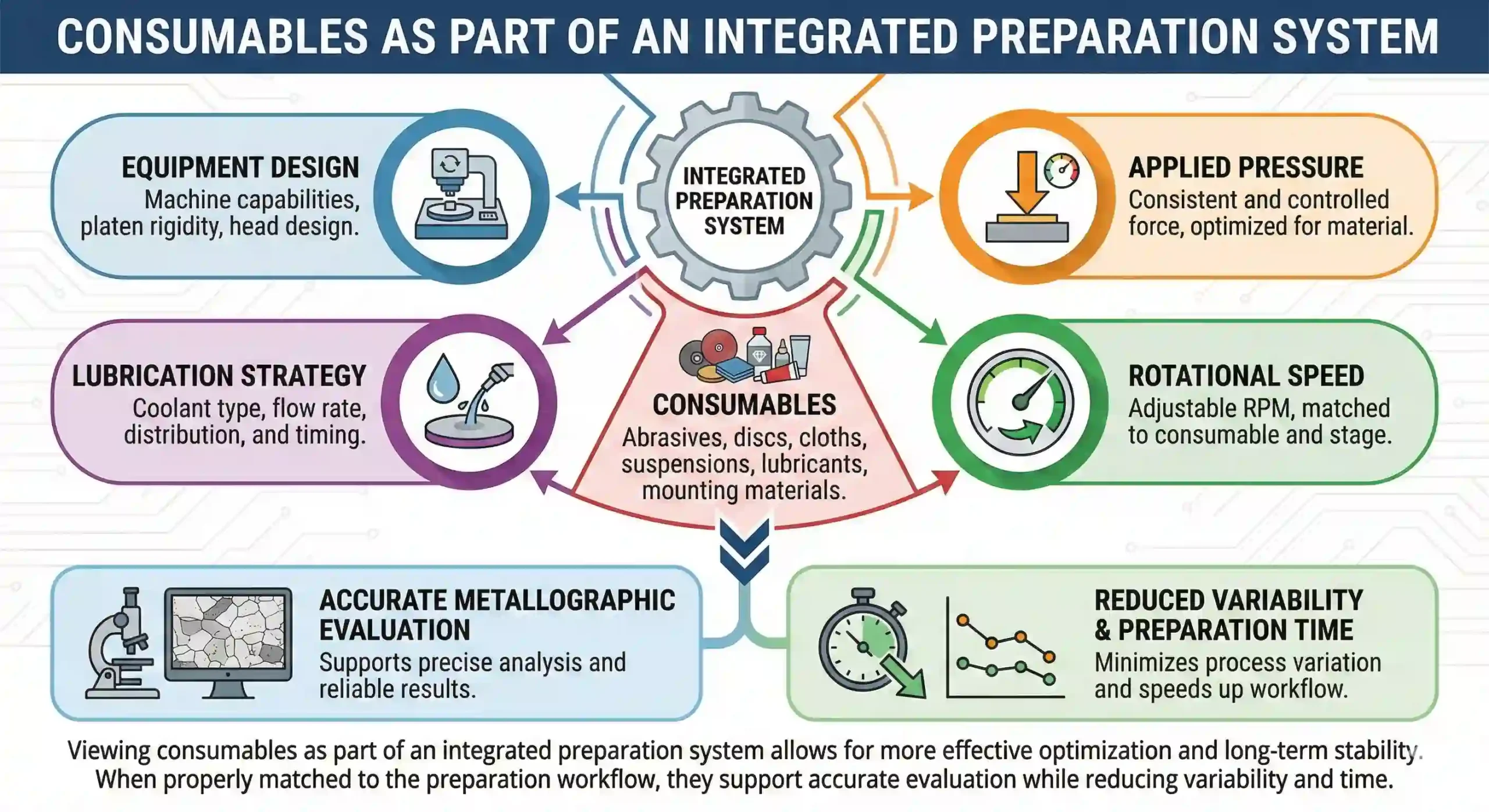

Consumables as Part of an Integrated Preparation System

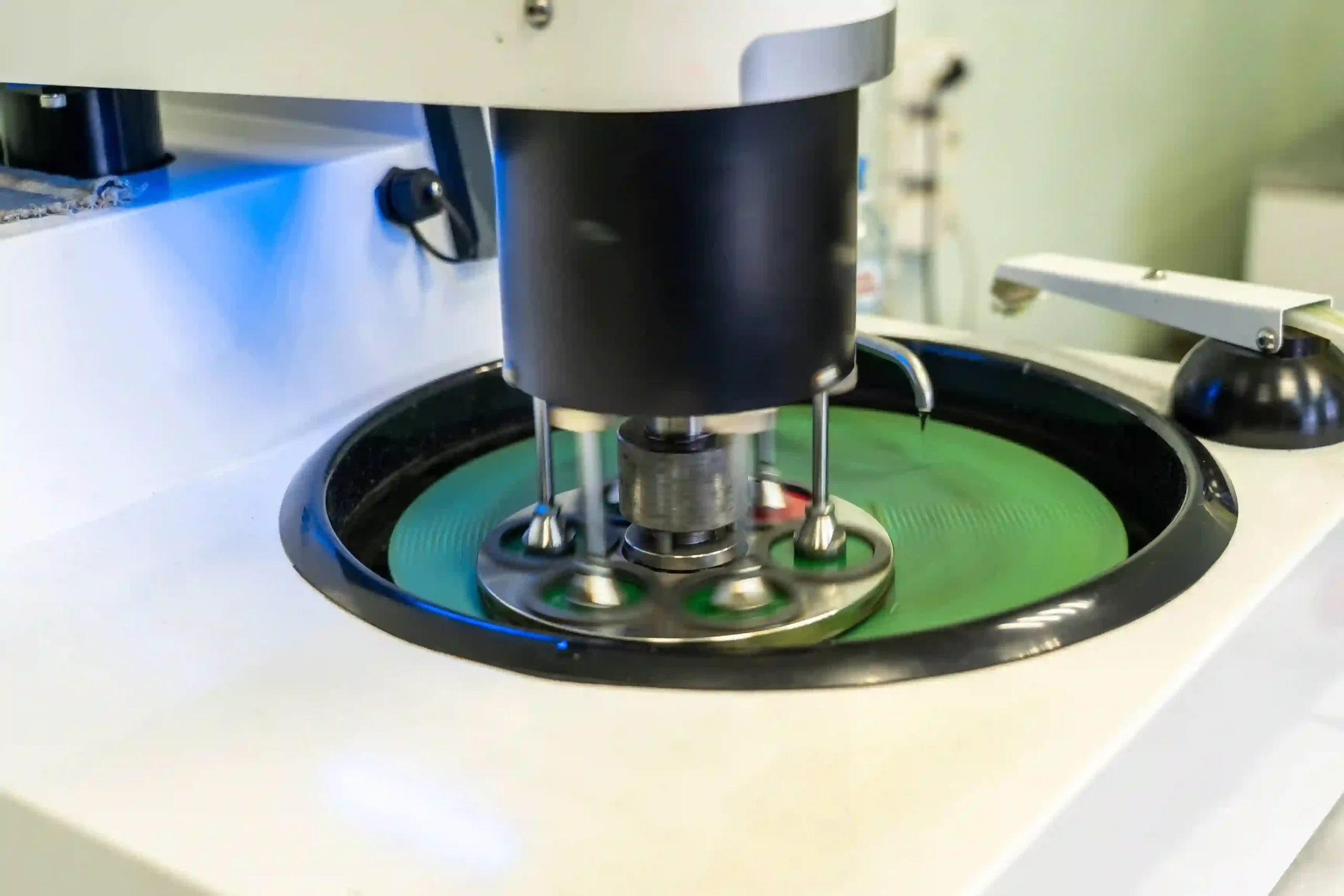

Sample preparation consumables should not be selected in isolation. Their performance is influenced by equipment design, applied pressure, rotational speed, and lubrication strategy. Viewing consumables as part of an integrated preparation system allows for more effective optimization and long-term stability.

When consumables are properly matched to the preparation workflow, they support accurate metallographic evaluation while reducing variability and preparation time.

Frequently Asked Questions (FAQs)

They are wear components such as grinding papers, polishing cloths, abrasives, and lubricants used during preparation.

They directly contact the sample surface and influence deformation, surface finish, and microstructural clarity.

No. Different materials require different abrasive types, sizes, and cloth characteristics.

Consumables should be replaced once wear begins to affect consistency or surface quality.

Yes. Standardized consumable selection is critical for consistent results across samples and operators.

Yes. Incorrect consumables can negate otherwise optimal machine parameters.

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.