Rubber Bond vs Resin Bond Thin Abrasive Cut Off Blades – A Practical Selection Guide for Precision Cutting

-

Posted by

contactor6

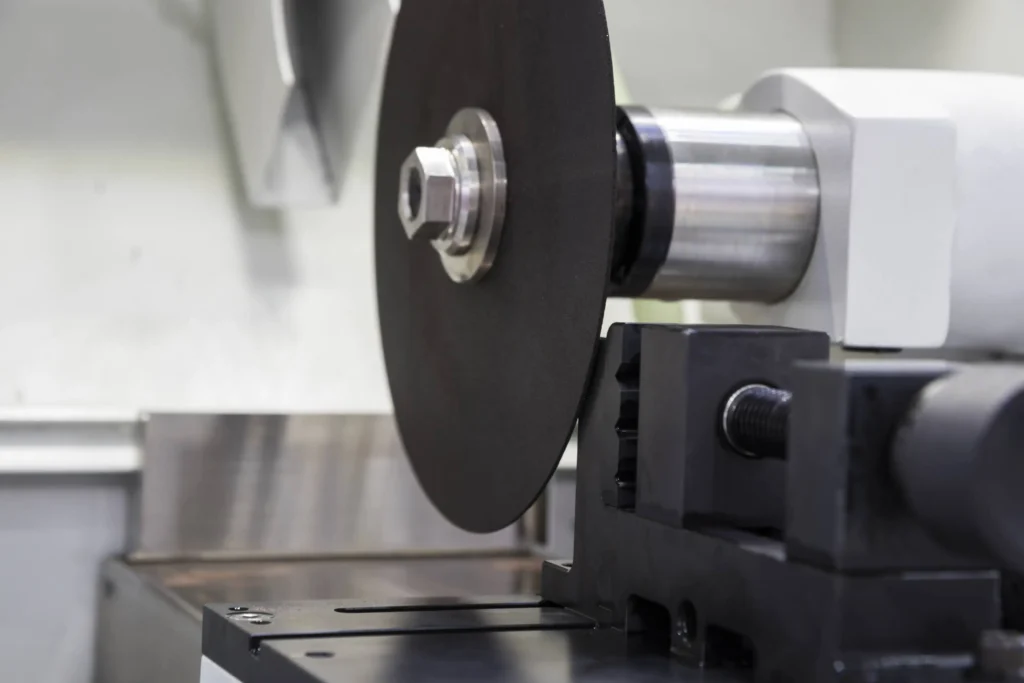

Thin abrasive cut off blades are widely used in precision tube cutting, needle manufacturing, metallography, and high accuracy production cutting. While abrasive type is important, the bond system often has a greater impact on performance. The two most common bond types for thin abrasive blades are resin bond and rubber bond. Each behaves differently during cutting and serves a different purpose.

Table of Contents

ToggleThis article explains how rubber bond and resin bond thin abrasive blades differ in performance, behavior, and ideal use cases. Bond selection directly affects cut quality, blade life, productivity, and process stability. Using the wrong bond often leads to burrs, heat damage, poor surface finish, or premature blade failure.

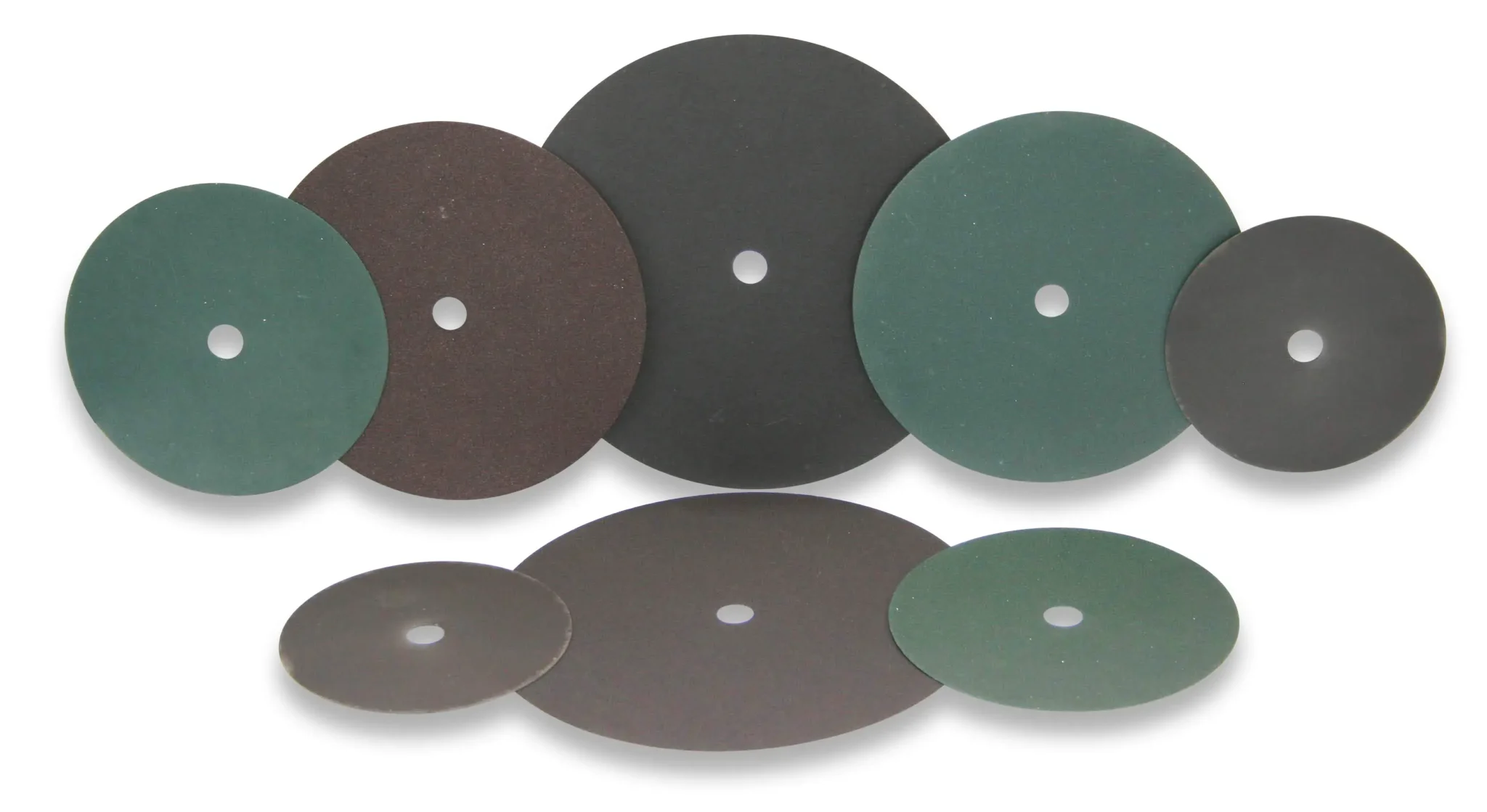

Resin bond thin abrasive blades are designed for precision. They produce clean, straight cuts with excellent surface finish. They maintain tight kerf control and minimize burr formation. These blades are preferred when dimensional accuracy matters and when post cut finishing must be reduced or eliminated. Resin bond blades are commonly used for precision tube cutting, hypodermic and dental needles, small bore stainless steel tubes, titanium tubing, tungsten components, and metallurgical sampling. They perform best in controlled cutting conditions and are often used in dry cutting operations.

Rubber bond thin abrasive blades are designed for productivity and durability. The rubber bond structure is more flexible and absorbs shock during cutting. This allows higher feed rates and improves blade life in continuous production environments. Rubber bond blades are more forgiving when cutting conditions vary, such as changes in wall thickness or material consistency. They are well suited for high volume production, automated cutting systems, and wet cutting operations where cooling and flushing are used. Minor burrs may occur but are typically acceptable or removed in downstream processes.

The article emphasizes that bond selection often has a greater impact on performance than abrasive type alone. Resin bond favors finish, precision, and control. Rubber bond favors stability, throughput, and blade life. Understanding this distinction helps engineers and operators select the correct blade for their application, reduce scrap, and improve overall process efficiency.

