-

0 items in quote

No products in the Quote Basket.

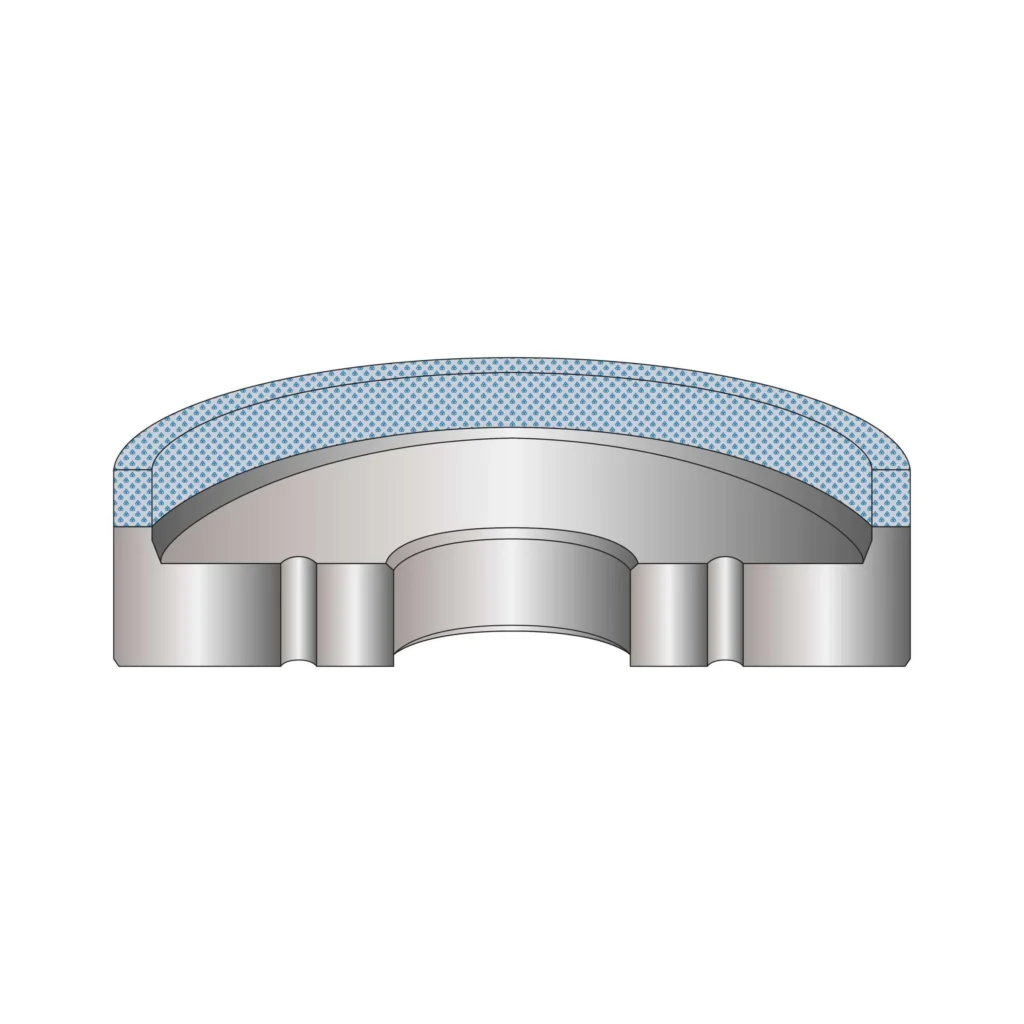

DIAMOND & CBN WHEELS Braised Bond

Diamond & Cbn Wheels

Braised Bond

SMART CUT® Vacuum-brazed Diamond & CBN Wheels are an excellent solution for various industries such as metal processing, automotive, aerospace, ceramics, and composites, where grinding, stock removal, and beveling are important processes.

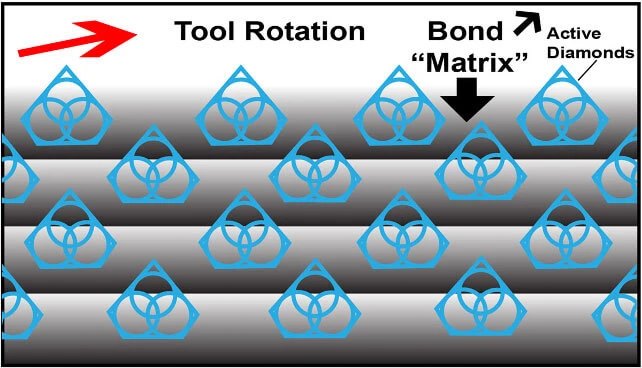

Made with a single layer of super abrasive grit bonded to the core with a proprietary alloy mixture, these wheels ensure the abrasive grit is securely locked in place once it has melted around it and cooled. The use of an extremely blocky diamond grit is deliberate, as these wheels are typically utilized in high-durability processes.

