Diamond Tools compared with Abrasive Tools

-

Posted by

Brian Farberov

Brian Farberov

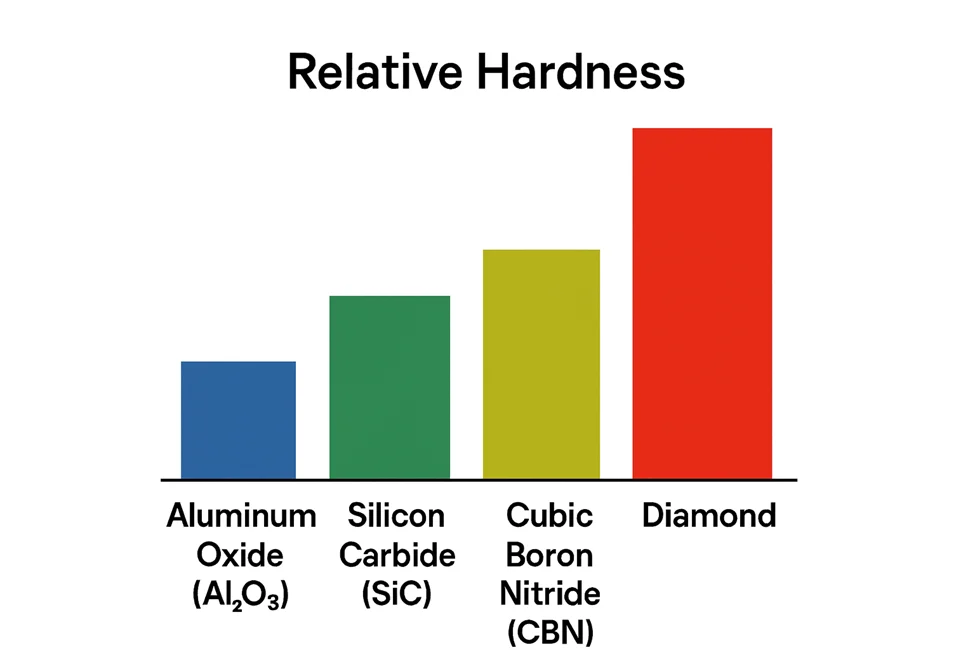

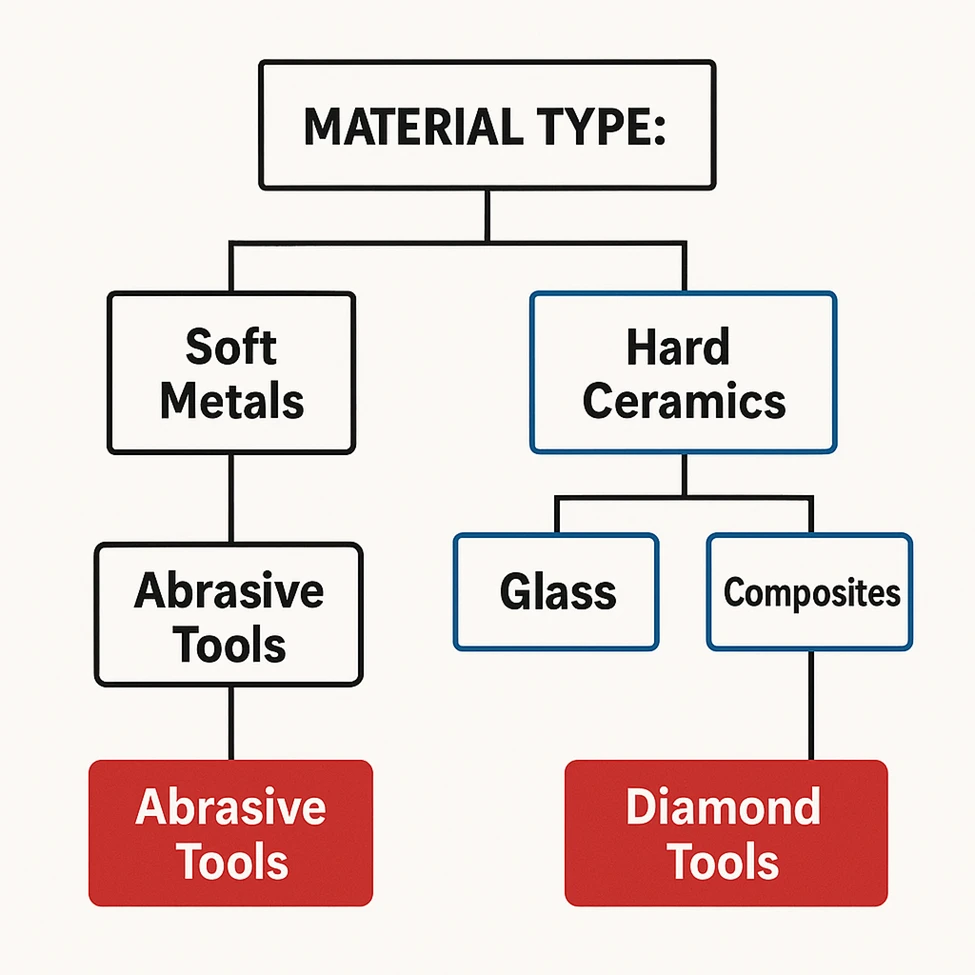

Abrasive tools and diamond tools are two of the most widely used solutions for cutting, grinding, drilling, and polishing in manufacturing, research, and materials processing. While both serve the same purpose of removing material and shaping components, their composition, hardness, and performance characteristics differ greatly. Abrasive tools, made from materials such as aluminum oxide (Al₂O₃) or silicon carbide (SiC), are cost-effective for softer metals and general applications. Diamond tools, built with industrial diamond or cubic boron nitride (CBN), provide unmatched hardness and precision for ultra-hard or brittle materials like ceramics, quartz, and glass.

