Improving Diamond Dicing Blade Performance: Key Factors and Strategies

-

Posted by

Leon Meyer

Leon Meyer

Table of Contents

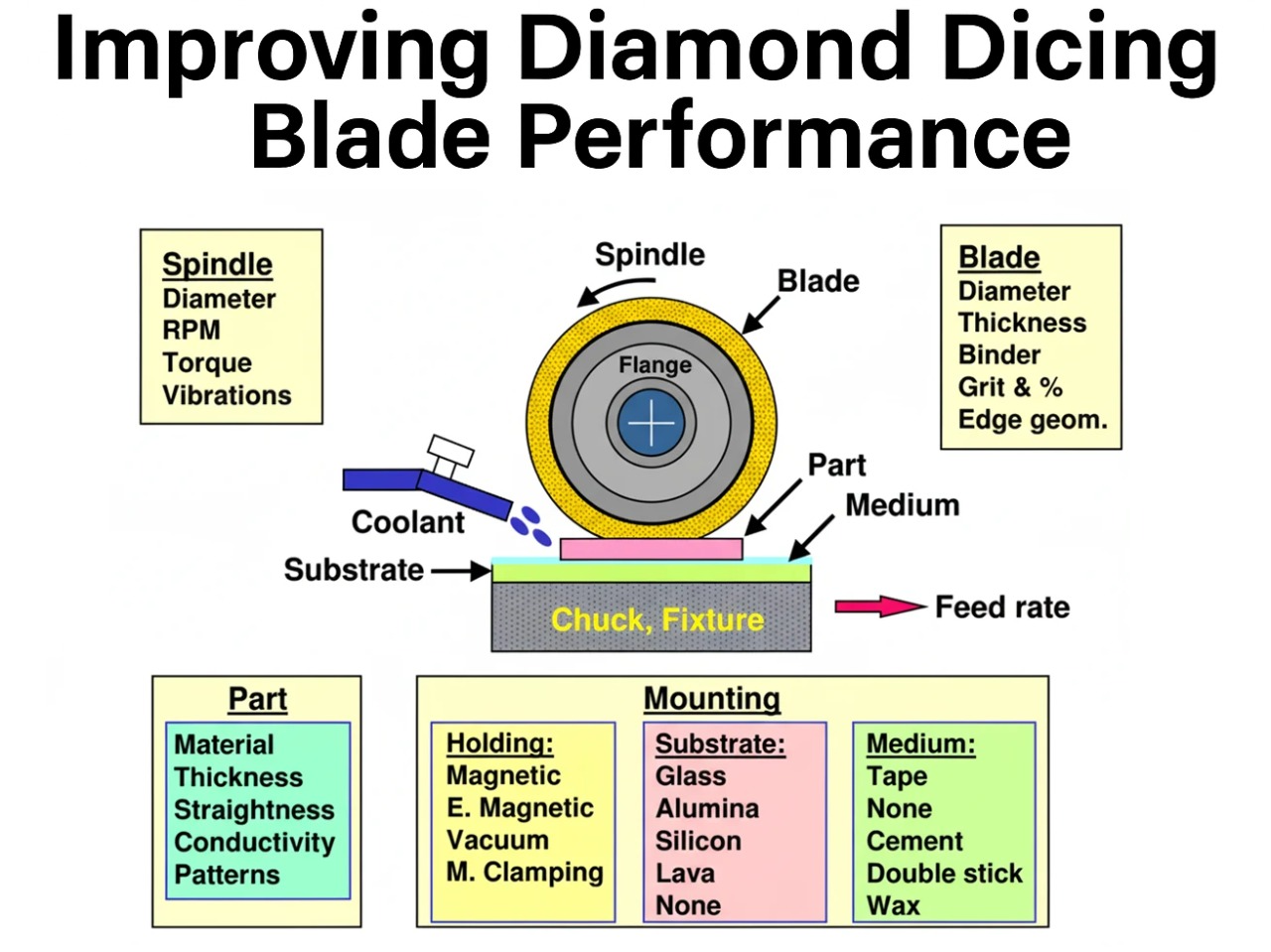

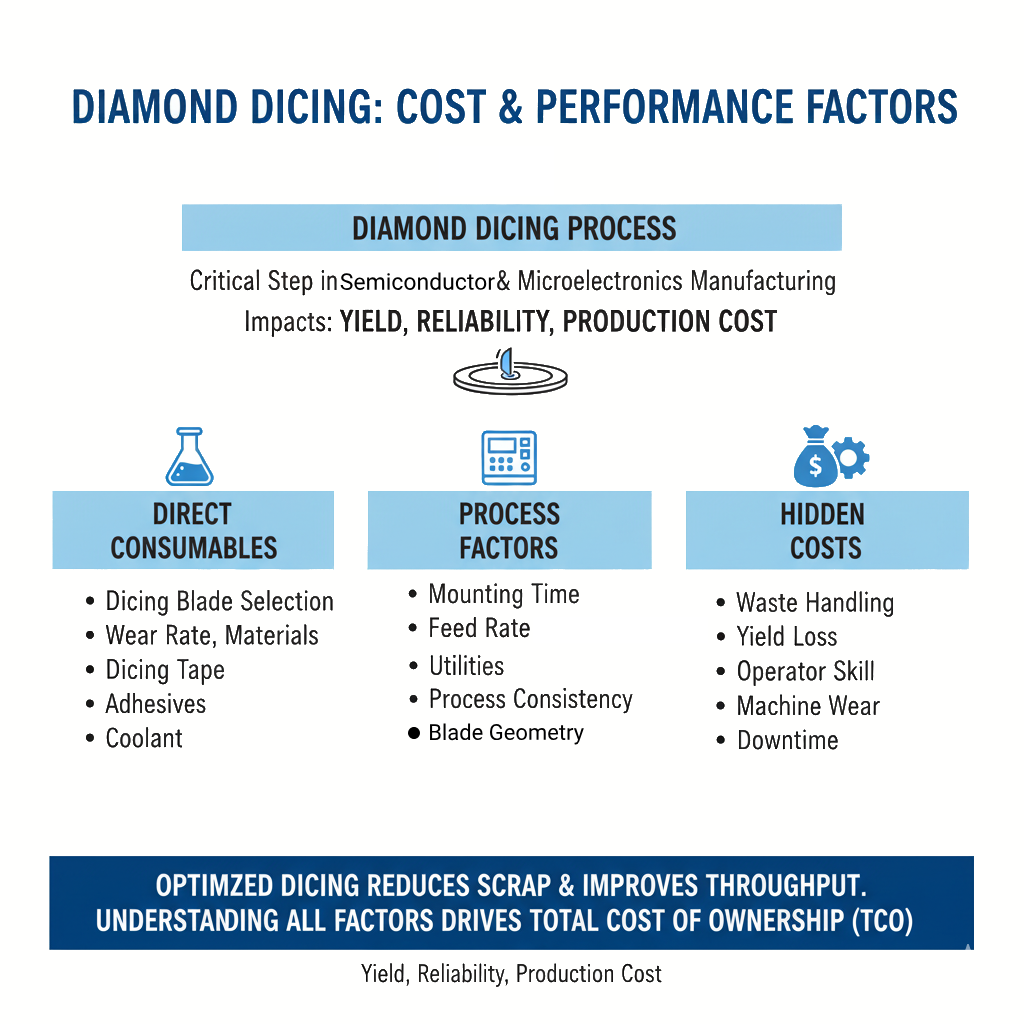

ToggleDiamond dicing is one of the most important step in semiconductor & microelectronics manufacturing package. Although the process itself does not add direct value to the finished device, it has a decisive impact on yield, reliability, and production cost. Every factor that affects dicing blade performance influences the economics of wafer processing. A well optimized dicing process can reduce scrap, extend blade life, and improve throughput. At the same time, poor control leads to frequent downtime, higher consumable costs, and unacceptable yield losses.

