How to Select an Diamond / CBN Grinding Wheel

-

Posted by

contactor6

Table of Contents

ToggleSelecting the proper Diamond grinding wheel directly impacts precision, efficiency, and tool longevity in metalworking operations. This comprehensive guide covers everything you need to know about choosing Diamond grinding wheels for optimal performance.

What Is an Diamond Grinding Wheel?

An Diamond grinding wheel is a specialized abrasive tool designed to grind and finish the interior surfaces of cylindrical components. These precision tools create smooth, accurate Diamond diameters in parts such as engine cylinders, hydraulic components, bearings, and bushings.

Diamond grinding wheels work by rotating at high speeds while contacting the inner surface of a workpiece, removing material through abrasive action to achieve precise dimensions and superior surface finishes.

Key Components of Diamond Grinding Wheels

Understanding the fundamental characteristics helps you make informed selection decisions:

Common Mistakes Buyers Make

1. Wheel Diameter and Thickness

The wheel size must correspond to your workpiece’s Diamond diameter. Smaller diameter wheels access tighter spaces, while larger wheels provide more stability for bigger bores.

2. Abrasive Material

Common abrasive materials include:

- Aluminum Oxide: Ideal for grinding carbon steel, alloy steel, and tough bronze

- Silicon Carbide: Best for cast iron, non-ferrous metals, and non-metallic materials

- Cubic Boron Nitride (CBN): Superior for hardened steels and superalloys

- Diamond: Optimal for ceramics, carbides, and ultra-hard materials

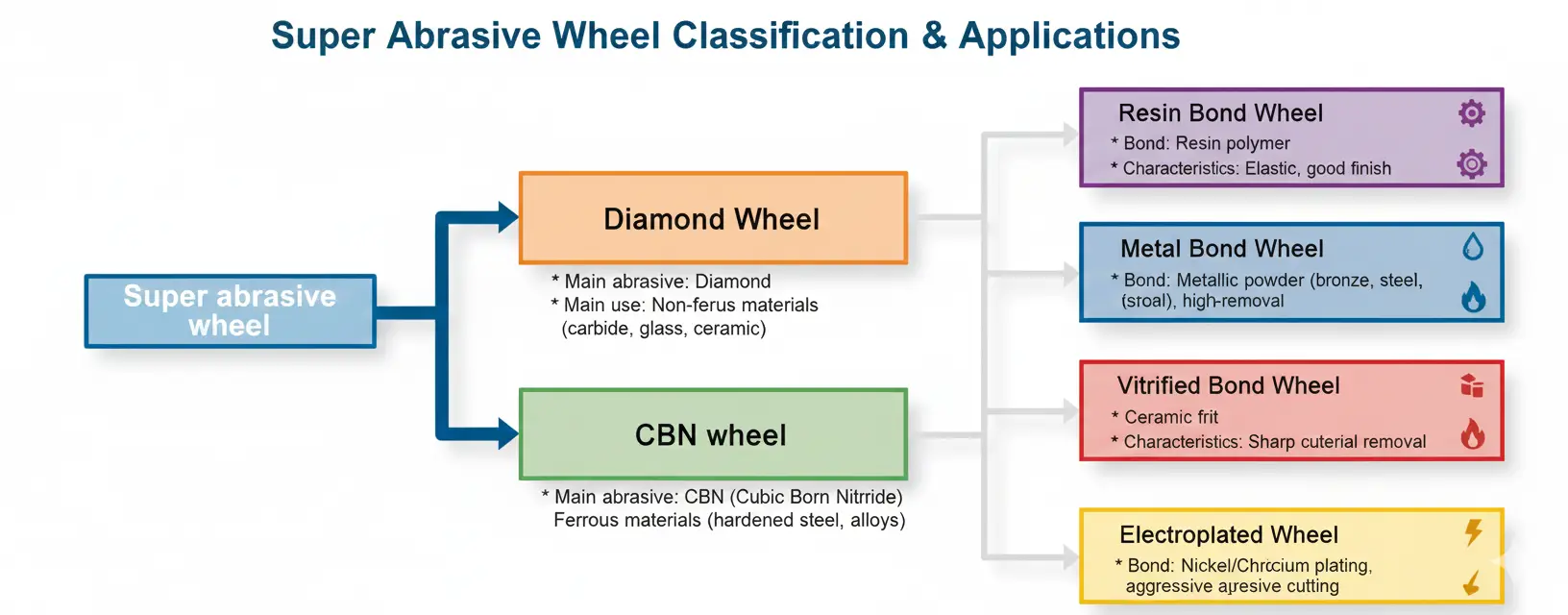

Diamond vs CBN (cubic boron nitride) Tools

- Alloy steels (45-68 RC)

- Carbon tool steels (45-68 RC)

- Die steel (45-68 RC)

- High speed steel (45-68 RC)

- Chilled cast iron

- Ni Hard

- Forged steel

- Meehanite iron

- Moly chrome steel rolls

- Inconel 600

- Rene

- Incoloy

- Monel

- Stellite

- Colmonoy

- Waspoloy

3. Grit Size

Diamond or CBN Grit Size determines surface finish and material removal rate. Coarse grits (24-60) remove material quickly but leave rougher surfaces. Fine grits (80-220) produce smooth finishes but remove material more slowly.

4. Bond Type

The bond system holds abrasive particles together:

- Vitrified Bond Diamond & CBN Wheels: Provide rigidity and maintain wheel shape well

A vitrified Bond is a Fired Ceramic Bond matrix, which is very brittle and porous. Also known as a ceramic bond. Based on fusible glasses combined with fillers and abrasive grains. Offers durability of sintered (metal bond), along with free cutting action of resin bond. Vitrified bond has higher bonding strength than resin bonds. Vitrified bond diamond tools are free-cutting, produce good surface roughness, have good wear resistance, and retain straightness and form very well.

- Resin Bond Diamond & CBN Wheels: Offer flexibility and cooler cutting action

- Metal Bond (Sintered) Diamond & CBN Wheels: Deliver maximum retention for diamond and CBN wheels

When high level of performance and consistency is required, our (sintered) metal-bonded diamond and CBN wheels stand out from the crowd. These wheels are