These Braised Bond Diamond & CBN wheels are available in large range of grit sizes, from 25 to 1,200 with a high portion of the grit exposed for an extremely aggressive grinding experience.

Specifications

A range of Diamond & CBN grit sizes from 25 to 1,200 mesh.

Diameters from 0.080" to 30".

Custom tool specifications available with short lead times.

Applications of Brazed Bond Diamond & CBN Wheels:

Ideal for machining tough-to-cut materials, such as non-metallic materials like graphite epoxy, FRP, graphite, fiberglass, friction material, honeycomb, and other composites.

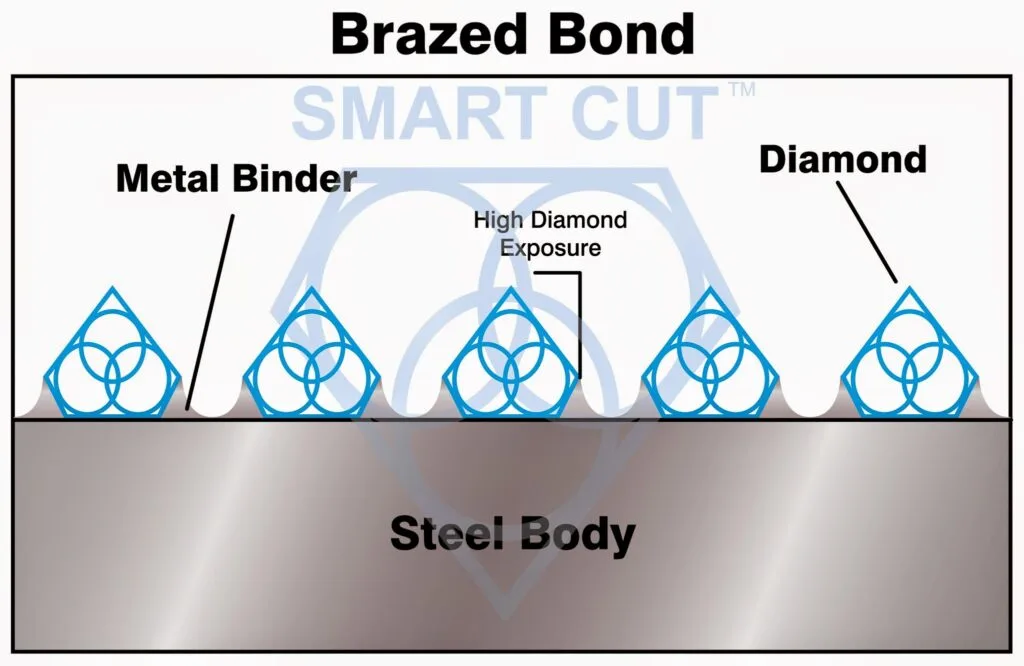

About Brazed Bond

Produced inside a vacuum oven at high temperatures, these tools utilize a fusion process between diamonds and the metal bond. This ensures the diamond section will not strip or peel from the steel body, reducing the loss of diamond particles through pull-out. As a result, users benefit from aggressive tools that last longer, cut faster, run cooler, and load less, thereby increasing productivity and part consistency.

CHARACTERISTICS OF

Braised Bond Diamond & CBN Wheels:

- Main Boding Agent: Various Metals

- Dressability: Good

- Hardness: Very Hard

- Required RPM's: Hight

- Shape of Diamond & CBN Used: Semi blocky Crystal

- Form Holding: Excellent

- Lifespan: Medium

- Cutting Action: Good / Excellent

- Can be Used Dry: Yes

- Cost: Low / Medium

Benefits

- Versatility: With a range of Diamond & CBN grit sizes from 40 to 1,200 mesh and diameters from 0.080" to 30", there is a wheel to suit every need.

- Customization: Custom tool specifications can be produced per your requirements with short lead times.

- Ideal for Tough Materials: Perfect for machining hard-to-cut materials such as non-metallic materials like graphite epoxy, FRP, graphite, fiberglass, friction material, honeycomb, and other composites.

- Durability: The vacuum-brazed process creates a strong bond between the diamond grits and the wheel, ensuring long-lasting performance.

- Consistency: These wheels provide consistent results, contributing to increased productivity and part consistency.

- Cost-Efficiency: Despite their high performance, these wheels are cost-effective in the long run due to their longevity and efficiency.

- Compatibility: Suitable for a wide range of industries including ophthalmic lens, composites, construction, quartz, carbide, silicon, granite/marble, ceramics, plastics industry, glass, and more.

- Environmental Friendliness: Can be used dry and in tough environments, reducing the need for coolant and other potentially harmful substances.

