Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® Thin Wall Diamond Core Drills – the ultimate solution for precision drilling in hard materials. These sintered (metal bond) diamond core drills are engineered to provide unmatched performance, durability, and efficiency, They can be used in almost all diamond drilling application ranging from very soft & abrasive materials to ultra hard materials.

Typical applications include in order from hardness: Composites, Glass, Concrete, Sandstone/flagstone, Natural Stone, Optical Materials, Precious & Semiprecious stone, Advanced/Technical Ceramics, Ultra Hard & Brittle Materials, Advanced Materials, & Many Others. Sintered (metal bonded) diamond drills/bits are used & preferred in most Industrial/Manufacturing, R & D, Professional Contractor, & Serious Hobby Enthusiast / Craftsmen users. Sintered (metal bond) diamond core drills/bits are most widely used diamond drills across almost all industries & applications. They wear evenly, and are known for their long life & consistency.

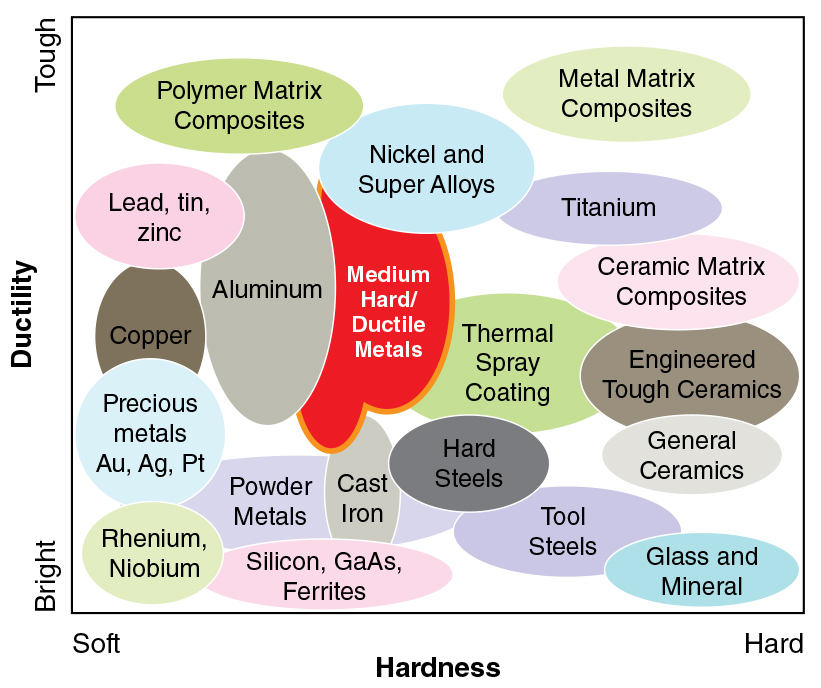

Application: Designed for drilling materials from 8.5 to 4.5 on mohe’s scale from Hard Ceramic down to Glass. You can’t beat their Universal Application.Examples of materials listed in order of hardness:

Pzt Ceramic, Agate, Opal, Porcelain, Granite, Marble, Quartz, Glass, etc

INDUSTRIES USED IN:

Ferrous & Non-Ferrous Metals:

The 120DE SMART CUT Series Thin Wall Diamond Core Drill is a high-performance drilling tool designed for precision drilling in hard materials. It utilizes sintered (metal bond) diamond technology to provide exceptional durability and efficiency.

These diamond core drills are versatile and can be used on a wide range of materials, including but not limited to composites, glass, concrete, sandstone/flagstone, natural stone, optical materials, precious and semiprecious stones, advanced/technical ceramics, ultra-hard and brittle materials, and many others. They are suitable for both industrial and hobbyist applications.

These core drills are available in diameters ranging from ¾” (19.05mm) to 4.75” (120.65mm).

They feature a 5/8-11″ female thread for easy attachment to drilling equipment.

The drilling depth is 2.25″ (75mm).

The overall length of these core drills is 2.5”.

Yes, these core drills must be used with coolant, which can include water, mineral oil, and water-soluble coolant, to ensure optimal performance and extend their lifespan.

Yes, these core drills are compatible with most popular drilling equipment, making them suitable for a wide range of applications and industries.

To maximize the lifespan of these core drills, it is essential to use them with coolant as recommended. Additionally, proper maintenance and following the manufacturer’s guidelines for usage will contribute to their longevity.

Yes, these core drills are suitable for both professional contractors and serious hobby enthusiasts or craftsmen. They are versatile and can be used in various applications.

Yes, these core drills are specifically designed to handle ultra-hard materials that might pose challenges to other types of drills. They excel in drilling such materials efficiently.

The tolerance on the outside diameter of these core drills is .0085″ (0.21mm), ensuring precise and consistent hole sizes.