characterized by their long life and minimal maintenance requirements. Our SMART CUT® sintered (metal bond) diamond & cbn wheels provide extreme abrasion resistance, making them ideal for grinding glass, certain composites, and specific metals. Their exceptional form-holding capabilities ensures that the wheel retains its shape for longer periods, thereby minimizing the need for frequent dressing or wheel changes.

Custom tool shapes, angles, and radii can be ground to meet your specific objectives. Precision grinding ensures high tolerance maintenance. With a wide range of diamond grit sizes from 20 to 9,000 mesh, and diamond concentrations ranging from 12 to 100 con, our Metal Bond Grinding Wheels are versatile enough to meet any client’s needs in terms of surface finish, cutting speed, tool life, and consistency.

Invest in our SMART CUT® sintered (metal bond) diamond & cbn wheels today and experience the difference in durability, performance, and yield. Its time you Expect more from your tools!

CHARACTERISTICS OF Sintered (Metal Bond) Diamond & CBN Wheels:

- Form Holding: excellent

- Lifespan: Very High

- Cutting Action: Good

- Form Holding: excellent

- Form Holding: excellent

- Form Holding: excellent

- Form Holding: excellent

- Form Holding: excellent

- Hardness:excellent

- Required RPM's: excellent

- Shape of Diamond Used: excellent

- Electroplated Bond Diamond & CBN Wheels: Enable single-layer abrasive construction for precise profiling

SMART CUT® Electroplated (Nickel Bond) Bond Diamond & CBN WheelsOur top-of-the-line diamond & CBN whels are meticulously crafted with the finest diamonds, ranging from 0.5 microns to 20 grit diamond mesh size, available in Synthetic, Natural Diamond, or CBN (cubic boron nitride) to suit a diverse array of applications, materials, and industries.

They have several layers of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration, better diamond crystal retention and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster cutting action with minimum heat generation.

Advantages of this type of technology include: longer tool life, more uniformity in performance, less stress to material being worked on, minimum material deformation, and better preservation of true material micro structure. This is specially important for more delicate, sensitive applications such as: glass, crystals, silicon wafers, carbon composites, sapphire, etc.

CHARACTERISTICS OF

Electroplated (Nickel Bond) Diamond & CBN

Wheels

- Dressability:Good

- Hardness : Very Hard

- Required RPM's: Medium/Hight

- Shape of Diamond & CBN Used: Semi blocky Crystal

- Form Holding: Good / Excellent

- Lifespan: Low / Medium

- Cutting Action: Good / Excellent

- Can be Used Dry: Yes (depending on tool type, diamond size and type)

- Cost: Low / Medium

- Hybrid Bond Diamond & CBN Wheels – wheels combining benefits of resin and sintered (metal bond) bond types

SMART CUT® Hybrid Bond Wheels are designed to extend the application of tooling, overcoming the limitations of conventional resin bond diamond wheels. They provide a perfect blend of the cutting speed and improved surface finish offered by resin bond wheels, with the durability, consistency, and performance associated with sintered (metal bond) wheels

UKAM Industrial manufactures and offers many types and forms of Hybrid bond diamond tools. Complex tool shapes can be made. Large variety of Diamond & CBN grit sizes from 250 to 3 microns can be used to achieve the clients desired surface finish, cutting speed, tool life and consistency. Diameters from small as .080″ to large as 20″ (500mm). Custom Tool specifications in this bond can be produced per your specification and requirements with short lead time.

CHARACTERISTICS OF

Hybrid Bond Diamond & CBN Wheels

- Main Boding Agent : Phenolic Resin, Specialize Fillers, & Metallurgical Powders

- Dressability: Excellent

-

Hardness: Soft

-

Required RPMs: High

-

Shape of Diamond & CBN Used: Irregular-shaped crystals

-

Can Be Used Dry: Sometimes (depending on tool type, diamond size, and type)

-

Cost: Medium to high

- Form Holding: Good

-

Lifespan: Long

- Cutting Action: Good to excellent

- Brazed Bond Diamond & CBN Wheels

Critical Selection Factors

Match Diamond or CBN Wheel to Workpiece Material

Different materials require specific grinding wheel characteristics. Hardened steel demands CBN or aluminum oxide wheels with appropriate hardness grades. Soft materials like aluminum need silicon carbide wheels that resist loading.

Selecting Diamond/CBN Grit Size - Consider Your Application Requirements

Wet core drills are the preferred choice for heavy-duty drilling applications where heat buildup and dust control are critical. By using water as a coolant and lubricant, these drills operate at lower temperatures, extend bit life, and enable deeper penetration into tough materials such as concrete, reinforced concrete, brick, and large-diameter holes. In contrast, dry core drills are designed with special segment geometry that disperses heat and expels debris without requiring water, making them ideal for environments where water use is impractical—such as indoor installations, occupied spaces, or overhead drilling. They perform best on masonry, block, soft to medium concrete, and other light-duty tasks where speed and convenience are key.

For Precision Grinding: Choose fine-grit wheels (120-220) with vitrified bonds to achieve tight tolerances and excellent surface finishes on components like bearing races and precision bushings.

For Heavy Stock Removal: Select coarse-grit wheels (24-60) with robust bond systems that withstand aggressive grinding conditions in rough machining operations.

For Surface Finish Quality: Fine-grit wheels produce mirror-like finishes, while medium grits (60-80) balance material removal with surface quality.

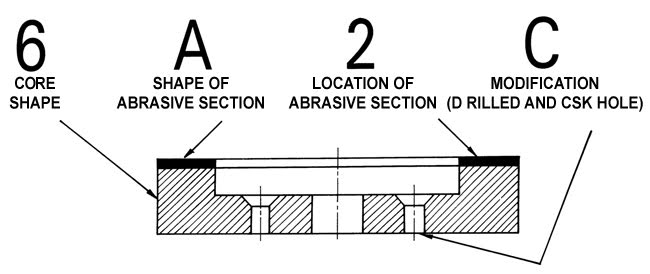

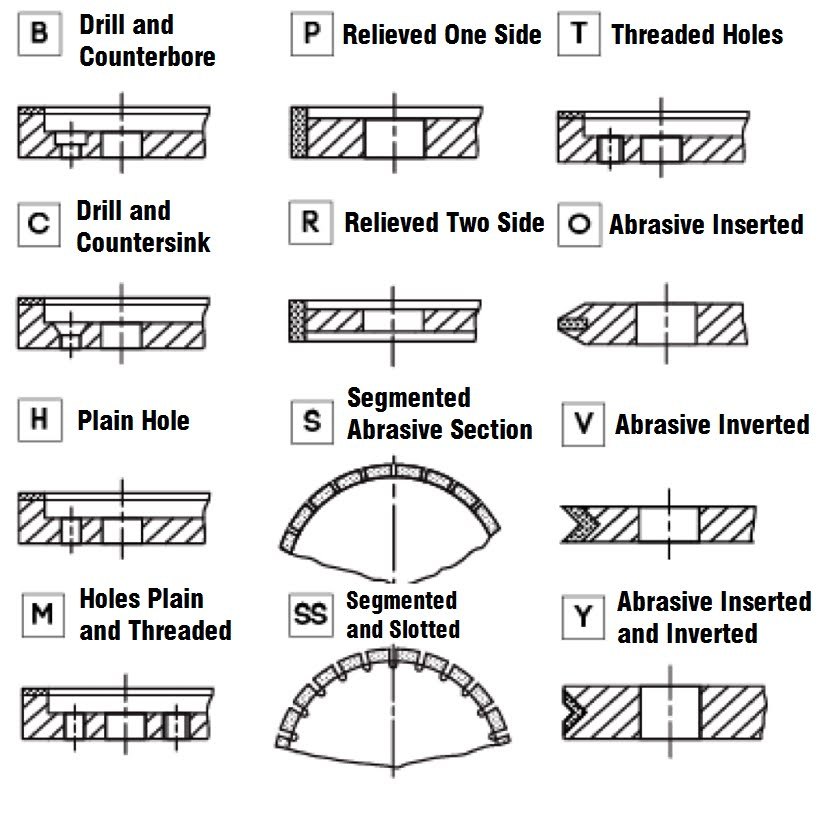

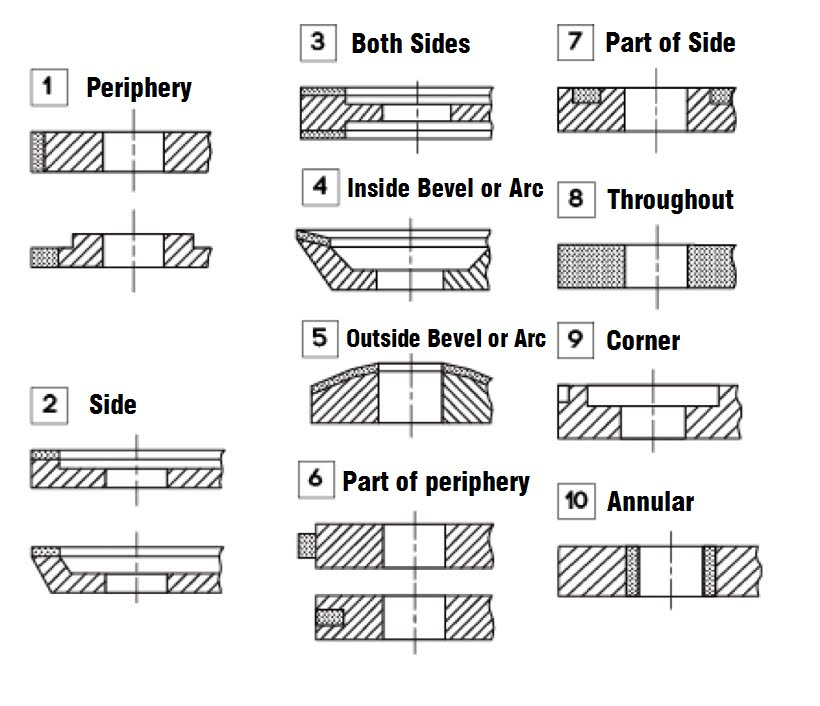

Select the Appropriate Wheel Shape

Straight Wheels: Standard cylindrical profile for general Diamond grinding of consistent bore diameters.

Tapered Wheels: Angled profile for grinding conical Diamond surfaces and angular features.

Cylindrical Wheels: Uniform diameter throughout the length for maintaining consistent bore dimensions across deep holes.

Professional Performance Tips

Proper Installation and Alignment

Accurate mounting prevents vibration, ensures uniform wheel-to-workpiece contact, and maintains grinding precision. Always verify concentricity after mounting and before starting operations.

