How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

-

Posted by

Brian Farberov

Brian Farberov

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing applications on glass, ceramics, stone, composites (stone (as in construction), concrete (reinforced), etc. rees (PCD & PCBN)), semiconductors like quartz, sapphire ceramic rods, and cemented carbides. When properly applied, diamond tools offer numerous benefits that include greater accuracy, longer tool life, better surface finish, and increased overall performance.

Table of Contents

ToggleBut diamond tools can easily cause overheating, fast wear, glazing of the tool, bad cutting results, and material damage if not used properly or due to ignorance. It is really important to know how the diamond tools for the concrete grinding process work and when to use them.

This complete overview of diamond tool use in the machining stage will help anyone about to use them for a cutting project know exactly how to handle tools and materials, what they can cut, the coolant flow required to keep the equipment from overheating or burning up, and warnings regarding safety dressing hazards.

Understanding How Diamond Tools Work

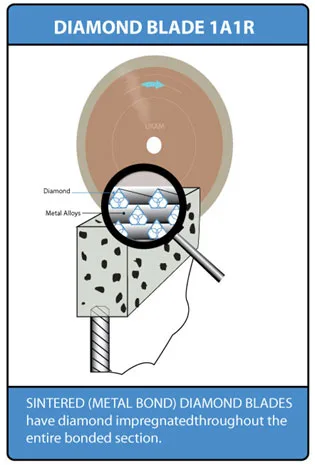

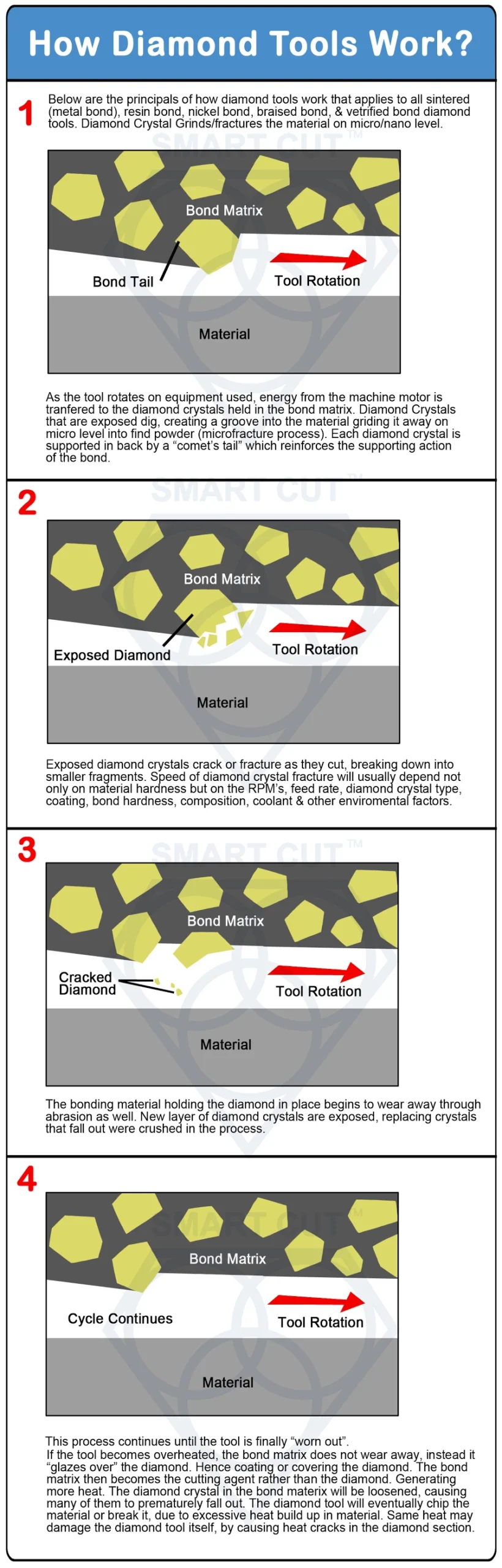

Diamond tools differ fundamentally from conventional cutting tools. Instead of slicing or shearing material, diamond tools remove material through abrasive grinding action. Each diamond particle functions as a microscopic cutting edge that gradually wears away the surface of the work piece.

