-

0 items in quote

No products in the Quote Basket.

SMART CUT® 435BS

BRAISED DIAMOND CUT OFF BLADES, SLOTTED

Braised Bond is a Slotted diamond cut off wheel that replaces general purpose abrasive cut off wheels/blades. Fast & efficient cutting without use of coolant, this blade can be used on any simple hand held machine or abrasive cut off saw. Designed for large variety of “Rough Cutting” metal applications, where cut quality, surface finish, and preserving material micro structure is not important.

This blade will also work on large variety of other materials including wood, plastics, composite materials, masonry and ceramics. For optimum results on steel and stainless steel, use on sheet/section material up to 3/8” thick and solid bar/bolts up to 3/4”.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Typically used for dry cutting (without coolant). Blade life will far exceed abrasive cut off wheels such as aluminum oxide, zirconia, alumina or silicon carbide. Typically over 50+ abrasive blades put together. Another advantage of this blade compared to abrasive cut off blades is the amount of sparks is very minimal, odor eliminated, and debris is only from material being cut (not from blade itself) when using these blades compared.

Also unlike abrasive blades which as susceptible to fracture and breakage that can cause possible injuries. This blade is made from strong steel with diamond strongly embedded to the edge, which is almost impossible to break or fracture. Diamond Grit Size: 40/50 mesh

SPECIFICATIONS

Bondy Type: Braised Bond

Diamond type: Synthetic

Diameters Range: 3″ (75mm) to 9″ (225mm)

Standard Inside Diameters: 3/8”, 7/8”, 5/8″ (15.875mm), we can also machine any inside diameter needed same day

Kerf Thickness: .050″ (1.27mm) to .060″ (2.41mm)

Diamond Size: very coarse

Concentration: High

Diamond Edge: Slotted

Core Type: Steel

RPM’s range: 25,00 to 6,000 (based on diameter of the blade)

Recommended Coolant: dry cutting or can be used with coolant

FREQUENTLY ASKED QUESTIONS

Tab Content

INDUSTRIES USED IN

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Advantages

- Very fast & aggressive cutting speed

- Maximum diamond crystal exposure

- Ideal for hard to machine materials

- Strong retention of diamond grits

- Can be used at faster cutting speeds

- Can be used dry and tough environments

- Less Required Power

- Capability to Retain Form

- Minimizing & Often Eliminating Need for Dressing

- Ability to Strip and re-plate the tool (re-use)

- Lower Cost

Equipment Used On

- abrasive chop saws

- hand held grinders

- die grinders

Showing 1 – -1 of 7 results Showing all 7 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Image | Item No. | Diameter | Thickness | Arbor Size | Max RPM | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|

3" (76mm) | .050" | 3/8" | 25,000 | $35.00 | Max: Min: 1 Step: 1 | |||

4" (102mm) | .050" | 5/8" | 19,000 | $40.00 | Max: Min: 1 Step: 1 | |||

4-1/2" (114mm) | .050" | 7/8" | 13,600 | $45.00 | Max: Min: 1 Step: 1 | |||

5" (127mm) | .050" | 7/8" | 12,225 | $50.00 | Max: Min: 1 Step: 1 | |||

6" (152mm) | .050" | 7/8" | 10,200 | $55.00 | Max: Min: 1 Step: 1 | |||

7" (178mm) | .060" | 7/8" | 8,600 | $75.00 | Max: Min: 1 Step: 1 | |||

9" (229mm) | .060" | 7/8" | 6,600 | $85.00 | Max: Min: 1 Step: 1 |

3302302,3302303,3302304,3302305,3302306,

Application

- High and Low Carbon Steel

- Cast Iron

- Wood

- bolts

- Composites

- Hard Facing Alloys

- Plastic

- PVC

- nonferrous materials

- concrete

- rubber

- Steel Section Bar & Tube

- Rail Track

- Ceramic

- bolts

- tile

- alloys

- Ductile Iron

- FRP

- Stainless Steel

- fiberglass

- brick

- MANY OTHERS

Feature

- Fastest Cutting Speed Possible

- Cutting Almost Any Type of Material

- Cut Dry (no coolant)

