-

0 items in quote

No products in the Quote Basket.

SMART CUT Diamond Slabbing Blades

SMART CUT

Diamond Slabbing Blades

SMART CUT Slabbing blades are are used for cutting through large, thick pieces of material, turning them into thinner, more manageable slabs. These are available from 16″ (400mm) to 48″ (2,19mm) with many differen tabor sizes, segment types, configurations, for use on many different type of cutting saws.

These are used for cutting natural stone, semi precious stone, synthetic materials, various types of glass, composites, advanced ceramics, silicon, metal and many other materials. Many options are available from stock and custom manufacturing to fit your particular requirements is available with usually no minimum order quantities.

SMART CUT® 320MS SLABING DIAMOND CUT OFF BLADES

Narrow Slot Segment Design – Diamond Depth (Height): 5mm – 16″ to 36″ Diameter. SMART CUT® Series slabing sintered (metal bond) diamond cut off blades, are Segmented Design with (narrow spacing between the segments). Designed for smooth cutting of ultra hard materials.

SMART CUT® SERIES 330 MS

Wide Slot Segment Design - Diamond Depth (Height): 20mm. SMART CUT® Series 330MS Wide spacing between segments. Designed for fast and more aggressive cutting, where chipping and very smooth cut

SMART CUT® 325M Continuous Slabbing Blade

SMART CUT® Series – 325M Continuous Rim – Diamond Depth (Height): 8mm, Sintered (Metal Bond) blade is designed for delicate cutting and minimum chipping of wide variety of natural stone, semi precious stone, glass, and related materials. Continuous rim diamond blades produce the best surface finish and minimum amount of chipping possible.

Braised Bond Slabbing Blades

Braised bond slabbing blades are used on larger cutting machines, slab saws & other equipment for Cutting large variet of hard to soft Materials....

Nickel Bond Slabbing Blades

Electroplated (Nickel Bond) Diamond Slabbing Blades are used for cutting large variety of fiberglass, graphite, composites, silicon, composites, plastic, and many other soft and gummy materials. Can be used dry (without coolant for some applicaitons.

Large Diameter Slabbing Blades

Large Diamond Diamond Slabbing Blades larger then 36" (914mm) to 72" (1,828mm) are used for cutting larg variety of materials on specialized cutting machines. These are typically made to order.

Why Work With Us?

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Expect More From Your Tools

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

ARE YOU USING RIGHT DIAMOND & CBN BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN BLADES?

Knowledge Center

02

Jun

The diamond blade itself is only a small factor in your cutting operation. Successful diamond sawing is both an art & science. Requiring proper use and understanding of the right: RPM's, Coolants, Equipment, Dressing Devices, Accessories...

02

Jun

Precision & Ultra Thin Diamond Blade Guide

Diamond and CBN blades are available in an extensive array of varieties, each differing in bond types, manufacturing methods, and design specifics. Ultra Thin & High Precision Diamond Blades are particularly versatile, applicable...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

31

Jul

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

05

Aug

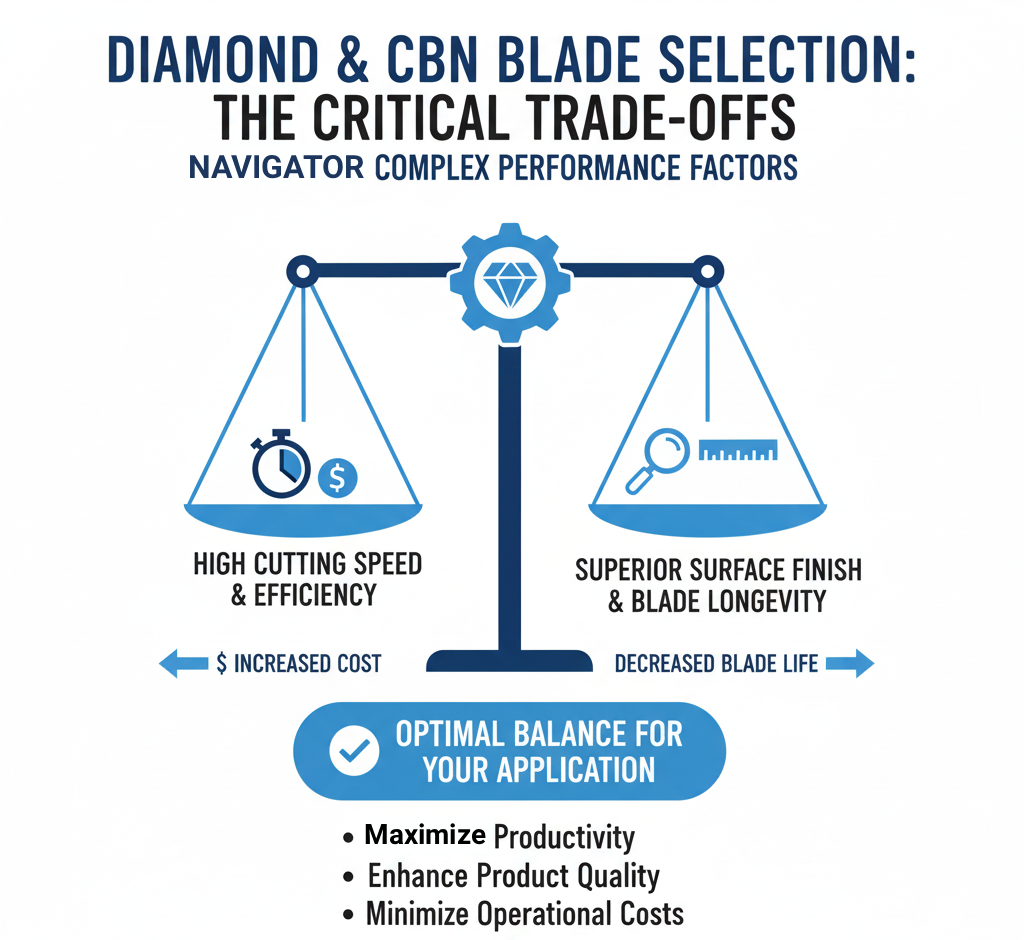

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade...