-

0 items in quote

No products in the Quote Basket.

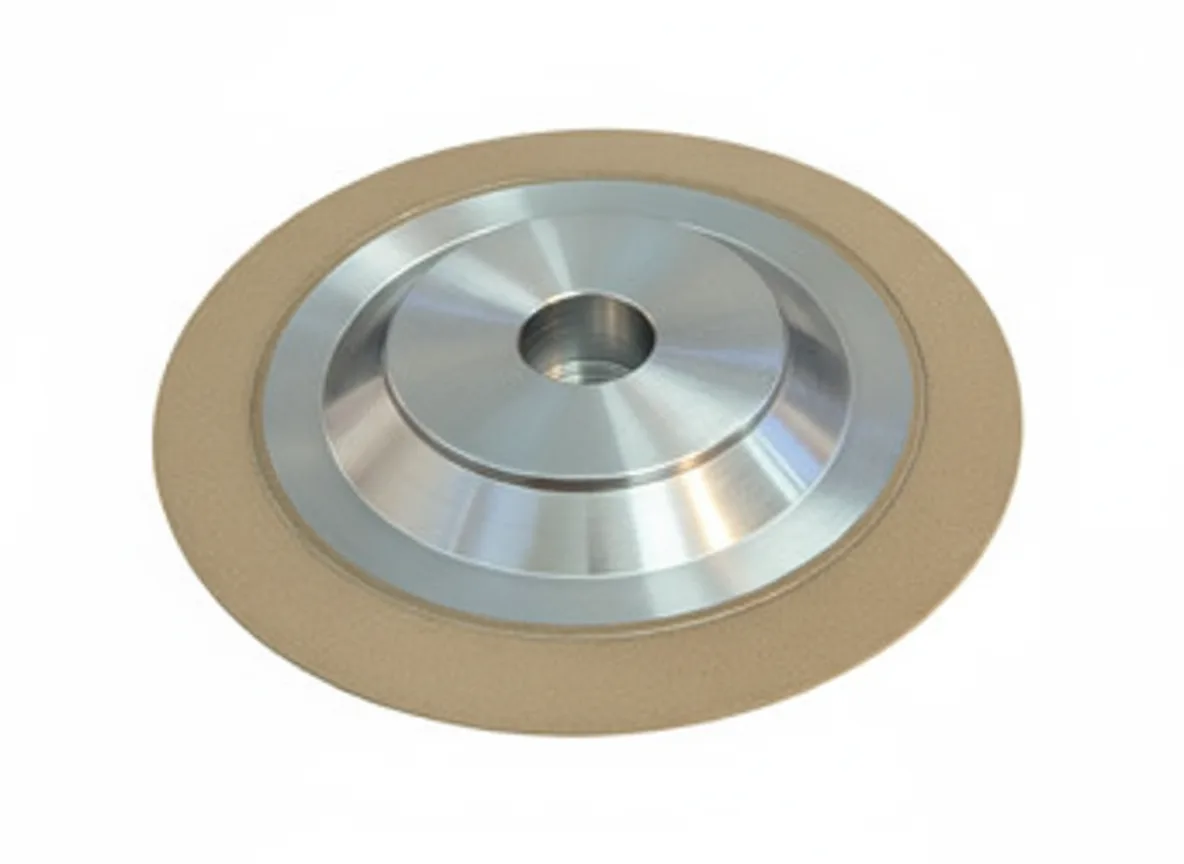

SMART CUT Diamond Groving Wheels for Natural Diamond & Gemstones

SMART CUT Diamond Grooving Tool, expertly designed for intricate diamond shaping tasks. Crafted with precision to meet the detailed requirements necessary for creating stunning heart-shaped diamonds, this tool excels in both rapid cutting and achieving a flawless polish. Its durable, sharp edge ensures longevity and efficiency. The tool offers a diverse range of angles and sizes, catering to a variety of unique diamond shapes and other artistic designs, crafted by skilled artisans.

DESCRIPTION

SPECIFICATIONS

INDUSTRIES USED IN

FAQ

ACCESSORIES

USAGE RECOMENDATION

DESCRIPTION

Our grooving wheel is an essential asset in diamond setting for jewelry making, tailored to suit the specific demands of this delicate process. It enhances the jewelry manufacturing process, accommodating all diamond shapes and sizes. This versatile tool is perfect for various pattern creation, including pie cut, illusion, and invisible settings, ensuring a secure fit of the diamond in the jewelry, significantly reducing the risk of diamond detachment.

SMART CUT grooving wheel is a product of precise engineering, offering a remarkable service life, consistent quality, and results. It provides efficient cutting and polishing capabilities, while minimizing vibrations during use, ensuring a smooth operation throughout.

SPECIFICATIONS

Tab Content

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMENDATION

Tab Content

Advantages

- Made From High Quality Materials: The diamond grooving wheels are crafted from premium-grade industrial diamonds, ensuring exceptional durability and longevity. This makes them ideal for continuous, heavy-duty use in cutting and shaping natural diamonds and gemstones.