- Very Long Life compared to abrasive blades

- Minimal Sparks

- No Odor

- Unbreakable

- Cannot be Fractured

- No Dressing Required

- Can by Used in Harsh Environments

- Very Aggressive

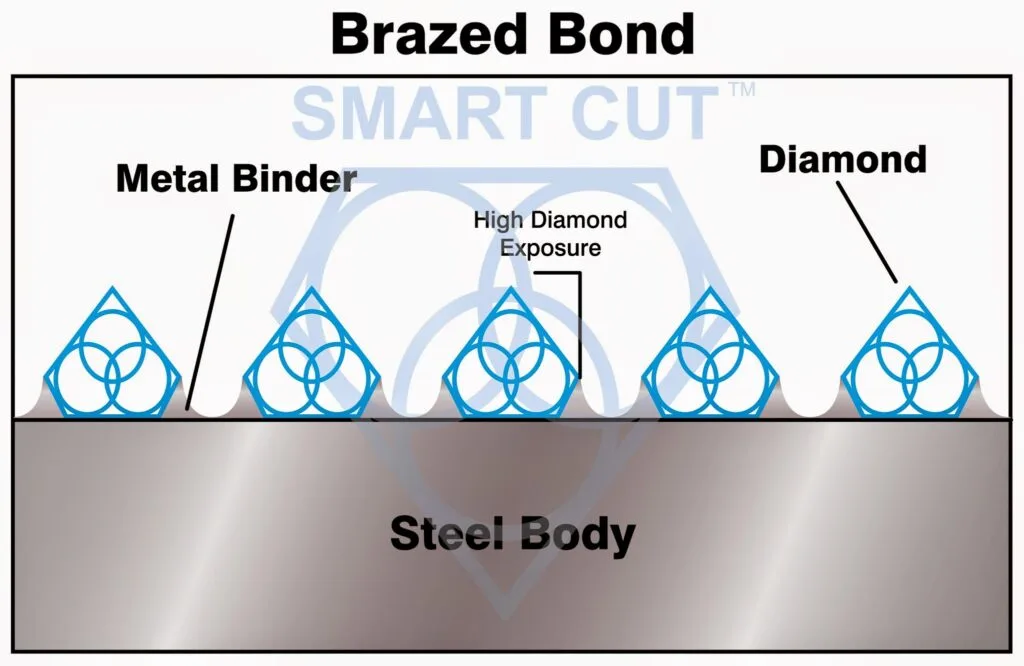

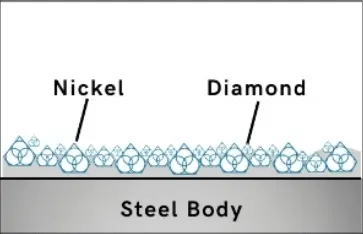

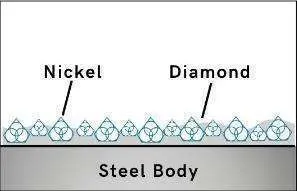

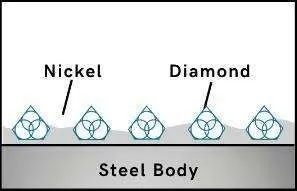

Characteristics of Braised Bond Diamond Cutting Blades

Brazed Bond Diamond Blades are perfect for machining tough-to-cut materials where fast stock removal and deep cuts are required. Including applications such as: non-metallic materials such as graphite epoxy, FRP, graphite, fiberglass, friction material, honeycomb and other composites.

No Glazing

Diamond & CBN tools with SMART CUT® technology require minimum dressing, the bond renews itself.

Faster Cutting Action

Diamond & CBN tools made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

Manufactured Using The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Best Performance & Value on the Market

SMART CUT® Resin Bond, CBN Blades are the best investment you can make! While the initial investment in CBN Blades may be higher than traditional abrasive wheels, their long lifespan and efficiency often result in a lower cost per cut. This can provide to significant saving in time and money.

Longer Life

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional Sintered (Metal Bond) diamond & CBN drills. SMART CUT® diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

More Consistent Performance

SMART CUT® Resin Bond, CBN Blades have hundreds of diamond layers impregnated inside the Resin Bond matrix. Unlike Many Other drill Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials.

