About Us

New Generation Technology

Expect MORE from your tools

Who We Are:

UKAM Industrial Superhard Tools is a U.S. Based High Technology Speciality Manufacturer of Diamond and CBN Tools and Equipment.

We specialize in producing ultra thin & high precision cutting blades and precision cutting machines, diamond drills, diamond micro tools, advanced industrial diamond and cbn tools, and consumables for a wide variety of industries and applications.

What We Do:

We provide real solutions to your everyday cutting, drilling, grinding, and machining challenges. Our products are used worldwide by over 30,000 customers across industry, research and development, contractors, and hobby applications. We maintain thousands of diamond & cbn tools in stock in a wide range of sizes and specifications, and we also offer custom designed and custom manufactured solutions to meet your exact requirements.

Let us be a partner in your success.

Established in

1990

Custom manufacturing

Company By The Numbers

Company By The Numbers

36

Years in Business

1,500

Different Tool Specifications

120

Countries Exported

10

Different Diamond Technologies

30,000

Custom Tools Made

50+

Years of Experience

30,000+

Clients Around the World

World Class Industrial Diamond & CBN Tools

From stock & manufactured to your specifications

DIFFERENT PRODUCT

Products & Solutions

Different Product

UKAM Industrial Superhard Tools manufactures world class industrial diamond and CBN tools, from standard stock to fully custom- manufactured solutions. We offer sintered (metal bond), resin bond, hybrid, nickel bond (electroplated), braised, vitrified, PCD, and CVD diamond products, including ultra-thin precision blades, diamond drills, and grinding wheels. Our engineers work directly with you to select or develop the correct solution for your specific application.

|

Cutting Solutions |

Drilling Solutions |

Grinding, Shaping & Profiling Tools |

|---|---|---|

|

|

Machines & Equipment |

Services & Engineering Capabilities |

Accessories |

|---|---|---|

|

Polishing, Lapping & Sample Preparation Consumables |

Advanced Superabrasive Tooling |

Dressing & Conditioning Tools |

|---|---|---|

ULTRA THIN & HIGH PRECISION

Diamond & CBN Blades

UKAM Industrial Superhard Tools manufactures precision diamond slicing and dicing blades used for slicing, dicing, wafering, cut-off, singulation, grooving, slotting, cross-sectioning, gang sawing, slabbing, and rough cutting applications. As well as diamond band saw blades & diamond wire.

Our blades are engineered for use on laboratory precision saws, dicing saws, wafering saws, low-speed saws, high-speed cut-off saws, and custom cutting systems.

They are designed for processing a wide range of advanced materials, including ferrous and non-ferrous metals, ultra-hard materials, precision optics, semiconductors, ceramics, glass, and electronic components.

DIAMOND DRILLS

From Micro to Large for Demanding Applications

UKAM Industrial Superhard Tools manufactures a full range of precision diamond drilling tools, micro tools, and diamond core drills, covering diameters from 0.001" to 48", for drilling virtually any material.

We offer a wide selection of standard stock drills as well as custom engineered diamond drills & diamond core drills, available in multiple diameters, drilling depths, bond types, diamond mesh sizes, mountings, and tolerances.

Our applications engineers work directly with you to select and optimize the right drill for your specific material and process, helping you achieve better results, longer tool life, and lower overall cost.

LARGE INVENTORY

Standard Tools & Custom Manufacturing

UKAM Industrial Superhard Tools maintains an extensive inventory of sintered (metal bond) and electroplated diamond products, along with broad custom manufacturing capability.

Our standard stock sintered (metal bond) diamond tools include ultra-thin diamond slicing, wafering, and dicing blades, diamond core drills, diamond wheels, and many other metal bond diamond products.

Our standard stock electroplated diamond products include diamond drills, diamond micro drills, ultra-thin diamond blades, diamond burs, diamond grinding wheels, and additional precision diamond tooling.

UNIQUE

Custom Manufacturing Capability

Nearly any diamond & cbn tools can be designed and manufactured to your drawings or specifications.

Our experienced engineers and applications laboratory, equipped with advanced slicing, dicing, wafering, drilling, and micro-drilling equipment, are available not only to help you develop the right tools, but also the right process for your specific material and application.