Purpose of the Bond in Thin Abrasive Blades

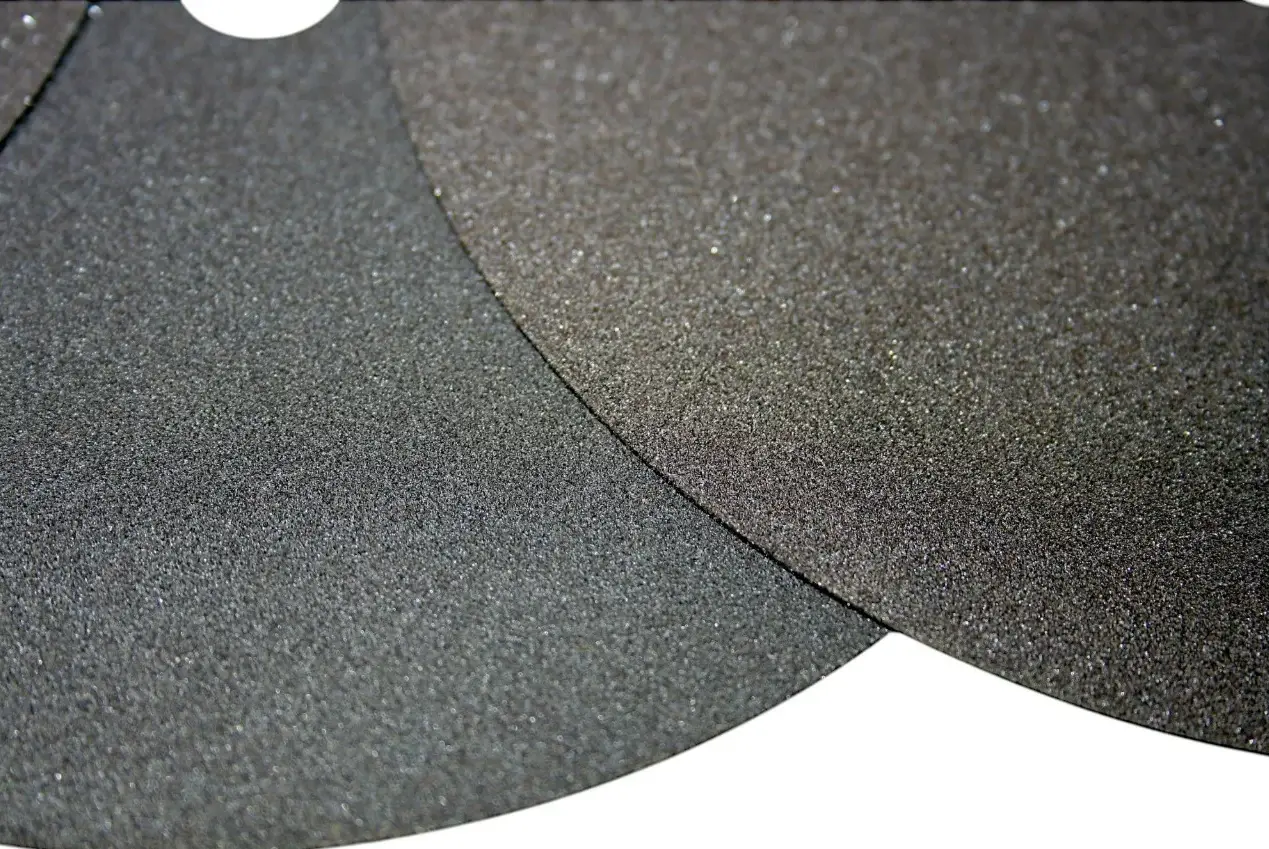

The bond holds the abrasive grains in place and controls how the blade wears during cutting. In thin blades, the bond also influences blade stiffness, vibration, heat generation, and edge quality. Because thin blades operate with very small margins for error, bond selection becomes critical.

Resin bond and rubber bond differ in hardness, elasticity, and wear behavior. These differences directly affect surface finish, burr formation, blade life, and cutting stability.