Choosing between these tools is not just a matter of cost. It directly impacts tool life, surface finish quality, productivity, and total cost of ownership (TCO). Abrasives are often the best choice for low-budget or non-critical work, but they wear quickly and require frequent replacement. Diamonds demand a higher upfront investment yet deliver longer service life, superior accuracy, and improved return on investment (ROI), especially in industries where downtime or scrap rates carry high costs. By understanding when to apply abrasive tools and when diamond tools are the smarter option, engineers, technicians, and researchers can achieve the right balance between performance, reliability, and cost-effectiveness.

Composition and Bonding Systems

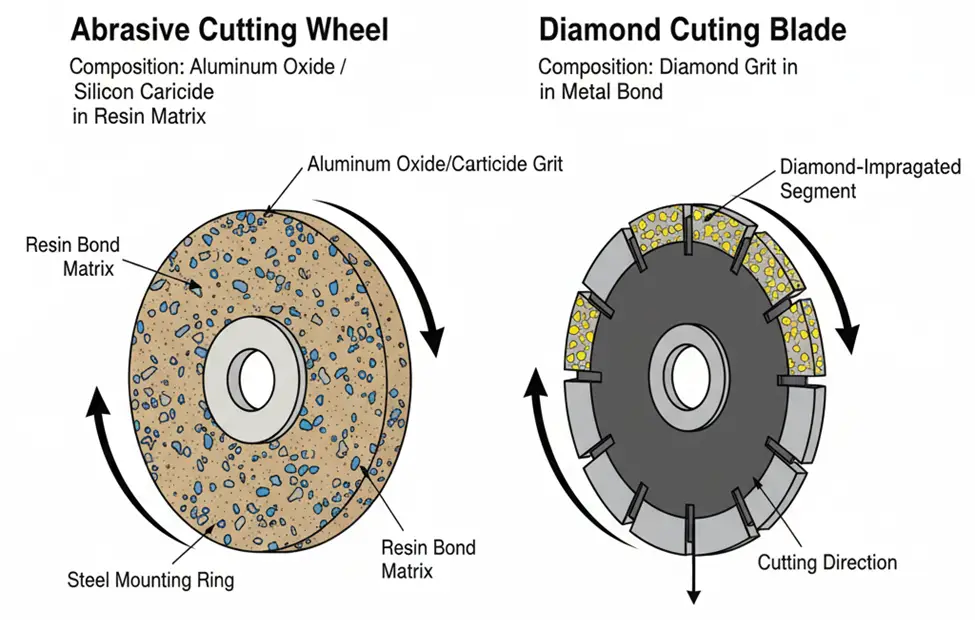

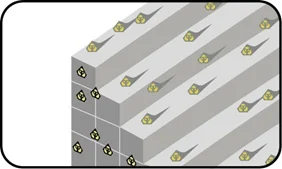

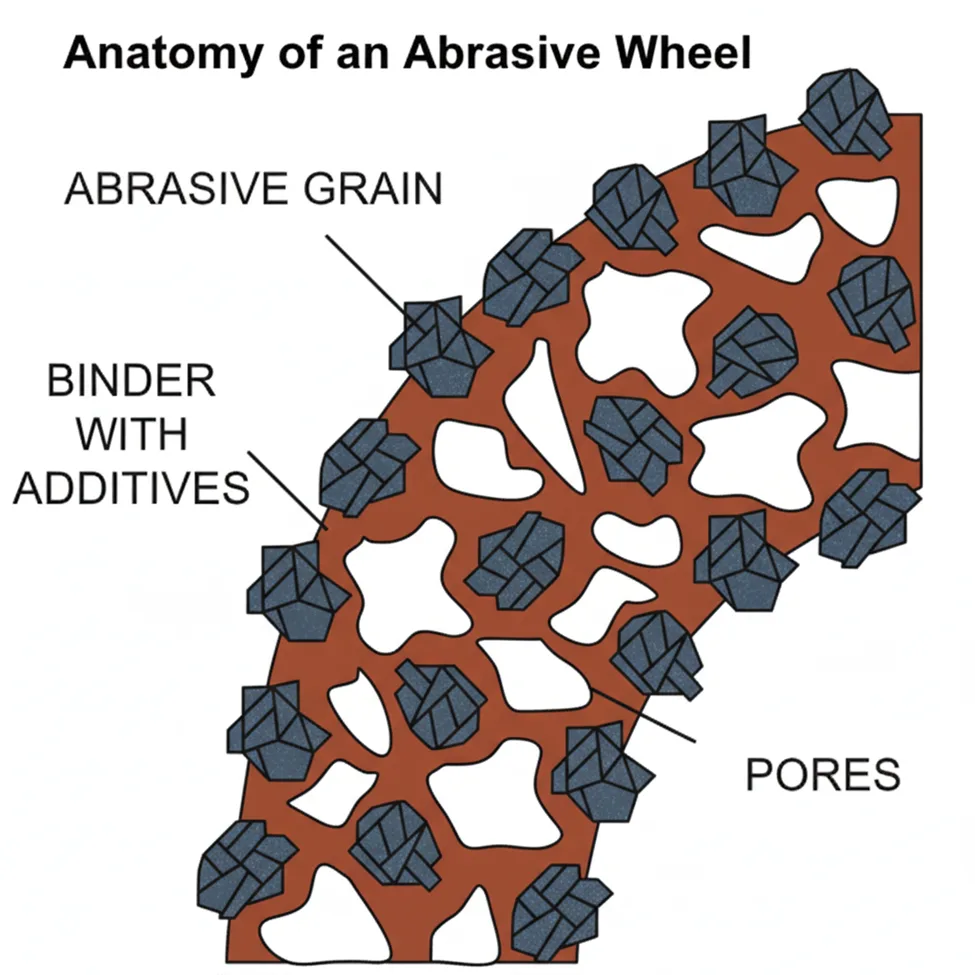

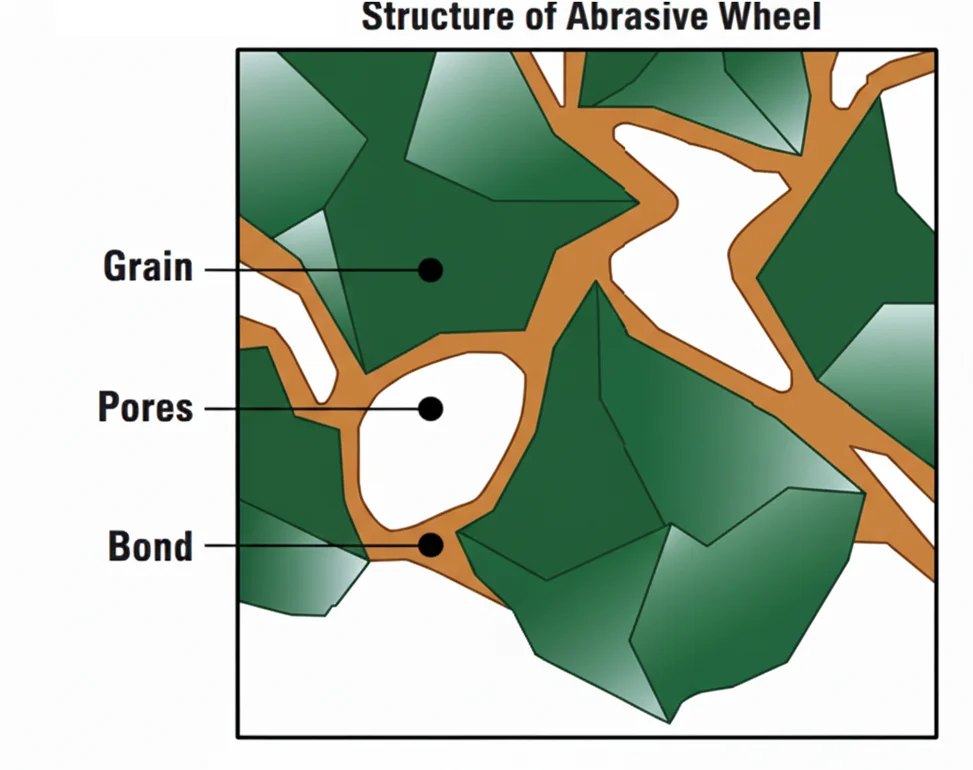

Abrasive tools are made from conventional abrasive grains such as aluminum oxide (Al₂O₃), silicon carbide (SiC), or zirconia alumina. These grains act as the cutting medium and are held together by a bonding system that shapes the tool and determines how it behaves during cutting or grinding. The most common bonds for conventional abrasive tools are resin and vitrified (ceramic), with rubber, shellac, or silicate bonds also used in specialized cases.

Resin bonds provide flexibility, faster cutting, and are widely used in general grinding applications. Vitrified bonds are harder and more rigid, offering excellent heat resistance, high strength, and dimensional stability. Because abrasive grains are designed to fracture and wear during use, these tools require regular dressing to maintain sharpness and efficiency. Abrasive tools are generally cost-effective, widely available, and versatile, making them suitable for soft metals, steels, and general machining tasks where extreme precision is not the primary concern.

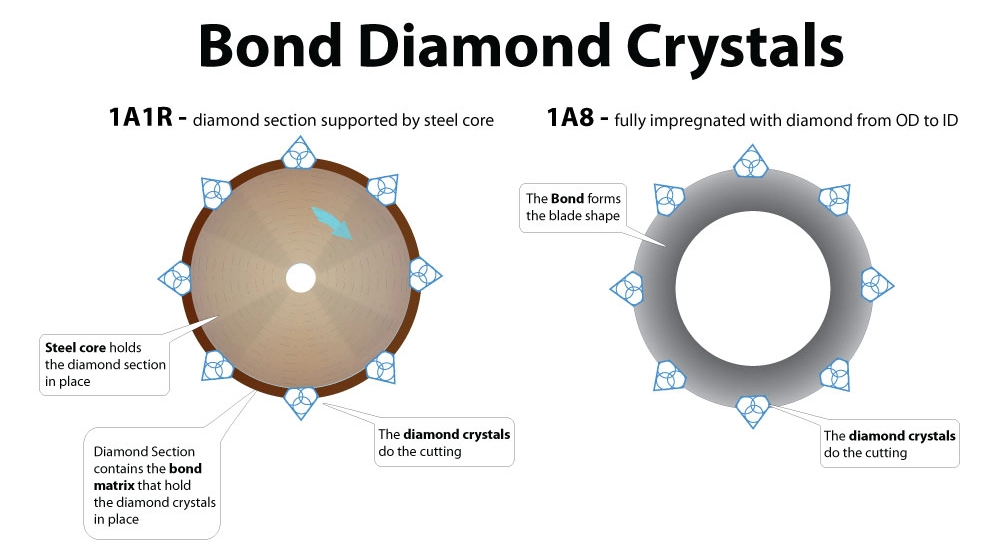

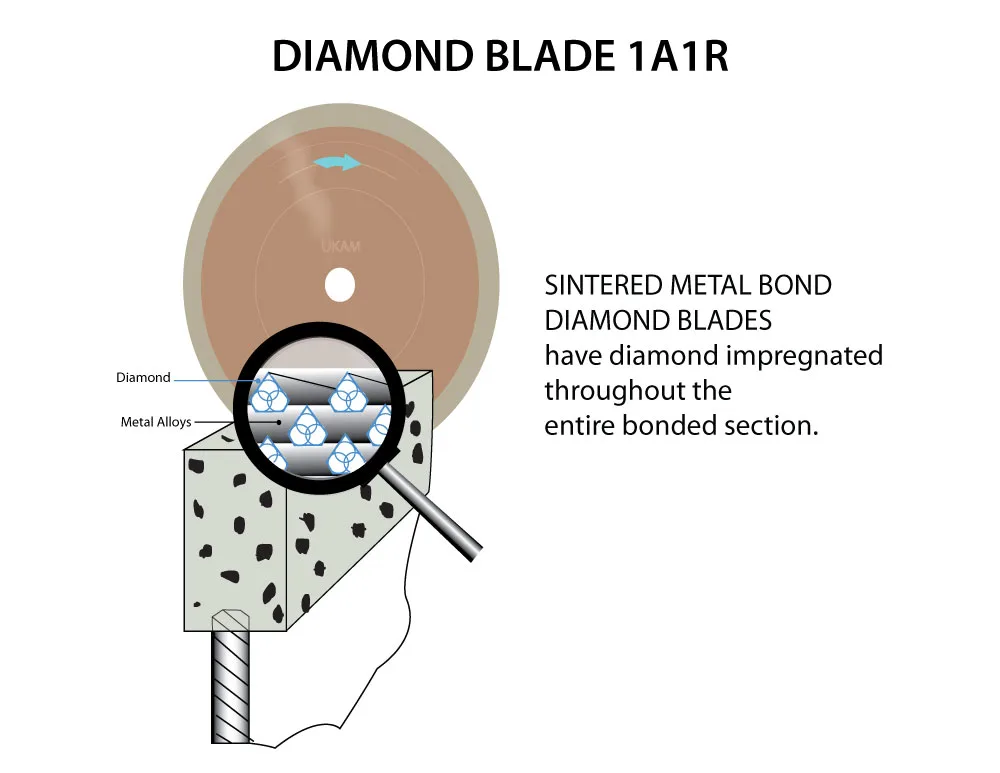

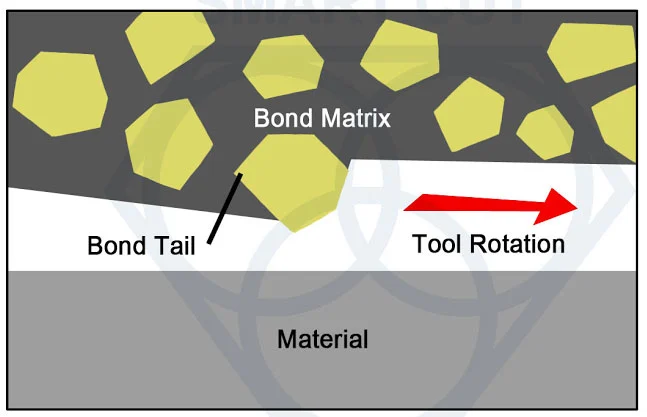

Diamond and CBN tools are fundamentally different because they use superhard crystals either synthetic diamond or cubic boron nitride (CBN)as the cutting medium. These crystals are embedded in specialized bonds, which can be metal, resin, vitrified, or electroplated. Each bond system provides distinct performance benefits.

Metal bond tools are extremely durable and wear-resistant, making them ideal for long production runs and cutting very hard materials. Resin bond tools deliver a smoother finish, lower cutting forces, and reduced risk of chipping, which is essential in applications like glass or ceramics. Vitrified bond tools provide excellent porosity, thermal stability, and coolant access, making them suitable for precision grinding of advanced ceramics and aerospace alloys. Electroplated tools feature a single layer of diamond or CBN particles fixed to the tool surface, producing very sharp edges for high-precision and delicate operations.

Because of their composition, diamond and CBN tools can process ultra-hard, brittle, and high-value materials such as ceramics, quartz, sapphire, composites, and hardened steels with greater accuracy, longer life, and superior surface finish compared to conventional abrasives. While they involve a higher initial cost, their ability to reduce downtime, minimize dressing, and extend tool life often results in a better return on investment (ROI) in demanding industrial applications.

Hardness and Wear Resistance

Conventional abrasives such as aluminum oxide and silicon carbide are considered hard materials by most industrial standards, but they have clear limits when used on ultra-hard or brittle substrates. These abrasives tend to fracture and wear down relatively quickly, which reduces their cutting efficiency over time. As a result, tools made with conventional abrasives require frequent dressing and replacement, leading to more downtime and higher long-term operating costs when used on demanding materials. While they perform adequately on softer metals and general machining tasks, they are not ideal for applications that require consistent precision and extended tool life.

In contrast, diamond and cubic boron nitride (CBN) are recognized as the hardest known cutting materials. Diamond rates 10 on the Mohs scale, while CBN follows closely behind at around 9.5, making both significantly harder and more wear-resistant than conventional abrasives. This extreme hardness allows diamond and CBN tools to maintain sharper cutting edges for longer periods, resulting in superior wear resistance, tighter tolerances, and improved surface finishes. Because they retain their sharpness even under heavy loads, diamond and CBN tools are the preferred choice for cutting, grinding, and drilling ultra-hard materials such as advanced ceramics, glass, quartz, composites, and hardened steels. The combination of high hardness and durability reduces the frequency of tool changes, lowers overall downtime, and increases productivity, delivering a clear advantage in precision-focused industries.

Composition and Construction

Conventional abrasive tools are made with synthetic abrasive grains such as aluminum oxide (Al₂O₃), silicon carbide (SiC), or zirconia alumina. These grains are produced in controlled sizes and shapes, then bonded together using systems such as resin, vitrified (ceramic), rubber, shellac, or silicate. The bond material not only holds the abrasive grains in place but also controls tool strength, porosity, and cutting behavior.

For example, resin bonds provide flexibility and faster cutting action but wear faster under heavy loads, while vitrified bonds are more rigid, thermally stable, and dimensionally accurate, making them suitable for applications requiring higher precision. The design ensures that grains fracture and renew themselves during use, exposing sharp edges, but it also means abrasive tools must be dressed frequently to maintain performance. Overall, these tools are designed for cost-effectiveness and versatility, particularly in machining softer metals and general-purpose materials.

Diamond and CBN tools, by contrast, are built with superhard crystals either synthetic diamond or cubic boron nitride (CBN) which are far harder than conventional abrasives. These crystals are held in place using specialized bond systems such as metal bonds, resin bonds, vitrified bonds, or electroplated layers.

Each bond type is selected to match the application. Metal bond offer maximum durability and form-holding for long runs in hard materials. Resin bond provide cleaner cutting and reduced chipping, ideal for brittle materials like glass or ceramics. Vitrified bondadd controlled porosity, excellent coolant access, and thermal stability for high-precision grinding. Electroplated toolsapply a single, sharp layer of diamond or CBN particles to the tool surface, producing an aggressive cutting action for delicate or complex geometries. Because of their construction, diamond and CBN tools can cut, grind, or drill ultra-hard and brittle materials that would quickly destroy conventional abrasives. They maintain long tool life, high accuracy, and superior surface finishes, but they also require higher upfront investment, correct coolant flow, and proper handling to achieve their full potential.

Cutting Mechanism

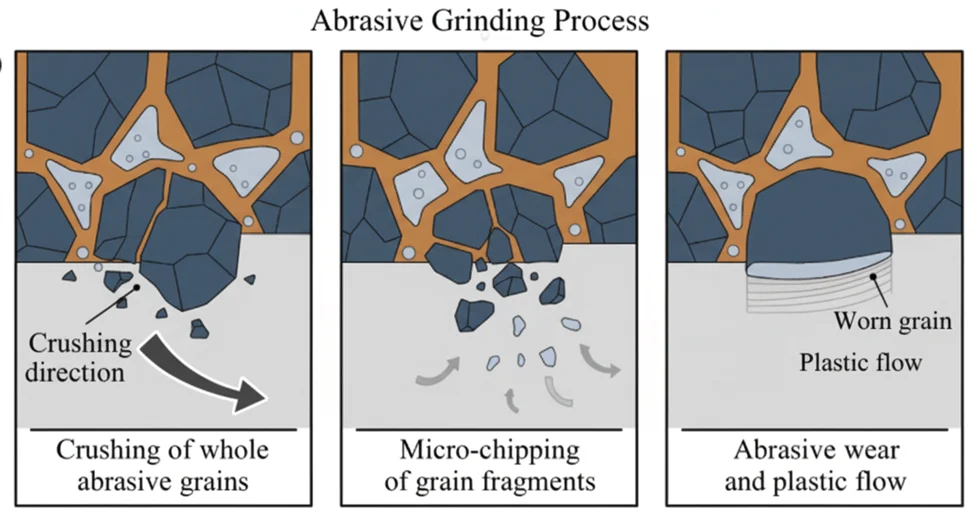

Conventional abrasive tools remove material through a process of gradual surface wear. Each abrasive grain functions as a tiny cutting edge, but unlike a true sharp edge, it primarily acts by scratching, plowing, and fracturing the surface. Because thousands of grains are in contact with the workpiece at once, the result is a progressive wearing action where material is slowly abraded away.

This mechanism is effective on softer metals and general materials but becomes less efficient on ultra-hard or brittle substrates, since the abrasive grains themselves dull and break down more quickly. As a result, abrasive tools often require frequent dressing to restore sharpness and maintain cutting efficiency.

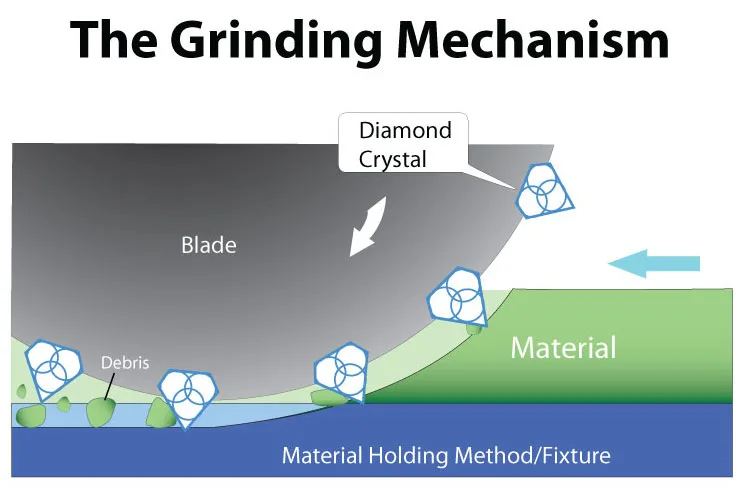

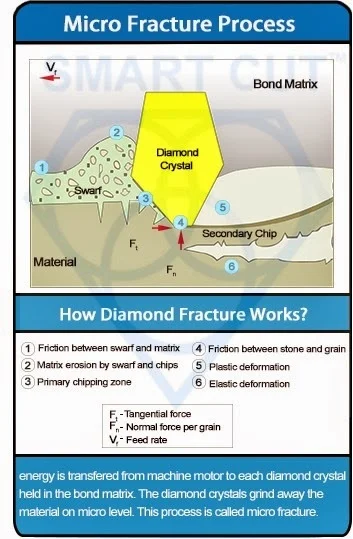

Diamond and CBN tools work by a distinctly different principle. Their superhard crystal edges penetrate and shear the workpiece, functioning more like a true cutting edge rather than a plowing surface.

The sharp, high-hardness edges of diamond and CBN can slice into even the hardest materials, such as sapphire, ceramics, hardened steels, and composites, where conventional abrasives would rapidly wear out.

Because the cutting action is based on penetration and shearing, diamond and CBN tools maintain tighter tolerances, cleaner surface finishes, and greater efficiency. This sharper mechanism not only extends tool life but also reduces cutting forces, lowers heat generation, and minimizes subsurface damage, which is critical in precision industries like optics, electronics, and advanced ceramics.

Cooling and Lubrication

Conventional abrasive tools typically use standard coolants such as water-based emulsions, oils, or air mist to manage heat during operation. These fluids help control grinding temperatures, wash away swarf, and extend tool life. Because abrasive grains like aluminum oxide and silicon carbide are more forgiving, their coolant requirements are not highly specialized. The main objectives are to minimize thermal damage, prevent burns on the workpiece, and reduce glazing on the wheel. In many cases, even a modest coolant flow is sufficient to keep abrasive tools cutting effectively.

Diamond and CBN tools require a much higher level of control. Their extreme hardness concentrates cutting forces at very small contact points, creating intense localized heat. If not managed, this heat can weaken the bond, shorten tool life, and damage the workpiece. For this reason, coolant is not optional but essential for temperature control, lubrication, bond protection, and debris removal. The most common choice is water-soluble coolants with additives for lubricity, anti-foaming, and corrosion resistance. In precision applications such as dicing, wafering, or machining ceramics, coolants must also be chemically compatible with the workpiece, since certain materials can react with the coolant and accelerate tool wear.

Delivery of coolant is just as important as the fluid itself. Diamond and CBN tools demand a strong, properly directed flow to reach the cutting zone. Poor delivery can leave parts of the edge dry, leading to thermal cracks in the workpiece or glazing of the tool. Advanced setups often use high-pressure pumps, fine filtration, and recirculation systems to keep coolant clean and effective. This ensures maximum tool performance, consistent cut quality, and longer tool life.

Application

Both abrasive and diamond tools are used across many of the same industries, particularly in grinding and cutting applications involving metals, ceramics, and composites. At first glance they can appear interchangeable, but the choice of tool has a direct impact on performance, cost, and the quality of the final result. The overlap comes from the fact that both categories are capable of removing material efficiently, yet their suitability depends heavily on the hardness of the material, the required tolerances, and the economics of the process.

Abrasive tools are most effective when working with softer steels, aluminum, and other non-critical materials. They are widely available, less expensive, and perform adequately in environments where tool longevity and ultra-high precision are not essential. For general grinding, shaping, or polishing tasks where the goal is material removal at low cost, conventional abrasives remain the preferred option. Their lower initial cost makes them attractive for projects where budget is the primary concern or where tools are expected to be replaced frequently.

Diamond and CBN tools become indispensable when the application involves ultra-hard or brittle materials such as sapphire, quartz, silicon, advanced ceramics, hardened steels, or technical glass. These tools maintain sharp edges and consistent tolerances over long production runs, which is vital in industries such as semiconductors, optics, aerospace, and research laboratories. They are also chosen in cases where reduced downtime, longer tool life, and repeatable accuracy outweigh the higher upfront investment. In environments that demand precise cuts, minimal chipping, and high surface quality, diamond and CBN tools consistently outperform conventional abrasives.

An important factor in today’s market is that the cost of diamond and CBN abrasives has been steadily decreasing due to advances in synthesis technology and large-scale production efficiencies. Where these tools were once prohibitively expensive and reserved only for the most demanding applications, they are now far more cost-effective and increasingly competitive with conventional abrasives. This shift means that many manufacturers who previously relied only on standard abrasives are now able to incorporate diamond or CBN tools into their processes, gaining the benefits of higher precision, longer service life, and better overall cost-effectiveness.

In practice, both types of tools often coexist in the same workshop. Abrasives handle routine, less demanding jobs efficiently, while diamond and CBN tools are reserved for the most critical operations where failure or inconsistency would be far more costly than the price of the tool itself. This balance allows manufacturers and researchers to optimize productivity while controlling costs, ensuring that the right tool is used for the right material and application.

Application Examples

The choice between abrasive tools and diamond tools is most evident when looking at specific industries. In construction, conventional abrasives are commonly used for general grinding, smoothing, and surface preparation, where precision is not the primary concern. For more demanding tasks, such as cutting concrete, reinforced materials, stone, or asphalt, diamond blades are indispensable. Their ability to withstand high loads, maintain sharpness, and cut efficiently through aggregates and rebar makes them the tool of choice for contractors who require durability and consistent performance on site.

In metallography and materials research, abrasives play a vital role in polishing and surface preparation, where sequential steps with progressively finer grits are used to create a mirror finish for microscopic analysis. However, when it comes to precise sectioning of samples without introducing deformation or thermal damage, diamond blades are relied upon. Their ability to maintain accuracy and minimize subsurface alteration ensures that the material’s true microstructure can be studied without artifacts caused by the cutting process.

In the fields of electronics and optics, the advantages of diamond tools are even more pronounced. Applications such as dicing silicon wafers, machining sapphire substrates, cutting quartz components, and processing delicate optical glass demand extreme precision, tight tolerances, and clean edges with minimal chipping. In these cases, diamond dicing blades and diamond saws are standard, as conventional abrasives cannot maintain the necessary performance or cut quality. The use of diamond tools in these industries not only improves yield but also reduces the risk of costly damage to high-value components.

When evaluating tool choice, the balance of advantages and disadvantages becomes critical. Conventional abrasive tools remain widely used because of their lower purchase cost and broad availability. They are suitable for a wide range of general-purpose applications, particularly where budget is a primary concern and where ultra-high precision is not required. Their accessibility makes them an attractive option for workshops handling softer steels, aluminum, and routine grinding or polishing tasks.

However, abrasive tools come with clear limitations. Their tool life is significantly shorter compared to diamond or CBN products, and they require frequent dressing and replacement to maintain performance. On hard or brittle materials, they struggle to achieve tight tolerances and clean surface finishes, often leading to greater downtime, more scrap, or the need for secondary finishing steps. This makes them less suitable for industries where consistency and accuracy are critical.

Diamond and CBN tools, on the other hand, provide clear performance benefits. Their extreme hardness and durability result in a much longer service life, allowing them to maintain sharpness and cutting efficiency even under demanding conditions. They are capable of delivering high precision and tight tolerances, which is especially important in fields such as electronics, optics, aerospace, and advanced ceramics.

Their ability to achieve faster cutting speeds with reduced chipping means less rework and more consistent results. Just as importantly, they contribute to less downtime by reducing the frequency of tool changes, which directly improves productivity.

These advantages are balanced by certain challenges. Diamond and CBN tools typically involve a higher initial purchase price, which may not be justified in jobs involving soft or easily machinable materials where conventional abrasives perform adequately. In addition, they require proper coolant selection and delivery, as well as correct mounting methods, to achieve their full potential. Failure to meet these conditions can lead to premature wear, bond damage, or inconsistent results.

|

Variable |

Abrasive Tools |

Diamond & CBN Tools |

|---|---|---|

|

Initial Cost |

Low purchase cost, ideal for tight budgets and general work. |

Higher upfront cost, but steadily decreasing due to improved production methods. |

|

Availability |

Widely available globally in many standard formats. |

Available in a wide range but usually from specialized suppliers. |

|

Tool Life |

Short lifespan, grains wear quickly and tools must be replaced often. |

Very long lifespan, edges stay sharp on ultra-hard materials. |

|

Maintenance |

Require frequent dressing to expose new grains and prevent glazing. |

Minimal dressing needed, but require careful coolant management. |

|

Precision |

Good enough for general machining, but limited on hard or brittle materials. |

High precision and tight tolerances, essential for critical industries. |

|

Cutting Speed |

Slower cutting rates, more friction and wear. |

Faster cutting speeds, reduced chipping, smoother edges. |

|

Surface Finish |

Produces rougher surfaces, often needs additional polishing. |

Produces superior finishes, often eliminating secondary processes. |

|

Downtime |

Frequent tool changes and dressing increase downtime. |

Fewer tool changes, reducing interruptions and increasing productivity. |

|

Cooling & Lubrication |

Standard coolants (water-based emulsions, oils, air mist) usually sufficient. |

Require specialized coolants and directed flow to avoid thermal damage. |

|

Mounting Requirements |

Simple mounting, forgiving of minor setup issues. |

Precise mounting essential; poor setup can cause premature wear or tool failure. |

|

Material Compatibility |

Best for soft steels, aluminum, and non-critical materials. |

Best for sapphire, silicon, advanced ceramics, quartz, glass, hardened steels. |

|

Versatility |

Works across many general-purpose applications. |

Specialized for precision and ultra-hard applications. |

|

Economic Tradeoff |

Cost-effective only in low-precision, short-run jobs. |

Increasingly cost-effective in high-value industries due to falling prices and longer life. |

|

Environmental Factors |

More dust, swarf, and heat; requires frequent cleaning. |

Cleaner operation with proper coolant; lower waste due to long tool life. |

|

Operator Skill |

Easier to use, less demanding on setup and handling. |

Requires trained operators to manage coolant, speeds, and precision settings. |

Comparing Diamond / CBN & Abrasive Tool Total Cost of Ownership and Return on Investment

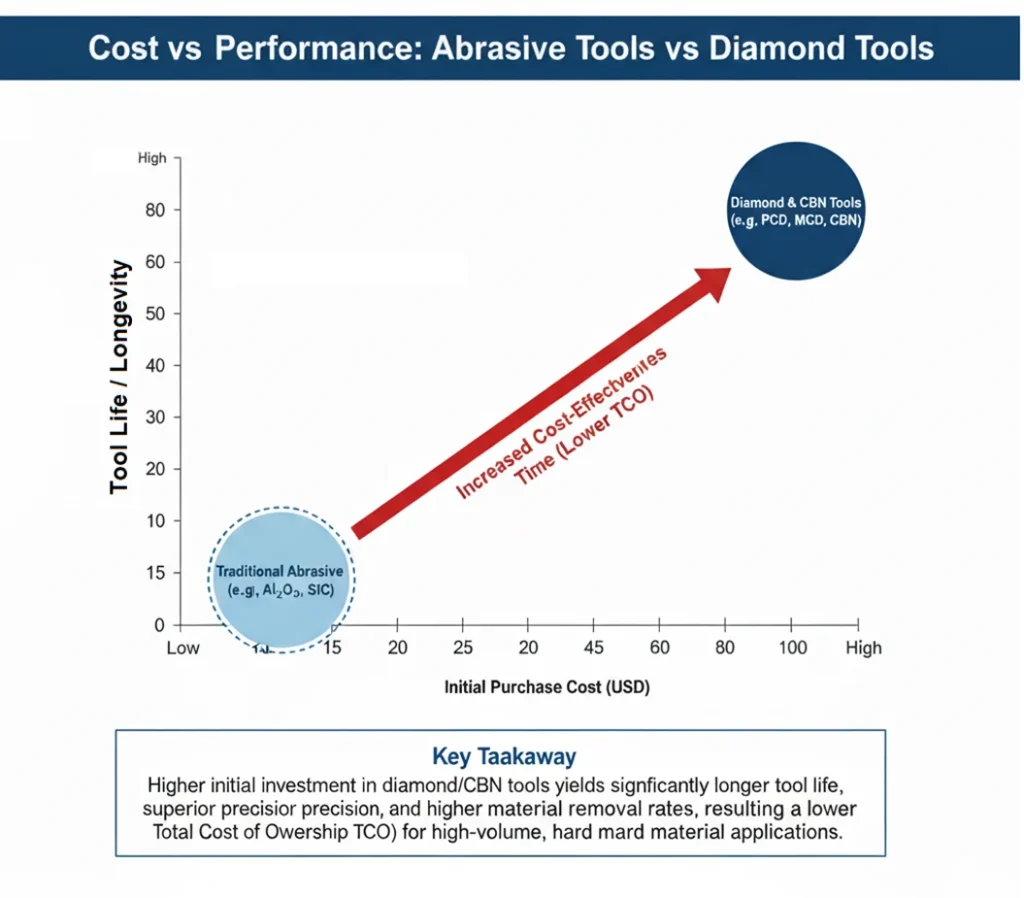

When comparing abrasive tools to diamond and CBN tools, the decision is rarely determined by upfront purchase price alone. What matters more is the total cost of ownership (TCO) and the overall impact on productivity, consistency, and material yield. A tool that appears less expensive at the point of purchase may, in practice, cost more due to frequent replacements, downtime, or the need for rework.

For many high-value and high-precision industries, TCO strongly favors diamond and CBN tools. Their longer service life, reduced dressing frequency, and consistent performance lower the number of tool changes and interruptions. This leads to less downtime and fewer rejected parts, both of which have a direct effect on profitability. In applications where every component carries high value, such as electronics, optics, aerospace, and advanced ceramics, a single failure or scrap can cost far more than the price difference between an abrasive wheel and a diamond tool.

The return on investment (ROI) also often improves with diamond tools. Because they cut faster, generate less chipping, and maintain tolerances for longer runs, they help achieve higher throughput and more stable processes. In industries where process consistency and material yield are critical, these factors add up to significant savings. With fewer interruptions, fewer defective parts, and longer tool intervals, diamond and CBN tools can easily recover their higher initial cost and continue delivering value throughout their lifespan.

That said, abrasive tools remain the more economical choice for many low-cost and low-precision applications. In routine jobs involving soft steels, aluminum, or non-critical materials, where tool wear is not catastrophic and precision is secondary, the lower purchase price of abrasives makes them practical. Their widespread availability and ability to perform adequately without specialized coolants or mounting methods keep them attractive for general-purpose work.

A notable trend is that the cost of diamond and CBN tools has been steadily decreasing due to advances in synthetic crystal production and large-scale manufacturing. This has made superabrasives increasingly competitive with conventional abrasives, even outside the most demanding industries. As the price gap continues to narrow, more manufacturers are finding that diamond and CBN tools are not only technically superior but also cost-effective in a growing range of applications.

Diamond Grit Size vs. Conventional Abrasive Grit Size

Diamond Grit Size: This is measured in terms of mesh size, which refers to the number of holes per inch of a screen through which the diamond particles are sized. Diamond mesh size is inversely related to the diamond particle size—larger mesh numbers indicate smaller particles.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.

ARE YOU USING RIGHT PCD Diamond & CBN TOOLs

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT PCD Diamond & CBN Tools?

Knowledge Center

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

Diamond vs CBN (cubic boron nitride) Tools

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

What is Chemical Vapor Deposition and its application

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.