FOR INDUSTRY & SAMPLE PREPARATION

Precision Cutting & Grinding Machines

We offer a complete range of diamond saws, precision cutting and grinding/polishing machines, and accessories for processing advanced materials and ultra-hard and brittle materials. Typical applications include ceramics, glass, quartz, metals, graphite, plastics, optics, and composites.

DIFFERENT TECHNOLOGY

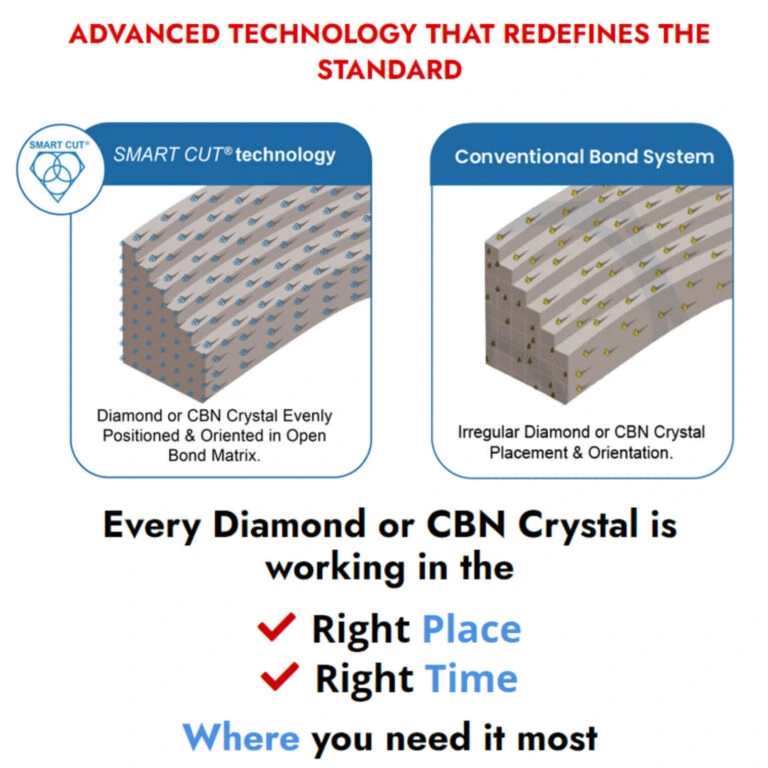

SMART CUT® technology

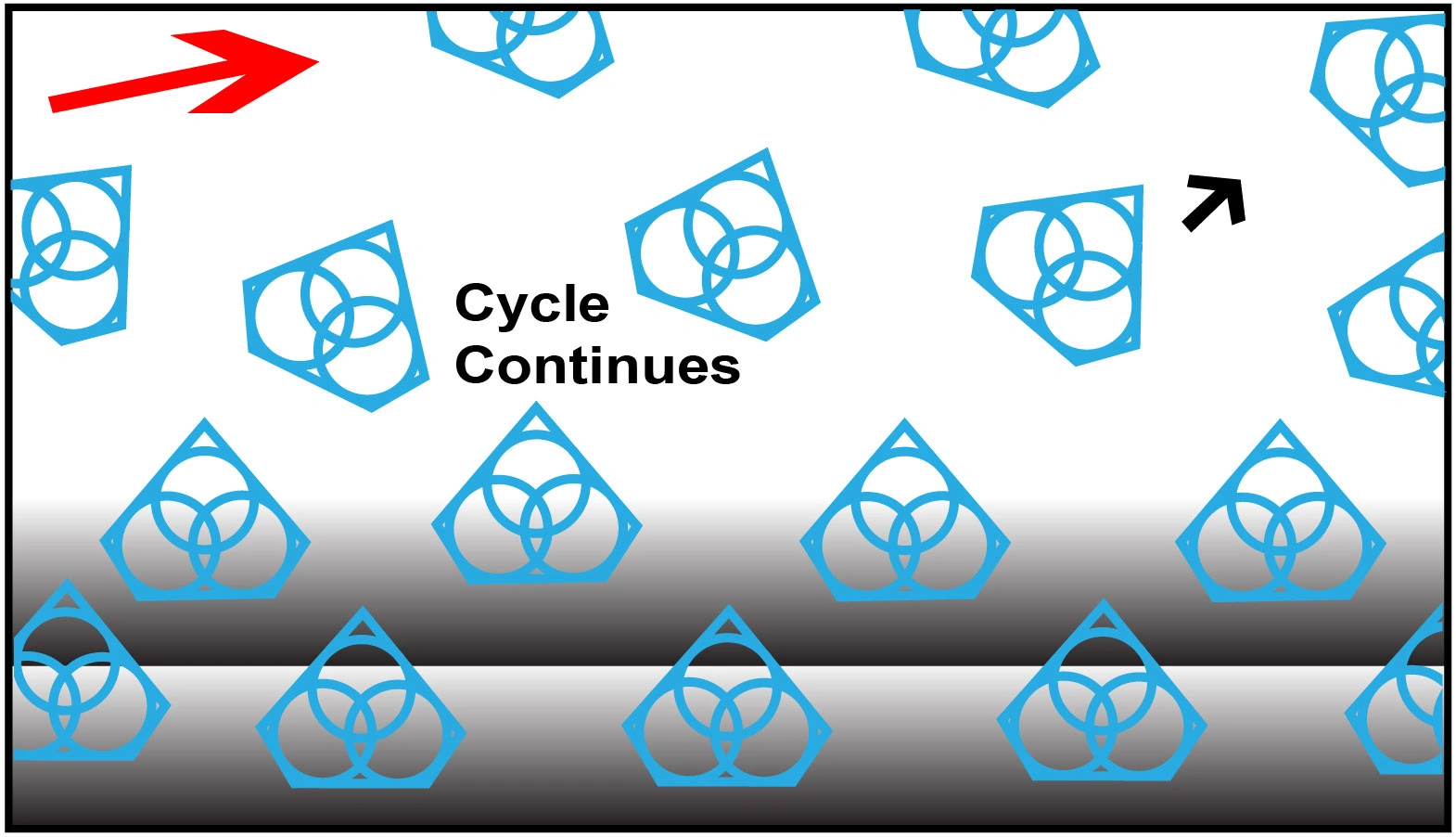

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

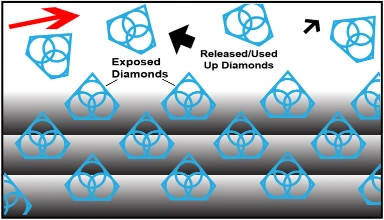

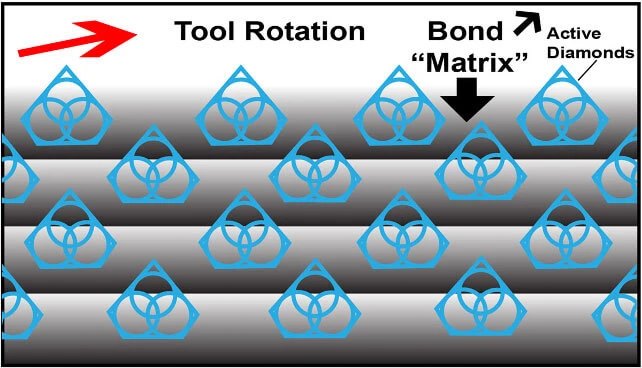

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

ADVANCED TECHNOLOGY

Higher Quality & Superior Product Consistency

UKAM Industrial Superhard Tools uses proprietary bond formulations, precision manufacturing methods, and modern quality control processes to control and regulate the many variables that affect tool life, cut quality, and surface finish. This allows us to reduce, and in many cases eliminate, secondary processing steps.

Our diamond & cbn tools are manufactured and available from inventory to meet your specific material, application, and surface finish requirements.

We work closely with you to determine your needs and to develop the right bond formulation, diamond concentration, and grit size for your application. Our tools & consumables are engineered to deliver maximum possible tool life, while achieving your desired cut quality and cutting speed.

HIGH QUALITY PRODUCTS

Made Using Premium Raw Materials &

Sophisticated Inspection & Measurement Equipment

Only the highest quality synthetic diamond and CBN crystals and premium raw materials are used in our manufacturing process. All incoming materials are verified to meet strict specifications prior to production and are sourced from qualified, long-term suppliers.

Strict quality standards and consistent product performance are maintained through the use of sophisticated inspection and measurement equipment, in-process controls, and final inspection of finished tools, in accordance with documented internal quality procedures and controlled manufacturing processes.

This ensures excellent repeatability, long tool life, and predictable cutting performance from lot to lot.

DIFFERENT COMPANY

Trusted by Tens of Thousands of Manufacturers, Laboratories, Research Institutions Worldwide Since 1990

Our products and solutions are used worldwide by thousands of customers, from Fortune 500 manufacturers, military, science and space organizations, and universities to machine shops, contractors, and serious hobbyists. We take pride in supplying tools for mission-critical applications, including defense and national security. Our technologies also support advanced and emerging fields such as micro machining, MEMS, and nanotechnology.

MATERIALS WE WORK WITH:

Advanced Ceramics

Alumina (Al₂O₃), Zirconia, Silicon Carbide (SiC), Silicon Nitride (Si₃N₄), Steatite, Cordierite, Technical Ceramics

Sapphire & Technical Crystals

Sapphire, Ruby, Quartz, Fused Silica, Cubic Zirconia, Optical Crystals

Glass & Technical Glass

Borosilicate Glass, BK7, Fused Silica, Crown Glass, Float Glass, Optical Glass, Electronic Glass, Quartz Glass

Semiconductors & Electronic Materials

Silicon, Silicon Carbide (SiC), Quartz, Photonics Materials

Carbides & Hard Materials

Tungsten Carbide, Boron Carbide, Boron Nitride, Diboride Materials, Ferrites

Composites

CFRP, GFRP, Aramid, Polymer Matrix Composites, Ceramic Matrix Composites, Metal Matrix Composites

Metals & Alloys

Aluminum, Stainless Steel, Titanium, Specialty Metals

Stone & Engineered Stone

Granite, Marble, Limestone, Basalt, Slate, Sandstone, Quartzite, Artificial / Engineered Stone

Gemstones & Minerals

Agate, Amethyst, Emerald, Garnet, Jade, Opal, Topaz, Tourmaline, Tanzanite

Optical, UV & IR Materials

Calcium Fluoride (CaF₂), ZnSe, ZnS, ULE, ZKN-7, Optical Substrates

And hundreds of additional materials. If your material is not listed, contact us. We likely support it or can develop a solution

INDUSTRIES WE SERVE:

UKAM Industrial Superhard Tools

Research & Development

Our clients are demanding longer tool life, better surface finish and tolerances. Always pushing the boundaries of what is possible. What once seemed a figment of the imagination is now, a standard routine.

We are constant developing new bond formulations, experimenting with various different materials, to use in our bond formulations, exploring new technologies and automation, testing and refining our products and technological process. We compliment our own internal research and development efforts through partnerships with some of the leading world renowned Universities, Research centers and industry expert consultants.

UKAM INDUSTRIAL SUPERHARD TOOLS

Different Company

As one of the very few remaining U.S.-based manufacturers of high-precision and ultra-thin diamond and CBN blades and tools, UKAM Industrial Superhard Tools is committed to delivering exceptional quality and performance.

We place strong emphasis on automation, high quality standards, research and development, and custom manufacturing to provide our customers with the best products and services.

LOWER COST OF OWNERSHIP &

OPTIMAL RETURN ON INVESTMENT

By continuously Improving Manufacturing Efficiency, Tightening Quality Control, and Extending Tool Life, we reduce your Total Cost Per Cut, Per Part, and Per Process.

Helping you achieve the Best Possible Return on

your tooling Investment.

THERE IS NO SUBSITUTE

for Experience

The saying “There is no substitute for experience” is something we strongly believe in. It is one of the key factors that sets UKAM Industrial Superhard Tools apart.

Our engineering staff is comprised of individuals with diverse educational backgrounds and extensive hands-on experience. Our team includes:

- Design engineers

- Mechanical engineers

- Chemical engineers

- Electrical engineers

- Metallurgical engineers

- Specialists in ultra-hard and brittle materials, optics, composites, semiconductors, and microelectronics machining

Many of our team members have been working in their respective fields for over 30 to 50 years, building a deep foundation of practical knowledge.

While technology continues to evolve, many of the core challenges our customers face remain the same. Our experience has been further strengthened through the acquisition of assets, processes, and know-how from some of the oldest American tool manufacturers, along with their decades of research and development.