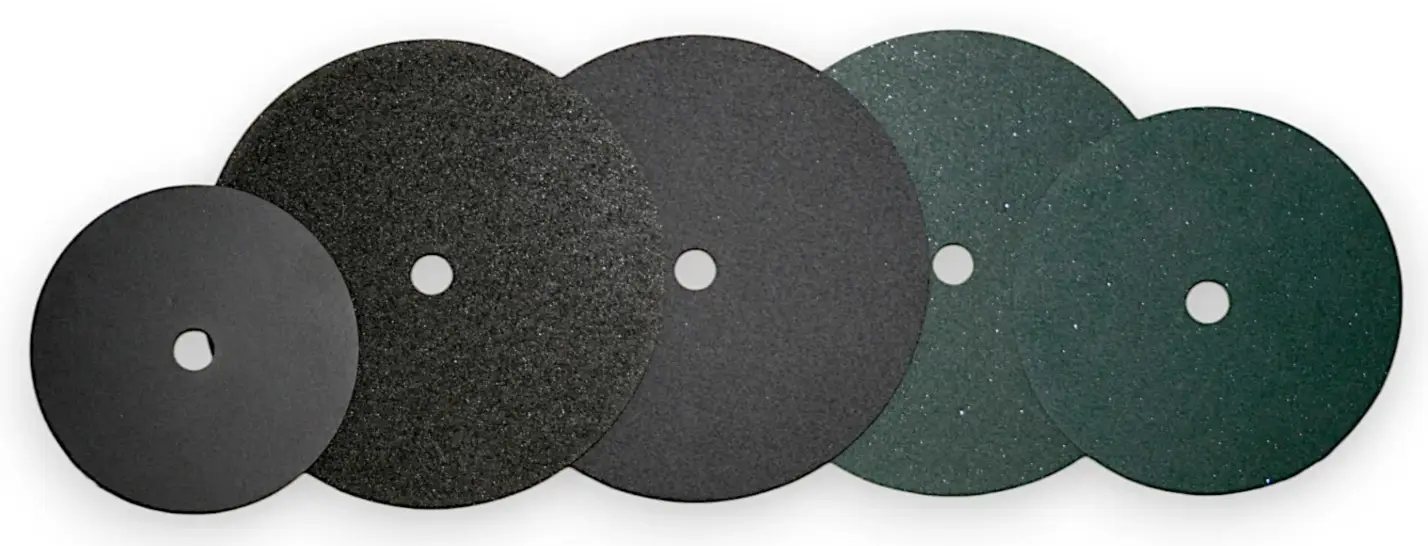

Resin Bond Thin Abrasive Cut Off Blades

Resin bond blades are designed for precision and surface quality. The bond structure is rigid and stable. This allows the abrasive grains to cut cleanly and consistently.

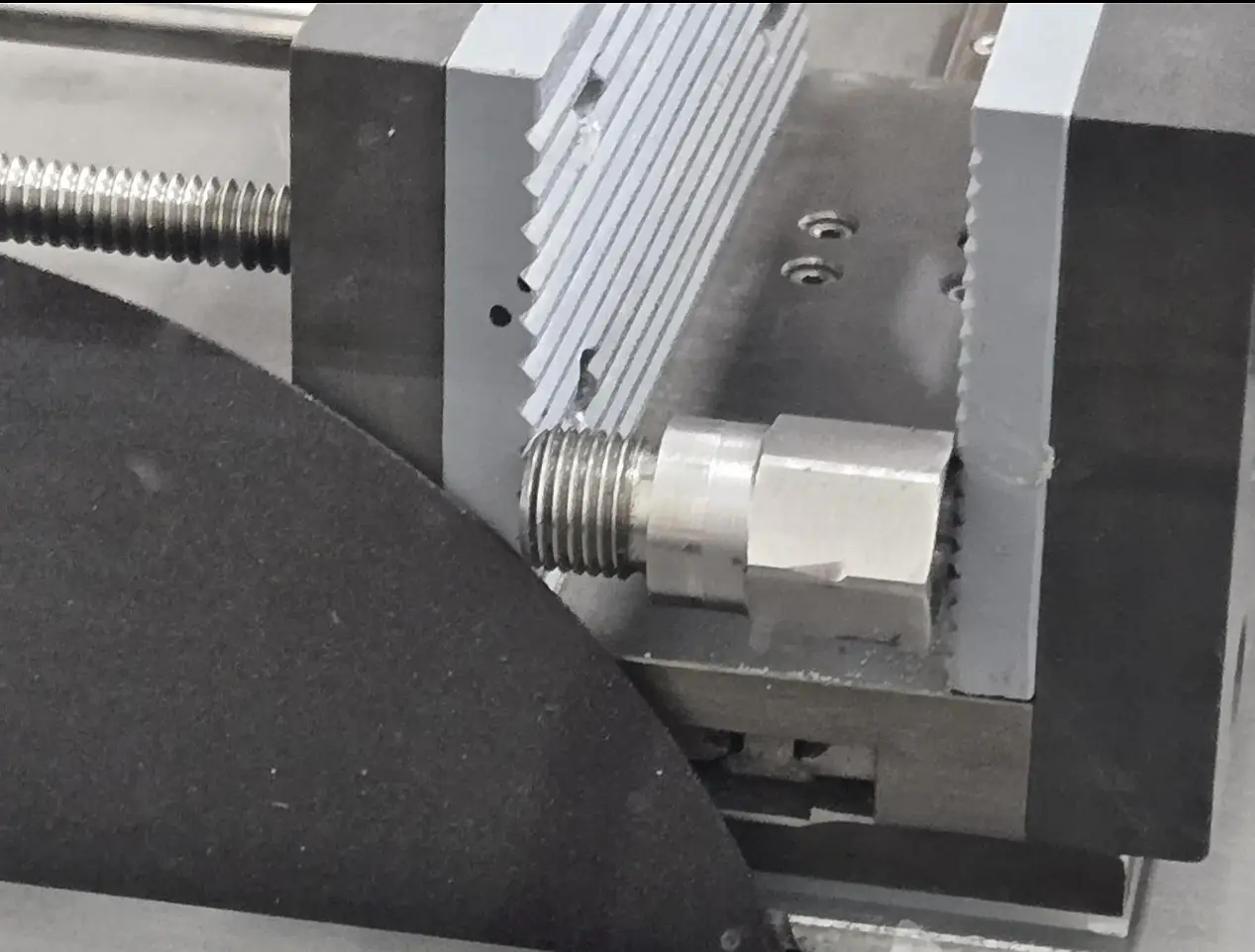

Resin bond blades produce smooth, straight cuts with excellent edge quality. Burr formation is minimal. Kerf width remains consistent throughout the cut. Dimensional accuracy is high.

These blades are commonly used when the cut face is a functional surface or when secondary finishing must be minimized or eliminated.

Typical applications include precision tube cutting, hypodermic and dental needles, small bore stainless steel tubes, copper and nickel alloy tubing, titanium tubes, tungsten and molybdenum components, and metallurgical sampling.

Resin bond blades perform best in controlled cutting conditions. Stable fixturing and consistent feed rates are important. They are often used in dry cutting operations, although wet cutting may be used to manage heat in some cases.

If your priority is cut quality, straightness, and repeatability, resin bond is usually the correct choice.

Rubber Bond Thin Abrasive Cut Off Blades

Rubber bond blades are designed for productivity and durability. The bond structure is more elastic. This allows the blade to absorb shock and vibration during cutting.

This flexibility makes rubber bond blades more forgiving. They tolerate variations in material hardness, wall thickness, and feed rate better than resin bond blades. Blade breakage risk is lower in demanding production environments.