Its what you cant see that makes all the Difference

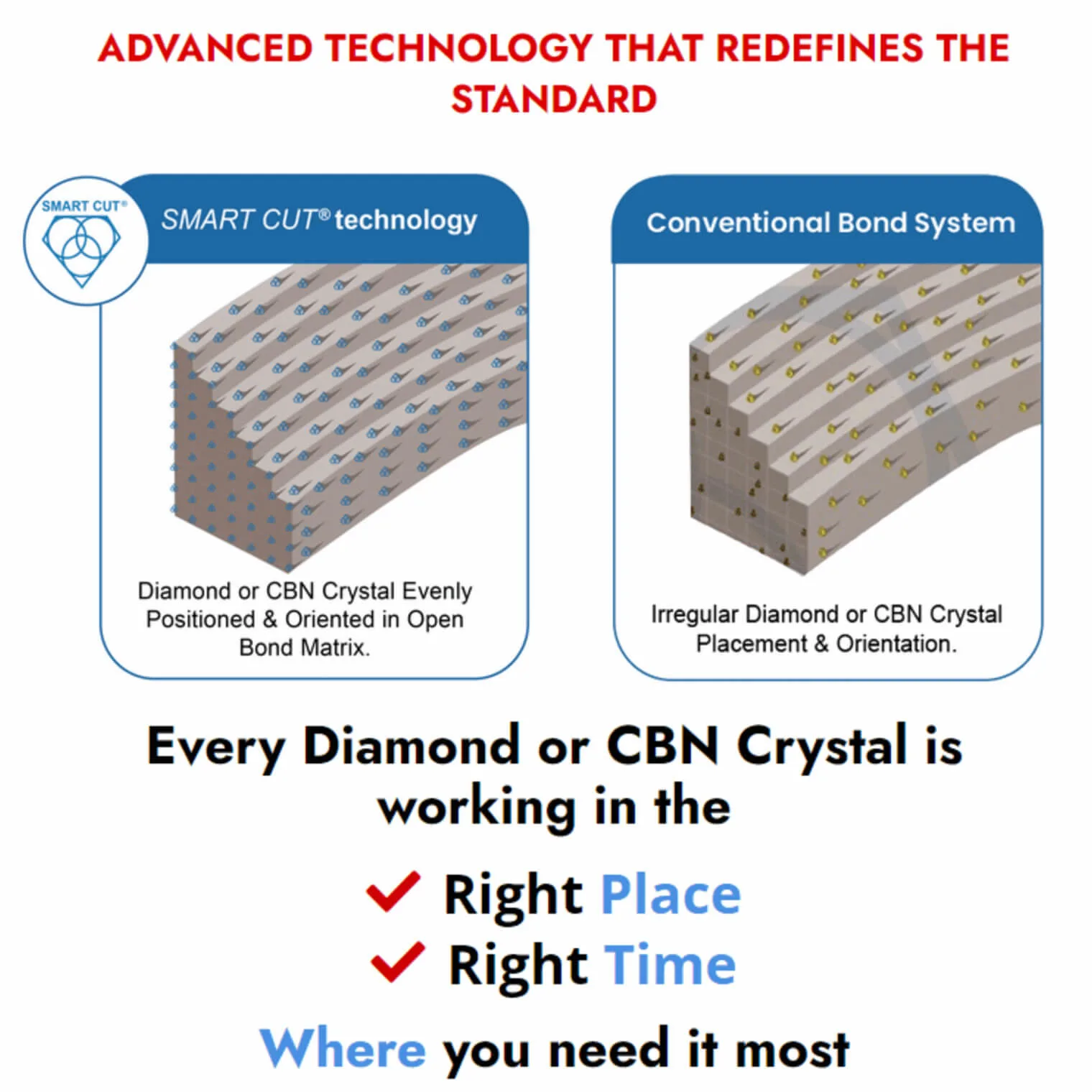

How SMART CUT® Bond Works?

Step 1

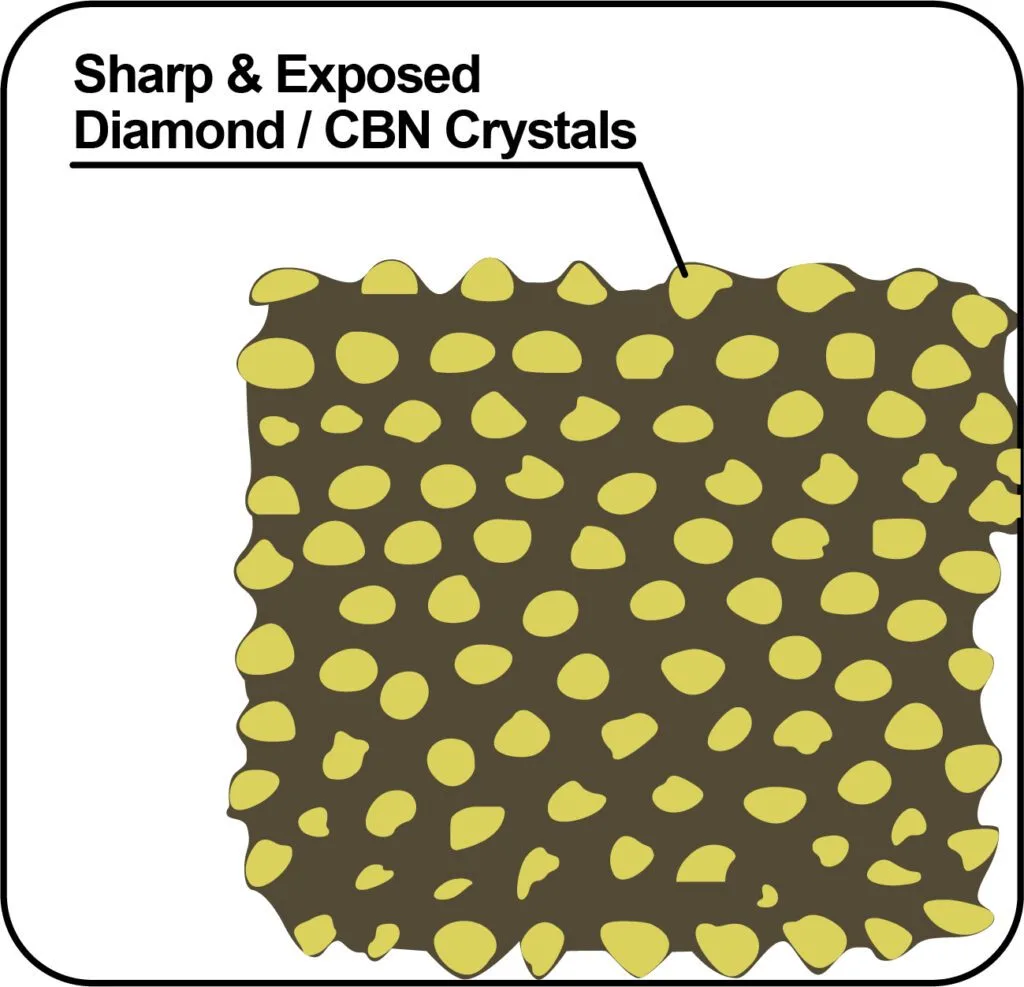

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond Wafering Blade

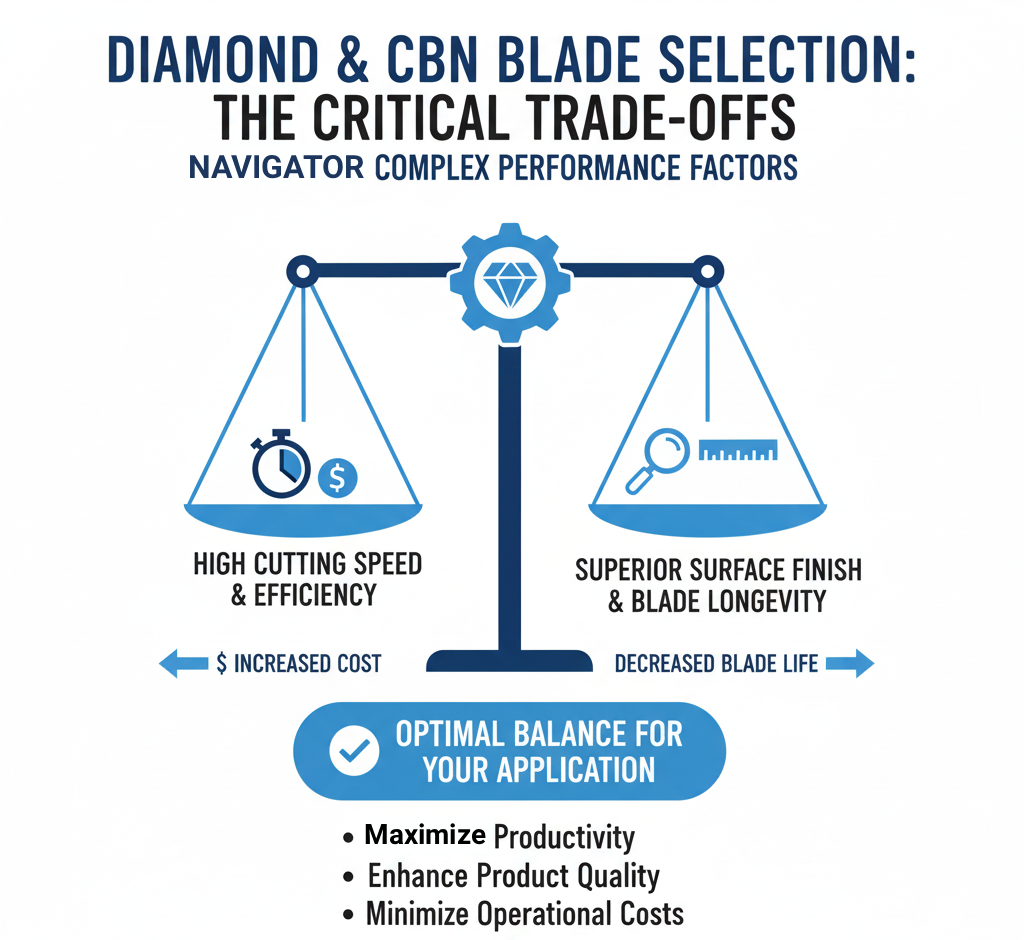

Selection Variables

Diamond Concentration

Diamond Concentration – Diamond Concentration is still a factor in determining the life and cutting speed of your Diamond Sectioning/Wafering Blade. Higher diamond concentration is recommended and usually used for cutting softer and more abrasive types of materials. However, the trade off is significantly slower cutting speed. Low diamond concentration is recommended and widely used for cutting ultra hard and brittle materials.

Low Diamond Concentration - typically low concentration wafering blades should be for cutting ultra hard and brittle materials such as ceramics and glass. In Low Concentration Wafering Blades, diamond works by fracture process. Pressure on each diamond crystal/particle is higher which provides enough stress to chip off small flakes in the cut.

High Diamond Concentration - High concentration diamond wafering blades are recommended for cutting metals, plastics and polymers. In this application, materials cut by a plowing mechanism. In this applications diamond plough through the material, work hardened strips of materials become brittle and break off. The greater number of diamond by volume, the quicker the cutting action will be. Increasing the number of diamond s also lowers the per unit force. For metals where it is possible to induce deep deformation layers, a lower per unit force is desirable to reduce the deformation during the cut.

Blade Thickness

Wafering blade thickness typically ranges from .006” to .040” (1mm). Thinner and thicker wafering blade are available, frequently from stock upon request. Kef thickness typically increases with blade diameter (in proportion to diameter of the blade). Kerf is the amount of material removed from the material/sample due to the thickness of blade passing though the material/sample. Blade thickness is important for users requiring most minimal amount of material loss during sectioning

For example if the user requires precision position of the cutting plane relative to the detail on the sample (IC circuit for example), a thinner and smaller diameter blade would be best for this application. Blades ranging from 3” to 5” (75mm to 125mm) in diameter and thickness .006” to .015” (0.2mm to 0.4mm) would be bet suited for this purpose. There are large variety of factors that will contribute to optimal blade thickness for your material/application Including your desired cutting speed, load/feed rate, material diameter, thickness, hardness, density, and shape. As well as skill & experience of the operator. Thicker wafering blades are more stiff and can whistand higher loads/feed rates. Another advantage of thicker kerf blades is they are more forgiving to operator error and abuse. Thicker kerf blade are recommended for use in environment where large number of individuals will be sharing and using same equipment. Perfect for less experienced and novice saw operators, such as in University laboratory.

.

Diamond Particle/Grit size

Diamond Mesh Size plays a major role in determining your cutting speed, cut quality/surface finish, level of chipping you will obtain, and material microstructure damage you will obtain. Diamond Mesh size does have considerable effect on cutting speed. Coarse Diamonds are larger than finer diamonds and will cut faster. However, the tradeoff is increase in material micro damage. If you are cutting fragile, more delicate materials then finer mesh size diamond wafering blades are recommended.

Bond Type

Metal bonding offers long life and durability, while resin bonding creates less heat, provides better surface finish and is well suited for cutting hard, delicate or brittle materials.

Blade Outside Diameter

typically wafering blade diameters range form 3” (75mm) to 8” (200mm). Wafering blade diameter should be selected based on material diameter and thickness being cut. Smaller diameter wafering blades are thinner than the larger diameter blades and are more prone to bending and warping. Although large diameter blades are thicker, they are typically used for cutting larger and heavier samples at higher loads and speeds than smaller blades

Feed Rates

load/feed rate applied to wafering blades typically vary from 10-1000 grams. Generally, harder specimens are cut at higher loads and speeds (e.g. ceramics and minerals) and more brittle specimens are cut at lower loads and speeds (e.g. electronic silicon substrates). The Speeds/RPM’s you are using, shape/geometry of the specimen, and how the specimen is being clamped/hold in place will affect the load that can be used for your application.

Bond Hardness

Ability of the bond matrix to hold diamonds. As the hardness of the bond is increased, its diamond retention capabilities increase as well. However the trade off is slower cutting speed. Life of the diamond blade is usually increased with hardness of its bond matrix. Bonds are designated on their scale of hardness from Soft, Medium, and Hard. There are dozens of variations and classification schemes based on bond degree of hardness or softness.

Using diamond blades with optimum bond hardness for your application is important to successful precision diamond sawing operation. Bond matrix that is too soft for the material being cut will release diamond particles faster than needed, resulting in faster wear and shorter diamond blade life. On other hand bond matrix that is too hard will result in much slower cutting speeds and require constant dressing to expose the next diamond layer. As rule of thumb, harder materials such as sapphire and alumina generally require a softer bond. Whereas softer and more brittle materials require a harder bond.

Blade Speeds/RPM’s

Most wafering blades are used between 50 to 6,000 RPM’s Typically harder and more denser materials such as Silicon Carbide, are cut at higher RPM’s/speeds Where more brittle materials such as silicon wafers and gallium arsenide are cutting at lower RPM’s. Low Speed saws RPM’s are typically limited from 0 to 600 RPM’s. Where high speed saws offer much large variety of cutting speeds from 0 to 6,000 RPM’s.

Related Products

Petrographic Diamond Blades

Abrasive Polishing Powders

Grinding & Polishing Powders Aluminum Oxide, & Silicon Carbide Powdered Abrasives

UKAM Industrial Superhard Tools offers a wide range of precision abrasives for grinding and polishing large variety of samples. Including petrographic specimens other metals, alloys, electronic devices, semiconductors, ceramics, ferrous metals and many others. Abrasive Powders are available in the following quantities: 1 lb, 5 lb, 10 lb containers Grit Sizes: 120 grit to 8 micronsDiamond, Nickel Bond Cut Off Blades for Laboratory & Other Saws

SMART CUT® Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

SMART CUT® Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

Recently Viewed Products

ARE YOU USING RIGHT DIAMOND & CBN BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN BLADES?

Knowledge Center

02

Jun

The diamond blade itself is only a small factor in your cutting operation. Successful diamond sawing is both an art & science. Requiring proper use and understanding of the right: RPM's, Coolants, Equipment, Dressing Devices, Accessories...

02

Jun

Precision & Ultra Thin Diamond Blade Guide

Diamond and CBN blades are available in an extensive array of varieties, each differing in bond types, manufacturing methods, and design specifics. Ultra Thin & High Precision Diamond Blades are particularly versatile, applicable...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...