A typical diamond tool consists of:

- Diamond abrasives that perform the cutting or grinding

- Bond material (metal, resin, vitrified, or electroplated) that holds the diamonds in place

- The tool body or core that provides structural stability

As cutting progresses, the bond slowly wears down, allowing dull diamonds to be released and fresh, sharp diamonds to become exposed. This self-sharpening mechanism is essential for consistent performance. Proper heat management ensures the bond wears at the correct rate and prevents glazing.

Importance of Using Diamond Tools Correctly

Using diamond tools properly is essential for several reasons:

- Maximizes tool life and reduces replacement costs

- Improves cutting accuracy and surface finish

- Prevents thermal damage to the tool and material

- Enhances operator safety

- Ensures consistent and repeatable results

Incorrect speeds, excessive pressure, or insufficient cooling can significantly reduce tool efficiency and lead to premature failure.

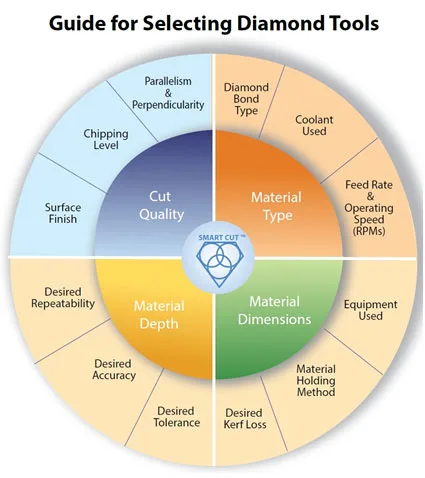

Selecting the Right Diamond Tool for Your Application

Proper tool selection is the foundation of successful diamond machining.

Match the Tool to the Material

Different materials require different diamond tool designs. Factors to consider include:

- Material hardness and abrasiveness

- Thickness and density of the material

- Desired cutting speed and finish quality

For example:

- Ceramics and glass are hard and brittle products; they need to be cut at controlled cutting speeds with very fine grit sizes.

- For softer materials like stone or concrete, aggressive bonds and coarse grits may be more suitable.

- For precision applications, the abrasives have a close grit distribution and excellent bonding, which prevents clogging for a high-quality finish.

The use of the wrong tool may lead to poor cutting, excessive wear, or an inferior surface.

Choose the Correct Bond Type

Diamond tools are available with different bond types, each suited for specific applications:

- Metal bond: Long life, used for hard materials

- Resin bond: Smooth finishes, lower cutting forces

- Vitrified bond: High precision and excellent coolant penetration

- Electroplated bond: High cutting efficiency, single-layer diamonds

Understanding bond behavior helps optimize performance and tool longevity.

Ensure Machine Compatibility

The machine must be capable of:

- Operating within the recommended RPM range

- Providing sufficient power and torque

- Delivering adequate coolant flow

- Maintaining proper alignment and stability

Supplying accurate machine details to the tool manufacturer allows for better tool recommendations and performance optimization.