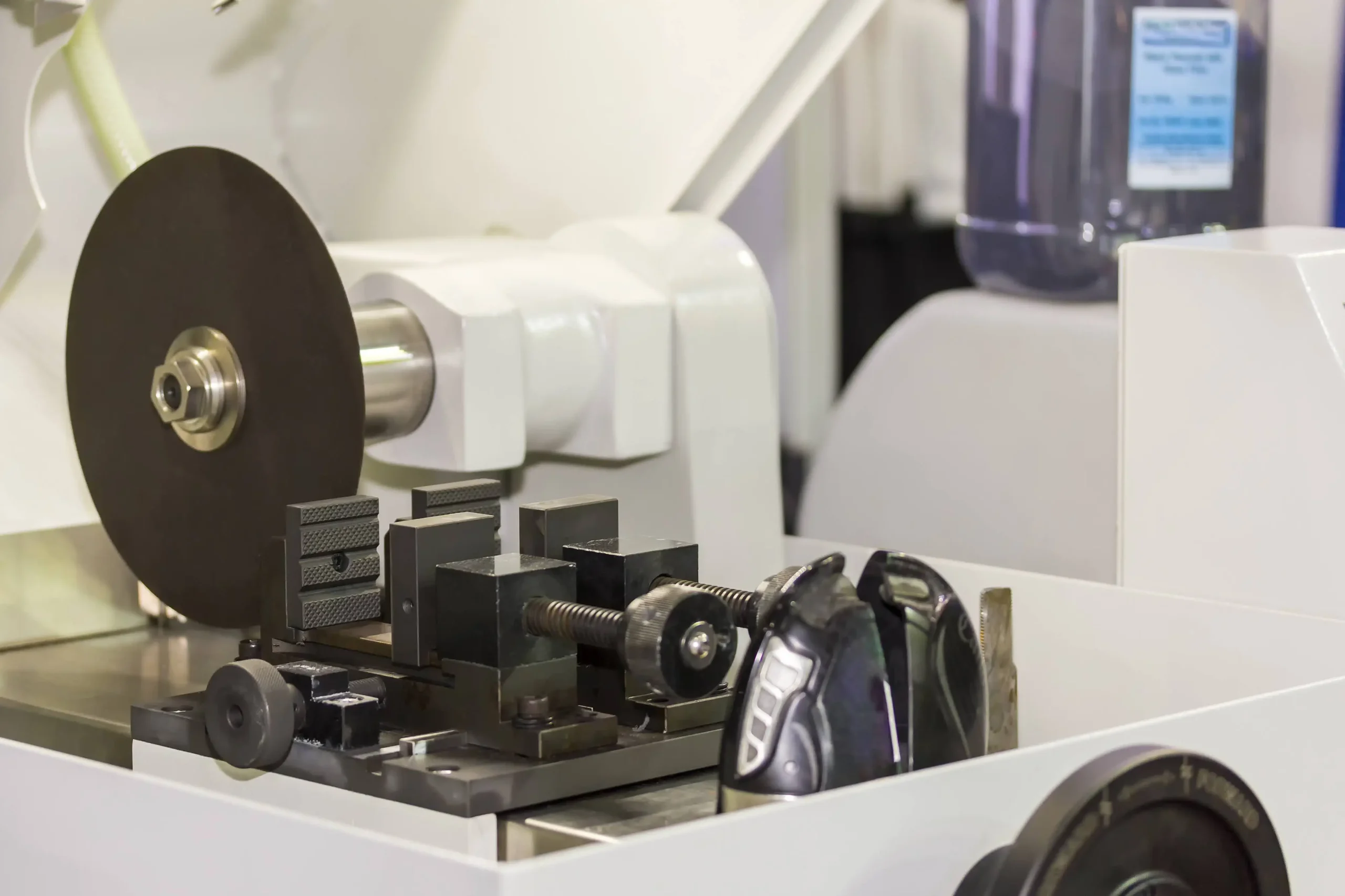

Rubber bond blades typically allow higher feed rates. Blade life is often longer in continuous cutting operations. These blades are well suited for automated systems and high volume production.

Surface finish is good but not as fine as resin bond. Minor burrs may be present, especially at higher feed rates. In many production processes, this is acceptable or corrected in a downstream operation.

Rubber bond blades are most commonly used in wet cutting applications. Coolant helps control heat, flush debris, and extend blade life.

If your priority is throughput, uptime, and robustness, rubber bond is usually the better choice.

Direct Comparison of Performance Priorities

Resin bond abrasive wheels focuses on precision. It delivers the best surface finish, tight dimensional control, and minimal burrs. It is ideal for thin wall parts, small diameters, and high value components.

Rubber bond abrasive wheels focuses on productivity. It delivers better shock resistance, longer life in continuous cutting, and greater tolerance to process variation. It is ideal for high volume manufacturing.

Choosing the Correct Bond for Your Application

You should choose resin bond when surface finish matters, burrs must be minimized, tolerances are tight, or post cut finishing must be avoided.

You should choose rubber bond when production volume is high, feed rates are aggressive, cutting conditions vary, or blade life and uptime are the main concerns.

Practical Engineering Insight

In thin abrasive cut off blades, bond selection often has more impact than abrasive grain size alone. A high quality abrasive in the wrong bond will still perform poorly. Selecting the correct bond aligns the blade behavior with your process requirements.

Careful bond selection reduces scrap, improves consistency, and lowers total cutting cost. For precision cutting applications, understanding the difference between rubber bond and resin bond is essential.

Application Examples and Practical Guidance

Precision tube and needle cutting Use resin bond when cutting hypodermic, dental, or veterinary needles. Use resin bond for thin wall stainless steel tubes and nickel alloys. These parts require straight cuts, clean edges, and minimal burrs. Resin bond provides better control of kerf width and edge quality. This reduces the risk of deformation and rework.

Aerospace and high value components

Use resin bond blades or titanium, tungsten, and molybdenum components. These materials are sensitive to heat and edge damage. Resin bond cuts more cleanly at controlled feed rates. This helps preserve material integrity and dimensional accuracy.

High volume production cutting

Use rubber bond blades when cutting large quantities of tubes or rods. Rubber bond handles higher feed rates and longer run times. It tolerates small variations in material and setup. This reduces blade changes and downtime.

Automated and wet cutting systems

Use rubber bond in automated machines with coolant. The elastic bond works well with wet cutting. It absorbs vibration and reduces the chance of blade fracture. Coolant improves heat control and extends blade life.

SMART CUT® Electroplated (Nickel Bond) Bond Diamond & CBN WheelsOur top-of-the-line diamond & CBN whels are meticulously crafted with the finest diamonds, ranging from 0.5 microns to 20 grit diamond mesh size, available in Synthetic, Natural Diamond, or CBN (cubic boron nitride) to suit a diverse array of applications, materials, and industries.

They have several layers of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration, better diamond crystal retention and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster cutting action with minimum heat generation.

Advantages of this type of technology include: longer tool life, more uniformity in performance, less stress to material being worked on, minimum material deformation, and better preservation of true material micro structure. This is specially important for more delicate, sensitive applications such as: glass, crystals, silicon wafers, carbon composites, sapphire, etc.

