-

0 items in quote

No products in the Quote Basket.

SMART CUT® Slotted Diamond Electroplated Saw Blades

SMART CUT® Slotted Diamond Electroplated Saw Blades are precision-engineered to meet the rigorous demands of industries such as aerospace, tool and die manufacturing, ceramics, and composite applications. Designed for cutting highly abrasive materials like alumina, fiberglass, plastics, and other nonmetallic composites, these blades deliver exceptional performance and reliability. The innovative slot design helps maintain blade coolness during operation by effectively dissipating heat and minimizing thermal stress.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Exposed diamond particles provide aggressive cutting action, ensuring efficient material removal and smooth, precise cuts. The slots also break up the cut, reducing heat buildup and material loading, which extends the blade’s lifespan and enhances overall efficiency. Ideal for applications requiring precision and durability, these blades are the perfect solution for challenging cutting tasks in advanced industries. These blades can be used for dry and wet on large variety of cutting equipment such as die grinders, air grinders, angle grinders, tile and masonry saw and other types of cutting machines.

SPECIFICATIONS

DIAMOND RETURN: 1/8″ ON BOTH SIDES

DIAMOND GRIT SIZE: 40/60 (other diamond grit sizes available)

FREQUENTLY ASKED QUESTIONS

Tab Content

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Advantages

- Precision cutting for abrasive materials

- Slots for effective heat dissipation

- Exposed diamond for aggressive cutting

- Reduced material loading

- Extended blade lifespan

- Versatile for various applications

- Reliable performance in demanding tasks

Materials Used On

- Fiber reinforced composites

- Green Ceramics

- Mounted Samples

- Fiberglass

- Softer alloy Metals

- Plastics

- Epoxy

- Silicon

- Bones

ADVANTAGES

- Precision cutting for abrasive materials

- Slots for effective heat dissipation

- Exposed diamond for aggressive cutting

- Reduced material loading

- Extended blade lifespan

- Versatile for various applications

- Reliable performance in demanding tasks

Filters Sort results

Reset Apply

Image | Item Number | Blade Diameter | Thickness (Kerf) | Arbor Hole | Get A Quote |