Operating Parameters for Proper Diamond Tool Use

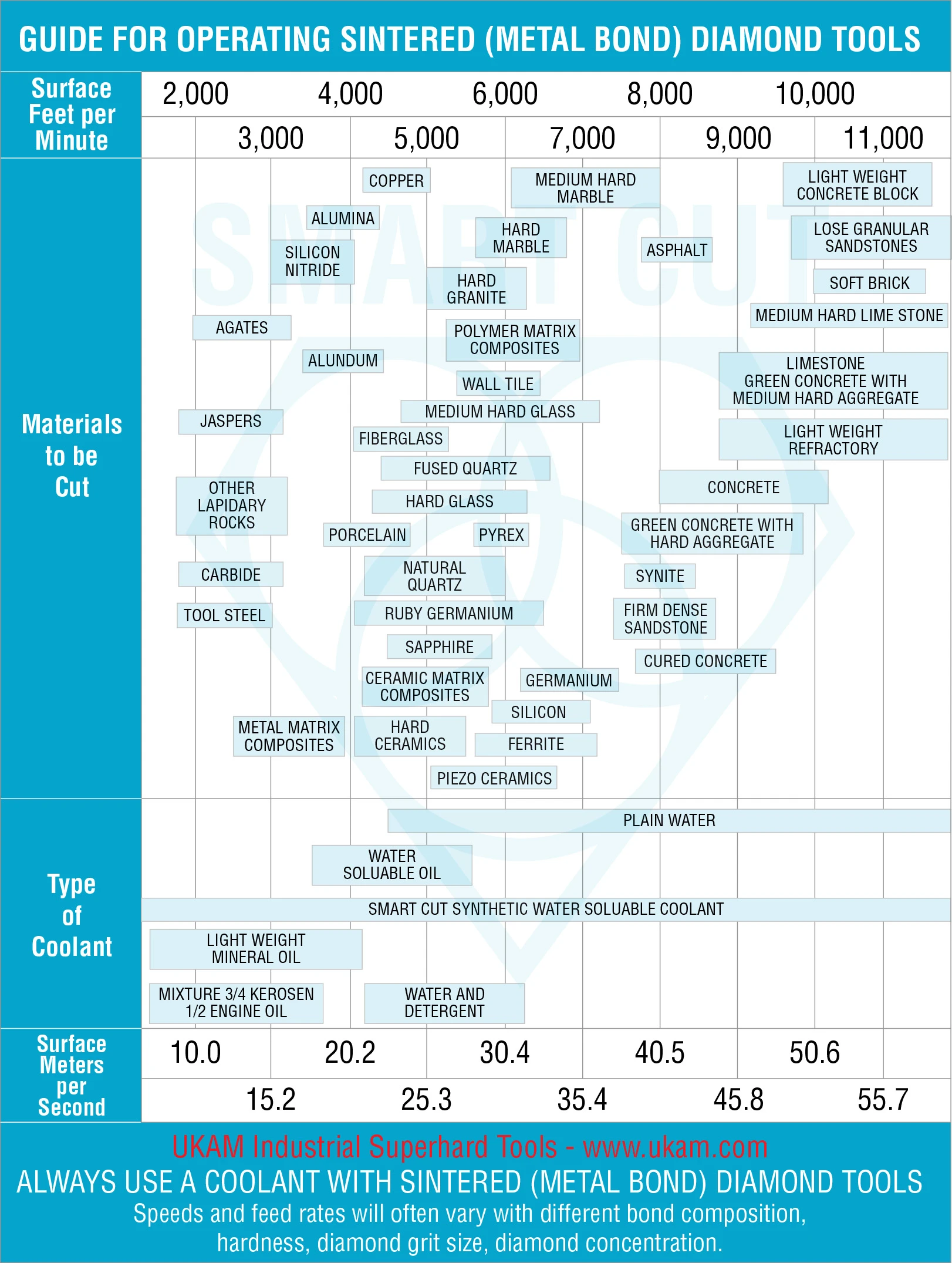

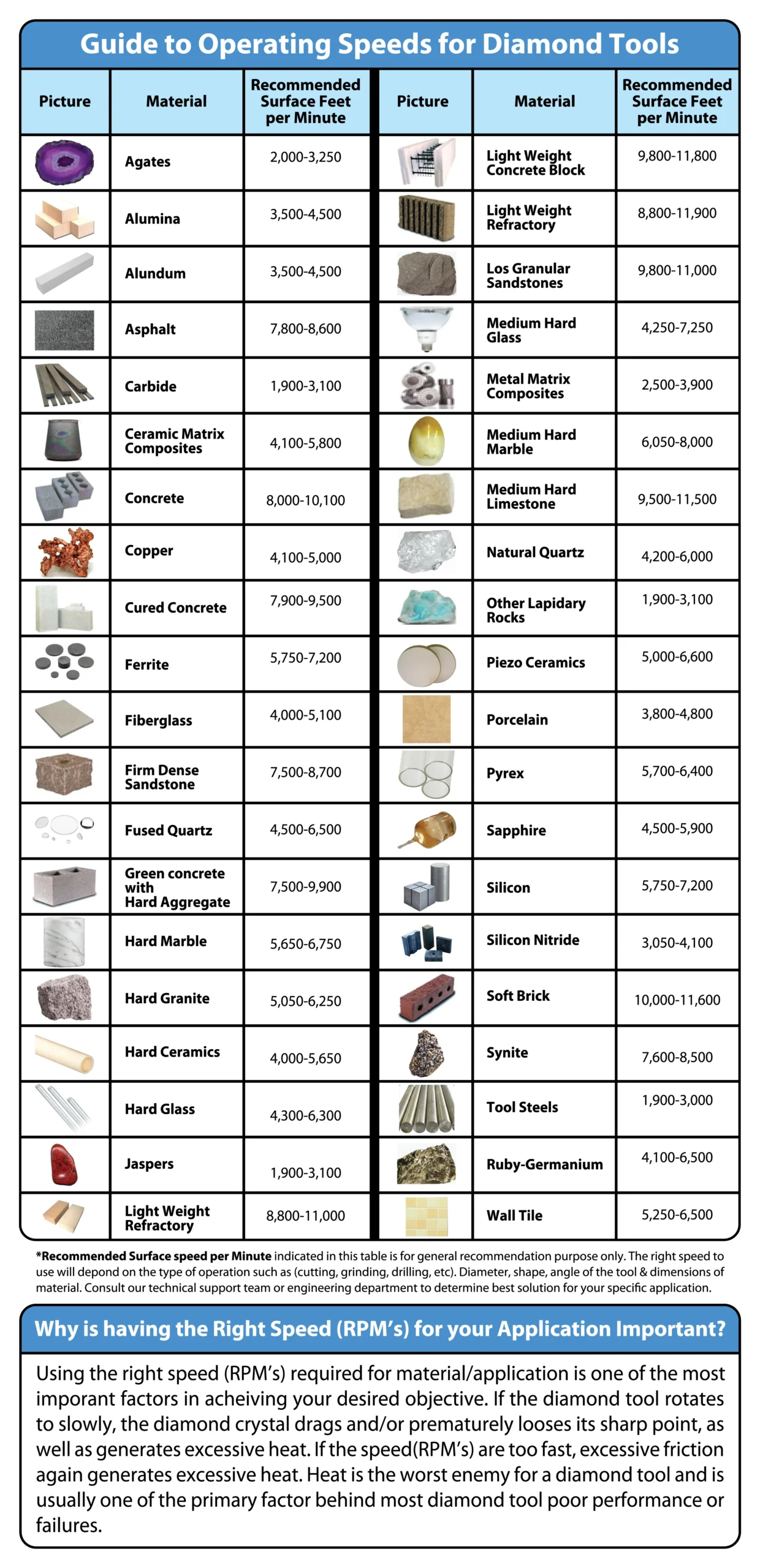

Correct RPM and Surface Speed

Maintaining proper rotational speed is critical when using diamond tools. Excessive speed generates heat and accelerates wear, while insufficient speed can cause inefficient cutting.

General guidelines include:

- Larger diameter tools require lower RPM

- Harder materials typically require lower surface speeds

- Variable-speed machines allow better control and adjustment

Always follow manufacturer-recommended RPM or surface speed values whenever available.

Feed Rate and Cutting Pressure

Diamond tools are designed to cut efficiently under controlled pressure. Applying excessive force does not increase productivity and often causes damage.