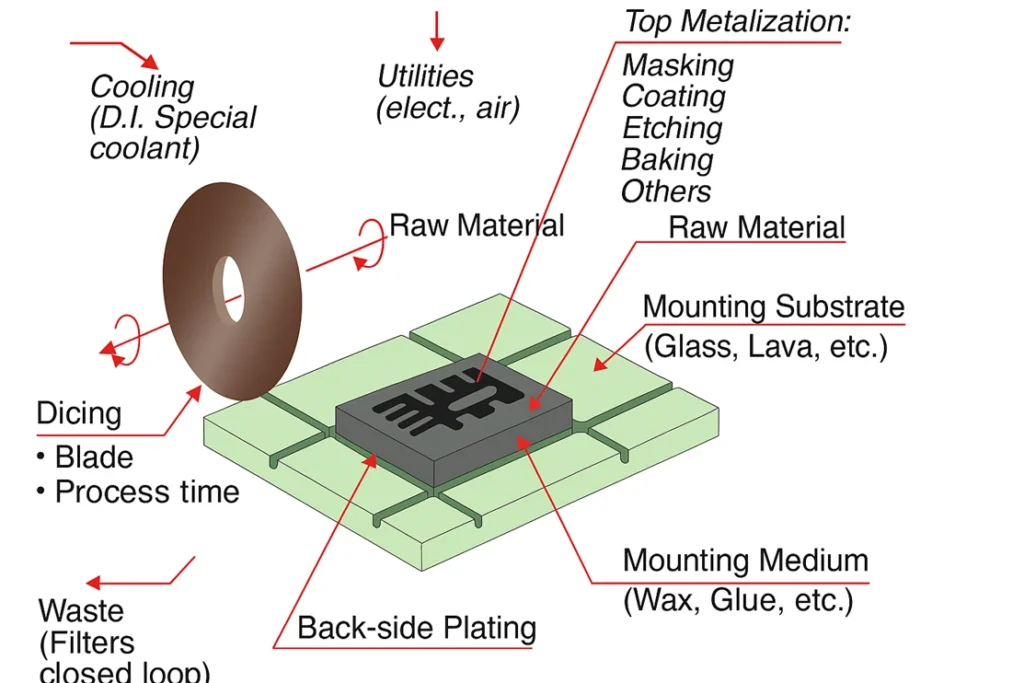

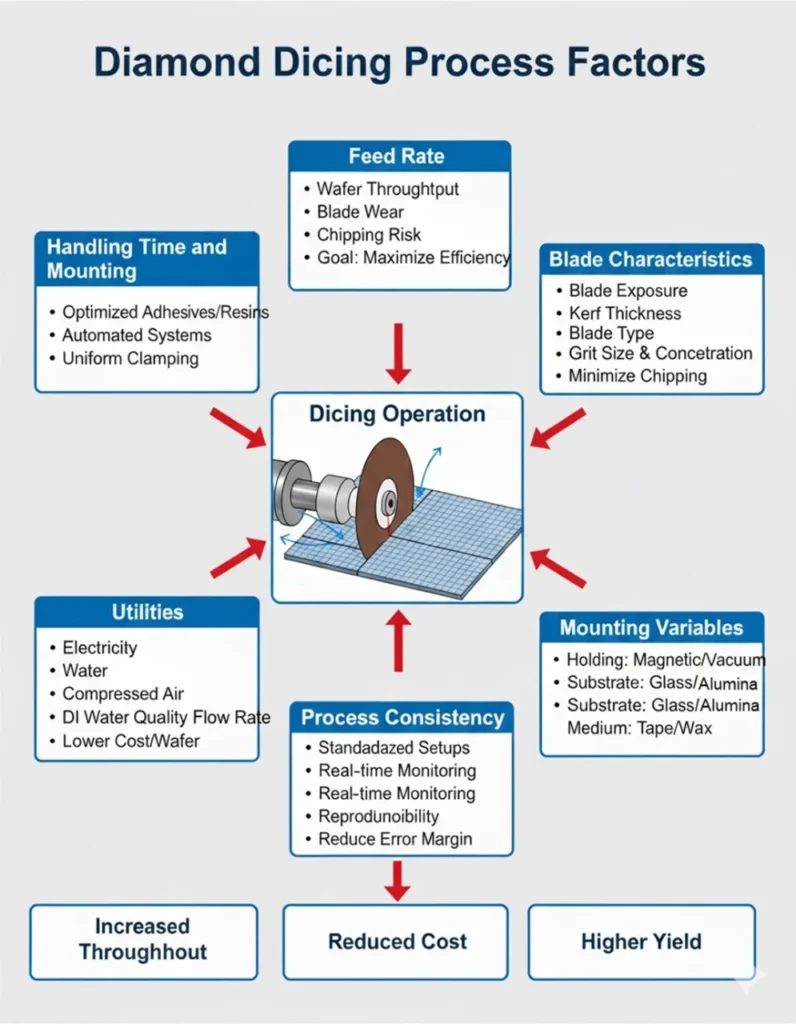

To truly improve diamond dicing blade performance, manufacturers must look beyond the blade alone. Success depends on understanding three interconnected areas: direct consumables, process factors, and hidden costs. Direct consumables such as dicing blade selection, wear rate, mounting materials, dicing tape, adhesives, and coolant account for much of the recurring expense. Process factors like mounting time, feed rate, blade geometry, utilities, and process consistency determine how efficiently wafers can be diced without compromising quality. Hidden costs such as waste handling, yield loss, operator skill, machine wear, and downtime often remain invisible but significantly affect the total cost of ownership

Equally important are the mechanics of dicing. Parameters such as spindle speed, feed rate, torque, and coolant flow directly shape cut quality. If not properly controlled, they result in front-side chipping, back-side chipping (BSC), misplacement, or contamination. Issues with cleanliness further affect downstream assembly, while even minor deviations in cut placement accuracy can drastically reduce usable die count. Maintaining wafer stability, proper coolant delivery, and controlled blade exposure are therefore essential for both yield and reliability.

Modern strategies for improving dicing performance rely on data driven process monitoring and optimization. Real-time torque monitoring allows operators to detect early signs of blade wear, excessive force, or coolant inefficiency, reducing the risk of wafer loss. Design of Experiments (DOE) methods identify which variables—such as grit size, bond type, coolant pressure, or feed rate have the greatest impact on outcomes. Together, torque monitoring and DOE provide a structured approach that replaces trial-and-error with predictable, repeatable process control.

Finally, dressing and process stability are critical for achieving consistent performance. Proper dressing ensures that cutting diamonds are exposed and stabilized from the start, preventing unpredictable variations. Maintaining stable torque values across runs indicates a controlled process, protecting both wafers and equipment. When combined with proactive maintenance and operator training, these strategies create a highly stable and efficient dicing operation.

This article presents a comprehensive framework for improving diamond dicing blade performance. By focusing on cost control, yield protection, process optimization, and monitoring, engineers can achieve higher throughput, longer blade life, and lower overall cost per good die. The goal is not only to cut wafers, but to build a process that is faster, cleaner, more consistent, and more profitable.

Diamond Dicing Process

| Category |

Parameter |

Explanation |

|---|---|---|

|

Blade Edge Design |

Blade cost (Initial Price) |

Purchase cost of the dicing blade. |

|

Blade wear |

Determines usable blade life and replacement frequency. |

|

|

Mounting material |

Waxes, resins, or adhesives used to secure workpieces. |

|

|

Dicing tape, rings, adhesives |

Recurring consumables needed for each operation. |

|

|

Coolant and filtration |

Type, concentration, flow rate, and filter maintenance. |

|

|

Process Factors |

Handling time of mounting |

Labor cost and setup time for wafers or substrates. |

|

Speed of the dicing process (Feed rate) |

Affects productivity, blade life, and chipping. |

|

|

Blade exposure, kerf thickness, geometry |

Controls stability, chipping, and usable blade life. |

|

|

Utilities |

Electricity, water, and compressed air used during dicing. |

|

|

Process consistency and reproducibility |

Ensures uniform cut quality and yield. |

|

|

Indirect / Hidden Costs |

Waste handling |

Collection, filtration, and disposal of debris/slurry. |

|

Yield losses and scrap |

Poor cut quality increases cost per part. |

|

|

Operator training and labor skill |

Skilled labor minimizes downtime and errors. |

|

|

Machine wear and maintenance |

Spindle bearings, vibration, and calibration affect cut quality and blade life. |

|

|

Downtime and changeover time |

Idle machine hours during blade changes or setup. |

|

|

Initial investment |

Cost of equipment purchase and installation. |

Direct Consumables Cost

When optimizing the dicing process, it is important to recognize that direct consumables represent a significant share of ongoing production costs. Their proper selection and management not only reduce operating expenses but also improve cut quality, blade life, and yield.

The first factor is the purchase cost of the dicing blade. While the initial price is important, the real cost lies in how long the blade maintains performance and how many wafers it can process before replacement. A blade that costs more but delivers longer life and cleaner cuts may ultimately reduce cost per wafer compared to a cheaper alternative that wears quickly or causes higher yield loss.

Blade wear determines usable blade life and replacement frequency. If wear occurs too quickly, operators must stop production more often to change blades, which reduces throughput and increases labor costs. Optimizing feed rate, spindle speed, coolant flow, and dressing schedules helps slow blade wear while maintaining stable torque. Selecting the right bond type, grit size, and concentration for the wafer material is equally important.

Dicing tape, rings, and adhesives are recurring items in every operation. Their quality affects wafer handling during mounting, cutting, and die separation. Inferior tape can release debris, cause uneven stress distribution, or make die pick-up difficult. Optimizing tape thickness, adhesion strength, and cleanliness improves both cutting precision and downstream processing.

Finally, coolant and filtration are essential for keeping the blade cool, flushing away debris, and preventing particle contamination. The type, concentration, and flow rate of coolant directly influence cut quality and blade life. Proper filtration ensures that silicon dust and slurry do not recirculate, which would otherwise damage wafers and accelerate blade wear. Maintaining clean filters and stable flow prevents torque fluctuations and contributes to process stability.

Optimizing these consumables as part of the dicing process leads to lower cost per good die, fewer stoppages for maintenance, and improved process consistency. Rather than focusing only on blade price, manufacturers must take a total cost of ownership perspective, where blade life, consumable quality, and process efficiency together define the economics of wafer dicing.

Process Factors

Optimizing the dicing process requires close control of the process factors that influence cost, throughput, and yield. Each stage of wafer handling and cutting introduces variables that, if not managed carefully, can lead to higher consumable use, lower productivity, or increased yield loss.

One of the first considerations is the handling time of mounting. Every wafer or substrate must be properly secured before cutting. If mounting takes too long, labor costs rise, and machine utilization falls. Inconsistent mounting also introduces stress and misalignment, which directly reduce cut accuracy. Using optimized adhesives, resins, or automated mounting systems can reduce handling time and ensure uniform clamping, thereby lowering variation in cut placement.

The speed of the dicing process, defined by the feed rate, is the main driver of productivity. A higher feed rate increases wafer throughput, but it also accelerates blade wear and raises the risk of chipping. If feed rate is set too conservatively, throughput suffers and blade life may be wasted. Process optimization requires finding the highest possible feed rate that still preserves cut quality and keeps blade torque within limits. This balance ensures maximum efficiency without sacrificing yield.

Blade exposure, kerf thickness, and geometry all have a strong impact on stability and cut quality. Longer blade exposure increases vibration and decreases stability, while thicker blades reduce die count. Optimizing exposure to the minimum necessary and selecting kerf geometry matched to street width minimizes chipping and extends usable blade life. A stable, well-supported blade cuts cleaner and lasts longer, reducing both consumable costs and wafer scrap.

Utilities such as electricity, water, and compressed air also contribute to process cost. Blades that cut inefficiently require more spindle torque and higher coolant flow, which increases power consumption and coolant demand. Optimizing blade sharpness, grit size, and coolant delivery reduces utility usage, lowering cost per wafer while improving environmental sustainability.

Finally, process consistency and reproducibility are crucial for yield optimization. Even if parameters are optimized for a single run, inconsistency between wafers, operators, or shifts undermines results. Standardizing setups, monitoring torque and spindle load, and maintaining coolant systems ensure that the same conditions are reproduced every time. This consistency allows the process to run closer to its performance limits with less margin wasted on error correction.

When all of these process factors are optimized together, the result is a dicing operation that runs faster, produces cleaner cuts, extends blade life, and reduces overall cost per good die. The challenge for process engineers is to treat each factor not in isolation but as part of a controlled system where changes in one variable are balanced by adjustments in others to maintain stability and maximize yield.