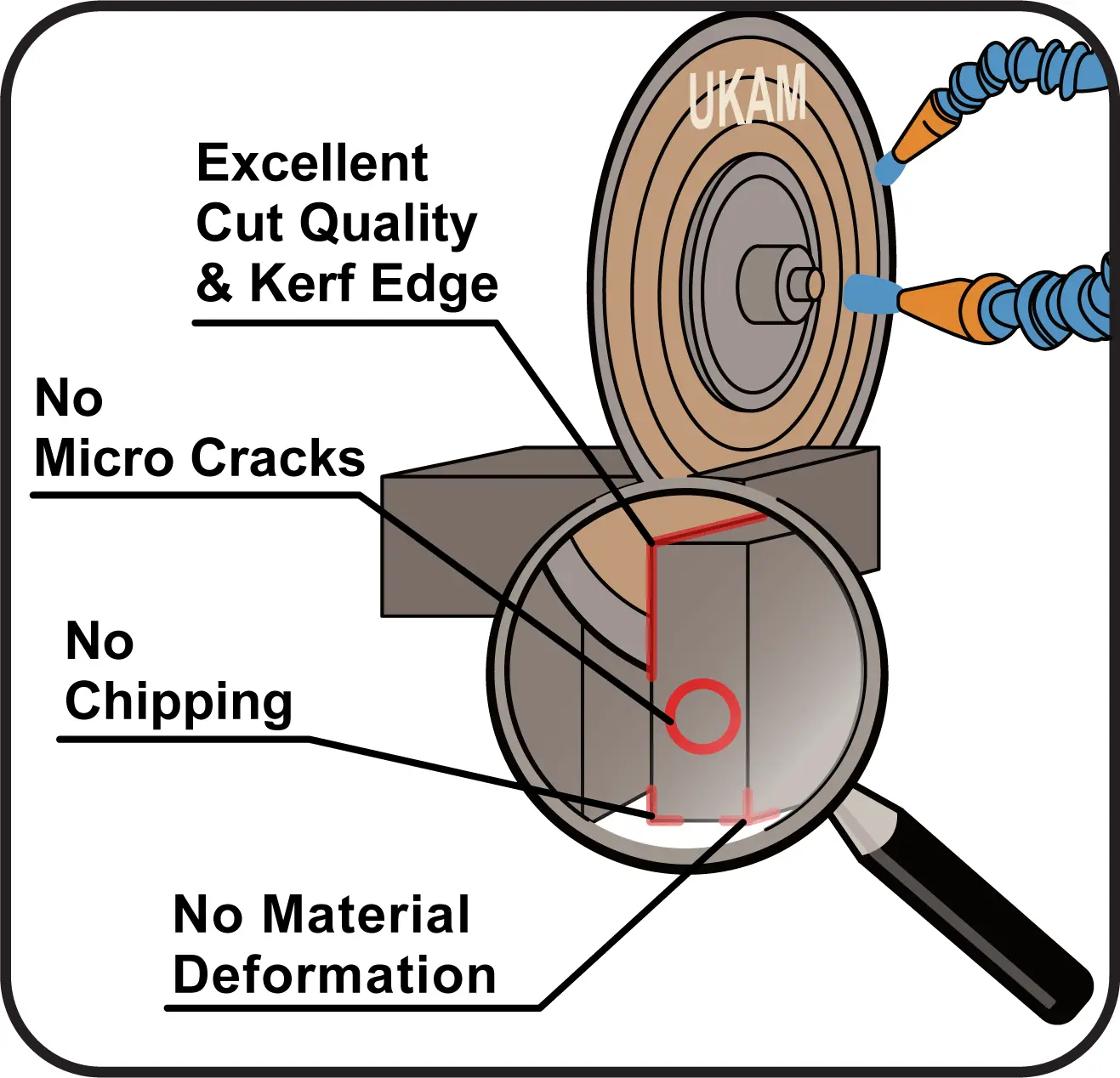

- Precision Cutting and Shaping: Designed for accuracy, these wheels offer precise control in grooving, allowing for intricate and detailed work on various gemstones. This precision ensures that each cut enhances the natural beauty and brilliance of the diamonds and gemstones.

- Versatile Application: Suitable for a range of gemstones, these grooving wheels are versatile tools for any jeweler or gemstone cutter. They are capable of handling different types of cuts, from simple grooves to complex patterns, catering to a wide range of design requirements.

- Enhanced Safety Features: Safety is paramount in the design of these wheels. They come with features that reduce the risk of chipping and breaking both the tool and the gemstones, ensuring a safer working environment.

- Improved Efficiency: The wheels are engineered to remove material quickly and efficiently, reducing the time and effort required for grooving tasks. This efficiency does not compromise the quality of the cut, making them an excellent investment for time-sensitive projects.

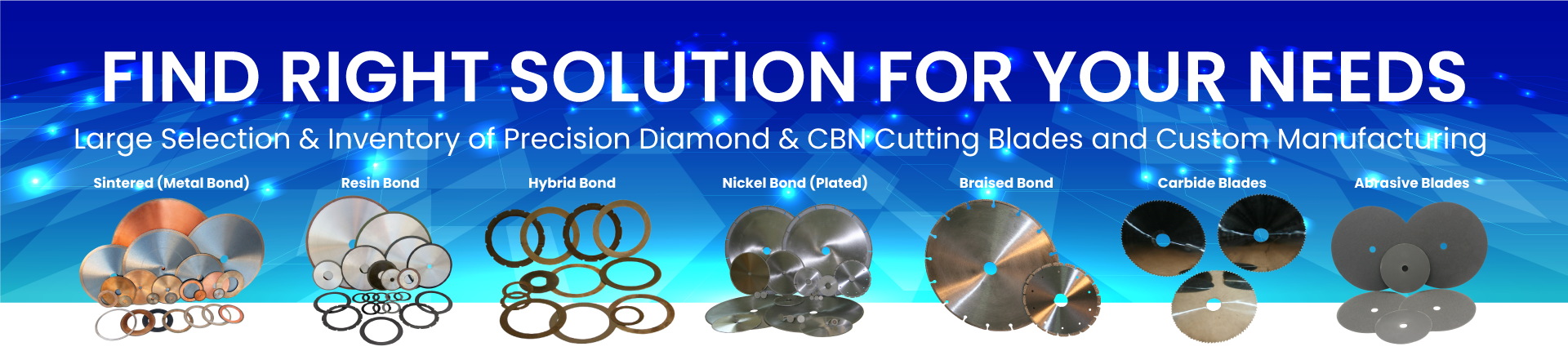

- Customizable Options: Available in various sizes and specifications, these diamond grooving wheels can be tailored to meet specific needs and preferences. This customization allows for optimal performance on different types of gemstones and for various design requirements.

- Long-Lasting Performance: With their robust construction and high-quality materials, these wheels are designed to withstand the rigors of gemstone processing, ensuring long-lasting performance and reducing the need for frequent replacements.

- Cost-Effective Solution: Despite their high-quality features, these diamond grooving wheels are an economical choice, offering superior performance at a competitive price point.

- Superior Finish and Polish: The diamond grooving wheels are not only efficient in cutting but also provide a superior finish. The high-grade diamond particles ensure a smooth, polished surface on the gemstones, enhancing their natural luster and appeal. This is particularly important for high-end jewelry and precision gemstone applications.

- Reduced Heat Generation: Innovative design elements in the wheels help in minimizing heat generation during cutting and grooving. This feature is crucial as excessive heat can damage both the diamond tool and the gemstone. Reduced heat generation ensures safer operations and preserves the quality of the gemstones.

- Easy to Install and Use: The wheels are designed for easy installation on a variety of equipment, making them suitable for different workshop setups. They are user-friendly, ensuring that even those new to gemstone cutting can achieve professional results with minimal training.

- Environmentally Friendly: In line with modern sustainability standards, these diamond grooving wheels are produced with environmentally responsible practices. They are designed to minimize waste and reduce the environmental impact of gemstone processing activities.

- Wide Range of Grit Sizes: The wheels come in a variety of grit sizes, allowing for customization based on the coarseness or fineness required for specific gemstone materials and designs. This range ensures that users can achieve the desired texture and finish on different types of gemstones.

- Consistent Performance: Users can expect consistent performance from these wheels, with each wheel maintaining its cutting efficiency and precision over numerous uses. This consistency is key for businesses that require uniform quality in their gemstone products.

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Share this Article...

02

Jun

Why use diamond

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material...

02

Jun

Selecting Right Wafering Blade for your application

Cross Sectioning is the first and most important step in the sample preparation process. Getting the best results involves obtaining a smooth surface finish, minimum chipping, material deformation, without sacrificing cutting speed. Today, most laboratories, work with dozens...

02

Jun

Wafering Blade Usage Recommendations

The wafering/sectioning blade itself is only a small factor in your sectioning operation. Successful wafering/sectioning operation is both an art & science. Requiring proper use and understanding of selecting the right diamond wafering/sectioning...

02

Jun

Wafering Blade Case Studies

Diamond & CBN Wafering Blade Case Studies

This study evaluates the cutting performance of SMART CUT® Diamond & CBN Wafering Blades compared to Conventional Wafering Blades under identical test conditions. The objective was to measure differences...

22

Apr

Diamond & CBN Wafering Blade Performance Metrics

When evaluating Diamond & CBN wafering blades, especially for metallography and sample preparation, it is critical to consider a set of key evaluation criteria and performance metrics. These factors help determine the effectiveness of a...

24

Apr

Understanding & Comparing Diamond & CBN Wafering Blades

Share this Article with Friend or Colleague

Diamond wafering blades are designed for sectioning a large variety of materials and sample types. In order to identify the best diamond wafering blade for your specific material/application,...

25

Apr

Diamond & CBN Wafering Blade Guide

Share this Article with Friend or Colleague

All you need to know about wafering blades (understanding variables & specifications)

This guide is designed to help you navigate the various variables and possibilities associated with diamond wafering...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools facilitate detailed tasks such as engraving and finishing, offering precise control and enabling you to work...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...