Resin Bond Diamond Tools: Full Expert Buyer Guide

-

Posted by

Brian Farberov

Brian Farberov

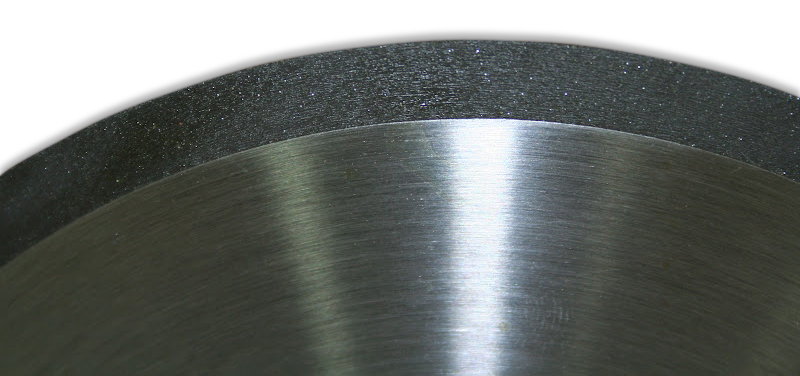

Grinding, polishing, and processing of materials frequently rely on tools with a good balance between accuracy, stability, and surface quality. This is the point on which reliance has to be placed upon resin bond diamond tools. For glass, ceramics, carbides, composite materials, and other hard-to-grind materials, resin bond tools are the perfect option for grinding delicate substrates with minimal grinding forces while generating incredibly smooth finishes.

Table of Contents

ToggleIn this complete guide, you’ll learn what resin-bond tools are all about, how they work, when to use them and when not to, why they are better (or worse) than other types of bonds, and most importantly – how to select the right tool for your application.

What Are Resin Bond Diamond Tools?

Resin-bonded diamond tools are made up of diamond abrasive, combined with light filling and resin bond. And, finally, these resins slowly wear off in the course of use to continually expose fresh, sharp abrasive.

This natural tendency for self-sharpening is the reason that resin bond tools provide a cooler cut, minimizing machine wear and preventing chipping and scratching of the workpiece. It also makes them perfect for grinding and polishing brittle or heat-sensitive materials.

Why Resin Matters

The softer nature of the resin bond allows:

- controlled diamond release

- reduced cutting pressure

- improved temperature stability

- minimal subsurface damage

- cleaner edges and smoother surfaces

These characteristics make resin bond tools a must-have for industries requiring precision and consistency.

How Resin Bond Tools Are Manufactured

Producing resin bond tools is a sophisticated, multi-step process that determines the final performance of the tool. Proper manufacturing ensures stability, uniformity, and repeatability across different applications.

1. Raw Material Selection

The process starts by selecting:

- Diamond or CBN grit (size, shape, and quality)

- Resin powders (phenolic or polyimide)

- Metallic fillers

- Lubricants

- Heat-resistant additives

Each component influences hardness, wear resistance, and grinding behavior.

2. Mixing & Granulating

Resin powders and abrasives are mixed thoroughly. Depending on the application, lubricants or performance-enhancing materials are added to improve grain exposure, heat resistance, or chip evacuation.

3. Hot Pressing & Shaping

The mixed material is placed into a mold and compressed under high pressure while heating to a controlled temperature. This forms the basic wheel shape or tool profile.

4. Curing Process

Curing solidifies the bond and stabilizes abrasive distribution. Polyimide resin bonds require significantly higher curing temperatures than phenolic bonds and deliver higher performance in demanding applications.

5. Finishing, Truing & Balancing

Once cured, tools undergo:

- truing

- dressing

- geometry correction

- dynamic balancing

These final adjustments ensure the wheel runs perfectly true, minimizes vibration, and produces predictable results.

6. Quality Testing

Every high-performance resin bond tool goes through:

- bond hardness checks

- dimension verification

- burst and impact testing

- sample grinding tests

This ensures repeatable performance for precision machining.

Advantages of Resin Bond Diamond Tools

Resin bond tools are preferred when surface quality and dimensional accuracy take priority over aggressive material removal.

Key Advantages

- Excellent surface finish ideal for optics and precision parts

- Self-sharpening behavior provides consistent cutting action

- Lower grinding forces reduce the risk of cracking or micro-fracturing

- Cooler cutting prevents thermal shock in brittle materials

- Customizable bond hardness and grit sizes for any application

- Quiet, smooth tool operation compared to metal-bond tools

Resin-bond tools are engineered to protect the integrity of sensitive materials — a major reason they dominate semiconductor, optical, and ceramic industries.

Resin Bond Tool Applications

Industries That Rely on Resin Bond Tools

- Optics & glass manufacturing

- Ceramics & advanced materials

- Semiconductor wafer processing

- Carbide tool manufacturing

- Aerospace composites machining

- Precision medical components

- Magnetic materials processing

- Superhard materials finishing

Materials Commonly Machined

- Optical glass

- Quartz

- Alumina and zirconia ceramics

- Tungsten carbide

- Carbide-tipped tools

- Ferrites and magnets

- Carbon composites

- Graphite

- Silicon carbide

- Sapphire

The versatility makes resin bond tools indispensable for both R&D and production lines.

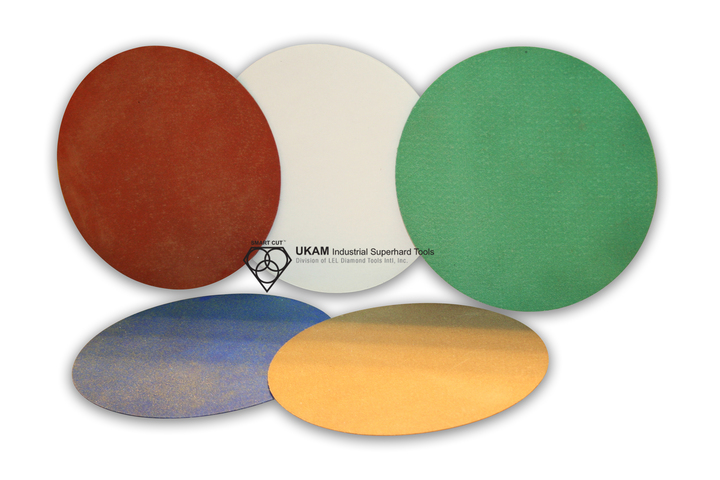

Types of Resin Bonds

Not all resin bond tools perform the same – the bond formulation drives cutting speed, surface quality, and heat resistance.

1. Phenolic Resin Bond

- Most common type

- Suitable for standard precision grinding

- Moderate heat resistance

- Cost-effective

- Ideal for glass, ceramics, carbides

2. Polyimide Resin Bond

- High-performance

- Excellent thermal stability

- Longer tool life

- Suitable for demanding applications

- Preferred for semiconductor, aerospace, and optical work

3. Hybrid Resin Bonds

These combine resin with metal powders to improve:

- durability

- heat dissipation

- form-holding ability

They are often used for profile grinding or applications requiring higher mechanical strength.

Choosing the Right Resin Bond Tool

Choosing the right tool starts with understanding your material and the performance requirements of your process.

1. Material Hardness

- Brittle materials → softer bond for cleaner edges

- Harder materials → stronger bond for durability

2. Required Surface Finish

- Fine grits (200–3000 mesh) → optical-quality finish

- Medium grits (120–200 mesh) → general-purpose grinding

- Coarse grits (80–100 mesh) → aggressive stock removal

3. Coolant Conditions

Wet grinding allows:

- longer tool life

- reduced heat

- better finishes

Some resin bond tools can run dry, but coolant is recommended for consistent performance.

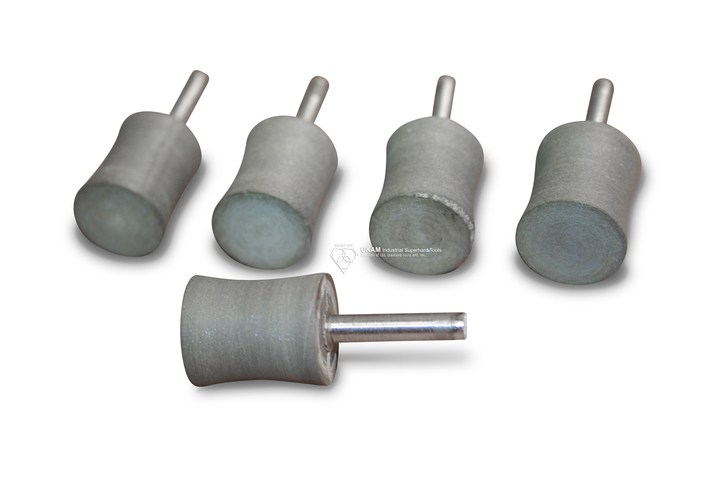

4. Wheel Geometry

Resin bond tools come in:

- flat wheels

- cup wheels

- peripheral wheels

- mounted points

- segmented wheels

- custom shapes

Custom geometries can significantly improve efficiency and quality.

5. Bond Hardness

Bond hardness determines how fast fresh diamonds are exposed.

Soft bond → sharper cuts

Hard bond → longer tool life

Selecting the right hardness prevents glazing, burning, and surface damage.

Resin Bond vs. Other Bond Types

Understanding the difference between bond types helps ensure you choose the right tool for your workflow.

|

Feature |

Resin Bond |

Metal Bond |

Electroplated |

|---|---|---|---|

|

Surface Finish |

Excellent |

Moderate |

Moderate |

|

Cutting Temperature |

Low |

High |

Low |

|

Cutting Aggressiveness |

Medium |

High |

High (initial) |

|

Tool Life |

Medium |

Very High |

Low–Medium |

|

Grit Exposure |

Self-sharpening |

Limited |

None |

|

Best Used For |

Precision & brittle materials |

Heavy stock removal |

Thin kerf, fast cutting |

Resin bond tools are the best choice when finish and accuracy matter more than aggressive cutting.

FAQs

Yes, especially polyimide bonds, which withstand high temperatures.

Yes, resin bond wheels are excellent for carbide tool grinding.

Occasionally, to maintain sharpness and profile accuracy.

Water-based synthetic coolants provide excellent thermal control.

Yes, grit size, concentration, thickness, and bond hardness can all be customized.

Conclusion

The stability of Resin Bond is excellent, which keeps the process consistent and provides accurate control over removal rates. They are designed for sensitive and fragile materials, which require clean, controlled grinding with no transfer of impurities or damage from heat or mechanical stress.

Resin bonded with a variety of bond types, grit sizes, and shapes, including small diameter wheels as small as 2mm in height, is popular among users but remains a traditional product due to its great performance.

If you’re unsure which resin bond tool fits your exact material or process, UKAM’s technical team can recommend the ideal solution and even manufacture a customized tool tailored to your specifications.

Brian is an experienced professional in the field of precision cutting tools, with over 27 years of experience in technical support. Over the years, he has helped engineers, manufacturers, researchers, and contractors find the right solutions for working with advanced and hard-to-cut materials. He’s passionate about bridging technical knowledge with real-world applications to improve efficiency and accuracy.

As an author, Brian Farberov writes extensively on diamond tool design, application engineering, return on investment strategies, and process optimization, combining technical depth with a strong understanding of customer needs and market dynamics.