Metallographic Ultra Thin

Abrasive Cut Off Blade - Selection Guide

|

Attribute |

Resin Bond (Aluminum Oxide) |

Resin Bond (Silicon Carbide) |

Rubber Bond (Aluminum Oxide) |

Rubber Bond (Silicon Carbide) |

|---|---|---|---|---|

|

|

|

|

|

|

|

Abrasive Type |

Aluminum Oxide |

Silicon Carbide |

Aluminum Oxide |

Silicon Carbide |

|

Primary Metallographic Use |

Ferrous metals such as carbon steel, alloy steel, and cast iron |

Brittle and non-ferrous materials such as ceramics, glass, carbides, and non-ferrous metals |

Delicate ferrous or mixed materials sensitive to heat and stress |

Delicate brittle and non-ferrous materials sensitive to chipping and cracking |

|

Typical Metallographic Application |

General-purpose metallographic sectioning |

Sectioning of brittle or hard non-ferrous samples |

Sectioning of brittle or hard non-ferrous samples |

Precision sectioning of fragile brittle samples |

|

Cutting Method |

Wet cutting with coolant required |

Wet cutting with coolant required |

Wet cutting with coolant required |

Wet cutting with coolant required |

|

Recommended Operating Speed |

Low to Medium |

Low to Medium |

Low |

Low |

|

Feed / Force Sensitivity |

Moderate |

Moderate |

High |

High |

|

Coolant Compatibility |

Water-based, water-soluble synthetics, emulsions |

Water-based, water-soluble synthetics, emulsions |

Water-based, water-soluble synthetics, emulsions |

Water-based, water-soluble synthetics, emulsions |

|

Cut Quality |

Good to very good when properly selected |

Good to very good on brittle materials |

Excellent with minimal deformation |

Excellent with minimal chipping |

|

Risk of Thermal Damage |

Moderate if parameters are incorrect |

Moderate if parameters are incorrect |

Low when used correctly |

Low when used correctly |

|

Wear Behavior |

Moderate wear with long usable life |

Moderate wear dependent on material hardness |

Faster controlled wear to maintain sharp cutting |

Faster controlled wear to maintain sharp cutting |

|

Precision Capability |

High, dependent on blade thickness, runout, and setup |

High, dependent on blade thickness, runout, and setup |

Very high, ideal for delicate samples |

Very high, ideal for delicate samples |

|

Dressing Frequency |

Occasional |

Occasional |

More frequent |

More frequent |

|

Suitability for Delicate Samples |

Limited |

Limited |

Excellent |

Excellent |

|

Relative Cost |

Low to moderate |

Low to moderate |

Moderate to high |

Moderate to high |

*Recommended operating speed and feed classifications are provided as general metallographic guidance.

Actual RPM and feed or force depend on blade diameter, material hardness and cross section, blade thickness, machine rigidity, coolant flow, and sample mounting.

Always start at the lowest practical settings and adjust based on cutting stability and sample condition.

Common Mistakes in Bond Selection - Detailed Technical Explanation

Selecting rubber bond for precision work

A frequent mistake is choosing rubber bond blades for applications where surface finish and edge quality are critical. Rubber bond is more elastic by design. This elasticity allows the blade to absorb shock, but it also permits slight movement of the abrasive grains during cutting. In precision applications, this movement can translate into micro chatter at the cut interface.

The result is often a cut edge with light burrs, slight edge rollover, or inconsistent squareness. On thin wall tubes and small diameter parts, even minor edge distortion can cause fitment issues or functional failures. Operators then compensate by reducing feed rate, adding secondary deburring steps, or rejecting parts. These corrective actions increase cycle time and total production cost.

Rubber bond abrasive blades should not be used when the cut face is a functional surface, when tight dimensional tolerances are required, or when post cut finishing must be avoided. In these cases, resin bond provides superior control and consistency.

Selecting resin bond for aggressive production cutting

Another common error is using resin bond abrasive blades in high throughput production environments with aggressive feed rates. Resin bond is rigid and precise, but it is less forgiving. When feed rates are pushed beyond the blade’s optimal range, cutting forces increase rapidly.

Under aggressive conditions, resin bond abrasive blades can experience accelerated wear, glazing, or thermal damage. In extreme cases, blade cracking or catastrophic failure may occur. Operators may misinterpret this as a blade quality issue, when in reality the blade is being used outside its intended operating window.