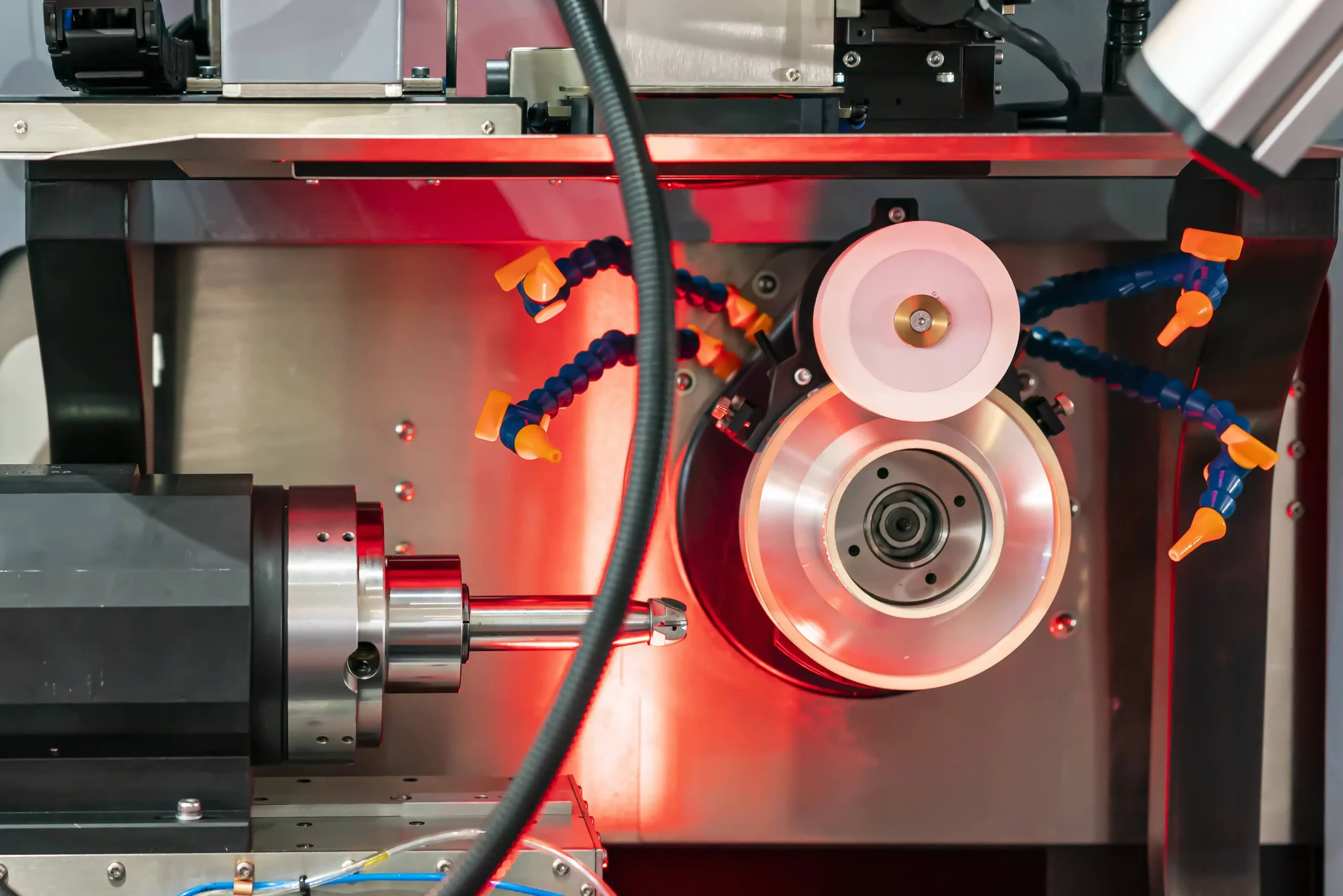

Implement Effective Coolant Strategy

Proper coolant application reduces grinding temperatures, prevents thermal damage to workpieces, extends wheel life, and improves surface finish. Match coolant type and flow rate to your specific grinding operation.

Maintain Regular Wheel Conditioning

Dressing Diamond & CBN Wheels restores wheel sharpness and profile accuracy by exposing fresh abrasive particles. Truing corrects wheel runout and maintains dimensional accuracy. Schedule conditioning based on workpiece quality requirements and wheel wear patterns.

Monitor Wheel Wear Patterns

Regular inspection identifies is sues early, preventing quality problems and extending wheel life. Replace wheels showing excessive wear, glazing, or loading.

Where to Find Quality Diamond Grinding Wheels

For professional-grade Diamond grinding wheels and expert technical support, UKAM Industrial Superhard Tools offers an extensive selection of precision grinding wheels. Their inventory includes aluminum oxide, silicon carbide, CBN, and diamond wheels in various specifications for diverse industrial applications.

UKAM provides custom grinding wheel solutions tailored to specific machining requirements, backed by technical expertise to help you select the optimal wheel for your application.

Quick Reference FAQ

Use CBN for ferrous materials like hardened steel and tool steel. Choose diamond for non-ferrous materials, ceramics, carbides, and composites.

Use 24-60 grit for heavy material removal, 60-100 grit for general purpose grinding, and 120-220 grit for precision finishing work.

Vitrified bonds are rigid, maintain shape better, and work well for precision grinding. Resin bonds are more flexible, absorb shock better, and produce cooler cutting action.

No. Steel typically requires aluminum oxide wheels, while aluminum needs silicon carbide wheels to prevent loading and maintain cutting efficiency.

Coolant is essential. It controls temperature, prevents thermal damage, reduces wheel wear, improves surface finish, and extends both wheel and machine tool life.

Loading occurs when grinding soft materials, using too fine a grit, insufficient coolant, incorrect wheel speed, or excessive feed rates. Select appropriate specifications and operating parameters.

Use CBN for ferrous materials like hardened steel and tool steel. Choose diamond for non-ferrous materials, ceramics, carbides, and composites.

Conclusion

Selecting the right Diamond or CBN grinding wheel requires understanding workpiece material, application requirements, wheel specifications, and operational best practices. By matching abrasive type, grit size, bond system, and wheel geometry to your specific needs, you achieve superior grinding results, extended tool life, and improved productivity.

For expert guidance on Diamond grinding wheel selection and access to premium quality grinding tools, visit UKAM Industrial Superhard Tools to explore their comprehensive product range and technical resources.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990