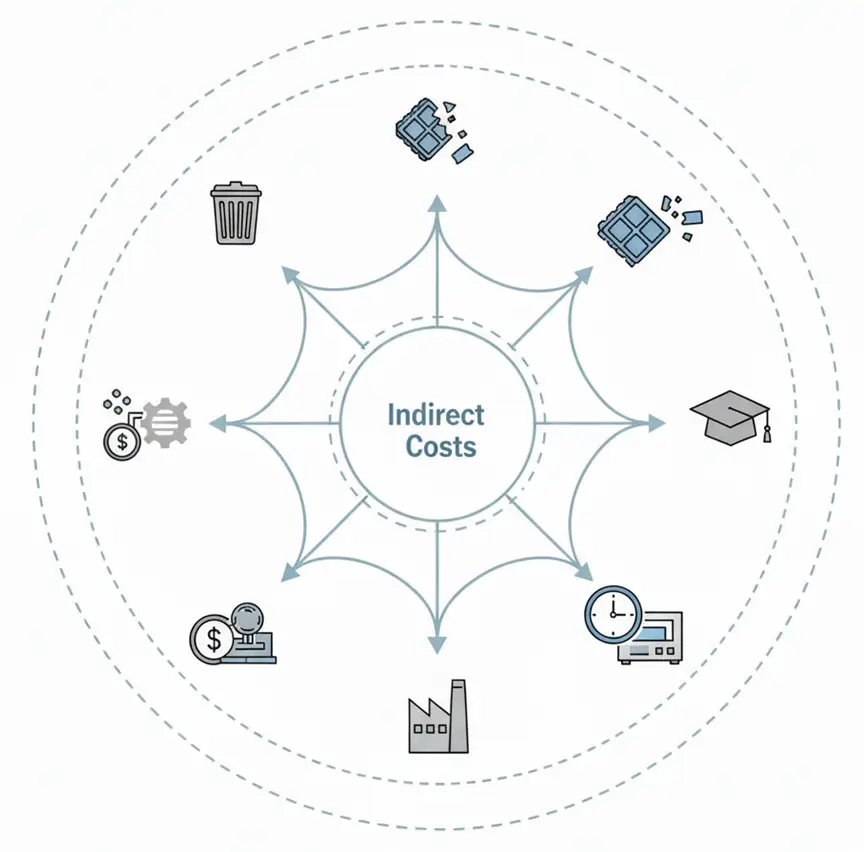

Indirect Costs

In addition to direct costs like blades and consumables, indirect or hidden costs play a major role in determining the overall efficiency and profitability of a dicing operation. These costs are often overlooked, yet they have a direct impact on total cost of ownership and long-term process optimization.

One of the first hidden costs is waste handling. Every wafer cut generates debris, slurry, and particles that must be collected, filtered, and disposed of properly. Inefficient waste handling increases downtime, contaminates the work environment, and raises maintenance costs for pumps and filters. Optimizing coolant filtration systems and scheduling filter replacement at the right intervals reduces these expenses and prevents contamination-related yield losses.

Yield losses and scrap represent the most expensive hidden cost. Every die lost due to poor cut quality, misplacement, or excessive chipping increases the cost per functional die. Even a small percentage of yield loss, multiplied across thousands of wafers, translates into significant financial impact. By optimizing blade selection, feed rate, spindle speed, and coolant conditions, engineers can reduce chipping and misalignment, ensuring that more dies survive the process and lowering the effective cost per unit.

Operator training and labor skill also contribute to indirect cost. A skilled operator minimizes downtime by quickly diagnosing issues, performing blade changes efficiently, and keeping the process within control limits. In contrast, insufficiently trained operators increase the likelihood of misalignment, over-dressing, or improper coolant setup. Investment in training programs pays back in fewer errors, improved consistency, and higher machine utilization.

Machine wear and maintenance are another area of hidden expense. Spindle bearings, guide rails, and vibration control systems degrade over time. Poor blade choice or unstable cutting parameters accelerate wear, leading to higher repair costs and calibration requirements. Optimizing dicing parameters not only protects wafers but also reduces stress on machine components, extending their service life and reducing unplanned downtime.

Downtime and changeover time are major contributors to cost. Every blade change, dressing cycle, or machine recalibration represents lost production. If these events occur too frequently due to suboptimal process setup, throughput declines and labor costs rise. Establishing stable process conditions and optimizing blade life reduces the frequency of interruptions and maximizes machine availability.

Finally, initial investment in equipment purchase and installation must be considered within the optimization framework. While high-precision dicing machines may cost more up front, they often pay for themselves through improved accuracy, reduced chipping, and lower long-term consumable use. Evaluating equipment not only on initial price but also on its ability to deliver consistent process stability and reduced hidden costs is key to true process optimization.

When these indirect and hidden costs are managed proactively, the dicing process becomes more predictable, efficient, and cost-effective. Optimization efforts should therefore focus not just on direct expenses but on the total cost of ownership, where waste handling, yield, training, maintenance, downtime, and investment decisions all interact to determine the final cost per good die.

Dicing throughput is dependent on the rate at which the wafer substrate is fed into the cutting blade. The major limitations on feed rate are the formation of chipping and yielding of the blade. To determine the maximum feed rate without exceeding these limitations, a special monitoring method is recommended. The parameter monitored is the torque applied on the blade.

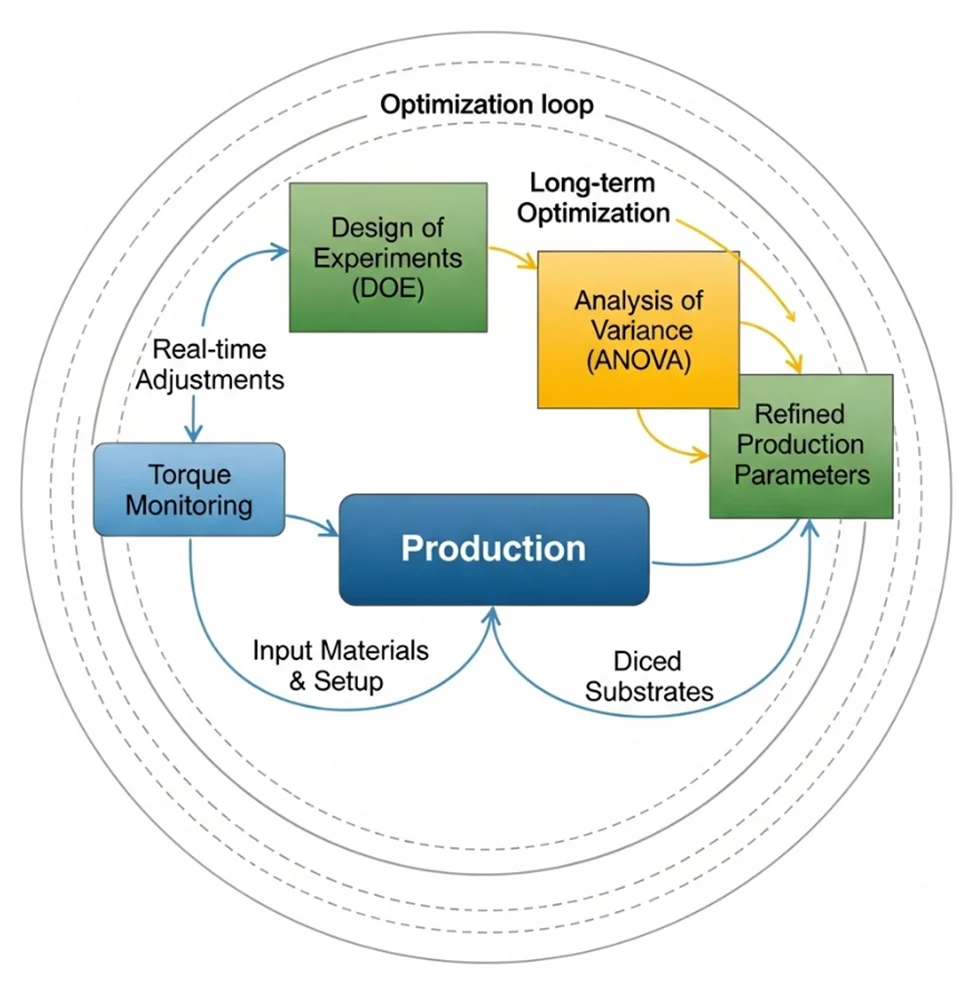

Another tool crucial for process optimization is the Designed Experiment or Design of Experiment (DOE) method. DOE is an alternative to the trial and error loop often used for process optimization. This article explains the advantages of using DOE in combination with torque data to determine the major factors affecting the wafer dicing process.

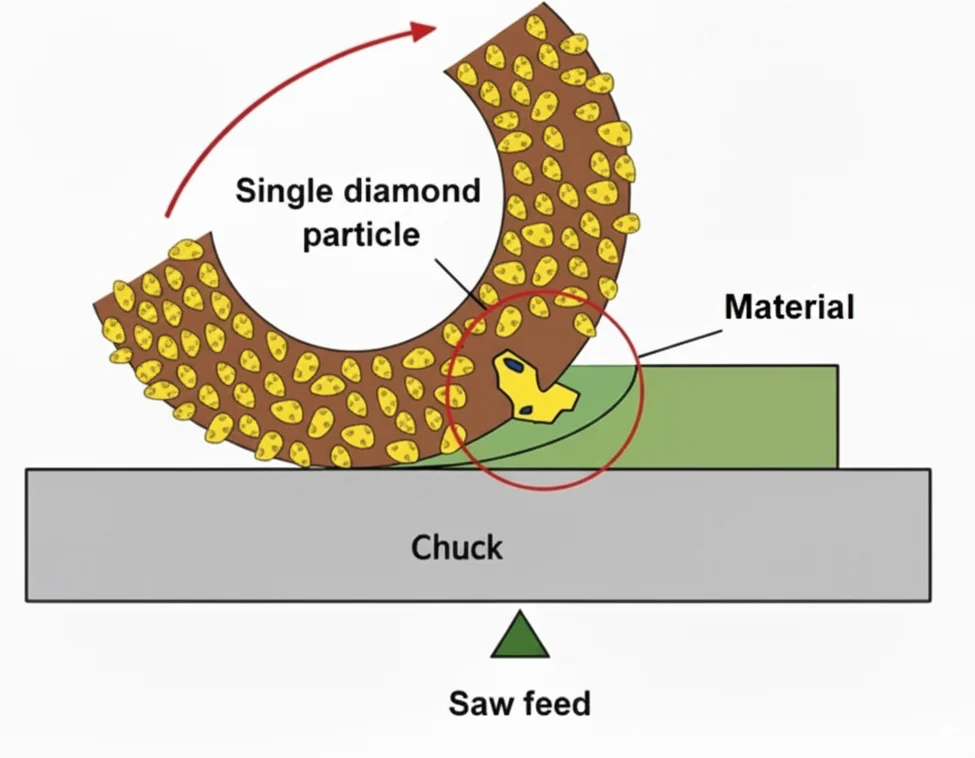

The Mechanism of Dicing

During the silicon wafer dicing process, the wafer is divided into single units, or dice. A rotating abrasive disc (blade) performs the dicing, while a spindle at high speed, 30,000 to 60,000 rpm (linear speeds of 83 to 175 m/sec) rotates the blade. The blade is made of diamond abrasive grit embedded in an electroplated nickel matrix, which acts as the binder.