Best practices include:

- Applying light to moderate, steady pressure

- Allowing the diamonds to grind naturally

- Avoiding sudden changes in feed rate

- Monitoring chip formation and cutting sound

Consistent feed pressure promotes even wear and optimal cutting performance.

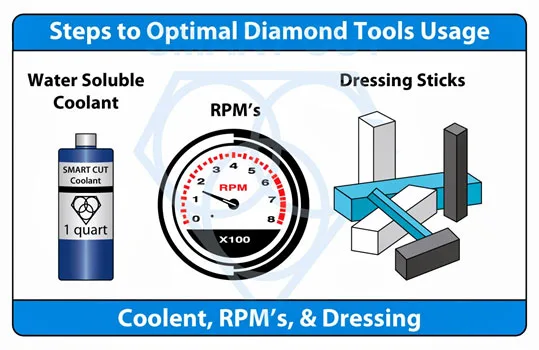

Coolant and Lubrication Requirements

Coolant plays a crucial role in the operation of diamond tools. It:

- Reduces heat at the cutting interface

- Flushes away debris and swarf

- Prevents bond glazing

- Improves surface finish

- Extends tool life

Water is the most commonly used coolant, though additives may improve lubrication. Coolant should be delivered directly to the cutting zone. For drilling applications, internal coolant delivery is strongly recommended for effective cooling.