|---|---|---|---|---|---|

1-1/2" (38.1 mm) | 0.060" - 0.080" (1.524 - 2.032 mm) | Specify | |||

2" (50.8 mm) | 0.060" - 0.080" (1.524 - 2.032 mm) | Specify | |||

2-1/2" (63.5 mm) | 0.060" - 0.080" (1.524 - 2.032 mm) | Specify | |||

3" (76.2 mm) | 0.060" - 0.080" (1.524 - 2.032 mm) | Specify | |||

3-1/2" (88.9 mm) | 0.060" - 0.080" (1.524 - 2.032 mm) | Specify | |||

4" (101.6 mm) | 0.090" - 0.110" (2.286 - 2.794 mm) | Specify | |||

5" (127 mm) | 0.090" - 0.110" (2.286 - 2.794 mm) | Specify | |||

6" (152.4 mm) | 0.090" - 0.110" (2.286 - 2.794 mm) | Specify | |||

7" (177.8 mm) | 0.090" - 0.110" (2.286 - 2.794 mm) | Specify | |||

8" (203.2 mm) | 0.120" - 0.130" (3.048 - 3.302 mm) | Specify | |||

10" (254 mm) | 0.120" - 0.130" (3.048 - 3.302 mm) | Specify | |||

12" (304.8 mm) | 0.120" - 0.130" (3.048 - 3.302 mm) | Specify | |||

14" (355.6 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

16" (406.4 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

18" (457.2 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

20" (508 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

22" (558.8 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

24" (609.6 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

26" (660.4 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

30" (762 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

36" (914.4 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify | |||

48" (1219.2 mm) | 0.140" - 0.150" (3.556 - 3.81 mm) | Specify |

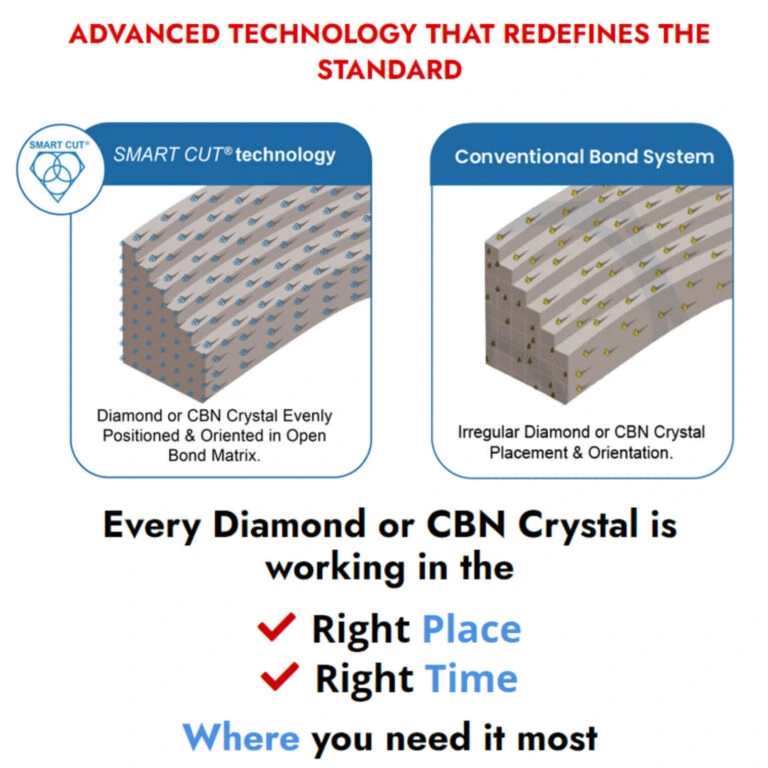

How SMART CUT® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

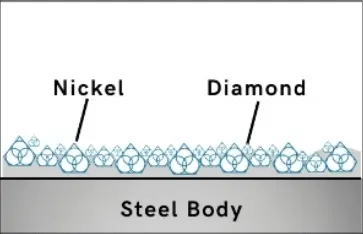

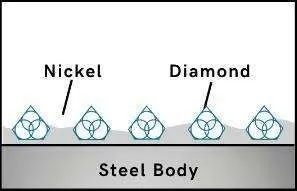

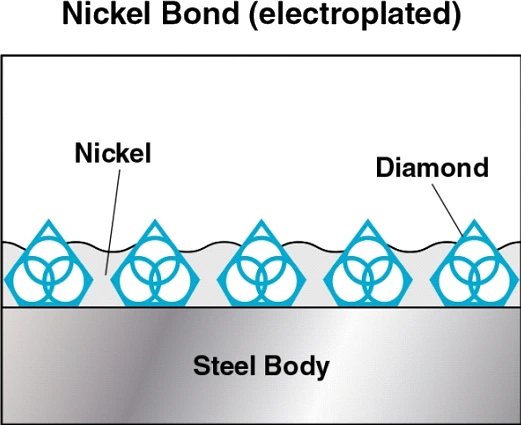

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside.

Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

Faster

Faster Cutting Action

Diamond cutting blades made utilizing SMART CUT® technology are much more aggressive than your conventional tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

longer

Life

In most cases tools manufactured utilizing SMART CUT® technology, will outlast other conventional nickel bonded diamond cutting blades. SMART CUT® diamond & CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

MORE

Consistent Performance

SMART CUT® Multi Layered Electroplated diamond cutting blade three diamond layers impregnated inside the bond matrix. Unlike Many Other Blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials.

Best

Performance & Value on the Market

SMART CUT® Multi Layered diamond cutting blades are the best investment you can make! They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

Manufactured Using

The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Related Products

SMART CUT® Miniature Sintered Turbo Type Diamond Wheels Mounted on a Mandrel

Miniature Diamond Cut Off Blades, Electroplated (Nickel Bond)

Used on Dremel, Fordedom Hand Pieces, Die Grinders, and other cutting machines. Use for cutting, slotting, and grooving of large spectrum of materials. Ranging from ultra hard & brittle materials (such as Al203, sapphire, etc), Ultra Hard Metals, Glass, Composites. Hundreds of Sintered (metal bond), Miniature Diamond Cut Off Blades are available in stock in all diameters, thicknesses, inside diameters, specifications (grit sizes, concentrations, shapes, radiuses, etc).

Diamond Slitting Wheels (Plated)

Recently Viewed Products

ARE YOU USING RIGHT DIAMOND & CBN BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN BLADES?

Knowledge Center

02

Jun

The diamond blade itself is only a small factor in your cutting operation. Successful diamond sawing is both an art & science. Requiring proper use and understanding of the right: RPM's, Coolants, Equipment, Dressing Devices, Accessories...

02

Jun

Precision & Ultra Thin Diamond Blade Guide

Diamond and CBN blades are available in an extensive array of varieties, each differing in bond types, manufacturing methods, and design specifics. Ultra Thin & High Precision Diamond Blades are particularly versatile, applicable...

02

Jun

How to Improve & Optimize Your Diamond Sawing Operation

There are numerous variables that affect the performance of diamond and CBN cutting blades. Understanding these variables will help end users select the right diamond blade specifications for their applications and optimize their cutting operations...

02

Jun

Evaluating & Comparing Diamond Blades

Share this Article with Friend or Colleague

Proper testing procedures and methodologies must be set up and used to obtain accurate as well as repeatable testing results. This article will discuss several simple procedures which...

31

Jul

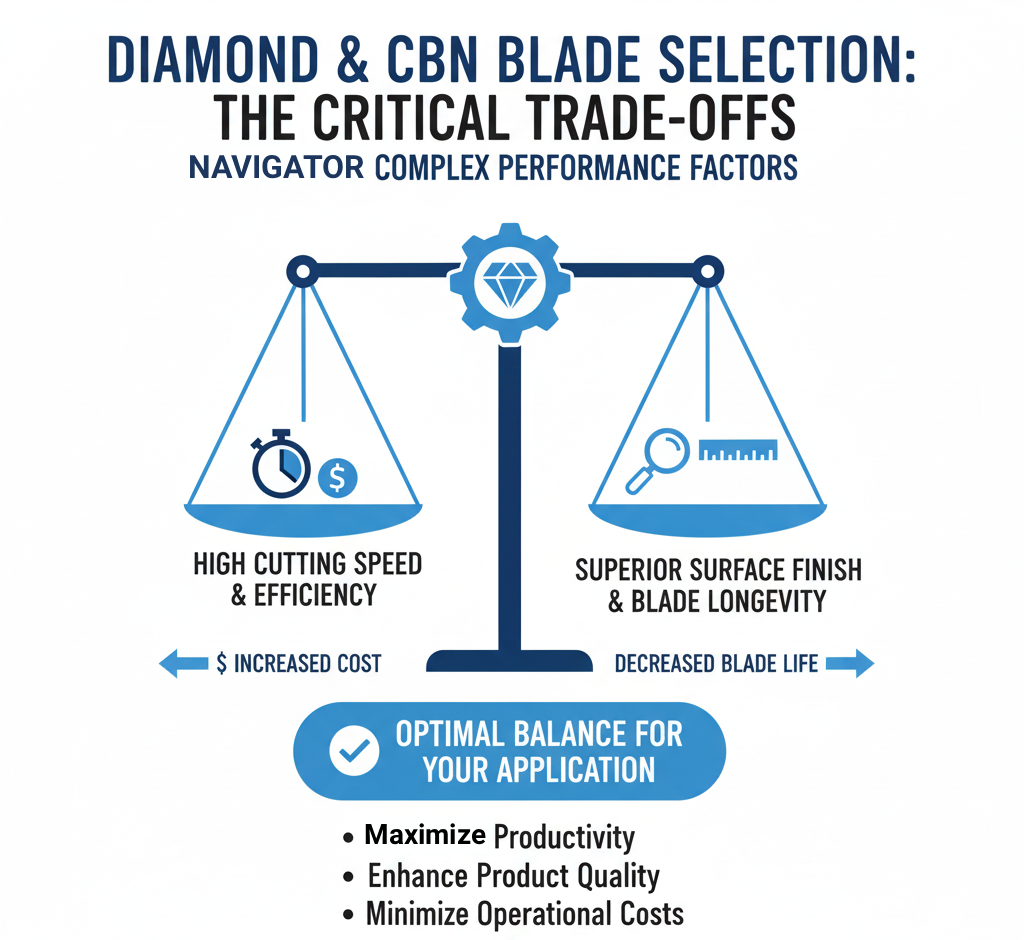

Top 5 Diamond & CBN Cutting Blade Performance Metrics

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it...

01

Aug

Diamond & CBN Cutting Blade Performance Metrics that you Should Know

Share this Article with Friend or Colleague

When evaluating diamond and cubic boron nitride (CBN) cutting blades, it's crucial to consider key performance metrics and criteria. Different applications have varying goals, making it important to...

02

Aug

Total Cost of Ownership & Why its Important

Share this Article with Friend or Colleague

Diamond and CBN cutting blades are available in a myriad of specifications, with virtually limitless options. The industry is saturated with numerous manufacturers, each professing to offer the...

05

Aug

Understanding Tradeoffs- Searching for Perfect Diamond & CBN Blade

Share this Article with Friend or Colleague

Choosing the right blade diamond or cbn blade can significantly impact efficiency, cost, and quality. However, this is not simple and clear cut process. Selecting the optimal blade involves...