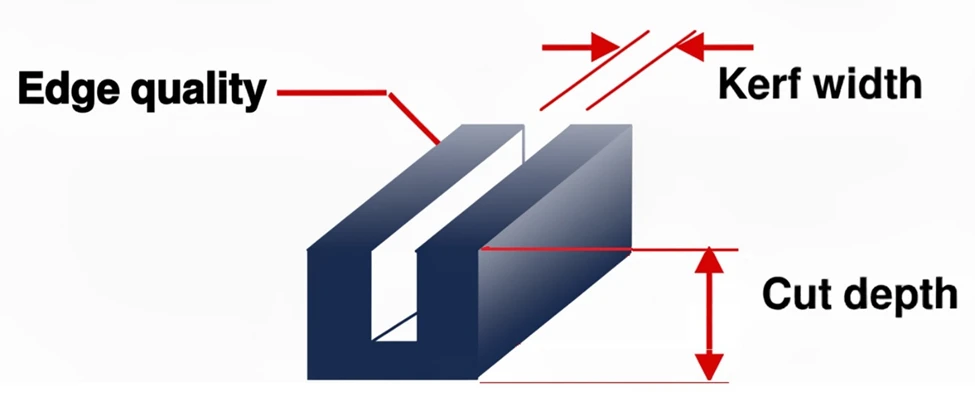

During the separation of dice, the blade crushes the substrate material and removes debris simultaneously. Material removal occurs along dedicated dicing lines (streets) between the active areas of the dice. As the blade advances along these streets, it forms a groove in the substrate. The groove width (kerf) is directly proportional to the thickness of the blade.

The throughput of the dicing process is measured by the number of wafers diced per hour. The feed rate the speed at which the blade advances along the substrate determines throughput. The higher the feed rate, the higher the throughput. To achieve maximum dicing yield and productivity, the dicing system must operate at the highest throughput possible within process quality limits.

The optimal dicing process is the one that maintains the highest feed rate without sacrificing cut accuracy, producing excessive chipping, breaking the blade, or shortening blade life. Proper selection of parameters ensures both efficiency and quality, allowing manufacturers to balance speed, yield, and blade longevity.

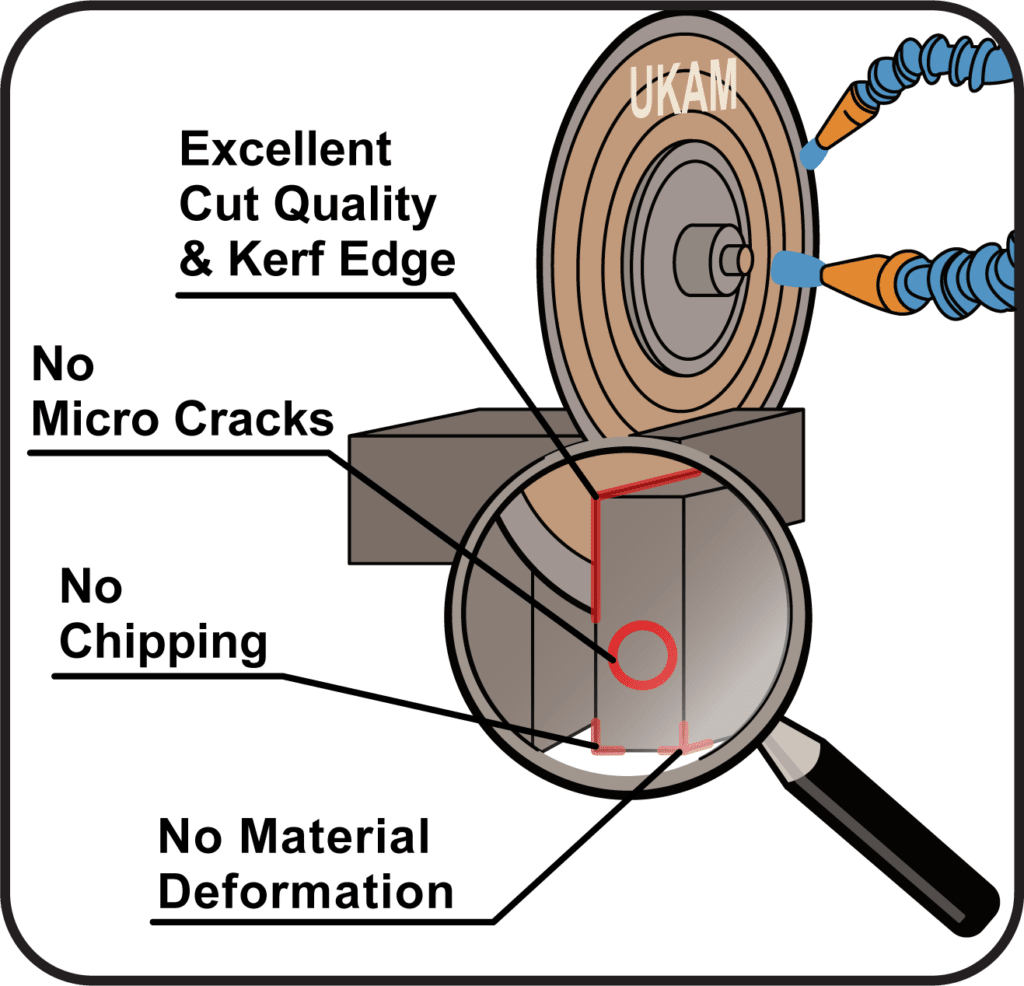

Cut Quality

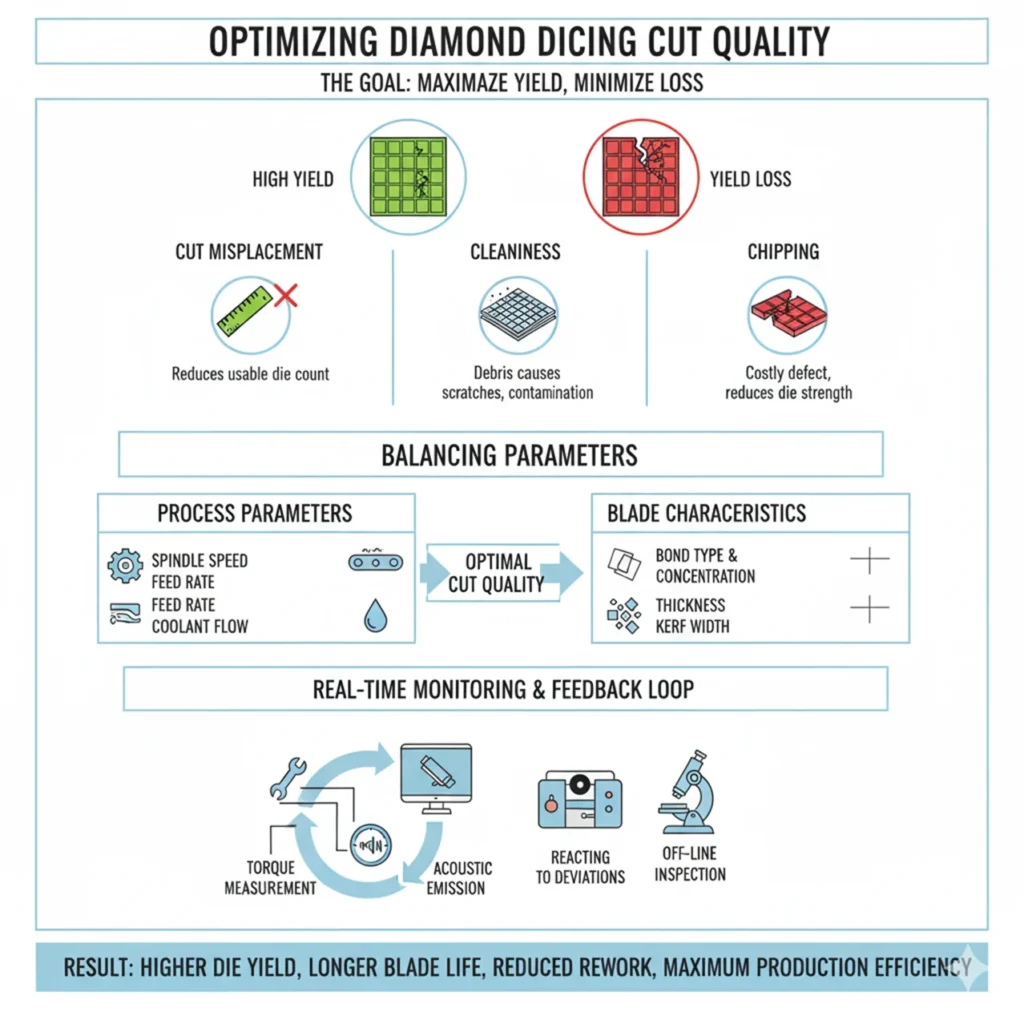

Cut quality is one of the most critical factors in optimizing diamond dicing blade performance. Dicing itself does not add value to the finished device; instead, its value lies in preserving the integrity of the wafer and ensuring that each die is free from defects. For this reason, the quality of the dicing process is measured by the yield loss it may cause, and process optimization is focused on minimizing this loss.

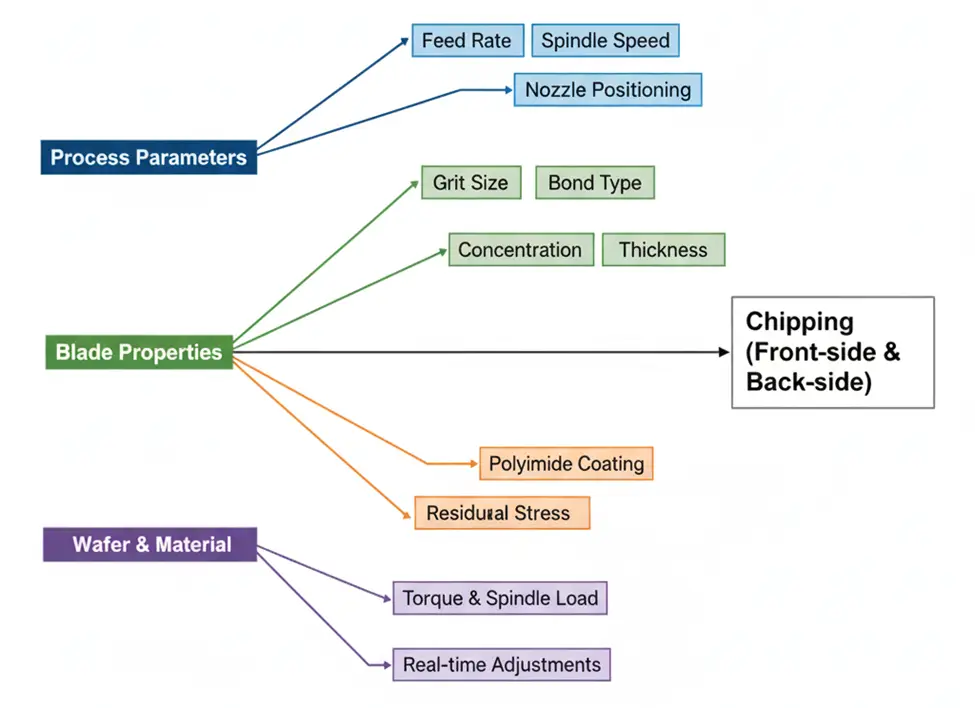

The main contributors to yield loss are cut misplacement, cleanliness, and chipping. Even small deviations in cut placement can reduce the usable die count per wafer. Poor cleanliness leads to debris accumulation, which can scratch active areas and increase the risk of contamination. Chipping, both on the top side and back side, is the most visible and costly defect. Excessive chipping reduces die strength, compromises reliability, and often renders entire sections of the wafer unusable.