Dry cutting should only be used when the tool is specifically designed for it.

Best Practices for Cutting, Drilling, and Grinding

Cutting with Diamond Blades

To achieve clean and accurate cuts:

- Clamp the workpiece for the best stability to eliminate vibration

- Begin slower and then build momentum.

- Keep a straight and true line as you cut.

- Do not twist or side-load the blade.

- Retract the blade occasionally to cool down and clear out debris

These practices help prevent chipping, overheating, and uneven wear.

Drilling with Diamond Core Bits

Proper drilling technique is essential for tool life and hole quality:

- Start drilling in the other perpendicular direction to the face.

- Apply steady, controlled pressure

- Maintain continuous coolant flow

- Peck drilling for deeper holes

- Prevent the tool from being bent or wobbled

Proper alignment reduces stress on the diamonds and improves hole accuracy.

Grinding and Polishing Applications

Grinding and polishing require careful control:

- Select the correct grit size for each stage

- Use even, consistent pressure

- Avoid dwelling in one spot

- Progress gradually from coarse to fine grits

- Allow sufficient cooling between passes

These steps ensure a uniform surface finish and reduce thermal damage.

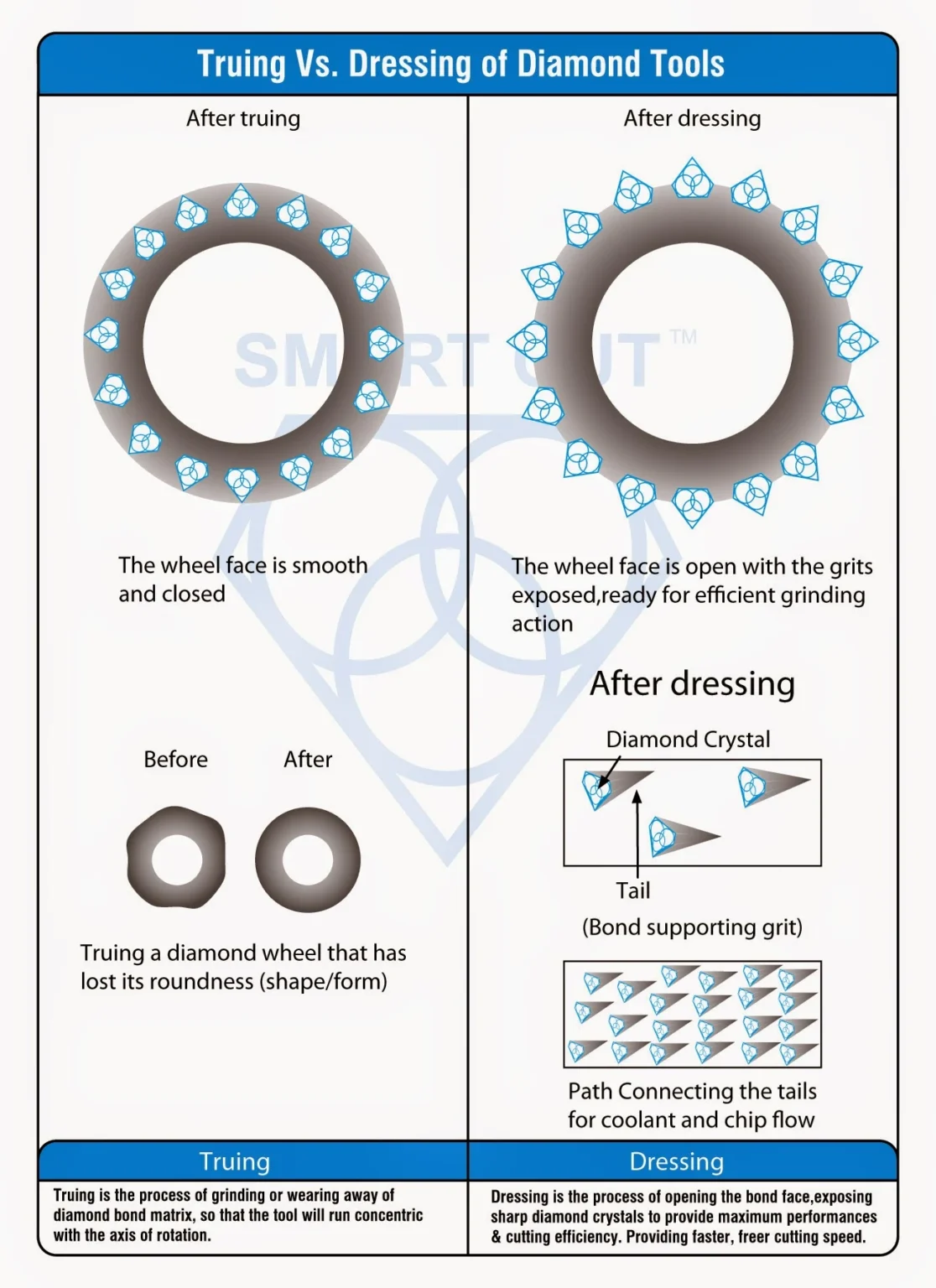

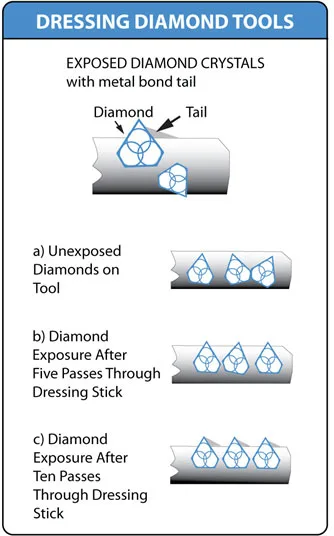

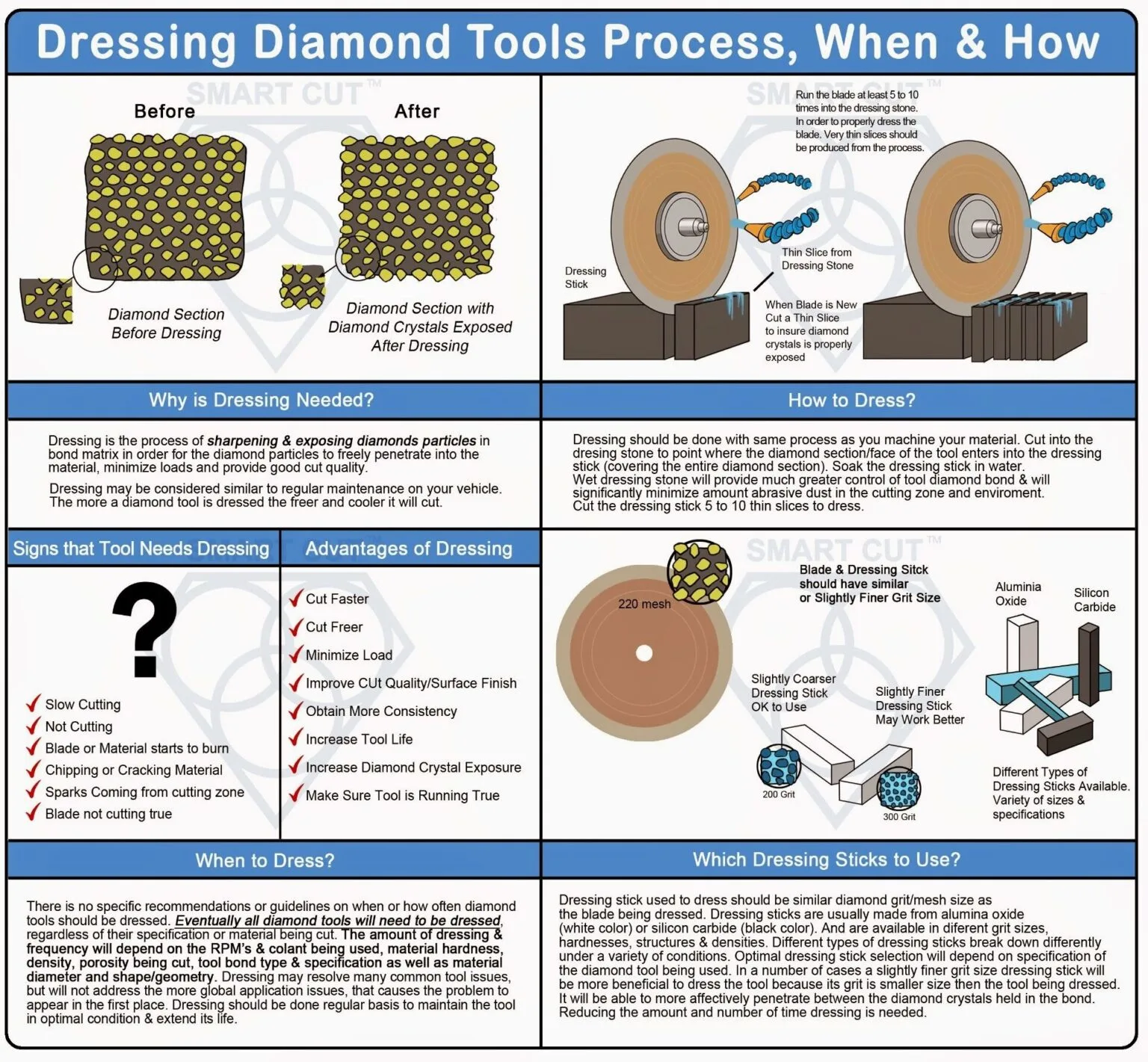

Truing and Dressing Diamond Tools

Even new diamond tools often require truing and dressing before use.

- Truing ensures the tool runs concentric and balanced

- Dressing exposes fresh diamond particles and restores cutting efficiency