Yes, these core drills are suitable for drilling materials ranging from 8.5 to 4.5 on Mohs scale, making them versatile for a wide range of applications, from hard ceramics to glass.

When using these core drills, it’s essential to follow safety guidelines, including wearing appropriate personal protective equipment (PPE), using coolant as recommended, and ensuring proper machine setup and operation to minimize risks associated with drilling.

Sintered (metal bond) diamond core drills are known for their long life and consistency, but eventually, they may wear out. They can be re-tipped, however its not usually worthwhile as it would cost more then a new drill.

While the use of coolant helps reduce dust generation, drilling may still produce some dust. It’s essential to use proper dust extraction equipment and follow safety guidelines to minimize dust exposure.

These core drills are primarily designed for wet drilling applications, as they are recommended to be used with coolant. Dry drilling without coolant may lead to reduced performance and increased wear on the drill.

Maintenance requirements typically include keeping the core drills clean and well-lubricated, checking for any signs of wear or damage, dressing and follow our usage recommendations

In addition to using coolant, you may need accessories such as a suitable drillingmachine, or guide for precise drilling.

These core drills can be used for both horizontal and vertical drilling applications, offering versatility in various drilling orientations.

Yes, these core drills are suitable for a wide range of projects, from professional industrial applications to DIY or home improvement projects.

To maintain their performance and longevity, it’s recommended to store these core drills in a clean, dry, and cool environment, preferably in their original packaging or protective cases.

The expected lifespan can vary depending on factors such as material hardness, usage frequency, and maintenance practices. However, sintered (metal bond) diamond core drills are known for their durability and long life compared to other drilling methods.

While these core drills are primarily designed for creating round holes, they can be used as a starting point for creating larger or differently shaped holes with additional tools or machining processes.

When handling coolant, it’s essential to follow safety guidelines and use appropriate personal protective equipment (PPE) to prevent skin and eye contact. Ensure proper containment and disposal of used coolant according to local regulations.

Core drills can produce noise during operation, and it’s advisable to use hearing protection when working with them. Additionally, working in a controlled and insulated environment can help reduce noise levels.

These core drills are primarily designed for wet drilling applications using coolant. While dry cutting may be possible, it is generally recommended to use them with the recommended coolant for optimal performance and longevity.

Image | Item No. | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

1 Gallon Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $99.81 | Max: Min: 1 Step: 1 | |||

1 Quart Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $34.81 | Max: Min: 1 Step: 1 | |||

5 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $317.41 | Max: Min: 1 Step: 1 | |||

55 Gallons Blue SMART CUT® General Materials Formula Synthetic Water Soluble Coolant | $1,745.00 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ White Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

1/2″ x 1/2″ x 6.0″ White For use on diamond tools 150 to 220 Grit Size. | $8.65 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $15.39 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for use in Diamond Tools 150 Grit Size (mesh size) or finer. | $39.47 | Max: Min: 1 Step: 1 | |||

1.0″ x 1.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $15.99 | Max: Min: 1 Step: 1 | |||

2.0″ x 2.0″ x 6.0″ Black Recommended for coarser grits found in segment wheels, core drills, or Blanchard grinding. Excellent performance on 120 grit tools. | $39.47 | Max: Min: 1 Step: 1 |

Image | Item No | Diameter | Drill Depth | Wall thickness | Thread Size | Price | Add to cart |

|---|---|---|---|---|---|---|---|

3/4" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $91.05 | |||

1.0" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $95.41 | |||

1.125" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $107.73 | |||

1.125" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $112.60 | |||

1.375" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $117.30 | |||

1.5" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $142.25 | |||

1.75" | 2.36" (60mm) | .060" (1.5mm) | 5/8-11” | $150.82 | |||

2" | 2.36" (60mm) | .080″ (2.0mm) | 5/8-11” | $162.40 | |||

2.375" | 2.36" (60mm) | .080″ (2.0mm) | 5/8-11” | $173.65 | |||

2.375" | 2.36" (60mm) | .080″ (2.0mm) | 5/8-11” | $189.90 | |||

3" | 2.36" (60mm) | .080″ (2.0mm) | 5/8-11” | $228.30 | |||

4" | 2.36" (60mm) | .080″ (2.0mm) | 5/8-11” | $242.85 | |||

4.75" | 2.36" (60mm) | .080″ (2.0mm) | 5/8-11” | $259.72 |

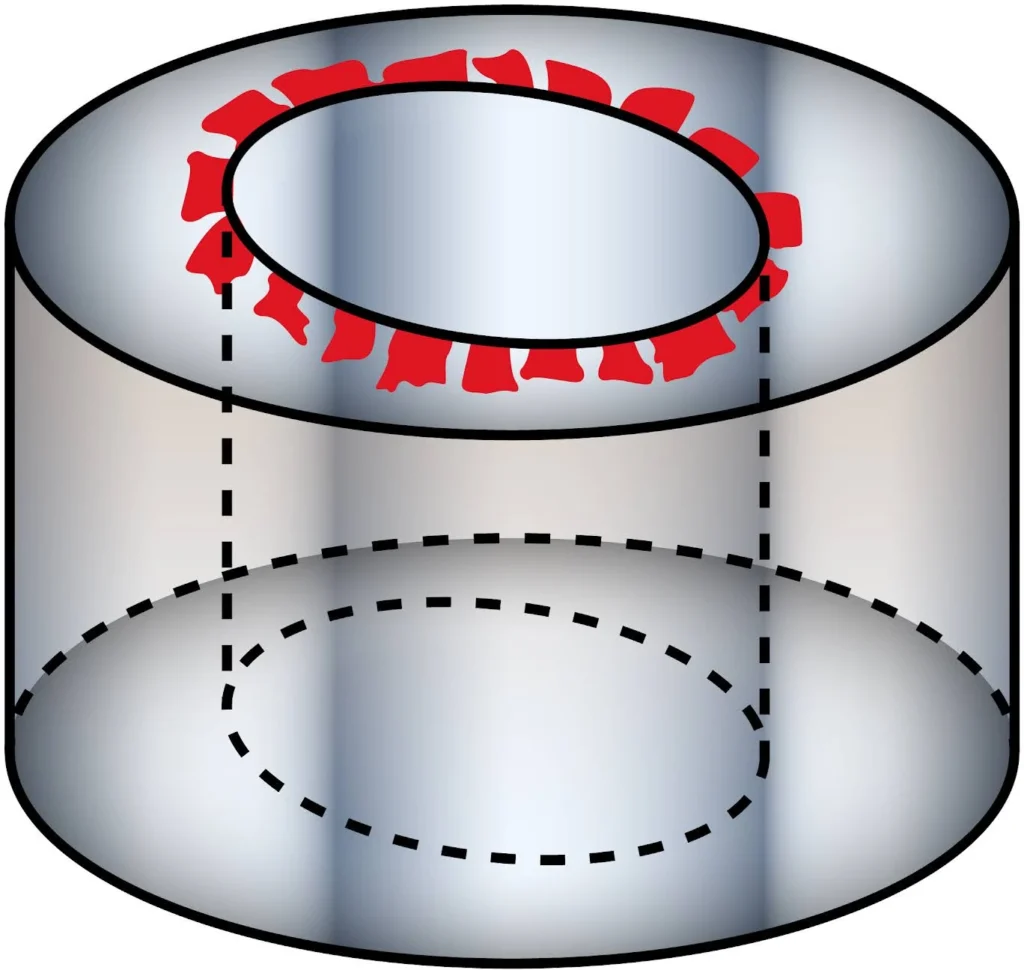

Sintered (Metal Bond) diamond tools have multiple layers of diamonds impregnated inside the metal matrix. Diamonds are furnaces sintered in a matrix made of iron, cobalt, nickel, bronze, copper, tungsten, alloys of these powders or other metals in various combinations. Metal bonded diamond tools are “impregnated” with diamonds. This means that selected diamonds are mixed and sintered with specific metal alloys to achieve the best cutting performance possible on any materials such as sapphire, advanced ceramics, optics, glass, granite, tile and etc. The metal bond surrounding the diamonds must wear away to continuously keep re-exposing the diamonds for the diamond tool to continue cutting. Sintered (metal bonded) diamond tools are recommended for machining hard materials from 45 to 75 on rockwell scale (5 to 9.5 on mohe’s scale of hardness).

Diamond & CBN tools made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional Sintered (Metal Bond) diamond & CBN drills. SMART CUT® diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

SMART CUT® Sintered (Metal Bond) Diamond Core Drills have diamonds crystals oriented and evenly positioned inside bond matrix. Unlike Many Other drill Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials.

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

SMART CUT® Sintered (metal bond) Diamond Drills are the best investment you can make! Although they may cost more than Sintered (metal bond)Sintered (metal bond), Diamond Drills. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

SMART CUT® Sintered (metal bond) Diamond Drills have diamonds oriented and evenly distributed in a bond matrix. Providing faster, freer cutting action with minimum heat generation. This translates in improved surface finish and minimum chipping.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

100DE SMART CUT® Series Thin Wall Multi-Layered Electroplated Diamond Core Drills, Manufactured by UKAM Industrial are Multi Layered. They have 3 layers of diamonds, not just 1 layer of diamonds like conventional electroplated drills. This provides longer drilling life, smoother surface finish, faster and freer drilling action, & more consistent performance.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales