Diamond Backgrinding Wheels: An In-Depth Guide to Wafer Thinning and Precision Grinding

-

Posted by

Brian Farberov

Brian Farberov

Table of Contents

ToggleWith the further shrinking of semiconductor devices and ramping up of performance, wafer processing has become increasingly stringent. Perhaps one of the most important steps, and yet often underemphasized, is backgrinding. Key to this is diamond backgrinding wheels that allow exact wafer thinning and prevent the fragile substrates from damage.

Backgrinding has very little margin for error, unlike standard grinding applications. The goal is not aggressive material removal but controlled thickness reduction with minimal stress, consistent flatness, and predictable surface integrity. This article explores diamond backgrinding wheels in detail – how they work, where they are used, and why correct specification matters far more than many realise.

Understanding Backgrinding in Semiconductor Manufacturing

Backgrinding is an operation to be performed after a wafer has been fabricated and after the front-side circuitry of the wafer is formed. At this point, the wafer has substantial worth, and any mistake can lead to expensive yield defects.

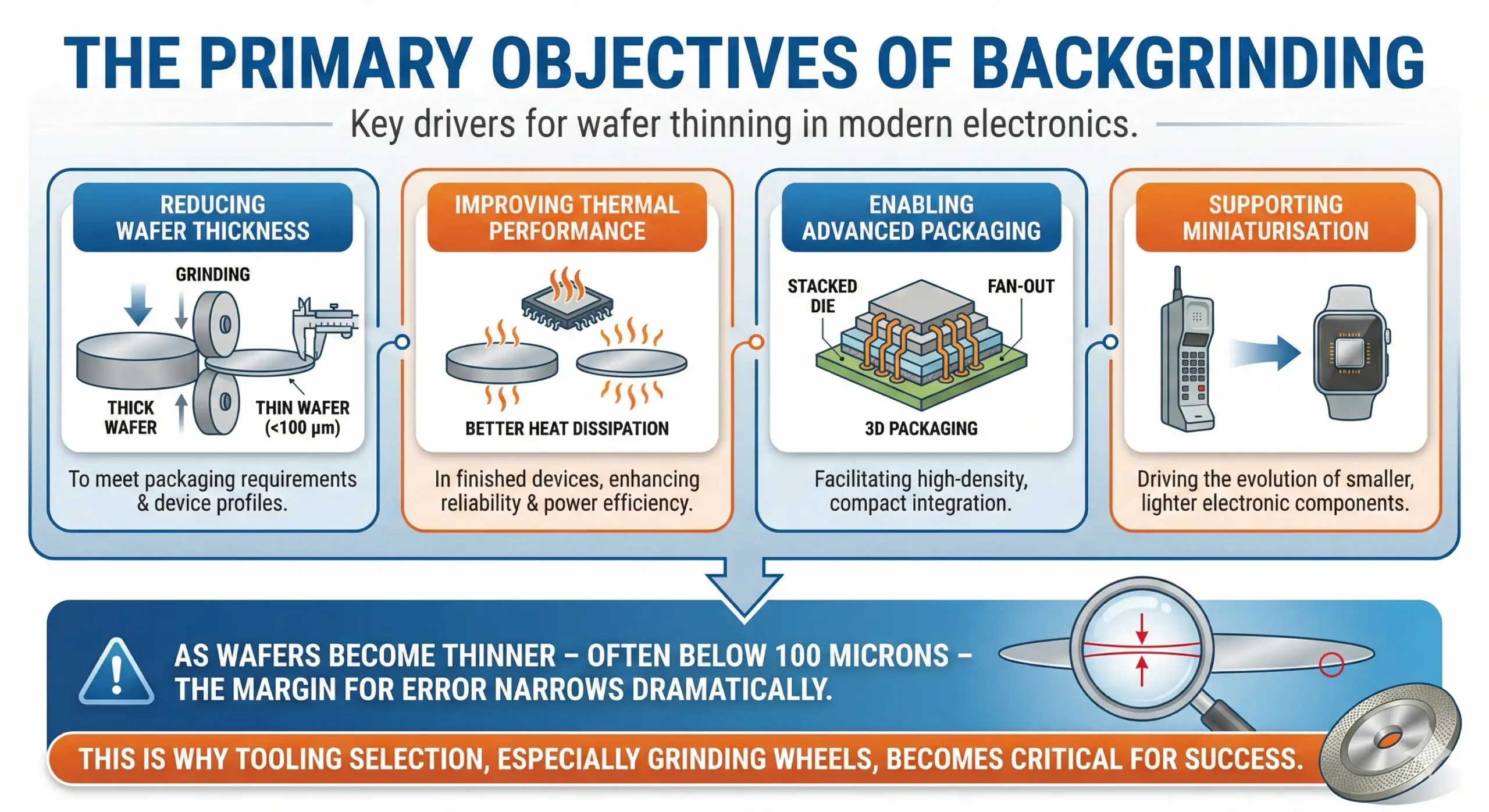

The primary objectives of backgrinding include:

- Reducing wafer thickness to meet packaging requirements

- Improving thermal performance in finished devices

- Enabling stacked die, fan-out, and advanced 3D packaging

- Supporting miniaturisation of electronic components

As wafers become thinner – often below 100 microns—the margin for error narrows dramatically. This is why tooling selection, especially grinding wheels, becomes critical.

Why Diamond Backgrinding Wheels Are Essential

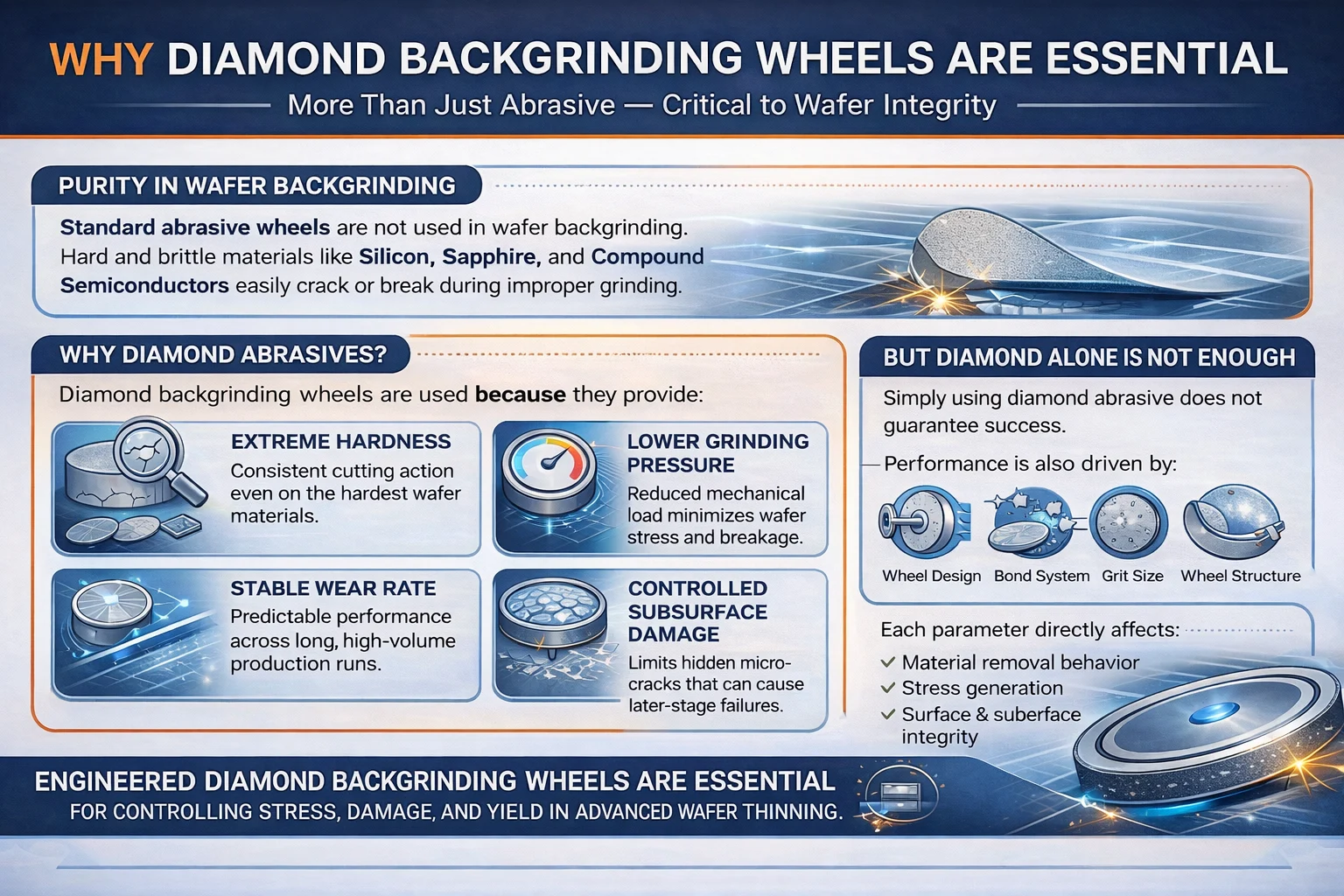

Purity: The Wafer Backgrinding process does not use standard abrasive wheels. Hard and brittle Silicon, sapphire, compound semiconductor, etc., break easily during the bad grinding process.

Diamond abrasives are used because they offer:

- Extremely high hardness for consistent cutting action

- Reduced grinding pressure, lowering wafer stress

- Stable wear rates over long production runs

- Better control of subsurface damage

However, simply using a diamond is not enough. The wheel design, bond system, grit size, and structure all influence performance.

Key Components of a Diamond Backgrinding Wheel

The Backgrinding wheel is an extremely accurate piece of equipment. Each part has a particular purpose in the way the wheel works while running.

1. Diamond Abrasive Characteristics

The size, quality, and distribution of diamond particles directly affect surface finish and removal rate.

- Coarse diamond grains are typically used during initial thinning

- Fine diamond grains are preferred for finishing stages

- Uniform distribution ensures even material removal

Poorly graded diamond abrasives can result in uneven wear and localised stress points on the wafer.

2. Bond System and Wheel Structure

The bond holds diamond particles in place while allowing controlled release as the wheel wears.

Important bond-related factors include:

- Bond hardness

- Porosity for chip evacuation

- Thermal conductivity

- Wear behaviour under constant load

If the bond is too hard, the workpiece will not be subjected to normal grinding forces and cause glazing; if the bond is too soft, it will wear much faster. The proper ratio is a function of material, tooling, and volume.

3. Wheel Geometry and Flatness

Backgrinding wheels must maintain exceptional flatness and balance. Even minor deviations can lead to:

- Non-uniform wafer thickness

- Edge chipping

- Increased downstream breakage

Precision manufacturing and quality control during wheel production are essential for maintaining dimensional stability over time.

Materials Commonly Processed Using Backgrinding Wheels

Diamond backgrinding wheels are used across a range of advanced materials, including:

- Silicon wafers

- Gallium arsenide (GaAs)

- Silicon carbide (SiC)

- Sapphire substrates

- Glass and ceramic wafers

Each material responds differently to grinding forces, which is why wheels must be matched carefully to the application rather than selected generically.

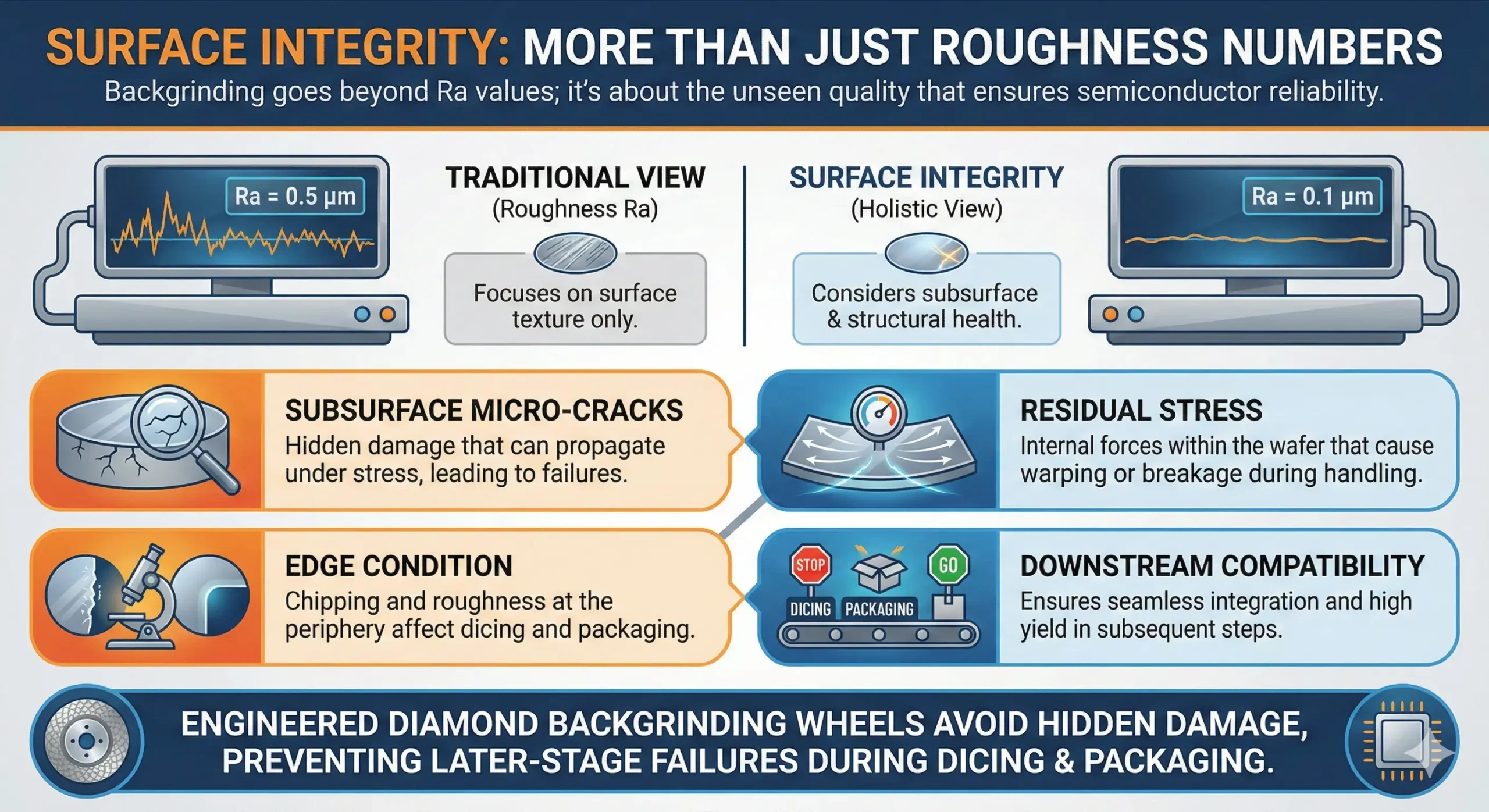

Surface Integrity: More Than Just Roughness Numbers

Many backgrinding discussions focus on surface roughness (Ra), but surface integrity goes far beyond numerical values.

Key considerations include:

- Subsurface micro-cracks

- Residual stress within the wafer

- Edge condition after grinding

- Compatibility with downstream processes

Diamond backgrinding wheels for semiconductor applications are engineered to avoid damage that is not readily apparent, but which may lead to failures during dicing or packaging at a later stage.

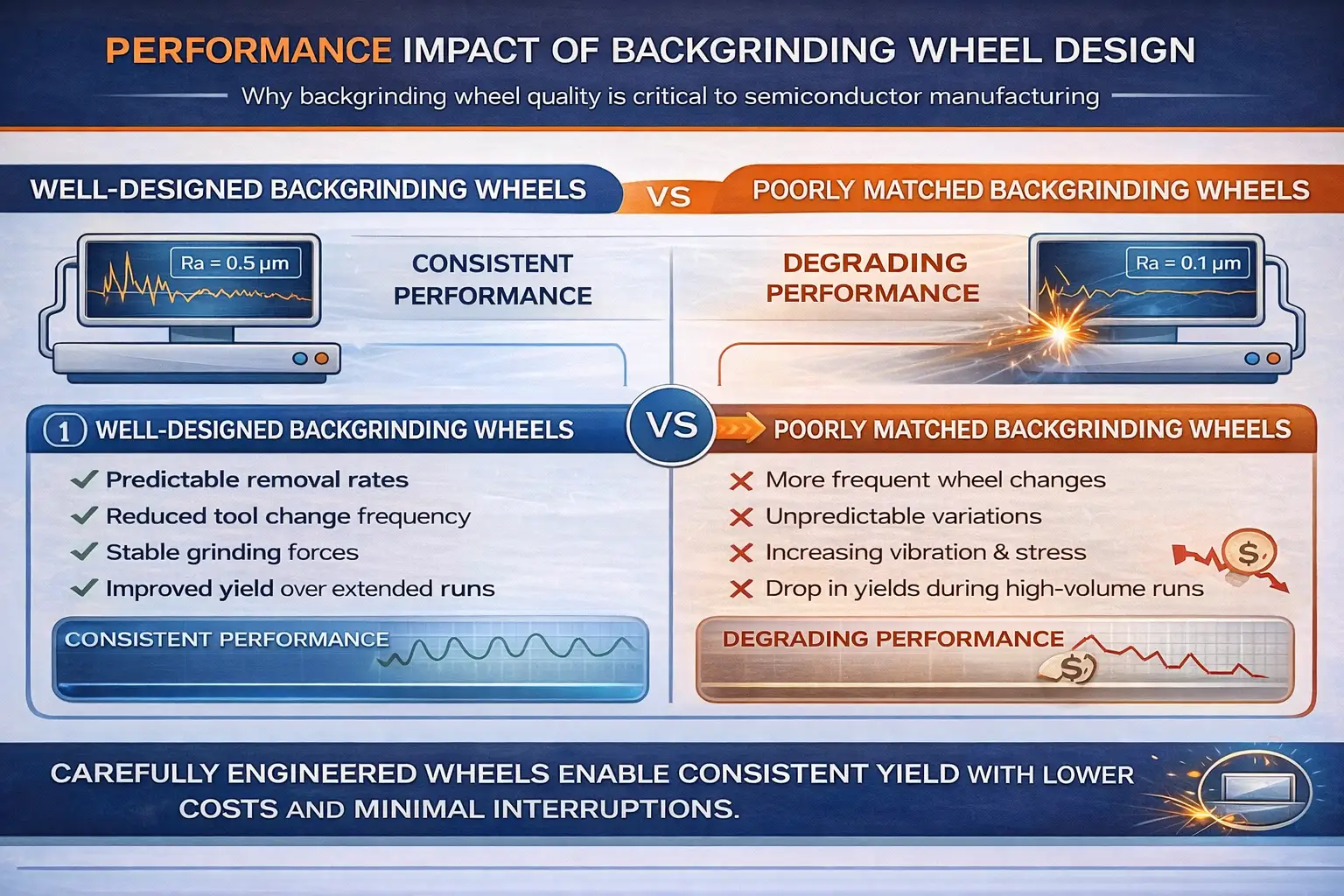

Process Stability and Long-Term Performance

In high-volume manufacturing, consistency is more important than peak performance in short trials.

Well-designed backgrinding wheels contribute to:

- Predictable removal rates

- Reduced tool change frequency

- Stable grinding forces

- Improved yield over extended runs

On the other hand, poorly matched wheels may show acceptable performance in preliminary testing but quickly break down during high-volume production.

Common Problems Linked to Improper Wheel Selection

When grinding issues arise, machine parameters are often blamed first. However, many problems originate from incorrect wheel specification.

Common issues include:

- Wafer cracking during thinning

- Excessive heat buildup

- Surface contamination

- Premature wheel wear

- Uneven thickness profiles

Identifying and correcting wheel-related causes early can prevent costly downtime and scrap.

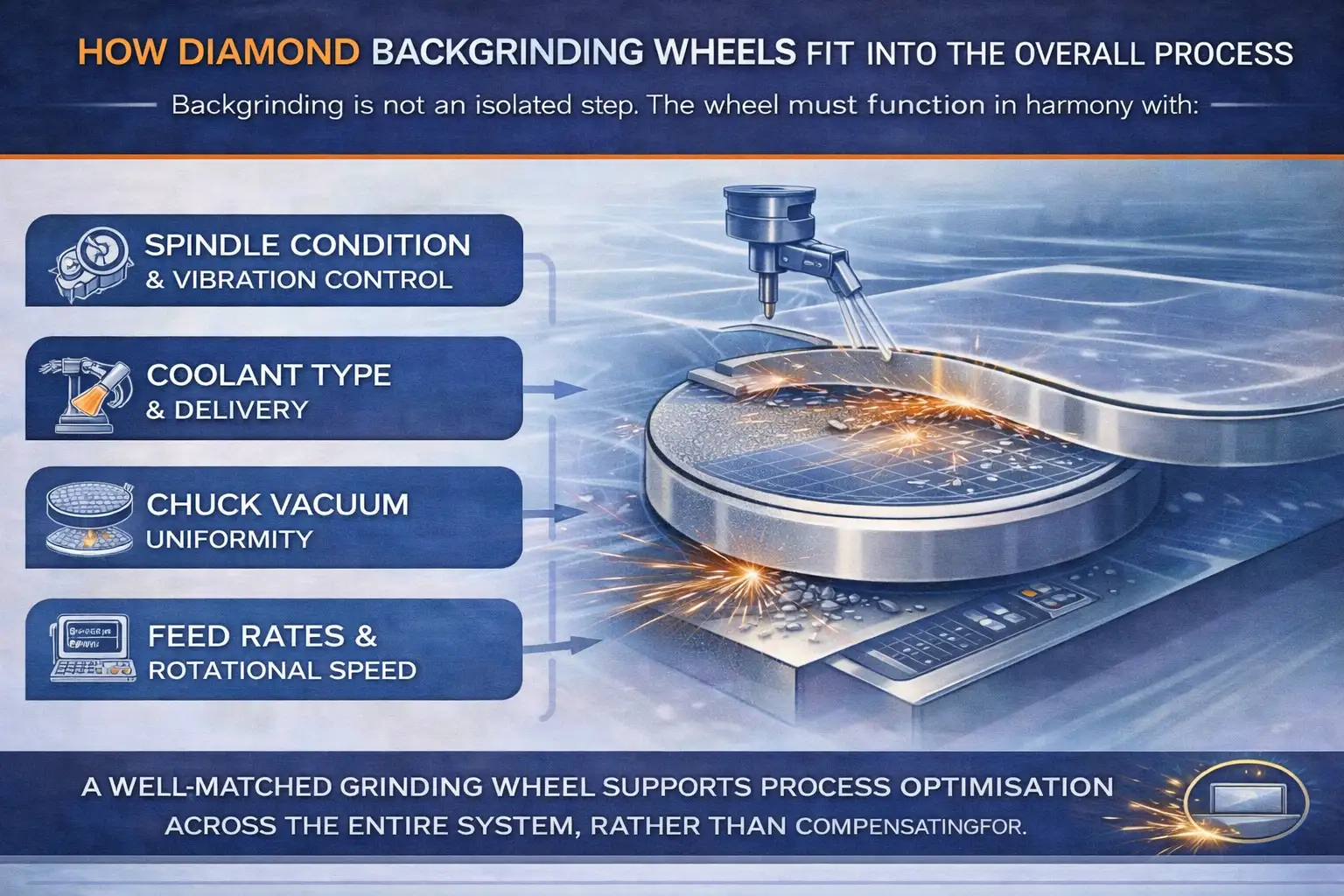

How Diamond Backgrinding Wheels Fit into the Overall Process

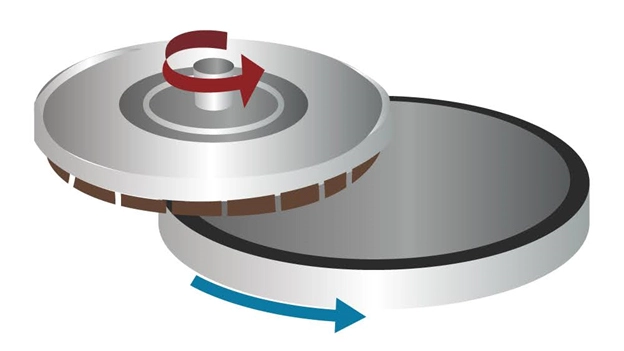

Backgrinding is not an isolated step. The wheel must function in harmony with:

- Spindle condition and vibration control

- Coolant type and delivery

- Chuck vacuum uniformity

- Feed rates and rotational speed

A well-matched grinding wheel supports process optimisation across the entire system, rather than compensating for poor conditions.

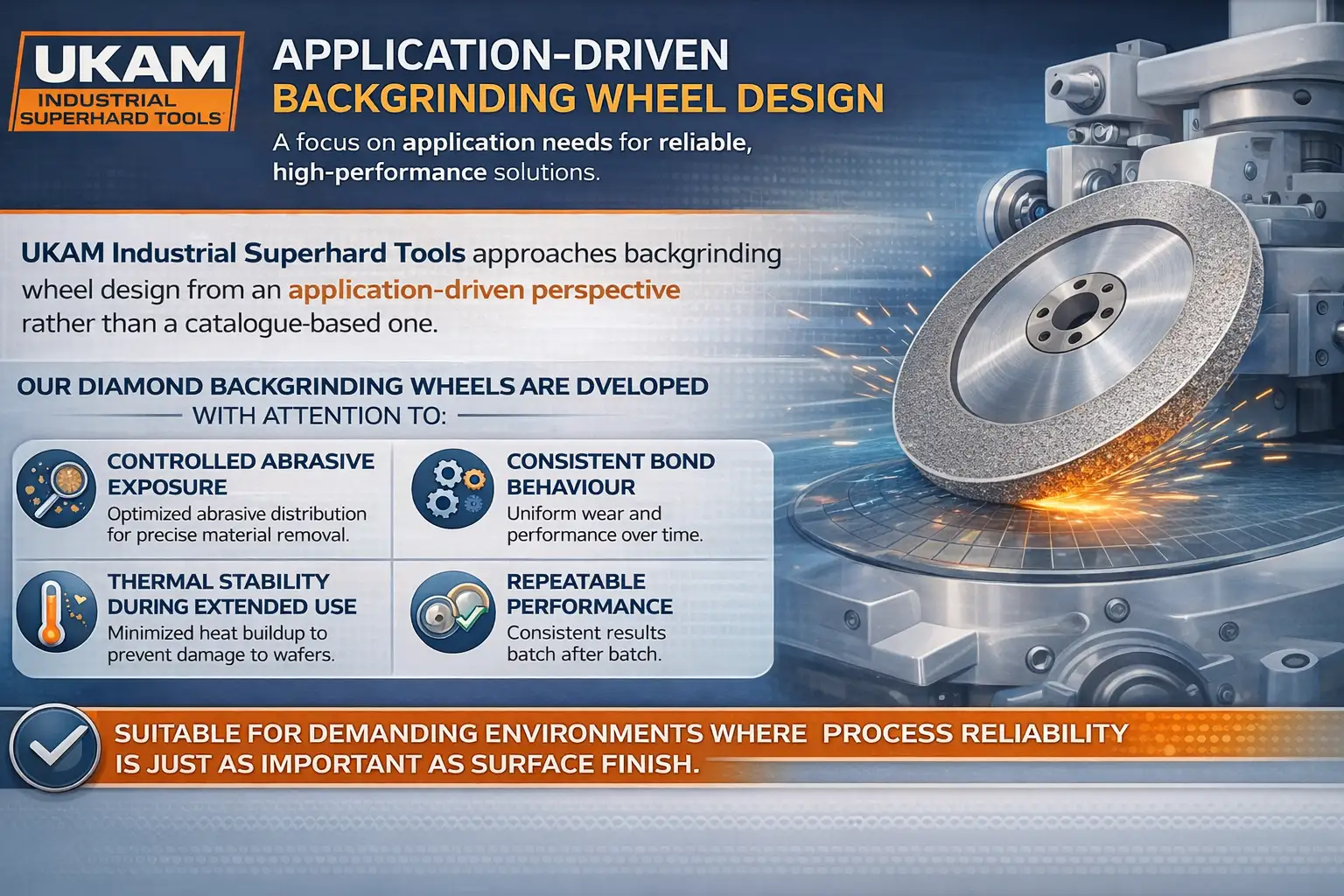

UKAM’s Engineering Philosophy for Backgrinding Applications

UKAM Industrial Superhard Tools approaches backgrinding wheel design from an application-driven perspective rather than a catalogue-based one.

Their diamond backgrinding wheels are developed with attention to:

- Controlled abrasive exposure

- Consistent bond behaviour

- Thermal stability during extended use

- Repeatable performance from wheel to wheel

This focus makes them suitable for demanding environments where process reliability is as important as surface finish.

Wheel Handling, Storage, and Maintenance

Even the best-engineered wheel can fail prematurely if mishandled.

Best practices include:

- Storing wheels in dry, temperature-controlled environments

- Avoiding mechanical shocks during transport and mounting

- Ensuring correct spindle mounting procedures

- Monitoring wear patterns regularly

Preventive handling helps maintain consistent performance and extend tool life.

The Future of Backgrinding Technology

As the industry moves toward ultra-thin wafers and advanced packaging, backgrinding technology continues to evolve.

Emerging trends include:

- Damage-free thinning for ultra-thin substrates

- Improved compatibility with compound semiconductors

- Integration with automated inspection systems

- Increased emphasis on process repeatability

Diamond backgrinding wheels will remain central to these advancements due to their unmatched performance characteristics.

Short FAQs

Backgrinding reduces wafer thickness post front-side processing to enable advanced packaging and device scaling.

Diamond provides excellent wear resistance, cutting performance, and low grinding force when working on hard/brittle materials.

In the worst cases: no. For perfectly provided workpieces with push stored material, hard and finishing is also best to use different wheels for pruning, thinning, and fine finishing.

Damage can be caused by too much pressure, improper wheel bond or lack of flatness.

Extremely important. Even small deviations can lead to uneven thickness and downstream failures.

No. They are also used on sapphire, ceramics, glass, and compound semiconductor materials.

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.