Resin bond blades require stable fixturing, consistent feed, and controlled machine dynamics. They are not designed to compensate for vibration, misalignment, or rapid feed changes. In production environments where these variables cannot be tightly controlled, rubber bond is usually the better choice.

For example, a fine grit abrasive in a rubber bond may not achieve the expected surface finish due to bond elasticity. Conversely, a coarse abrasive in a resin bond may cut cleanly but wear rapidly if feed rates are too high.

Effective blade selection requires considering abrasive type, grit size, bond type, blade thickness, and cutting conditions as a system. Ignoring bond selection often leads to inconsistent results, reduced blade life, and

Process Optimization Tips - Detailed Practical Guidance

Match bond to process priority

Another common error is using resin bond abrasive blades in high throughput production environments with aggressive feed rates. Resin bond is rigid and precise, but it is less forgiving. When feed rates are pushed beyond the blade’s optimal range, cutting forces increase rapidly.

Under aggressive conditions, resin bond abrasive blades can experience accelerated wear, glazing, or thermal damage. In extreme cases, blade cracking or catastrophic failure may occur. Operators may misinterpret this as a blade quality issue, when in reality the blade is being used outside its intended operating window.

Resin bond blades require stable fixturing, consistent feed, and controlled machine dynamics. They are not designed to compensate for vibration, misalignment, or rapid feed changes. In production environments where these variables cannot be tightly controlled, rubber bond is usually the better choice.

Control feed rates and fixturing

Feed rate directly affects cutting force, heat generation, and blade wear. Resin bond blades are sensitive to changes in feed rate. Sudden increases or inconsistent feeding can overload the blade and degrade cut quality.Stable fixturing is essential when using resin bond blades. Parts must be securely supported to prevent vibration or deflection. Even small movements can translate into edge damage or dimensional variation.Rubber bond blades allow more flexibility in feed rate and setup. However, this does not eliminate the need for proper support. Poor fixturing still increases wear and reduces blade life. Rubber bond compensates for variation but does not correct poor machine setup.Consistent feed and proper fixturing improve performance for both bond types and reduce overall process variability.

Under aggressive conditions, resin bond abrasive blades can experience accelerated wear, glazing, or thermal damage. In extreme cases, blade cracking or catastrophic failure may occur. Operators may misinterpret this as a blade quality issue, when in reality the blade is being used outside its intended operating window.

Resin bond blades require stable fixturing, consistent feed, and controlled machine dynamics. They are not designed to compensate for vibration, misalignment, or rapid feed changes. In production environments where these variables cannot be tightly controlled, rubber bond is usually the better choice.

Use coolant appropriately

Coolant plays a different role depending on bond type. Rubber bond blades benefit significantly from wet cutting. Coolant reduces heat buildup, flushes debris from the cut zone, and extends blade life. Wet cutting also stabilizes cutting forces at higher feed rates.

Resin bond blades can be used dry in many precision applications, especially when heat input is low and cycle times are short. Dry cutting simplifies setup and avoids contamination of parts or work areas.

In applications where heat generation becomes excessive, resin bond blades can also be used with coolant. The key is to maintain consistent coolant delivery. Intermittent or uneven coolant flow can cause thermal cycling, which negatively affects blade wear and cut consistency.

Selecting the correct coolant strategy improves both cut quality and blade longevity.

Test before full production

Small scale testing is one of the most effective ways to optimize a cutting process. A short trial using the intended material, feed rate, and cutting environment provides immediate feedback.

Testing helps confirm whether resin bond or rubber bond is the better match for the application. It also helps fine tune feed rates, spindle speed, and coolant usage before committing to full production.

Skipping this step often leads to costly adjustments later. Tool changes, rework, and scrap during production are far more expensive than a controlled trial.

A structured test approach reduces risk, validates assumptions, and ensures the selected blade aligns with real operating conditions.

Final Technical Perspective

Rubber bond thin abrasive blades and resin bond thin abrasive cut off blades serve different roles. Neither is universally better. Each is optimized for a specific cutting objective.

Resin bond delivers precision, clean edges, and dimensional control. Rubber bond delivers durability, higher throughput, and process tolerance.

Selecting the correct bond aligns blade behavior with your application. This improves cut quality, increases efficiency, and reduces overall operating cost.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

Written by: UKAM Industrial Superhard Tools Appilcations Engineering Team

Our applications engineers have over 100+ years of combined experience in diamond and CBN cutting, grinding, drilling, and polishing tools for advanced materials, ceramics, composites, glass, metals, optics, semiconductor, micro electronics, stone, and semi precious stone.