Soft dressing sticks are recommended to prevent damaging the diamonds. A properly dressed tool will have a slightly rough texture, indicating exposed cutting edges.

Regular dressing maintains consistent performance and prevents glazing.

Safety Guidelines When Using Diamond Tools

Diamond tools operate at high speeds and require strict adherence to safety practices.

Personal Protective Equipment (PPE)

- Safety glasses or face shields

- Hearing protection

- Gloves and protective clothing

- Respiratory protection when dust is present

Machine and Workplace Safety

- Ensure all guards and shields are in place

- Keep your hands clear of rotating tools

- Avoid loose clothing or jewelry

- Maintain a clean and organized workspace

- Use wet cutting whenever possible to minimize airborne dust

Safety should always be a top priority when working with diamond tools.

Common Mistakes to Avoid

Applying Excessive Pressure

Forcing the tool increases heat and accelerates wear without improving cutting speed.

Insufficient Coolant

Inadequate cooling leads to glazing, reduced performance, and potential tool failure.

Incorrect Speed Settings

Operating outside recommended RPM ranges causes inefficient cutting and premature wear.

Poor Setup and Alignment

Misalignment results in uneven wear, chipping, and inaccurate cuts.

Avoiding these mistakes significantly improves tool life and cutting quality.

Maintenance and Storage of Diamond Tools

Proper maintenance and storage extend the tool’s lifespan:

- Clean tools thoroughly after use

- Inspect for cracks, uneven wear, or damage

- Dress tools when cutting efficiency declines