- Lower Power Requirement: Requires less power to operate, saving on energy costs.

- Ability to Retain Form: Capable of retaining form, minimizing the need for adjustments during operation.

Advantages of Brazed Bond Diamond Wheels

- Very fast & aggressive cutting speed

- Maximum diamond crystal exposure

- Ideal for hard-to-machine materials

- Strong retention of diamond grits

- Can be used at faster cutting speeds

- Suitable for dry and tough environments

- Requires less power

- Capable of retaining form

- Minimizes the need for dressing

- Ability to strip and re-plate the tool for reuse

- Lower cost

Diamond & CBN wheels

Braised Bond

Find Diamond & CBN Wheels

By Wheel & Tool shape

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

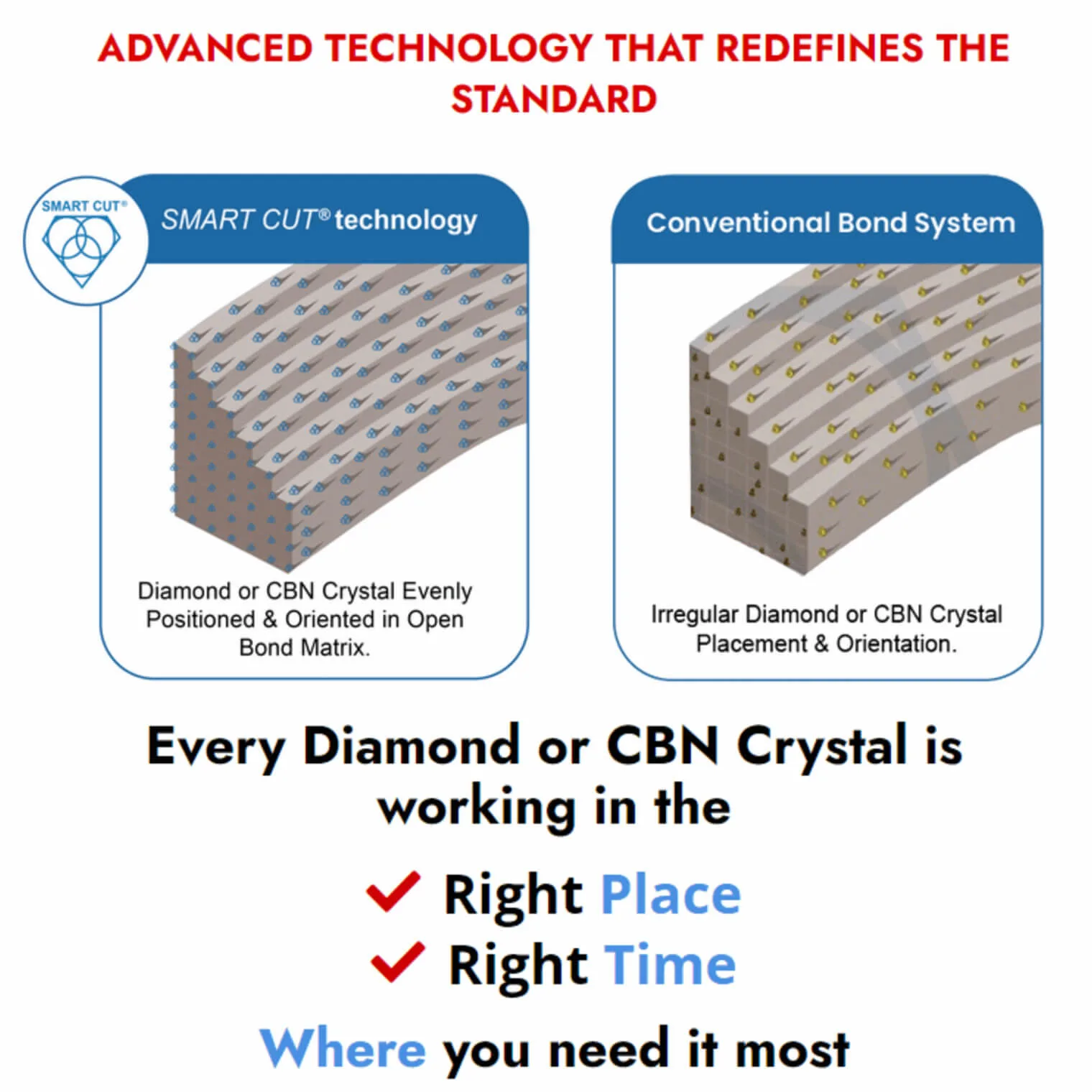

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

How SMART CUT ® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

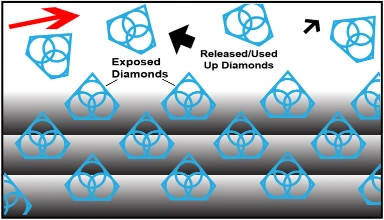

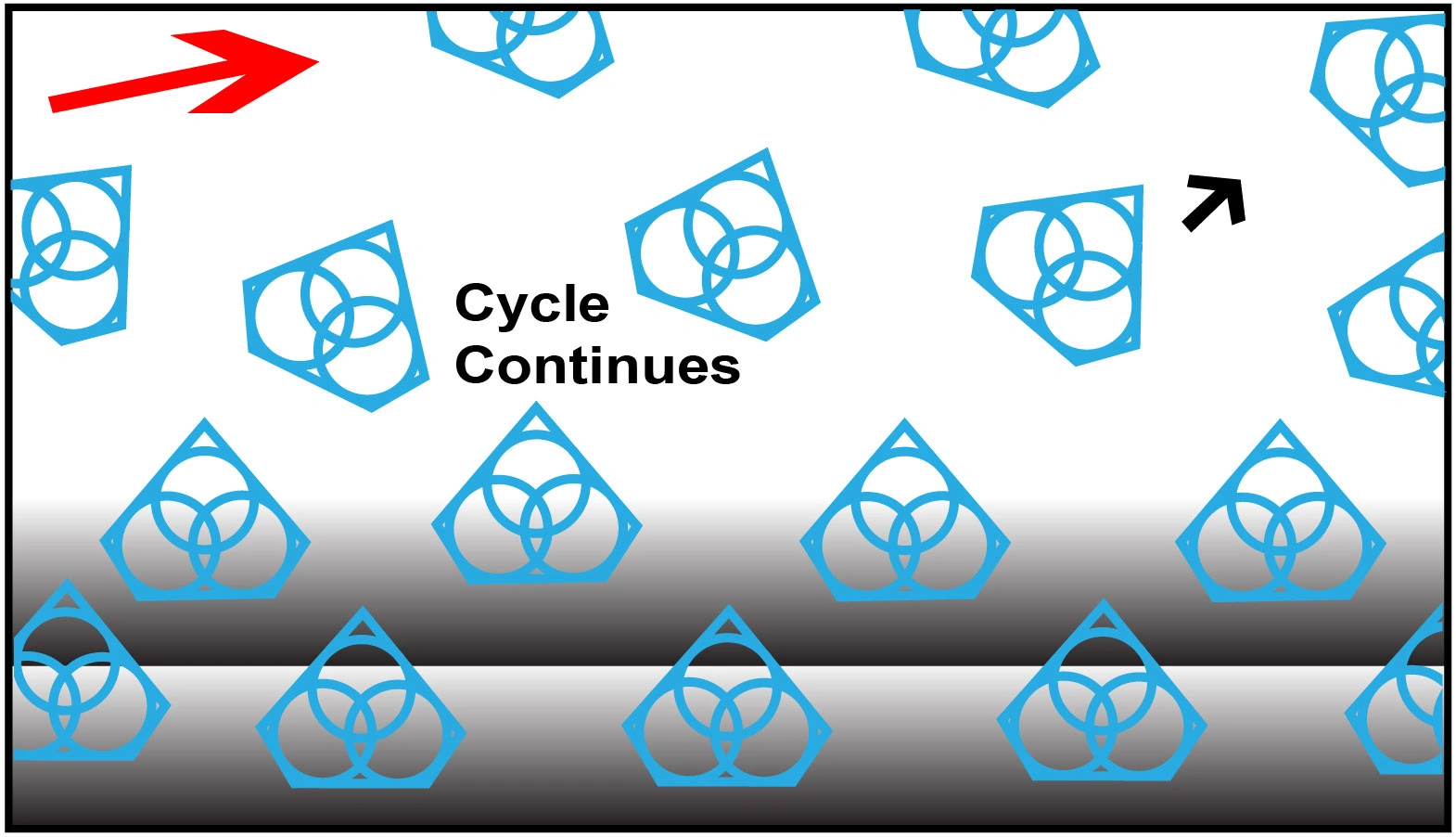

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 2

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

ARE YOU USING RIGHT DIAMOND/CBN WHEEL

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND/CBN WHEELS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

02

Jun

CBN (Cubic Boron Nitride) Grinding Wheels – Everything you wanted to know

Share this Article with Friend or Colleague

Why Use Cubic Boron Nitride (CBN) Wheels?

Cubic boron nitride (CBN) grinding wheels are gaining recognition as superior tools for machining difficult metals. Initially used in toolrooms and cutter-grinding applications,...

02

Jun

Diamond & CBN Wheel Troubleshooting Guide

Our illustrated troubleshooting guide was designed to help you optimize your grinding operations. It assists in diagnosing most possible issues that may arise when using diamond & CBN WHEELS. This guide highlights the signs to watch out for, their...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...