Optimizing for cut quality requires balancing process parameters such as spindle speed, feed rate, and coolant flow with the blade characteristics including bond type, grit size, concentration, and thickness. The kerf width must be controlled precisely, since excessive kerf reduces die count, while insufficient kerf may cause incomplete separation or wafer breakage. Equally important is maintaining sharp diamonds on the blade surface through proper dressing and monitoring, ensuring that the cut is clean and consistent.

Real-time process monitoring can further enhance cut quality. Torque measurement, acoustic emission monitoring, and spindle load data can all provide early indications of conditions that lead to chipping. By setting threshold values and reacting to deviations immediately, operators can prevent defects before they spread across the wafer. Off-line inspection should complement these methods to calibrate the monitoring system and confirm long-term process stability.

Ultimately, optimizing cut quality in diamond dicing means running the process at the highest possible feed rate and throughput without compromising accuracy or increasing chipping beyond acceptable limits. Every adjustment in process parameters must be evaluated in terms of its effect on die yield. When properly optimized, cut quality improvements not only increase yield but also extend blade life, reduce rework, and maximize overall production efficiency.

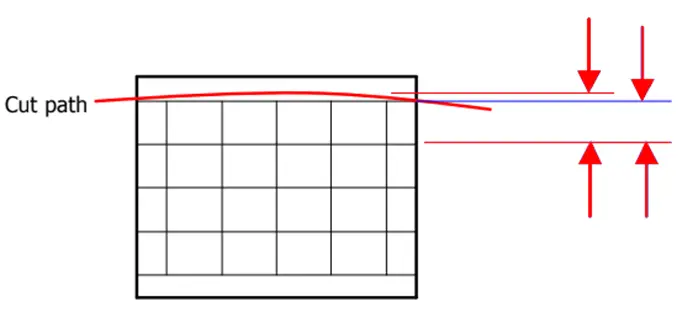

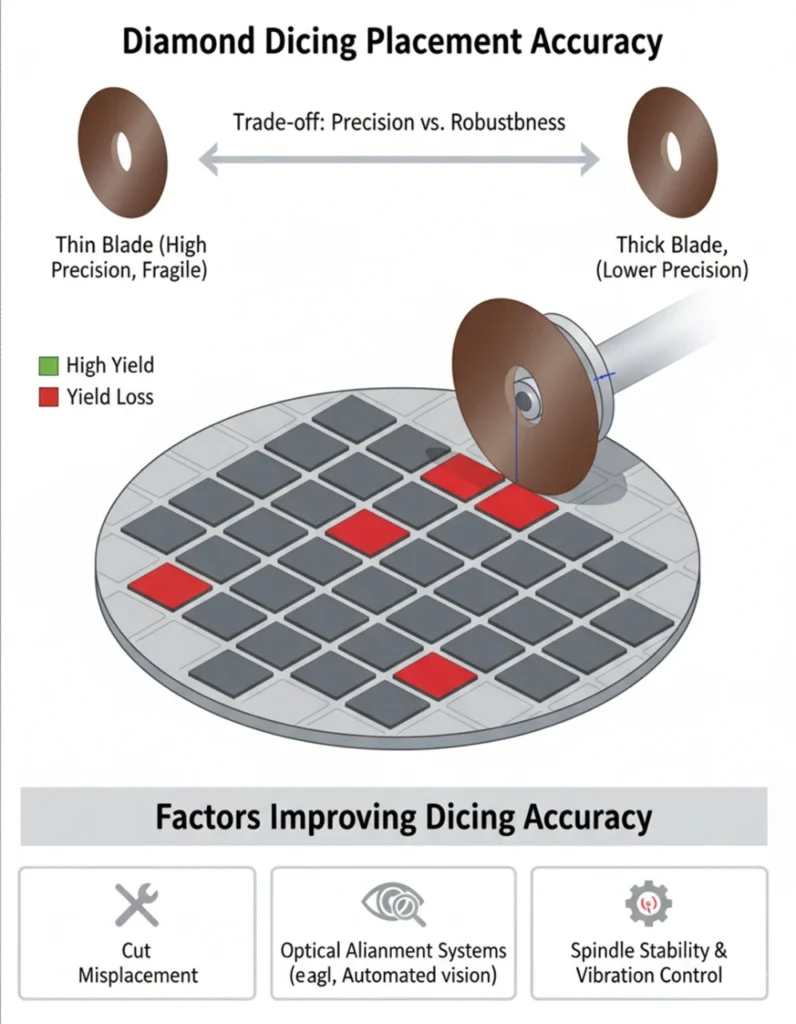

Cut Placement Accuracy

Cut placement accuracy is one of the most important parameters in achieving consistent dicing yield. As wafers continue to shrink in design rules and incorporate more dies per wafer, the available street width has become narrower. For wider streets, typically 70 to 100 µm or more, most standard dicing systems are sufficient. However, for narrow-street wafers, where available streets are often less than 70 µm, the process demands extremely precise placement of each cut, often within just a few microns of the street center.

This level of precision requires high indexing axis accuracy, capable of repeatedly positioning the blade with minimal error. It also demands high optical magnification to clearly resolve alignment marks and street edges, as well as advanced alignment algorithms that can automatically correct for wafer distortion, warpage, or expansion. Without these capabilities, even minor misplacement results in kerf overlap into active die areas, leading directly to yield loss.

A common recommendation for dicing narrow-street wafers is to use the thinnest possible blade in order to preserve maximum die count. However, this introduces its own trade-offs. Very thin blades, especially those 20 µm or less, are mechanically weaker and more prone to premature breakage, deflection, or accelerated wear. The reduced stiffness of ultra-thin blades can also affect cut straightness and stability during long runs. For this reason, the recommended blade thickness for 50 to 76 µm streets is generally 20 to 30 µm, which balances die count with blade strength and process reliability.

The optimization of cut placement accuracy is best understood as a relationship between several interacting factors. The formula presented, where W = street width, P = cut placement factor, K = kerf width factors, and s = standard deviations—captures how blade width, placement accuracy, and process variation combine to determine whether the process can consistently achieve the required results. A tighter street width requires not only thinner blades but also lower standard deviation in cut placement, which in practice means better machine precision, optimized clamping, and stable environmental conditions.

From a process optimization perspective, improvements in cut placement accuracy can be achieved by focusing on several areas. Machine calibration must be performed regularly to ensure that indexing accuracy remains within specification. Optical systems should be set up with appropriate magnification and illumination to clearly define the cutting path. The choice of blade should consider not only thickness, but also bond type, grit size, and concentration, all of which influence how stably the blade tracks the cutting line. Additionally, coolant delivery and spindle stability play a role in preventing blade deflection, which can compromise placement accuracy.

Ultimately, cut placement accuracy is a balancing act. Thinner blades maximize die yield but require higher machine precision and tighter process control. Thicker blades offer more robustness but reduce the number of usable dice per wafer.

Cleanliness

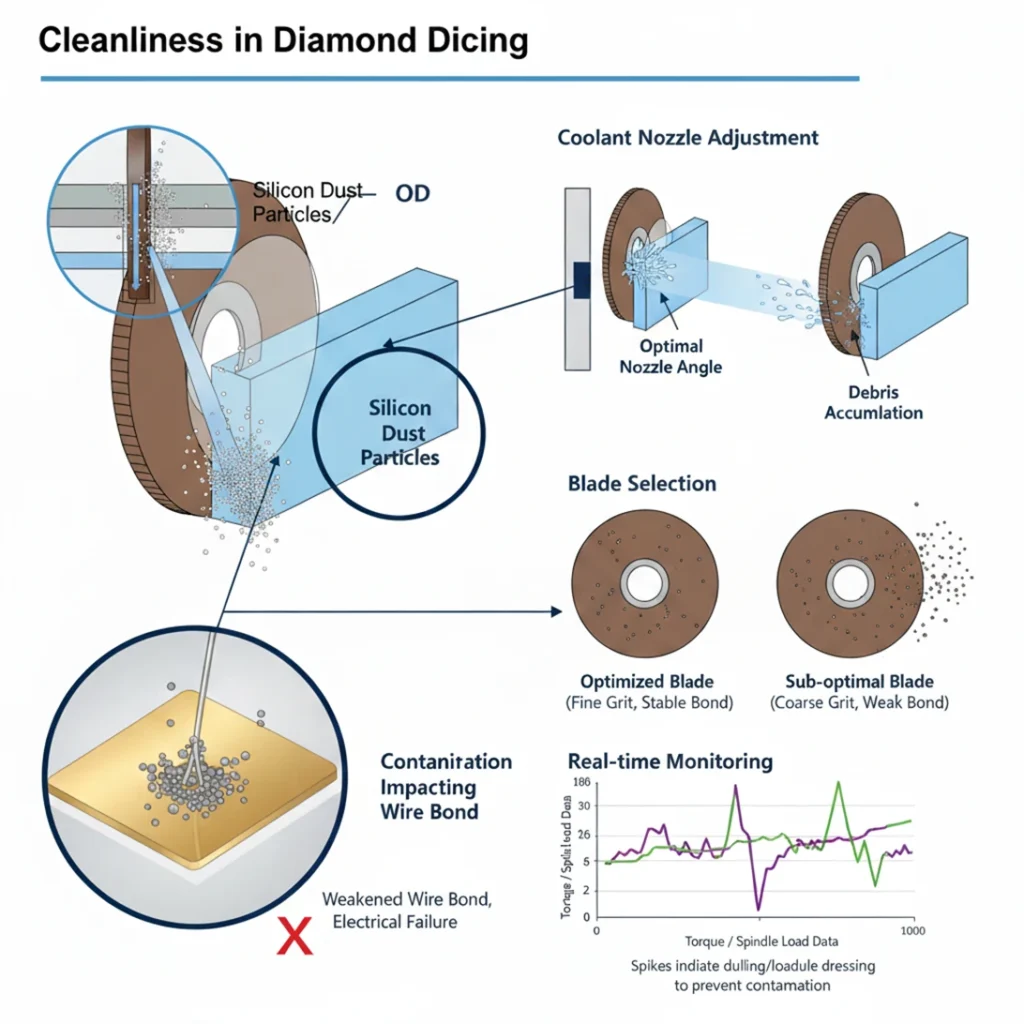

Cleanliness is a critical factor in diamond dicing blade process optimization because it directly affects downstream assembly and long-term device reliability. After dicing, silicon dust residue often remains on the wafer surface and terminal pads. This dust is highly problematic because it can reduce the strength and reliability of wire bonds, leading to electrical failures during device operation. Once silicon particles have settled on the pads, they are often difficult to remove completely, even with high-pressure cleaning operations, which makes prevention far more effective than correction.

To optimize cleanliness, process engineers must ensure proper blade cooling and precise coolant nozzle adjustment. Correct coolant flow has two primary functions: first, it reduces blade and wafer temperature, preventing thermal stress that can worsen particle adhesion; second, it flushes away debris from the kerf in real time, minimizing the chance that particles redeposit on sensitive surfaces. Even small deviations in nozzle angle or flow rate can cause particles to accumulate, so nozzle alignment and maintenance should be part of routine setup.

Beyond coolant control, blade selection also influences cleanliness. A blade with the wrong bond type, grit size, or concentration may generate excess debris or create fine particles that are more likely to stick to wafer surfaces. Optimized blade specifications can help produce cleaner cuts with less dust generation, improving both process consistency and yield.

Real-time monitoring further enhances cleanliness. Torque or spindle load sensors can indicate when the blade begins to dull or load with debris, signaling a higher risk of particle buildup. By using this data to schedule dressing or blade changes at the right time, operators can maintain stable cutting conditions and prevent unnecessary contamination.

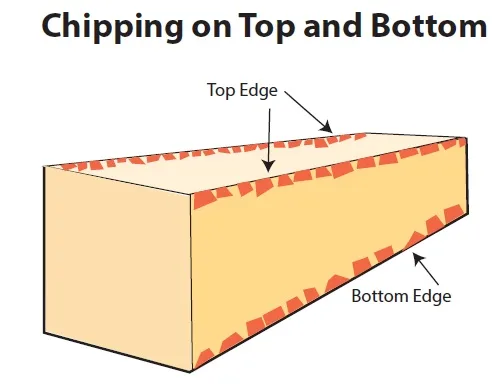

Chipping

Chipping is one of the most common and damaging forms of unnecessary contamination in the dicing process, and optimizing diamond dicing blade parameters is the key to controlling it. Chipping can occur on either the front (top) surface or the back (bottom) surface of the wafer. Front-side chipping is critical because it can extend into the active die area, directly reducing usable yield. The extent of front-side chipping is strongly influenced by blade grit size, coolant flow, and feed rate. Coarser grits and higher feed rates tend to increase chipping, while insufficient coolant flow fails to remove debris and heat, further worsening chip formation.

Back-side chipping (BSC) is an even more persistent challenge. It occurs when micro-cracks propagate from the bottom of the cut and join together into larger chips. As the blade interacts with the substrate, a network of micro-cracks develops, and once connected, pieces of the substrate are pulled away. This not only reduces yield but also impacts long-term device reliability. When micro-cracks exceed critical lengths, devices become more sensitive to thermal cycling and mechanical stress. Flip-chip packages are particularly vulnerable, as the back side of the die is directly exposed to molding material. Cracked or chipped edges can lead to voids or air bubbles in the molding compound, which may then form weak points that cause mold cracking during packaging.

BSC becomes more severe in polyimide-coated wafers, wafers with heavy metal layers in the streets, or wafers that have undergone extensive back-grinding, which introduces residual tensile stress at the wafer’s bottom surface. Because wafer material and design are fixed variables in most production environments, the main tools available to process engineers are blade selection and parameter optimization.

Process optimization involves carefully choosing the right blade bond type, grit size, concentration, and thickness for the wafer being diced. A blade that is too hard may increase micro-crack formation, while a blade that is too soft may wear prematurely and generate unstable cuts. Feed rate and spindle speed must be balanced so the blade removes material efficiently without overloading the substrate. Coolant flow and nozzle positioning are equally important, as they help reduce heat, flush away debris, and limit crack propagation.

Monitoring plays a crucial role in optimization. Torque and spindle load measurements can provide early warning signs of blade dulling or excessive force, both of which increase chipping risk. By adjusting feed rates or scheduling blade dressing based on real-time data rather than fixed intervals, engineers can prevent unnecessary contamination before it occurs.

Process Optimization

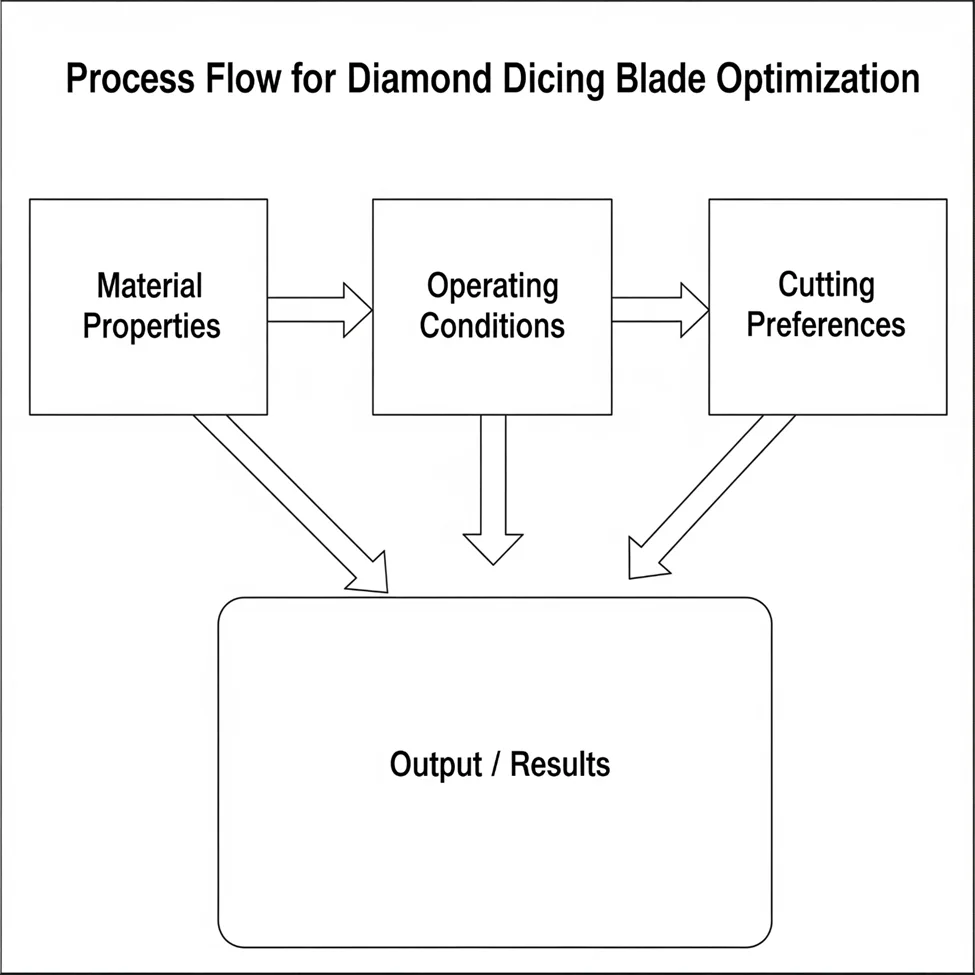

Process optimization in diamond dicing is the systematic effort to balance throughput, cut quality, and blade life. The goal is to achieve the highest possible feed rate without inducing chipping or exceeding blade limitations. Since dicing itself does not add direct value, the process is only as good as the yield it preserves and the efficiency it delivers. Optimizing parameters ensures that wafers are cut cleanly, dice remain strong, and production schedules are met.

Throughput is driven primarily by the feed rate, which in turn depends on spindle speed, blade design, and wafer properties. A higher spindle speed allows for faster feed rates, but the process window is limited by blade rigidity, grit size, bond type, and coolant effectiveness. Pushing feed rate too far leads to front-side and back-side chipping (BSC), which directly reduces yield. The challenge is not simply to run fast, but to find the combination of parameters that keeps speed high while maintaining clean, accurate cuts.

One of the most effective tools in optimization is blade torque monitoring. Every process parameter spindle speed, feed rate, coolant delivery, blade type, wafer hardness correlates with the torque measured at the spindle. When torque rises above a certain threshold, chipping begins to appear, especially BSC. By establishing torque limits for each wafer type and blade, engineers can adjust process settings in real time to ensure that torque stays below the critical level. This method allows operators to run at the maximum safe feed rate without relying on guesswork or over-conservative margins.

Experimental validation is required to fine-tune parameters. However, testing each variable separately consumes too many wafers and machine hours. This is where Design of Experiments (DOE) becomes essential. DOE provides a structured approach to test multiple variables simultaneously in a reduced number of experiments. By arranging variables such as blade thickness, spindle speed, feed rate, and coolant pressure in a test matrix, engineers can measure their combined impact on responses like chipping and kerf quality.

Once test data is collected, Analysis of Variance (ANOVA) identifies which parameters have the strongest influence on the outcome. For example, DOE may reveal that coolant flow has a stronger effect on reducing BSC than grit size within a certain blade series, or that feed rate adjustments contribute more to yield improvements than spindle speed once a minimum RPM is achieved. This clarity allows resources to be focused on the most impactful factors rather than trial-and-error testing.

The combination of torque monitoring, DOE testing, and statistical analysis creates a feedback loop for process optimization. Torque data provides real-time insight into process stability. DOE and ANOVA identify the variables most responsible for yield loss. Together, they guide blade selection, feed rate tuning, coolant optimization, and dressing schedules. This systematic approach ensures that the dicing process operates at peak throughput while preserving die integrity and minimizing unnecessary blade wear.

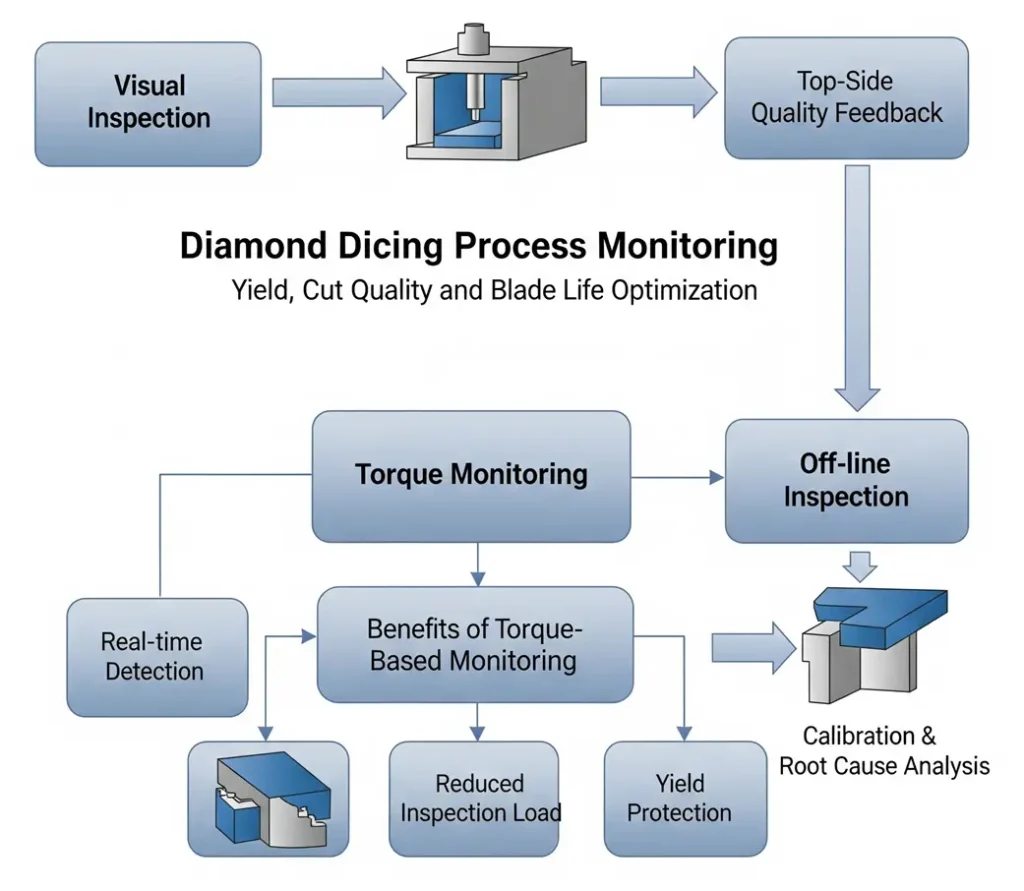

Process Monitoring in Diamond Dicing

Effective process monitoring is critical for maintaining yield, ensuring cut quality, and extending blade life in semiconductor dicing. Because diamond blades operate at high speeds and cut fragile substrates, even small process variations can lead to back-side chipping (BSC), misalignment, or premature blade wear. Monitoring helps operators detect deviations in real time and take corrective actions before defects spread across an entire wafer batch.

Visual Inspection –The most common practice is on-line visual inspection of the wafer’s top side. Operators check cut position accuracy and observe the degree of chipping visible at the kerf edges. While this provides immediate feedback on top-side quality, it does not reveal back-side defects. Since back-side chipping can significantly reduce die strength, additional off-line inspections are usually necessary.

Back-Side Chipping (BSC) Detection – BSC monitoring traditionally requires the wafer to be removed from the machine and inspected under a microscope or metrology system. This adds inspection time and can delay corrective action. To address this, manufacturers are adopting on-line BSC monitoring techniques that provide earlier detection. One practical solution is torque measurement.

Torque Monitoring – The torque generated by the blade during cutting reflects changes in key factors such as:

- Substrate hardness and thickness

- Blade sharpness and wear condition

- Feed rate and spindle speed

- Coolant flow and lubrication efficiency

- Mounting stability of the wafer

When torque values remain within a predefined control range, the process is considered stable. A rise in torque often indicates increasing blade resistance, which can precede higher levels of chipping or blade damage. By defining acceptable torque thresholds, operators can:

- Detect early signs of BSC

- Monitor blade wear progression

- Adjust cutting parameters (feed rate, spindle speed, coolant) in real time

- Prevent catastrophic blade failure

Benefits of Torque-Based Monitoring

- Real-time detection: Alerts operators immediately when cutting conditions drift outside the optimal window.

- Reduced inspection load: Limits the need for frequent off-line checks, saving time and labor.

- Yield protection: Prevents large-scale wafer loss by flagging deviations before defects accumulate.

- Data-driven optimization: Torque trends over multiple runs help refine blade selection, mounting methods, and process parameters.

Complementary Role of Off-line Inspection – Even with advanced on-line monitoring, off-line inspection remains essential. It serves as a calibration method for torque thresholds and confirms the root cause of deviations. A hybrid strategy that combines on-line torque monitoring with periodic off-line inspections ensures both speed and accuracy in quality control.

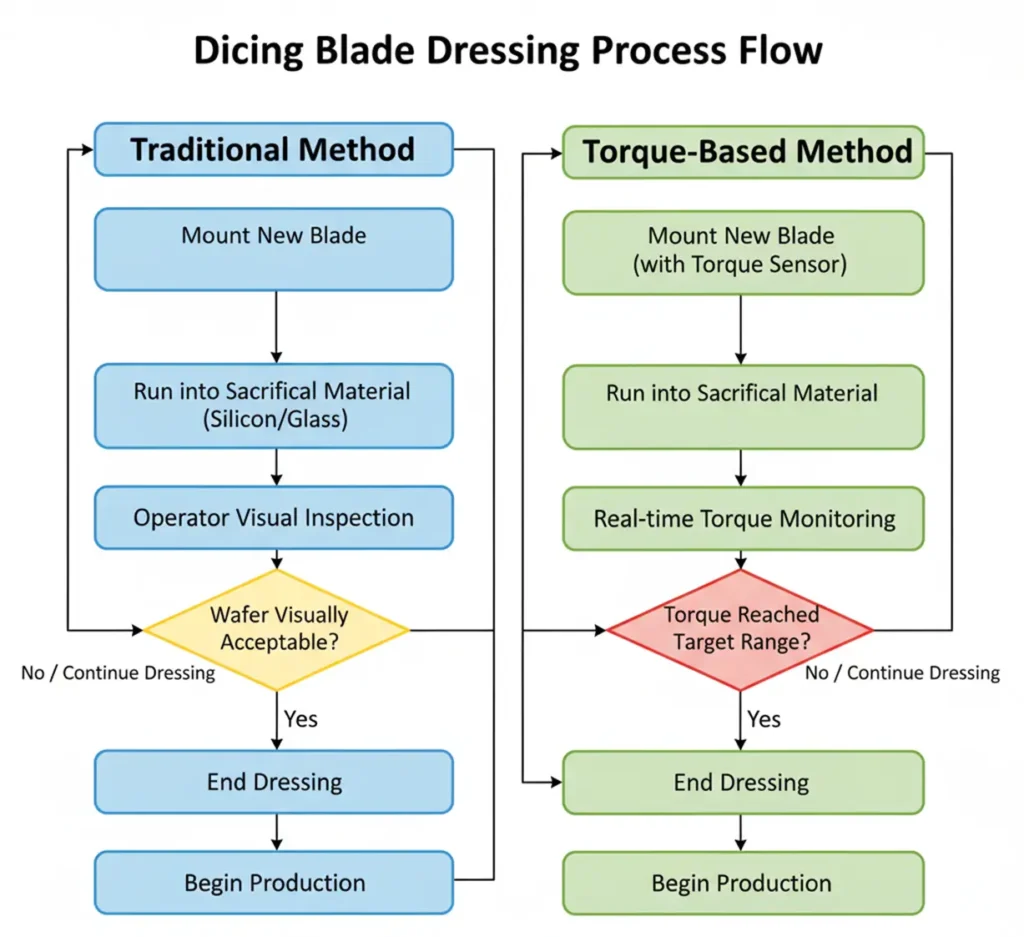

Dressing

Dressing is an essential step in preparing a new dicing blade for production. It conditions the blade so that diamonds are properly exposed and ready for continuous cutting. Without this step, the blade may cause unpredictable cut quality, poor surface finish, or chipping. When a blade is first mounted, the bond material often covers part of the cutting diamonds. Dressing removes this excess bond layer and allows sharp diamonds to take part in the cutting process. This stabilizes performance and reduces sudden variations during the first wafer runs.

Traditionally, dressing is performed by running the blade into a sacrificial material such as silicon or glass. The process starts at a low feed rate and gradually increases until the operating feed rate is reached. Operators usually determine the dressing duration by inspecting the wafer after cutting. If the dressing time is too short, diamonds remain embedded in the bond and cutting performance is inconsistent. If the dressing time is extended as a safety margin, it consumes machine time and shortens blade life. This method often relies on operator judgment and experience, which introduces variability and reduces productivity.

The main challenge with dressing is its time-consuming and uncertain nature. Because the exact mechanism of blade stabilization is not fully understood, many facilities use extra dressing cycles to ensure quality. This affects throughput and reduces the number of wafers that can be processed per shift. In high-volume production, even small reductions in dressing time can lead to significant gains in output.

One of the most effective ways to optimize dressing is through torque monitoring. The torque generated by the blade during dressing reflects the resistance it encounters in the material. As the blade stabilizes, torque values follow a predictable pattern. By establishing a reference torque profile for each blade and material, operators can stop the dressing process once the target range is reached. This eliminates guesswork and ensures that the blade is ready for production at the earliest possible point.

Using torque-based dressing provides several advantages. It reduces the need for excessive dressing time, improves consistency between operators, and ensures that blades begin production in a stable condition. It also prevents under-dressing, which often results in excessive chipping during the first cuts. Over time, data from torque monitoring can be used to refine process parameters, improve yield, and extend blade life.

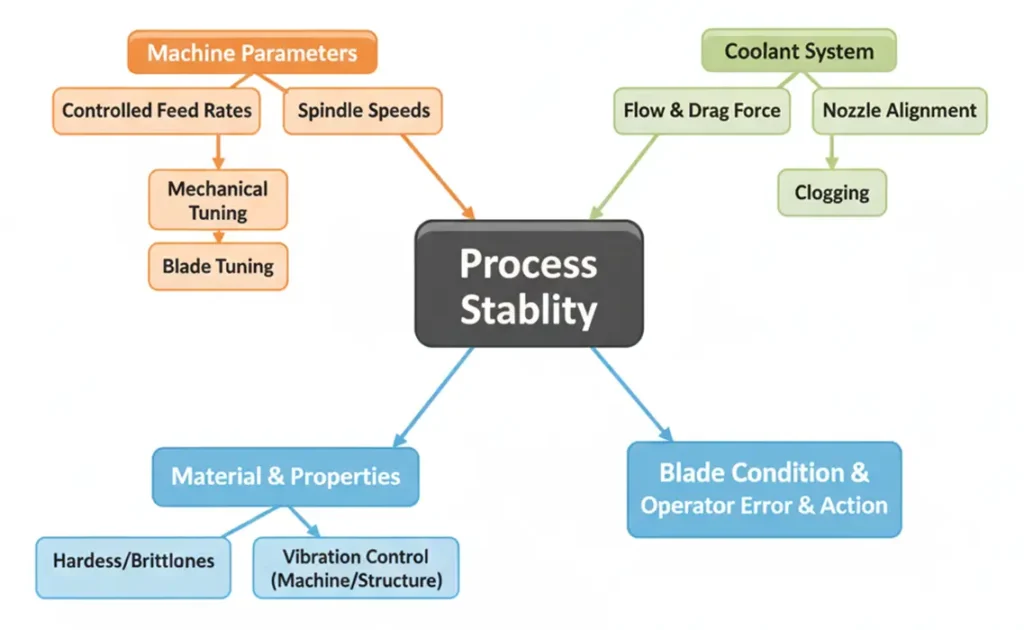

Process Stability

Process stability is central to optimizing diamond dicing blade performance. A stable process ensures that wafers are cut cleanly, yield remains high, and blades achieve their expected service life. The most direct indicator of stability is steady blade torque values. Once torque values for a given process are established, all other parameters spindle speed, feed rate, coolant flow should be tuned to keep torque consistent. Any fluctuation in torque reflects a deviation in the process, often caused by blade vibration, which can progress into blade breakage, excessive chipping, or even cracking damage to the wafer.

To maintain stability, the dicing system must run with controlled feed rates, consistent spindle speeds, and reliable coolant flow. Coolant flow is especially important because it not only cools and cleans the blade, but also introduces drag force. This drag force contributes directly to measured torque. If the coolant stream is unstable, torque values will fluctuate even if all other parameters are correct. For this reason, stabilizing coolant flow and ensuring proper nozzle alignment are as essential as mechanical tuning of the machine.

When dicing systems are operating under stable coolant conditions and parameters are kept within control, torque remains steady. Any deviation from steady torque should be considered a red flag for uncontrolled factors. These can include nozzle clogging, nozzle misalignment, variations between different blades, changes in blade condition, or operator error. Each of these introduces variability that destabilizes the process and increases the risk of wafer damage.

From a process optimization standpoint, monitoring torque and linking it to corrective action is one of the most effective ways to maintain stability. By recording torque in real time, engineers can detect anomalies before they evolve into defects. A sudden torque spike, for instance, might indicate coolant blockage or rapid blade wear. A gradual upward drift may suggest bond loading or blade dulling. When operators act on these signals promptly, they prevent yield loss and preserve blade integrity.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

Optimizing QFN Package Dicing Process Using SMART CUT® Dicing Blades

Select right Diamond Dicing Blade for your application

Dicing Blade Operations Recommendations

Optimizing your Diamond Dicing Performance

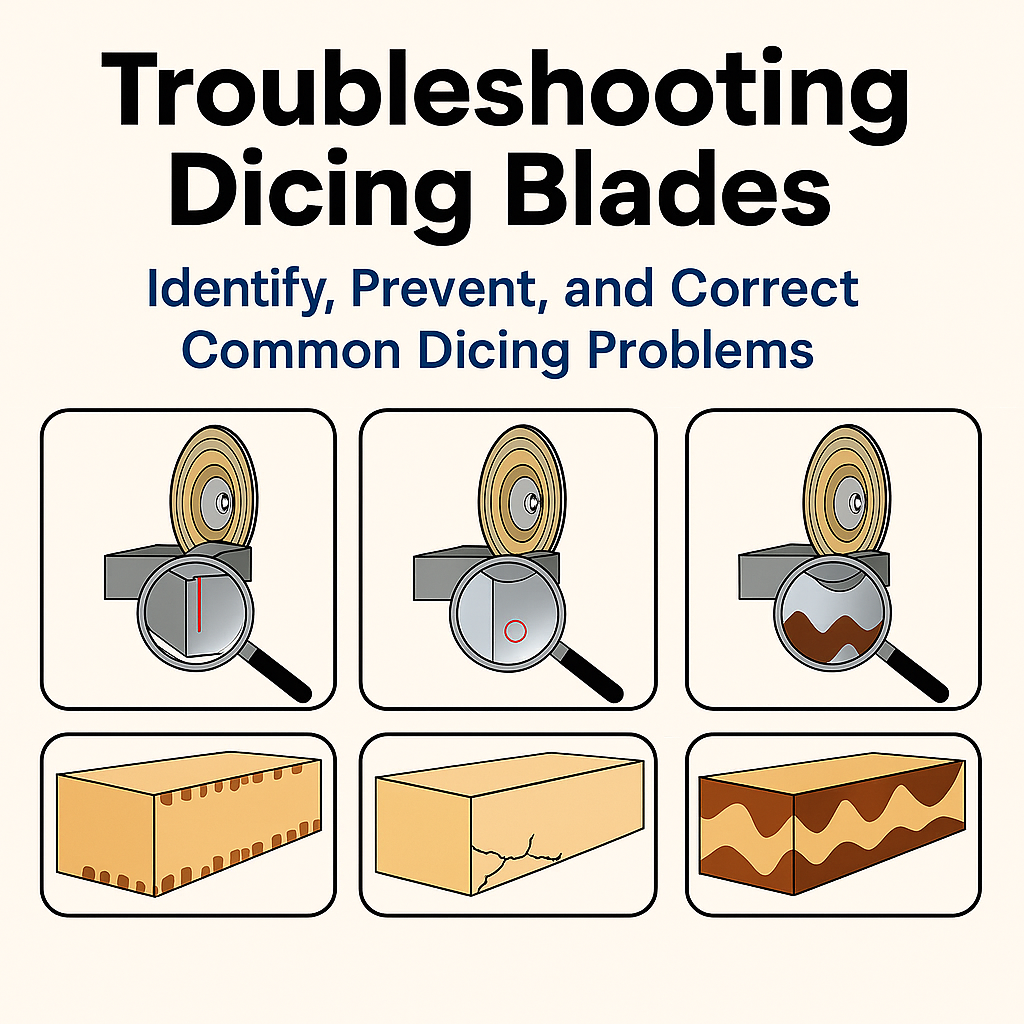

Trouble Shooting Dicing Problems

Application Recommendations

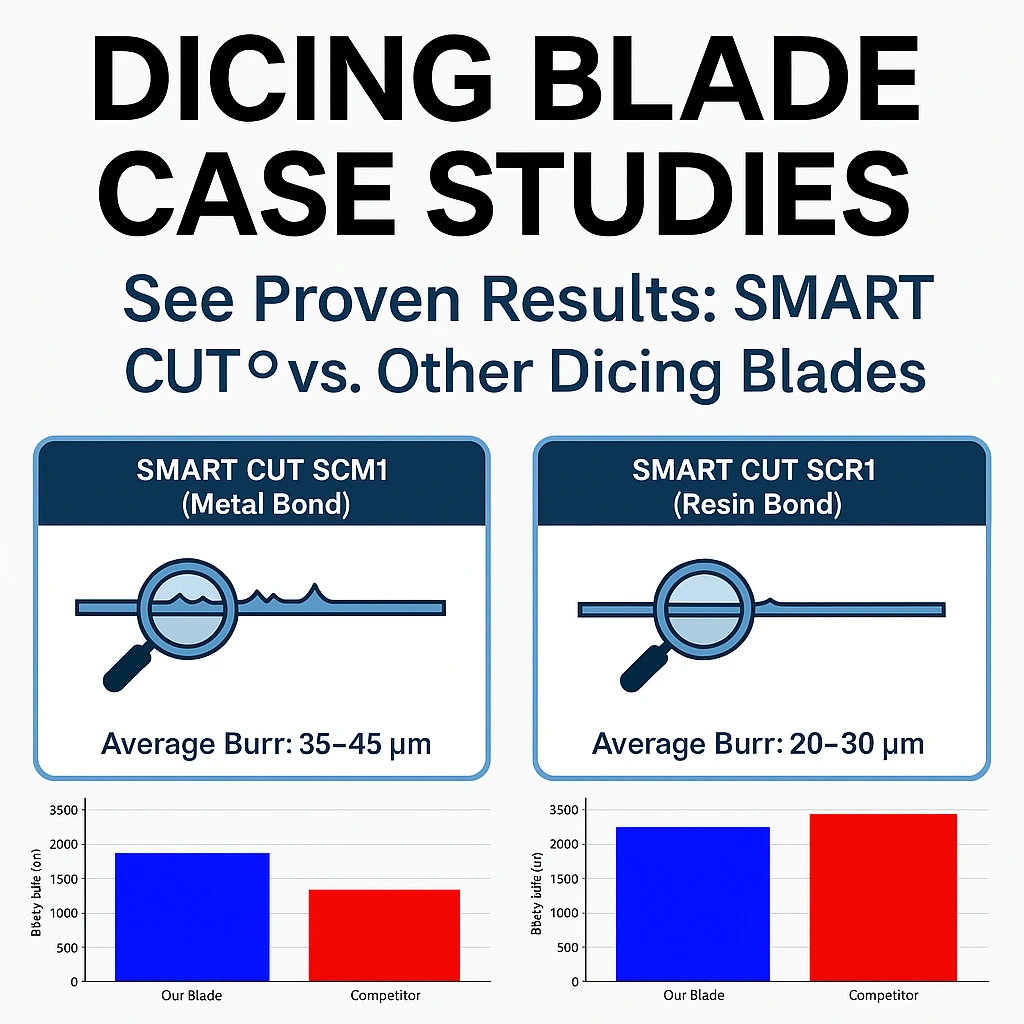

Dicing Blade Case Studies

Selecting the Right Wafer Dicing Saw Practical Guide

Total Cost of Ownership – Measuring the Real Economics of Diamond Dicing

From Silicon Wafer to Microchip: The Role of Dicing in Integrated Circuit Manufacturing

Improving Diamond Dicing Blade Performance: Key Factors and Strategies

Practical Guide to Semiconductor Wafer Dicing: Materials, Blades, and Process Optimization

Selecting the Right Dicing Surfactant / Fluid for Your Application

How to Use SMART CUT XP Dicing Surfactants

Dicing Surfactants Guide

Leon Meyer is a veteran manufacturing engineer and technical consultant with over 50 years of experience in the development, implementation, and troubleshooting of industrial diamond tooling systems. Having spent his career at the intersection of tool design, precision manufacturing, and production engineering, Mr. Meyer is widely regarded as one of the most experienced voices in the application of ultra-thin diamond blades, sintered core drills, and CBN grinding wheels across heavy industry, advanced materials, and research sectors.

Known for his pragmatic, no-nonsense approach, Leon has advised manufacturers across the United States, Europe, and East Asia—helping streamline cutting processes, extend tool life, and solve complex issues related to material breakage, chipping, and tolerance drift. His expertise has directly contributed to improved production efficiency in industries ranging from aerospace alloys and technical ceramics to optics, composites, and high-nickel superalloys.

As an author, Mr. Meyer brings a lifetime of field knowledge to his writing, with a focus on real-world problem solving, cost-performance optimization, and tool reliability under demanding conditions.