- Store tools in a dry, protected environment

- Avoid impacts or improper stacking

Consistent maintenance ensures reliable performance and reduces operating costs.

Frequently Asked Questions (FAQs)

Select the right tool for the material, follow recommended cutting conditions, and apply uniform pressure with appropriate coolant to control heat and wear.

Yes, the majority of diamond tooling needs cooling to take away heat, avoid glazing, and maintain tool life. Dry use should be done only with tools designed for it. Select the right tool for the material, follow recommended cutting conditions, and apply uniform pressure with appropriate coolant to control heat and wear.

How Do Diamond Tools Stop Cutting? Diamond tools will stop cutting when they get hot, are run at the wrong speed, pressure is too high, or coolant isn’t applied, which causes the bond to glaze over.

Yes, many new diamond tools require dressing to expose fresh diamonds and achieve optimal cutting performance.

Yes, when used correctly with proper PPE, correct machine setup, and recommended operating parameters, diamond tools are safe and reliable.

Conclusion

Proper knowledge of applying diamond tools is necessary for maximum performance, safety, and tool life. The right choice of tools, application parameters, working coolant, and consistent cutting conditions is what leads to successful diamond machining.

Applying the best practices described in this guide can help maximize cutting efficiency, optimize surface finish, and minimize downtime, while also prolonging the life of a diamond tool on many different applications.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.