Over the years, we have designed and manufactured thousands of custom tools, custom machines, and work-holding fixtures, positioning UKAM as one of the most experienced companies in the industry.

WE LISTEN TO YOU

We Continue to Raise Standards for the Industry

You will find that we provide more than just tools. We provide real solutions to your everyday cutting, drilling, grinding, and machining challenges.

Our products are continuously improved, updated, and refined to better meet your needs. However, our greatest innovations do not originate only in research and development. They originate from listening to our customers and solving real-world problems.

KNOWLEDGE IS POWER

Your Success Is Our Success

UKAM Industrial Superhard Tools is a partner in your success. We work with customers of all sizes and understand that achieving the best results depends on selecting the right tools and optimizing them for your specific application.

We believe that the best customer is a well-informed customer. The more you understand what we can do for you, the stronger our partnership becomes and the better results you achieve.

Explore our Knowledge Center for application guides, tool selection resources, and technical articles to help you achieve the best results.

INNOVATION

Company Vision & Tradition

As one of the few remaining independent U.S. diamond tool manufacturers

UKAM Industrial Superhard Tools is committed to continuous innovation and to setting a high standard for technological advancement.

Through ongoing research and development, we provide our customers with the tools, equipment, and process solutions they need to remain competitive in today’s global economy.

For decades, UKAM has played a key role in advancing diamond / cbn tooling technology across a wide range of industries, including:

- Semiconductor wafer slicing

- Road renovation and construction

- Aerospace and space exploration

- Advanced ceramics and next-generation materials

Today, we continue to work on the challenges presented by new and emerging materials. Backed by decades of experience and a strong tradition of engineering excellence, we help our customers stay at the forefront of technology.

Depend on UKAM to deliver the technology of tomorrow, today.

OUR STORY: Built on Experience,

Innovation, and the American Dream

Founded in 1990 by highly experienced engineers who fled persecution and communism in the 1980s with only a few personal belongings, UKAM Industrial Superhard Tools was built on a vision to develop a new generation of diamond cutting tools and precision cutting, grinding, and polishing machines that were not available in the market at that time.

Through decades of hard work, research and development, continuous testing, and steady reinvestment, the company has expanded its capabilities by acquiring assets, technologies, and know-how from some of the oldest American diamond tool manufacturers, as well as through close collaboration with academia and industry experts.

Today, UKAM Industrial Superhard Tools stands as a U.S. Based manufacturer serving customers worldwide with advanced diamond and CBN tooling solutions for demanding applications.

UKAM Industrial Superhard Tools

Our Mission

We design & manufacture high precision diamond and CBN tools that provide consistent results, extended tool life, low cost of ownership, and strong return on investment, while preserving the legacy of American quality and manufacturing know-how.

Our History / Timeline

Incorporated

in state of California

1990

1992

Started electroplating

Start production of thin

kerf diamond cutting blades

1994

1998

Start production of thin kerf diamond cutting blades

Start production of hybrid

bond tools

2006

2007

Aquired assets/equipment of one of the oldest sintered (metal bond) tool manufacturers in California

Start production of Precison Cutting

Machines

2009

2023

Aquired some of the assets/equipment of Industrial Tools Inc (one of the oldest US ultra thin & high precision blade manufacturers)

-

Incorporated in state of California

1990

-

Started electroplating

1992

-

Start production of thin kerf diamond cutting blades

1994

-

Developed SMART CUT technology

1998

-

Start production of hybrid bond tools

2006

-

Aquired assets/equipment of one of the oldest sintered (metal bond) tool manufacturers in California

2007

-

Start production of Precison Cutting Machines

2009

-

Aquired some of the assets/equipment of Industrial Tools Inc (one of the oldest US ultra thin & high precision blade manufacturers)

2023

KNOWLEDGE CENTER

Most Comprehensive Source of Information

On our web site you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond tools, diamond drilling, cutting, grinding, & polishing. We are focused on your long term success and take great pride in helping you grow and prosper.

“One of the most experienced companies in the industry”

This has positioned us as one of the most experienced companies in the industry. Over the years have made thousands of custom tools, built custom machines, work-holding fixtures, etc.

Knowledge Centre

Most Comprehensive Source of information

On our web site you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond tools, diamond drilling, cutting, grinding, & polishing. We are focused on your long term success and take great pride in helping you grow and prosper.